Fig. 1. The studied harwarder consisting of a Ponsse Buffalo Dual forwarder and the Moipu 300 F1 harwarder head. The harvesting of brushwood was based on the dual purpose machine system.

Fig. 2. JAK SP-180 spiral cutter was attached to the boom tip of wheeled Neuson 6503 WD mini-excavator. The clearing of brushwood was done with the spiral cutter in the study.

| Table 1. The statistical characteristics of tree species specific regression models for height and DBH in which the stump diameter (x1, x2, x3 and x4 for the stump diameters of birch, spruce, pine and other broadleaves in respective order) is the independent variable. | ||||||||||

| Tree model | Dependent variable | R2 | F-test | N | Term | Constant/Coefficient | t-test | |||

| F-value | p | Estimate | Std. error | t-value | p | |||||

| DBH | DBHBirch | 0.946 | 521.531 | <0.001 | 31 | Constant | –1.268 | 4.359 | –0.291 | 0.773 |

| x1 | 0.830 | 0.036 | 22.837 | <0.001 | ||||||

| DBHSpruce | 0.936 | 824.357 | <0.001 | 57 | Constant | –5.009 | 2.404 | –2.083 | 0.042 | |

| x2 | 0.897 | 0.031 | 28.712 | <0.001 | ||||||

| DBHPine | 0.965 | 2029.299 | <0.001 | 75 | Constant | –3.075 | 1.923 | –1.599 | 0.114 | |

| x3 | 0.875 | 0.019 | 45.048 | <0.001 | ||||||

| DBHOther broadleaf | 0.989 | 3342.685 | <0.001 | 39 | Constant | –5.847 | 1.289 | –4.536 | <0.001 | |

| x4 | 0.933 | 0.016 | 57.816 | <0.001 | ||||||

| Height of the tree | HeightBirch | 0.764 | 97.260 | <0.001 | 31 | Constant | 2.432 | 0.746 | 3.261 | 0.003 |

| x1 | 0.061 | 0.006 | 9.862 | <0.001 | ||||||

| HeightSpruce | 0.827 | 263.788 | <0.001 | 57 | Constant | 0.159 | 0.279 | 0.571 | 0.570 | |

| x2 | 0.061 | 0.004 | 16.242 | <0.001 | ||||||

| HeightPine | 0.965 | 196.838 | <0.001 | 75 | Constant | 2.083 | 0.324 | 14.030 | <0.001 | |

| x3 | 0.046 | 0.003 | 6.419 | <0.001 | ||||||

| HeightOther broadleaf | 0.911 | 391.037 | <0.001 | 39 | Constant | 1.751 | 0.253 | 19.775 | <0.001 | |

| x4 | 0.063 | 0.003 | 6.922 | <0.001 | ||||||

| Table 2. Work elements with detailed definitions in harvesting roadside brushwood with the harwarder. | |

| Work element | Definition of the work element |

| Moving between the working locations | Begins when the harwarder starts to move (wheels are turning) and ends when the harwarder stops moving to perform another activity at the working location, e.g. positioning to cut. |

| Positioning to cut | Begins when the boom starts to swing towards the first tree and ends when the empty harwarder head is resting on the tree before the felling cut at stump height begins. With tall trees (higher than 8 m), the harwarder head is first placed halfway along the tree to be felled. |

| Accumulating the felling | Begins when the felling cut starts (either at the stump height or halfway of the tree) and ends when the accumulated tree bunch starts moving to the load space of the harwarder. With tall trees the top is cut first, after which the harwarder head is moved vertically downward and the tree is cut again at the stump height. The number of trees in each harwarder head bunch is observed and recorded. |

| Loading | The harwarder loads directly felled trees to the load space of the harwarder. Begins when the accumulated tree bunch starts moving to the load space of the harwarder and ends when the empty harwarder head start positioning to cut, the load is full or harwarder starts to move to the next working location. |

| Driving loaded or unloaded | Driving with load begins when the brushwood is harvested from the time study plot (harwarder head is positioned for driving loaded and wheels are turning) and ends when the harwarder stops to begin unloading at the landing area. Driving unloaded begins when the load is empty, the harwarder head is positioned for driving unloaded and its wheels are turning. Driving unloaded ends when the harwarder stops at the working location and positioning to cut starts. |

| Sorting of trees placed in the load space of the harwarder | Sorting of trees placed in the load space of the harwarder before the final grip for unloading. |

| Unloading | Starts when the harwarder stops at the landing for unloading and ends when the load is empty and harwarder head is positioned for driving unloaded. The number of harwarder head loads during unloading is recorded. |

| Table 3. Work elements with detailed definitions in roadside brushwood clearing with the spiral cutter. | |

| Work element | Definition of the work element |

| Continuous clearing of brushwood | The mini-excavator is driving forward at a steady pace, brushwood is fed continuously to the blades by rotating spirals, brushwood is cut down in a desirable direction (backwards) and the work is not interrupted |

| Slow down clearing of brushwood | The mini-excavator has to slow down the driving speed or stop because brushwood is cut down slowly, improperly or fell in an undesirable direction (towards mini-excavator). The clearing work is partly interrupted, but the spirals continue to rotate either forward or backwards |

| Table 4. Regression model statistics for harvesting with the harwarder (x1 = number of harvested trees per hectare, x2 = the average volume of the harvested trees (dm3), x3 = grapple load size during loading (m3), x4 = grapple load size during unloading (m3), x5 = forwarding distance (m)). | ||||||||||

| Work phase model | Dependent variable | R2 | F-test | N | Term | Constant/Coefficient | t-test | |||

| F-value | p | Estimate | Std. error | t-value | p | |||||

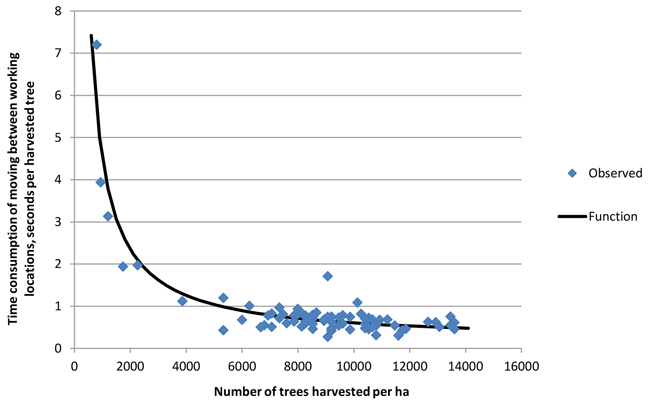

| Moving | TMoving | 0.881 | 576.779 | <0.001 | 80 | Constant | 0.168 | 0.045 | 3.721 | <0.001 |

| 1/x1 | 4351.5 | 181.2 | 24.016 | <0.001 | ||||||

| Cutting | TCutting | 0.724 | 204.102 | <0.001 | 80 | Constant | –4.571 | 0.680 | –6.719 | <0.001 |

| ln(x2) | 3.400 | 0.238 | 14.286 | <0.001 | ||||||

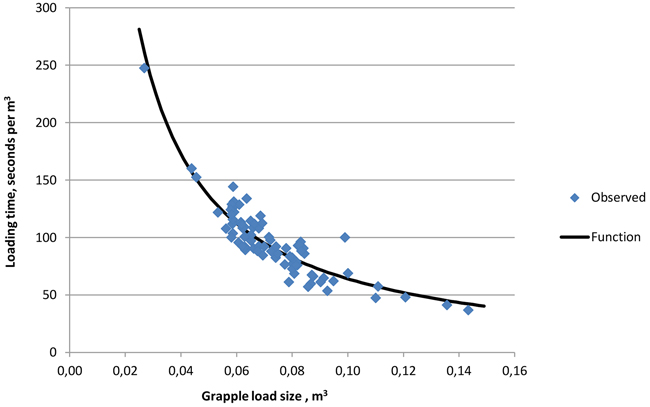

| Loading | TLoading | 0.848 | 434.187 | <0.001 | 80 | Constant | –8.222 | 5.176 | –1.588 | 0.116 |

| 1/x3 | 7.237 | 0.347 | 20.837 | <0.001 | ||||||

| Number of trees in the grapple | NNumber of trees | 0.487 | 73.960 | <0.001 | 80 | Constant | 1.163 | 0.411 | 2.830 | 0.006 |

| 1/x2 | 53.675 | 6.241 | 8.600 | <0.001 | ||||||

| Unloading | TUnloading | 0.203 | 19.919 | <0.001 | 80 | Constant | 99.030 | 8.259 | 11.990 | <0.001 |

| x4 | –140.211 | 31.416 | –4.463 | <0.001 | ||||||

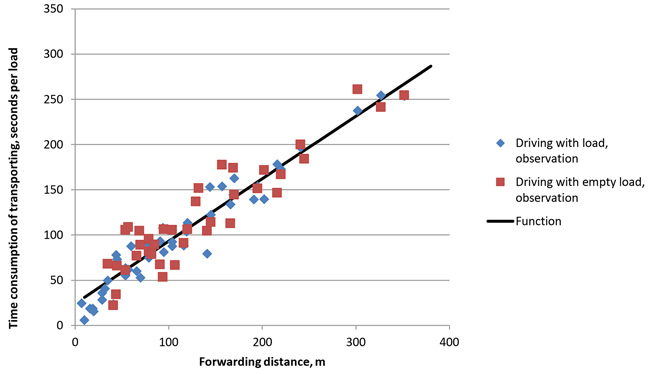

| Forwarding | TForwarding | 0.900 | 757.519 | <0.001 | 85 | Constant | 24.154 | 3.688 | 6.549 | <0.001 |

| x5 | 0.691 | 0.025 | 27.523 | <0.001 | ||||||

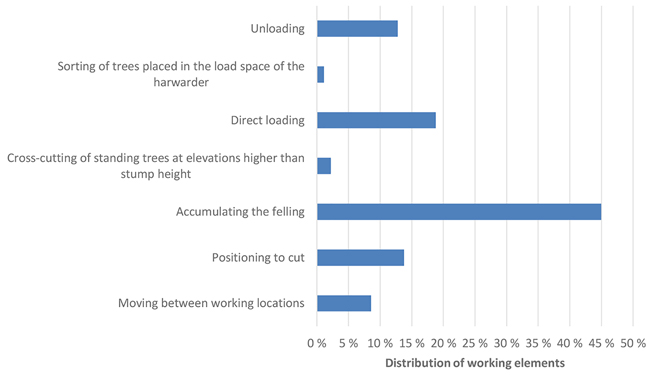

Fig. 3. Average proportion of various working elements in the harwarder harvesting of roadside brushwood.

Fig. 4. The time consumption of moving between work locations as a function of trees harvested per ha in the harwarder harvesting of roadside brushwood.

Fig. 5. Time consumption of loading as a function of grapple load size in the harwarder harvesting of roadside brushwood.

Fig. 6. Time consumption of driving loaded and driving unloaded as a function of forwarding distance (m) in the harwarder harvesting of roadside brushwood.

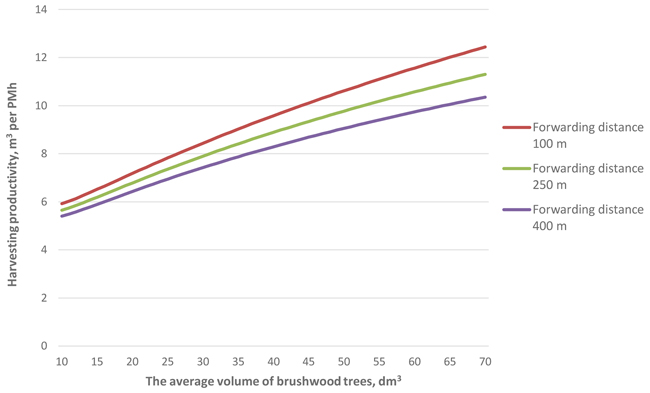

Fig. 7. The harvesting productivity of roadside brushwood with the harwarder as a function of forwarding distance and average volume of harvested brushwood trees. The harwarder’s payload was 7.1 m3 and the number of harvested trees per ha was 6000.

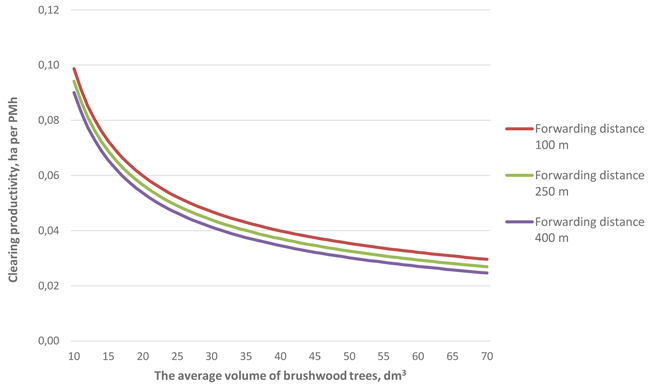

Fig. 8. The clearing productivity of roadside brushwood with the harwarder as a function of forwarding distance and average volume of harvested brushwood trees. The harwarder’s payload was 7.1 m3 and the number of harvested trees per ha was 6000.

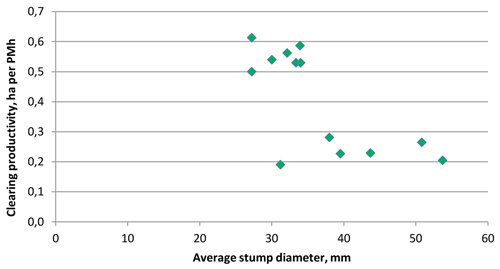

Fig. 9. The time study plot-wise clearing productivity (ha per PMh) of the JAK SP-180 spiral cutter as a function of average stump diameter of brushwood trees, mm.

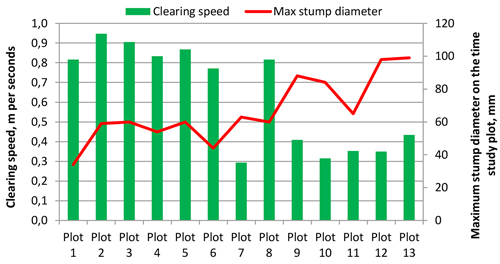

Fig. 10. The clearing speed (m per s) and the max. brushwood stump diameter (mm) by the study plot of the JAK SP-180 spiral cutter.

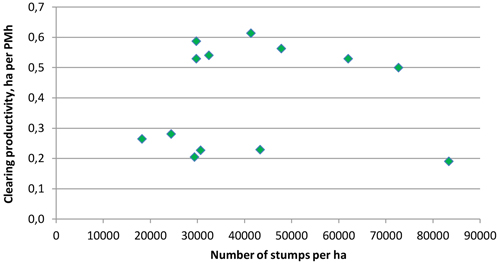

Fig. 11. The time study plot-wise roadside brushwood clearing productivity (ha per PMh) of the JAK SP-180 spiral cutter as a function of stump density per ha.

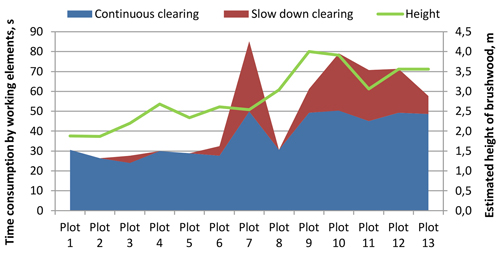

Fig. 12. The time consumption (seconds per time study plot) of continuous clearing and slowed down clearing working elements in brushwood clearing and estimated brushwood height by the time study plots of JAK SP-180 spiral cutter.

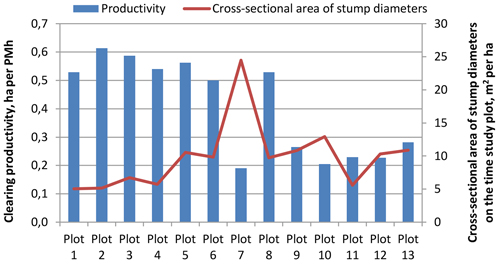

Fig. 13. The time study plot-wise clearing productivity (ha per PMh) of the JAK SP-180 spiral cutter as a function of cross-sectional area of stump diameters (m2 per ha) by the time study plot.