| Table 1. The terrain models’ descriptive parameters. | ||||||

| Terrain model | Description | Stumps ha–1 | Stump basal area (m2 ha–1) | Boulder quota a) (%) | Stone frequency (n m–2) | Mean stone volume (dm3) |

| 0 | No obstacles | 0 | 0 | 0 | 0 | 0 |

| 1 | Few stumps, few stones | 230 | 71.5 | 25 | 14 | 1.8 |

| 2 | Many stumps, few stones | 635 | 95.5 | 25 | 14 | 1.8 |

| 3 | Few stumps, many stones | 230 | 71.5 | 75 | 25 | 3.6 |

| 4 | Many stumps, many stones | 635 | 95.5 | 75 | 25 | 3.6 |

| 5 | Moderate stumps, moderate stones | 390 | 35.5 | 55 | 21 | 3.0 |

| a) As defined by the Swedish Terrain Classification System (Berg 1982). Also termed stoniness or rockiness. | ||||||

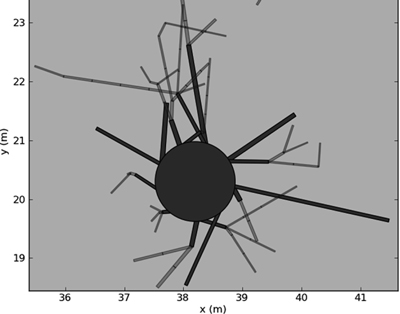

Fig. 1. A modelled stump. The large, dark circle comprises both the annular root plate and the actual stump. The visible main lateral roots originate from the root plate’s edge and are shaded darker while the non-visible secondary roots are lighter in shade.

| Table 2. The assumed technical specifications of the machine models. | ||||

| Description | 1a1h | 1a2h | 2a2h | 2a4h |

| Crane arms | 1 | 1 | 2 | 2 |

| Planting heads | 1 | 2 | 2 | 4 |

| Total machine mass (t) | 22.5 a) | 23 a) | 27 b) | 27.5 b) |

| Seedlings per reload | 72 c) | 162 c) | 144 | 324 |

| a) Including standard monoblock boom and dipperstick (3 tonnes), rotator (0.4 tonnes) and one planting device (Bracke Planter: 1.1 tonnes / M-Planter: 1.5 tonnes). b) Including crane pillar from two-piece boom (1.1 tonnes), two smaller sized outer booms and dippersticks (3 tonnes), attachment plate (1 tonne), one extra rotator and one extra planting device. c) According to Rantala et al. (2009). | ||||

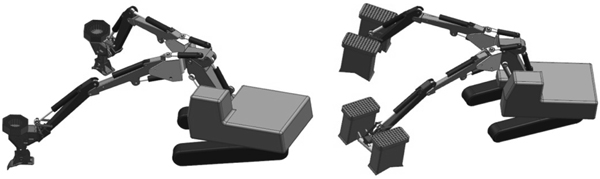

Fig. 2. Conceptual two-armed excavator with one-headed (2a2h, left) and two-headed (2a4h, right) planting devices. Seedlings are reloaded piecewise into carousels mounted on top of each planting device.

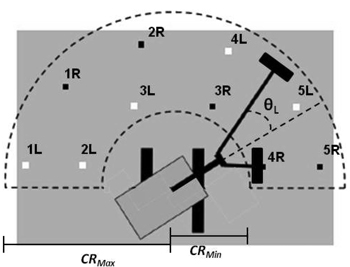

Fig. 3. The semiannular working area, work pattern, radial limits (CRMax and CRMin), and the left arm’s lateral angle (θL) of the 2a4h model. The ten small squares are the ideally spaced crane stops in numerical order for two-headed planting devices; the white and black squares for the left (L) and right arm (R) of two-armed machines respectively. The working area was assumed to be equally large for all four machine models.

| Table 3. Time consumption coefficients for the machine models’ work tasks. | |

| Task | Value (s) |

| Mounding, total time | 5 a) |

| Digging | 3 |

| Heaping | 2 |

| Planting, total time | 3 a) |

| Dibble down | 1 |

| Release seedling | 1 |

| Dibble up and firm soil | 1 |

| Halting mounding or planting | 1 |

| Remounding | 5 |

| Switching operator focus between planting arms | max 2 b) |

| Reloading seedlings | 223 c), 366 c), 362, 648 d) |

| a) Values are approximations sourced from manufacturers b) For 2a-machines only, see section 2.3.2 c) From Rantala et al. (2009) d) For 1a1h, 1a2h, 2a2h, 2a4h respectively | |

| Table 4. Coefficients for modelling crane pillar, outer boom and base machine movement. | ||

| Parameter | Unit | Value (s) |

| CCrane | s | 1.5 a) |

| CLat | s | 0.1 a) |

| CRad | s | 0.1 a) |

| CBM | s | 5 a) and 7.5 b) |

| VSlew | ° s–1 | 71 c) |

| VLat | ° s–1 | 15 c) |

| VRad | m s–1 | 1.6 c) |

| VBM | m s–1 | 0.3 d) and 0.23 b) |

| a) From Eliasson (1999) b) For 1a- and 2a-machines respectively c) Values sourced from manufacturers d) According to measurements from Karlsson (2007) | ||

Fig. 4. Screen snapshot of the SimPy discrete-event simulation tool’s visualization feature.

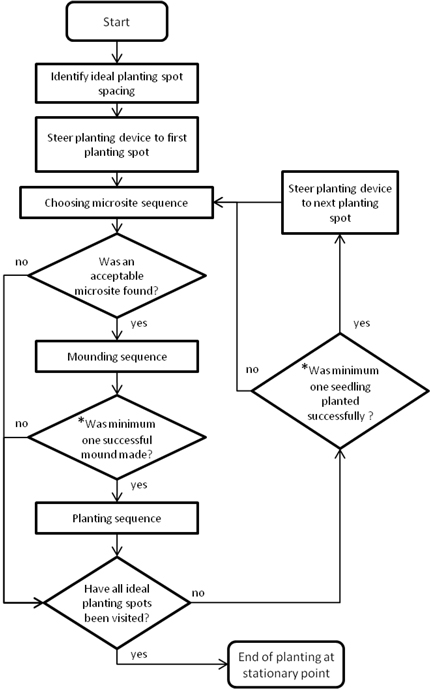

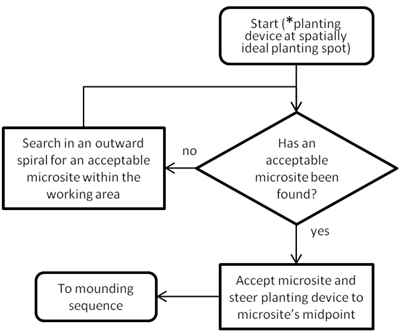

Fig. 5. Flowchart for determining the machine models’ work pattern (* only relevant for two-headed planting devices).

Fig. 6. Flowchart for choosing microsites with two-armed machines (* relevant for automated two-armed crane movement).

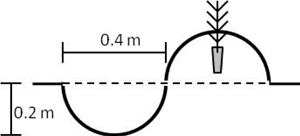

Fig. 7. Dimensions of the simulated scoops and mounds (the dashed line represents ground level). The seedlings were assumed to be cultivated in Hiko v93 trays (cf. Ersson et al. 2011) and having a standard root plug length of 9 cm.

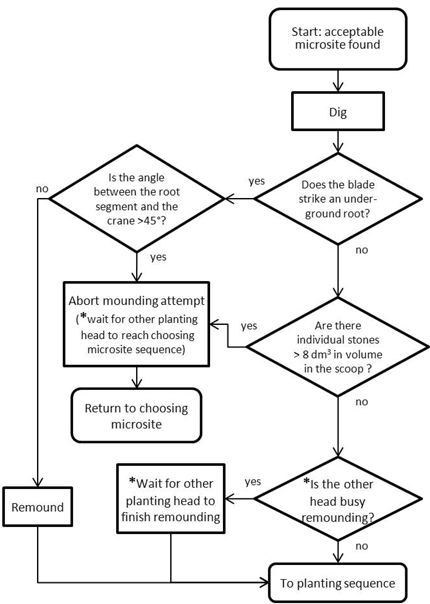

Fig. 8. Flowchart for mounding with two-headed planting devices (* only relevant for two-headed planting devices).

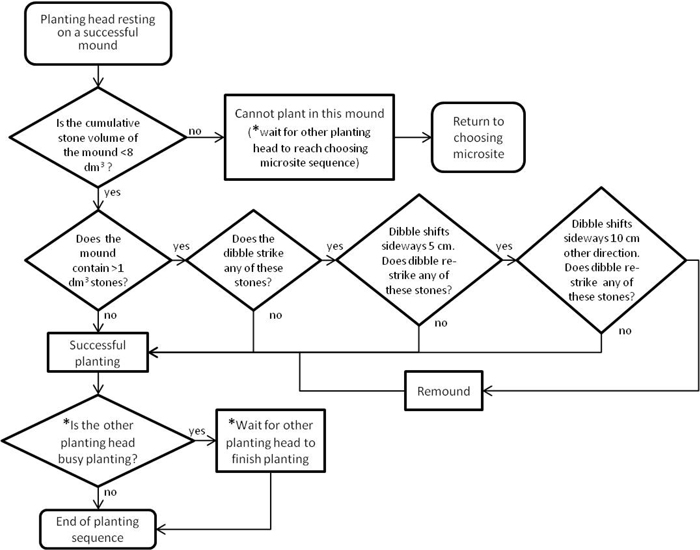

Fig. 9. Flowchart for planting with two-headed planting devices (* only relevant for two-headed planting devices).

| Table 5. Change in parameter values from the basic scenario. | ||||

| Parameter | Unit | Basic scenario | Sensitivity analysis | |

| Minimum | Maximum | |||

| Machine model | ||||

| Maximum crane reach (CRMax) | m | 9 | 9 | 11 |

| 2a attachment plate location (from swing point) | m | 3 | 3 | 5 |

| 2a lateral range of motion (θ) | degrees (°) | min 0, max 45 | –20 | 60 |

| Radial crane velocity (VRad) | m s–1 | 1.6 | 0.8 | 3.2 |

| Mounding blade width (WMB) | cm | 40/45a) | 40 | 60 |

| Distance between planting dibbles a) | cm | 201 | 100 | 201 |

| Simulation model | ||||

| Minimum seedling spacing | m | 1.5 | 1 | 1.5 |

| Target stocking rate (TSR) | pl ha–1 | 2000 | 1500 | 2500 |

| a) For 2h planting device. | ||||

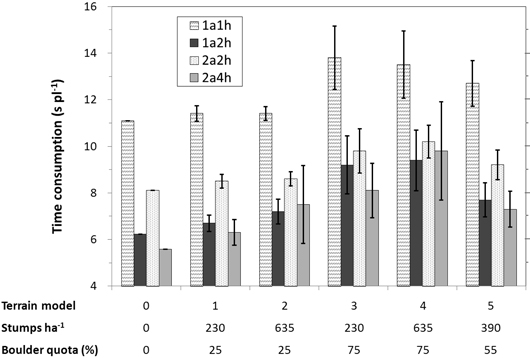

Fig. 10. The four machine models’ mean time consumption per planted seedling excluding seedling reloading on the deterministic terrain model (0) and the five terrain models with stochasticity (1–5). Vertical bars are the range.

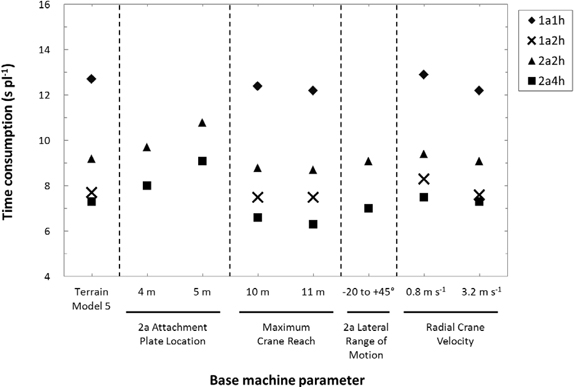

Fig. 11. The effect of selected base machine parameter values on the machine models’ simulated mean time consumption per planted seedling excluding seedling reloading when reforesting terrain model 5. The 2a attachment plate location and 2a range of motion parameters are only relevant for 2a-machines.

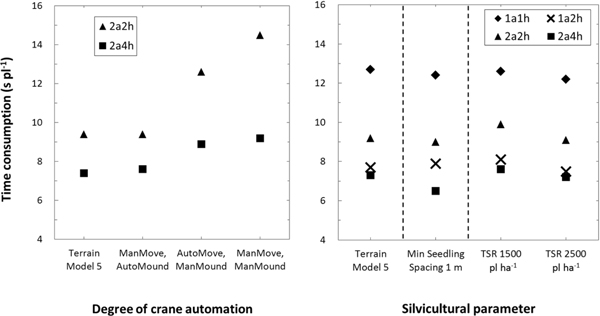

Fig. 12. The effect of simpler two-armed automation regimes (left) and different silvicultural prescriptions (right, see Table 5 for parameter clarification) on the machine models’ mean time consumption per planted seedling excluding seedling reloading when reforesting terrain model 5. Man: manually controlled; Auto: automated; Move: moving crane between planting spots; Mound: mounding; TSR: target stocking rate.

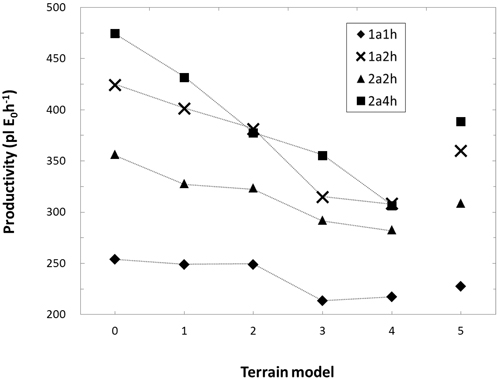

Fig. 13. Mean productivity (planted seedlings per effective hour including seedling reloading) per machine and terrain model (see Table 1 for terrain model clarification).

| Table 6. Average time consumption (TC) values and proportions per machine model and work element when reforesting terrain model 5. | |||||||||

| Work element | TC (s pl–1) | Proportion of TC (%) | |||||||

| Machine model | |||||||||

| 1a1h | 1a2h | 2a2h | 2a4h | 1a1h | 1a2h | 2a2h | 2a4h | ||

| Main task | |||||||||

| Moving crane | 2.59 | 1.83 | 2.31 | 2.15 | 16.3 | 18.3 | 19.8 | 23.2 | |

| Choosing microsite | - | 0.28 | - | 0.29 | - | 2.8 | - | 3.1 | |

| Mounding (incl. halting mounding and remounding) | 5.72 | 2.85 | 2.91 | 1.71 | 36.1 | 28.4 | 25.0 | 18.4 | |

| Planting (incl. halting planting and reattempts) | 3.28 | 1.60 | 1.62 | 0.98 | 20.7 | 16.0 | 13.9 | 10.6 | |

| Switching operator focus between planting arms | - | - | 0.74 | 0.46 | - | - | 6.3 | 5.0 | |

| Secondary task | |||||||||

| Moving base machine | 1.16 | 1.20 | 1.58 | 1.69 | 7.3 | 11.9 | 13.5 | 18.2 | |

| Reloading seedlings | 3.10 | 2.26 | 2.51 | 2.00 | 19.6 | 22.6 | 21.5 | 21.5 | |

| Total | 15.84 | 10.01 | 11.67 | 9.27 | 100 | 100 | 100 | 100 | |