Fig. 1. The excavator-based harvester used for the research.

| Table 1. Specifications of excavator-base and harvester head used in the study. |

| Component | Specification |

| Base machine |

| Make and model | Sumitomo SH210 |

| Weight | 20 000 kg |

| Power rating | 117.3 kW |

| Width | 2800 mm |

| Length (without boom) | 4810 mm |

| Height | 2960 mm |

| Ground clearance | 440 mm |

| Boom outreach | 8700 mm |

| Head |

| Make | Waratah 616 C |

| Weight | 1680 kg |

| Max cutting capacity | 55 cm |

| Saw bar length | 75 cm |

| Number of feed-rollers | 3 |

| Feed-roller type | steel with angled bars |

| Number of knives | 2 fixed, 3 moving |

| Hydraulic fluid requirement | 320 – 360 l/min |

| Max hydraulic pressure requirement | 35 MPa |

| Table 2. Site description. |

| Plantation | Sappi Venus |

| Compartment | A44 |

| Species | E. grandis (Coppiced) |

| Area (ha) | 42.0 |

| Age (yrs) | 11.0 |

| Average DBH (cm) | 21.0 |

| Average Height (m) | 33.7 |

| Spacing (m) | 2.4 × 2.4 |

| Trees per hectare (after mortality) | 1383 |

| Average tree volume (m3) | 0.466 |

| Removal per hectare (m3) | 645 |

| Original sample size (trees) | 769 |

| Ground roughness | Smooth |

| Slope | Level to Gentle (less than 20%) |

| Table 3. Description of time elements of the cutting process. |

| Time element | Description |

| Moving | Any time the tracks were rolling. |

| Felling | Positioning the harvester head around the standing tree, which began when the boom reached out; felling proper, which began when the chainsaw started advancing and ended when the tree started to fall and the head was horizontal, ready to process the tree. |

| Processing | Began when the head was horizontal and included delimbing, debarking and crosscutting. Ended when the last assortment had been processed. |

| Other work | Any other productive time (e.g., removing of obstacles, stacking logs etc.). |

| Delays | Non-productive time, including mechanical, operational and personal delays. |

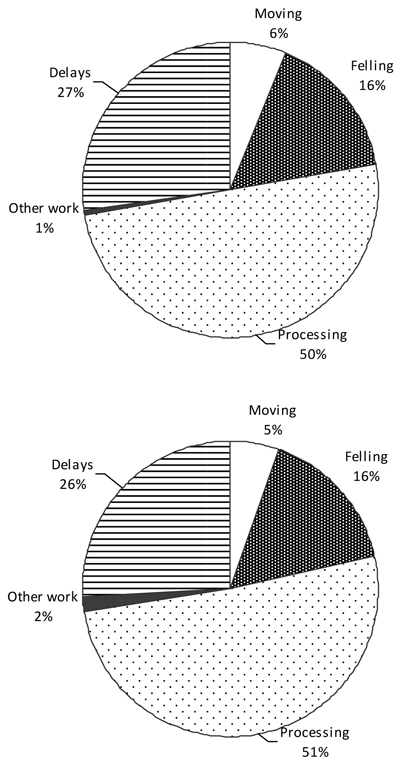

Fig. 2. Breakdown of worksite time by activity type for single stems (above) and double stems (below).

| Table 4. Multiple regression models for time consumption. |

| Moving |

| T = | 5.147 |

| Felling | R2 adjusted = 0.428 |

| Ln T = a + b DBH^2 + c OPB |

| | Coeff | SE | T | P |

| a | 2.149 | 0.031 | 68.635 | < 0.001 |

| b | 9.389 * 10–4 | 0.511 * 10–4 | 18.381 | < 0.001 |

| c | 0.217 | 0.048 | 4.526 | < 0.001 |

| Processing (= delimb, debark, cross cut) | R2 adjusted = 0.715 |

| T = a + b DBH^2 + c OPB + d OPB * DS |

| a | 19.672 | 1.038 | 18.942 | < 0.001 |

| b | 0.057 | 0.002 | 33.871 | < 0.001 |

| c | 4.942 | 2.431 | 2.032 | 0.043 |

| d | 6.653 | 2.991 | 2.224 | 0.027 |

| Cutting (= felling + processing) | R2 adjusted = 0.750 |

| T = a + b DBH^2 + c OPB + d OPB * DS |

| a | 26.516 | 1.227 | 21.612 | < 0.001 |

| b | 0.074 | 0.002 | 36.944 | < 0.001 |

| c | 9.038 | 2.863 | 3.157 | 0.002 |

| d | 7.295 | 3.521 | 2.072 | 0.039 |

| Other work |

| T = | 1.168 |

| Delays |

| (Moving + Cutting + Other work) * 0.208 |

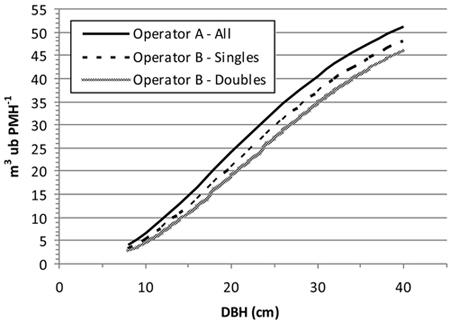

Fig. 3. Harvester productivity as a function of tree size and treatment (single vs. double stem). DBH = Stem diameter at breast height (1.37 m).