Performance of a small and a medium sized professional chippers and the impact of storage time on Scots pine (Pinus sylvestris) stem wood chips characteristics

Laitila J., Routa J. (2015). Performance of a small and a medium sized professional chippers and the impact of storage time on Scots pine (Pinus sylvestris) stem wood chips characteristics. Silva Fennica vol. 49 no. 5 article id 1382. https://doi.org/10.14214/sf.1382

Highlights

- The storage time of pulpwood had no significant effect on particle size distribution in any chip size classes

- The study confirms the knowledge that chipping time consumption is inversely proportional to engine power and grapple load size in feeding

- The use of an narrower 80 mm × 80 mm sieve on Scots pine material does not seem to offer any benefit compared to a 100 mm × 100 mm sieve from the perspective of chip quality.

Abstract

The primary aim of this study was to clarify the chipping productivity and fuel consumption of tractor-powered and truck-mounted drum chippers when chipping pine pulpwood at a terminal. The secondary aim was to evaluate the impact of wood storage time on the chemical and physical technical specifications of wood chips by chipping pulpwood from eight different storage time groups, using Scots pine (Pinus sylvestris) pulpwood stems logged between 2 and 21 months previously at the terminal with the above-mentioned chippers. Thirdly, the impact of sieve mesh size on the particle size distribution of wood chips from different age groups was compared by using an 80 mm × 80 mm sieve for a tractor-powered chipper and a 100 mm × 100 mm sieve for a truck-mounted chipper. With both chippers, the chipping productivity grew as a function of grapple load weight. The average chipping productivity of the tractor-powered chipper unit was 19 508 kg (dry mass) per effective hour (E0h), and for the truck-mounted chipper the average productivity was 31 184 kg E0h–1. The tractor-powered drum chipper’s fuel consumption was 3.1 litres and for the truck-mounted chipper 3.3 litres per chipped 1000 kg (dry mass). The amount of extractives or volatiles did not demonstrate any statistically significant differences between storage time groups. The particle size distributions with both chippers were quite uniform, and the storage time of pulpwood did not have a significant effect on the particle size distribution in any chip size classes. One reason for this might be that the basic density of chipped wood was homogenous and there was no statistical difference between different storage times. The use of new sharp knives is likely to have affected chip quality, as witnessed by the absence of oversized particles and the moderate presence of fines. The use of narrower 80 mm × 80 mm sieves on Scots pine material does not seem to offer any benefit compared to 100 mm × 100 mm from the chip quality point of view.

Keywords

chipping;

productivity;

quality;

fuel;

particle size;

storage time;

sieve;

stem wood

-

Laitila,

Natural Resources Institute Finland (Luke), Bio-based business and industry, P.O. Box 68, FI-80101 Joensuu, Finland

E-mail

juha.laitila@luke.fi

- Routa, Natural Resources Institute Finland (Luke), Bio-based business and industry, P.O. Box 68, FI-80101 Joensuu, Finland E-mail johanna.routa@luke.fi

Received 29 April 2015 Accepted 26 August 2015 Published 11 September 2015

Views 236788

Available at https://doi.org/10.14214/sf.1382 | Download PDF

1 Introduction

Comminuting is an important element of all forest fuel supply chains, because the size reduction of wood biomass from its initial form into finer particles improves transport economy and is essential when feeding modern biomass boilers (Jensen et al. 2004; Hartmann et al. 2006; Strehler 2000; Lu et al. 2010; Spinelli et al. 2011a; Spinelli et al. 2011b; Röser et al. 2012; Spinelli et al. 2013; Wolfsmayr and Rauch 2014). Heat and combined heat and power plants (CHP) are the main consumers of forest chips. Other potential consumers are biorefineries and thermal treatment plants. Wood chips, used as fuel or for industrial purposes, have to meet both chemical and physical technical specifications (Suadicani and Gamborg 1999; Jensen et al. 2004; Hartmann et al. 2006; Strehler 2000; Lu et al. 2010; Nati et al. 2010; Spinelli et al. 2011a; Spinelli et al. 2011b; Pari et al. 2013; Spinelli 2013; Nati et al. 2014; Eliasson et al. 2015). The main quality parameters are moisture and ash content, particle size distribution and percentage of fine particles (Suadicani and Gamborg 1999; Jensen et al. 2004; Hartmann et al. 2006; Strehler 2000; Nati et al. 2010; Spinelli et al. 2011a; Spinelli et al. 2011b; Anerud and Jirjis 2011; Laurila 2013; Eriksson et al. 2014b; Wolfsmayr and Rauch 2014).

Particle size distribution has an impact on handling and combustion efficiency and emissions at heating plants (Mattsson 1990; Kristensen and Kofman 2000; Jensen et al. 2004; Paulrud and Nilsson 2004; Bäfver and Renström 2013). Particle size also affects the energy requirement of the hydrothermal pre-treatment needed for the conversion of wood biomass into liquid biofuels (Hosseini and Shah 2009) and the yield of bio-oil obtained from pyrolysis (Shen et al. 2009). Particle size distribution is a function of different variables and is significantly affected by wood material, moisture content, comminuting method, chipper type, blade wear and screen size (Suadicani and Gamborg 1999; Spinelli et al. 2005; Nati et al. 2010; Spinelli et al. 2011b). The most homogenous chips can be produced from stemwood, while much more heterogeneous chips are produced from logging residues (Suadicani and Gamborg 1999).

Demand for forest fuels is often diachronic, and shortages are usually buffered by means of stored material (Jirjis 1995; Rauch 2010; Filbakk et al. 2011; Laurila 2013; Rauch 2013; Eriksson et al. 2014a; Nurmi 2014). After logging, the fuel wood is stored at roadside landings for a longer or shorter time, usually from 6 months to 24 months (Laurila 2013). The storage of fuel wood may improve fuel quality by reducing moisture content (Jirjis 1995; Filbakk et al. 2011; Rauch 2013; Nurmi 2014), but on the other hand, biodegradation leads to loss of dry matter (kg m–3) and loss of energy rich extractives (Suadicani and Gamborg 1999; Jirjis 1995; Rauch 2010; Filbakk et al. 2011; Rauch 2013; Nurmi 2014; Routa et al. 2015a). Together, these factors will determine the volumetric energy density (Nurmi 2014). From the procurement point of view, an unfortunate disadvantage that accompanies storage is tied up in capital (Rauch 2013; Nurmi 2014). Deterioration of fuel wood also has a negative impact on particle size distribution, thus increasing the incidence of fines (Pochi et al. 2015).

The comminuting is performed using tractor-powered chippers especially in smaller operations and heavy truck-mounted chippers or stationary grinders in large-scale operations. Chippers with sharp tools are exclusively applied to clean wood and offer a more consistent product (Hakkila 1989; Rinne 2010; Spinelli et al. 2011c; Spinelli et al. 2012; Eriksson et al. 2013). Drum and disk chippers are the primarily technology used, whereas cone-screw chippers are rarely used (Hakkila 1989; Eriksson et al. 2013; Spinelli et al. 2013; Wolfsmayr and Rauch 2014). The grinders are more consistent against interruptions caused by impurities. However, grinding consumes more fuel than chippers. Moreover, grinders offer a rather coarse product that is unsuitable for use in some smaller plants (Hakkila 1989; Strelher 2000; Rinne 2010; Eriksson et al. 2013). Currently, roadside chipping is the dominant chipping system in Finland and Sweden as well as in other European countries (Junginger et al. 2005; Stampfer and Kanzian 2006; Kärhä 2011; Eriksson et al. 2013; Holzleitner et al. 2013; Rottensteiner et al. 2013; Routa et al. 2013; Wolfsmayr and Rauch 2014; Eliasson et al. 2015). Large disc chippers or drum chippers are used on terminals for chipping large-sized stemwood, while drum chippers dominate the chipping of logging residues and small trees on landings in Finland (Kärhä 2011).

During the cold season, chipping machinery is in intensive use, while during the summer months, the problem is a lack of work (Laitila 2012; Routa et al. 2013). The seasonal nature of fuel chip production lowers the utilisation rate of machinery and gambles on the availability of a professional workforce (Laitila 2012; Routa et al. 2013). Buffer storing of wood chips is one way to smooth out seasonal fluctuations, but the advantages gained do not always justify the expense (Pochi 2015). Wood chips are very vulnerable to microbial degradation during storage, which often leads to high dry matter losses, a reduction of energy value and a risk of self-ignition, and produced fungal spores are also a health risk to employees working with wood chips (Jirjis and Theander 1990; Jirjis 1995; Jirjis 2005; Eriksson et al. 2013; Wolfsmayr and Rauch 2014; Pochi et al. 2015; Routa et al. 2015a). The versatility of base machinery represents another way of achieving year-round employment and improving the profitability of machine contracting businesses.

Two main chipper set-up categories that operate on landings can be identified: those that are permanently mounted on truck, and those mounted on a trailer that can be attached to a tractor (Hakkila 1989; Röser et al. 2012; Eriksson et al. 2013; Rottensteiner et al. 2013; Spinelli and Magagnotti 2013; Spinelli and Magagnotti 2014; Wolfsmayr and Rauch 2014; Eliassson et al. 2015). Tractor-towed chippers are usually powered by the tractor power take-off (PTO) and it is possible to utilise the tractor for other purposes while there is no chipping work (Spinelli and Magagnotti 2014; Eliassson et al. 2015). Tractor-powered units are also cheaper to acquire and easier to resell in sections than truck-mounted chippers (Spinelli and Magagnotti 2014), but tractor-powered units cannot relocate between worksites as quickly as truck-mounted units, and chipping productivity is lower (Spinelli and Magagnotti 2013; Spinelli and Magagnotti 2014). The chipper’s engine power and the grapple load size in feeding are the two most important elements that affect chipping productivity (Spinelli and Hartsough 2001; Van Belle 2006; Spinelli and Magagnotti 2010; Ghaffariyan et al. 2013) if operational delays are excluded (Spinelli and Visser 2009; Holzleitner et al. 2013; Spinelli and Magagnotti 2014). Evidently, truck-mounted chippers are most suited to contractors with large annual chipping volumes and wide procurement areas, whereas tractor-powered chippers are interesting options for contractors who work locally.

1.1 Aim of the study

There is an important need to identify the areas in which areas technology, equipment and operational environment should be improved in order to improve the cost and resource efficiency of forest chip procurement for fuel or industrial purposes. Several important variables must be considered when evaluating the performance of chipping systems, including their productivity and energy consumption, the required initial investment, employment effects, wood characteristics and the quality of final product (Eriksson et al. 2013).

The primary aim of this study was to clarify the chipping productivity and fuel consumption of tractor-powered and truck-mounted drum chippers when chipping pine pulpwood at a terminal. The tractor-powered chippers were represented by a Kesla C 4560 LF (current model code Kesla C 645 T) and the larger ones by a Kesla C 1060 A. Secondly, the impact of wood storage times on the chemical and physical technical specifications of wood chips was evaluated by chipping wood from eight different storage time groups pulpwood stems logged between 2 and 21 months previously at the terminal with the above-mentioned Kesla chippers. Samples from each storage time group were collected in order to define the moisture content, basic density, particle size distribution, amount of acetone extractives and ash content of chipped raw material. Thirdly, the impact of sieve mesh size on the particle size distribution of wood chips from different age groups was compared by using an 80 mm × 80 mm sieve for a tractor-powered chipper and a 100 mm × 100 mm sieve for a truck-mounted chipper.

The produced parameters represent valuable information when developing forest chip procurement for biorefineries or making appropriate choices of machinery and equipment. As a result, investment costs can be optimised, operational costs reduced and quality of raw material improved.

2 Material and methods

2.1 The time study and data analysis of the chipping experiment

The chipping study was carried out from 10 to 11 November 2014 at the Fortum Power Plant wood terminal in Joensuu, Finland. The chipped pulpwood was from eight different age groups from stems logged 2 to 21 months previously. The experiment was carried out under natural light during the daytime (07:30–15:00), the temperature was +4–6 °C, the open asphalted ground was free of snow and the wood was unfrozen. The chipped material was Scots pine (Pinus sylvestris) pulpwood from first thinnings and the volume of each of the eight woodpiles was about 50 m3 (solid). The bolt length was 4–5 m in the woodpiles. The minimum top diameter was 6 cm and the diameters of the butt ends ranged from 15 to 20 cm. The observation unit was a truck container with 50 m3 or 43 m3 gross cargo volumes. Each truck container load was measured with a certified weight scale at the plant, and both filled and empty weights of the load were recorded. The chipping machinery was positioned parallel to the pile and during chipping; the chips were blown directly into the truck container (Fig. 1). The random order of chipped pulp wood piles was according to the storage time: 9, 17, 4, 12, 2, 7, 15 and 21 months. The total amount of chipped wood was 103 317 kg (dry mass).

Fig. 1. Chipping Scots pine pulpwood with Kesla C 1060 A and Kesla C 4560 LF chippers at the asphalted wood terminal in Joensuu. The chipping experiment started with the Kesla C 1060 A chipper.

Both chippers were operated by skilled contractors with more than six years’ work experience in wood chipping, and they were experienced with the studied chippers. After filling four truck containers, the chipper was fitted with a new set of sharp knives. The fuel consumption of the chipper units were measured at a local fuel station after chipping trials. Chipper units were parked in exactly the same place at the beginning and end of the shift and the tanks were filled up. The accuracy of the fuel pump was to 0.1 litres and the fuel consumption was presented per dry mass (1000 kg) of the produced forest chips.

The Kesla C 4560 LF chipper had six and the Kesla C 1060 A chipper had ten angled blades that were positioned in a spiral around the drum. A square mesh sieve was placed beneath the drum to prevent oversized chips from spilling out of the drum casing. The Kesla C 4560 LF chipper was equipped with an 80 mm × 80 mm sieve and the Kesla C 1060 A chipper with a 100 mm ×100 mm sieve. The width and height of the intake opening was 600 mm × 450 mm for the Kesla C 4560 LF chipper and 1000 mm × 600 mm for the Kesla C 1060 A chipper. The hydraulic infeed systems were equipped with an automatic feeding control.

The Kesla C 4560 LF drum chipper and the Kesla 600T timber loader for feeding were mounted on a tandem axle trailer and were powered by a Valtra S280 farm tractor with a rated engine power of 209 kW (Fig. 1). The chipper was connected to the rear power take-off (PTO) shaft of the tractor, set to the standard speed of 1000 rpm. The commands for manoeuvring the timber loader and chipper were positioned in the cabin of the farm tractor. The Kesla C 1060 A drum chipper was mounted on a three-axle Volvo FH 750 truck chassis (Fig. 1) and was powered by the truck’s 559 kW engine by an intermediate transmission. The raw material was fed into the chipper’s feeding table with the Kesla 1200T timber loader, which had a cabin for the operator during chipping (Fig. 1).

The time study was carried out manually with a Rufco-900 field computer (Nuutinen et al. 2008). The working time was recorded through the application of a continuous timing method wherein a clock ran continuously and the times for different elements were separated from each other under distinct numeric codes (e.g. Harstela 1991; Magagnotti et al. 2013). During the experiment, the researcher observed the work performance outside the risk zone so that he did not disturb the work of the operator. The operation time of the studied chippers was recorded, and the working time was divided into work elements in order of priority:

Boom out: Boom movement from the chipper to the piled material

Grip: Gripping of material

Boom in: Boom movement from the pile to the feeding table

Feeding: Placing the material into the feed orifice and releasing the grapple load

Adjustment: Possible adjustments of the material on the feeding table

Chipping: Chipping while the timber loader is idle

Moving and preparation: Repositioning the chipper to the next pile and preparing the chipper ready for chipping work

Delays: Time not related to chipping work, but for which the reason for the interruption was recorded.

The effective hourly productivity (E0h) of the chipping operation are presented per dry mass (kg) of the forest chips. The data analysis was conducted for direct chipping time only (E0h), in order to avoid the confounding effect of delay and preparation time, which is typically erratic (e.g. Spinelli and Visser 2009; Eliasson et al. 2012a; Holzleitner et al. 2013). The studies were also too short to record representative delay times. The effective working time (E0h) included the work phases of boom out, grip, boom in, feeding, adjustment and chipping. The number of grapple loads for each full truck container load was counted, in order to calculate the average weight of the grapple load in feeding.

The truck container-wise time-study data and chipped timber amounts were combined as a data matrix. The chipping productivity of chippers was formulated through the application of regression analysis, in which the average grapple load in feeding was the independent variable. The regression analysis was carried out using IBM SPSS Statistics version 20, and the characteristics of regression models are detailed in Table 1. The chipping productivity was expressed in dry masses per effective hour (kg E0h–1).

| Table 1. Statistical characteristics of regression models. | ||||||||||

| Productivity model | Dependent variable | r2 | F-test/F-value p | N | Term | Constant/Coefficient | t-test | |||

| Estimate | Std. error | t-value | p | |||||||

| Chipping productivity of the Kesla C 1060 A powered by a Volvo FH 750 | PChipping1060 | 0.67 | 12.332 0.013 | 8 | Constant ln(x1060) | –127429.105 30132.281 | 45182.677 8580.522 | –2.820 3.512 | 0.030 0.013 | |

| Chipping productivity of the Kesla C 4560 LF powered by a Valtra S 280 | PChipping4560 | 0.62 | 9.600 0.021 | 8 | Constant ln(x4560) | –438.103 4100.515 | 6440.559 1323.463 | –0.068 3.098 | 0.948 0.021 | |

2.2 Sampling and analyses of wood chips

The chip samples were taken directly from the truckloads arriving as part of the normal delivery process at the wood terminal of the Fortum Power Plant, after unloading chipped wood to the ground (Uusvaara 1978; Uusvaara and Verkasalo 1987). Samples were taken to define the moisture content, amount of extractives, amount of volatiles, basic density, particle size distribution, ash content, and net calorific value of the chipped wood, and samples were analysed in the laboratory of the Natural Resources Institute Finland according to the following standards: EN 14780; EN 14774-1; EN 14774-2; EN 14774-3; SCAN-CM 43:95; EN 15149-1; EN 14775; EN 14918; SCAN-CM 67:03; SCAN-CM 49:03 and EN 15148.

Five samples were taken from each truckload, and wood samples were stored in plastic bags, which were carefully closed and marked. Moisture samples were packed in double bags in order to minimise the risk of bag outbreak or evaporation. The dimensions of the plastic bags were 35 × 35 cm (8 litres in volume), and the raw material, date and time were written on the label. In addition, plastic bags were wrapped in a plastic sack, and each load was packed in a corrugated paperboard box of its own. The samples were extracted from six different locations in the pile using a sampling shovel, so that the results would be representative of the load.

The Kruskal-Wallis test, a non-parametric method, was used with IBM SPSS Statistics version 20 to determine whether the length of storage or chipper type affects particle size distribution, the critical level being p < 0.05. The Kruskal-Wallis test was also used to determine the effect of storage time or chipper type on ash content, net calorific value, moisture content, amount of extractives and amount of volatiles.

3 Results

3.1 Chipping productivity and fuel consumption

The average chipping productivity of the Kesla C 4560 LF chipper unit was 19 508 kg (dry mass) per effective hour (E0h) and standard deviation (SD) was 827 kg E0h–1. The average weight of the grapple load was 131 kg (SD 20). The average chipping productivity of the Kesla C 1060 A chipper unit was 31 184 kg E0h–1 (SD 5444) and the average weight of the grapple load was 195 kg (SD 29).

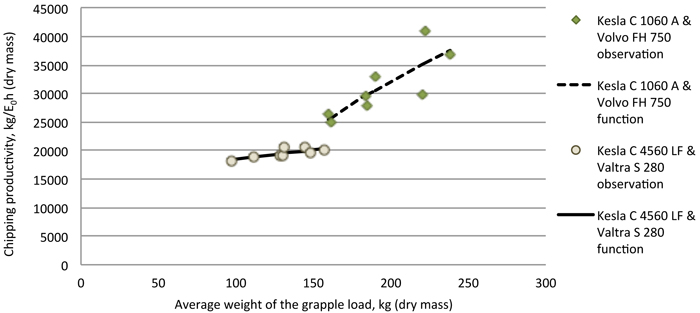

With both chippers, productivity grew as a function of grapple load weight (Fig. 2). The Kesla C 1060 A chipper had a larger feed orifice and a more powerful engine than the Kesla C 4560 LF chipper unit, which enabled bigger grapple loads in feeding and a significantly greater response (Fig. 2) to chipping productivity (kg E0h–1) as a function of grapple load weight (kg).

Fig. 2. Chipping productivity of Kesla C 1060 A and Kesla C 4560 LF chippers (kg E0h–1) according to the weight of the grapple load (kg).

The chipping productivity of the Kesla C 1060 A and the Kesla C 4560 LF chippers (Fig. 2) were modelled (Eq. 1 and Eq. 2) from the average weight of grapple load as:

where

PChipping1060 = Chipping productivity of the Kesla C 1060 A powered by a Volvo FH 750, expressed in kg E0h–1 (dry mass)

x1060 = average weight of the grapple load, kg (dry mass)

r2 = 0.67

where

PChipping4560 = Chipping productivity of the Kesla C 4560 LF powered by a Valtra S 280, expressed in kg E0h–1 (dry mass)

x4560 = average weight of the grapple load, kg (dry mass)

r2 = 0.62

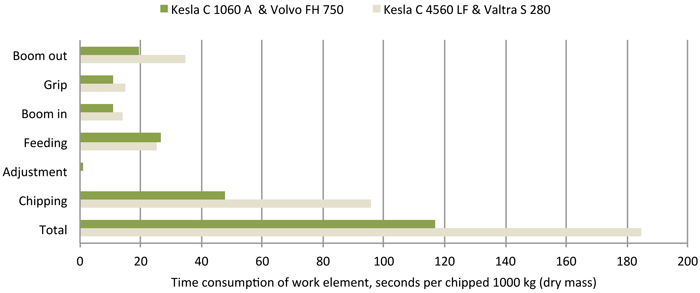

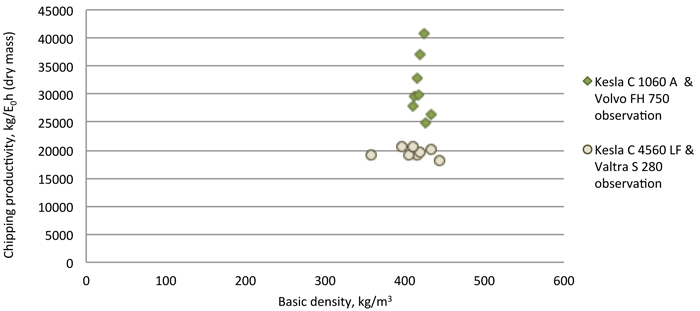

The total chipping time per 1000 kg (dry mass) was 117 seconds for the Kesla C 1060 A chipper and 185 seconds for the Kesla C 4560 LF chipper (Fig. 3). Chipping while the timber loader was idle took 41–52% of the effective working time. Loading accounted for 34–35% and feeding 14–23% of the effective working time (Fig. 3). The Kesla C 1060 A and the Kesla C 4560 LF chippers were not momentarily idle because the timber loader could feed the chippers sufficiently quickly. The large grapple loads and the length of pulpwood reduced the number of cycles that the timber loader had to carry out. Thus, the loading of pulpwood was not the weak link in the process and chippers were in operation about 100% of the time. The basic density of pulpwood (kg m–3) had no observed impact on chipping productivity when the basic density of the wood material was in the range of 358–443 kg m–3 (Fig. 4). The fuel consumption of the Kesla C 1060 A chipper was 3.3 litres per chipped 1000 kg (dry mass) and for the Kesla C 4560 LF chipper the fuel consumption was 3.1 litres.

Fig. 3. Time consumption of work elements per chipped 1000 kg (dry mass) with the Kesla C 1060 A and the Kesla C 4560 LF chippers.

Fig. 4. Chipping productivity (kg E0h–1) of the Kesla C 1060 A and the Kesla C 4560 LF chippers according to basic density (kg m–3) of chipped wood material.

3.2 Wood characteristics and particle size distribution

The average moisture content (wet basis) of pulpwood was 46.26% (SD 5.76). The moisture content of pulpwood varied depending on storage time, and the difference was statistically significant (p = 0.047) (Table 2). Fresh wood (storage time 2 months) was naturally very moist (55.1%), and wood which had been stored for 21 months was the driest (37.8%). However, one of the woodpiles had been stored for seven months and the moisture content was 41.25%.

| Table 2. Moisture content (%), calorific value (MJ kg–1), basic density (kg m–3) and ash content (%) of different storage time groups of pulpwood. | ||||||||

| Age of storage, months | Moisture content, % | Calorific value MJ kg–1 | Basic density kg m–3 | Ash content, % | ||||

| Kesla C 1060 A | Kesla C 4560 LF | Kesla C 1060 A | Kesla C 4560 LF | Kesla C 1060 A | Kesla C 4560 LF | Kesla C 1060 A | Kesla C 4560 LF | |

| 2 | 55.8 | 54.4 | 20.66 | 20.70 | 434 | 443 | 0.43 | 0.43 |

| 4 | 47.0 | 46.8 | 20.35 | 20.61 | 417 | 416 | 0.62 | 0.38 |

| 7 | 41.6 | 40.9 | 20.32 | 20.32 | 411 | 406 | 0.63 | 0.58 |

| 9 | 45.7 | 45.3 | 20.56 | 20.54 | 412 | 396 | 0.54 | 0.42 |

| 12 | 56.0 | 50.3 | 20.36 | 20.54 | 418 | 420 | 0.47 | 0.35 |

| 15 | 47.2 | 47.4 | 20.43 | 20.29 | 420 | 410 | 0.46 | 0.41 |

| 17 | 40.7 | 45.6 | 20.28 | 20.32 | 426 | 433 | 0.49 | 0.47 |

| 21 | 37.0 | 38.6 | 20.37 | 20.42 | 425 | 358 | 0.49 | 0.39 |

| Average | 46.38 | 46.16 | 20.42 | 20.47 | 420 | 410 | 0.52 | 0.43 |

| Standard deviation | 6.82 | 4.95 | 0.13 | 0.15 | 7.69 | 25.83 | 0.08 | 0.07 |

The average net calorific value was 20.44 MJ kg–1 (SD 0.13), and there was no statistical difference (p = 0.119) between different storage times. The basic density of wood varied between 358–443kg m–3 (average 415 kg m–3, SD 19.13), and there was no statistically difference (p = 0.146) between different storage times. The average ash content of the stem wood was 0.47% (SD 0.08). Storage time had no effect (p = 0.540) on the ash content of wood (Table 2).

The average amount of extractives was 5.5% (SD 0.76) of dry mass and the difference was not statistically significant (p = 0.077) between different storage times. The same was true with the volatiles; on average the amount was 84.12% (SD 0.50) of extractives, and the difference was not statistically significant (p = 0.825).

The chipper type did not affect moisture content, net calorific value, amount of extractives and amount of volatiles (p > 0.05), but the chipper type was statistically significant (p = 0.012) in terms of ash content (Table 3).

| Table 3. Yield of extractives (% of dry mass) and volatiles (% of extractives) of pulpwood in different storage time groups with the Kesla C 1060 A and the Kesla C 4560 LF chippers. | |||||

| Extractives | Volatiles | ||||

| Age of storage, months | Chipper | Lipophilic yield, % | Hydrophilic yield, % | In total, % | % |

| 2 | Kesla C 1060 A | 5.90 | 1.14 | 7.04 | 84.9 |

| 4 | 4.68 | 1.24 | 5.92 | 83.8 | |

| 7 | 3.28 | 1.27 | 4.55 | 84.4 | |

| 9 | 4.31 | 1.26 | 5.57 | 83.6 | |

| 12 | 4.53 | 1.10 | 5.63 | 83.3 | |

| 15 | 3.56 | 1.06 | 4.62 | 84.8 | |

| 17 | 4.09 | 1.36 | 5.45 | 83.4 | |

| 21 | 3.64 | 1.27 | 4.91 | 84.1 | |

| Average | 5.46 | 84.04 | |||

| Standard deviation | 0.81 | 0.62 | |||

| 2 | Kesla C 4560 LF | 5.95 | 1.13 | 7.08 | 83.9 |

| 4 | 4.86 | 1.09 | 5.95 | 84.4 | |

| 7 | 4.24 | 1.08 | 5.31 | 83.4 | |

| 9 | 4.31 | 1.22 | 5.53 | 84.5 | |

| 12 | 4.60 | 0.97 | 5.57 | 84.3 | |

| 15 | 3.96 | 0.92 | 4.88 | 84.3 | |

| 17 | 3.18 | 1.32 | 4.50 | 84.4 | |

| 21 | 4.57 | 1.00 | 5.58 | 84.5 | |

| Average | 5.55 | 84.21 | |||

| Standard deviation | 0.77 | 0.38 | |||

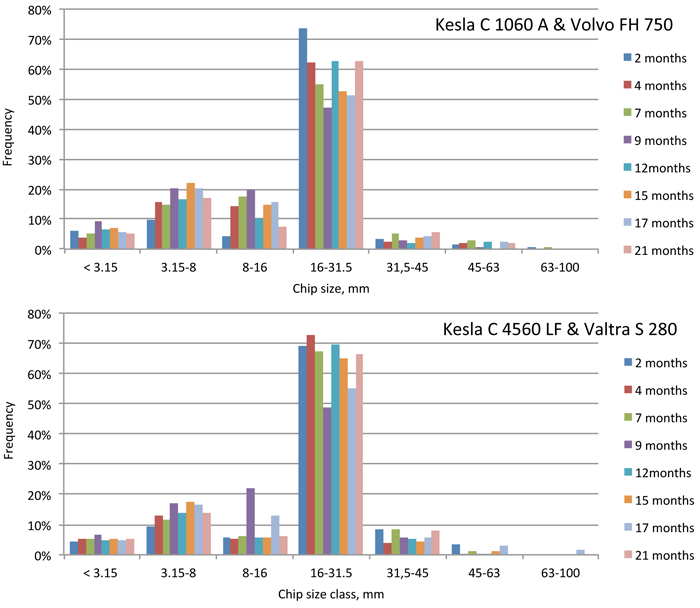

The particle size distributions with the Kesla C 1060 A and the Kesla C 4560 LF were quite uniform, as is presented in Fig. 5. The particle size class was P31 (Alakangas and Impola 2014) in all cases. The storage time of the pulpwood had no significant effect on particle size distribution in any chip size classes (Table 4). The effect of the chipper and sieve mesh size was significant (p = 0.007) in size class 31.5–45 mm (Table 5).

Fig. 5. Chip size distribution for the Kesla C 1060 A chipper (above) and the Kesla C 4560 LF chipper (below) with different storage times (2–21 months from logging).

| Table 4. Effect of storage time on chip size distribution. | ||||

| Effect of storage time | ||||

| Fraction, mm | df | Distribution, percentage, Mean | Std. deviation | P-value |

| 63–100 | 7 | 0.19 | 0.48 | 0.56 |

| 45–63 | 7 | 1.45 | 1.09 | 0.35 |

| 31.5–45 | 7 | 4.98 | 2.05 | 0.52 |

| 16–31.5 | 7 | 61.38 | 8.60 | 0.17 |

| 16–8.0 | 7 | 10.88 | 5.82 | 0.19 |

| 3.15–8 | 7 | 15.54 | 3.62 | 0.10 |

| < 3.15 | 7 | 5.62 | 1.25 | 0.42 |

| Table 5. Effect of chipper type and sieve mesh size on chip size distribution. | ||

| Effect of chipper type | ||

| Fraction, mm | df | P-value |

| 63–100 | 1 | 0.644 |

| 45–63 | 1 | 0.752 |

| 31.5–45 | 1 | 0.007 |

| 16–31.5 | 1 | 0.115 |

| 16–8.0 | 1 | 0.115 |

| 3.15–8 | 1 | 0.115 |

| < 3.15 | 1 | 0.292 |

4 Discussion

The time study confirms existing knowledge that chipping time consumption is inversely proportional to engine power and grapple load size in feeding (Spinelli and Hartsough 2001; Van Belle 2006; Spinelli and Magagnotti 2010; Ghaffariyan et al. 2013). However, it should be borne in mind that an upper boundary for dimensions exists that can be handled by a chipper with a given engine power. As expected, there was a productivity difference as the studied chippers represented two different size classes for professional chipping on landings. The average chipping time per 1000 kg (dry mass) was 117 seconds for the Kesla C 1060 A chipper and 185 seconds for the Kesla C 4560 LF chipper. The importance of the raw material itself and its dimensions have been highlighted in previous studies (e.g. Spinelli and Hartsough 2001; Spinelli and Magagnotti 2010; Eriksson et al. 2013) and the non-existence of chipper idling time matches the figures reported by Röser et al. (2012). This is due to the large grapple loads and low number of crane cycles when chipping pulpwood or stems, compared to the chipping of logging residues or whole trees. In order to minimise the waiting times of the timber loader, the chipper productivity has to be higher. Therefore, it is logical that large disc chippers or drum chippers are used at terminals for chipping large-sized stemwood (Kärhä 2011). Studies of entire chipping systems are, however, needed to understand interactions between their different components and to select the appropriate capacities or technology for each stage (Spinelli et al. 2012; Eriksson et al. 2013; Krajnc and Dolsak 2014; Di Fulvio et al. 2015).

The productivity of the Kesla C 4560 LF chipper was somewhat higher than the similarly-sized Bruks 605 and the Kesla 645 chippers powered by a 157 kW Valtra 213 and a 270 kW John Deere 8345R farm tractor (Johannesson et al. 2012; Eliasson et al. 2015) in the chipping of partly delimbed tree sections from mixture forests. The fuel consumption of tractor-powered Kesla chippers were similar, but 0.6 litres more than the fuel consumption of the Bruks 605 chipper (Johannesson et al. 2012). According to Spinelli et al. (2011), the drum chippers’ fuel consumption per unit of dry mass seem to be rather constant and in the range of 2.7– 3.6 litres per oven dry tonne (odt). In Austria a truck- mounted and powered chipper had an average fuel consumption of 3.2 litres per odt (Holzleitner et al. 2013). The productivity of the Kesla C 1060A chipper was more within range compared to the similarly-sized Eschlböck Biber 92 drum chipper powered by a 358 kW Claas Xerion farm tractor (Eliasson et al. 2015) and the truck-mounted Pezzolato PTH 1200/280 drum chipper powered by a 397 kW MAN TGA 540 truck engine (Eliasson et al. 2014). Equipped with a 100 mm × 100 mm sieve, the Eschlböck Biber 92 chipper produced 30 odt E0h–1 when chipping partly delimbed tree sections from mixed forests (Eliasson et al. 2015). The chipping productivity of the Pezzolato PTH 1200/280 chipper, equipped with a 170 mm × 60 mm sieve, was 39.3 odt E0h–1 when chipping pulpwood.

The chipping productivity and fuel consumption of the Morbark 30 RXL disc chipper (engine power 932 kW) ranged from 53 to 72 odt E0h–1 and from 2.3 to 3.6 litres odt–1, when chipping defective roundwood logs or partly delimbed birch and low-diameter spruce tree sections from thinnings at a terminal (Eliasson et al. 2012b). At a terminal, the large CBI 6400 drum chipper (engine power 787 kW) produced chips with 98 odt E0h–1 and consumed 1.6 litres of fuel per odt–1 when chipping defective roundwood logs (Eliasson and Johannesson 2014). The chipping productivity and fuel consumption of the Erjo 2300SMA disc chipper (total engine power 692 kW) ranged from 80 to 95 odt E0h–1 and 1.5 – 1.6 litres E0h–1 when chipping defective roundwood logs at a terminal (Eliasson et al. 2012c).

For the chippers, the particle size distribution can be adjusted by altering parameters such as speed of rotation, feeding rate, knife sharpening and sieve mesh size, with smaller average particle sizes requiring more time and energy (e.g. Eriksson et al. 2013; Di Fulvio et al. 2015). The feeding speeds of the Kesla C 4560 LF and the Kesla C 1060A were not measured but the presumably somewhat higher feeding speed of the Kesla C 4560 LF chipper might explain the observed statistically significant difference in the particle size class 31.5–45 mm (cf Krajnc and Dolsak 2013; Krajnc and Dolsak 2014; Eliasson et al. 2015). The Kesla C 4560 LF chipper was equipped with the narrower 80 mm × 80 mm sieve but the frequency was higher in the particle size class 31.5–45 mm compared to the Kesla C 1060A equipped with the 100 mm × 100 mm (Fig. 5).

There is inadequate information on the mechanisms of chip formation (e.g. Krajnc and Dolsak 2013; Krajnc and Dolsak 2014; Civitarese et al. 2015). For drum chippers, sieve mesh size may determine the mean particle size of the main particle fraction (Kuptz and Hartman 2015).The use of a sieve between the drum and auger, which extracts the chips from the drum casing, introduces resistance in the chip extraction and is dependent on the total sieve area, the mesh size of the sieve and the inflow of chips through the sieve (Eliasson et al. 2015). If the amount of chips per time unit is large, all chips smaller than the mesh will not be able to leave the drum casing but will be chipped further (Eliasson et al. 2015). Kuptz and Hartman (2015) found that smaller sieve meshes strongly reduced particle length. In addition, wood properties have an impact on chip formation. Nati et al. (2010) stated that the use of small sieve meshes on pine material does not seem to offer any significant reduction in oversize particles, the presence of which is already very limited compared to poplar material. Therefore, large sieve meshes should be used when chipping pine material (Nati et al. 2010).

The produced amount of chips, productivity and fuel were measured as dry masses to ensure comparability with other studies. The performed study was a rather short analysis of two chippers at the terminal and thus it was not possible to achieve representative data on delays, relocation times, etc., affecting the operational work. Therefore, all reported productivities and fuel consumptions relate to effective chipping work excluding all by times and delays. Different operators are known to have a significant effect on overall productivity in forest operations due to varying motoric skills, work experience and decision-making abilities (e.g. Ovaskainen et al. 2004; Purfurst 2010; Palander et al. 2012). However, the feeding of a chipper with pulpwood is a simpler operation than felling and processing trees with a harvester, and therefore we can assume that differences related to to an experienced operator’s skills are lower (Röser et al. 2012; Nati et al. 2014). Spinelli and Magagnotti (2010) regarded the operator’s effect on commercial chipping operations as secondary, and the between-operator’s differences were not significant, resulting in its exclusion from their models.

The impact of wood storage time on the chemical and physical technical specifications of wood chips was evaluated by chipping pulpwood from eight different age groups of stems that were logged between 2 and 21 months previously. It was expected that there would be some differences in the moisture content of pulpwood with different storage times. The observed difference was clear between fresh pulpwood (2 months in storage) and 21 months in storage, but it was not so clear in other age groups. Effects of weather conditions during storing are very important; after tree cutting, wood starts to react with the surrounding microclimate (Routa et al. 2015a). In Nordic conditions, the moisture content of wood drops rapidly in the spring. In late August and September, evaporation usually decreases and the moisture content of the wood increases, in some cases even above the “green” moisture after cutting. Maximizing natural drying and minimizing re-moistening are key elements in the quality assessment of energy wood (Routa et al. 2012). In Finnish conditions, the moisture content of wood can increase significantly during the winter, and it is important to cover energy woodpiles if there is a need to store them over the winter (Röser et al. 2011; Nurmi 2014; Routa et al. 2015b). It is possible to achieve the same results for moisture content of energy wood through natural drying after a couple of months’ storage in good conditions as would be the case after 20 months’ storage (Nurmi and Hillebrand 2007; Laurila and Lauhanen 2010; Kuptz and Hartmann 2015).

The amount of extractives had no statistically significant difference in terms of the different storage time groups. However, the total amount was highest with fresh pulpwood. The fresh pulpwood was logged two months before the study took place, which means that the wood was no longer so fresh. The amount of volatiles had no statistically significant differences in terms of the different storage time groups either. There was no discernible trend between storage time groups. The amount and composition of extractive organic compounds in wood depend on the species of tree, time of year, tree genetics and age, and they also vary within individual plants (Granström 2005).

The chipped pulpwood lots were selected randomly according to their storage time from normal timber flow, which limits the detailed generalisation of the impacts of storage time on the chemical and physical technical specifications of wood chips at stand or tree level. In this respect, it is useful to consider that in large-scale wood biomass procurement at biorefineries, the annual harvesting volumes are great and material parameters, excluding tree species and timber dimensions, cannot be influenced or are difficult to affect. Due to the seasonal nature of wood procurement in Finland, there is also an obvious need to store wood, and only the raw material available can be used during production which heterogeneousness storage times of raw materials. The reported basic densities (kg m–3) of chipped wood material are similar to the softwood raw material used for chemical pulping in Finnish sulphate pulp mills (Lindblad and Verkasalo 2001).

Chipper type was found to be statistically significant to the levels of ash content; the reason for this might be the working technique of the Kesla C 4560 LF chipper operator. He constantly shook the pulpwood grapple load during the boom movement from the pile to the feeding table of the chipper in order to get rid of contingent impurities such as sand, small stones or mineral soil. The particle size distributions with the Kesla C 1060 A and the Kesla C 4560 LF were quite uniform, and the storage time of the pulpwood had no significant effect on particle size distribution in any chip size classes. One reason might be that the basic density of chipped wood was homogenous and there was no statistical difference between different storage times. During shearing and the subsequent journey through the chipper mechanism, chips tend to break and breakage is likely to be greater with weaker wood (Spinelli and Maganotti 2013). The use of new sharp knives is likely to affect chip quality, as witnessed by the absence of oversized particles and by the moderate presence of fines. The use of a narrower 80 mm × 80 mm sieve on Scots pine material does not seem to offer any benefit compared to a 100 mm × 100 mm sieve in terms of chip quality.

References

Alakangas E., Impola R. (2014). Puupolttoaineiden laatuohje. [Quality norms for wood fuels]. VTT-M–07608–13 – päivitys 2014. Bioenergia ry, Energiateollisuus ry and Metsäteollisuus ry. 66 p. [In Finnish].

Anerud E., Jirjis R. (2011). Fuel quality of Norway spruce stumps – influence of harvesting technique and storage method. Scandinavian Journal of Forest Research 26(3): 257–266. http://dx.doi.org/10.1080/02827581.2011.561807.

Bäfver L., Renström C. (2013). Fraktionsfördelning som kvalitetsparameter för skogsbränsle – kraft- och värmeverkens perspektiv. [Fraction distribution as a quality parameter of energy wood, from the perspective of combined heat and power plants and heating plants]. Arbetsrapport Från Skogforsk nr. 805–2013. 26 p. [In Swedish with English summary].

Civitarese V., Del Giudice A., Suardi A., Santangelo E., Pari L. (2015). Study on the effect of a new rotor designed for chipping short rotation woody crops. Croatian Journal of Forest Engineering 36(1): 101–108.

Di Fulvio F., Eriksson G., Bergström D. (2015). Effects of wood properties and chipping length on the operational efficiency of a 30 kW electric disc chipper. Croatian Journal of Forest Engineering 36(1): 85–100.

Eliasson L., Johannesson T. (2014). Flisning av bränsleved och delkvistad energived med en stor trumhugg – CBI 6400. [Chipping of stem wood and partly delimbed energy wood using a large drum chipper, CBI 6400, at a terminal]. Arbetsrapport Från Skogforsk nr. 835 – 2014. 12 p. [In Swedish with English summary].

Eliasson L., Granlund P., von Hofsten H., Björheden R. (2012a). Studie av en lastbilsmonterad kross – CBI 5800. [Study of a truck-mounted CBI 5800 grinder]. Arbetsrapport Från Skogforsk nr. 775 – 2012. 16 p. [In Swedish with English summary].

Eliasson L., Granlund P., Johannesson T., von Hofsten H., Lundström H. (2012b). Flisstorlekens effekt på en stor skivhuggs bränsleförbrukning och prestation. [Effects of target chip size on performance, fuel consumption and chip quality for a large disc chipper]. Arbetsrapport Från Skogforsk nr. 776 – 2012. 10 p. [In Swedish with English summary].

Eliasson L., Granlund P., Lundström H. (2012c). Effekter på bränsleförbrukning, prestation och fliskvalitet av klenträd vs bränsleved som råvara vid flisning med en stor skivhugg. [Effects of raw material on performance, fuel consumption and chip quality of a large disc chipper]. Arbetsrapport Från Skogforsk nr. 777 – 2012. 10 p. [In Swedish with English summary].

Eliasson L., Lombardini C., Granlund P., Magagnotti N., Spinelli R. (2014). Prestation och bränsleförbrukning för en lastbilsmonterad Pezzolato PTH 1200/820 flishugg. [Performance and fuel consumption of a truck-mounted Pezzolato PTH 1200/820 chipper]. Arbetsrapport Från Skogforsk nr. 823 – 2014. 12 p. [In Swedish with English summary].

Eliasson L., von Hofsten H., Johannesson T., Spinelli R., Thierfelder T. (2015). Effects of sieve size on chipper productivity, fuel consumption and chip size distribution for open drum chippers. Croatian Journal of Forest Engineering 36(1): 11–17.

Eriksson A., Eliasson L., Hansson P.-A., Jirjis R. (2014a). Effects of supply chain strategy on stump fuel cost: a simulation approach. International Journal of Forestry Research. Volume 2014, Article ID 984395. 11 p. http://dx.doi.org/10.1155/2014/984395.

Eriksson A., Eliasson L., Jirjis R. (2014b). Simulation-based evaluation of supply chains for stump fuel. International Journal of Forest Engineering 25(1): 23–36. http://dx.doi.org/10.1080/14942119.2014.892293.

Eriksson G., Bergström D., Nordfjell T. (2013). The state of the art in woody biomass comminution and sorting in Northern Europe. International Journal of Forest Engineering 24(3): 194–215. http://dx.doi.org/10.1080/14942119.2013.852391.

Filbakk T., Høibø O.A., Dibdiakova J., Nurmi J. (2011). Modelling moisture content and dry matter loss during storage of logging residues for energy. Scandinavian Journal of Forest Research 26(3): 267–277. http://dx.doi.org/10.1080/02827581.2011.553199.

Ghaffariyan M.R., Spinelli R., Brown M. (2013). A model to predict productivity of different chipping operations. Southern Forests: a Journal of Forest Science 75(3): 129–136. http://dx.doi.org/10.2989/20702620.2013.816233.

Granström K. (2005). Emissions of volatile organic compounds from wood. Karlstad University Studies 2005:6. Dissertation. 56 p.

Hakkila P. (1989). Utilization of residual biomass. Springer series in wood science. Springer-Verlag. 568 p. http://dx.doi.org/10.1007/978-3-642-74072-5.

Harstela P. (1991). Work studies in forestry. University of Joensuu. Silva Carelica 18. 41 p.

Hartmann H., Böhm T., Jensen P.D., Temmerman M., Rabier F., Golser M. (2006). Methods for size classification of wood chips. Biomass and Bioenergy 30(11): 944–953. http://dx.doi.org/10.1016/j.biombioe.2006.06.010.

Holzleitner F., Kanzian C., Höller N. (2013). Monitoring the chipping and transportation of wood fuels with a fleet management system. Silva Fennica 47(1) article 899. http://dx.doi.org/10.14214/sf.899.

Hosseini S., Shah N. (2009). Multiscale modelling of hydrothermal biomass pretreatment for chip size optimization. Bioresource Technology 100(9): 2621–2628. http://dx.doi.org/10.1016/j.biortech.2008.11.030.

Jensen P., Mattson J., Kofman P., Klausner A. (2004). Tendency of wood fuels from whole trees, logging residues and roundwood to bridge over openings. Biomass and Bioenergy 26(2): 107–113. http://dx.doi.org/10.1016/S0961-9534(03)00101-6.

Jirjis R. (1995). Storage and drying of wood fuel. Biomass and Bioenergy 9(1–5): 181–190. http://dx.doi.org/10.1016/0961-9534(95)00090-9.

Jirjis R. (2005). Effects of particle size and pile height on storage and fuel quality of comminuted Salix viminalis. Biomass and Bioenergy 28(2): 193–201. http://dx.doi.org/10.1016/j.biombioe.2004.08.014.

Jirjis R., Theander O. (1990). The effect of seasonal storage on the chemical composition of forest residue. Scandinavian Journal of Forest Research 5(1–4): 437–448. http://dx.doi.org/10.1080/02827589009382626.

Johannesson T., Fogdestam N., Granlund P., Eliasson L. (2012). Effeter av olika inställningar av den eftersträvade flislängden på prestation och bränsleförbrukning för en Bruks 605 trumhugg. [Effects of chip-length settings on productivity and fuel consumption of a Bruks 605 drum chipper]. Arbetsrapport Från Skogforsk nr. 782– 2012. 15 p. [In Swedish with English summary].

Junginger M., Faaij A., Björheden R., Turkenburg W.C. (2005). Technological learning and cost reductions in wood fuel supply chains in Sweden. Biomass and Bioenergy 29(6): 399–418. http://dx.doi.org/10.1016/j.biombioe.2005.06.006.

Kärhä K. (2011). Industrial supply chains and production machinery of forest chips in Finland. Biomass and Bioenergy 35(8): 3404–3413. http://dx.doi.org/10.1016/j.biombioe.2010.11.016.

Krajnc M., Dolsak B. (2013). Computer and experimental simulation of biomass production using drum chipper. International Journal of Simulation Modelling 12(1): 29–49. http://dx.doi.org/10.2507/IJSIMM12(1)4.223.

Krajnc M., Dolsak B. (2014). The influence of drum chipper configuration on the quality of wood chips. Biomass and Bioenergy 64: 133–139. http://dx.doi.org/10.1016/j.biombioe.2014.03.011.

Kristensen E.F., Kofman P.D. (2000). Pressure resistance to air flow during ventilation of different types of wood fuel chip. Biomass and Bioenergy 18(3): 175–180. http://dx.doi.org/10.1016/S0961-9534(99)00089-6.

Kuptz D., Hartmann H. (2015). The effect of raw material and machine setting on chipping performance and fuel quality – a German case study. International Journal of Forest Engineering 26(1): 60–70. http://dx.doi.org/10.1080/14942119.2015.1021529.

Laitila J. Leinonen A., Flyktman M., Virkkunen M., Asikainen A. (2010). Metsähakkeen hankinta- ja toimituslogistiikan haasteet ja kehittämistarpeet. [Challenges and development needs of forest chips procurement and delivery logistics]. VTT Tiedotteita/Research – Notes 2564. 143 p. [In Finnish].

Laurila J. (2013). Moisture content, weight loss and potential of energy wood in South and Central Ostrobothnia regions in western Finland. Dissertationes Forestales 167. 45 p. http://dx.doi.org/10.14214/df.167.

Laurila J., Lauhanen R. (2010). Moisture content of Norway spruce stump wood at clear cutting areas and roadside storage sites. Silva Fennica 44(3): 427–434. http://dx.doi.org/10.14214/sf.140.

Lindblad J., Verkasalo E. (2001). Teollisuus- ja kuitupuuhakkeen kuivatuoretiheys ja painomittauksen muuntokertoimet. [Basic density and conversion factors for industrial and pulpwood chips]. Metsätieteen aikakauskirja 3/2001: 411–431. [In Finnish].

Lu H., Ip E., Scott J., Foster P., Vickers M., Baxter L. (2010). Effects of particle shape and size on devolatilization of biomass particle. Fuel 89(5): 1156–1168. http://dx.doi.org/10.1016/j.fuel.2008.10.023.

Magagnotti N., Kanzian C., Schulmeyer F., Spinelli R. (2013). A new guide for work studies in forestry. International Journal of Forest Engineering (24)3: 249–253. http://dx.doi.org/10.1080/14942119.2013.856613.

Mattsson J.E. (1990). Basic handling characteristics of wood fuels: angle of repose, friction against surfaces and tendency to bridge for different assortments. Scandinavian Journal of Forest Research 5(1–4): 583–597. http://dx.doi.org/10.1080/02827589009382641.

Nati C., Spinelli R., Fabbri P. (2010). Wood chips distribution in relation to blade wear and screen use. Biomass and Bioenergy 34(5): 583–587. http://dx.doi.org/10.1016/j.biombioe.2010.01.005.

Nati C., Eliasson L., Spinelli R. (2014). Effect of chipper type, biomass type, and blade wear on productivity, fuel consumption and product quality. Croatian Journal of Forest Engineering 35(1): 1–7.

Nurmi J. (2014). Changes in volumetric energy densities during storage of whole-tree feed stocks from silvicultural thinnings. Biomass and Bioenergy 61: 114–120. http://dx.doi.org/10.1016/j.biombioe.2013.12.001.

Nurmi J., Hillebrand K. (2007). The characteristics of whole tree fuel stock from silvicultural cleanings and thinnings. Biomass and Bioenergy 31(6): 381–392. http://dx.doi.org/10.1016/j.biombioe.2007.01.010.

Ovaskainen H., Uusitalo J., Väätäinen K. (2004). Characteristics and significance of a harvester operators’ working technique in thinnings. International Journal of Forest Engineering 15(2): 67–77.

Palander T., Ovaskainen H., Tikkanen L. (2012). An adaptive work study method for identifying the human factors that influence the performance of human-machine system. Forest Science 58(4): 377–389. http://dx.doi.org/10.5849/forsci.11-013.

Pari L., Civitarese V., del Giudice A., Assirelli A., Spinelli R., Santangelo E. (2013). Influence of chipping device and storage method on the quality of SRC poplar biomass. Biomass and Bioenergy 51: 169–176. http://dx.doi.org/10.1016/j.biombioe.2013.01.019.

Paulrud S., Nilsson C. (2004). The effects of particle characteristics on emissions from burning wood fuel powder. Fuel 83 (7–8): 813–821. http://dx.doi.org/10.1016/j.fuel.2003.10.010.

Pochi D., Civitarese V., Fanigliulo R., Spinelli R., Pari L. (2015). Effect of poplar fuel wood storage on chipping performance. Fuel Processing Technology 134: 116-121. http://dx.doi.org/10.1016/j.fuproc.2015.01.023.

Purfurst F.T. (2010). Learning curves of harvester operators. Croatian Journal of Forest Engineering 31(2): 89–97.

Rauch P. (2010). Stochastic simulation of forest fuel sourcing models under risk. Scandinavian Journal of Forest Research 25(6): 574–584. http://dx.doi.org/10.1080/02827581.2010.512876.

Rauch P. (2013). Improving the primary forest fuel supply chain. Bulletin of the Transilvania University of Brasov. Series II. Vol. 6 (55) No. 1 – 2013. 8 p.

Rinne S. (2010). Energiapuun haketuksen ja murskauksen kustannukset. [The cost of wood fuel chipping and crushing]. Lappeenranta University of Technology. Master’s thesis. 102 p. [In Finnish].

Röser D., Mola-Yudego B., Sikanen L., Prinz R., Gritten D., Emer B., Väätäinen K., Erkkilä A. (2011). Natural drying treatments during seasonal storage of wood for bioenergy in different European locations. Biomass Bioenergy 35: 4238–4247. http://dx.doi.org/10.1016/j.biombioe.2011.07.011.

Röser D., Mola-Yudego B., Prinz R., Emer B., Sikanen L. (2012). Chipping operations and efficiency in different operational environments. Silva Fennica 46(2): 275–286. http://dx.doi.org/10.14214/sf.60.

Rottensteiner C., Tsioras P., Neumayer H., Stampfer K. (2013). Vibration and noise assessment of tractor-trailer and truck-mounted chippers. Silva Fennica 47(5) article 984. http://dx.doi.org/10.14214/sf.984.

Routa J., Kolström M., Ruotsalainen J., Sikanen L. (2012). Forecasting moisture changes of energy wood as a part of logistic management. In special Issue: Abstracts for international conferences organized by LSFRI Silava in copoperation with SNS and IUFRO. Mezzinatne 25: 33–35.

Routa J., Asikainen A., Björheden R., Laitila J., Röser D. (2013). Forest energy procurement - state of the art in Finland and Sweden. WIREs Energy and Environment 2(6): 602–613. http://dx.doi.org/10.1002/wene.24.

Routa J., Kolström M., Ruotsalainen J., and Sikanen L. (2015a). Precision measurement of forest harvesting residue moisture change and dry matter losses by constant weight monitoring. International Journal of Forest Engineering 26(1): 71-83. http://dx.doi.org/10.1080/14942119.2015.1012900.

Routa J., Kolström M., Ruotsalainen J., and Sikanen L. 2015b. Validation of prediction models for estimating the moisture content of small diameter stem wood. Croatian Journal of Forest Engineering, submitted.

Shen J., Wang X., Garcia-Perez M., Mourant D., Rhodes M., Li C. (2009). Effects of particle size on the fast pyrolysis of oil mallee woody biomass. Fuel 88 (10): 1810–1817. http://dx.doi.org/10.1016/j.fuel.2009.05.001.

Spinelli R., Hartsough B.R. (2001). A survey of Italian chipping operations. Biomass and Bioenergy 21(6): 433–444. http://dx.doi.org/10.1016/S0961-9534(01)00050-2.

Spinelli R., Magagnotti N. (2010). A tool for productivity and cost forecasting of decentralised wood chipping. Forest Policy and Economics 12(3): 194–198. http://dx.doi.org/10.1016/j.forpol.2009.10.002.

Spinelli R., Magagnotti N. (2013). Performance of a small-scale chipper for professional rural contractors. Forest Science and Practice 15(3): 206–213. http://dx.doi.org/10.1007/s11632-013-0308-5.

Spinelli R., Magagnotti N. (2014). Determining long-term chipper usage, productivity and fuel consumption. Biomass and Bioenergy 66: 442–449. http://dx.doi.org/10.1016/j.biombioe.2014.04.016.

Spinelli R., Visser R. (2009). Analyzing and estimating delays in wood chipping operations. Biomass and Bioenergy 33(3): 429–433. http://dx.doi.org/10.1016/j.biombioe.2008.08.003.

Spinelli R., Hartsough B.R., Magagnotti N. (2005). Testing mobile chippers for chip size distribution. International Journal of Forest Engineering 16(2): 29–35.

Spinelli R., Nati C., Sozzi L., Magagnotti N., Picchi G. (2011a). Physical characterization of commercial woodchips on the Italian energy market. Fuel 90(6): 2198–2202. http://dx.doi.org/10.1016/j.fuel.2011.02.011.

Spinelli R., Magagnotti N., Paletto G., Preti C. (2011b). Determining the impact of some wood characteristics on the performance of a mobile chipper. Silva Fennica 45(1): 85–95. http://dx.doi.org/10.14214/sf.33.

Spinelli R., Ivorra L., Magagnotti N., Picchi G. (2011c). Performance of a mobile mechanical screen to improve the commercial quality of wood chips for energy. Bioresource Technology 102: 7366–7370. http://dx.doi.org/10.1016/j.biortech.2011.05.002.

Spinelli R., Cavallo E., Facello A., Magagnotti N., Nati C., Paletto G. (2012). Performance and energy efficiency of alternative comminution principles: chipping versus grinding. Scandinavian Journal of Forest Research 27(4): 393–400.

Spinelli R., Cavallo E., Eliasson L., Facello A. (2013). Comparing the efficiency of drum and disc chippers. Silva Fennica 47(2) article 930. http://dx.doi.org/10.14214/sf.930.

Stampfer K., Kanzian C. (2006). Current state and development possibilities of wood chip supply chains in Austria. Croatian Journal of Forest Engineering 27(2): 135–145.

Strelher A. (2000). Technologies of wood combustion. Ecological Engineering (16): 25–40. http://dx.doi.org/10.1016/S0925-8574(00)00049-5.

Suadicani K., Gamborg C. (1999). Fuel quality of whole-tree chips from freshly felled and summer dried Norway spruce on a poor sandy soil and a rich loamy soil. Biomass and Bioenergy 17(3): 199–208. http://dx.doi.org/10.1016/S0961-9534(99)00039-2.

Uusvaara O. (1978). Teollisuushakkeen ja purun painomittaus. [Estimation of industrial chip and sawdust weight]. Folia Forestalia 341. 18 p. [In Finnish with English summary].

Uusvaara O., Verkasalo E. (1987). Metsähakkeen tiiviys ja muita teknisiä ominaisuuksia. [Solid content and other technical properties of forest chips]. Folia Forestalia 683. 53 p. [In Finnish with English summary].

Van Belle, J-F. (2006). A model to estimate fossil CO2 emissions during the harvesting of forest residues for energy-with an application on the case of chipping. Biomass and Bioenergy 30(12): 1067–1075. http://dx.doi.org/10.1016/j.biombioe.2005.12.019.

Wegener J., Wegener T. (2014). Wood chipping with helical chippers: observations based on the construction and the use of different prototypes. Applied Engineering in Agriculture 28(4): 491–501. http://dx.doi.org/10.13031/2013.42079.

Wolfsmayr U.J., Rauch P. (2014). The primary forest fuel supply chain: a literature review. Biomass and Bioenergy (60): 203–221. http://dx.doi.org/10.1016/j.biombioe.2013.10.025.

Total of 80 references.