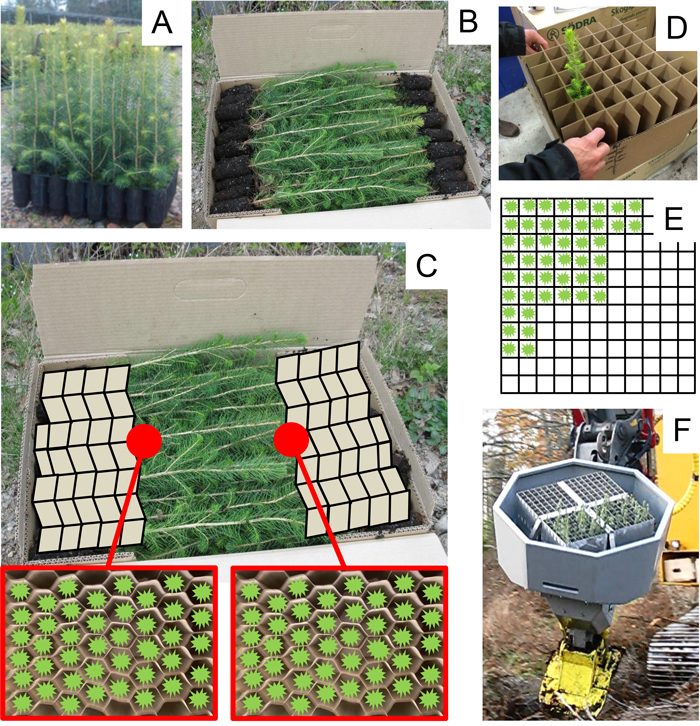

Fig. 1. Hiko v93 cultivation trays were the starting point for all systems. The Hiko supply system uses cultivation trays also as the seedling packaging (A). ManBox is today’s standard seedling supply system (B). The ManBox_fast system is conceptual and uses similar cardboard boxes as ManBox, but the novelty of ManBox_fast is that the seedlings are placed singly within the cells of two collapsible, compressible paper grid spacers (C). In the MechBox_49 (D) and MechBox_121 (E) systems, seedlings are packed into square cardboard boxes while standing upright within individual cells created by a carton grid spacer. The difference between the two MechBox systems is the grid spacers resulting in two different cell densities. ManBox_fast and both MechBox systems require a tree planting device equipped with a high-capacity seedling carousel (F) matching the geometry of the seedling packaging’s grid spacers.

| Table 1. Overview of the five seedling (Picea abies) packaging systems that were compared in the cost analysis from southern Sweden. | |||||

| Packaging system | Intended use | Developmental stage | Seedling position / description | Number of seedlings per handling unit (pl) | End point |

| Hiko (plastic cultivation trays) | Manual planting | Operational use in southern Sweden since the 1970s | Standing upright within individual tray cells/cavities | 40 | Reuse by nursery |

| ManBox (simple divisible cardboard box) | Manual planting | Operational use in southern Sweden since 2010 | Lying down, stems intertwined, in one large open space | 165 | Recycling |

| ManBox_fast (same box as in ManBox but with a collapsible, compressible paper grid spacer within the box) | Mechanized planting | Conceptual | Lying down, stems intertwined, but seedlings mounted in individual pockets of paper strips | 149 | Recycling |

| MechBox_49 (cardboard box with removable 7×7 carton grid spacer) | Mechanized planting | Existing prototype | Standing upright within individual cells created by the grid spacer | 49 | Recycling |

| MechBox_121 (cardboard box with removable 11×11 carton grid spacer) | Mechanized planting | Conceptual | Standing upright within individual cells created by the grid spacer | 121 | Recycling |

| Seedlings are abbreviated pl. | |||||

| Table 2. Cost factors for the five seedling (Picea abies) supply systems’ packaging materials. The total material cost is that of the basic scenario. | ||||||

| Intended use | Cost factor | Hiko | ManBox | ManBox_fast | MechBox_49 | MechBox_121 |

| Handling unit | Capacity (pl) | 40 | 165 | 149 | 49 | 121 |

| Dimensions (cm) | 22×35×40 | 60×40×28 | 60×40×28 | 40×40×45 | 40×40×45 | |

| Mass when loaded with seedlings (kg) | 3 | 11 | 10.5 | 4 | 9.5 | |

| Shipping unit | Capacity (pl) | 40 | 2640 | 2384 | 1176 | 2904 |

| Dimensions (cm) | 22×35×40 | 80×120×130 | 80×120×130 | 80×120×194 | 80×120×194 | |

| Mass when loaded with seedlings (kg) | 3 | 200 | 192 | 120 | 252 | |

| Total material cost (Euro (1000 pl)–1) | 15.58 | 10.00 | 31.20 | 59.80 | 24.20 | |

| Seedlings are abbreviated pl. | ||||||

| Table 3. Tariff (linear cost function; the total transport cost CTotalTrans = fixed cost + variable cost × invoiced distance in km) in the basic scenario for the primary transport of one week’s demand of seedlings from the nursery to the contractor’s depot (100 km one-way) for the five seedling (Picea abies) supply systems. The tariff gives the total transport cost (CTotalTrans) per 1000 seedlings including loading and unloading of seedlings in handling units of: i) cultivation trays for Hiko; and ii) stacked cardboard boxes shrink-wrapped together on Euro-pallets for the four cardboard box systems. | ||||

| Packaging system | Weekly consumption of seedlings (pl week–1) | Fixed cost (Euro (1000 pl)–1) | Variable cost (Euro (1000 pl)–1 km–1) | Invoiced distance (km) |

| Hiko | 7000 | 15.48 | 0.255 | 200 |

| ManBox | 6735 | 3.86 | 0.520 | 100 |

| ManBox_fast | 7780 | 3.67 | 0.449 | 100 |

| MechBox_49 | 7485 | 4.82 | 1.408 | 100 |

| MechBox_121 | 7870 | 3.31 | 0.622 | 100 |

| Seedlings are abbreviated pl. | ||||

| Table 4. Outplanting cost (COutplant) factors in the cost analysis of seedling supply systems from southern Sweden. The values are those of the basic scenario. | ||||||

| Packaging system | Handling units handled per shift | Time consumption for reloading seedlings (s pl–1) | Planting machine productivity (pl h–1) | Production per shift (pl shift–1) | Planting machine hourly cost (Euro h–1) | Additional investments required by the contractor |

| Hiko | 35 | 2.6 | 200 | 1400 | 85.0 | - |

| ManBox | 9 | 3.3 | 192 | 1347 | 85.0 | - |

| ManBox_fast | 11 | 0.8 | 222 | 1556 | 86.9 | Conceptual 296 seedling carousel |

| MechBox_49 | 31 | 1.45 | 214 | 1497 | 87.4 | Existing 196 seedling carousel + modified seedling storage box |

| MechBox_121 | 14 | 0.6 | 225 | 1574 | 87.4 | Conceptual 484 seedling carousel + modified seedling storage box |

| Seedlings (Picea abies) are abbreviated pl. | ||||||

| Table 5. The extent of the sensitivity analysis of the five seedling (Picea abies) packaging systems in southern Sweden. The last two columns show the change in cost variables from the basic scenario. | |||

| Variable | Basic scenario | Sensitivity analysis | |

| Minimum | Maximum | ||

| Primary transport distance (distance between nursery and depot) | 100 km | 0 km | 400 km |

| Mean planting time excluding seedling (Picea abies) handling | 15.4 s pl–1 | –40% | +40% |

| Yearly demand for mechanically planted seedlings | 500 000 pl year–1* | –0% | +1000% |

| Planting machine’s hourly cost | 85.0–87.4 Euro** | –8% | +70% |

| Planting device reload time | 0.6–3.3 s pl–1** | –50% | +30% |

| Number of seedlings per box of ManBox_fast | 149 pl | –45% | +10% |

| Planting device’s carousel capacity (for Hiko and ManBox only) | 70 pl | 70 pl | 484 pl |

| Interest rate, for contractor and nursery respectively | 6 and 10% | 3% | 12% |

| Seedlings are abbreviated pl. *See Table 3. **See Table 4. | |||

| Table 6. Aggregated costs per activity in the basic scenario for the five seedling (Picea abies) packaging systems in southern Sweden. Costs are given as Euro per thousand planted seedlings (Euro (1000 pl)–1) excluding the seedling purchase price. | |||||

| Packaging system | |||||

| Activity (cost variable) | Hiko | ManBox | ManBox_fast | MechBox_49 | MechBox_121 |

| Packing at the nursery (CPack) | 15.6 | 55.0 | 89.7 | 151.3 | 113.5 |

| Freezer storage (CFreezer) | - | 17.0 | 18.8 | 61.3 | 24.8 |

| Primary seedling transport (Total transport; CTotalTrans)* | 66.5 | 55.0 | 48.0 | 142.9 | 64.6 |

| Watering (CWater) | 6.2 | - | - | - | - |

| Loading secondary transport vehicle (CV.Load) | 6.8 | 3.4 | 3.5 | 8.1 | 4.1 |

| Loading planting machine (CPM.Load) | 7.7 | 4.2 | 4.3 | 8.7 | 4.8 |

| Outplanting seedlings (COutplant)** | 425.0 | 441.9 | 391.0 | 408.7 | 388.8 |

| Returning cultivation trays (CReturns) | 7.8 | - | - | - | - |

| Recycling cardboard boxes (CRecycling) | - | 8.4 | 8.3 | 17.4 | 9.5 |

| Total (i.e. aggregated) cost (CTotal) | 535.5 | 584.9 | 563.6 | 798.4 | 610.1 |

| Seedlings are abbreviated pl. * Including loading at the nursery and unloading at the depot. ** Including reloading planting device. | |||||

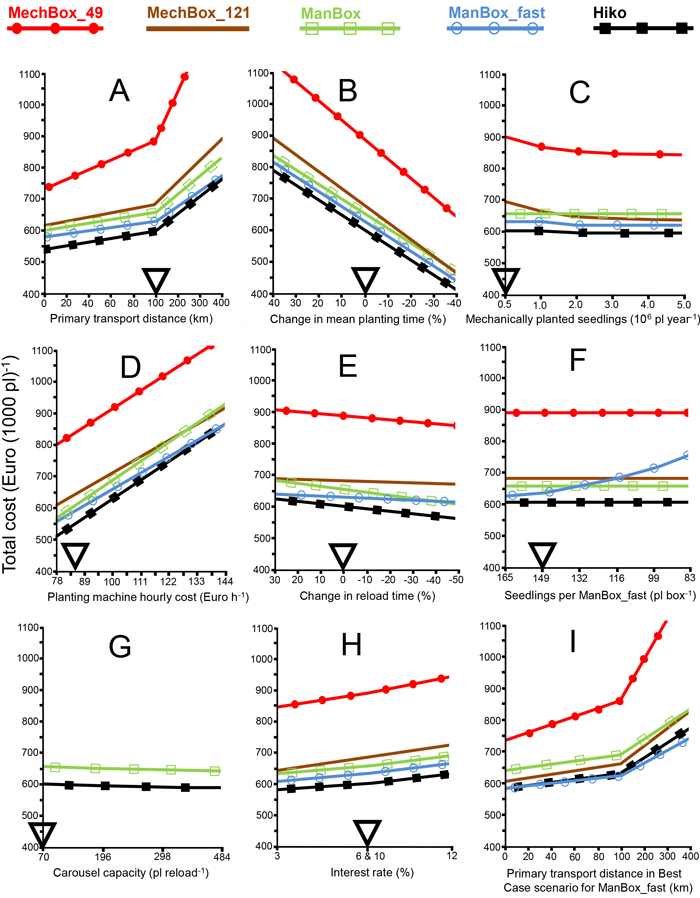

Fig. 2. The effect on the total cost of the studied seedling (Picea abies) packaging systems per thousand seedlings (pl) when varying the distance between nursery and depot (A), the mean planting time excluding seedling handling (B), the yearly demand for mechanically planted seedlings (C), the planting machine’s hourly cost (D), the relative planting device reload time (E); the number of seedlings per box of ManBox_fast (F), the planting device’s carousel capacity (for Hiko and ManBox only (G), the interest rate (H), and the primary transport distance during a best case scenario from ManBox_fast’s point-of-view (I). The triangles on the x-axes denote the default values used in the basic scenario.