| Table 1. Harvests and net exports of wood in seven production alternatives considered for Norway. iH2021: harvest and forest industry production as in 2021. iH2021Fibr: as iH2021 but with pulpwood exports used for textile fibre and insulation materials production instead of paper pulp. iH2021Fuel: as iH2021 but with pulpwood exports used for transportation biofuels. iH2021-20%: industrial roundwood harvests are 20% lower than in 2021. Forest industry production based on exported wood is cut down. iH2021+20%: industrial roundwood harvests are 20% higher than in 2021. Production increases in existing product categories. iH2021+20%Fibr: as iH2021+20% but production of textile and insulation materials increase. iH2021+20%Fuel: else as iH2021+20% but production of transportation biofuels increases. | ||||||||

| Harvest, Mm3 | Net exports, Mm3 | Side product from sawlog net exports and changes in domestic sawnwood production, Mm3 | ||||||

| Fuelwood | Sawlogs | Pulpwood | Total | Sawlogs | Pulpwood | Wood chips and particles | Wood chips and particles | |

| iH2021 | 2.1 | 6.9 | 4.6 | 13.6 | 1.7 | 1.9 | 0.2 | 0.6 |

| iH2021Fibr | 2.1 | 6.9 | 4.6 | 13.6 | 1.7 | - | - | 0.6 |

| iH2021Fuel | 2.1 | 6.9 | 4.6 | 13.6 | 1.7 | - | - | 0.6 |

| iH2021-20% | 2.1 | 5.5 | 3.7 | 11.3 | 0.3 | 0.9 | 0.2 | 0.1 |

| iH2021+20% | 2.1 | 8.2 | 5.6 | 15.9 | 3.0 | 2.8 | 0.6 | 1.1 |

| iH2021+20%Fibr | 2.1 | 8.2 | 5.6 | 15.9 | 1.7 | - | - | 1.1 |

| iH2021+20%Fuel | 2.1 | 8.2 | 5.6 | 15.9 | 1.7 | - | - | 1.1 |

| Table 2. Production of forest industry products in the seven cases considered for Norway. Abbreviations: SaW = sawnwood, MeP = mechanical pulp, ChP = chemical pulp, DiP = Dissolving pulp, ParB = particleboard, FiB = fibreboard, WhP = white pellets, BlP = black pellets, TeF = textile fibre, InsM = insulation materials, BE = bioethanol. Wood inputs for textile fibre and ethanol were randomized between 4.9–5.3 m3 Mg–1 and 6.0–7.3 m3 m–3, respectively. Notation [min, max] gives the resulting minimum and maximum production levels that appeared in the 15 000 states of nature. Mg refers to tonne, and Tg to millions of tonnes. For short description of the cases, see Table 1. | |||||||||||

| SaW | MeP | ChP | DiP | ParB | FiB | WhP | BlP | TeF | InsM | BE | |

| Mm3 | Tg | Tg | Tg | Mm3 | Mm3 | Tg | Tg | Tg | Tg | Mm3 | |

| iH2021 | 3.73 | 0.90 | 0.53 | 0.15 | 0.32 | 0.18 | 0.15 | 0.07 | 0.00 | 0.04 | 0.02 |

| iH2021Fibr | 3.73 | 0.90 | 0.12 | 0.15 | 0.32 | 0.18 | 0.15 | 0.07 | [0.29, 0.35] | 0.20 | 0.02 |

| iH2021Fuel | 3.73 | 0.90 | 0.12 | 0.15 | 0.32 | 0.18 | 0.15 | 0.07 | 0.00 | 0.04 | [0.28, 0.38] |

| iH2021-20% | 2.97 | 0.90 | 0.24 | 0.15 | 0.32 | 0.18 | 0.15 | 0.07 | 0.00 | 0.04 | 0.02 |

| iH2021+20% | 4.49 | 0.90 | 0.82 | 0.15 | 0.32 | 0.18 | 0.15 | 0.07 | 0.00 | 0.04 | 0.02 |

| iH2021+20%Fibr | 4.49 | 0.90 | 0.12 | 0.15 | 0.32 | 0.18 | 0.15 | 0.07 | [0.48, 0.59] | 0.31 | 0.02 |

| iH2021+20%Fuel | 4.49 | 0.90 | 0.12 | 0.15 | 0.32 | 0.18 | 0.15 | 0.07 | 0.00 | 0.04 | [0.47, 0.65] |

| Table 3. Carbon displacement factors (DFs) for 2030, end uses, and other assumptions made on harvested wood products (HWPs) originating from Norwegian wood. Unless otherwise mentioned, unit for DF is MgC per unit of finished product expressed in MgC stored in it. For the parameters varying across the 15 000 states of nature, the ranges used in defining these states by random draw are indicated either by [lowest value, highest value] or by a default value with a 30% percentage variation around it. Thus e.g., 0.9 + 30% could also be written [0.63, 1.17]. | |||

| HWP | Variation in end-use share or wood input & other assumptions | DF, Production | DF, End-of-Life |

| Sawnwood for | |||

| Construction: | [70%, 80%] of sawnwood (1) | ||

| -Structural | [60%, 73%] of construction (2), (3) | 0.9 + 30% (2) | 0.55 + 30% |

| -Non-structural | Rest of construction | 1.2 + 30% (2) | 0.55 + 30% |

| Furniture | [2%, 4%] of sawnwood (4), (5) | 0.9 + 30% (4) | 0.55 + 30% |

| Packaging | [81%, 91%] of what is left after construction and furniture. Mean 19%. (4), (5) | 1.1 + 30% (4) | 0.55 + 30% |

| Other uses | What is left from all other uses. Mean 3%. (4), (5) | 0 (4) | 0.55 + 30% |

| Fibreboard | Various end-uses | [–0.16, 0.33] (6), (7) | 0.55 + 30% |

| Particleboard | Various end-uses | [0.26–1.60] (2), (6), (7), (8), (15) | 0.55 + 30% |

| Insulation materials | |||

| Blow in | [40%, 60%] (3) | [2.9, 3.8] (9), (10), (11) | 0.55 + 30% |

| Board form | Rest of insulation materials | [1.5, 3.8] (9), (10), (11) | 0.55 + 30% |

| Mechanical pulp | Used for newsprint and magazine papers | 0 | 0.55 + 30% |

| Wood-based textile fibres | Substituting oil-based fibre. Wood input [4.9, 5.3] m3 per Mg of pulp (3) | [2.5, 3.7] (12), (13), (14) | 0.55 + 30% |

| Chemical pulp made from exported wood | |||

| Printing and writing papers | 50% end-use share (3) | 0 (4) | 0.55 + 30% |

| Paperboard replacing plastics | 50% end-use share (3) | 1.3 + 30% (8) | 0.55 + 30% |

| Pellets (white) | Substituting [heating oil, coal] | - | [0.35, 0.43] MgC per Mg of pellets (3) |

| Pellets (black) | Substituting coal | - | [0.45, 0.49] MgC per Mg of pellets (3) |

| Bioethanol | Substituting gasoline. Wood input [6, 7.3] m3 per m3 of fuel (3) | - | [0.35, 0.44] MgC per m3 of fuel (3) |

| Fuelwood | Household fuelwood | - | [0.10, 0.60] (3) |

| Sources: 1) Treindustrien 2021. 2) Leskinen et al. 2018. 3) Calculated or assumed by authors, 4) Hurmekoski et al. 2020. 5) Sandberg et al. 2014. 6) Suter et al. 2017. 7) Trømborg and Sjølie 2011, 8) Knauf et al. 2015. 9) Kallio et al. 2023, 10) Hunton 2017, 2020a, 2020b, 11) Schulte et al. 2021, 12) Shen et al. 2010, 13) Rüter et al. 2016, 14) Spinnova 2022. 15) Brunet-Navarro et al. 2021. | |||

| Table 4. Assumptions used for calculating the carbon sinks in Norway for harvested wood products (HWP) with half-life of 2 years or more. The half-life values vary across the 15 000 states of nature, and ranges used in defining these states by random draw are indicated by [lowest value, highest value]. Lifetime data are based on various sources reviewed and indicated in Kallio et al. (2023, p. 260). | ||

| HWP | Mean lifetime (ML). Years. | Half-life range used in sampling. HL = ln(2) × ML. [Min, Max] years. |

| Sawnwood | Weighted average over the uses in Table 3 | [20, 50] |

| -Structural construction | 52–100 | [36, 69] |

| -Non-structural construction | 10–60 | [7, 42] |

| Furniture | 13–43 | [9, 30] |

| Packaging | 0–9 | [0, 6] |

| Other uses of sawnwood | 0–9 | [0, 6] |

| Particleboard | Weighted average of various uses: [40%, 50%] for furniture with ML of 13–43 years, rest [50%, 60%] for non-structural construction, with ML of 10–60 years. | [8, 37] |

| Insulation materials | [28, 42] | |

| Paper pulp | 2 | |

| Pulp for textiles | 3 | |

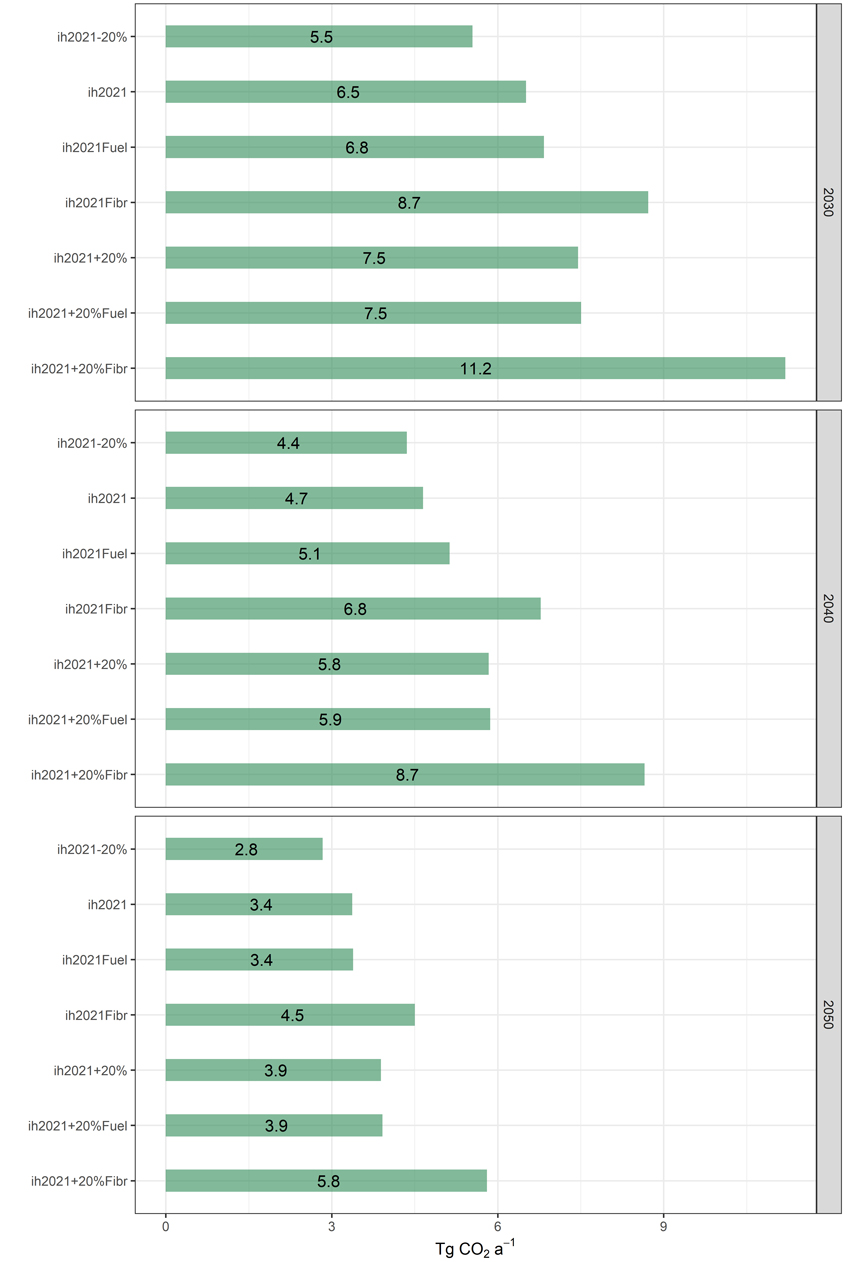

Fig. 1. Mean substitution effects of Norwegian forests for seven production alternatives evaluated in 2030, 2040, and 2050, Tg CO2 a–1. The figures are calculated for total production quantities, as in Table 2. The cases are arranged in the order of increasing substitution effects. The production alternatives are explained in Tables 1 and 2, and Section 2.1.

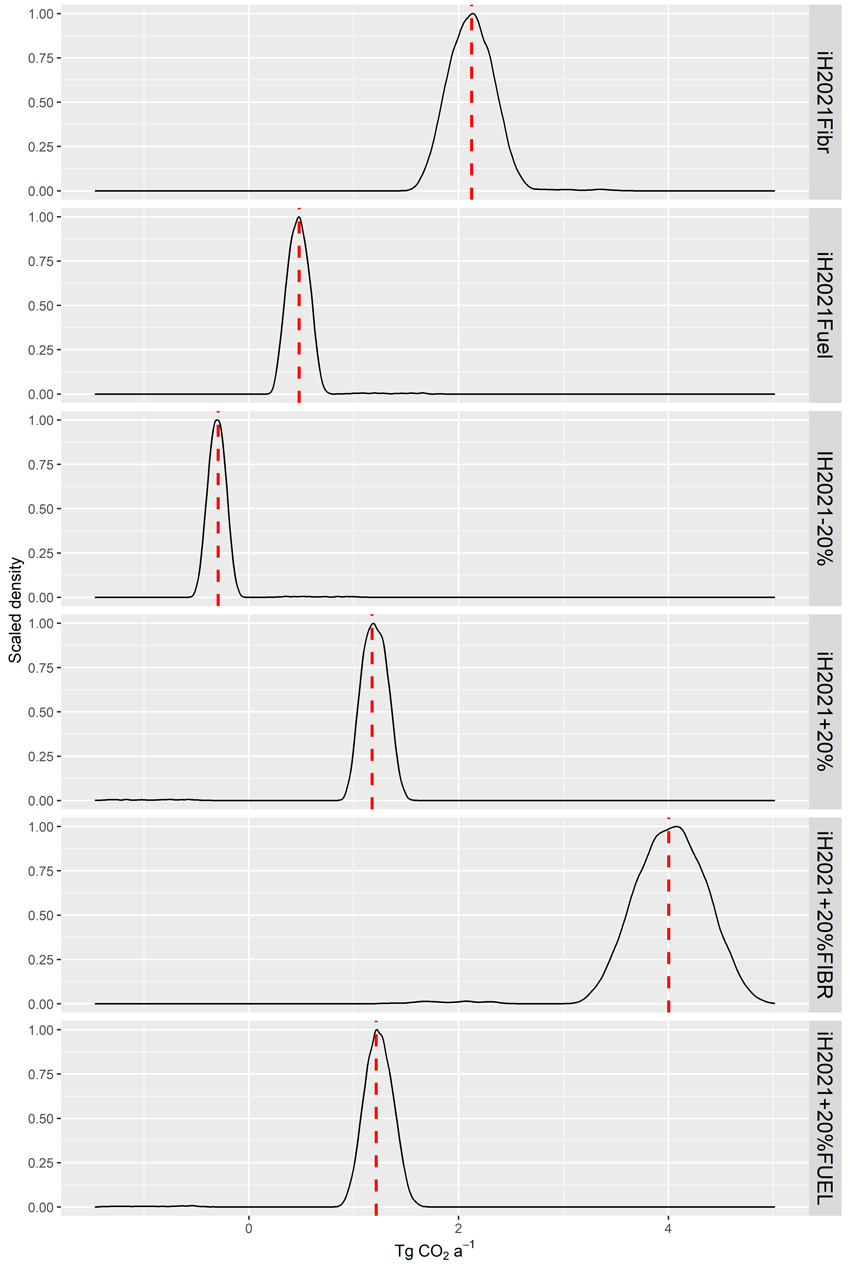

Fig. 2. Probability distributions of the difference in avoided emissions (substitution effects) among six production alternatives for Norway compared to the iH2021 case, evaluated across 15 000 states of nature in 2040, Tg CO2 a–1. See Tables 1 and 2 in Section 2.1 for the explanations of the production alternatives.

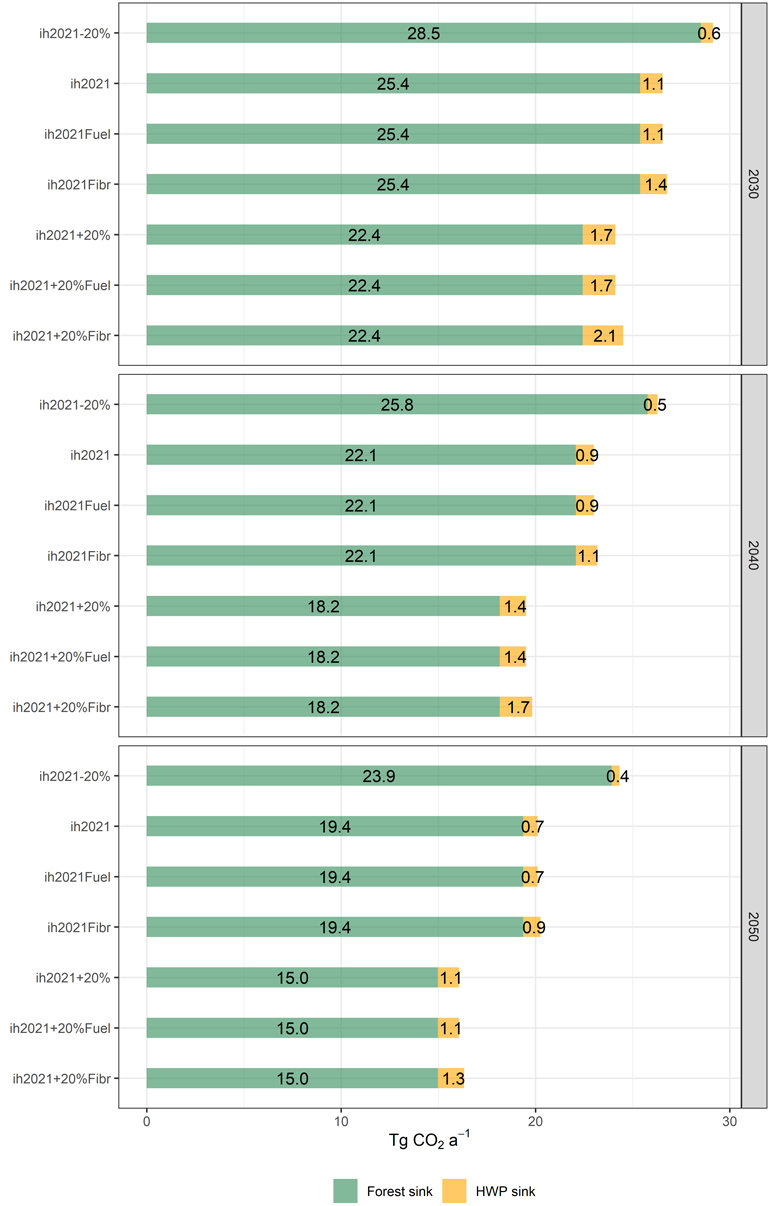

Fig. 3. Mean carbon sinks in forests and harvested wood products related to Norwegian forests for seven cases evaluated in years 2030, 2040, and 2050, Tg CO2 a–1. The cases are arranged in the order of declining carbon sinks. The cases are explained in Tables 1 and 2, and Section 2.1.

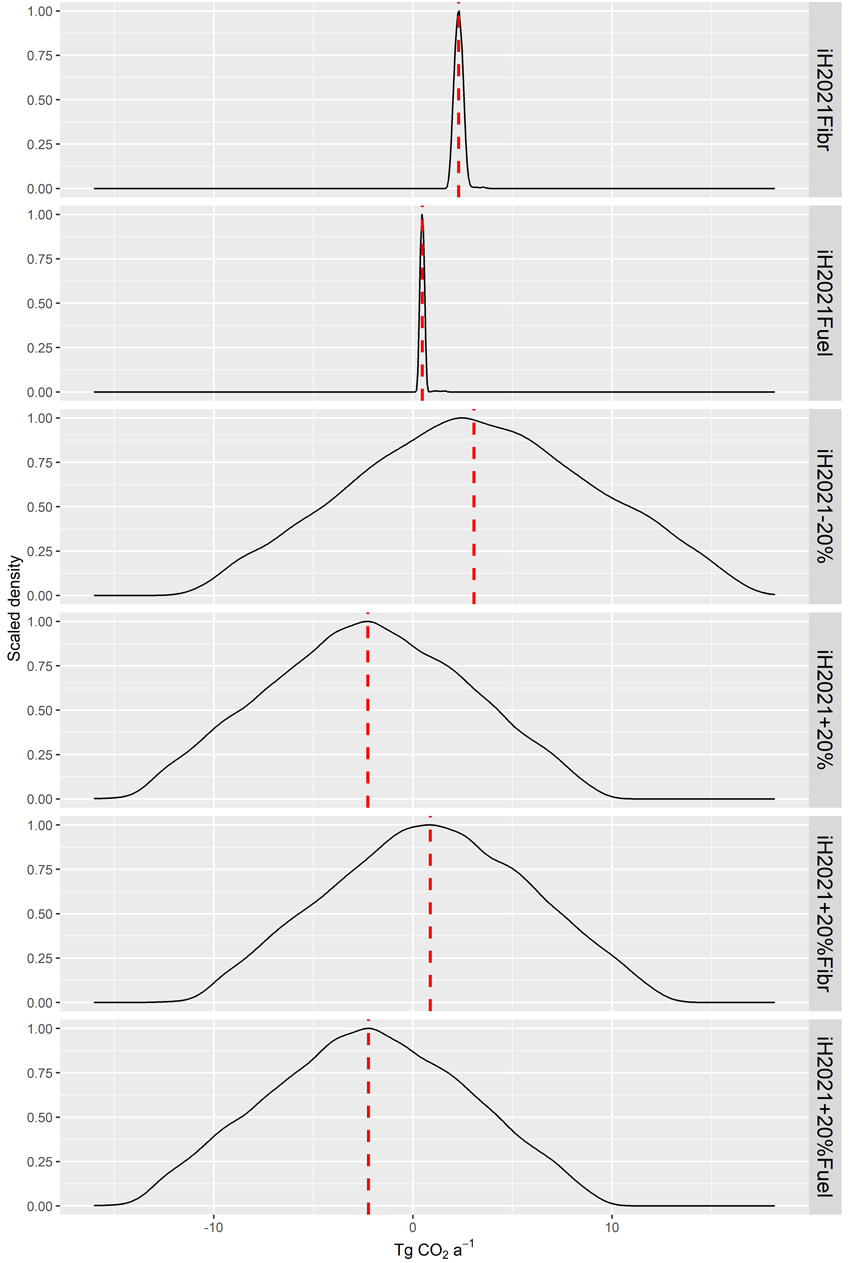

Fig. 4. Probability distributions of the difference in climate effects among six production alternatives for Norway compared to the iH2021 case, evaluated across 15 000 states of nature in 2040. The effects compared include the carbon sinks of forests and harvested wood products and avoided emissions resulting from the use of harvested wood products, Tg CO2 a–1. See Tables 1 and 2 in Section 2.1 for the explanations of the production alternatives.