| Table 1. Categorization of related review papers. | |||||||

| Researcher (year) | Region | Journal | DES | OM | WSC | B | MT |

| D’Amours et al. (2008) | CAN | Information Systems and Operational Research | X | X | |||

| Manuj et al. (2009) | USA | International Journal of Physical Distribution & Logistics Management | X | ||||

| Tako and Robinson (2012) | GBR | Decision Support Systems | X | ||||

| Shashi and Pulkki (2013) | CAN | American Journal of Industrial and Business Management | X | X | X | ||

| Seay and Badurdeen (2014) | USA | Current Opinion in Chemical Engineering | X | X | X | ||

| Wolfsmayr and Rauch (2014) | AUT | Biomass & Bioenergy | X | X | X | X | |

| Lautala et al. (2015) | USA | Environmental Management | X | X | X | X | |

| Atashbar et al. (2016) | FRA | IFAC-PapersOnLine | X | X | X | ||

| Borodin et al. (2016) | FRA | European Journal of Operational Research | X | X | X | ||

| Oliveira et al. (2016) | BRA | Simulation Modelling Practice and Theory | X | X | |||

| Mirkouei et al. (2017) | USA | Renewable & Sustainable Energy Reviews | X | X | |||

| Opacic and Sowlati (2017) | CAN | Forest Products Journal | X | X | |||

| Kogler and Rauch (2018) | AUT | Silva Fennica | X | X | X | ||

| DES = Discrete Event Simulation, OM = Optimization Models, WSC = Wood Supply Chain, B = Biomass, MT = Multimodal Transportation | |||||||

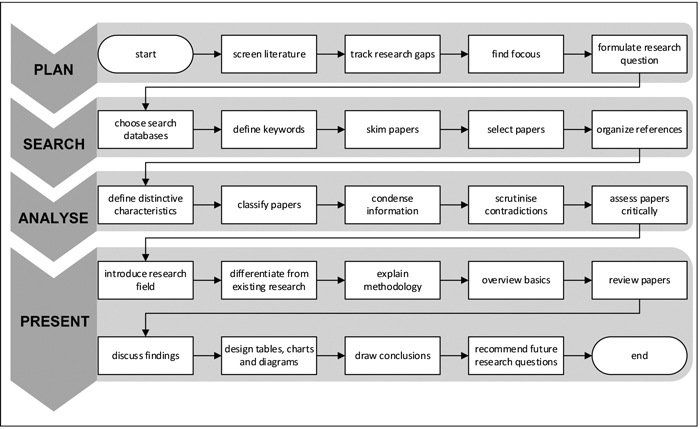

Fig. 1. Methodology of the literature research (cf. Oliveira et al. (2016)).

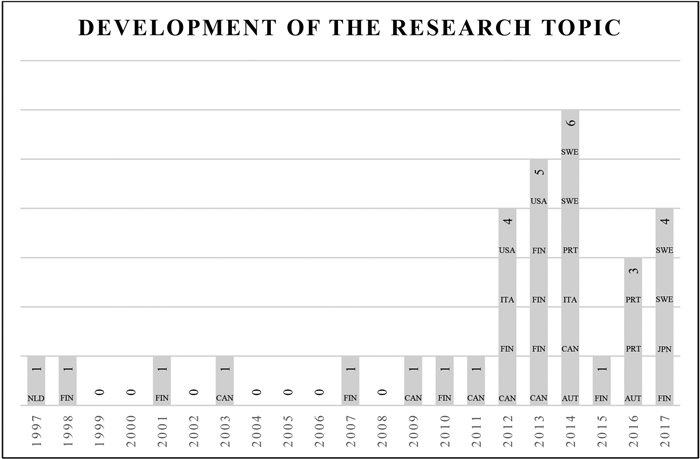

Fig. 2. Amount of analyzed papers per year and country.

| Table 2. Multimodal DES models. | |||||

| Reference (year) | RC | CS | Simulation period (resolution time) | Supply network | Objective |

| De Mol et al. (1997) | (X) | 1 year | source, collection, pre-treatment, transhipment, energy plant | gain insight into the costs and energy consumption of logistics | |

| Asikainen (2001) | X | 1 month | harvesting, forwarding, 15 vessel terminals, powered barge / push barge, mill | cost comparison of push barge systems to a powered barge system for waterway transport | |

| Saranen and Hilmola (2007) | X | 2 weeks | 28 rail terminals, railway network, 2 mills | evaluate the competitiveness of a unit train concept by cost considerations | |

| Karttunen et al. (2012) | X | X | 9 months | 3 fuel terminals at harbors, waterway network, 3 bio-power plants | determine the efficiency of waterway transport and compare the costs to truck transport of forest chips for Lake Saimaa |

| Karttunen et al. (2013) | X | 1 year | roadside storage, chipping, container truck transport, terminal, railway transportation, combined heat and power plant | compare the cost-efficiency of a multimodal supply chain with an intermodal container supply chain for long-distance transportation of wood chips by road and rail with a combined simulation and GIS model | |

| Mobini et al. (2013) | X | X | 1 year | 5 suppliers, transportation (10 trucks, railcar, ocean vessel), raw material handling and storage, 1 pellet mill (drying, size reduction, pelletization, cooling, storage, packing, distribution), end customer | estimate delivery cost to customer and CO2 emissions along the wood pellet supply system in scenarios with different fuel types and different raw material mixtures for pellets |

| Etlinger et al. (2014) | X | X | 1 year (minutes) | forest and prehaulage, 4 rail terminals, railway network, 2 saw mills, 2 paper mills | improve efficiency of supply chain and determine transhipment time / cycle time, stock levels at terminals over time, utilization of terminal infrastructure, network capacity and terminal size |

| Mobini et al. (2014) | X | X | 1 year | 5 suppliers, truck transport, export port for incoming rail and outgoing vessels, raw material handling and storage, 1 pellet mill (drying, torrefaction, pelletization, cooling, storage, packing, distribution), end customer in north western Europe, Japan, Korea or China | extend a wood pellets simulation model by developing a torrefaction process module to compare the delivered cost to markets, distribution costs, energy consumption and carbon dioxide emission with those of regular pellets |

| Wolfsmayr et al. (2016) | X | 1 year (minutes) | 3 rail terminals | investigate potentials of existing transhipment infrastructure (rail sidings, storage areas, access roads) for biomass | |

| Gronalt and Rauch (2018) | X | X | 1 year (minutes) | forest and prehaulage, 4 rail terminals, railway network, 2 saw mills, 2 paper mills | compare scenarios for different railway operation schedules (shuttle train vs. single wagon traffic) |

| RC = Risk Considered, CS = Case Study include | |||||

| Table 3. Unimodal DES models. | |||||

| Reference (year) | RC | CS | Simulation period (resolution time) | Supply network | Objective |

| Asikainen (1998) | X | (minutes) | residue storage, terminal, truck with draw bar trailer/semitrailer/interchangeable container, crusher, tub grinder, wheel loader, power plant | compare chipping into truck, chipping onto ground and loading using a wheeled loader, long-distance transport by truck with draw-bar trailer, by truck with a semitrailer and by a truck with interchangeable platforms to quantify the impact of machine interactions in monetary terms | |

| Myers and Richards (2003) | X | 5 years (weeks) | standing inventory, ground-based harvesting, cable based harvesting, transportation, mill yard operations, mill operations | evaluate central tire inflation and cable-based harvesting systems to reduce inventory, handling and holding costs of a mill | |

| Mahmoudi et al. (2009) | X | X | 1 year | forest, felling, skidding, processing, moving, chipping, extracting, power plant gate | develop a simulation model for forest biomass logistics and apply it to the case study of supplying a potential power plant with roadside residues from a mountain pine beetle-infested forest |

| Asikainen (2010) | X | 1 week (minutes) | 50 stump storages, crusher, 1–4 semi-trailer trucks, heat plant | find the optimal number of trucks for different road transport distances of at the landing crushed wood chips and compare the findings of static as well as dynamic simulation approaches | |

| Mobini et al. (2011) | X | X | 20 years | forest, felling, skidding, loading, transportation, delimbing, processing, moving, chipping, extracting, gate of the power plant | use full tree chipping, conventional harvesting and satellite harvesting to simulate forest biomass logistics over the service life of a power plant to measure delivery cost, carbon emissions and moisture content |

| Beaudoin et al. (2012) | X | 1 day (minutes) | loaded trucks with different trailers, 3 mobile loader, stockyard, slasher, wave, scale, stocks | reduce average truck cycle times and loaders driving distances by advantageous loader to truck allocation strategies | |

| Cavalli et al. (2012) | X | X | (minutes) | stump extraction: tractor with forest winch, landing and cross cut operation: tractor with loader, offroad transport: tractor with trailer, on-road transport: truck and trailer, terminal | compare in different scenarios the productivity of a firewood supply chain to evaluate the influence of a forest road network extension, supported by a GIS network analyses of the transportation network |

| Zhang et al. (2012) | X | 20 years (days) | harvest/process, forward to landing, load at landing, transport, unload and store at biorefinery | evaluate a biofuel supply chain by delivered feedstock cost, GHG emissions and energy consumption for different locations and plant size under consideration of low value pulpwood and spring break up in a GIS network | |

| Windisch et al. (2013a) | X | X | not mentioned | finding stands, stand evaluation, negotiation and completion of contract, logging, measurements, chipping, accounting, payment | provide a method for structural analysis of forest fuel supply chains including the measurement of processes and work time expenditure in different operational environments |

| Windisch et al. (2013b) | X | X | not mentioned | finding stands, stand evaluation, negotiation and completion of contract, logging, measurements, chipping, accounting, payment | improve logistics of an integrated round wood and energy wood supply chain by business process reengineering and calculate cost saving potential of new business processes |

| Zamora et al. (2013) | X | X | (minutes) | chipper, truck with single or double trailer, chipping, dumping, transporting, loading/unloading, drop/hook trailers, chipping site, bioenergy facility | minimize mobile chipping processing and transportation costs under uncertainty to improve the efficiency of the forest biomass supply chain in steep slope terrain |

| Eriksson et al. (2014a) | X | not mentioned | 10 harvesting areas, harvesting, forwarding, storage, transport and comminution, fuel delivery, excavator with stump lifter, mobile truck or trailer-mounted grinder, self-loading chip truck with crane and bucket, loose residue stump truck, stationary crusher | evaluate the impact of site characteristics, fuel quality, biomass losses, machine performance on fuel costs to deliver stump fuel at a competitive price | |

| Eriksson et al. (2014b) | X | not mentioned | 20 landings, mobile crusher, 1–3 self-loading chip truck/hook-lift trucks/chip trucks, loose-stump truck, large scale crusher, end user (terminal or heating plant) | model systems for stump comminution and transport from landing to the end user to enhance resource efficiency by quantifying and reducing process costs | |

| Marques et al. (2014) | X | X | 1 day (minutes) | stockyard, trucks, trailers, arrival, queuing, unloading | compute performance metrics, provide visualization and identify bottlenecks in deterministic harvesting and transportation plans generated by optimization techniques, when stochastic events occur |

| Spinelli et al. (2014) | X | X | not mentioned | chipper on the trailer of a farm tractor, farm tractors with trailer bins, loader, forwarder, buffer pile, heavy road trucks | examine the interaction delays between individual units along the logging resides supply chain and criteria for the right chipping location |

| Windisch et al. (2015) | X | X | 1 year | 328 storages, truck-mounted mobile chipper, two truck trailer combinations, CHP plant | compare productivity, transportation distance, moisture content and storage volume of a current supply chain and an information based approach for a forest biomass supply chain |

| Pinho et al. (2016a) | X | (X) | 1 day | depot, 4 wood piles, 2 chippers, 4 trucks, 4 power plants | measure the impact of deterministic behavior, machine delay and stochastic behavior in a daily working plan of a biomass supply chain |

| Pinho et al. (2016b) | X | (X) | 1 day | depot, 4 wood piles, 2 chippers, 4 trucks, 6 power plants | estimate dynamic system behavior of a biomass supply chain to predict deadlocks and impact of disturbances on scheduling |

| Eliasson et al. (2017) | 1 week (minutes) | logging residues, chipper, landing, 3/6 buffer containers, forwarder, 2/3/4 trucks for three containers, heating plant | reduce supply costs for forest chips and increase chipper efficiency, forwarder and container trucks interaction by taking into account the effect of shunting distance, buffer size, truck scheduling and number of trucks available | ||

| Eriksson et al. (2017) | X | (X) | 5 years (minutes) | harvest, store in heaps, forwarding, store at road site, transport and comminute, store at CHP plant, 4 forwarders, 6 chipper trucks | assess delivery strategies due to storage time, fuel quality, transport distance, machine utilization and delivery quality to create benefits for supply company and end user |

| Kishita et al. (2017) | (X) | X | 20 years | import, collecting, chipping, land transportation, timber production, landfill, pelletizing, selling | compare scenarios to examine conditions for a sustainable forest biomass energy life cycle based on CO2 emissions and economic profit |

| Väätäinen et al. (2017) | X | 1 year (minutes) | roadside storages of forest biomass, four forest chip suppliers operating with one truck-mounted chipper and two chip trucks, terminal, wheeled loader, shuttle truck with higher capacity truck and trailer unit, combined heat and power plant | examine the impact of terminal location and investment costs, truck utilization and quality changes in stored forest chips for cost comparisons of direct forest chip supply to the integration of feed-in terminals | |

| RC = Risk Considered, CS = Case Study included | |||||

| Table 4. Classification of the research articles. | |||||||

| Reference (year) | Region | Journal | Abstraction level | Planning horizon | Assortment | Transport mode | Software |

| De Mol et al. (1997) | NLD | Netherlands Journal of Agricultural Science | abstract | tactical | forest biomass | multimodal | ProSim |

| Asikainen (1998) | FIN | Scandinavian Journal of Forest Research | intermediate | tactical | forest chips | unimodal | Witness |

| Asikainen (2001) | FIN | International Journal of Forest Engineering | detailed | tactical | timber | multimodal (vessel) | Witness |

| Myers and Richards (2003) | CAN | Information Systems and Operational Research | abstract | tactical | timber | unimodal | AWESIM |

| Saranen and Hilmola (2007) | FIN | World Review of Intermodal Transportation Research | abstract | operational | timber | multimodal (train) | Quest |

| Mahmoudi et al. (2009) | CAN | Scandinavian Journal of Forest Research | detailed | tactical | forest biomass | unimodal | EXTEND |

| Asikainen (2010) | FIN | Scandinavian Journal of Forest Research | abstract | tactical | forest chips | unimodal | Witness |

| Mobini et al. (2011) | CAN | Applied Energy | detailed | strategical | forest biomass | unimodal | ExtendSim |

| Beaudoin et al. (2012) | CAN | Information Systems and Operational Research | abstract | operational | timber | unimodal | AnyLogic |

| Cavalli et al. (2012) | ITA | Journal of Agricultural Engineering | intermediate | operational | firewood | unimodal | Witness |

| Karttunen et al. (2012) | FIN | Silva Fennica | abstract | tactical | forest chips | multimodal (vessel) | Witness |

| Zhang et al. (2012) | USA | Renewable Energy | intermediate | strategical | forest biomass | unimodal | Arena |

| Karttunen et al. (2013) | FIN | Silva Fennica | intermediate | tactical | forest chips | multimodal (train) | AnyLogic |

| Mobini et al. (2013) | CAN | Applied Energy | detailed | strategical | forest pellets | multimodal (train, ocean vessels) | ExtendSim |

| Windisch et al. (2013a) | FIN | Biomass and Bioenergy | detailed | operational | forest biomass | unimodal | SigmaFlow |

| Windisch et al. (2013b) | FIN | International Journal of Forest Engineering | detailed | tactical | forest biomass | unimodal | SigmaFlow |

| Zamora et al. (2013) | USA | Silva Fennica | detailed | operational | forest chips | unimodal | Arena |

| Eriksson et al. (2014a) | SWE | International Journal of Forestry Research | intermediate | tactical | forest chips | unimodal | ExtendSim |

| Eriksson et al. (2014b) | SWE | International Journal of Forest Engineering | abstract | tactical | forest chips | unimodal | ExtendSim |

| Etlinger et al. (2014) | AUT | HMS Conference Paper | detailed | tactical | saw logs, pulp wood | multimodal (train) | AnyLogic |

| Marques et al. (2014) | PRT | Scandinavian Journal of Forest Research | abstract | operational | timber | unimodal | Simio |

| Mobini et al. (2014) | CAN | Journal of Cleaner Production | detailed | strategical | forest pellets | multimodal (train, ocean vessels) | ExtendSim |

| Spinelli et al. (2014) | ITA | Scandinavian Journal of Forest Research | abstract | operational | forest chips | unimodal | Arena |

| Windisch et al. (2015) | FIN | Applied Energy | intermediate | tactical | forest biomass | not mentioned | Witness |

| Pinho et al. (2016a) | PRT | International Federation of Automatic Control Conference Paper online | abstract | operational | forest biomass | unimodal | SimPy |

| Pinho et al. (2016b) | PRT | International Federation of Automatic Control Conference Paper online | intermediate | operational | forest biomass | unimodal | SimEvents |

| Wolfsmayr et al. (2016) | AUT | Annals of Forest Research | intermediate | operational | timber, forest chips | multimodal (train) | AnyLogic |

| Eliasson et al. (2017) | SWE | Applied Energy | intermediate | operational | forest chips | unimodal | not mentioned |

| Eriksson et al. (2017) | SWE | Applied Energy | detailed | tactical | forest chips | unimodal | ExtendSim |

| Kishita et al. (2017) | JPN | Journal of Cleaner Production | abstract | strategical | forest biomass | unimodal | not mentioned |

| Väätäinen et al. (2017) | FIN | Global Change Biology Bioenergy | intermediate | operational | forest chips | unimodal | Witness |

| Gronalt and Rauch (2018) | AUT | International Journal of Forest Engineering | detailed | operational | timber, forest biomass | multimodal (train) | AnyLogic |

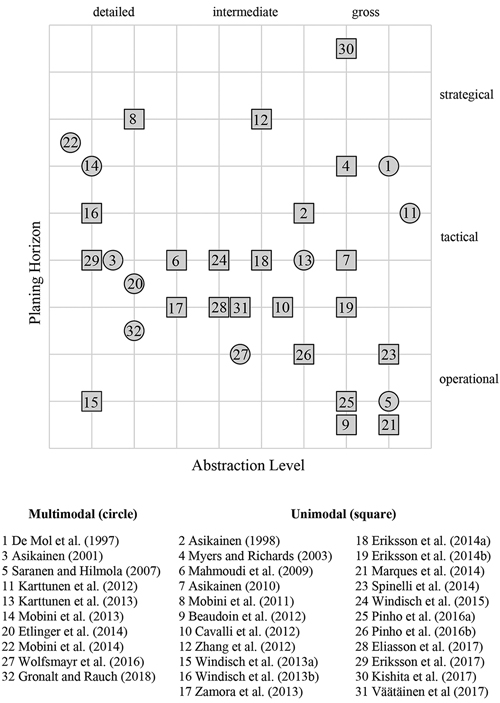

Fig. 3. Categorization according to abstraction level and planning horizon.

| Table 5. Reported model descriptions in the papers. View in new window/tab. |