Finnish wood harvesting contractors’ risks in Russia

Karvinen S., Nummelin T. (2015). Finnish wood harvesting contractors’ risks in Russia. Silva Fennica vol. 49 no. 5 article id 1394. https://doi.org/10.14214/sf.1394

Highlights

- Disagreements on wood measurement and payment delays were the most important economic risks

- Dependency on a few clients created risk for unfavourable agreements and work interruptions

- Fires in site huts caused the risk of personal injury

- Inadequate professional skills were serious economic and work interruption risks

- Unhealthy competition, the functioning of the authorities, and infrastructure were important external risk factors.

Abstract

Finnish wood harvesting contractors have been working in Russia since the 1990s and new entrepreneurs are still interested in starting operations there, even though Russia is not an easy business environment. This study identifies the most significant risks in contracting in Russia. Risks were identified through expert evaluation and a risk analysis was conducted by using a risk matrix. Possible preventative measures were assessed for the identified risks. Some risks were found to be common in Russia and Finland, for example a limited number of clients, dependency on a few clients, and weak negotiating positions. A stable amount of work, i.e. the availability of stands for harvesting, was also a challenge on the both sides of border. Typical problems in Russia were breaches of contract, especially disagreements on wood measurement and payment delays, potentially causing serious economic losses. Specific to Russia were problems related to machine service and spare parts, as well as security issues. The professional skills of machine operators, as well as changing work motivation were risks in Russia. Cultural differences lead to more challenging supervision and management of staff. Among the external factors, the most challenging in Russia were unhealthy competition in the marketplace and non-transparent and the unpredictable procedures of the authorities. In Russia problems caused by seasonality are amplified by the sparse road network and longer downtime. The revealed specific features of the Russian business environment can help Finnish wood harvesting companies to plan a risk management process for operations in Russia.

Keywords

Russia;

contracting;

wood harvesting;

risk analysis

Received 20 May 2015 Accepted 21 August 2015 Published 9 September 2015

Views 90594

Available at https://doi.org/10.14214/sf.1394 | Download PDF

1 Introduction

Dozens of Finnish wood harvesting contractors have been operating in Russia since the 1990s. Even though many of the contractors have ended operations in Russia due to numerous challenges, a number of them continue and new entrepreneurs are still interested in contracting in Russia. A special training program was even organised during 2013–2014 to enhance the business opportunities of Finnish wood harvesting companies in Russia (WOPE 2015), and a study was conducted to collect the necessary information on business security for the training (Karvinen et al. 2014).

Every company faces factors that make it uncertain whether and when its objectives will be achieved, and the effect of this uncertainty on the objectives is “risk” (International Organization for Standardization 2009). Russia is a challenging business environment and risks are present in all kind of activities. Therefore, risk management should be an essential part of any operation.

In general, the most significant internal risks of machine contractors in Finland are related to personnel, machines, and materials (Nippala and Sauni 2004b). Some risks may also be involved in management, agreements, business activity and production (Nippala and Sauni 2004b). External risks are related to customers, subcontractors, the labour force, technology, markets, the public sector, and interest groups (Nippala and Sauni 2004b). Finnish wood harvesting contractors are typically small companies with three to six employees in addition to the entrepreneur (Rieppo 2010). The importance of professional employees is very high, which increases the risk involved in changes of personnel. For example, the skills of a harvester operator have a considerable impact on a company’s result and the difference between operators in work productivity can reach 40 per cent (Väätäinen et al. 2005). If the entrepreneur gets ill, in the worst case the company will be closed down (Mäkinen 1988). The ability to develop a business model and adapt to the changing business environment are characteristics for a successful wood harvesting contractor (Soirinsuo and Mäkinen 2009). Knowledge of economics and management skills are needed to a greater extent for successful business and retaining skilled personnel (Rummukainen et al. 2014). Rieppo (2010) finds that small entrepreneurs have good skills in their core business, but business knowledge is often inadequate in marketing, accounting, and administration. In this context, inadequate business skills are a weakness that poses risks to wood harvesting contractors.

The main part of wood harvesting is carried out in winter time and therefore seasonality notably affects the work of the wood harvesting contractor. As Väätäinen et al. (2008) state, changing amounts of harvesting work and unexpected downtime create uncertainty for a profitable business in Finland. The lack of suitable stands for harvesting is causing problems in operative management and increases downtime, and due to the seasonality machinery is not in full use and the work contracts of employees are suspended (Väätäinen et al. 2008). These factors of uncertainty lead to business and personnel risks. High capital expenditure and low solidity cause problems for small companies when adapting to seasonal variations (Penttinen et al. 2011). The wood harvesting contractor often has one or two permanent clients, i.e. dependency on the client is strong (Mäkinen 2002). As a result, the negotiation power of the contractor is weaker and the risk related to contracts increases.

In Russia the state owns the forests and leases them for wood harvesting for 10–49 years (Forest Code of the Russian Federation 2006). Traditionally, wood harvesting in Russia is the least profitable branch of the forest sector and wood harvesting companies face several problems (Karvinen et al. 2011; State Council of the Russian Federation 2013). In Russia the seasonality of wood harvesting is emphasised, as wood harvesting is concentrated in the winter months due to a lack of year-round forest roads (Goltsev et al. 2011; Suhanov 2014). The low-quality and sparse forest road network is a risk to wood harvesting contractors, as in the worst case scenario harvesting areas are unreachable or forest machines are left in the forest during frost heave periods (Shegelman and Lukashevich 2011).

According to Gerasimov and Karjalainen (2008), the weaknesses and threats associated with wood harvesting in Russia for a foreign company are, in addition to the poor infrastructure, for example a poor knowledge about wood resources, the low productivity of the labour, a high risk of accidents, a lack of qualified workers, corruption, and unsound business practices. The Russian studies indicate that the political risk is emphasised in the Russian forest sector, as state regulation and the political situation have a strong effect on this branch of industry (Golovko and Oganezova 2013; Katkova 2013). The heavy bureaucracy and non-transparent procedures of the authorities increase the possibility of corruption (Katkova 2012). Along with the road infrastructure and the functioning of the authorities, risks for Russian wood harvesting companies include forest damage, changes of export regulations, increased costs, the quality of forest resources, unfavourable weather conditions, a lack of qualified labour, and work safety (Golovko and Oganezova 2013; Katkova 2012; Kislenok 2008). However, no information is available on risks and risk management in wood harvesting in Russia from a foreign company’s or wood harvesting contractor’s perspective.

The purpose of this study was to identify the most significant risks for Finnish wood harvesting contractors working in Russia and to put them into perspective relative to work in Finland. The International Standard ISO 31000 for risk management (International Organisation for Standardization 2009), as well as the existing risk management guidelines tailored specially for Finnish machine contractors were used as guidance in the process. The consequences and probability of identified risks were assessed and risks evaluated in the framework of a hypothetical company. Furthermore, possible measures for risk treatment were described. The purpose was to produce information that can be useful for planning risk management process, and in particular for risk identification in the Finnish wood harvesting companies carrying out operations in Russia. The work was focused on the Russian business environment, while the general risks of machine contractors were not considered.

2 Materials and methods

2.1 Target group

The study’s target group consists of 40 Finnish wood harvesting contractors working in Russia. In Finland there are no relevant statistics available, and therefore statistics of the Russian Federation Customs were used to estimate the number of enterprises. It can be assumed that at the beginning of the contracting in Russia, machines were exported temporarily. During 2005–2007 forest machines were imported temporarily to Russia by 40 companies, excluding machine manufacturers and their dealers (Karvinen et al. 2014). The temporary export of forest machines ended by 2009 (Jutila et al. 2014; Karvinen et al. 2014). It is not possible to determine the number of wood harvesting contractors in the permanent export statistics, and for this reason the estimated number is the most reliable information available.

2.2 Risk identification

Risk identification was carried out by expert evaluation as evidence-based methods were not usable due to a lack of systematically collected data or checklists from earlier risk analysis. The team of experts consisted of three wood harvesting entrepreneurs and one wood procurement specialist, each with 20 years of experience in wood harvesting in Russia. Brainstorming was used as a supporting technique. Risks were recorded in lists according to themes using keywords as guidelines. Lists were circulated among the experts as long as new risks were noted, after which the theme was changed. Keyword lists were compiled according to the risk map of the machine contractor (Nippala and Sauni 2004a), taking into account the special characteristics of the Russian business environment (Table 1).

| Table 1. Keywords used in the risk identification process. | |

| Theme | Keywords |

| Business | profitability, solvency, cost calculation, pricing, investment planning, invoicing |

| Contracts | own contractual obligations and rights, attractiveness as contract partner, partners, lack of contracts |

| Services/ products | machine manufacturers, maintenance services, insurance, financing, accounting |

| Production | work on site, planning, interruptions, waste management, theft and vandalism, logistics, transfers |

| Machines/ premises | forest machines, transfer trucks, machine halls, storage, storage of dangerous materials |

| Culture | new operational environment, attitudes of local people, adaptation to the local business environment, differences in organisational culture and behaviour |

| Entrepreneur | key person risk, own knowledge and management, work motivation, economic conditions, family, use of time |

| Personnel | preconditions for working, professional skills, traffic, work safety, welfare at work, local labour, communication, work culture, health care |

| Markets | demand, business cycle, dependency on clients, competition, clients’ solvency, payment schedules, clients’ demands |

| Policy and authorities | political stability, legislation, customs clearance, taxation, working permissions, other permissions, supervision, regional practices |

| Infrastructure | road network, phone network, IT network, sites, accommodation |

| Natural conditions | storms, frost, rainy seasons, frost heave, animals, quality of forest resources |

To improve risk recognition an open question was included in a questionnaire concerning the operation models of Finnish wood harvesting contractors in Russia realised as a part of a thesis (Jurvanen 2015). Ten experienced forest machine contractors participated in the questionnaire. Respondents were asked to identify the most significant risks in contracting in Russia and to evaluate the probability and consequences of each risk. In addition, they assessed the significance of the risks identified by the expert team. The results were utilised in selecting risks for further processing.

2.3 Risk analysis

Risk analysis was realised in a working group that consisted of the two wood harvesting entrepreneurs participating in the risk identification team and an operational manager of a foreign wood harvesting company working in Russia. To ensure open discourse, the risk analysis was conducted for a hypothetical company. If a real company had been used, issues related to confidentiality and business secrets could have led to skewed results. The imaginary enterprise is registered in Russia and has over 10 years’ experience contracting in Russia. The company has 6–8 machines and the machinery is 5–10 years old, i.e. the share of liabilities is low. The annual amount of wood harvested is 250 000–300 000 m³. Risks were analysed for the last five years.

The consequence/probability matrix (risk matrix) was used as a tool for risk analysis. The risk matrix combines qualitative ratings of consequence and probability to produce a risk rating (International Electrotechnical Commission 2009). The matrix was also used to select the most significant risk among those identified for detailed evaluation. Probability was defined with a five-point numerical scale (Table 2), and consequences with a six-point numerical scale separately for economic losses, work interruptions, and personal injuries (Table 3).

| Table 2. Probability of risk. | ||

| Rate | Probability | Interpretation |

| 1 | Remote | Happens once in 50 years or less frequently |

| 2 | Unlikely | At most once in 10 years |

| 3 | Possible | At most once in 5 years |

| 4 | Likely | Once in a year |

| 5 | Very likely | More than once in a year |

| Table 3. Consequences of risk. | |||

| Rate | Economic loss | Interruption of work | Personal injury |

| 0 | No loss | No interruption | No injuries |

| 1 | < €5 000 | < 2 days | Mild injury of one person |

| 2 | €5 000–€9 999 | < 1 week | Mild injury of several people |

| 3 | €10 000–€49 999 | < 1 month | Serious injury of one person (permanent injury) |

| 4 | €50 000–€99 999 | < 3 months | Serious injury of several people (permanent injury) |

| 5 | €100 000–€300 000 | < 5 months | Death of one person |

| 6 | > €300 000 | > 6 months | Death of several people |

Scales of probability and consequence were adjusted to the context during the first expert meeting. The most severe personal injury was defined based on a real incident experienced by the team members. The highest rate of economic loss was adjusted to the average turnover of a wood harvesting enterprise in Finland, i.e. 300 000 euros (Rieppo 2010). The economic loss was evaluated on an annual basis. Work interruption was assessed in time, as it would have been difficult to unambiguously estimate the impact of interruption to turnover.

Risk levels 1–5 in the risk matrix were defined according to the risk management guide for machine contractors (Koneyrityksen riskienhallinta 2007): 1) Trivial risk; 2) Minor risk; 3) Moderate risk; 4) Serious risk; and 5) Extreme risk. The risk level of each matrix cell can be adjusted by weighting consequences or probability, or it can be symmetric (International Electrotechnical Commission 2009). As the target group of the study mainly consists of small companies with a low risk-bearing capacity, emphasis was put on consequences (Table 4). Risk levels were defined separately for economic losses, work interruptions, and personal injuries to avoid problems in weighting risks. When using one consequence class it is necessary to equalise personal injuries, money, and time, and it was not seen as reasonable in this study.

| Table 4. Consequence/probability matrix for producing risk level. | |||||||

| Probability | Consequence | ||||||

| 1 | 2 | 3 | 4 | 5 | 6 | ||

| 5 | Very likely | II | III | IV | V | V | V |

| 4 | Likely | II | III | III | IV | V | V |

| 3 | Possible | I | II | III | IV | IV | V |

| 2 | Unlikely | I | II | III | III | IV | V |

| 1 | Remote | I | I | II | III | IV | IV |

2.4 Risk evaluation and treatment

The meaning of risk was also evaluated according to the risk management guide of a machine contractor (Table 5). Relevant preventative measures were recorded for risk treatment, i.e. removing sources of risks and changing the probability of occurrence or consequences. Contract risk was assessed as extreme by the expert group, and it was selected for more detailed study. Fault tree analysis was used as a method of recognising and analysing sources of risk. A fault tree can be used qualitatively to identify causes and pathways that lead to a failure, i.e. a so-called top event (International Electrotechnical Commission 2009).

| Table 5. Action plan for risk treatment (Koneyrityksen riskienhallinta 2007). | |

| Risk severity | Action |

| 1. Trivial | Risk is so small that no action is needed |

| 2. Minor | Action is not necessarily needed Situation has to be followed to be able to control it |

| 3. Moderate | Action is needed to check or clarify the situation Action is possibly needed |

| 4. Serious | Necessary to reduce risk, but taking into account social, economic, and other aspects Action is needed |

| 5. Extreme | Removing or reducing risk is necessary regardless of costs If reducing risk is not possible, work should be forbidden permanently |

3 Results

3.1 Identified risks

The expert team and respondents of the questionnaire “Finnish wood harvesting contractor in Russia” identified approximately 30 risks present in working in Russia (Table 6). The list covers the risks estimated as moderate, serious, or extreme by over half of the questionnaire respondents. The estimation of a risk’s importance was only approximate, as response alternatives only provided a risk level without the unambiguous explanation of terms and scoring. Therefore, the results were only used to screen out less significant risks among those identified in the expert meeting.

| Table 6. Possible risks for Finnish wood harvesting contractors in Russia. | |

| Theme | Risk |

| Business | Breaches of contract by client |

| Dependency on client, limited number of potential clients | |

| Low profitability of business | |

| Machines, premises, and production | Availability and professionalism of service |

| Changing production volumes make planning difficult and decrease profitability | |

| Problems in operational planning caused by interruptions in work between harvesting sites | |

| Availability of spare parts | |

| Theft of equipment and supplies | |

| Machinery and hall fires | |

| Personnel and culture | Inadequate know-how of the entrepreneur regarding Russian conditions |

| Workers’ inadequate professional skills and ability to work independently | |

| Difficulties in supervision of work due to different mindset (ideas about right and wrong, agreeing, respecting others’ property) | |

| Misunderstandings caused by interpretation of foreign language | |

| Neglecting one’s own and others’ safety | |

| Use of alcohol during work hours | |

| Markets | Sensitivity to general economic fluctuations |

| Lack of financing | |

| Underpricing competitors | |

| Policy and authorities | Non-transparent procedures of the authorities, unpredictability of the authorities (interpretation of legislation, waiting for inspections) |

| Quick and unexpected changes of laws and regulations | |

| Inflexible practice of receiving permissions | |

| Forest fires not extinguished, danger for people and machinery | |

| Infrastructure and natural conditions | Long frost heave period causing downtime |

| Roads are not ploughed in winter, no access to harvesting site | |

| Unpredictable time consumption and productivity due to the changing structure of forests | |

| Help is not available quickly in cases of sickness and injury | |

3.2 Probability and consequences of identified risks

The probability and consequences were estimated for the identified risks. Business risks were very likely to happen, i.e. there were breaches of contract more than once a year. Differences in measured wood volumes could cause, for example, an economic loss of up to 300 000 euros for a company. Delays of payments could cause tens of thousands of euros in losses, if the claims are compared to the costs of loans. A limited number of clients and their large size lead to business risk when new contracts are concluded, which was usually once every five years. The contractor’s negotiation power is weaker than that of a big client, and thus rates can be unfavourable for the contractor and reduce profitability. For example, the rate for one cubic meter can be one euro less, and consequently the economic loss reaches 300 000 euros over the course of a year. Dependency on one client could possibly lead to over 50 000 euros economic loss and interruption of work for months, if the client meets difficulties and contractor needs to substitute this with a new client.

Spare parts and service caused a risk that was likely to happen for the example company. More than once a year needed spare parts were not available, and once a year machinery repairing services were delivered with too long delay. However, economic losses were small, amounting to a couple of thousand euros, and work interruptions lasted less than a week. Thefts of spare parts and supplies were repeated several times per year and caused thousands of euros in losses. An annually occurring risk related to production and operative planning was the lack of suitable stands for harvesting. Machinery is expected to be in full utilisation, but the client’s operation may lead to work interruptions. In these cases, economic losses were from five to ten thousand euros annually, and interruptions lasted less than a week. Fires were an unlikely risk, but they could have serious consequences and even lead to death if they happened in site huts. Fires in machinery could bring economic losses equal to up to 100 000 euros.

Risks related to personnel and cultural differences were common for the studied company. More than once a year the inadequate professional skills of workers caused damage to machinery; the losses could be in the tens of thousands of euros and mean work interruptions for over a month. It is very likely that the different mindset of the workers made supervision difficult, although the losses caused by this were minor. Instead, decreasing work motivation could bring tens of thousands of euros in losses annually. In addition, it was very likely that alcohol was used during working hours, causing small losses in the produced wood volumes. The use of alcohol could also lead to minor injuries. Tens of thousands of euros in losses could possibly be caused by the entrepreneur’s inadequate ability to adapt to the Russian operational environment.

Unhealthy competition was a possible market-related risk; this process is repeated once every five years and leads to economic losses of up to 300 000 euros. Underpricing by competitors and competition from the client’s own harvesting department could have led to lower rates.

More than once a year risks arose due to the government policy and the actions of the authorities. The varying interpretation of laws and regulations could lead to fines and economic losses could be 50 000 euros annually. Inflexible and slow permission practices caused small economic losses every year. Once every five years authority inspections could interrupt the enterprise’s work or changes in legislation could generate unforeseeable payments, both leading to the economic loss of 10 000 euros at the most.

Weak infrastructure, especially roads in a poor condition, caused long downtime during the heave frost period in springs and autumns. Economic loss was less than 10 000 euros, but the work interruptions could be for several months.

Some of the identified risks were not considered, as they were seen as trivial. For example, the different structure of forests in Russia compared with Finland is not a risk for a company with over ten years of experience in Russia, as time consumption and productivity can be estimated correctly on the basis of earlier experience. For a new, inexperienced company it is difficult to take into account additional costs caused by stand structure and different tree species, such as aspen, and the average rate of harvesting work may not cover the costs of less favourable stands. As a consequence, risk related to profitability would be extreme and economic losses could reach 300 000 euros.

3.3 Risk evaluation and identification of risk management actions

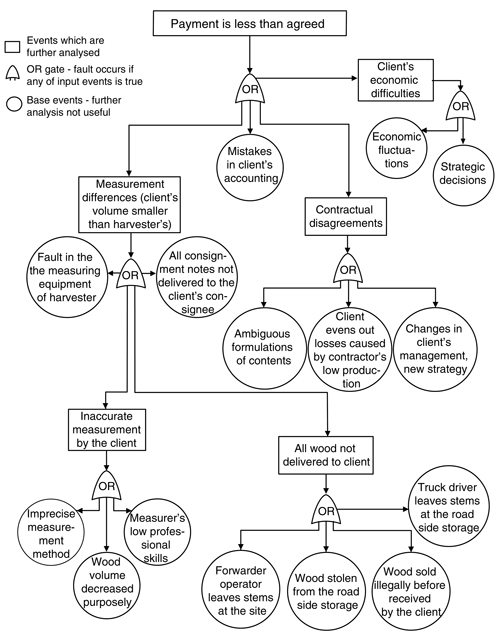

Possible preventative measures were assessed for the rated risks. The majority of the hypothetical company’s risks that required management actions were related to business activities. The only extreme economic risk identified in the study was a breach of contract related to results of wood measurement. In addition, the delay of payments was a serious risk. Thus, it was common that the company was paid less than agreed, and this situation was selected as the top event in a fault tree constructed to recognise risk sources (Fig. 1).

Fig. 1. Sources of common economic risk regarding payment defaults in contracting in Russia.

Risks connected with payments were mitigated by trying to minimise the probability of their occurrence by dealing with the sources that the company was capable of influencing. Internal quality control ensured that the measuring equipment was in good condition and that the working methods of the machine operators were improved. The sources derived from the action of the client could hardly be influenced, although the occurrence of costly events could be prevented through detailed contracts and the profound selection of clients. To avoid payment delays penalty interest was included in contracts, and it was invoiced immediately after the first delay. Working for several clients decreased the economic consequences.

Other serious economic risks that required action were dependency on one client and the unequal negotiating position of client and contractor, which could potentially lead to unfavourable agreements for the contractor. Risk was mitigated by selecting a favourable contracting period and by organising negotiations in autumn when the client had the highest need for harvesting work. The company’s own negotiation power was improved by having flexibly movable machinery and a good labour reserve. Dependency on one client also caused serious risk of the interruption of work due to need to find new clients or, in the worst case, due to work termination if problems arose. Constant mapping of potential clients and other operators in the business, as well as wide networking, facilitated preparation for consequences.

Machine service and spare parts represented a moderate risk of work interruptions, which could be avoided by minimising service need through staff training, as well as by storing spare parts. The correct size and location of the storage was important, as theft was causing moderate economic risk. Large fires in site huts posed a serious risk of personal injury, and therefore alarm systems and fire extinguishers were necessary ways of mitigating the risk. Fire damage to machines was a moderate business risk that could be avoided by regularly washing the forest machines and establishing detailed fire security instructions. Training staff prevented all injuries and damages posed by fire. Production involved moderate economic and interruption risk, as machines were not in full utilisation as a consequence of problems in operative planning. As issuing stands for harvesting was the responsibility of the client, the contractor’s measures for risk mitigation were limited. Attempts could be made to reduce this risk by fulfilling contract obligations carefully and working in close cooperation with the client’s operational managers.

Regarding staff, inadequate professional skills were a serious economic and interruption risk. Risk sources could be removed by compiling a specific recruiting strategy for staff, as well as by providing good work management and instructions. Changing work motivation and decreasing output created a moderate economic risk. High productivity could be achieved with hiring criteria and bonuses, at the same time avoiding an increase in productivity at the expense of the machinery. Overall commitment could be improved by engaging employees in the company, especially by recruiting local people. The ability to adapt to the Russian operational environment was a moderate risk of economic loss and interruptions for an experienced entrepreneur.

Unhealthy competition in the markets was a serious economic risk due to lower rates. External factors were difficult to change, but the risk could be prepared for by taking care of the company’s own competitiveness and reputation through reliable operation, high quality, and effectiveness.

The ways in which authorities functioned posed a serious economic risk due to the changing interpretation of laws and rules. It was not possible to remove the source of the risk, so action could only be taken to minimise the consequences. Negotiation with the authorities was the first measure and in severe cases expert services were employed. Expert counselling was constantly utilised to secure operation.

Infrastructure was the only extreme interruption risk for the example company. Downtime during frost heave periods also formed a moderate economic risk. Even though removing or reducing extreme risk was essential, the company had no possibility of constructing forest roads. Instead, an attempt to avoid the risk was made by selecting clients on the basis of harvesting site locations, as well as the profound long-term planning of work.

3.4 Uncertainties

The risk analysis of the studied hypothetical company involved great uncertainty, in particular when selecting the consequence class for damage. The classification of economic loss was ambiguous and this uncertainty prevailed, especially near the class boundaries. As a result, it is possible that a risk was classified as minor and was left out of consideration, even if it was moderate and would require possible action. All hazards and problems classified as a minor economic risk would become moderate if their consequence class were raised by one point. Furthermore, almost all risks rated as moderate would become serious if their class was one point higher. Thus, it is possible that underestimation of moderate risks led to inadequate consideration of action.

Uncertainty in assessing probabilities, work interruption periods, and personal injuries was lower due to the long experience that the analysts had in the industry that the studied company operates in. Regarding work interruption, some uncertainty may be involved in short term interruptions. All minor work interruptions would become moderate if their class was increased from “less than two days” to “less than a week”. The trivial risk caused by machinery fires would become minor with the aforementioned class increase.

The combination of different events or circumstances and their consequences were not taken into account in the risk analysis, which increased uncertainty within the severity ranking. The risk identification process based on a brainstorming process is relatively unstructured, thus it is not possible to indicate its completeness. Therefore, it was not expected that all the risks in the Russian business environment would be identified, which increases the uncertainty of the risk analysis. However, due to the extensive knowledge of the experts, the semi-structured approach, and the combination of two different information sources for risk identification it is likely that the most important risks which the hypothetical company may encounter when contracting in Russia were revealed.

4 Discussion

The most important risks for a Finnish wood harvesting contractor in Russia were related to profitability and clients in the studied case. A limited number of clients, dependency on a few clients, and a weak negotiating position are also problems in Finland (Markkula 2005; Mäkinen 2002; Rieppo 2010), and therefore can be considered general characteristics of the industry rather than typical challenges of the Russian business environment. Typical problems for contracting in Russia are breaches of contract, challenges related to machine servicing and spare parts, as well as security issues.

Personnel risks in Russia differ from Finland in some respects. In Russia, the professional skills of the machine operators can be low due to an inadequate training system (Karjalainen et al. 2009). The risk analysis showed that the cultural differences lead to more challenging supervision and management of staff in Russia, and therefore leadership skills are emphasised even more than in Finland. Similar culture-induced differences have also been observed in the roundwood trade between Finland and Russia (Vinokurova et. al. 2009). In Finland, changing personnel can be a risk to productivity (Väätäinen et al. 2005), whereas in Russia employees’ changing motivation can become a problem. For the entrepreneur it is important to be able to adapt to the changing environment and maintain business expertise at a high level in Russia, as well as in Finland (Soirinsuo and Mäkinen 2009).

Among the external factors, the most challenging in Russia were unhealthy competition in the market and, as expected on the basis of other studies, the non-transparent and unpredictable procedures of the authorities (Golovki and Oganezova 2013; Katkova 2013). In Finland, price competition between wood harvesting contractors was observed in the 1990s (Mäkinen 1993), but by the 2000s a high dependency on a few clients resulted in a static market situation with low competition (Markkula 2005). Problems caused by seasonality are amplified by the sparse road network and longer downtime in Russia. A stable amount of work, i.e. the availability of stands for harvesting, is a challenge in Russia, as well as in Finland (Rummukainen et al. 2014).

Qualitative risk analysis based on expert assessment is highly subjective, thus results may vary greatly according to the background and experience of the analyst. In addition, it may be difficult to reveal new type of risks that have not yet been experienced but are possible especially in the changing political environment. A risk matrix should be used in companies’ risk analysis with caution, as it may lead to misinformed decisions and as it does not necessarily support effective resource allocation. As Cox (2008) points out, the classification of risk severity may require, in addition to the subjective judgments, arbitrary decisions about how to aggregate multiple small and frequent events into fewer and less frequent but more severe events. He remarks that there may not be an objectively correct way of filling out a risk matrix due to need for subjective judgments and the potential for inconsistencies in their construction by different persons. This finding is also supported by Ball and Watt (2013). In addition, an apparently simple tool may even militate deeper thinking in risk analysis (Ball and Watt 2013).

Due to the subjectivity of the method, as well as the unique context and risk bearing capacity of each company, the results are not directly usable for another company. Nevertheless, the produced information can be utilised to identify the possible risks present in wood harvesting contracting in Russia when planning the risk management process.

Acknowledgements

This work was supported by the “WOPE – Wood Procurement Entrepreneurship” project funded by the South-East Finland – Russia ENPI CBC 2007-2013 Programme.

References

Ball D.J., Watt J. (2013). Further thoughts on the utility of risk matrices. Risk Analysis 33: 2068–2078. http://dx.doi.org/10.1111/risa.12057.

Cox Jr. A.L. (2008). What’s wrong with risk matrices? Risk Analysis 28: 497–512. http://dx.doi.org/10.1111/j.1539-6924.2008.01030.x.

Forest Code of the Russian Federation (2006). No. 200-FZ dated 04.12.2006.

Gerasimov Y., Karjalainen T. (2008). Development program for improving wood procurement in Northwest Russia based on SWOT analysis. Baltic Forestry 14: 87–92.

Golovko A.V., Oganezova N.A. (2013). Влияние рисков на экономическую деятельность предприятий лесопромышленного комплекса Республики Коми. [The influence of risk to the economic activities of forestry enterprises Komi Republic]. Corporate Governance and Innovative Economic Development of the North 3: 138–151. [In Russian with English summary].

Goltsev V., Tolonen T., Syunev V., Dahlin B., Gerasimov Y. (eds.) (2011). Wood harvesting and logistics in Russia – focus on research and business opportunities. Metlan työraportteja / Working Papers of the Finnish Forest Research Institute 210. 157 p.

International Electrotechnical Commission (2009). IEC/ISO 31010:2009. Risk management. Risk assessment techniques. IEC, Geneva. 176 p.

International Organization for Standardization (2009). ISO 31000:2009. Risk management. Principles and guidelines. ISO, Geneva. 24 p.

Jurvanen J. (2015). Suomalaisten metsäkoneyritysten etabloituminen Venäjälle. [Finnish forest contractors establishing in Russia]. Karelia University of Applied Sciences. Thesis. 57 p. [In Finnish with English summary].

Jutila L., Karvinen S., Leinonen T., Välkky E. (2010). Venäjän tullipolitiikan vaikutuksista Suomen ja Venäjän väliseen metsäsektorin kauppaan. [Effect of Russian customs policy on the Finnish–Russian forest sector trade]. Metlan työraportteja / Working Papers of the Finnish Forest Research Institute 155. 32 p. http://www.metla.fi/julkaisut/workingpapers/2010/mwp155.htm. [Cited 23 Sep 2014]. [In Finnish].

Karjalainen T., Leinonen T., Gerasimov Y., Husso M., Karvinen S. (eds.) (2009). Intensification of forest management and improvement of wood harvesting in Northwest Russia – final report of the research project. Metlan työraportteja / Working Papers of the Finnish Forest Research Institute 110. 151 p.

Karvinen S., Välkky E., Gerasimov Y., Dobrovolsky A. (2011). Northwest Russian forest sector in a nutshell. Finnish Forest Research Institute, Sastamala. 138 p.

Karvinen S., Nummelin T., Jurvanen J. (2014). Suomalaisen metsäkoneyrittäjän riskit Venäjällä. [Finnish wood harvesting contractors’ risks in Russia]. Metlan työraportteja / Working Papers of the Finnish Forest Research Institute 315. 31 p. http://www.metla.fi/julkaisut/workingpapers/2014/mwp315.htm. [Cited 2 Dec 2014]. [In Finnish].

Katkova T.E. (2012). Особенности механизма управления рисками в лесном хозяйстве в условиях реформирования отрасли. [Features of the mechanism of risk management in forestry in the conditions of branch reforming]. European Social Science Journal 11: 394–401. [In Russian with English summary].

Katkova T.E. (2013). Проблема исследования риска как экономической категории лесной экономики. [Risk as an economic category of forest economy]. Izvestiya Sankt-Peterburgskoy lesotehnicheskoy akademii. Vypusk 205: 184–197. [In Russian].

Kislenok A.A. (2008). Оценка предпринимательского риска лесозаготовительных предприятий Дальнего Востока. [Business risks of wood harvesting companies in Far East]. Power and Administration in the East of Russia 1: 55–59. [In Russian].

Mäkinen P. (1988). Metsäkoneurakoitsija yrittäjänä. [The forest machine contractor as an entrepreneur]. Folia Forestalia 717: 1–37. [In Finnish].

Mäkinen P. (1993). Success factors for forest machine contractors. Folia Forestalia 818: 27–35. [In Finnis, with English summary].

Mäkinen P. (ed.) (2002). Metsä- ja puualan pk-yritysten menestystekijät. [Success factors for SMEs in forestry and woodworking]. Finnish Forest Research Institute Research Papers 869: 1–52. [In Finnish].

MAMK University of Applied Sciences (2015). WOPE – Wood Procurement Entrepreneurship. http://www.mamk.fi/wope_wood_procurement_entrepreneurship. [Cited 1 April 2015].

Markkula V. (2005). Metsäalan yrittämisen liiketoimintaympäristö – alan toimijat ja markkinalähtöisen toiminnan kehittämisen ongelmat. [Business environment in forestry – actors and problems in developing market-based activity]. University of Helsinki, Department of Economics and Management, Selvityksiä / Working Papers, No. 37. 31 p. http://hdl.handle.net/1975/668. [Cited 5 Nov 2014]. [In Finnish].

Nippala E., Sauni S. (2004a). Koneyrittäjän riskienarviointi. [Risk assessment of machine contractor]. Koneyrittäjä-julkaisut No. 23c. The Trade Association of Finnish Forestry and Earth Moving Contractors. 23 p. http://www.koneyrittajat.fi/tiedosto.php?id=df6fbd1d777ff1d3113640406c9359cc. [Cited 22 Sep 2014]. [In Finnish].

Nippala E., Sauni S. (2004b). Koneyrittäjän riskit. [Risks of machine contractor]. Koneyrittäjä-julkaisut No. 23a. The Trade Association of Finnish Forestry and Earth Moving Contractors. 12 p. http://www.koneyrittajat.fi/tiedosto.php?id=0a9dc20f132b4b5248a8b6559d6e0042. [Cited 31 Oct 2014]. [In Finnish].

Penttinen M., Rummukainen A., Mikkola J. (2011). Profitability, liquidity and solvency of wood harvesting contractors in Finland. Small-scale Forestry 10: 211–229. http://dx.doi.org/10.1007/s11842-010-9143-x.

Rieppo K. (ed.) (2010). Kasvun eväät metsä- ja puualan pienyrityksille. [Seeds of growth for small enterprises in forestry and wood-processing industries]. TTS:n julkaisuja No. 406. 76 p. [In Finnish].

Rummukainen A., Penttinen M., Mikkola J., Tikakoski S., Dahlin B. (2014). Puunhankinnan palveluliiketoiminnan kannattavuuden kehittäminen. [Improvement of profitability of service business in wood procurement]. In: Asikainen A., Ilvesniemi H., Muhonen T. (eds.). Bioenergiaa metsistä – tutkimus- ja kehittämisohjelman keskeiset tulokset. [Bioenergy from Forest – results of the research and development programme]. Metlan työraportteja / Working Papers of the Finnish Forest Research Institute 289. 223 p. http://www.metla.fi/julkaisut/workingpapers/2014/mwp289.htm. [Cited 23 Sep 2014]. [In Finnish].

Shegelman I.R., Lukashevich V.M. (2011). Assessment of seasonality in preparation of forest harvesting works. Fundamental Research 12: 599–603. [In Russian with English summary].

Soirinsuo J., Mäkinen P. (2009). Importance of the financial situation for the growth of a forest machine entrepreneur. Scandinavian Journal of Forest Research 24: 264–272. http://dx.doi.org/10.1080/02827580902932829.

State Council of the Russian Federation (2013). Доклад о повышении эффективности лесного комплекса. [Report on improving the effectiveness of the forest sector]. 139 p. http://region.adm.nov.ru/vlast/governor/doclad_les.php. [Cited 4 Nov 2014]. [In Russian].

Suhanov V. (2014). О стратегии и тактике развития лесопромышленного комплекса России. [Development strategy and tactics of the Russian forest sector]. Palmarium Academic Publishing, Saarbrücken. 232 p. [In Russian].

The Trade Association of Finnish Forestry and Earth Moving Contractors (2007). Koneyrityksen riskienhallinta. [Machine contractors’ risk management]. 24 p. http://www.koneyrittajat.fi/tiedosto.php?id=20504e3e4a1342bdd04fe64a33e90ed3. [Cited 2 Nov 2014]. [In Finnish].

Väätäinen K., Ovaskainen H., Ranta P., Ala-Fossi A. (2005). Hakkuukoneenkuljettajan hiljaisen tiedon merkitys hakkuutulokseen työpistetasolla. [The significance of harvester operator’s tacit knowledge on cutting with a single-grip harvester]. Metsäntutkimuslaitoksen Tiedonantoja 937. 100 p. [In Finnish].

Väätäinen K., Lappalainen M., Asikainen A., Anttila P. (2008). Kohti kustannustehokkaampaa puunkorjuuta – puunkorjuuyrittäjän uusien toimintamallien simulointi. [Towards cost efficient wood harvesting – simulation of new operational models for the wood harvesting entrepreneur]. Metlan työraportteja / Working Papers of the Finnish Forest Research Institute 73. 52 p. http://www.metla.fi/julkaisut/workingpapers/2008/mwp073.htm. [Cited 22 Sep 2014]. [In Finnish].

Vinokurova N., Ollonqvist P., Viitanen J., Holopainen P., Mutanen A., Goltsev V., Ihalainen T. (2009). Russian–Finnish roundwood trade – some empirical evidence on cultural based differences. Metlan työraportteja / Working Papers of the Finnish Forest Research Institute 129. 36 p. http://www.metla.fi/julkaisut/workingpapers/2009/mwp129.htm. [Cited 26 Sep 2014].

Total of 34 preferences.