Evaluation of a new pruning and tending system for young stands of Douglas fir

Schönauer M., Hoffmann S., Nolte M., Jaeger D. (2021). Evaluation of a new pruning and tending system for young stands of Douglas fir. Silva Fennica vol. 55 no. 2 article id 10447. https://doi.org/10.14214/sf.10447

Highlights

- Electric pruning shears combined with workflow re-organization reduced time demand for pruning

- Thinning by chainsaw was more productive than using the clearing saw Husqvarna 535FBX, which on the other hand showed lower physical workload

- Overall cost savings through the use of the new system were quantified at 6%.

Abstract

In Germany, management restrictions for Norway spruce (Picea abies (L.) H. Karst.) due to climate change lead to increasing interest in Douglas fir (Pseudotsuga menziesii (Mirb.) Franco) as a potential substituting species. However, Douglas fir requires cost-intensive silvicultural treatments, such as periodic thinnings and, in particular, pruning. In order to improve the efficiency of such treatments, a new tending system with an adapted two-step work system was analyzed. The new system, using electric pruning shears and the backpack clearing saw Husqvarna 535FBX ‘Spacer’, was compared to the conventional three-step work system, using handsaw and chainsaw and characterized by tree selection previously conducted as an independent work step. Time and motion studies to determine productivity and costs, as well as ergonomic analysis through heart rate measurements and posture analysis were conducted. Overall, the new system was found to be more productive and to have lower costs, with 8.9 trees per scheduled system hour (4.17 € tree–1), compared to the conventional system with 8.1 trees per scheduled system hour (4.44 € tree–1). Ergonomic improvements with the new system could be mainly observed during the felling of competing trees, when the level of heart rate reserve was reduced by 9.3 percent points, compared to the conventional system. However, significant advantages in reducing unfavorable body postures expected for the ‘Spacer’ could not be confirmed. Since time savings within the new system were mainly attributed to the adaptation of workflow and the use of the electric shears during pruning, it should be considered to replace the ‘Spacer’ within the new system by light chainsaws for best results under the conditions investigated.

Keywords

thinning;

time study;

Pseudotsuga menziesii;

body posture;

heart rate;

OWAS;

physical workload;

young stand

-

Schönauer,

Department of Forest Work Science and Engineering, University of Göttingen, Göttingen/Germany

E-mail

marian.schoenauer@uni-goettingen.de

-

Hoffmann,

Department of Forest Work Science and Engineering, University of Göttingen, Göttingen/Germany; School of Forestry, University of Canterbury, Christchurch/New Zealand

https://orcid.org/0000-0002-8077-967X

E-mail

stephan.hoffmann@uni-goettingen.de

https://orcid.org/0000-0002-8077-967X

E-mail

stephan.hoffmann@uni-goettingen.de

- Nolte, Forest Education Center FBZ / State Enterprise Forestry and Timber NRW, Arnsberg/Germany E-mail Martin.Nolte@wald-und-holz.nrw.de

- Jaeger, Department of Forest Work Science and Engineering, University of Göttingen, Göttingen/Germany E-mail dirk.jaeger@uni-goettingen.de

Received 8 October 2020 Accepted 6 April 2021 Published 6 May 2021

Views 56411

Available at https://doi.org/10.14214/sf.10447 | Download PDF

Supplementary Files

1 Introduction

The German approach of sustainable forest management, with its multi-purpose focus, aims at creating various products and ecosystem services (Schmithüsen 2013). Within this approach, Norway spruce (Picea abies (L.) H. Karst.) evolved to a key species for timber production, becoming the dominant species with an overall areal share of 25.4% in Germany (Thünen-Institut 2012) due to its wide-spread cultivation. However, the prevailing share of stands show low resilience towards changing climate conditions, characterized by successive drought periods, frequent storms of high intensity and heavy wet snow events, causing stand losses of substantial magnitude in recent years (Hanewinkel et al. 2011; Honkaniemi et al. 2020). Henceforth, silvicultural approaches aim at creating stands more diverse in species as well as at a shift to species with higher climate resilience, including non-native ones (Bolte et al. 2009), such as Douglas fir (Pseudotsuga menziesii (Mirb.) Franco).

Douglas fir is a highly productive species, able to outcompete yields of Norway spruce and silver fir (Abies alba Mill.) by 50% (Brosinger and Baier 2008), and further possesses an ecological amplitude, which matches expected future climate conditions for German sites (Vitali et al. 2017; Pötzelsberger et al. 2019). In addition, favorable wood properties, such as high mechanical strength and low content of resins, characterize Douglas fir as a valuable timber species with a wide range of products, e.g. construction timber, veneer or laminated timber (Brosinger and Baier 2008). Consequently, considering the current and most likely further evolving risks associated with the cultivation of Norway spruce, Douglas fir can be seen as a valuable substitute for spruce at many sites across Germany. Thus, there is a generally increasing interest in the cultivation of this species, and in concepts for enhancing its timber quality through appropriate silvicultural treatments (Ruge et al. 2019).

In particular, early thinnings are vital in order to obtain stable stands with high timber revenues. The lowered competition and increased light exposure of the individual tree after thinning is known to increase epicormic branching and the development of thick branches (Marchi et al. 2013). Knots are a detrimental factor for wood quality, and need to be considered for Douglas fir in particular due to its poor self-pruning ability (FVA BW 2000; Lerch 2011; Weller 2019). Although known to be cost-intensive, pruning of Douglas fir is a necessity for the production of high-quality timber, with a clear bole of good market value (Brazier 1977; Fillbrandt and Leisinger 2010). Best results are generally achieved if the first pruning is targeting trees which have reached a diameter at breast height (dbh) of 10 to 12 cm (Hartsough and Parker 1996).

But, pruning is physically demanding work which requires the skills of suitably trained professionals and appropriate tools. Handsaws are widely used for pruning due to the easy handling compared to shears (Nutto et al. 2013). However, the use of pruning shears results in better pruning quality (Stackpole 2001) and faster occlusion of wounds (Wardlaw and Neilsen 1999). Shears are therefore preferred for the production of valuable saw logs, and commonly used for pruning Douglas fir plantations in New Zealand (Hartsough and Parker 1996; Kirk and Parker 1996). Attempts to increase the efficiency of pruning with shears have been undertaken with the introduction of pneumatic systems already in the late 1970s, leading to good pruning results (Esser 2000). These pneumatic systems did not prevail due to the limited mobility, discomfort and increased logistic effort associated with the compressor and air hose needed. More recently, the use of electric pruning shears, originating from viticulture, showed increased productivity at reduced work fatigue among pruners in Eucalyptus (Eucalyptus grandis W. Mill ex Maiden) plantations (Nutto et al. 2013).

Pruning activities are commonly combined with early thinnings in a three-step work system in Germany. Thereby, tree selection and marking are conducted in an independent first step, ahead of the actual tending operation. The subsequent pruning is executed using a handsaw (second step) and the thinning by using a chainsaw (third step). The tree selection within the first step is commonly done by a forester with academic silvicultural education, leading to a timely deferred scheduling of the consecutive work steps. However, due to today’s more comprehensive training of professional forest workers, they are technically capable of selecting future crop trees themselves. Therefore, the separation of the three work steps does not seem expedient anymore, and a re-organization of the work offers potential efficiency gains.

Within the present study, the conventional three-step work system is compared with a recently developed two-step work system. Apart of work re-organization, the new system also includes the use of new tending equipment, to replace the commonly used handsaw and chainsaw, which are known to entail cost-intensive and tedious work (Ligné et al. 2005). The study aims to compare the two work systems in respect to: (i) work productivity and associated costs, and (ii) physical workload. Integrated into real-world operations, the study does not aim to investigate the technical properties of the used equipment per se, but rather focuses on the holistic system approach of the whole work process through operational case studies.

2 Material and methods

2.1 Study sites

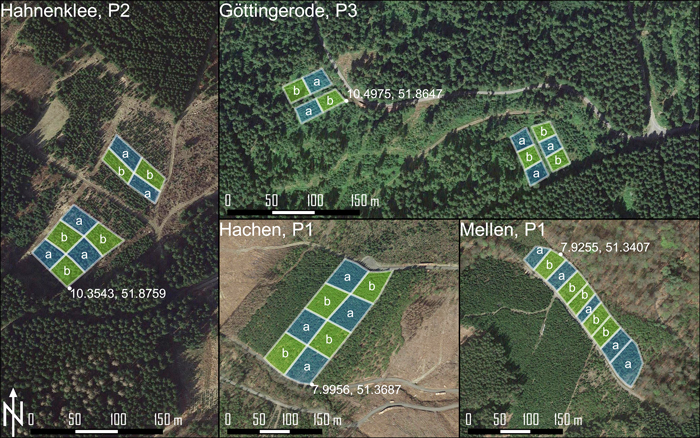

In-field operational case studies were conducted in July and October 2018, and in September and October 2019, in the German states of North-Rhine Westphalia (sites ‘Hachen’ and ‘Mellen’) and Lower Saxony (sites ‘Göttingerode’ and ‘Hahnenklee’), respectively. Different young stands of Douglas fir due for tending were selected, and divided into blocks for comparisons between the surveyed work systems (Fig. 1). Priority was given to dense stands, with trees having dead branches in the lower stem compartment. The selected stands were established after the storm Kyrill in 2007, with an initial spacing of approximately 2.5–3.0 m (Table 1). Overall, average dbh of trees selected for pruning was 12.3 ± 2.3 cm, measured with a diameter tape. Tree height averaged at 11.1 ± 3.0 m, measured on a subsample (consisting of 63 selected trees) using a Vertex IV (Haglöf Sweden AB, Sweden).

Fig. 1. Pruning and thinning of young stands of Pseudotsuga menziesii were applied at four different sites. Each site was treated by a test person (P1, P2, P3), whereas P1 treated two stands (‘Hachen’ and ‘Mellen’). Two systems were compared: (a) conventional, (b) new. Coordinates given correspond to WGS 84 standard.

| Table 1. Characteristics of pruned Pseudotsuga menziesii trees in the study, on four different stands (site). For pruning, a conventional three-step system (hand-held pruning saw and chainsaw) and a new two-step system (electric pruning shears and ‘Spacer’) were applied. With number of observations (n, trees), mean values, standard deviation (SD), minimum and maximum of diameter at breast height (dbh), tree height and number of branches per tree. | |||||||

| site | system | n | mean | SD | min. | max. | |

| dbh (cm) | Göttingerode | conventional | 71 | 11.7 | 1.98 | 8.2 | 17 |

| new | 62 | 11.4 | 1.92 | 7.9 | 16 | ||

| Hachen | conventional | 40 | 13.3 | 1.99 | 10.0 | 19 | |

| new | 48 | 13.4 | 1.60 | 10.0 | 17 | ||

| Hahnenklee | conventional | 50 | 13.2 | 2.15 | 8.1 | 17 | |

| new | 46 | 13.5 | 1.99 | 10.1 | 18 | ||

| Mellen | conventional | 26 | 10.6 | 2.48 | 7.0 | 15 | |

| new | 35 | 10.9 | 2.19 | 7.0 | 15 | ||

| height (m) | Göttingerode | conventional | 6 | 12.5 | 2.56 | 11.1 | 18 |

| new | 3 | 13.8 | 2.52 | 11.7 | 17 | ||

| Hachen | conventional | 10 | 8.4 | 1.01 | 7.0 | 10 | |

| new | 22 | 9.4 | 1.30 | 7.0 | 12 | ||

| Hahnenklee | conventional | 6 | 15.7 | 2.73 | 11.0 | 18 | |

| new | 6 | 15.2 | 1.84 | 13.0 | 18 | ||

| Mellen | conventional | 6 | 10.8 | 0.76 | 9.5 | 12 | |

| new | 4 | 11.0 | 1.08 | 9.5 | 12 | ||

| quantity of branches | Göttingerode | conventional | 72 | 83.4 | 9.41 | 54.5 | 103 |

| new | 64 | 74.2 | 11.54 | 51.0 | 97 | ||

| Hachen | conventional | 40 | 86.6 | 16.57 | 51.5 | 123 | |

| new | 47 | 90.2 | 16.14 | 58.0 | 130 | ||

| Hahnenklee | conventional | 52 | 86.6 | 11.80 | 64.5 | 115 | |

| new | 46 | 100.1 | 17.06 | 64.0 | 134 | ||

| Mellen | conventional | 25 | 66.1 | 14.13 | 46.5 | 116 | |

| new | 34 | 65.0 | 12.81 | 43.0 | 98 | ||

2.2 Work systems and equipment used

Three professional forest workers (Table 2), being proficient users of the investigated equipment, were monitored when applying both work systems in alternation. For this purpose, the operators were assigned to select approximately 80 future crop trees per hectare at the study sites. The selected trees should receive a first pruning lift until a height of 2.3–2.5 m, as feasible to reach for an operator standing close to the tree without the support of a ladder. Depending on the individual situation and operators’ appraisal, up to three competing trees to the future crop trees were removed if necessary. Within the study, two systems for fulfilling this assignment were compared through a block design (Fig. 1). Each operator worked with both systems, changing at hourly levels, allocated throughout the various periods of the work day.

| Table 2. Test person’s characteristics (heart rate at rest, HRr; estimated maximum heart rate, HRmax) and corresponding study sites. Each person conducted a tending and pruning on young stands of Pseudotsuga menziesii, applying a conventional and a new system. | |||||

| ID | sex | age | HRr | HRmax | study sites |

| P1 | male | 59 | 65 | 161 | ‘Hachen’, ‘Mellen’ |

| P2 | male | 30 | 51 | 190 | ‘Hahnenklee’ |

| P3 | male | 57 | 68 | 163 | ‘Göttingerode’ |

The two investigated systems are referred to as: (I) the new system, developed by the Forest Education Center FBZ in Arnsberg/Germany and (II) the conventional system, which consists of three separately conducted steps, each of them completed for the entire operation before commencing the subsequent step:

(1) Future crop trees and adjacent competing trees are selected and marked by a forest worker. (In practice, this work step is usually conducted by a forester with academic education. Within the present study, the forest worker selected the future crop trees.)

(2) Marked future crop trees are searched in the stand, pruned by a forest worker using a conventional hand-held pruning saw (Table 3).

(3) The marked and pruned trees are searched and individual competing trees are removed by a forest worker using a chainsaw (Table 4).

| Table 3. Two systems of pruning (Pseudotsuga menziesii) were compared, the new system using electric pruning shears, the conventional system using hand-held pruning saws. Technical specifications of pruning equipment used and associated costs based on scheduled machine hours (SMH). | |||

| STIHL ASA 85 | INFACO F3015 Medium | Handsaw | |

| max. cutting diameter (mm) | 45 | 45 | – |

| battery | Li-Ion | Li-Ion | – |

| nominal voltage (V) | 36 | 48 | – |

| energy load (Wh) | 1 187 | 120 | – |

| weight incl. battery (kg) | 1.77 | 1.60 | 0.42 |

| retail price, incl. battery and charger (€) | 1 1597.00 | 1713.60 | 66.70 |

| operational costs per unit (€ SMH–1) | 2 2.14 | 2 2.30 | 2 0.04 |

| operational costs, incl. labor (€ SMH–1) | 3 37.64 | 3 37.80 | 3 35.54 |

| 1 AP200 battery pack. 2 estimate based on an economic life of 1500 SMH, over a depreciation period of 5 years (only periodic use in seasonal tending), at common input values for fixed and variable costs in the German forestry sector (Kuratorium für Waldarbeit und Forsttechnik e.V., 2006). 3 fringed operator rate of 35.50 EUR SMH–1. | |||

| Table 4. Technical specifications of felling equipment used for tending of young stands of Pseudotsuga menziesii. With specific costs based on scheduled machine hours (SMH). | ||||

| ‘Spacer‘ | Chainsaws | |||

| Husqvarna 535 FBX | STIHL MS 261 C-M VW | STIHL MS 241 C-M VW | Husqvarna 550XP | |

| bar length (cm) | 33 | 35 | 35 | 38 |

| engine displacement (cm³) | 34.6 | 50.2 | 42.6 | 50.1 |

| nominal power (kW) | 1.6 | 3.0 | 2.3 | 3.0 |

| weight, excl. bar, chain, fuel, lubs (kg) | 12.4 | 5.1 | 4.8 | 5.3 |

| retail price, incl. cutting unit (€) | 1199 | 1057 | 961 | 954 |

| operational costs per unit (€ SMH–1) | 1 6.37 | 2 7.05 | 2 6.86 | 2 7.19 |

| operational costs, incl. labor (€ SMH–1) | 3 41.87 | 3 42.55 | 3 42.36 | 3 42.69 |

| 1 estimate based on an economic life of 1500 SMH, over a depreciation period of 5 years (only periodic use in seasonal tending). 2 estimate based on an economic life of 1500 SMH, over a depreciation period of 3 years (all year use, including designated logging operations). 3 based on input values for fixed and variable costs in the German forestry sector (Kuratorium für Waldarbeit und Forsttechnik e.V., 2006) and a fringed operator rate of 35.50 EUR SMH–1. | ||||

In contrast, within the new system, steps (1) and (2) of the conventional system are jointly conducted, leading to a system comprising two steps:

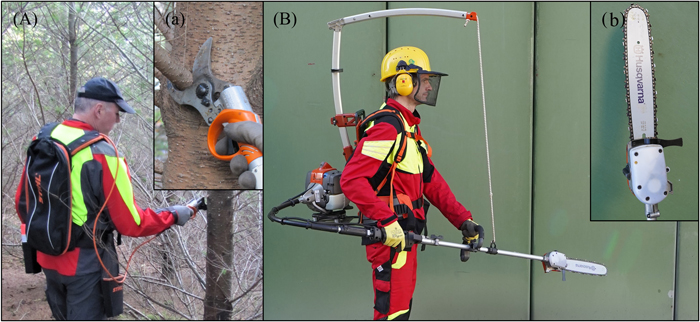

(1) At the same time, the forest worker selects, prunes and permanently marks future crop trees, as well as marking adjacent competing trees, in a continuous work process – tree by tree. The pruning is conducted using electric pruning shears (Figs. 2 A,a and Table 3).

(2) Marked competing trees, adjacent to the selected future crop trees are searched and removed by the forest worker, using a ‘Spacer’ (Figs. 2 B,b and Table 4).

Fig. 2. Equipment used in the new system for pruning and thinning of young stands of Pseudotsuga menziesii. Electric pruning shears Stihl ASA 85 (a) with battery units carried on the back (A) and a clearing saw Husqvarna 535 FBX (‘Spacer’) (B) with a cutting unit with push blade (b).

The new system is characterized by a re-organized workflow, and additionally by the employment of novel equipment (Fig. 2). The electric pruning shears STIHL ASA 85 (Andreas Stihl AG & Co. KG, Waiblingen/Germany) and INFACO F3015 (INFACO s.a.s. Cahuzac-sur-Vère/France) were used at the study sites in North-Rhine Westphalia and Lower Saxony, respectively. Both models are renowned for use in forestry, and comparable in both their technical specifications (Table 3) and their handling. Therefore, an effect on the outcomes of this study from the usage of one or the other of these two tools is not assumed. However, it should be noted that the INFACO F3015 was equipped with an optional safety glove for the hand not operating the shears that interrupts the cutting action if the shears touch a conductive fabric. This extra safety feature is an asset when pruning while standing on a ladder, with vision obstructed by the tree trunk, but will not be of influence in the set-up of this study, where the worker can walk around the trunk to reach all branches to be cut.

During removal activities, conventional brushcutters allow a fast work progress within early stand tending, at much better ergonomics compared to chainsaws. But the circular saw cutting unit of conventional brushcutters cannot cope with stump diameters exceeding 80% of the blade radius (approximately 7 cm) (Wagner and Nolte, 2014). As an alternative for both conventional brushcutters and chainsaws, the new work system is complemented by the Husqvarna 535FBX ‘Spacer’ (Husqvarna AB, Stockholm/Sweden, Table 4). This power tool is combining a backpack brushcutter with a pole-saw-type chainsaw, complemented with a push-and-pull blade, supporting clearing work in young and dense stands. In order to reduce the static strain on the operator’s arms caused by the weight of the cutting unit, a lightweight aluminum arch is added to the harness (Figs. 2 B,b). The cutting unit is suspended from this arch by an adjustable flexible synthetic rope, allowing the release of both hands if needed for other intermittent work tasks.

2.3 Time and motion study

An elemental time study, following the REFA (1998) method with the continuous time measurement, was conducted. Thereby, the treatment of each future crop tree was defined as one work cycle, which was further split into two subcycles; pruning and removal (Table 5). Within the subcycles, work elements were defined and classified according to the REFA (1998) timing system, with the corresponding delay factors (Table 5). The recording of five discrete work elements was conducted in a net-time approach, excluding delay times and additional supportive work time. Preparatory time and the time for searching the first tree at each block were excluded as well. This approach allowed a work cycle modelling based on main work time (MWt) and complementary work time (CWt) only, and led to PSH0 (productive system hours, excluding all delays). For estimations of overall costs and gross-productivity of the systems, scheduled system hours (SSH) are required. Therefore, element-specific delay factors were applied onto PSH0 times, according to Hittenbeck (2015).

| Table 5. Defined work elements and applied delay time factors for the time study, observing pruning and tending of young stands of Pseudotsuga menziesii. The work cycle is defined as pruned and exempted future crop tree, and split up into two subcycles, with complementary work time (CWt) and main work time (MWt), according to REFA (2008). | |||||

| Subcycle | Element | Endpoint | REFA Time classification | Delay factor 1 | |

| Work cycle | pruning | search | pruning saw or electric pruning shears touches the branch of the future crop tree for the first cut | CWt | 1.20 |

| cutting | pruning saw or electric pruning shears is placed in the holder | MWt | 1.20 | ||

| marking | spray can is placed in the holder | CWt | 1.20 | ||

| removal | search | chain of the cutting device touches the bark of the competing tree | CWt | 1.20 | |

| saw work | forest operator leaves the contemporary cut tree | MWt | 1.45 (chainsaw), 1.35 (‘Spacer’) | ||

| 1 empirically determined delay factors according to Hittenbeck (2015) were used. | |||||

2.4 Ergonomic analysis

In order to rate the physiological workload of the monitored forest workers (Table 2) when applying the two work systems, they carried a holter ECG (electrocardiogram) for heart rate (HR) monitoring throughout the entire work shifts, which were synchronized with the elemental time studies. This holter ECG is recording cardiac activities with a lightweight chest belt, transmitting wirelessly to the ECG unit in form of a wrist watch with storing device (custo med GmbH, Ottobrunn/Germany). In order to compare the HR measurements at work (HRw) between work systems, HR was transferred to an individual percentage of heart rate reserve (%HRR) according to Karvonen et al. (1957) and Eq. 1.

where:

HRw = heart rate at work,

HRr = heart rate at rest,

HRmax = maximum heart rate.

For the determination of the individual’s heart rate at rest (HRr, Table 2), the person’s HR was consecutively measured, at least for 10 minutes without major fluctuations, in a seated and relaxed position at the beginning of the work day. The maximum HR (HRmax, Table 2) was determined by the common approach, given as 220 minus age of the monitored operator (Robergs and Landwehr 2002). Unfortunately, due to the limited budget within the study, a full performance diagnostic, including a ramp test to determine more precise HRmax figures, could not be realized.

Principally, HR measurements, also with limited precision levels, can generate valuable information regarding cardiovascular workload. However, a comprehensive workload assessment should include postural workload, too. Therefore, the time studies were combined with an analysis of postural workload according to the Ovako Working Posture Assessment System (OWAS) (Karhu et al. 1977). The OWAS is an observational technique, where body postures causing discomfort and fatigue are rated according to a code system and their frequency of occurrence during the execution of specific work tasks. The code system covers three body sections – upper limbs, lower limbs and back – creating, together with the weight to handle, a four-digit code. The resulting codes are used for rating the postural strain in four action classes, based on the increasingly urgent need for remedial intervention, as follows: class 1 = normal postures, which do not need any special attention; class 2 = slightly harmful postures that must be considered during the next regular check of work methods; class 3 = distinctly harmful postures that need consideration in the near future; class 4 = extremely harmful postures that need immediate consideration. For that purpose, video footage of the operations was analyzed by an additional time study, using a frequency method with 30-second intervals. This interval length was reasonable for this analysis, since 80% of all captured work elements exceeded this margin. In order to compare and rate the overall difference in work-posture strain between the two work systems, the OWAS-based Lundqvist-index (Lundqvist 1988) was calculated. This index is calculated from the occurrence-weighted frequency of the individual codes during the time of observations.

2.5 Statistical analysis

Analysis were conducted using the programming language R (R Core Team 2020) together with RStudio (RStudio Team 2020). Linear mixed-effect models (package ‘lme4’, Bates et al. 2015) were used to compare net time demands between the fixed effect of system, considering the study site as random effect. Contrast-sums were set to zero for included fixed effects, motivated by unbalanced groups and significant interactions. Subsequently, type-III analyses of variance (Fox and Weisberg 2019) and post-hoc analyses (Tukey HSD tests, Lenth et al. 2019 and Hothorn et al. 2008) were applied to compare mean values per element, work system, subcycles and sites. Residuals of all linear models were checked for normal distribution via QQ-plots and histograms. The occurrences of action class 4 according to OWAS was compared between the systems by use of a Poisson test. All statistical tests were carried out on net-time values and %HRR averaged for each element and cycle. The significance level used for all tests was α = 0.05. Reference values are given as mean ± standard deviation (SD).

3 Results

3.1 Total time demand per future crop tree

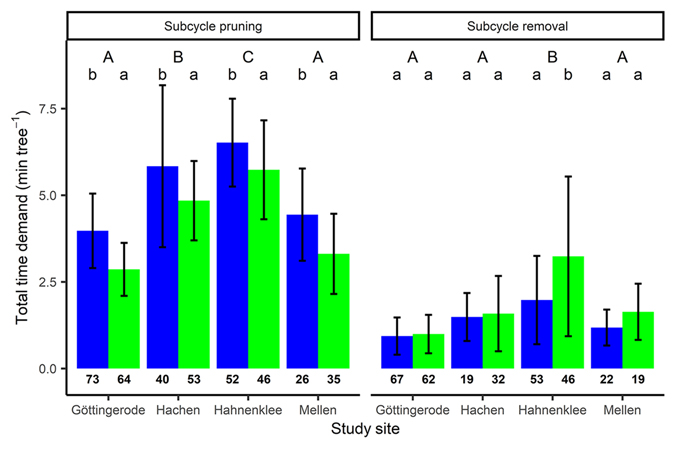

Total required net work time (MWt + CWt, Table 5) per selected and pruned future crop tree, consisting of pruning and removal of competing trees if necessary, was found to be 6.09 ± 2.37 min tree–1 for the conventional system (Table 6). The time study provided clear evidence that total work time could be reduced through the application of the new system by 0.62 min tree–1 (p = 0.002, Table 7), resulting in an average total time demand per treated future crop tree of 5.48 ± 2.68 min tree–1 (Table 6). Substantial differences were observed between study sites, during both subcycles (Fig. 3).

| Table 6. Summary of total time demand (minutes) for two subcycles: pruning (of future crop trees) and removal (of competing trees) in young stands of Pseudotsuga menziesii. Within the conventional system, handsaw (pruning) and chainsaw (removal) was used, whereas electric pruning shears and a ‘Spacer’, respectively, were used during the new system. Presented are the number of observations (n), mean values, standard deviation (SD) and extreme values (min., max.). | ||||||

| System | Subcycle | n | mean | SD | min. | max. |

| conventional | pruning | 191 | 5.12 | 1.85 | 0.80 | 13.12 |

| removal | 161 | 1.38 | 0.97 | 0.08 | 5.983 | |

| total | 191 | 1 6.09 | 2.37 | 0.55 | 14.38 | |

| new | pruning | 198 | 4.14 | 1.61 | 1.03 | 9.42 |

| removal | 159 | 1.84 | 1.67 | 0.15 | 9.72 | |

| total | 198 | 1 5.48 | 2.68 | 0.20 | 16.70 | |

| 1 Note, that total required work time was less than the sum of its parts, since the quantity of removal activities was lower compared to pruning. | ||||||

| Table 7. Summary of coefficients of the linear mixed effects model fitted to values of: (Model 1) total time demand per tree, (Model 2) total time demand for pruning activities of future crop trees and (Model 3) total time demand for removal of competing trees to adjacent, pruned future crop trees in young stands of Pseudotsuga menziesii for two systems: the conventional and the new one, using hand-held pruning saws and a chainsaw or electric pruning shears and the ‘Spacer’, respectively. | ||||

| Coefficient | Model 1 | Model 2 | Model 3 | |

| Intercept | Estimate | 6.14 | 5.2 | 1.37 |

| Std. Error | 0.9 | 0.63 | 0.35 | |

| df | 3.1 | 3.1 | 3.3 | |

| t value | 6.8 | 8.2 | 3.9 | |

| Pr(>|t|) | 0.006 | <0.001 | 0.025 | |

| newsystem | Estimate | –0.62 | –1 | 0.49 |

| Std. Error | 0.2 | 0.13 | 0.13 | |

| df | 395.1 | 384.1 | 315.5 | |

| t value | –3.2 | –7.5 | 3.7 | |

| Pr(>|t|) | 0.002 | <0.001 | <0.001 | |

Fig. 3. Mean values (bars) and standard deviation (error bars) of time demand for pruning of future crop trees and removal of competing trees in four stands of young Pseudotsuga menziesii. Blue bars (left) represent the conventional system, green bars (right) the new system. Numbers of observations are given in bold. Small letters indicate significant differences between applied systems, capital letters indicate differences between sites within each subcycle, according to a Tukey-test (p < 0.05).

3.2.1 Total time demand for the subcycle pruning

Total time demand per treated tree, defined as work cycle, was divided into two subcycles (Table 5): One represents pruning (consisting of the work elements search, cutting and marking), where either the electric pruning shears or handsaw was used. The second subcycle represents removal of competing trees (consisting search and saw work), where either a chainsaw or the ‘Spacer’ was used.

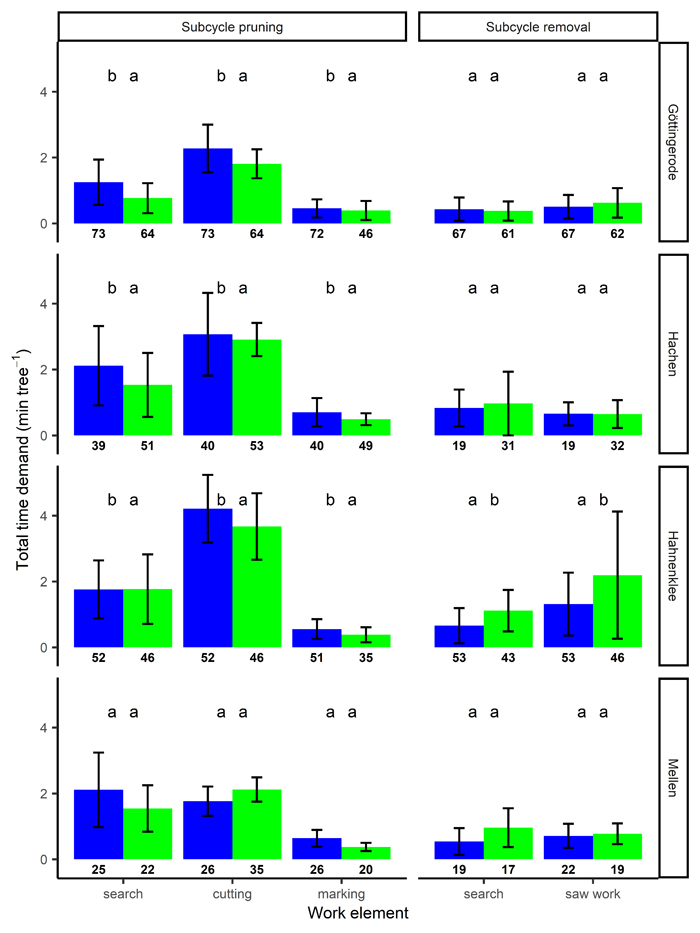

As given in Table 6, total time demand for pruning was considerably higher when the operator followed the conventional system. Through the application of the new system, time demand for pruning could be reduced by almost one minute per tree (p < 0.001). The marked time savings were realized through a higher efficiency when using the electric pruning shears (see Supplementary file S1 for details). In particular, when the electric pruning shears were used, cutting was on average 0.35 min tree–1 (Suppl. file S2) faster (p < 0.001, Suppl. file S1), compared to cutting with a hand saw. As can be seen in Fig. 4, this was statistically significant for all sites, except for ‘Mellen’, where required time for cutting was equal for both systems.

Fig. 4. Mean values (bars) and standard deviation (error bars) of time demand for work elements of the subcycles pruning of future crop trees and removal of competing trees in young Pseudotsuga menziesii stands. Facets depict values of four study sites. Blue bars (left) represent the conventional system, green bars (right) the new system. Numbers of observations are bold. Small letters indicate significant differences between the compared systems, within each subcycle, according to a Tukey-test (p < 0.05).

On average, 82 branches were removed from each pruned tree. Time demand for cutting clearly responded to the number of branches (p < 0.001). It was estimated, that one additional branch would result in an increase of 1.77 seconds, required for the element cutting. Still, this increase was significantly reduced when working with the electric pruning shears (p = 0.007). Besides changes within the element cutting, time savings within this subcycle also occurred during the search of future crop trees (Fig. 4 and Suppl. file S1), which was usually more time demanding when done separately (three-step system), following the conventional system.

3.2.2 Total time demand for the subcycle removal

While time savings occurred during pruning when applying the new system, drawbacks on efficiency appeared during the subcycle removal (Fig. 4). This subcycle covers the search for future crop trees and saw work on usually one competing tree, except for the site ‘Mellen’, where more than two competing trees were removed on average (data not shown). Still, no correlation between the quantity of removed trees and total required work time could be observed. Total required work time for the subcycle removal was significantly higher during the application of the new system (p < 0.001), resulting in 1.84 ± 1.67 min tree–1, compared to 1.38 ± 0.97 min tree–1 (Table 6) when using the chainsaw (conventional system). But, the significant differences within the model applied are mainly driven by values gathered at ‘Hahnenklee’, since pairwise comparisons of mean time values of all remaining study sites did not reveal any differences between both systems (Fig. 4).

Accordingly, efficiency is hampered by higher time demand for the element search, when the forest workers were equipped with the ‘Spacer’ (p = 0.049, Suppl. file S1). In addition to search, also the element saw work on competing trees had a considerably higher time demand (p < 0.001, Suppl. file S1) by 0.28 min–1 (Suppl. file S2) and averaged 1.10 ± 1.30 min per released crop tree when following the new system, compared to 0.82 ± 0.71 min tree–1 required when the conventional system was applied (Fig. 4 and Suppl. file S2).

3.3 Ergonomic analysis

3.3.1 Heart rate measurements

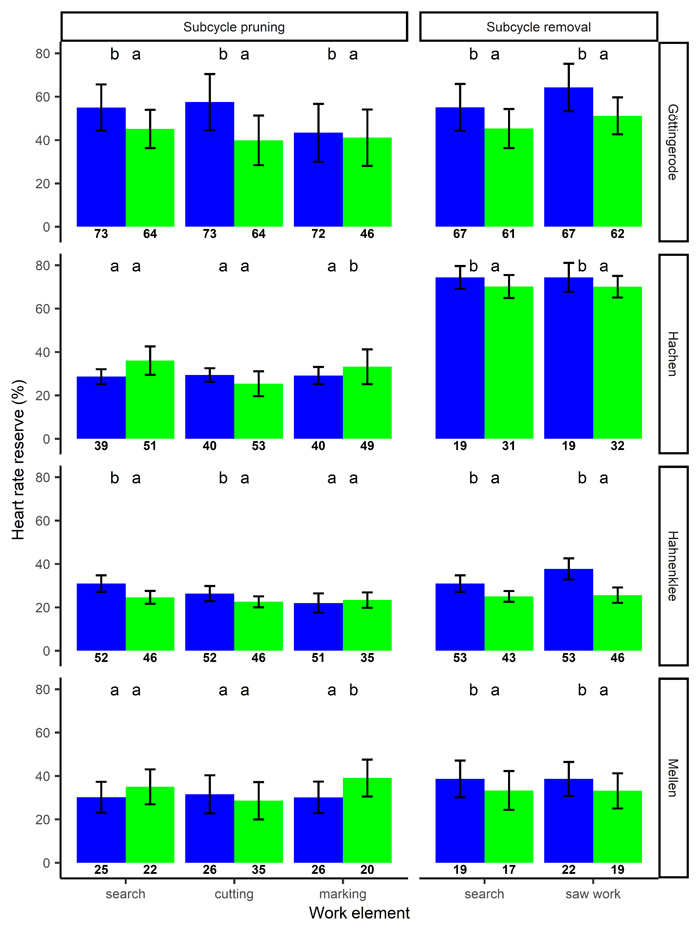

The new system significantly reduced the operators’ cardiovascular workload, as indicated through the %HRR, which was derived from heart rate measurements. During the subcycle pruning, the overall difference was 4.40 %HRR (p < 0.001), even though no clear differences could be observed during the elements search and marking (Fig. 5 and Suppl. file S3). Subsequently, the reduction of %HRR during pruning was predominantly driven through the decreased cardiovascular workload during cutting of branches (p < 0.001, Suppl. file S3), whereas extents of these differed between sites (Fig. 5). Overall, during cutting of branches for pruning the future crop trees with electric pruning shears, %HRR was reduced by as much as 7.54 percent points.

Fig. 5. Mean values (bars) and standard deviation (error bars) of heart rate reserve for work elements of pruning of future crop trees and removal of competing trees in young Pseudotsuga menziesii stands. Facets depict values of four study sites. Blue bars (left) represent the conventional system, green bars (right) the new system. Numbers of observations are bold. Small letters indicate significant differences between the compared systems, within each subcycle, according to a Tukey-test (p < 0.05).

Maximum values of %HRR reached during the study, 86.5 %HRR, were detected for saw work with a chainsaw during the conventional system. Likewise, mean values for this element were 9.34 %HRR higher compared to the new system (p < 0.001, estimated, Suppl. file S3). When competing trees were removed, lower values of %HRR appeared during both elements included (search and saw work, p < 0.001, Suppl. file S3), as shown in Fig. 5. Considering the differences in both elements, physiological workload during removal activities averaged at 50 ± 17 %HRR and 44 ± 18 %HRR for the conventional and new system, respectively.

3.3.2 Postural analysis

During both work systems, and among the subcycles, the frequency occurrence of OWAS action class 1 (normal) was predominant, with 76% for pruning, and 83% for removal during the application of the new system. Application of the conventional system lead to 79% observations allocated to class 1 during pruning and 81% during removal. The remaining observations could mainly be allocated to class 2 (slightly harmful postures), with both systems causing higher, and similar, postural workload during pruning (21% of observations for the conventional and 22% for the new system), compared to removal, where the posture workload with the ‘Spacer’ was lower (16% of observations), compared to the use of a chainsaw (19% of observations). Critical postures of class 3 (distinctly harmful) and 4 (extremely harmful) occurred only to a minor extent for both systems. Yet, a slightly negative tendency with the new system was observed in a direct comparison. Both pruning and removal accounted for 1.4% of class 3 observations with the new system each, in contrast to 0.63% (pruning) and 0.0% (removal) for the conventional system. Postures of class 4 were almost not observable, and limited to the pruning process for both systems (0.34% for the new system; 0.06% for the conventional system), only.

With respect to reduced strain on the muscle-skeleton system, no obvious differences emerged between the two work systems, with the Lundqvist index being 122 and 124 for the conventional and the new system, respectively. When separating according to the subcycles, a slightly more favorable Lundqvist index is generated during removal, resulting in 119 for both systems, compared to 122 (conventional) and 126 (new) during pruning.

4 Discussion

The increasing need for tending of young Douglas fir stands requires consistently improved work systems for efficient operations. Within this study, the conventional practice of pruning by handsaw and removal of competing trees by chainsaw was compared with a new system in field trials. The new system did not only replace the commonly used equipment (i.e. pruning saw and chainsaw), by electric pruning shears and the ‘Spacer’ clearing saw, but also adapted the workflow and organization. Primary aim with this new work system was to increase productivity at reduced costs, and to reduce work-related fatigue and occupational health risks by improved ergonomics.

Overall, the new system resulted in time savings compared to the conventional system during the observed tending operations, with a net time demand of 5.48 ± 2.68 min tree–1 versus 6.09 ± 2.37 min tree–1 (or 10.9 versus 9.9 trees PSH0–1) (Table 6), reducing the work time demand by 10%. By adding the work-element-specific delay factors (Table 5), gross productivity can be determined at 8.9 trees SSH–1 (6.7 min tree–1) for the new system, and 8.1 trees SSH–1 (7.4 min tree–1) for the conventional system. Although with the new system costs per SSH were increased by 1.20 €, the higher productivity of this system reduced the costs per tree from 4.44 € tree–1 (for the conventional system) to 4.17 € tree–1, a cost reduction of 6%. Most noticeable improvements of productivity were caused by the less complex two-step work system and the use of the electric pruning shears (Suppl. file S1). Whereas the pruning shears appeared to work within its optimal branch diameter capacity range, being superior to the handsaw, the stand conditions apparently did not match the requirements of the ‘Spacer’, which demanded more work time compared to the use of a chainsaw (Suppl. file S3). This was even more pronounced when tree dimensions required generally higher work time input, as it was the case at the ‘Hahnenklee’ site (Fig. 4).

For the operators, it was difficult to maneuver through the stands with the bulky arch and long pole of the ‘Spacer’ (Fig. 2), since all stands were very dense. In contrast, the chainsaw operator had a clear advantage with its compact equipment, allowing faster movements through the stand. This resulted in a lower time demand during the element search within the subcycle removal. Further, the larger tree dimensions at the ‘Hahnenklee’ site (Table 1) did not allow a simple oblique cut, but rather required a multiple side-cut, or even the formation of a felling notch for directional felling, causing significantly higher saw work time (Fig. 4). Generally, the element saw work was more time consuming with the ‘Spacer’ compared to the use of a chainsaw, probably since the ‘Spacer’ is difficult to guide for precise multiple cuts in various angles. In contrast, chainsaws are directly guided at the stump and with handles specifically designed for multiple cutting angles.

The re-organization of the work within the new system led to a decreased time demand for search (Fig. 4), since the work steps required for pruning and cutting were merged. Hence, the operator selected a suitable tree in an appropriate spacing to the previously pruned one and could directly commence the cutting of branches. In contrast, the two separated steps in the conventional system resulted in a higher time demand (Table 6), since it is necessary to cruise twice through the stand and to retrieve the previously marked tree before commencing the second step cutting. Further, it has to be considered that if tree marking is conducted during a different time period, way in advance to cutting, as it is for example common when a professional forester does the tree selection, additional costs will arise from extra travel efforts and preparatory times, not contained in the presented figures. However, although not explicitly captured within this study either, it should be noted that extra preparatory time is required with the equipment used in the new system. This is mainly related to the slightly higher effort of the operator to assemble the electric pruning shears and the ‘Spacer’, compared to the handsaw and the chainsaw.

Besides time and cost savings, the new system considerably reduced the cardiovascular workload during both subcycles (Suppl. file S4). According to Garber et al. (2011), exercise intensity can be classified as: very light (%HRR < 30), light (30 < %HRR < 40), moderate (40 < %HRR < 60), vigorous (60 < %HRR < 90) and near to maximum (%HRR ≥ 90). The reduced %HRR during cutting with the electric pruning shears is classified with a mean %HRR of 31.3 as ‘light work’, whereas the use of the handsaws can be classified as moderate work already (mean %HRR of 41.0, Suppl. file S4). The positive effect on task demand by using electric pruning shears, instead of handsaws, was already assumed by Nutto et al. (2013), while investigating pruning in Eucalyptus plantations, but could not be confirmed.

The lower cardiovascular workload of the new system during the element search, within the subcycle removal (Fig. 5 and Suppl. file S3), may be attributed to the obstructing arch of the ‘Spacer’, forcing the operator to move slower through the dense stands. Although rated as negative for the work time demand, it has to be seen as positive from an ergonomic point of view. During this element, lower mean values of %HRR were measured for the new system (43.3 %HRR) compared to the conventional system (47.3 %HRR), yet both classified as moderate work (Fig. 5 and Suppl. file S4). It can be assumed, that slower but also constant pace allowed the operator to recover during search from the more demanding work element cutting, whereas the faster movement with the chainsaw, holding it in a one-sided static posture, is physically more demanding. Since with the ‘Spacer’ a different group of muscles is used with light loads, it can be considered as a disguised pause (Gallis, 2013). The relevance of such small recovery periods that avoid fatigue and allow for maintaining a constant performance level throughout the day was found already when studying e.g. cable skidding work (Berendt et al. 2020).

During the actual saw work, the ‘Spacer’ showed ergonomic advantages compared to the chainsaw through a lower %HRR, too. The mean %HRR measurements showed considerable differences between the use of the ‘Spacer’ (45.4 %HRR) or a chainsaw (53.2 %HRR, Suppl. file S4). Both values are marking saw work as the most labor-intensive work element of the investigated systems. However, the use of both the ‘Spacer’ and a chainsaw remain in average below a 59 %HRR, indicating still a moderate work level (Garber et al. 2011). Surprisingly, the OWAS assessment exposed a nearly similar Lundqvist index for the use of both tools, not confirming any advantage with the use of the ‘Spacer’ (purposely designed to ergonomic construction principles) with respect to avoiding unfavorable forced body postures. In fact, for the felling cuts close to the tree base the operator had to bend forward when using either the ‘Spacer’ or the chainsaw, leading to similar body postures. An advantage of the ‘Spacer’ can be pinpointed only to the fact that the machine weight (although higher in total) is causing less concentrated static forces due to its weight distribution over the whole body and suspension through the harness and arch. In contrast, the chainsaw’s weight needs to be fully suspended by the upper limbs.

However, it should be considered that the chainsaws used have been generally high in engine output (>2.3 kW) and weight (>4.8 kg), with respect to the conducted operation. A lighter chainsaw (~1.8 kW, ~4.0 kg), would have probably been sufficient too, bearing a further positive effect on the experienced workload in favor of the conventional system.

A comprehensive rating of the chainsaw vs. the ‘Spacer’ cannot be conducted within this study due to the limited scope of the trials, where in particular operator and site effects were not the main focus of our investigations. The practice-oriented character of our study clearly limits the interpretation of the results, although they give legitimated indications. For instance, test person P1 working at the two sites ‘Hachen’ and ‘Mellen’ was directly exposed to differing site conditions. The ‘Hachen’ site, where warm temperatures prevailed during data collection, is further characterized by steeper terrain in contrast to the flat ‘Mellen’ site which also had smaller tree dimensions. These easier work conditions in return reduced the overall work time during removal, although at small magnitude, with an advantage to the use of the chainsaw on both sites (Fig. 4). In contrast, the labor effort in terms of %HRR differed noticeably between the two sites during removal, obviously related to the site conditions, but still at both sites in favor of the ‘Spacer’ (Fig. 5). In general, the inclusion of site as random-effect within the linear model applied allows a comparison between both systems, and a more general evaluation of the suitability for the investigated systems in the defined operational range. Nevertheless, in further investigations more focus should be given to varying operational conditions in terms of stand structure (i.e. diameter and height range, especially of removed competing trees, thickness of branches, terrain and understory vegetation), but also worker age and qualification. This would enable to clearly define best application areas for the two individual systems and allow to set realistic operator rates for best practices.

With respect to the current investigation, improvements through the application of the new system are primarily seen in the modified work organization. In addition to time and cost savings during the investigated execution of work, considerable savings due to obsolete preceding site visits for tree selection by a worker or professional forester can be expected, although this was not quantified in the experiment. Although still practiced in many regions, the overall need for a professional forester for tree selection is on general debate. Forest workers are better qualified these days and experienced workers and contractors proved to be qualified to conduct target-orientated tree selection in complex silvicultural systems to a satisfying level (e.g. Spinelli et al. 2016). Therefore, the trend of leaving tree selection to the appraisal of the designated worker will continue. However, scheduling this task ahead and completely separating it from the actual tending operation as in the conventional system clearly proves to be a restriction for efficient operations.

Besides work organization, the introduction of new equipment did not attain any specific cost savings, nor ergonomic improvements of the workflow. While the use of the electric pruning shears can be rated as more advantageous compared to the conventional handsaw, the ‘Spacer’ did not show the expected major advantages compared to the use of a chainsaw for the removal of competing trees, at least for the investigated stand conditions. In fact, with respect to productivity, the chainsaw can be rated as superior, and the ergonomic improvements by the use of the ‘Spacer’ neither considerably changed the labor effort required for motor-manual tending operations, nor resulted in the expected relief of the muscle-skeleton system. A dense stand structure, tree heights far above the operator and low branched trees seem to limit efficient work progress with the ‘Spacer’ due to the bulky construction, less convenient cutting guidance and limited engine power. In this respect, the development stage of the selected stands was out of its optimal working range, limiting the achievement potential of the ‘Spacer’. Subsequently, the application of the ‘Spacer’ seems to be more appropriate in much earlier pre-commercial thinning stages, with a focus on schematic stem number reduction, only. If such stands comprise multiple species and a selective approach needs to be followed, the ‘Spacer’ proved already to be indeed an efficient tool to be considered as an alternative to the conventional brushcutter (Wagner and Nolte 2014; Suchomel and Jaeger 2017).

5 Conclusion

With respect to the limited operational range of the ‘Spacer’, a modification of the new system can provide potential advantages. While the subcycle pruning of the new system clearly outperformed the conventional one, drawbacks towards efficiency arose during removal. Therefore, as indicated by the results, the chainsaw seems to be the equipment of choice for removal of competing trees within tending operations. However, the use of smaller chainsaws should be considered. Due to the fact that the costs of a hand tool are nearly neglectable, no major cost savings from introducing the new system should be expected. However, further contributions to reducing work fatigue due to lower weight and lower coupling forces can be assumed. In this respect, the use of the currently upcoming professional-grade battery saws can provide further ergonomic benefits such as reduced noise and vibrations and the elimination of exhaust fumes. In combination with the electric pruning shears, an efficient battery-based work system with numerous benefits for the forest worker could be established.

Data availability

The analyzed data is available via https://doi.org/10.25625/6DBKZI (Schönauer 2021).

Disclosure statement

No potential conflict of interest was reported by the authors.

Acknowledgements

This research was funded by Eva Mayr-Stihl Stiftung and supported by the Forest Education Center FBZ / State Enterprise Forestry and Timber NRW – both are much appreciated. The authors acknowledge the support of “Niedersächsisches Forstliches Bildungszentrum (NFBz)”, Münchehof, in particular Sören Schönhals and Michael Thätner. We acknowledge the valuable contribution from Maxi-Paula Mrozek. Further, we would like to acknowledge the help of the professional forest workers, who remain unnamed in order to protect person-related data. We acknowledge the support from Dr. Lorenz Breinig, who edited the manuscript. We acknowledge support by the Open Access Publication Funds of the University of Göttingen.

References

Berendt F, Hoffmann S, Jaeger D, Prettin S, Schweier J (2020) Application of spiroergometry to determine work metabolism related strain in the course of cable work with a mini forestry crawler. Int J For Eng 31: 114–125. https://doi.org/10.1080/14942119.2020.1735198.

Bolte A, Ammer C, Löf M, Madsen P, Nabuurs G-J, Schall P, Spathelf P, Rock J (2009) Adaptive forest management in central Europe: climate change impacts, strategies and integrative concept. Scand J For Res 24: 473–482. https://doi.org/10.1080/02827580903418224.

Brazier JD (1977) The effect of forest practices on quality of the harvested crop. Forestry 50: 49–66. https://doi.org/10.1093/forestry/50.1.49.

Brosinger F, Baier R (2008) Chancen und Grenzen des Waldbaus mit der Douglasie in Bayern. [Strength and weaknesses of Douglas fir in Bavaria]. LWF Wissen 59: 33–38.

Esser F (2000) Der Forstwirt. Ulmer, Hohenheim, Stuttgart.

Fillbrandt T, Leisinger M (2010) Beurteilung der Wertästung mit dem Baumvelo an Douglasien in Rheinland-Pfalz hinsichtlich der langfristigen Folgen für die Holzqualität: Forschungsprojekt Rheinland-Pfalz. Project report. Freiburg im Breisgau, Germany.

Fox J, Weisberg S (2019) An r companion to applied regression. Sage, Thousand Oaks, CA.

FVA BW (2000) Wertästung. [Pruning]. Freiburg im Breisgau, Germany.

Gallis C (2013) Increasing productivity and controlling of work fatigue in forest operations by using prescribed active pauses: a selective review. Croat J For Eng 34: 103–112.

Garber CE, Blissmer B, Deschenes MR, Franklin BA, Lamonte MJ, Lee I-M, Nieman DC, Swain DP (2011) Quantity and quality of exercise for developing and maintaining cardiorespiratory, musculoskeletal, and neuromotor fitness in apparently healthy adults: guidance for prescribing exercise. Med Sci Sports Exerc 43: 1334–1359. https://doi.org/10.1249/MSS.0b013e318213fefb.

Hanewinkel M, Hummel S, Albrecht A (2011) Assessing natural hazards in forestry for risk management: a review. Eur J For Res 130: 329–351. https://doi.org/10.1007/s10342-010-0392-1.

Hartsough B, Parker R (1996) Manual pruning of Douglas-fir. New Zealand Journal of Forestry Science 26: 449–459.

Hittenbeck J (2015) Zeitstudien. [Time and motion studies]. Leistungen des Produktionsfaktors Arbeit, Universität Göttingen, Germany. https://www.uni-goettingen.de/de/520577.html. Accessed 1 August 2020.

Honkaniemi J, Rammer W, Seidl R (2020) Norway spruce at the trailing edge: the effect of landscape configuration and composition on climate resilience. Landsc Ecol 35: 591–606. https://doi.org/10.1007/s10980-019-00964-y.

Hothorn T, Bretz F, Westfall P (2008) Simultaneous inference in general parametric models. Biom J 50: 346–363. https://doi.org/10.1002/bimj.200810425.

Karhu O, Kansi P, Kuorinka I (1977) Correcting working postures in industry: A practical method for analysis. Appl Ergon 8: 199–201. https://doi.org/10.1016/0003-6870(77)90164-8.

Kirk PM, Parker R.J (1996) Heart rate strain in New Zealand manual tree pruners. Int J Ind Ergon 18: 317–324. https://doi.org/10.1016/0169-8141(95)00089-5.

Lenth RV, Buerkner P, Herve M, Love J, Riebl H, Singmann H (2019) emmeans: estimated marginal means aka least-squares means. https://CRAN.R-project.org/package=emmeans.

Lerch A (2011) Holzarbeit im Niederösterreichischen Voralpenraum. [Forest operations in Lower Austria]. Diploma thesis. Universität Wien, Vienna, Austria.

Ligné D, Nordfjell T, Karlsson A (2005) New techniques for pre-commercial thinning – time consumption and tree damage parameters. Int J For Eng 16: 89–99. https://doi.org/10.1080/14942119.2005.10702518.

Lundqvist P (1988) Working environment in farm buildings. Results of studies in livestock buildings and greenhouses. Doctoral thesis. Swedish University of Agricultural Sciences, Department of Farm Building, Lund.

Marchi E, Neri F, Fioravanti M, Picchio R, Goli G, Di Giulio G (2013) Effects of cutting patterns of shears on occlusion processes in pruning of high-quality wood plantations. Croat J For Eng34: 295–304.

Nutto L, Malinovski R, Brunsmeier M, Schumacher Sant’Anna F (2013) Ergonomic aspects and productivity of different pruning tools for a first pruning lift of Eucalyptus grandis Hill ex Maiden. Silva Fenn 47, article id 1026. https://doi.org/10.14214/sf.1026.

Pötzelsberger E, Eckhart T, Hasenauer H (2019) Wachstumspotenziale für Douglasie in Österreich und Deutschland. [Mapping the growth potential of Douglas-fir in Austria and Germany]. Austrian J For Sci 136: 69–86.

R Core Team (2020) R: a language and environment for statistical computing. The R Foundation for Statistical Computing, Vienna, Austria.

REFA (2008) Organisation in der Forstwirtschaft: Mit REFA-Methoden zu effizienten Arbeitsprozessen. Ergonomia Verlag, Darmstadt, Germany.

REFA - Fachausschuss Forstwirtschaft (1998) Arbeitsstudien, Arbeitsorganisation und Qualitätsmanagement in der Forstwirtschaft. Institut für Arbeitsorganisation, Stuttgart.

Robergs RA, Landwehr R (2002) The surprising history of the ”HRmax= 220-age” equation. J Exerc Physiol Online 5: 1–10.

RStudio Team (2020) RStudio: integrated development environment for r. RStudio, PBC, Boston, MA.

Ruge F, Nicke A, Kohnle U (2019) Douglasien-Naturverjüngung unter Schirm. [Natural regeneration of Douglas fir]. AFZ-DerWald 17: 42–46.

Schmithüsen FJ (2013).Three hundred years of applied sustainability in forestry. Unasylva 240(64): 3–11.

Schönauer MJ (2021) Supplementary data for: evaluation of a new pruning and tending system for young stands of Douglas fir. Göttingen Research Online / Data.

Spinelli R, Magagnotti N, Pari L, Soucy M (2016) Comparing tree selection as performed by different professional figures. For Sci 62: 213–219. https://doi.org/10.5849/forsci.15-062.

Stackpole D (2001) Eucalypt stem pruning. Agriculture Notes AG0773. State of Victoria, Department of Primary Industries, Australia.

Suchomel C, Jaeger D (2017) Optimized clearing and early thinning by spacer and chainsaw. Bulletin of the Transilvania University of Brasov, Series II, Forestry, Wood Industry, Agricultural Food Engineering 10: 73–80.

Technik bei der Jungwuchs- und Jungbestandspflege (2006) Groß-Umstadt.

Thünen-Institut (2012) Dritte Bundeswaldinventur. [National forest inventory]. Accessed 2 July 2020. https://bwi.info.

Vitali V, Büntgen U, Bauhus J (2017) Silver fir and Douglas fir are more tolerant to extreme droughts than Norway spruce in south-western Germany. Glob Chang Biol 23: 5108–5119. https://doi.org/10.1111/gcb.13774.

Wagner T, Nolte M (2014) Jungbestandspflege mit dem Spacer. [Tending by the use of ‘Spacer’]. AFZ-DerWald 69: 8–11.

Wardlaw TJ, Neilsen WA (1999) Decay and other defects associated withpruned branches of Eucalyptus nitens. Tasforests 11: 49–57.

Weller A (2019) Auswirkungen der Wertastung auf das Douglasien-Wachstum: Ergebnisse aus Nordwestdeutschland. [Impacts of pruning on growth of Douglas fir]. Schweizerische Zeitschrift fur Forstwesen 170: 207–215. https://doi.org/10.3188/szf.2019.0207.

Total of 41 references.