Cost-efficiency and ergonomic study of two methods for planting Eucalyptus spp. seedlings in plantation forestry

Kaakkurivaara T., Kaakkurivaara N. (2021). Cost-efficiency and ergonomic study of two methods for planting Eucalyptus spp. seedlings in plantation forestry. Silva Fennica vol. 55 no. 4 article id 10580. https://doi.org/10.14214/sf.10580

Highlights

- We present a first assessment of the planting stick method as used in Thailand for planting Eucalyptus spp. seedlings in plantations in terms of time, cost and ergonomic parameters

- Parallel analysis shows that the planting tube method may be superior for planting Eucalyptus spp. seedlings

Abstract

In Thailand and various other countries tree seedlings are generally planted using simple manual tools, often a ‘planting stick’, but the method requires time-consuming, labour-intensive teamwork. However, use of a ‘planting tube’ allows a single person to perform both the preparation and planting work. Thus, in a classical time study and ergonomic survey we compared the productivity, cost-effectiveness, and ergonomic impact of planting Eucalyptus spp. seedlings using the two tools at the same planting site in Western Thailand. The planting tube method proved to be more productive, more cost-efficient, and less burdensome than the planting stick method (with time and cost requirements of 21 s and €0.0061 per seedling, versus 16.6 s and €0.0463 per seedling, respectively). In conclusion, the planting tube method may be a viable alternative to reduce costs and increase productivity, while maintaining reasonable workloads for the workers, despite the higher purchase price of planting tubes.

Keywords

productivity;

time study;

planting stick;

planting tube;

REBA;

work load;

work sampling

-

Kaakkurivaara,

Department of Forest Engineering, Faculty of Forestry, Kasetsart University, 50 Phahonyothin Rd, Lat Yao, Chatuchak, Bangkok 10900, Thailand

E-mail

tomi.kaakkurivaara@gmail.com

- Kaakkurivaara, Department of Forest Engineering, Faculty of Forestry, Kasetsart University, 50 Phahonyothin Rd, Lat Yao, Chatuchak, Bangkok 10900, Thailand E-mail ffornrm@ku.ac.th

Received 9 June 2021 Accepted 29 August 2021 Published 2 September 2021

Views 55671

Available at https://doi.org/10.14214/sf.10580 | Download PDF

List of symbols

AVI = average value of annual investment,

CDep = cost of annual depreciation,

CInt = cost of annual interest,

CLabor = labour cost for a given method per hour,

CPer = hourly salary,

CSeed = cost per planted seedling,

CTot= total cost per hour,

DH = duration of working hours per day,

h = acceptable error probability in percent,

Int = interest percentage on capital value invested annually,

NPer = number of workers used per method,

NT = number of tools,

ne = minimum sample size in the ergonomic study,

np = minimum sample size in the productivity study,

PHour = productivity (seedlings planted hour–1),

PP = purchase price,

p = percentage occurrence of delay in decimal format,

QD = number of working days per planting season,

SL = service life,

SV = total salvage value,

t = t-value,

WE = average time elapsed in a given work element (s),

z = standard normal deviate for desired confidence level,

σx2 = variance.

1 Introduction

The estimated area of Eucalyptus spp. plantations in Thailand rose from 480 000–600 000 ha at the turn of the millennium (FAO 2001; Luangviriyasaeng 2003) to about 1.8 million ha in 2016 (Haruthaithanasan 2016) and continues to increase. They are located in areas along canals and beside paddy fields, mainly planted in large block-like patterns, and managed mainly by numerous small farmers and private companies (Luangviriyasaeng 2003). The wood produced is used by the Thai pulp, board and sawn timber industries (Chujit 2001).

The planting techniques and tools used to plant Eucalyptus spp. seedlings vary widely, depending on the country. Containerized seedlings are commonly planted manually using a planting stick in Thailand (Korwanich 1983) and in the USA (Whitesell et al. 1992), while a planting hoe or bar is preferred in The Philippines (Laarman et al. 1981). Some partly mechanized techniques are used in e.g. South Africa, where a hand-held motor-manual auger is used to make planting pits, in which the seedlings are planted manually using a planting tube, and a hydrogel/water mixture is added from a tank mounted on a farm tractor (SA Forestry Online 2016). In South America, seedlings are widely planted with the help of a tractor (Foelkel 2009). The planting stick method commonly applied in Thailand is laborious and requires team work. Locations of planting pits are established using iron wires to set regular grids, planting pits are made using iron-tipped sticks, and then seedlings are manually placed in the pits. Due to labour shortages in forestry, there is a need for planting methods with higher productivity and lower costs (Thailand National Statistical Office 2017). There is a diverse range of manual planting tools, of which the planting tube is the most sophisticated and widely used. A planting tube tool was developed in Finland in the 1970’s for containerized seedlings, and models made by the Sisuputki and Pottiputki companies have been and still are used in the Nordic countries (Sisuputki 2021; Pottiputki 2021).

Harstela (1993) presented three categories for forest mechanization: basic technology (e.g., manual tools), intermediate technology (e.g., farm tractors), and advanced technology (e.g., harvesters). The most appropriate technology depends on multiple criteria, such as ecological conditions, characteristics of the enterprise, productivity, costs, and both environmental and socio-economic impacts. Country-specific conditions and factors must also be considered when deciding the optimal technology for productive and cost-efficient planting. For example, ecological and socio-economic conditions in Thai forestry strongly differ from those in Nordic countries and elsewhere, so Nordic planting techniques may not be suitable without modification in Thailand. Possible ways to mechanize the planting process have been actively researched for many decades, and mechanization began in practice in Canada, Finland, and Sweden at the end of the 1970s, following introduction of machines that can till soil and plant seedlings simultaneously, either through continuous planting work or spot mounding (Stjernberg 1985). In later studies, the productivity of the machines developed for planting was studied with coniferous seedlings (Rantala and Laine 2010), their cost-effectiveness was compared to manual planting (MP) (Hallongren et al. 2013), and the reloading of seedlings into a planting head was studied (Ersson et al. 2014). Regardless of the planting process, productivity needs to be improved (Laine 2017) and costs reduced (Ersson 2014), before mechanized planting can be competitive in comparison to MP (Ersson et al. 2018). Therefore, particularly in a country with relatively low levels of mechanization and low labour costs such as Thailand, a basic technology planting method is required that optimizes productivity and cost-effectiveness.

Scarratt and Ketcheson (1974) found that the productivity of the planting tube and planting stick methods, in terms of effective working hours (E0), was 4.1 and 4.6 seedlings min–1 or 246 and 276 seedlings per hour, respectively. Coniferous seedlings were used in the cited Nordic studies. In addition, 600 Eucalyptus spp. seedlings per day can be planted in good working conditions and 300 seedlings per day on difficult terrain using a planting stick, according to Whitesell et al. (1992), when one person prepares a hole, while a second person plants the seedlings and compacts the soil. In Thailand, Sangvisitpirom et al. (2018) found that the productivity of hoe planting, was 72 seedlings per hour or 50 seconds per seedling. Half of the time was used to making a planting pit. However, despite further research and development to mechanize the planting, it has not become a common method in Finland. In 2016, the areas in Finland planted by manual and mechanized methods amounted to about 82 000 and 1200 ha, respectively (Luke 2021). Saarinen et al. (2013) found that the productivity of MP was 158–165 seedlings h–1 or 10.93–11.39 hours ha–1, with a planting density of 1800 seedlings per hectare, depending on the level of soil preparation. Strandström et al. (2009) and Harstela (2004) reported that the productivity of the planting tube method with 2-year-old seedlings varied from 0.6 to 1.1 ha per working day, and was affected by the size of the root plugs and terrain.

In many forms of MP, planting tools, such as a dibble, stick, hoe, spade, or auger are used that require the planter to bend down to place the seedlings in the planting pits (Haywood et al. 2013). This is problematic and almost 30 years ago the FAO concluded (1992a) that the methods used to plant trees in developing countries were physically strenuous, the tools were ergonomically poor, and the working methods and tools have not received much research and development attention before or since then. One of few relevant studies showed that the work load is ergonomically lighter with a planting tube than with dibble, as it can be used with an upright posture (Scarratt and Ketcheson 1974). Another focused on the ergonomics of planting pine seedlings with a spade, and found that mean working heart rates ranged from 132.7 (± 16.2) to 134.9 beats min–1 (± 13.8) and productivity from 154 to 202 seedlings h–1, depending on the type of tilling (Sullman and Byers 2000). A method that can be used to evaluate planting-related stress more thoroughly is to study work postures of the workers’ bodies. Many observational techniques are available for such ergonomic study, which have been developed for diverse purposes and applied in workplaces with diverse conditions. One, Rapid Entire Body Assessment (REBA), involves systematic analysis of posture, provides sensitive indications of musculoskeletal risks associated with various tasks and is especially useful for assessing common working postures in healthcare and other service industries (Hignett and McAtamney 2000). The basic idea of REBA is to observe positions of individual body segments and give postural scores that rise with increases in the postures’ deviations from neutral positions. REBA is highly suitable for studying planting work, as it can be used for ergonomic assessment of all postures of a moving body during the planting process. Thus, in this study work (activity) sampling was used in conjunction with REBA to obtain time-based estimates of postural stress distributions.

No previous studies have reported the productivity or costs of the planting stick method in Thailand, and there have been no comparative studies of the productivity or costs of using planting sticks, planting tubes or other MP tools for planting Eucalyptus spp. seedlings either. Clearly, there is a need to study the efficiency and ergonomics of Eucalyptus spp. planting in Thailand using the planting stick and other tools to improve planting productivity in both Thailand and other countries with similar conditions. Thus, the presented study had two main aims. First, to determine the productivity, costs, and physical stress associated with the conventional multi-person planting stick method. Second, to compare it in these terms to use of the planting tube method, by a single person, for planting containerized Eucalyptus spp. seedlings. For these purposes we defined the work elements of both planting methods, then evaluated their time consumption and associated postural stress.

2 Materials and methods

2.1 Study area

The study was carried out in an area of privately owned land, formerly used for rice cultivation, in the Ratchaburi province of western Thailand (13°25´N, 99°48´E) at the end of July 2017, when the average daytime temperature was 32 °C. The soil in the study area is a clay-dominated gleyic acrisols (Dominant soil types 2021). The site was tilled twice, two weeks and three days before planting started, using a tractor-drawn plough to 20 cm depth. Double ploughing was necessary to eliminate undesirable vegetation and obtain favourable soil properties for seedling establishment. Eucalyptus spp. seedlings were then planted with 3.0 × 2.0 m spacing (1666 seedlings ha–1), by one moderately experienced worker using the planting tube method, and a team of moderately experienced workers using the planting stick method, as described below. The moderate means one to three planting season experiences.

2.2 Planting with a planting stick

The planting stick tool used in the study is a 110 cm long wooden rod with single-handed grip and steel tip, which is driven into a selected spot to create a planting pit (Fig. 1). The depth of the pit depends on the stiffness of the soil and both the force and number of thrusts. Ten cm (visually assessed by the worker) is regarded as an adequate depth. Another worker then plants the seedlings from a plastic bag of 50 seedlings carried by the planter. The planter is also responsible for setting the seedlings by compacting the soil around them using his/her foot.

Fig. 1. A typical planting stick (left), consisting of a wooden rod with an iron planting tip, and iron wire with bolts indicating precise planting spots. Photo on the right shows a worker in the middle stretching a wire line to prepare the next row, a worker on the left waiting for her turn, and a worker on the right doing actual planting and soil compaction work.

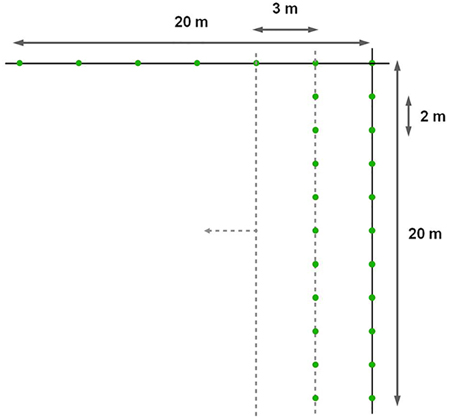

In this study, the planting team that used the planting stick consisted of 10 workers, and for analysis the work was separated into soil preparation and seedling planting phases, both of which included several work elements (Table 1). In the preparation phase, the location of planting rows was determined using two marking chains (Fig. 2), consisting of iron wires with bolts and nuts attached at 3- or 2-m spacing (to mark positions within and between rows, respectively). The former was first placed along the edge of the planting area to mark starting points of the planting rows, and then the latter was placed perpendicularly to those points to indicate the planting spots, which were marked by sticks. In this manner, positions of seven rows of 11 seedlings were marked.

| Table 1. Description of work elements of the two planting methods. | |||

| Method | Work phases | Work elements | Description |

| Planting stick | Preparation | Moving | Begins when the worker starts walking towards a new location and ends when s/he reaches it |

| Aligning | Begins when the worker starts looking at colleagues to set the marking chains perpendicular to each other (visually) and ends when workers have finished putting marking sticks in the ground | ||

| Planting | Walking | Begins when the worker starts walking to a marked location and ends when s/he reaches it | |

| Preparing | Begins when the worker puts a planting stick in the soil and ends when s/he moves to the next spot | ||

| Planting | Begins when the worker takes a seedling from his/her bag and ends when s/he is back in the standing position | ||

| Tamping | Begins when the worker starts to compact the soil by foot and ends when s/he is ready to move on | ||

| Planting tube | Preparation | Measuring | Begins when the worker starts to measure the correct distance for the next row from the previous row and ends when the location is defined |

| Walking | Begins when the worker starts walking towards the new location of a marking stick and ends when s/he reaches it | ||

| Locating | Begins when the worker puts a marking stick in the ground and ends when it is checked and corrected, to ensure that it is parallel with others | ||

| Moving | Begins when the worker starts to walk ahead of a marking stick to the next location and ends when s/he reaches it | ||

| Planting | Walking | Begins when the worker starts walking to a planting spot and ends when s/he reaches the spot | |

| Preparing | Begins when the worker presses the planting tube to the ground and ends when the jaws are opened | ||

| Planting | Begins when the worker moves his/her hand to the basket and ends when a seedling is dropped out of the tube | ||

| Pulling up | Begins when the worker starts to pull up the tube and ends when the jaws are closed | ||

| Tamping | Begins when the worker compacts soil by foot and ends when s/he is ready to move on | ||

| Navigating | Begins when the worker sets the tube next to the planted seedling and ends when s/he lifts up the tip of the dimension stick from the next planting spot | ||

Fig. 2. Alignment layout applied in the planting stick method by using two wires (20 m). The three meters indicates space between the rows and the two meters indicates the space between planting spots.

The planting stick method enabled the planting team to carry out both work phases simultaneously. Ten workers performed the whole planting process. In the preparation phase, three workers moved the marking chains to locate the planting spots in each row, moving the chain with 2 m spacing to the location of the next row after all planting pits in a row had been dug or all the seedlings planted. The rest of the planting team prepared the planting pits, put the seedlings in the soil then tamped the soil around the seedlings. These work elements of the planting phase were carried out either by each person executing all elements simultaneously or by specific team members taking responsibility for specific work elements, depending on the situation at each planting position.

2.3 Planting with a planting tube

The planting tube used, manufactured by Pottiputki™, has an outer diameter of 50 mm is 92 cm long, and made of 2.5 mm thick steel (Fig. 3). To mark positions of the planting spots within rows a 1.78 m long measuring stick was attached to the upper part of the planting tube, and the planting tube was tilted so that the other end of the stick was pressed into the ground, thereby marking a point 2 m away, according to Pythagoras’ Theorem (Fig. 3).

Fig. 3. Photos showing a planting tube with a measuring rod used to indicate the correct distance between the seedlings (left panel), and a planter using marker sticks for correct alignment (right panel).

In the preparation work phase, four sticks were placed in a line per row to make the rows as straight as possible, with locations determined from the previously planted row using measuring tape. The planter carried a seedling container with a shoulder strap, belt and 40 l capacity, sufficient for carrying up to 150 seedlings. Each row was approximately 100 m long, and 48 seedlings were planted per row. The planting procedure was as follows. The tube was pressed vertically into the ground, its jaws were opened by stepping on a lever, and then a containerized seedling was dropped into the tube by the planter. The tube was then lifted and twisted slightly, the soil around the planted seedling was compressed by foot, the jaws were closed using a second lever and finally the tube was removed (Metsäteho 2001; Uusitalo 2010). The method is described in more detail in Table 1.

2.4 Minimum sample size calculation

The productivity of the two methods was assessed by a time study, after determining the minimum number of observations required in each case for validity, following Ackerman et al. (2014), using Eq. 1:

here: np = the minimum sample size, t = the t-value, obtained from a t-table with an error probability of 0.05, and σx2 = the variance. Consideration of the variation in duration of work phases is essential for an adequate confidence level. Eq. 1 indicates that observations of at least 88 and 111 planting stick preparation phase and planting phase replications, respectively, were needed. These requirements were easily met as the final numbers of observed planting phases were 108 and 323, respectively. The planting tube method required only 12 repetitions, due to minimal variation, although 438 were observed. The preparation and planting phases of the planting tube method were combined, because one person carried out the whole planting process.

2.5 Productivity and cost calculation formulas

To assess the two planting methods’ productivity, the duration of the work elements involved in planting each seedling was determined from video-recordings of the work, and average times were calculated. As use of the planting tube only involved a single worker, while use of the planting stick method involved a team of workers, there were some restrictions in comparison of the two systems. The work elements of the planting tube method are easy to identify, but several workers simultaneously carry out different work elements of the planting stick method, so precise allocation of time for work elements was important. During the preparation phase, the time consumption of the work elements had to be divided by the number of seedlings in a planting row to calculate the time spent per seedling. In this study, effective working time (E0), which does not include breaks, was used in the time consumption calculations, and if a subject stopped working another worker was followed. The number of seedlings planted per hour was calculated according to Eq. 2:

where PHour = productivity (seedlings hour–1) and WE = average time elapsed in a given cycle element (s).The factors used in cost calculation are shown in Table 2. Labour costs included only direct hourly wages, with no indirect costs or daily allowances, in accordance with Thai labour market policy. The hourly wage was the minimum hourly salary set by the Thai Government. This salary was the only cost variable and the same for both methods. Fixed costs were allocated to the planting stick and planting tube methods. In addition to the purchase price of the tool, the cost of other necessary equipment, such as the position-marking wires for the planting stick method and strapped seedling container for the planting tube method, was also taken into account. The planting tube was purchased locally, but there is a notable cost difference between a planting tube and planting stick. The salvage value and service life for both tools were determined based on user experience. Annual utilization time is the duration of the Thai planting season (May – July).

| Table 2. Cost factors used for both planting methods. | ||||

| Cost factor | Planting stick | Planting tube | Unit | |

| Fixed cost | Purchase price of the tool | 8.00 | 141.30 | € |

| Number of tools | 10 | 1 | ||

| Purchase price of the iron wires per seedling basket | 10.70 | 48.00 | € | |

| Total purchase price | 90.70 | 189.30 | € | |

| Service life | 2 | 5 | a | |

| Salvage value | 15 | 15 | % | |

| Total salvage value | 13.60 | 28.40 | € | |

| Interest on capital | 6 | 6 | % | |

| Variable cost | Hourly wage | 1.00 | 1.00 | € h–1 |

| Number of workers | 10 | 1 | Person per method | |

| Duration of a working day | 8 | 8 | Hours day–1 | |

| Number of working days | 120 | 120 | Days year–1 | |

It was important, for comparison, to evaluate relative costs of the two methods and hence rigorously calculate their costs. The following equations were used to determine the fixed costs. The average value of the average annual investment was calculated using Eq. 3 (Miyata 1980; FAO 1992b; Kaakkurivaara and Kaakkurivaara 2018):

where AVI = average value of annual investment, PP = purchase price, NT = number of tools, SV = total salvage value, and SL = service life. The resulting values were used to calculate the average annual investment costs with Eq. 4:

![]()

where CInt = cost of annual interest, and Int = interest percentage on the capital value invested annually. We also calculated annual straight-line depreciation (CDep), following Kaakkurivaara and Korpunen (2017), using Eq. 5:

![]()

The variable costs included labour costs per hour, which were based on the hourly wage and number of workers using each planting method (Eq. 6):

![]()

where CLabor = labour cost of the method per hour, CPer = hourly salary, and NPer = the number of workers involved. The total cost per hour, consisting of the abovementioned labour and fixed costs, was divided by the total number of working hours in a planting season to evaluate the cost according to the actual annual workload (Eq. 7):

The cost per planted seedling (CSeed) was then determined with Eq. 8:

2.6 Ergonomic evaluation

The ergonomics of the two planting methods were studied by monitoring work postures using the same videos as in the productivity study, but using REBA and work sampling (Madani and Dababneh 2016). REBA is based on diagrams of body parts including the upper arms, forearms, wrist, trunk, neck, and legs, divided into Groups A (the trunk, neck, and legs) and B (upper and lower arms and wrists). Scores for these groups are combined into one of 144 possible posture combinations that are transformed into a general postural code. The codes reflect the extent of the external load/forces exerted, muscle activity caused by static, dynamic, rapidly changing or unstable postures, and a coupling effect. These scores are summed to give a single score for each observation (Takala et al. 2010). This technique provides final scores ranging between 0and 4 to evaluate the level of corrective actions. In this study, levels 0–4 were called negligible, low, medium, high, and very high, respectively. Durations of the work elements were determined by recording their frequencies in 15 s intervals in the videos used to evaluate and classify postures. The total numbers of observations were 167 and 185, excluding delays, for the planting stick and tube methods, respectively. According to these observations, delay times for the planting stick and tube methods were 12% and 9%, respectively. These percentages were used in calculations to ensure that there were sufficient observations in the work sampling (in contrast to the time study, where delays were excluded from corresponding validity calculations). The minimum work sampling size was determined, following Tryfos (1988), using Eq. 9.

where: ne = the minimum sample size, z = the standard normal deviate for the desired confidence level (0.95 = 2), p = percentage of delay in decimal format (0.09 and 0.12), and h = acceptable error probability (0.05). The confidence level and acceptable error are commonly used and were selected because they were deemed to offer a close-to-optimal compromise between maximizing sampling sizes to enhance the results’ reliability and keeping them within manageable ranges. The calculated minimum sample sizes for the planting stick and tube methods were 169 and 132 observations, respectively.

3 Results

3.1 Productivity

Effective working time durations for the work phases and elements of the planting stick method are presented in Table 3. The preparation work phase included two work elements (moving and aligning), which jointly did not account for a remarkable proportion of the total time. During the planting work phase, the observed working times were divided quite evenly between four elements (walking, preparing, planting and tamping), although tamping took the least time. The total time was 16.60 seconds per seedling, with the largest proportion of working time taken up by preparation during the planting phase (29% of the total).

| Table 3. Productivity of the planting stick method, performed by a group of workers, and average time for each work element. | ||

| Planting stick | Work element | s seedling–1 |

| Moving | 0.59 | |

| Aligning | 0.78 | |

| Preparation | Subtotal | 1.37 |

| Walking | 4.39 | |

| Preparing | 4.82 | |

| Planting | 3.12 | |

| Tamping | 2.90 | |

| Planting | Subtotal | 15.23 |

| Total | 16.60 | |

Corresponding productivity statistics for the planting tube method are presented in Table 4. The most time consuming work element during the preparation phase was moving, in which new planting rows were marked on the ground, and the distance between rows was measured. These elements accounted for 84% of the preparation phase time. In the planting work phase, the most time-consuming work element was tamping (compaction of the soil around the seedlings by foot). This process accounted for a third of the total planting work time, which was 21 s on average per seedling. Other work elements did not differ substantially from each other. The overall productivity of the planting tube and stick methods, in terms of number of seedlings planted per hour, was 171 and 217, respectively. The planting stick method was therefore around 27% more efficient. The subtotal time of the preparation phase was slightly over 1 s per seedling for both methods. However, the planting work phase was 31% longer per seedling for the planting tube method than the planting stick method. The most substantially differing element was the soil compaction by foot, which took on average 4.13 s longer in the planting tube than in the planting stick method. Comparisons of other work elements are not possible due to the differences in elements between methods.

| Table 4. Productivity of the planting tube method, performed by one person. The preparation time was calculated for a planting row, which consisted of 48 seedlings. | ||

| Planting tube | Work element | s seedling–1 |

| Measuring | 0.29 | |

| Walking | 0.08 | |

| Locating | 0.09 | |

| Moving | 0.59 | |

| Preparation | Subtotal | 1.05 |

| Walking | 3.01 | |

| Preparing | 3.24 | |

| Planting | 2.4 | |

| Pulling up | 1.37 | |

| Tamping | 7.03 | |

| Navigating | 2.90 | |

| Planting | Subtotal | 19.95 |

| Total | 21.00 | |

3.2 Cost calculations

The fixed costs, variable costs, cost per hour, and cost per seedling of each method are presented in Table 5. The contribution of fixed costs per hour was low, due to the use of cheap planting tools. For the planting stick method, the variable costs were substantial due to the 10-person working group, so its hourly costs were over ten times higher, and the unit costs seven and half times higher, than for the planting tube method.

| Table 5. Fixed, variable, hourly, and unit costs of the two planting methods, based on the productivity study and cost calculation. | ||

| Planting stick | Planting tube | |

| Fixed costs, € h–1 | 0.0446 | 0.0413 |

| Variable costs, € h–1 | 9.99 | 1.00 |

| Hourly cost, € h–1 | 10.04 | 1.04 |

| Unit cost, € seedling–1 | 0.0463 | 0.0061 |

3.3 Ergonomics

Results regarding the work-related stress associated with the planting stick method are presented in Table 6. These include percentages and numbers of observations (n) indicating how often specific work elements were performed, and five-level grades indicating the strenuousness of work postures required to execute them according to the REBA classification. The moving and aligning work elements accounted for roughly a quarter and three quarters of observations in the preparation work phase, respectively. Around half of the observations were assigned to the low stress class, and almost all of the others were classified as negligible or medium. Two observations of work elements during the preparation phase (out of 63 in total) were assigned to the high stress level. The most commonly observed work elements during the planting work phase were walking and planting, for which the work-related stress was mainly low and high, respectively. Generally, the work elements were classified either as low or medium during the planting work phase. Around 24% of the observed work during this phase was classified as high stress, and the other 76% as low or medium stress. None was classified as very high stress.

| Table 6. Results of REBA evaluation of work-related stress incurred using the planting stick method. Values in the ‘additional’ row include waiting time. The letter n in the first row indicates the respective number of observations. | |||||||||||||

| Work phase | Work element | Negligible | Low | Medium | High | Very High | Total | ||||||

| % | n | % | n | % | n | % | n | % | n | % | n | ||

| Preparation | Moving | 9.5 | 6 | 14.3 | 9 | 23.8 | 15 | ||||||

| Aligning | 27.0 | 17 | 39.7 | 25 | 6.3 | 4 | 3.2 | 2 | 76.2 | 48 | |||

| Total | 27.0 | 17 | 49.2 | 31 | 20.6 | 13 | 3.2 | 2 | 100 | 63 | |||

| Planting | Walking | 23.1 | 24 | 4.8 | 5 | 27.9 | 29 | ||||||

| Preparing | 1.0 | 1 | 16.3 | 17 | 3.8 | 4 | 21.1 | 22 | |||||

| Planting | 3.8 | 4 | 20.2 | 21 | 24.0 | 25 | |||||||

| Tamping | 5.8 | 6 | 5.8 | 13 | 18.3 | 19 | |||||||

| Additional | 8.7 | 9 | 8.7 | 9 | |||||||||

| Total | 38.5 | 40 | 37.5 | 39 | 24.0 | 25 | 100 | 104 | |||||

Corresponding results regarding the work-related stress associated with the planting tube method are presented in Table 7. The percentages and number of observations (n) show, how often a work element was found in the video recorded data, and the stress of the work element was classified using five-step grading, based on the working posture, according to the REBA classification. During the preparation work phase, most observations were of the moving element, in which all work postures were assigned to the negligible level. Half of all observations in the preparation work phase were also assigned to the negligible level. However, some observations during the measuring work element were assigned to the medium and high stress levels, and those observed during the walking and locating elements were generally assigned to the negligible and low levels. During the planting work phase slightly more than half the observations were assigned to the low stress level, and the rest to the negligible or medium level. Compacting soil around the planted seedlings accounted for 46 out of 139 observations. There were no observations of pulling up the planting tube due to its rapidity. No high or very high stress level postures were observed during any elements of the planting tube method.

| Table 7. Results of REBA evaluation of work-related stress for the planting tube method. Values in the ‘additional’ row includes addition of seedlings to a container. | |||||||||||||

| Work phase | Work element | Negligible | Low | Medium | High | Very High | Total | ||||||

| % | n | % | n | % | n | % | n | % | n | % | n | ||

| Preparation | Measuring | 15.2 | 7 | 19.6 | 9 | 4.4 | 2 | 39.2 | 18 | ||||

| Walking | 8.7 | 4 | 2.2 | 1 | 10.8 | 5 | |||||||

| Locating | 8.7 | 4 | 8.7 | 4 | 17.4 | 8 | |||||||

| Moving | 32.5 | 15 | 32.6 | 15 | |||||||||

| Total | 49.9 | 23 | 26.1 | 12 | 19.6 | 9 | 4.4 | 2 | 100 | 46 | |||

| Planting | Navigating | 1.4 | 2 | 9.4 | 13 | 0.7 | 1 | 11.5 | 16 | ||||

| Walking | 2.2 | 3 | 10.1 | 14 | 0.7 | 1 | 13.0 | 18 | |||||

| Preparing | 2.2 | 3 | 10.1 | 14 | 9.4 | 13 | 21.5 | 30 | |||||

| Planting | 3.6 | 5 | 6.5 | 9 | 7.2 | 10 | 17.3 | 24 | |||||

| Pulling up | |||||||||||||

| Tamping | 3.6 | 5 | 15.8 | 22 | 13.7 | 19 | 33.1 | 46 | |||||

| Additional | 2.9 | 4 | 0.7 | 1 | 3.6 | 5 | |||||||

| Total | 15.8 | 22 | 51.8 | 72 | 32.4 | 45 | 100 | 139 | |||||

4 Discussion

In this study we assessed and compared productivities of a planting stick method conventionally applied in Thailand and an alternative (planting tube) method that could be implemented in plantation forestry. The raw results indicate that the planting stick method is suitable for planting Eucalyptus spp. seedlings as it provided 46 seedlings higher per hour productivity than the planting tube method. However, 10 people were involved in the planting stick method, so its productivity per worker was only 21.7 seedlings per effective working (E0), while a single worker planted 171 seedlings per hour (9.74 hours ha–1) using the planting tube method. These values are consistent with previous findings regarding differences in time consumption between the two methods in Finland (Harstela 2004; Saarinen et al. 2013). This is despite major differences in conditions, as harsh terrain and scattered locations of planting spots reduce productivity in Nordic plantation forestry, while seedlings are planted in straight rows and working conditions after tillage are homogenous at our study site.

However, the stiffness of the soil at our site increased the tamping time and decreased productivity. Thus, use of a planting tube with a smaller diameter could potentially reduce the amount of compaction work needed. This would be easily possible, at least with the types of seedlings used in this study, as neither the diameter of the root plug (3 cm) nor dimensions of the foliage would cause any problem. If reducing the tube diameter halved the time consumed by tamping, which seems eminently feasible, productivity would increase by about 10%. Time could also be saved by marking positions of planting spots in several rows in advance with additional sticks to allow workers to spend longer periods actually planting, thereby further decreasing the preparation time per seedling. With these two improvements, the productivity would be even higher. In contrast, despite being the most popular method in Thailand and many other countries, the planting stick method does not seem to be efficient, at least in the way in which it was applied in this study. However, the use of iron wires to determine positions to plant seedlings in a strict grid pattern is advantageous as it facilitates subsequent weeding and grass-cutting work, and positions of hidden seedlings can be quickly determined from locations of seedlings in the same and adjacent rows. In contrast, locations of seedlings vary slightly from grid positions when the planting tube method is used. We regard results of the productivity study as reliable because we were able to determine work elements for both methods and measure their durations in both cases. Nevertheless, it should be noted that we only monitored one working group using the planting stick method and one person using the planting tube method, at just one site. This would be a concern if the difference in productivity was not so large.

The cost of planting work includes fixed costs, such as costs of tools and equipment, and operational costs, such as salaries, which must be considered in relation to the time-dependent productivity rate. An important factor in the cost comparison of the methods was the purchase price of tools, as the total fixed cost for one worker using the planting tube method was higher than the total price of tools and equipment for 10 workers using the planting stick method. However, the higher initial investment was quickly compensated by higher productivity of the planting work, when the salary costs were taken into account. A seven-fold difference in the unit cost per planted seedling clearly justifies recommendation of the planting tube method for planting Eucalyptus spp. seedlings. Due to a lack of local dealers, the resale price is an estimate, but the cost per seedling would not sufficiently differ from our estimates, even if the purchase price was substantially higher. The tools used were technically simple, so their maintenance and repair would not add major costs either.

The ergonomic study and cost calculations provide new information about both of the planting methods, although the planting tube method has been used for a long time in Western countries, and the planting stick method in the tropics (Scarratt and Ketcheson 1974; Korwanich 1983). Due to the similarity of work in planting Eucalyptus spp., boreal coniferous and other seedlings, the results may enhance general understanding of the stresses incurred using the methods for wide groups of users and forestry professionals. We found that working postures involved in the planting tube method were less strenuous than those involved in the planting stick method, during both the preparation and planting work phases. This finding is essential, as it is important to reduce stress-related workloads in hot climates, thereby helping planters to work longer hours and still maintain good work efficiency.

A important finding regarding the planting tube method were that the tamping work consumed substantially more time and was more stressful than the other elements. The reason for this is that the tube was too wide, so a lot of tamping was needed for good quality planting to assure high seedling survival rates. Observed postures associated with this element were assigned to the medium stress level (higher than levels of all other elements). The stress and time consumption would be reduced with a thinner tube or looser soil, further reducing the overall stress. In the planting stick method, the planting work element contributed most strongly to overall stress, as it required bending down to place a seedling in a planting pit. Generally, the planting tube method is clearly better than the planting stick method in terms of stress. However, working in a group is less stressful than working alone, as tasks can be rotated between the workers during a working day. As a single worker is responsible for all the tasks in the planting tube method such circulation is not possible, and short-duration planting work phases have to be frequently repeated for a long time.

5 Conclusions

Our results show that the planting tube method was better than the planting stick method, and can provide substantial improvements in productivity, unit costs, and work load. They also indicate that manual planting productivity and ergonomic parameters are strongly associated, and will be improved when working methods and tools are improved. The planting tube method has clear apparent utility for planting Eucalyptus spp. seedlings globally, and other containerized seedlings of tropical tree species with appropriate modification. Moreover, two modifications could enhance its usability for planting Eucalyptus spp. seedlings. First, the diameter of the planting tube should be optimized for the containerized seedlings to reduce the tamping work required. In this study, too large planting pits and the clay-dominated soil caused extra work. Second, the tube should be shorter for tall seedlings. This would prevent seedlings being damaged when the worker closes the jaws too early and the top of a seedling is still inside the tube. These modifications would also reduce the weight of the planting tube, making it lighter and thus easier to handle and carry to planting sites.

Declaration of openness of research materials and data

Directly analyzable data are available on request from the corresponding author. Other research materials are not available.

Declaration of competing interest

The authors report no declarations of interest.

References

Ackerman P, Gleasure E, Ackerman S, Shutteworth B (2014) Standards for time studies for the South African forest industry. ICFR/FESA 2014.

Chujit N (2001) Alternatives for Eucalyptus spp. planting in the Northeastern Region of Thailand. Royal Forest Department. [in Thai].

Dominant soil types (2021) https://thailand.opendevelopmentmekong.net/layers/tha-soil-types/. Accessed 4 June 2021.

Ersson BT (2014) Concepts for mechanized tree planting in southern Sweden. Acta Universitatis Agriculturae Sueciae 76. PhD thesis, Swedish University of Agricultural Sciences, Sweden.

Ersson BT, Laine T, Saksa T (2018) Mechanized tree planting in Sweden and Finland: current state and key factors for future growth. Forests 9, article id 370. https://doi.org/10.3390/f9070370.

Ersson BT, Bergsten U, Lindroos O (2014) Reloading mechanized tree planting devices faster using a seedling tray carousel. Silva Fenn 48, article id 11064. https://doi.org/10.14214/sf.1064.

FAO (1992a) Introduction to ergonomics in forestry in developing countries. FAO Forestry Paper No. 100. FAO, Rome, Italy.

FAO (1992b) Cost control in forest harvesting and road construction. FAO Forestry Paper No.99. FAO, Rome, Italy.

FAO (2001) Global forest resources assessment, Main report. FAO Forestry Paper No.140. FAO, Rome, Italy.

Foelkel C (2009) The production of Eucalyptus plantation forests from the perspective of eco-effectiveness, eco-efficiency, and cleaner production. Eucalyptus online book & newsletter, ABTCP.

Hallongren H, Laine T, Rantala J, Saarinen V-M, Strandström M, Hämäläinen J, Poikela A (2014) Competitiveness of mechanized tree planting in Finland. Scand J Forest Res 29: 144–151. https://doi.org/10.1080/02827581.2014.881542.

Harstela P (1993) Forest work science and technology, part I. Silva Carelica 25. University of Joensuu, Faculty of Forestry. Joensuu, Finland.

Harstela P (2004) Kustannustehokas metsänhoito. [Cost-efficient silviculture]. Gravita Ky.

Haruthaithanasan M (2016) Eucalyptus plantation management in Thailand. In: Proceedings of the 11th Biennial Short Rotation Woody Crops Operations Working Group Conference, Florida, USA.

Haywood JD, Leduc DJ, Sung S-J (2013) Comparing seven planting tools for container-grown longleaf pine seedlings. Tree Planters’ Notes 56: 30–34.

Hignett S, McAtamney L (2000) Rapid Entire Body Assessment (REBA). Appl Ergon 31: 201–205. https://doi.org/10.1016/S0003-6870(99)00039-3.

Kaakkurivaara N, Kaakkurivaara T (2018) Productivity and cost analyses of three timber extraction methods on steep terrain in Thailand. Croat J For Eng 39: 213–221.

Kaakkurivaara T, Korpunen H (2017) Increased fly ash utilization – value addition through forest road reconstruction. Can J Civil Eng 44: 223–231. https://doi.org/10.1139/cjce-2016-0193.

Korwanich A (1983) Forestry hand tools. The Forestry Association of Thailand. [in Thai].

Laarman JG, Virtanen K, Jurvelius M (1981) Choice of technology in forestry: a Philippine case study. International Labor Office, ILO. New Day publishers, Quezon City, Philippines.

Laine T (2017) Mechanized tree planting in Finland and improving its productivity. Dissertation Forestales 239. https://doi.org/10.14214/df239.

Luangviriyasaeng V (2003) Eucalypt planting in Thailand. In: Turnbull JW (ed) ACIAR Proceedings on Eucalypts in Asia, No. 111, Zhanjiang, Peoples Republic of China, 7–11 April 2003, pp 28–31. Elect Printing, Canberra, Australia.

Luke (2021) Forest management and forest improvement work 2015-. http://statdb.luke.fi/PXWeb/pxweb/fi/LUKE/LUKE__04%20Metsa__02%20Rakenne%20ja%20tuotanto__12%20Metsanhoito-%20ja%20metsanparannustyot/05_Metsanhoito-ja-metsanparannustyot.px/?rxid=fcd7d587-2b9b-4770-ad2f-a4cebd20d1d0. Accessed 27 March 2021.

Madani DA, Dababneh A (2016) Rapid entire body assessment: a literature review. Am J Eng Appl Sci 9: 107–118. https://doi.org/10.3844/ajeassp.2016.107.118.

Metsäteho (2001) Metsänviljelyopas. [Reforestation handbook]. Metsäteho Oy. ISBN 951-673-173-2.

Miyata E (1980) Determining fixed and operating costs of logging equipment. Gen Tech Rep NC-55, Forest Service, North Central Forest Experiment Station, St. Paul, Mn. https://doi.org/10.2737/NC-GTR-55.

Pottiputki (2021) http://pottiputki.com/. Accessed 3 May 2021.

Rantala J, Laine T (2010) Productivity of the M-Planter tree-planting device in practice. Silva Fenn 44: 859–869. https://doi.org/10.14214/sf.125.

Saarinen V-M, Hyyti H, Laine T, Strandström M (2013) Kohti jatkuvatoimista koneistutusta. [Towards continuously operating planting machines]. Metsäteho Report 227.

SA Forestry Online (2016) KISS planting system keeps it simple and productive. SA Forestry magazine No. 6, October 2016.

Sangvisitpirom P, Rianthakool L, Kaakkurivaara N (2018) Design, analyze and evaluate of Eucalyptus seeding planter by finite element analysis. In: Wantongchai K, Kaewchapa N, Phalakit K, Sukmasuang R, Leksoongnern N, Mangkala Y, Phoomsathan S, Niamsuwan T, Suanphaka W, Riantrakul L, Phumalee U, Klinhuan T, Srirodchan C, Klinluan J, Chomchai S, Taophimai L, Sangthian T, MAknuan C, Wanthongchai P, Praweenwongwut T, Phomchoo W, Mee V, Yamprasai S, Jeamjaratsilp D, Chumriang P, Phromsin N, Dejyosdee U, Chanmahasathien S, Ladpala P, Snowman W, Thongtapao T, Meekaew K, Athornturasuk S (eds) Proceedings of Thai Forest Conference 2018. Bangkok, Thailand 22–24 August 2018. Kasetsart University, Bangkok, pp 507–517. https://conference.forest.ku.ac.th/external_files/proceedings/proceedings2561.pdf .

Scarratt JB, Ketcheson DE (1974) Japanese paperpots for containerized planting of tree seedlings. II. Preliminary evaluation of planting tools. Information report 0-x-204, Great Lakes Forest Research Centre, Canadian forestry service. Ontario, Canada.

Sisuputki (2021) https://veme.fi/en/sisuputki-3/. Accessed 2 May 2021.

Stjernberg EI (1985) Tree planting machines: a review of the intermittent-furrow and spot planting types. Special report No. SR-31, Forest Engineering Research Institute of Canada. Vancouver, Canada.

Strandström M, Hämäläinen J, Pajuoja H (2009) Metsänhoidon koneellistaminen – visio ja T&K ohjelma. [Mechanization of silviculture – vision and R&D program]. Metsäteho Report 206.

Sullman MJM, Byers J (2000) An ergonomic assessment of manual planting Pinus radiata seedlings. Int J For Eng 11: 53–62.

Takala EP, Pehkonen I, Forsman M, Hansson GÅ, Mathiassen SE, Neumann WP, Sjogaard G, Veiersted KB, Westgaard RH, Winkel J (2010) Systematic evaluation of observational methods assessing biomechanical exposures at work. Scand J Work Env Hea 36: 3–24. https://doi.org/10.5271/sjweh.2876.

Thailand National Statistical Office (2017) The study of labor demanding trends in Thailand (During 2017 – 2021). [in Thai]. http://eng.rmutsv.ac.th/file/AC/2562_7.pdf.

Tryfos P (1988) On sample size determination and inference in work sampling, IEE Transactions 20: 255–263. https://doi.org/10.1080/07408178808966178.

Uusitalo J (2010) Introduction to forest operations and technology. JVP forest systems Oy.

Whitesell CD, DeBell DS, Schubert TH, Strand RF, Crabb TB (1992) Short-rotation management of Eucalyptus: guidelines for plantations in Hawaii. Gen Tech Rep PSW-GTR-137, Forest service, Pacific Southwest Research Station, U.S. Department of agriculture. California, USA. https://doi.org/10.2737/PSW-GTR-137.

Total of 41 references.