Reloading mechanized tree planting devices faster using a seedling tray carousel

Ersson B. T., Bergsten U., Lindroos O. (2014). Reloading mechanized tree planting devices faster using a seedling tray carousel. Silva Fennica vol. 48 no. 2 article id 1064. https://doi.org/10.14214/sf.1064

Highlights

- Seedling reloading onto the Bracke Planter crane-mounted planting device was twice as fast with the MagMat tray-wise-loaded carousel as today’s seedling-wise-loaded carousel

- Tray-wise reloading combined with deplugging seedlings from suitable cultivation trays has the potential to be an efficient and robust way to feed seedlings on any type of tree planting machine.

Abstract

On Nordic clearcuts, today’s tree planting machines produce high-quality but costly regenerations. Much of this high cost is attributable to the planting machines’ low productivity. One promising way of raising productivity is to lessen the time spent manually reloading seedlings onto the carousels of crane-mounted planting devices. Using MagMat, a carousel test-rig designed by engineering students, we studied how much faster tray-wise seedling reloading is on the Bracke Planter compared to reloading with today’s seedling-wise-loaded carousel. The MagMat test-rig held eight Hiko cultivation trays from which seedlings were deplugged individually and dropped into the planting tube. The time study confirmed that seedling reloading was on average twice as fast with MagMat compared to today’s seedling carousel, thereby increasing assumed planting machine productivity by 8–9% depending on the planting device used. MagMat’s cost-efficiency was analysed to be particularly reliant on its added investment cost, mechanical availability and how quickly trays can be switched automatically. Nevertheless, MagMat’s field performance illustrated the overall potential of tray-wise loading compared to piecewise seedling loading for increasing the productivity of crane-mounted planting devices. Also, deplugging proved to be a reliable method of extracting seedlings from the rigid, copper-painted Hiko cultivation trays even when performed at the excavator’s boom-tip during mounding work. We conclude that, rather than piecewise seedling loading, tray-wise loading combined with deplugging seedlings from suitable cultivation trays is a reliable and much more time-efficient method to feed seedlings on probably any type of tree planting machine.

Keywords

productivity;

cost analysis;

seedling feed;

silviculture;

time study;

tree planting machine;

containerized seedling

-

Ersson,

Department of Forest Biomaterials and Technology, SLU, SE-90183 Umeå, Sweden

E-mail

back.tomas.ersson@slu.se

- Bergsten, Department of Forest Biomaterials and Technology, SLU, SE-90183 Umeå, Sweden E-mail urban.bergsten@slu.se

- Lindroos, Department of Forest Biomaterials and Technology, SLU, SE-90183 Umeå, Sweden E-mail ola.lindroos@slu.se

Received 5 December 2013 Accepted 24 February 2014 Published 5 March 2014

Views 200660

Available at https://doi.org/10.14214/sf.1064 | Download PDF

1 Introduction

Mechanized tree planting has been revived in Sweden in the last few years because of the machines’ high quality planting results (Ersson et al. 2013; Ersson and Petersson 2013). Mechanized tree planting is growing in Finland as well; there mainly because of dwindling supplies of manual tree planters and ambitions to decrease silvicultural costs (Rantala and Laine 2010; Laine and Rantala 2013). However, in both countries, mechanized planting tends to be more expensive than mechanized soil preparation and manual planting, and much of this added expense can be attributable to the planting machines’ low productivities (Ersson 2010; Strandström et al. 2011). Therefore, it is arguably important for planting machine productivity to improve if a greater proportion of clearcuts are to be planted mechanically resulting in better quality regenerations, i.e. higher seedling survival and growth.

Although initial mechanized tree planting development in the Nordic countries focused on continuously advancing planting machines (Bäckström 1978; Malmberg 1990; Hallonborg 1997), those machines in use today are exclusively intermittently advancing (Strandström et al. 2009; Ersson 2010). Intermittently advancing planting machines comprise a crane-mounted planting device and a base machine, the latter usually being an tracked excavator (Ersson et al. 2013). There are many potential technical solutions to increase the productivity of today’s planting machines (Rantala et al. 2009) but previous experience has pointed to faster seedling reloading as being one of the most promising solutions (Normark and Norr 2002; Sønsteby and Kohmann 2003; Ersson et al. 2011). Today’s planting machines spend circa 15–20% of their productive work time standing still as the operator reloads the planting device with seedlings (Öhman 1994; Rantala et al. 2009), and this proportion grows the faster the machine works (Halonen 2002).

Today’s seedling reloading is so time-consuming mainly because seedlings are loaded piecewise onto the planting device’s carousel. Seedlings are both extracted from their packaging (mostly cardboard boxes or cultivation trays) and slotted into the carousel’s cavities one-by-one. This is a low-tech, highly robust yet flexible method. In contrast, several planting machines of the past used bundle-wise seedling reloading. Bundle-wise seedling reloading could entail loading seedlings pallet-wise (on the first Serlachius planting machine, Kohonen 1981), tray-wise (tray-by-tray, e.g. on one Silva Nova version and the second Serlachius planting machine, Stjernberg 1985; Hallonborg 1997), box-wise (of band-mounted seedlings on the Doppingen planting machine, Stjernberg 1985; Malmberg 1990), coils of band-mounted seedlings (on one EcoPlanter version, Normark and Norr 2002), or chains of linked pots/tray cells called PLS-belts (on another Silva Nova version, Hallonborg 1997; Ersson 2010); in other words, loading the seedling feeding mechanism with seedlings somehow clumped together.

When using bundle-wise reloading on planting machines, seedlings must somehow be extracted from the bundle. Hallonborg (1997) recognized three methods of seedling extraction; the first being lifting. With this method, seedlings are pulled out of tray cells/cavities by mechanical grippers/claws. This extraction method was used on the SwePlant prototype planting machine (Hallonborg et al. 1997) and on the PLS version of the Silva Nova. The second method is deplugging, or pushing seedlings out of tray cells by mechanical fingers/push rods. This method requires cultivation trays with cells having drainage holes wide enough to permit a push rod, and was used on the planting machines with tray-wise loading (Malmberg 1990). The third method is sideways extraction. Examples included cutting or tearing apart band-mounted seedlings and tearing apart two halves of special tray-cells from a proposed Finnish growing system described by Hallonborg (1997, p. 25). Arguably, the pallet-wise loading method of the first Serlachius planting machine could be considered to have used a fourth extraction method. There, seedlings were cultivated in peat pots and singulated on the planting machine by sawing so that each seedling was planted together with its tray cell (Stjernberg 1985). We could call this method singulation, based on the terminology of Graham and Rohrbach (1981) when singulating bareroot seedlings.

With all methods, extraction can be done manually or mechanically, but the latter option is considered essential for highly productive, cost-effective planting machines (Hallonborg et al. 1995). Nevertheless, mechanical lifting can sometimes damage seedlings (Hallonborg 1997) and is prone to being unreliable in shaky environments. Sideways extraction and singulation, on the other hand, disqualifies re-usable packaging or requires costly seedling transferring (cf. Ersson et al. 2011). Meanwhile, deplugging can be hampered by: wobbly cultivation trays (e.g. having side slits); cultivation trays with irregularly shaped cells (e.g. star-shaped or tapered); and inadequately dimensioned push rods that only penetrate the plug rather than pushing it out (Hallonborg 1997). Nursery equipment often combines both lifting and deplugging when extracting seedlings (Tuinbouw Technisch Atelier 2013). Deplugging using blasts of air has also been proposed for nursery activities (Brewer 1994).

Today, there are three crane-mounted planting devices available commercially in the Nordic countries. Two of them, the Bracke Planter P11.a and Risutec PM100, are one-headed while the M-Planter is a two-headed device. All three devices use carousels that are loaded piecewise with seedlings, and there is one carousel per head. The Bracke Planter is the oldest of the three, being invented more than 20 years ago (von Hofsten 1993), and uses the simplest carousel design. It comprises one hydraulic cylinder and one solid metal circle of seedling-holding cavities.

Over the years, there have been several attempts to build new carousels for the Bracke Planter: one holding over 200 piecewise-loaded seedlings and at least two carousels that were loaded tray-wise. Since none of these inventions are commercially available, and there exists to our knowledge no documented study on the productivity improvement offered by bundle-wise-loaded carousels on crane-mounted planting devices, a project to design such a carousel was initiated in 2010. First, engineering students were given the task to choose a method of extracting seedlings from copper-painted Hiko cultivation trays. Hiko trays have round, solid-walled, evenly distributed cells with large drainage holes. Circa half of all containerized seedlings planted in southern Sweden are grown in copper-painted Hiko trays, and copper-painting reduces root tangling and spiralling which otherwise hamper gentle seedling extraction (Landis 1990; Nelson 1992) and lower seedling performance after outplanting (Zahreddine et al. 2004; Johnsson 2010), respectively. Deplugging was chosen as the extraction method and MagMat, a tray-wise-loaded carousel for the Bracke Planter (Fig. 1), was subsequently designed in a Master’s thesis (Safrani and Lideskog 2011). As theoretical calculations pointed to significant time savings when using MagMat for the seedling reloading task, a test-rig was built. Hence, the objectives of this study were to: (1) quantify the reduction in time consumption when reloading the Bracke Planter with seedlings in cultivation trays using the MagMat tray carousel compared to today’s standard seedling-wise-loaded carousel; (2) analyze the cost-efficiency of MagMat carousels on crane-mounted planting devices.

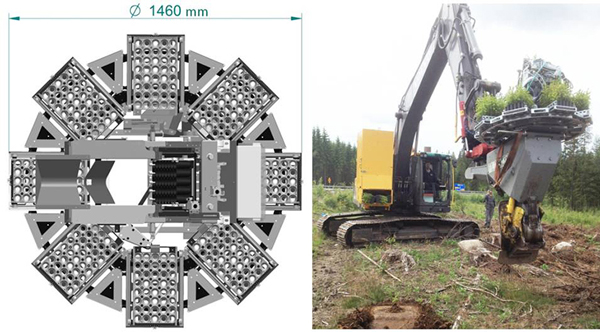

Fig. 1. Top view drawing of the MagMat tray carousel (left) and the test-rig mounted on a Bracke Planter during the field testing (right). Note that the test-rig lacks a protective barrier around the carousel. Photo and drawing: Rikard Wennberg.

2 Materials and methods

2.1 Time study

The planting machine used in the study was a Bracke Planter P11.a mounted on a 23 tonne Volvo EC210 tracked excavator. A rotator allowed the planting device to rotate freely around the crane attachment point. Hiko v93 cultivation trays, holding 40 seedlings per tray, comprised the packaging for the seedlings (cf. Ersson et al. 2011). The trays were stored in a ground-accessible storage box mounted beside the crane pillar (Fig. 1, right).

The Bracke Planter’s standard seedling carousel (hereinafter called 70Car) held 72 seedlings but was only refilled with 70 seedlings per reload to avoid jams in the planting tube. Meanwhile, the MagMat carousel was refilled with 320 seedlings in eight trays per reload (Fig. 1, left). These trays were then latched onto frames arranged in a circle (Fig. 2). The carousel platform could be spun by hand so that all trays could be latched while standing at one place. The frames were then towed individually during machine operation up onto the deplugging tower located in the circle’s centre where seedlings were deplugged individually from the slanting trays and tipped into the planting tube.

Fig. 2. Loading a Hiko cultivation tray onto one of MagMat’s eight frames. Photo: Rikard Wennberg.

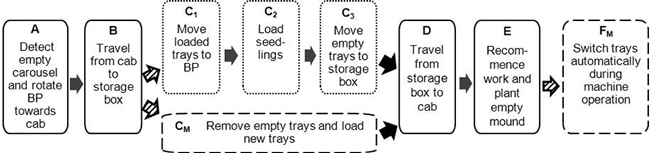

Reloading seedlings onto 70Car and MagMat involves several work elements, some shared and some exclusive to each carousel (Fig. 3). During mechanized planting, the reloading task starts when planting yields no seedling in a mound (work element A), thus signalling an empty carousel to the operator, and ends when the empty mound is replanted (element E). For 70Car, moving between the storage box and planting device (elements C1 and C3) also includes organizing the two trays and placing them somewhere convenient before loading the cavities piecewise with seedlings. This preorganization is not necessary with MagMat when the base machine is equipped with a rotator because the rotator allows the planting device to be placed right next to the base machine which, in turn, allows trays to be loaded directly from the ground-accessible storage box onto the carousel (element CM). However, MagMat’s reloading task also includes switching empty for full trays on the deplugging tower (element FM). This work element is performed automatically during machine operation and not when the operator is out of the cab.

Fig. 3. Flowchart of the work elements involved in reloading the Bracke Planter (BP) with seedlings. Dotted- and dashed-border boxes represent work elements exclusive to the 70Car and MagMat carousels respectively, while elements common to both carousels have a solid border.

The time study was conducted in June 2012 on a flat and obstacle-free landing 10 km northeast of Växjö, southern Sweden. Since reloading is most often performed on clearcuts, a nearby clearcut was used to validate the landing time study. This clearcut was generally flat but had slash left on-site. Three operators with varying experience levels partook: operator 1 had no previous planting machine experience whatsoever but had considerable experience handling seedlings; operator 2 had one season planting machine experience; and operator 3 had nearly three seasons of mechanized planting experience. All three operators practiced any unfamiliar work element until they were satisfied with their performance.

The time study was made as a comparative time study with continuous timing (Bergstrand 1987) in daylight under cloudy skies. Time consumption (TC) was measured in seconds using a stopwatch. During both the landing and clearcut studies, each replication/reload started with the operator seated in the cab with the door closed (Fig. 3, element B) and ended when the operator was reseated with the cab door closed (element D). Operators were asked to work at a normal pace. All replications with 70Car were performed first, then carousels were switched and the operators completed all replications with MagMat. The starting order of the operators with a specific carousel was randomly chosen but each operator performed all replications consecutively per carousel. Reloading was reiterated until no learning effect could be discerned, and the replications deemed to be influenced by this effect were excluded from the results. Thus, the number of relevant replications with 70Car and MagMat carousels was as follows: five and three respectively for operator 1; six and five respectively for operator 2; five and four respectively for operator 3.

Analysis of variance (ANOVA) was used to test if there were significant differences in TC between operators per work element and carousel type in the landing study. The following General Linear Model (GLM) was used:

![]()

where yoki is the TC of the work element during individual replication i; μ is the grand mean; ao is the fixed effect of operator o; bk is the fixed effect of carousel k; abok is the fixed interaction effect between the operator and carousel; and eoki is the error term for individual replication i. To ensure that the results from the landing study were also relevant under clearcut conditions, we also tested if there were significant differences in TC between operator 3 at the landing and on the clearcut using the following GLM:

![]()

where ysi is the TC of the work element during individual replication i; μ is the grand mean; as is the fixed effect of study environment s; and esi is the error term for individual replication i.

Operators and the landing/clearcut tests were compared pairwise in the Minitab 16 statistical package using Tukey’s HSD test at the 95% confidence level. The analyses’ assumptions of normality and homoscedasticity were satisfied (Anderson-Darling’s test), i.e. data was not transformed.

2.2 Cost analysis

In a deterministic analysis, we compared the cost-efficiency of mechanized tree planting with excavator-mounted one-headed Bracke Planter and two-headed M-Planter planting devices using the MagMat versus existing carousels. The calculations were made in Swedish kronor (SEK) but converted into Euros using the approximate average exchange rate from January 2002 to October 2013 of 9 SEK per Euro (Sveriges Riksbank 2013). The interest rate and the depreciation periods were always 5% and 7 years respectively, and we used the straight line method to calculate depreciation costs (cf. Miyata 1980). Fixed costs (including full labour costs) were calculated using Scheduled Machine hours (SMh) while variable costs (fuel, lubrication and maintenance costs) and machine productivities were based on Productive Work hours (PWh); see Björheden and Thompson (2000) for time definitions. Variable costs arose only during productive work.

The baseline cost factors include purchase prices for a new mid-sized 18 tonne tracked excavator and a Bracke Planter planting device (Table 1). We calculated with salvage values of 20%, 15%, and 0% for the excavator, planting device, and MagMat respectively. We assumed the effective tree planting season to be six months long. The base machine was assumed to be used for other duties, e.g. ditching and road construction, for 400 SMh per year more than the planting device (Table 1). We assumed that 100 SMh per year were spent repairing and maintaining the planting machine; that the mean number of planted seedlings per clearcut to be 4000; that each relocation took two SMh; and that the number of relocations per year increased as planting machine productivity increased (Rantala et al. 2009). Thus, under these conditions, the productive work time for the Bracke Planter and M-Planter equipped with standard seedling carousels was 1000 and 984 Productive Work hours per year (PWh yr–1) respectively. However, the ratio of PWh to SMh varied with planting machine productivity, i.e. higher productivity lead to fewer annual PWh because of more relocations.

| Table 1. Baseline cost factors for the base machine and Bracke Planter planting device. | ||

| Factor | Unit a) | Value |

| Mid-sized tracked excavator | ||

| Purchase price including seedling storage box | Euro | 172 200 |

| Full labour costs including operator travel costs | Euro SMh–1 | 32 |

| Insurance and administration | Euro SMh–1 | 2 |

| Maintenance, lubrication and fuel costs | Euro PWh–1 | 18.5 |

| Scheduled time | SMh yr–1 | 1600 |

| Bracke Planter planting device | ||

| Purchase price | Euro | 55 560 |

| Maintenance costs | Euro PWh–1 | 2.1 |

| Scheduled time | SMh yr–1 | 1200 |

| a) SMh = Scheduled Machine hour; PWh = Productive Work hour; yr = year | ||

The assumed productivity values were sourced from Ersson et al. (2011) for the Bracke Planter and from Rantala et al. (2009) for the M-Planter, and were set to 200 and 236 seedlings per Productive Work hour (pl PWh–1; including delays shorter than 15 minutes) respectively. According to Rantala et al. (2009), total TC when reloading the M-Planter’s existing 162 seedling carousel (hereinafter called 162Car) averaged 2.26 seconds per seedling (s pl–1), and the M-Planter’s total hourly costs are 4.1% higher than for Bracke Planter. Hence, under these circumstances, the total hourly cost for the Bracke Planter planting machine amounted to 78.5 Euro PWh–1, and to 81.8 Euro PWh–1 for the M-Planter planting machine.

According to the manufacturer and as confirmed by operator 3, 70Car’s design is very robust and breakdowns are extremely rare. Therefore, we assumed 100% mechanical availability (MA) of 70Car and 162Car. However, when analyzing the availability of MagMat, each percentage point reduction in MA resulted in the conversion of circa 10 PWh into repair-time SMh and a reduction in annual production (planted seedlings per year). Also, a spare parts cost-penalty of 0.1% of MagMat’s purchase price was assigned to MagMat for every eight repair-time SMh.

We also carried out sensitivity analyses on selected parameters (Table 2). When varying a value in the cost-analysis, the other values were held constant at the baseline rate. Because of limitations to the MagMat test-rig, the task of opening/closing a protective barrier was missing from the time study. A barrier will be necessary to protect the carousel from damage during operation, and this barrier could probably simply be a steel enclosure with an access point that the operator opens to latch the cultivation trays. Accordingly, we explored the effect of different TC values for this missing work element on MagMat’s cost-efficiency but assumed 10 s per reload as the baseline TC value.

| Table 2. Parameter values for the Bracke Planter and M-Planter used in the baseline and sensitivity analysis. | |||||

| Parameter | Unit a) | Baseline value | Sensitivity analysis | ||

| Bracke Planter | M-Planter | Minimum | Maximum | ||

| Mean planting time excluding seedling reloading | s pl–1 | 14.9 b) | 13.0 c) | –40% | +30% |

| Fixed costs (including full labour costs) | Euro SMh–1 | 58.0 | 61.0 | –10% | +40% |

| Variable costs | Euro PWh–1 | 20.5 | 20.8 | –10% | +40% |

| Interest rate | % | 5 | 5 | 3 | 10 |

| Opening/closing protective barrier on MagMat | s reload–1 | 10 | 10 | 0 | 60 |

| Automatic tray switching time | s tray–1 | 25 | 25 | 0 | 60 |

| Mechanical availability (MA) of MagMat | % | 100 | 100 | 80 | 100 |

| a) pl = seedling; SMh = Scheduled Machine hour; PWh = Productive Work hour b) from Ersson et al. (2011) c) based on values from Rantala et al. (2009) | |||||

3 Results

3.1 Time consumption

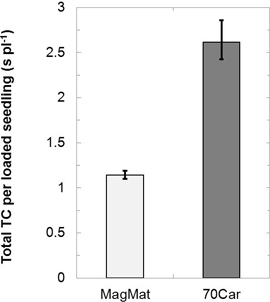

Seedling reloading was significantly faster with the MagMat carousel than the standard Bracke Planter seedling carousel (70Car) (p < 0.001); mean total TC per loaded seedling (s pl–1) was 57% lower and the range was also narrower (Fig. 4). When comparing the landing and clearcut time studies, no significant differences in TC for any work element or interaction effect were seen in the ANOVA for operator 3 (p ≥ 0.122).

Fig. 4. The mean total time consumption (TC) per loaded seedling for the standard Bracke Planter seedling carousel (70Car) and MagMat tray carousel. MagMat’s TC includes an assumed 10 s per reload for opening/closing a protective barrier. Vertical bars delineate the range of means for the landing time study’s three operators.

Although there were significant differences in total TC between operator 1 (novice) and operator 3 (the most experienced operator) when reloading both the 70Car and MagMat carousels (p < 0.001), the absolute difference was only 20 s and 17 s (10.4% and 12.8% of total TC) respectively per reload. There were no significant differences between operator 2 (the somewhat experienced operator) and the others (p ≥ 0.417). Therefore, we present only the pooled mean values and ranges of TC for all three operators (Table 3). As can be seen, seedling reloading was the most time consuming work element with 70Car while automatic tray switching was the most time consuming element with MagMat (57.4% and 56.5% of total reloading time respectively).

| Table 3. Average time consumption (TC) values and ranges per work element when three different operators reloaded seedlings during the time study. | |||

| Work element abbreviation in Fig. 3 | Work element | Mean TC per reload (s) | Range of TC per reload (s) |

| Common elements for both carousels | |||

| A | Detect empty carousel and rotate planting device | 13 | 8–15 |

| B + D | Travelling to and from cab – seedling storage box | 36 | 27–46 |

| E | Recommence work and plant in empty mound | 15 | 14–20 |

| 70Car (70 seedlings per reload) | |||

| C1 + C3 | Moving trays between storage box and carousel | 14 | 9–20 |

| C2 | Seedling reloading | 105 | 94–115 |

| Total for 70Car | 183 | 170–200 | |

| MagMat (320 seedlings per reload) | |||

| CM | Reloading trays including moving trays between storage box and carousel and removing empty trays | 90 a) | 83–99 a) |

| FM | Automatic tray switching during machine operation | 200 | 192–264 |

| Total for MagMat | 354 a) | 303–410 a) | |

| a) Not including an assumed 10 s per reload for opening/closing protective barrier | |||

3.2 Cost efficiency

As a consequence of the lower TC per loaded seedling, MagMat increased the Bracke Planter’s assumed mean productivity by 9% (from 200 to 218 pl PWh–1) and by 8% (from 236 to 255 pl PWh–1) for the M-Planter. Accordingly, the number of annual relocations also increased from 50 to 54 for the Bracke Planter and from 58 to 63 for the M-Planter. More relocations meant that the annual number of PWh spent planting fell from 1000 to 991 for the Bracke Planter and from 984 to 975 for the M-Planter. Still, annual production for the MagMat-equipped planting machines rose by 8% (from 200 000 to 215 965 pl yr–1) and 7% (from 232 224 to 248 282 pl yr–1) for the Bracke Planter and M-Planter respectively.

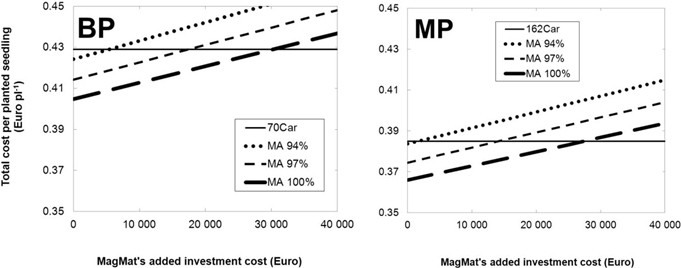

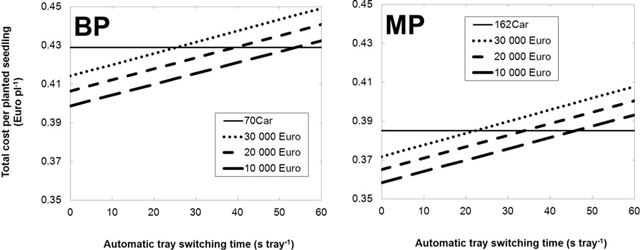

Under the baseline assumptions and providing 100% MA, MagMat was more cost-efficient than the standard carousels even at added investment costs of 30 000 and 27 500 Euros for the Bracke Planter and M-Planter respectively (Fig. 5). However, the added investment cost had to be almost halved if MagMat’s MA decreased even a few percentage points to 97%.

Fig. 5. Total cost per planted seedling of the Bracke Planter (BP) and M-Planter (MP) as a function of the added investment cost for MagMat and its mechanical availability (MA). 70Car and 162Car are the current seedling carousels for the Bracke Planter and M-Planter respectively. Note: the y-axes have been truncated.

Compared to the standard carousels, MagMat’s cost-efficiency improved on both the Bracke Planter and M-Planter when the interest rate decreased, with increased total fixed costs, and with increased planting machine productivity, i.e. decreased mean planting time excluding seedling reloading. For the levels tested, the absolute improvements were, however, relatively minor and never improved MagMat’s cost-efficiency advantage by more than 0.01 Euro pl–1 (corresponding to 2–3% of total cost per planted seedling; results not shown).

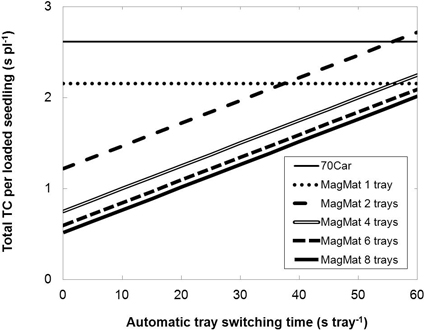

As Table 3 shows, the automatic switching of trays comprised over 56% of TC per reload with MagMat. Consequently, MagMat’s cost-efficiency was also greatly reliant on this work element’s duration (Fig. 6). Contrariwise, the TC for opening/closing a protective barrier had relatively little effect on MagMat’s cost-efficiency (results not shown).

Fig. 6. Total cost per planted seedling of the Bracke Planter (BP) and M-Planter (MP) as a function of how quickly seedling trays can be switched automatically on the MagMat tray carousel and its added investment cost (assuming 100% MA). 70Car and 162Car are the current seedling carousels for the Bracke Planter and M-Planter respectively. Note: the y-axes have been truncated.

4 Discussion

Our time study showed that the Bracke Planter device could be reloaded with seedlings twice as fast when using the MagMat tray carousel compared to the standard seedling carousel. This improvement is promising, but as the cost-analysis and previous experiences have shown, the cost-efficiency of any new carousel will be greatly reliant on its added investment cost and MA.

For example, von Hofsten (1993) recognized that the success of any improvement to 70Car will be highly dependent on the new carousel’s MA. Arnkil and Hämäläinen (1995) pointed to the challenge of building a highly reliable yet faster seedling feeding system on the Bracke Planter, while Rantala et al. (2009) viewed the added investment costs of any improved carousel as being the most crucial aspect. As far as we know, most previous attempts to build new carousels on the Bracke Planter have been abandoned because they could not be made mechanically reliable. Similarly, a project to speed up seedling reloading on the Risutec PM100, the other one-headed planting device, started with a high-tech, high capacity feeding system but has now been scaled down to a smaller and more robust solution (Risutec 2013).

On the other hand, our 100% MA assumption for 70Car could be considered well optimistic. Today’s carousel causes root plug deformation (von Hofsten 1993) to the extent that it causes jamming when a seedling does not drop into the planting tube. If the seedlings have “straggly root systems”, they can “cause missed planting actions and forcing second attempts at planting” during 1.8–10.1% of the total planting time (Drake-Brockman 1998). In a broader sense, this jamming can be seen as lowering 70Car’s MA. Although rootbound stock (Ritchie and Landis 2010) can effectively eliminate this jamming, these types of seedlings tend to have lower survival, growth, or stability after outplanting (South and Mitchell 2005), especially compared to seedlings cultivated in copper-painted cultivation trays (Kooistra 1991; Nelson 1992). MagMat does not suffer from this jamming problem since the seedlings are kept in their cultivation trays until a few seconds before planting.

Deplugging, MagMat’s seedling extraction method, proved very reliable, however. During the field tests, circa 15 trays (> 550 seedlings) were deplugged with > 98% success rate (not presented). When a seedling was not extracted from the tray, it was mainly because of an error in the test-rig’s control system when the power of the base machine was switched off. If seedlings can be extracted so reliably even at the boom-tip of an excavator, we conclude that the deplugging method can be useful on any type of tree planting machine or as part of automatic seedling feeding systems. Highly reliable seedling-feed systems are especially necessary for highly productive, continuously advancing planting machines (Hallonborg 1996).

With a cycle time of circa 3 seconds to deplug and tip a seedling into the planting tube, MagMat likely has the capacity to feed multi-dibble planting machines. Nonetheless, it would probably be best to equip MagMat with two deplugging units when mounted on two-headed planting devices like the M-Planter. Theoretically, the maximum seedling-feeding productivity of two deplugging units assuming 15 s automatic tray switching time would be > 2100 pl PWh–1; a capacity high enough to have sufficed even for the Silva Nova. The now-defunct Silva Nova was an expensive, continuously advancing planting machine with average productivities > 2000 pl PWh–1 at the best of times (Hallonborg et al. 1995; Ersson 2010).

Despite this study’s use of a test-rig lacking a protective barrier as well as a reliable tray-switching mechanism, the time study and cost analysis nonetheless provides a good appraisal of MagMat’s potential to improve planting machine productivity. The analysis is also realistic because the results showed that increased productivity led to more relocations and fewer annual PWh (cf. the analysis of Rantala et al. 2009).

The MagMat carousel has, however, some other weaknesses. First, 70Car is extremely reliable. It might therefore be unprofitable for contractors to change to something more productive but which requires more maintenance and might breakdown more often. Second, MagMat requires that seedlings be delivered to the planting machine in Hiko cultivation trays. This fact disqualifies e.g. seedlings grown using other cultivation systems (see Nieuwenhuis and Egan (2002) for various examples of containerized seedlings that have been planted with the Bracke Planter) or frozen-stored seedlings unless extra transferring is done at the nursery or landing with added costs incurred. In the future, as mechanized tree planting becomes more common (Nilsson et al. 2010), it might be more cost-efficient to use machine-specific seedling packaging (Ersson et al. 2011). Thus, we see the MagMat concept as an interim solution: an improvement to 70Car which has not been modified for over 20 years (cf. von Hofsten 1993).

Undoubtedly, future versions of MagMat can be designed to be more robust. The simplest way of achieving higher robustness is probably reducing MagMat’s tray-holding capacity. While fewer trays per reload increases the TC per loaded seedling, holding only four to six trays does not increase total TC very much (Fig. 7). Fewer trays probably allow for a lighter and more reliable, less costly design, and, especially, for faster automatic tray switching. Further testing should also be made using other types of cultivation trays, such as trays with irregular cell spacing and form, or air/side slits. If deplugging can be as successful with those trays as with Hiko, then this seedling extraction method will gain wider acceptance and help speed up the development of automatic seedling feeding systems on planting machines.

Fig. 7. The time consumption (TC) of various MagMat capacities as a function of how quickly seedling trays can be switched automatically for configurations with more than one tray. Mechanical availability (MA) is assumed to be 100% and that the TC for applicable work elements equal the mean values presented in Table 3.

In summary, we have shown that tray-wise seedling reloading with the MagMat concept can increase planting machine productivity by almost 10% depending on the planting device. However, the cost-efficiency of a future MagMat carousel is ultimately coupled to its added investment cost and mechanical availability, the latter being important because commercial versions of MagMat will invariably be more complex than today’s standard seedling carousels. Nevertheless, deplugging, MagMat’s method of extracting seedlings from cultivation trays, and rigid-walled copper-painted cultivation trays like Hiko, both show promise as providing a robust solution to feed seedlings to all types of tree planting machines. Indeed, using tray-wise reloading and multiple simultaneously working deplugging units, seedlings could be fed quickly enough to allow for highly productive, continuously advancing planting machines.

Acknowledgements

Funding for this study was provided by Södra Skog, Sveaskog and SLU’s Faculty of Forest Sciences through the FIRST research school. Thanks to Rikard Wennberg for constructing MagMat, making drawings and helping with MagMat’s field testing. MagMat’s construction was funded by Kempestiftelserna (the Kempe Foundations) and Skogstekniska klustret (the Forestry Technology Cluster).

References

Arnkil R., Hämäläinen J. (1995). Bräcke Planter- ja Ilves-istutuskoneiden tuottavuus ja työjälki. [Bräcke Planter and Ilves tree planting machines]. Metsätehon Katsaus 1/1995.

Bäckström P.O. (1978). Mechanized planting – basic conditions, techniques, productivity and costs. Forskningstiftelsen Skogsarbeten, Meddelande 74.

Bergstrand K.-G. (1987). Planering och analys av skogstekniska tidsstudier. [Planning and analysis of time studies on forest technology]. Forskningsstiftelsen Skogsarbeten, Meddelande 17.

Björheden R., Thompson M.A. (2000). An international nomenclature for forest work study. In: Field D.B. (ed.). Proceedings, IUFRO 1995 S3:04 subject area: 20th World Congress, 1995 August 6–12, Tampere, Finland. University of Maine, Miscellaneous Reports 422. p. 190–215.

Brewer H. (1994). Conceptual modeling automated seedling transfer from growing trays to shipping modules. Transactions of the ASAE 37(4): 1043–1051. http://dx.doi.org/10.13031/2013.28174.

Drake-Brockman G.R. (1998). Evaluation of the Bracke Planter on UK restock sites. Technical Development Branch, Forestry Commission, Technical Note 7/98.

Ersson B.T. (2010). Possible concepts for mechanized tree planting in southern Sweden – an introductory essay on forest technology. Department of Forest Resource Management, SLU, Arbetsrapport 269. ISSN 1401-1204. ISRN SLU-SRG-AR-269-SE.

Ersson B.T., Petersson M. (2013). Återinventering av 2010 års maskinplanteringar – 3-års uppföljning. [Three-year follow-up of 2010’s mechanically planted seedlings]. Skoglig service, Södra Skog, Rapport S048.

Ersson B.T., Bergsten U., Lindroos O. (2011). The cost-efficiency of seedling packaging specifically designed for tree planting machines. Silva Fennica 45 (3): 379–394.

Ersson B.T., Junden L., Bergsten U., Servin M. (2013). Simulated productivity of one- and two-armed tree planting machines. Silva Fennica 47(2) art. 958. http://dx.doi.org/10.14214/sf.958.

Graham L.F., Rohrbach R.P. (1981). Mechanical singulation of bare root pine seedlings. In: Forest Regeneration: Proceedings of the American Society of Agricultural Engineers’ Symposium on Engineering Systems for Forest Regeneration, Raleigh, North Carolina. p. 186–193.

Hallonborg U. (1996). Limiting factors in mechanized tree-planting. Journal of Forest Engineering 7(2): 35–41.

Hallonborg U. (1997). Aspects of mechanized tree planting. Acta Universitatis Agriculturae Sueciae Silvestria 29.

Hallonborg U., von Hofsten H., Mattson S., Hagberg J., Thorsén Å., Nyström C., Arvidsson H. (1995). Maskinell plantering med Silva Nova – nuvarande status samt utvecklingsmöjligheter i jämförelse med manuell plantering. [Mechanized planting with the Silva Nova tree planter – recent state and feasibility compared with manual planting]. Skogforsk, Redogörelse 6.

Hallonborg U., von Hofsten H., Mattsson S., Thorsén Å. (1997). Forestry planting machines – a description of the methods and the machines. Skogforsk, Redogörelse 7.

Halonen M. (2002). Koneellisen istutuksen tuotos- ja kehittämistutkimus – EcoPlanter 2000. [A study of productivity and development of mechanized planting – EcoPlanter 2000]. UPM-Kymmene Metsä.

von Hofsten H. (1993). Hög kvalitet även på högkvaliteten med Öje-Planter. [The Öje Planter machine – good performance at a competitive cost]. Skogforsk, Resultat 3.

Johnsson E. (2010). Rotutveckling och tillväxt i fält hos granplantor odlade i kopparbehandlade odlingssystem. [Root development and growth of copper pruned Norway spruce after outplanting]. Institutionen för sysdsvensk skogsvetenskap, SLU, Examensarbete 149.

Kohonen M. (1981). Automatic multifunction tree planter and plant production system. In: Forest Regeneration: Proceedings of the American Society of Agricultural Engineers’ Symposium on Engineering Systems for Forest Regeneration, Raleigh, North Carolina. p. 139–143.

Kooistra C.M. (1991). An overview of copper pruned Lodgepole pine in plantations. In: Proceedings of the Forest Nursery Association of British Columbia Conference in Prince George, B.C., September 24–27, 1991. p. 106–110.

Laine T., Rantala J. (2013). Mechanized tree planting with an excavator-mounted M-Planter planting device. International Journal of Forest Engineering 24(3): 183–193. http://dx.doi.org/10.1080/14942119.2013.844884.

Landis T.D. (1990). Containers and growing media. In: Landis T.D., Tinus R.W., MacDonald S.E., Barnett J.P. (eds.). The container tree nursery manual, Vol. 2. Agricultural Handbook 674. USDA Forest Service, Washington DC.

Malmberg C.E. (1990). Mekanisering av skogsodling. STU, Stockholm. ISBN 91-7850-353-1.

Miyata E.S. (1980). Determining fixed and operating costs of logging equipment. North Central Forest Experiment Station, USDA Forest Service, General Technical Report NC-55. 16 p.

Nelson W.R. (1992). Chemical root-pruning proves versatile. International Symposium on Transplant Production Systems. ISHS Acta Horticulturae 319: 353–357.

Nieuwenhuis M., Egan D. (2002). An evaluation and comparison of mechanised and manual tree planting on afforestation and reforestation sites in Ireland. International Journal of Forest Engineering 13(2): 11–23.

Nilsson U., Luoranen J., Kolström T., Örlander G., Puttonen P. (2010). Reforestation with planting in northern Europe. Scandinavian Journal of Forest Research 25(4): 283–294. http://dx.doi.org/10.1080/02827581.2010.498384.

Normark E., Norr M. (2002). EcoPlanter – sammanställning av ett utvecklingsprojekt. [EcoPlanter – a compilation of the development project]. Skogsvårdsavdelningen, Holmen Skog.

Öhman L. (1994). Prov med Bräcke Planter på bördiga marker inom Strängnäs och Holmens skogsförvaltningar. [Trials with the Bräcke Planter on fertile sites in Strängnäs and Holmen forest districts]. Skogsvårdsavdelningen, MoDo Skog.

Rantala J., Laine T. (2010). Productivity of the M-Planter tree-planting device in practice. Silva Fennica 44(5): 859–869.

Rantala J., Harstela P., Saarinen V.-M., Tervo L. (2009). A techno-economic evaluation of Bracke and M-Planter Tree Planting Devices. Silva Fennica 43(4): 659–667.

Risutec Oy (2013). Planting device information from the manufacturer. http://www.risutec.fi/en/products/risutec-pm100. [Cited 11 Nov 2013].

Ritchie G.A., Landis T.D. (2010). Chapter 2: Assessing plant quality. In: Landis T.D., Tinus R.W., MacDonald S.E., Barnett J.P. (eds.). The container tree nursery manual, Vol. 7. Agricultural Handbook 674. USDA Forest Service, Washington D.C.

Safrani E., Lideskog H. (2011). Konceptutveckling för kostnadseffektiv och tidseffektiv mekanisk skogsplantering. [Concept development for cost- and time-efficient mechanized tree planting]. Institutionen för teknikvetenskap och matematik, Luleå tekniska universitet, Examensarbete i Maskinteknik/Teknisk design.

Sønsteby F., Kohmann K. (2003). Forsøk med maskinell planting på Østlandet. [Mechanized planting trials in Østlandet]. Norsk Institutt for Skogforskning, Oppdragsrapport 3/03.

South D.B., Mitchell R.G. (2005). A root-bound index for container-grown pines. In: Colombo S.J. (ed.). The Thin Green Line: a Symposium on the State-of-the-Art in Reforestation: proceedings, (Thunder Bay, Ontario). Ontario Forest Research Institute, Forest Research Information Paper 160: 88–93.

Stjernberg E.I. (1985). Tree planting machines: a review of the intermittent-furrow and spot planting types. Forest Engineering Research Institute of Canada, Special Report SR-31. 118 p.

Strandström M., Hämäläinen J., Pajuoja H. (2009). Metsänhoidon koneellistaminen – visio ja T&K-ohjelma. Metsätehon raportti 206.

Strandström M., Saarinen V.-M., Hallongren H., Hämäläinen J., Poikela A., Rantala J. (2011). Koneellisen istutuksen ja taimikonhoidon kilpailukyky. [The competitiveness of mechanized planting and tending]. Metsätehon raportti 218.

Sveriges Riksbank (2013). Internet service – exchange rates. [Sweden’s Central Bank]. http://www.riksbank.com. [Cited 4 Nov 2013].

Tuinbouw Technisch Atelier BV (2013). Nursery equipment information from the manufacturer. http://www.tta.eu/products/transplanting/. [Cited 14 Nov 2013].

Zahreddine H.G., Struve D.K., Quigley M. (2004). Growing Pinus nigra seedlings in SpinoutTM-treated containers reduces root malformation and increases growth after transplanting. Journal of Environmental Horticulture 22(4): 176–182.

Total of 42 references