Carbon emissions displacement effect of Finnish mechanical wood products by dominant tree species in a set of wood use scenarios

Poljatschenko V. A.M., Valsta L. T. (2021). Carbon emissions displacement effect of Finnish mechanical wood products by dominant tree species in a set of wood use scenarios. Silva Fennica vol. 55 no. 1 article id 10391. https://doi.org/10.14214/sf.10391

Highlights

- Wood product consumption patterns are combined with production-based displacement factors to estimate displacement factors for logs by tree species

- The main tree species in Finland have somewhat unequal displacement factors

- Historical and projected wood use scenarios show large variation in the levels of avoided emissions between individual years and scenarios.

Abstract

The carbon emissions displacement effect of Finnish logs for mechanical wood products by dominant tree species (Scots pine, Pinus sylvestris L.; Norway spruce, Picea abies (L.) H. Karst.; Birch, Betula spp.) was assessed by combining information from previous studies of current consumption patterns with displacement factors (DF) for structural construction, non-structural construction, and energy usage. We did not conduct additional life cycle analyses compared to the current literature. Our aim was to identify the factors that most extensively influence the displacement effect and to estimate the overall climate effect of Finnish logs in light of current production levels of mechanical forest industry. The analyses were based on information from both statistics and proprietary sources. Contrary to previous studies, we provide DFs by main tree species in Finland, which has been an unidentified area of research to date. Additionally, we apply a more detailed classification of structural and non-structural wood products. This study did not include effects on the forest carbon sink, as they depend case-wise on forest resources and forest management. According to our results, with current production and consumption trends, the average displacement effects for domestic Scots pine, Norway spruce, and birch logs were 1.28, 1.16, and 1.43 Mg C/Mg C, respectively. The corresponding overall annual displacement effect caused by the current production of sawn wood and wood-based panels was 12.3 Tg CO2 for Finland for the BAU scenario and varied between 8.6 and 16.3 Tg CO2 depending on the wood use scenario.

Keywords

avoided emissions;

mechanical forest industry;

substitution effect;

wooden construction

Received 3 June 2020 Accepted 22 February 2021 Published 25 February 2021

Views 54162

Available at https://doi.org/10.14214/sf.10391 | Download PDF

Supplementary Files

1 Introduction

Finland is committed under the Paris Agreement (UNFCCC 2015) to limit global temperature rise to well below 2 °C compared to pre-industrial levels. The Finnish government of 2019 set the target for reaching carbon neutrality by 2035 (Finnish Government 2019). Finnish forest area represents some 10% of the total European Union forest area (Eurostat 2020) and, hence, Finnish forests are important for reaching both national and European Union emissions targets. In 2019, the carbon content of industrial roundwood harvest in Finland was approximately 52.6 Tg (millions of tons) CO2. (This value is based on roundwood removals for industry and export in 2019, assuming a wood density of 0.45 t m–3 and carbon content of 0.5). Incidentally, the harvested amount nearly equals the concurrent national greenhouse gas (GHG) emissions of 52.8 Tg CO2-eq (Land use, land-use change, and forestry (LULUCF) excluded) (Official Statistics of Finland 2020). In 2019, the net carbon sink, i.e. the increase in carbon storage of forested land, amounted to 25.6 TgCO2-eq (Official Statistics of Finland 2020) (includes both living biomass and soil carbon). This demonstrates the significance of carbon flows throughout industrial processes and the potential of Finnish forest industry in climate change mitigation.

In addition to carbon sequestration, forests are a source of renewable materials with several advantageous attributes. Harvested wood products (HWP) function as carbon storage and substitute energy-intensive materials. The biogenic carbon in HWP is considered a negative emission within LULUCF reporting, and it offsets some of the life cycle emissions from wood materials in analyses based on that approach. According to Pingoud and Perälä (2000), the climate change mitigation potential of wood use relies more heavily on substituting energy-intensive materials and fossil fuels rather than on using wood products as stored carbon stocks.

According to Official Statistics Finland (2020), harvested wood products represented a carbon sink of 3.4 Tg CO2-eq in 2019. In Finland, the forest industry is the single largest producer of bioenergy, mainly utilizing forest and industry residues. Although used primarily within the manufacturing processes of the forest sector, wood-based bioenergy was the largest single energy source in Finland in 2019 at a 28% share (Statistics Finland 2020). All side streams from sawmills can be used to produce pulp or as fuels (Hassan et al. 2018).

The most significant life cycle emissions from wood-based building materials arise from raw material acquisition and transportation. Harvesting immediately decreases the forest carbon stock roughly by the carbon content in the harvested roundwood and harvesting residues. Transportation is also a substantial source of emissions in countries where distances are long. However, transportation emissions of wood-based building materials were found to be smaller compared to substitutes due to their relatively light weight: Häkkinen and Wirtanen (2006) reported a 40% decrease in CO2 emissions when comparing the production and transportation stage emissions of two functionally equivalent office buildings with wooden and concrete frames. Due to low process energy requirements, wood material manufacturing causes relatively less GHG emissions compared to its substitutes. In addition, wood does not emit additional carbon in GHG reporting along industrial processes, unlike cement production: the calcination reaction alone during cement manufacturing accounts for some 50% of the total emissions of cement production and it cannot be decreased through improved technology (IPCC 2014, p.758).

The displacement potential of wood use is particularly significant in the construction sector, which is one of the largest wood-consuming and energy-intensive industries worldwide. Material processing is the main source of industry emissions, 44% of which originate from iron, steel, and non-minerals (most importantly cement) (IPCC 2014, p. 746). Consequently, material production accounts for a substantial share of buildings’ GHG life cycle emissions (Ruuska et al. 2013). A New Zealand study suggests that an increase of 17% in wood usage in the national building industry could result in a 20% decrease in carbon emissions arising from the manufacture of building materials (Buchanan and Levine 1999). Wood material use results in lower energy usage and CO2 emissions compared to alternative materials, such as concrete, aluminium, and steel (Pingoud and Perälä 2000; Lippke et al. 2004; Sathre and O’Connor 2010). According to Vares et al. (2017), a wooden 4-story residential building will reduce material-based GHG emissions by 40–44% compared to concrete element building and increase the external carbon stock by 174–547%.

Increased forest biomass usage leads to a lower average carbon stock in forests and to one-time emissions. However, the supply of forest biomass for the substitution of fossil energy and carbon-intensive material provides a continuing long-term climatic benefit with repeated harvest and regrowth cycles. Substituting wood for coal, oil, and natural gas in the energy sector, and concrete, aluminium, and steel in material production may result in substantial GHG emission reductions (Sathre and O’Connor 2010; Gustavsson et al. 2015). The IPCC (2014, p. 838) states that the integrated optimization of carbon stocks in forests and in long-lived HWPs together with efficient use of side streams and residues can result in the highest GHG benefit in agriculture, forestry, and other land-use (AFOLU) sectors.

According to our knowledge, previous studies have reported average displacement factors (DFs) only without tree species information. This is adequate for large-scale analyses, as their goal is to arrive at figures applicable for aggregated effects (Soimakallio et al. 2016; Smythe et al. 2017, 2019; Hudiburg et al. 2019; Seppälä et al. 2019). Tree species are used to varying degrees in wood products and building elements. Species-level information is necessary for computing the DFs of logs of different tree species. That enables a closer link between forest management scenarios and substitution effects. Therefore, the first objective of our study is to estimate DFs for the main tree species in Finland. In this analysis, we utilize existing life cycle assessments in the literature and do not perform additional life cycle assessments.

The other objective of this study is to assess the displacement effects of logs at the sectoral level in Finland for the end products of mechanical forest industry by applying a more detailed classification to structural and non-structural elements than previous Finnish studies have applied. As the quantity of the displacement effect depends on industry production level and structure, we also examine the effects of a set of production scenarios to highlight the variation in the total avoided emissions due to wood use. We estimated the displacement effects of Finnish saw logs by combining information on 1) current production and 2) consumption scenarios (Supplementary file S1) with 3) DFs from Leskinen et al. (2018) and Lippke et al. (2012).

2 Methods and data

2.1 Displacement factors

The DF is the key variable in the analysis of (GHG) displacement effects. A number of factors affect the DFs, such as wood product manufacturing technology, building construct, manufacturing technologies of alternative materials, and building demolition. Many of these depend on building practices, geographical location, and societal frameworks.

The comparison of life cycle GHG emissions between two products requires that they have the same functionality. This is because equal masses of different materials do not necessarily fulfil the same end function (Gustavsson et al. 2006). For that matter, displacement factors are always functional-unit-specific.

The construction sector has been a reasonably well-covered topic in existing displacement studies. The most comprehensive studies to date are the much-cited studies by Sathre and O’Connor (2010) and Leskinen et al. (2018). The first one is a meta-analysis based on 21 international studies focusing on the displacement potential of wood in the construction sector. The latter provides a critical review on the state of current displacement studies, presenting mean values based on 51 international studies. All existing studies provide DF values for various product categories. Displacement factors are indicators of the rate at which biomass usage reduces net GHG emissions compared to a functionally equivalent alternative (Leskinen et al. 2018). Most displacement studies to date are based on a comparison of life-cycle assessments that consider GHG emissions from all product life cycle stages. The remaining carbon content in the end product has been included to a varying extent. Given a wood-based alternative and a non-wood-based alternative, Sathre and O’Connor (2010) expressed the DF equation as follows:

GHGnon-wood and GHGwood are life cycle emissions resulting from the use of non-wood and wood material. WUwood and WUnon-wood refer to the quantity wood used in assessed functional units. Greenhouse gas emissions are expressed in mass units of C and wood use in mass units of C in wood material.

In most cases, the reported factor values are positive for wood products, indicating that they cause less GHG emissions than non-wood alternatives. Sathre and O’Connor (2010) found DF values ranging from a low of –2.3 to a high of 15, with most values lying in between 1 and 3. The average DF value was 2.1, which means that a GHG emission reduction of 2.1 tons C occurs for each ton of carbon in wood products substituting for a non-wood material.

The selected DFs (Leskinen et al. 2018) for long-lived wood products indicate the average displacement factor of wood in structural (1.3) and non-structural elements (1.6) in building construction. The selection of the examined functional unit groups is based on the domestic use of Finnish logs: logs are used by the sawmill and veneer industries, which produce raw materials for the construction sector.

The DF for short-lived elements was obtained from Lippke et al. (2012), as the study by Leskinen et al. (2018) did not provide a singular DF value for that functional unit group. The displacement potential of short-lived elements arises exclusively from the material displacement in energy production. As we focus on log wood usage in the mechanical wood industry, the short-lived elements consist of temporary elements at construction sites and landscape construction. The adopted DF of 0.4 for short-lived elements represents a relatively low level of displacement effect. Soimakallio et al. (2016) used an average of 0.8 for fossil fuel displacement. Leskinen et al. (2018) further noted that utilizing harvest residues for bioenergy production increased the DF by approximately 0.4–0.8 in several studies. Using a lower DF for short-lived elements was considered justifiable, as the displacement potential of wood-based energy sources is likely to decrease during upcoming years due to restrictive emission requirements for the energy sector and the resulting decreasing share of fossil energy. In addition, the lower value represents a conservative approach that prevents overestimates.

Most current displacement studies exclude the impact of harvesting on carbon fluxes in the forest ecosystem (because the carbon sink effect depends on the properties of forest resources and forest management scenarios) while focusing on those in the related techno system, which needs to be kept in mind. Soimakallio et al. (2016) and Seppälä et al. (2019) noted that wood products may be assumed to mitigate climate change only if their displacement effect is greater that the decrease in carbon stock of extended system boundaries. This was also discussed by Koskela et al. (2011), who highlighted the urge to consistently evaluate the environmental impact of land-use change and the temporal scope of carbon emissions when assessing life cycle emissions.

2.2 Data

We use mean values from years 2015–2018 as current production levels of mechanical wood industry, and they form the business-as-usual (BAU) scenario in the scenario setup. The values are obtained from the Natural Resources Institute Finland’s (Luke) statistics. The other scenarios include production volumes in the “with existing measures” (WEM) scenario of the PITKO report (long-term development of total emissions) scenarios (Koljonen et al. 2019), commissioned by the Prime Minister’s Office. In addition, Luke’s historic statistics on domestic production of sawn wood and wood-based panels were used. The scenarios are described in detail later in this chapter. The assessment of domestic consumption of sawn wood and wood-based panels is partly based on the Forecon (2018) report concerning the same matter for years 2017 and 2018.

The usage levels of annually produced glulam and cross-laminated timber (CLT) were relatively straightforward to estimate, as both product categories are only used unambiguously for one functional unit group, i.e. structural elements. Similarly, sawn birch (Betula spp.) was assumed to be used entirely in non-structural constructs. The product categories of wood-based panels and coniferous sawn wood deviated from the other product groups, as they are used in several of the examined functional unit groups. In addition, the use of various tree species in different elements is often not specified. For this reason, the usage of such product categories was estimated based on auxiliary data from the Forecon report (2018) on the domestic use of sawn wood and wood-based panels.

The structural elements of new building construction in Forecon (2018) (Suppl. file S1) were further classified following Leskinen et al.’s (2018) example of structural and non-structural elements as follows: outdoor and indoor wall cladding, ceiling and flooring, civil engineering, doors, and windows were included in non-structural elements; structural systems in walls, flooring, and roofing were included in structural elements. Renovation construction was assumed to be allocated into structural and non-structural elements at a ratio of 30/70, respectively. This assumption is based on structural elements as long-lived and permanent, and non-structural elements as replaceable. Wood utilization in other than reported construction was omitted, as it may be subject to either structural or non-structural construction. Relative shares of material allocation to different elements were applied to wood-based panels and coniferous sawn wood.

The panel statistics in the Forecon (2018) report presented the usage of different wood-based panels in carpentry, molds, and in other use during construction, new construction, and renovations. Carpentry is included in non-structural elements, whereas wood use at the construction site was considered short-lived. The use of wood-based panels in new construction and renovations were assumed to focus entirely on structural elements. This is merely because wood panels are more often used as structural elements on walls and flooring rather than in cladding.

In this study, the proportions of tree species involved in end production are derived from those in the wood raw material. The Forecon (2018) report did not disclose the used tree species. To elaborate on the displacement assessment of coniferous species, certain structural elements were considered to be made using only one species (Suppl. file S1). We assumed windows and doors to be made of pine (Pinus sylvestris L.) and external panelling to be made of spruce (Picea abies (L.) H. Karst.). These assumptions were based on the raw material usage of a large Finnish window and door manufacturer (Personal communication: Pekka Kiviniemi, Purchasing Manager, Inwido Finland Oy, 12 March 2019) and on traditions in Finnish wood construction. The allocation of coniferous sawn wood in examined functional units is based on domestic sawn wood production shares being 49% and 51% for pine and spruce, respectively.

Table 1 presents the current allocation patterns of sawn wood and wood-based panels to the functional unit groups that are used in all scenarios except the potential scenario. Given the total production volumes of all identified wood product categories (glulam, CLT, sawn wood, and wood-based panels; Suppl. file S1), the overall allocation of raw materials into structural, non-structural, and short-lived elements was: 30/51/19% for pine and 37/36/27% for spruce, respectively. Birch was assumed to be used merely in long-term elements, with a share of 57% in structural and 43% in non-structural elements.

| Table 1. Allocation of sawn wood and wood-based panels into functional unit groups is derived from the Forecon report (2018) on current consumption. Birch allocation in other than plywood is based on the authors’ judgements. The allocation is used to establish the current consumption pattern. The pattern is then used to estimate the resulting displacement effect of the functional unit groups for which displacement factors were selected. | ||||

| Product category | Functional unit group | Pine | Spruce | Birch |

| Sawn wood | Structural elements | 27% | 34% | |

| Non-structural elements | 53% | 41% | 100% | |

| Short-lived use | 20% | 25% | ||

| Particle board | Structural elements | 47% | 47% | |

| Non-structural elements | 45% | 45% | ||

| Short-lived use | 7% | 7% | ||

| Fiberboard | Structural elements | 57% | 57% | |

| Non-structural elements | 36% | 36% | ||

| Short-lived use | 5% | 5% | ||

| Plywood | Structural elements | 29% | 64% | |

| Non-structural elements | 16% | 36% | ||

| Short-lived use | 55% | |||

Assumed dry-weight densities were 0.46 Mg m–3, 0.41 Mg m–3, and 0.58 Mg m–3 for pine, spruce, and birch, respectively, following Repola (2009). The tree-species-specific carbon content of total end production was calculated using the Intergovernmental Panel on Climate Change (IPCC) carbon fraction for aboveground forest biomass (IPCC 2006)

Sensitivity analyses were carried out to assess the impacts of alternative consumption structures by altering the volumes in selected functional unit groups and production levels to the generated displacement effect. For this purpose, in addition to the BAU scenario, five scenarios were applied as follows:

Potential: Based on production levels from BAU and Forecon’s estimates on the potential usage of sawn wood in various building elements (Suppl. file S1).

WEM at year 2030: Based on increased production levels, but consumption structure similar to the BAU scenario.

WEM at year 2050: Based on increased production levels, but consumption structure reflects that in the BAU scenario.

Historical production in 2003: Based on historical production levels in 2003, but consumption structure similar to the BAU scenario.

Historical production in 2009: Based on historical production levels in 2009, but consumption structure reflects that in the BAU scenario.

The BAU scenario is based on current production levels and on prevailing consumption patterns estimated by Forecon (2018). The scenario labeled “Potential” for coniferous trees assessed the displacement effect of the potential use of coniferous sawn wood in new building construction and renovations. The potential usage is estimated by Forecon (2018) and based on an increased market share of wood material (Suppl. file S1) in construction materials. The potential volumes in the examined functions reduced wood usage in short-lived elements and led to the following relative shares: 31/50/19% for pine and 36/42/22% for spruce in structural, non-structural, and short-lived elements, respectively. Scenarios labeled WEM 2030 and 2050 include production volumes defined by the PITKO project (Koljonen et al. 2019). The WEM scenarios assume a steady increase in the demand of sawn wood by 2030 and 2050, which will lead to increased production volumes. The production levels of sawn wood in 2030 and 2050 are estimated to be 12.3 and 14.9 million cubic meters p.a. Note that the total mean annual production volume of Finnish mechanical wood industry in 2015–2018 was 11.4 million cubic meters of sawn wood and 1.12 million cubic meters of veneer and LVL (Luke 2019b). Similarly, the production of veneer and laminated veneer lumber (LVL) is estimated to reach 1.44 and 1.70 million cubic meters p.a. by 2030 and 2050, respectively (Koljonen et al. 2019). The historical scenarios of 2003 and 2009 were chosen to reflect the effect of economic cycle variation on production volumes. The production volume of 2009 represents the lowest level hitherto in the 21st century, resulting from a decrease in demand due to the financial crisis of 2008. On the contrary, the highest production volumes hitherto during the 21st century were reported in 2003.

3 Results

We first present results separately for the BAU scenario (Table 2). The largest absolute displacement effect results from pine usage in non-structural elements, being 1.06 Tg C, whereas the smallest absolute displacement effect arises from birch usage in non-structural elements. Pine is largely directed to non-structural elements, which have the highest DF value of the included functional unit groups. For comparability reasons, the displacement effect has not been converted into CO2 in Table 2. The C content is used in the denominator when dividing the overall absolute displacement effect to discover the DF value (Eq. 1).

| Table 2. Carbon content and the resulting displacement effect by 1) dominant tree species and 2) functional unit groups according to the BAU scenario (i.e. current production volumes and consumption pattern). | ||||

| Functional unit | Mass (Tg) | C Content (Tg) | Displacement effect (Tg C) | |

| Pine | Structural element | 0.75 | 0.38 | 0.50 |

| Non-structural element | 1.30 | 0.66 | 1.06 | |

| Short-lived use | 0.49 | 0.25 | 0.10 | |

| Sub total | 2.53 | 1.29 | 1.65 | |

| Spruce | Structural element | 0.97 | 0.49 | 0.64 |

| Non-structural element | 0.93 | 0.48 | 0.76 | |

| Short-lived use | 0.71 | 0.36 | 0.14 | |

| Sub total | 2.60 | 1.33 | 1.55 | |

| Birch | Structural element | 0.14 | 0.07 | 0.09 |

| Non-structural element | 0.11 | 0.05 | 0.08 | |

| Sub total | 0.25 | 0.12 | 0.17 | |

With the current prevailing production and consumption trends, the aggregated DF values for dominant tree species varied from a low of 1.16 for spruce to a high of 1.43 for birch (see BAU values in Table 3). Sensitivity analyses, i.e. scenario comparisons, showed minor differences in the DFs. An exception was that the DF value for spruce increased by 0.03 to 1.19 in the Potential scenario. This was due to its increased use in long-lived elements providing the largest substitution potential. Other scenarios did not significantly alter the aggregated DF values. This is because the volumes in each functional unit group increased proportionally with the increase in production volumes, i.e. the consumption pattern remained unchanged.

| Table 3. Aggregated displacement factor values and total displacement effect amounts in the examined scenarios based on the allocation of wood material into the functional unit groups. | |||

| Tree species | Scenario | Displacement factor | Displacement effect (Tg C) |

| Pine | BAU | 1.28 | 1.7 |

| Potential | 1.28 | 1.7 | |

| WEM 2030 | 1.28 | 1.8 | |

| WEM 2050 | 1.28 | 2.2 | |

| 2003 | 1.28 | 2.0 | |

| 2009 | 1.28 | 1.2 | |

| Spruce | BAU | 1.16 | 1.5 |

| Potential | 1.19 | 1.6 | |

| WEM 2030 | 1.16 | 1.7 | |

| WEM 2050 | 1.16 | 2.0 | |

| 2003 | 1.17 | 1.9 | |

| 2009 | 1.17 | 1.1 | |

| Birch | BAU | 1.43 | 0.2 |

| Potential | 1.43 | 0.2 | |

| WEM 2030 | 1.43 | 0.2 | |

| WEM 2050 | 1.43 | 0.2 | |

| 2003 | 1.43 | 0.2 | |

| 2009 | 1.43 | 0.1 | |

The Potential scenario focused on larger utilization volumes and on allocating more wood to long-lived elements in terms of utilized cubic meters. However, the potential allocation in-between long-lived and short-lived elements did not differ significantly from the current consumption pattern. Due to this, the overall displacement effect only increased by 1% compared to current consumption. This resulted most importantly from a 7% decrease in short-lived elements and equalled 0.10 Tg CO2 in total (Table 4). The climate impact of birch remained relatively similar throughout all the scenarios. A comparison between the BAU and WEM2030 scenarios showed that the increased production of sawn wood and wood-based panels from birch wood led to the largest proportional increase in displacement effect compared to coniferous tree species. The increase in production volumes divided by the resulting increase in the displacement factor indicated that each cubic meter of birch wood generated a climate impact of 1.44 Mg of CO2. Corresponding values for pine and spruce were 1.1 and 0.8 Mg, respectively. This demonstrates the potential of long-lived wood products in climate change mitigation, as the increase in birch wood usage was directed exclusively to long-lived elements with the highest displacement potentials. Comparison of the Potential and WEM2030 scenario results indicates that plausible changes in consumption patterns do not necessarily lead to a greater climate impact than a mere increase of wood material use.

| Table 4. Comparison of the scenario results against those of BAU, by 1) tree species and 2) functional unit group. Results are given for 1) the total amount of wood material and 2) the resulting displacement effect. | ||||||||||||

| BAU reference | Potential | WEM 2030 | WEM 2050 | 2003 | 2009 | |||||||

| m3 | Mg CO2 | m3 | Mg CO2 | m3 | Mg CO2 | m3 | Mg CO2 | m3 | Mg CO2 | m3 | Mg CO2 | |

| Pine | ||||||||||||

| 1.* | 1.62 | 1.82 | 0.19 | 0.21 | 0.12 | 0.14 | 0.48 | 0.53 | 0.32 | 0.36 | –0.44 | –0.49 |

| 2. | 2.81 | 3.87 | –0.14 | –0.20 | 0.24 | 0.32 | 0.92 | 1.26 | 0.62 | 0.85 | –0.84 | –1.16 |

| 3. | 1.05 | 0.36 | –0.05 | –0.02 | 0.09 | 0.03 | 0.34 | 0.12 | 0.23 | 0.08 | –0.32 | –0.11 |

| Sub total | 5.49 | 6.05 | 0.00 | 0.00 | 0.45 | 0.49 | 1.74 | 1.91 | 1.17 | 1.29 | –1.60 | –1.76 |

| Spruce | ||||||||||||

| 1. | 2.35 | 2.34 | 0.10 | 0.10 | 0.19 | 0.19 | 0.70 | 0.70 | 0.42 | 0.42 | –0.66 | –0.66 |

| 2. | 2.28 | 2.80 | 0.04 | 0.05 | 0.20 | 0.24 | 0.77 | 0.95 | 0.49 | 0.60 | –0.74 | –0.91 |

| 3. | 1.72 | 0.53 | –0.14 | –0.04 | 0.20 | 0.06 | 0.62 | 0.19 | 0.33 | 0.10 | –0.57 | –0.17 |

| Sub total | 6.35 | 5.67 | 0.00 | 0.10 | 0.59 | 0.49 | 2.10 | 1.84 | 1.24 | 1.12 | –1.97 | –1.74 |

| Birch | ||||||||||||

| 1. | 0.25 | 0.33 | 0.00 | 0.00 | 0.05 | 0.07 | 0.11 | 0.14 | 0.02 | 0.03 | –0.08 | –0.11 |

| 2. | 0.18 | 0.30 | 0.00 | 0.00 | 0.03 | 0.05 | 0.07 | 0.12 | 0.02 | 0.03 | –0.06 | –0.10 |

| Sub total | 0.43 | 0.62 | 0.00 | 0.00 | 0.08 | 0.12 | 0.18 | 0.26 | 0.04 | 0.06 | –0.14 | –0.20 |

| Total | 12.27 | 12.34 | 0.00 | 0.10 | 1.11 | 1.10 | 4.01 | 4.01 | 2.46 | 2.48 | –3.71 | –3.71 |

| * Numbers refer to structural (1), non-structural (2), and short-lived (3) elements, all figures are in millions | ||||||||||||

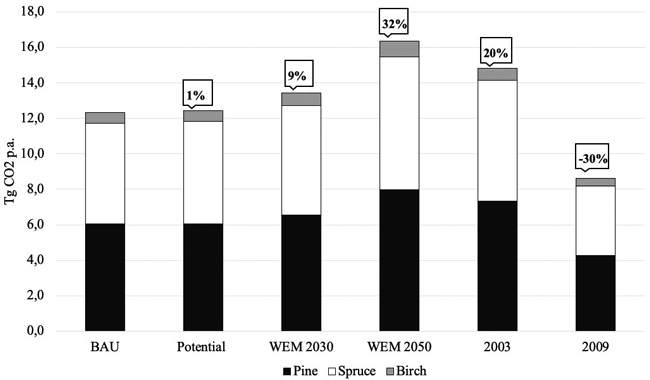

As shown in Fig. 1, the largest overall displacement effect was generated with the highest production volumes from the WEM 2050 scenario. These production volumes are relatively close to those once reached in 2003 (Table 4). Results from the 2009 scenario show that the decreased production volumes similarly led to a significant decrease in the displacement effect of produced wood use.

Fig. 1. Total annual displacement effect (Tg CO2) by scenario and tree species in Finland for total annual production of sawn wood and wood-based panels. Comparison to BAU is given in percentages.

Carbon storage in produced wood material together with the avoided emissions through wood material usage form a significant climate impact. The once sequestered carbon remains in the wood material for a given life cycle while substituting for emission-intensive materials. The average annual production volumes of mechanical wood industry comprise carbon as follows: 1.3 Tg C for pine and spruce, and 0.1 Tg C for birch. The corresponding displacement factor of produced sawn wood and wood-based panels in the BAU scenario totalled 1.7, 1.5, and 0.2 Tg C for pine, spruce, and birch, respectively. Converted into CO2, the carbon storage in total annual production corresponded to 10.0 Tg CO2, whereas the overall annual displacement effect of the same volume in use was 12.3 Tg CO2.

4 Discussion

The objective of our study was to assess the displacement effect of Finnish saw logs according to dominant tree species in a detailed classification of structural and non-structural elements. Contrary to previous ones, this study provides DF values for pine, spruce, and birch logs, which to date has been an unidentified area of research. The study is based on the application of current consumption trends and existing displacement factors from previous literature. The obtained results imply that the displacement effect of mechanical wood industry in Finland is notable, being 1.28, 1.16, and 1.43 carbon tons per each ton of carbon in pine, spruce, and birch logs, respectively.

Comparing the tree species DFs, we can note that, overall, pine logs have a somewhat larger value. This is mainly due to larger quantities of pine being used for doors and windows and smaller quantities used in external cladding, compared to spruce. Compared to conifers, the larger DF for birch mostly results from a proportionally greater use of plywood in non-structural elements.

As the DFs from Leskinen et al. (2018) used in this study are mean values based on numerous studies relating to structural and non-structural elements, it is not simple to identify the exact sources of uncertainty related to them. However, the literature indicates that, in general, the most important variations in existing DFs relate to their system boundaries.

Sathre and O’Connor (2010) identify six main factors in GHG effects of wood substitution: fossil fuel consumption in manufacturing, process emissions, carbon storage in products, carbon storage in forests, biofuel substitution, and carbon dynamics in landfills. As production technologies evolve in both wood product and substituted product manufacturing, the DFs are subject to changes over time.

The displacement effect of wood use depends on the alternative material and its carbon intensity. Displacement factor values are also highly sensitive to future development in product design, technologies, and energy supply. A decrease in either product’s manufacturing emissions will decrease the other one’s displacement potential. In the future, such development in the construction sector is most likely to result from a restrictive emission requirement for the energy sector that will probably decrease the life cycle emissions of energy-intensive materials. A similar expected future development in the energy sector emissions is the reasoning for us to select a lower displacement factor for short-lived elements. In addition, using a lower factor value follows the principle of conservativeness demanded by the IPCC in national GHG accounting. However, sensitivity analyses were carried out with a factor value of 0.8 from Pingoud et al. (2010). The results showed a 7% increase in the total displacement effect at the scenario level (Suppl. file S1). In the case of Finland, large forest product companies are already approximately carbon neutral in their production, i.e. the quantity of bioenergy supplied to external energy users from the forest company’s main production facilities exceeds the fossil energy used in their other facilities (Metsä Group 2020). Hence, substitute materials industries may apparently have more opportunities for emissions reductions through production technology improvements than forest product industries.

Most studies on displacement factors have been conducted in Northern America and the Nordic countries (Leskinen et al. 2018). They may not be appropriate for comparing conditions in other parts of the world. The technologies in manufacturing wooden products and in constructing buildings describe Finnish conditions. Due to similarities in the Nordic countries, the results have somewhat reduced applicability over this area but limited applicability outside the Nordic countries.

In addition to uncertainty relating to DFs from previous studies, the assumptions and uncertainties concerning current consumption trends will affect the tree-species-specific DF values in this study. The exact volumes of pine and spruce in structural and non-structural elements were not straightforward to estimate due to a lack of up-to-date studies. However, the BAU scenario was seen as an adequate estimate of current usage of coniferous trees in Finnish building construction. The results indicate that variations among scenarios and individual years have a notable impact on national GHG emissions. The largest differences correspond to 14% of Finland’s GHG emissions in 2019.

For Finland to achieve a net carbon emission reduction with increased harvest levels, Seppälä et al. (2019) estimated the required displacement factor to be 2.0–2.4, which is significantly larger than our values. The displacement effect from wood utilization and the resulting DF values could be improved by increasingly allocating side streams to future products with higher displacement potentials, such as textile and wood-plastic composite making (Leskinen et al. 2018; Hurmekoski et al. 2020). In light of our results, it seems unlikely that such high values can be obtained at the sectoral level of mechanical wood industry with the current production patterns. However, the accuracy of the computation would improve, and also likely bring the DF values slightly closer to the required DFs if geographical representativeness of applicable DF values were improved, i.e. if they were to consider the resource efficiency of the Finnish mechanical wood industry.

Recent results from Finland and Sweden emphasize the time-dependent nature of climate change mitigation impacts of forests. When including the effects of wood utilization on forest carbon stocks, Gustavsson et al. (2021) find that increased utilization produces more carbon emissions during an initial period of 30 years compared to the BAU scenario. After that period, the effect was reversed. Kalliokoski et al. (2020) include a wide array of radiative forcing agents and find that, during the first 50 years, increased utilization produces a greater radiative forcing, and thereafter, the reverse begins to happen. These studies highlight that the displacement factor alone is only a partial measure of the climatic impact of wood products.

We should also note that the DF values only describe marginal rates because the system boundaries in the studies are normally limited to a particular activity such as building construction. Market-level impacts and technological development are usually excluded (Forsström et al. 2012; Kallio and Solberg 2018), and they will also change the climate change mitigation impacts of wood use.

The effect of harvested biomass on the forest carbon sink should also be included in the scope of wood product displacement studies, along with consideration of the interlinked nature of the forest sector. As shown by Soimakallio et al. (2016) and Seppälä et al. (2019), the climatic impact of the forest sector should be assessed as a whole, as the fields of industry cannot be separated for independent evaluation in reality. We also note that the global nature of economies further increases the complexity of carbon flows and, ideally, a consequential life cycle analysis would be needed. As demonstrated by Kallio et al. (2018), market forces will eventually determine the supply levels of wood material from various geographical regions. Decreasing wood material production in Finland and other EU countries will likely lead to extensive harvesting and production leakages in the rest of the world with possibly less sustainable forest industry (Kallio et al. 2018). Leakage rates in some regional and national studies appear to be in the range of 70–80% (Nepal et al. 2013; Hu et al. 2014; Kallio et al. 2018). The carbon leakage effect is a significant consequence to consider when assessing the climate impacts of future harvesting levels. The scenarios based on historic production volumes demonstrate how the overall climate impact of wood use is subject to changes in the economy. A decrease in wood material demand reduces harvestings as well as its total displacement effect. In light of the prevailing megatrends, such as population growth and urbanization, the displacement effect of wood material usage is considerable, as renewable wood material is an important substitute for many fossil-intensive and non-renewable materials in the building construction sector.

Data availability

Data is available in the Supplementary file S1.

Author’s contributions

Poljatchenko: research design, data acquisition, computations, article writing.

Valsta: original research idea and research design, article writing.

Acknowledgements

The authors gratefully acknowledge the valuable comments by journal referees.

Funding

This research was funded, in part, by Simosol, Ltd and the University of Helsinki.

References

Buchanan A, Levine SB (1999) Wood-based building materials and atmospheric carbon emissions. Environ Sci Policy 2: 427–437. https://doi.org/10.1016/S1462-9011(99)00038-6.

Eurostat (2020) 43% of the EU is covered with forests. https://ec.europa.eu/eurostat/web/products-eurostat-news/-/EDN-20190321-1. Accessed 25 November 2020.

Finnish Government (2019) Programme of Prime Minister Sanna Marin’s government 10 December 2019. Inclusive and competent Finland – a socially, economically and ecologically sustainable society. Publications of the Finnish Government 2019:33. 232 p. http://urn.fi/URN:ISBN:978-952-287-811-3.

Forecon (2018) Sahatavaran ja puulevyjen käyttö Suomessa ja ennuste vuoteen 2019. [Use of sawn wood and wood-based panels in Finland and estimates for 2019]. Forecon Oy.

Forsström J, Pingoud K, Pohjola J, Valsta L, Vilén T, Verkerk H (2012) Wood-based biodiesel in Finland: market-mediated impacts on emissions and costs. VTT Technology 7. http://www.vtt.fi/inf/pdf/technology/2012/T7.pdf. Accessed 30 November 2020.

Gustavsson L, Pingoud K, Sathre R (2006) Carbon dioxide balance of wood substitution: comparing concrete-and wood-framed buildings. Mitig Adapt Strat Gl 11: 667–691. https://doi.org/10.1007/s11027-006-7207-1.

Gustavsson L, Haus S, Ortiz CA, Sathre R, Le Truong N (2015) Climate effects of bioenergy from forest residues in comparison to fossil energy. Appl Energy 138: 36–50. https://doi.org/10.1016/j.apenergy.2014.10.013.

Gustavsson L, Nguyen T, Sathre R, Tettey UYA (2021) Climate effects of forestry and substitution of concrete buildings and fossil energy. Renew Sust Energ Rev 136, article id 110435. https://doi.org/10.1016/j.rser.2020.110435.

Häkkinen T, Wirtanen L (2006) Metlan Joensuun tutkimuskeskuksen ympäristö- ja elinkaarinäkökokohtien arviointi. [Environmental and life cycle assessment of the Finnish Forest Research Institute’s (Metla) research centre in Joensuu]. VTT Tiedotteita – Research Notes 2342. http://www.vtt.fi/inf/pdf/tiedotteet/2006/T2342.pdf. Accessed 30 November 2020.

Hassan K, Villa A, Kuittinen S, Jänis J, Pappinen A (2018) An assessment of side-stream generation from Finnish forest industry. J Mater Cycles Waste 21: 265–280. https://doi.org/10.1007/s10163-018-0787-5.

Hu X, Shi GQ, Hodges DG (2014) International market leakage from China’s forestry policies. Forests 5: 2613–2625. https://doi.org/10.3390/f5112613.

Hudiburg TW, Law BE, Moomaw WR, Harmon ME, Stenzel JE (2019) Meeting GHG reduction targets requires accounting for all forest sector emissions. Environ Res Lett 14, article id 095005. https://doi.org/10.1088/1748-9326/ab28bb.

Hurmekoski E, Myllyviita T, Seppälä J, Heinonen T, Kilpeläinen A, Pukkala T, Mattila T, Hetemäki L, Asikainen A, Peltola H (2020) Impact of structural changes in wood-using industries on net carbon emissions in Finland. J Ind Ecol 24: 899–912. https://doi.org/10.1111/jiec.12981.

International Energy Agency (2018) CO2 emissions from fuel combustion highlights (excel). OECD/IEA, Paris.

IPCC (2006) 2006 IPCC guidelines for national greenhouse gas inventories. Vol. 4 – agriculture, forestry and other land use. The National Greenhouse Gas Inventories Programme, Eggleston HS, Buendia L, Miwa K, Ngara T, Tanabe K (eds). IGES, Japan. https://www.ipcc-nggip.iges.or.jp/public/2006gl/vol4.html. Accessed 30 November 2020.

IPCC (2014) Climate change 2014: mitigation of climate change. contribution of working group III to the fifth assessment report of the intergovernmental panel on climate change. Edenhofer O, Pichs-Madruga R, Sokona Y, Farahani E, Kadner S, Seyboth K, Adler A, Baum I, Brunner S, Eickemeier P, Kriemann B, Savolainen J, Schlömer S, von Stechow C, Zwickel T, Minx JC (eds). Cambridge University Press, Cambridge, United Kingdom, New York, NY, USA. https://www.ipcc.ch/report/ar5/wg3/. Accessed 30 November 2020.

John S, Nebel B, Perez N, Buchanan A (2009) Environmental impacts of multi-story buildings using different construction materials. Research report 2008-02. University of Canterbury. http://hdl.handle.net/10092/8359.

Kallio AMI, Solberg B (2018) Leakage of forest harvest changes in a small open economy: case Norway. Scand J For Res 33: 502–510. https://doi.org/10.1080/02827581.2018.1427787.

Kallio AMI, Solberg B, Käär L, Päivinen R (2018) Economic impacts of setting reference levels for the forest carbon sinks in the EU on the European forest sector. Forest Policy Econ 92: 193–201. https://doi.org/10.1016/j.forpol.2018.04.010.

Kalliokoski T, Bäck J, Boy M, Kulmala M, Kuusinen N, Mäkelä A, Minkkinen K, Minunno F, Paasonen P, Peltoniemi M, Taipale D, Valsta L, Vanhatalo A, Zhou L, Zhou P, Berninger F (2020). Mitigation impact of different harvest scenarios of Finnish forests that account for albedo, aerosols, and trade-offs of carbon sequestration and avoided emissions. Front For Glob Change 3, article id 562044. https://doi.org/10.3389/ffgc.2020.562044.

Koljonen T, Soimakallio S, Lehtilä A, Similä L, Honkatukia J, Hildén M, Rehunen A, Saikku L, Salo M, Savolahti M, Tuominen P, Vainio T (2019) Pitkän aikavälin kokonaispäästökehitys. [Long-term development of total emissions]. Prime Minister’s Office. Publications of the Governments analysis, assessment and research activities 24/2019. http://urn.fi/URN:ISBN:978-952-287-656-0.

Koskela S, Korhonen M-R, Seppälä J, Häkkinen T, Vares S (2011) Materiaalinäkökulma rakennusten ympäristöarvioinnissa. [Materials approach to environmental assessment of buildings]. Reports of the Finnish Environment 16/2011. Finnish Environment Institute (SYKE). http://hdl.handle.net/10138/39687.

Leskinen P, Cardellini G, González-García S, Hurmekoski E, Sathre R, Seppälä J, Smyth C, Stern T, Verkerk PJ (2018) Substitution effects of wood-based products in climate change mitigation. From Science to Policy 7. European Forest Institute, Joensuu. https://doi.org/10.36333/fs07.

Lippke B, Wilson J, Perez-Garcia J, Boyer J, Meil J (2004) CORRIM: life-cycle environmental performance of renewable building materials. For Prod J 54: 8–19.

Lippke B, Gustafson R, Venditti R, Steele P, Volk TA, Oneil E, Johnson L, Puettmann ME, Skog K (2012) Comparing life-cycle carbon and energy impacts for biofuel, wood product, and forest management alternatives. Forest Products Journal 62: 247–257. https://doi.org/10.13073/FPJ-D-12-00017.1.

Luke (2019a) Statistics database. Wood in energy generation in 2018. Natural Resources Institute Finland. http://statdb.luke.fi/PXWeb/pxweb/en/LUKE/. Accessed 4 June 2019.

Luke (2019b) Statistics database. Forest statistics 2018. Natural Resources Institute Finland. http://statdb.luke.fi/PXWeb/pxweb/en/LUKE/. Accessed 4 June 2019.

Metsä Group (2020) Tuotantoa uusiutuvalla energialla. [Production with renewable energy]. https://www.metsagroup.com/fi/kestava-kehitys/tehdaspaastot/bioenergia/Pages/default.aspx. Accessed 30 November 2020.

Nepal P, Ince PJ, Skog KE, Chang SJ (2013) Forest carbon benefits, costs and leakage effects of carbon reserve scenarios in the United States. Journal of Forest Economics 19: 286–306. https://doi.org/10.1016/j.jfe.2013.06.001.

OECD (2018) Global material resources outlook to 2060 – economic drivers and environmental consequences. OECD Publishing, Paris. https://www.oecd.org/environment/global-material-resources-outlook-to-2060-9789264307452-en.htm. Accessed 30 November 2020.

Official Statistics of Finland (OSF) (2020) Suomen kasvihuonekaasupäästöt 1990–2019. [Greenhouse gas emissions in Finland 1990–2019]. Ympäristö ja luonnonvarat 2020. http://www.stat.fi/static/media/uploads/tup/khkinv/yymp_kahup_1990-2019_2020.pdf. Accessed 30 November 2020.

Pingoud K, Perälä A-L (2000) 1. Skenaariotarkastelu potentiaalisesta puunkäytöstä ja sen kasvihuonevaikutuksesta vuosien 1990 ja 1994 uudisrakentamisessa. 2. Rakennuskannan puutuotteiden hiilivaranto Suomessa: inventaariot vuosilta 1980, 1990 ja 1995. [Studies on greenhouse impacts of wood construction. 1. Scenario analysis of potential wood utilisation in Finnish new construction in 1990 and 1994. 2. Inventory of carbon stock of wood products in the Finnish building stock in 1980, 1990 and 1995]. Technical Research Centre of Finland, VTT Julkaisuja – Research Notes 840. http://www.vtt.fi/inf/pdf/julkaisut/2000/J840.pdf. Accessed 30 November 2020.

Pingoud K, Pohjola J, Valsta L (2010) Assessing the integrated climatic impacts of forestry and wood products. Silva Fenn 44: 155–175. https://doi.org/10.14214/sf.166.

Repola J (2009) Biomass equations for Scots pine and Norway spruce in Finland. Silva Fenn 43: 625–647. https://doi.org/10.14214/sf.184.

Ruuska A, Häkkinen T, Vares S, Korhonen M-R, Myllymaa T (2013) Rakennusmateriaalien ympäristövaikutukset – selvitys rakennusmateriaalien vaikutuksesta rakentamisen kasvihuonekaasupäästöihin, tiivistelmäraportti. [Environmental impacts of construction materials. A report on the contribution of construction materials to greenhouse gas emissions of construction]. Reports of the Ministry of the Environment 8/2013. http://hdl.handle.net/10138/41423.

Sathre R, O’Connor J (2010) Meta-analysis of greenhouse gas displacement factors of wood product substitution. Environ Sci Policy 13: 104–114. https://doi.org/10.1016/j.envsci.2009.12.005.

Seppälä J, Heinonen T, Pukkala T, Kilpeläinen A, Mattila T, Myllyviita T, Asikainen A, Peltola H (2019) Effect of increased wood harvesting and utilization on required greenhouse gas displacement factors of wood-based products and fuels. J Environ Manage 247: 580–587. https://doi.org/10.1016/j.jenvman.2019.06.031.

Smyth CE, Rampley GJ, Lemprière TC, Schwab O, Kurz WA (2017) Estimating product and energy substitution benefits in national-scale mitigation analyses for Canada. Glob Change Biol Bioenergy 9: 1071–1084. https://doi.org/10.1111/gcbb.12389.

Soimakallio S, Saikku L, Valsta L, Pingoud K (2016) Climate change mitigation challenge for wood utilization – the case of Finland. Environ Sci Technol 50: 5127–5134. https://doi.org/10.1021/acs.est.6b00122.

Statistics Finland (2020a) Greenhouse gas emissions from Kyoto Protocol LULUCF activities. http://pxnet2.stat.fi/PXWeb/pxweb/en/StatFin/StatFin__ymp__khki/statfin_khki_pxt_111x.px/. Accessed 3 June 2020.

Statistics Finland (2020b) Energian hankinta ja kulutus. [Energy procurement and consumption. https://www.stat.fi/til/ehk/2019/04/ehk_2019_04_2020-04-17_fi.pdf. Accessed 26 April 2020.

UNFCC (2015) Paris agreement. United Nations framework convention on climate change. https://unfccc.int/sites/default/files/english_paris_agreement.pdf. Accessed 30 November 2020.

Vares S, Häkkinen T, Vainio T (2017) Rakentamisen hiilivarasto. [Carbon stock in construction]. VTT Technical Research Centre of Finland. Asiakasraportti VTT-CR-04958-17. http://www.ym.fi/download/noname/%7B2859F537-ECD2-479D-A62B-F13AD75403F2%7D/136827. Accessed 30 November 2020.

Total of 43 references.