The effects of number of stems per stool on cutting productivity in coppiced Eucalyptus plantations

McEwan A., Magagnotti N., Spinelli R. (2016). The effects of number of stems per stool on cutting productivity in coppiced Eucalyptus plantations. Silva Fennica vol. 50 no. 2 article id 1448. https://doi.org/10.14214/sf.1448

Highlights

- Double- and single stem coppice stools were harvested mechanically

- Stem size had the strongest impact on productivity

- An experienced operator performed equally well with both stool treatments

- Cost was ~10% higher with double stems for the less experienced operator

- Operator experience may play a major role when cutting coppice stands.

Abstract

A time study was conducted to determine whether stem crowding had any impact on harvester productivity in Eucalyptus grandis stands. This represents an important element when trying to balance the advantages and disadvantages of coppice management in fast growing plantations designated for mechanized harvesting (i.e. machine felling, delimbing, debarking and cross-cutting). The study material consisted of 446 coppice stems, half of which grew as single stems per stool and half as double stems per stool as a result of different coppice reduction strategies. The dataset was balanced and randomized, with both subsets replicating exactly the same stem size distribution and the single and double stems alternating randomly. Harvester productivity ranged between 6 and 50 m3 under bark per productive machine hour, following the variation of tree diameter from 10 to 40 cm at breast height (1.37 m according to South African standards). Regression analysis indicated that both tree size and stem crowding (e.g. one or two stems per stool) had a significant effect on harvester productivity, which increased with stem size and decreased with stem crowding. However, operator experience may overcome the effect of stem crowding, which was not significant when the harvester was manned by a highly experienced operator. In any case, the effect of stem size was much greater than that of stem crowding, which resulted in a cost difference of less than 10%. However, this figure excludes the possible effects of stem crowding on volume recovery and stem development, which should be addressed in the future.

Keywords

modeling;

logging;

short rotation forestry;

efficiency;

operator effect

- McEwan, Nelson Mandela Metropolitan University – George Campus, Saasveld, 6529, George, South Africa E-mail Andrew.McEwan@nmmu.ac.za

- Magagnotti, CNR IVALSA, Via Madonna del Piano 10, I-50019 Sesto Fiorentino (FI), Italy E-mail magagnotti@ivalsa.cnr.it

-

Spinelli,

CNR IVALSA, Via Madonna del Piano 10, I-50019 Sesto Fiorentino (FI), Italy

E-mail

spinelli@ivalsa.cnr.it

Received 30 August 2015 Accepted 7 January 2016 Published 15 February 2016

Views 101182

Available at https://doi.org/10.14214/sf.1448 | Download PDF

1 Introduction

Plantation forestry is widely acknowledged as being a sustainable source of timber production, and a viable alternative to the overexploitation of remaining natural forests. The majority of fast-growing commercial plantations are located in the Southern Hemisphere. They have very high growth rates that can range from 30 to 40 m3 under bark (ub) per hectare per year (Siry et al. 2005). A variety of species are used in plantation forestry due to site and market conditions. The dominant genera include Pinus, Eucalyptus, Populus and Acacia (FAO 2009). Eucalyptus plantations are becoming increasingly important, and their current expansion is linked to the growing global demand for wood fiber (FAO 2009). Eucalyptus is the most valuable planted industrial hardwood species in the world, with 18 million hectares in 90 countries (FAO 2005).

South Africa contains a plantation forestry industry that produces raw material mostly for the sawtimber and the pulp and paper markets. The forestry industry in South Africa is an important contributor to the national economy through the local and foreign consumption of its timber products, and is an important provider of jobs and infrastructure in many areas.

South Africa has 1 268 443 hectares of intensively managed exotic tree plantations, whereby 70% is used for the production of pulp and paper. Eucalyptus is the most widely planted hardwood in South Africa, consisting of 42% of the total planted area (Godsmark 2014) or 476 142 hectares (Forestry South Africa 2014). South Africa has a high diversity of site conditions, which is one of the main reasons for the use of Eucalyptus as a species (Herbert 2012). Furthermore, Eucalyptus is well suited to end-user requirements, especially for pulp and paper. Eucalyptus grandis is the most important and widely planted Eucalyptus species in South Africa, comprising 262 949 hectares, or 55% of the total Eucalyptus planted area (Forestry South Africa 2014).

Eucalyptus stools have the ability to coppice after the tree is felled. This introduces the option of either replanting the stand or allowing the existing stools to coppice. The decision whether to replant or allow the stool to coppice depends upon a number of factors. The existing genetic material of the felled crop still needs to be acceptable to meet current market requirements, and it must also achieve growth rates acceptable to justify an additional rotation. Coppicing does not require intensive site preparation and planting operations, and results in growth commencing immediately after felling due to a live and fully developed root system (Zbonak et al. 2007). If new trees are to be planted, there can be a delay in the planting operations until the correct season has arrived and sufficient rain has fallen. After planting, the young plant takes time to fully capture the site, needs fertilizing and needs to be well protected from weed competition until canopy closure is reached. Coppiced plants do not usually require any form of weed control or fertilisation and canopy closure is reached quickly. Stool survival needs to be sufficiently high to fully capture the growth potential of the site. In South Africa, if less than 1000 live stools per hectare remain after felling, the stand is replanted (Evans and Turnbull 2004). When the stools coppice, multiple shoots develop. Some of these shoots need to be removed or they begin to compete with each other. These shoots are removed to the desired final number during two reduction activities. The first reduction to 3 shoots usually takes place when the shoots are 3 to 4 meters high, while the second reduction to 1 to 2 shoots takes place when the shoots are 7 to 8 meters high (Little and McLennan 2000). Multiple shoots have the disadvantage that costs need to be incurred to remove the unwanted shoots, and the remaining shoots can be damaged. However, they have the advantage that the best shoots can be retained, and more than one shoot can be retained on stools where neighboring stools have died. The aim of the reduction is to retain the original stems per hectare when planted, even if there has been stool mortality (Evans and Turnbull 2004). Shoot selection during reduction also needs to consider aspects such as the acceptability of the attachment to the stool, and if more than one shoot is be retained, they should as far as possible be on opposite sides of the stool. Furthermore, the presence of multiple stems on the same stool raises some concerns about the efficiency of mechanized harvesting (Suchomel et al. 2012).

The introduction of mechanized harvesting offers distinct advantages in terms of increased labor productivity, simplified logistics and enhanced work safety (Bell 2002). Even where motor-manual harvesting techniques are still competitive, there is a strong interest to introduce mechanized harvesting as managers anticipate future labor shortages (Spinelli et al. 2009a).

Mechanized harvesters were originally designed to handle single stems and they are known to handle coppice stands with some difficulty (Spinelli et al. 2010). Stem crowding on the same stool hinders the work of the harvester, and requires much ability from the operator (Suchomel et al. 2012). When trying to single out a stem from a clump, the harvester rollers may bump against the other stems that are adjacent to the target one, making stem felling relatively laborious (Suchomel et al. 2011). Additionally, the form of a coppice clump limits the angles from which the harvester head can approach the target stem, often forcing the operator to carry out complex maneuvering (Spinelli et al. 2009b). That is especially true for the harvester heads used in Eucalyptus plantations, because the debarking function performed by these heads often requires a triangular roller configuration that increases the depth of the implement and makes it more difficult to navigate between adjacent stems (Magagnotti et al. 2011). For this reason, many operators still prefer to fell Eucalyptus coppice motor-manually, even when processing is mechanized with the use of modern harvesters (Spinelli et al. 2004). Recent studies on Eucalyptus grandis indicate that felling coppice stems with a harvester results in a significant productivity loss, unless shoot density is reduced to one single stem per stool prior to the final harvest (Ramantswana et al. 2013). However, both harvester design and operator training are improving very rapidly, which makes it difficult to reach a solid conclusion on this subject.

Therefore, the goal of this study was to define if (and how much) the productivity of a modern harvester decreases when the machine is dealing with multiple stems per stool, compared to the base productivity level obtained when negotiating single stems per stool. Other studies have already addressed the subject, and the novelty of this study resides in a stricter experimental design than found in previous similar experiments. In fact, most previous studies tested the different treatments (i.e. single stem vs. multiple stems per stool) separately in different stands, and not randomly distributed in the same stand. It is indeed very difficult to find single stems and coppice stems mixed at random in the same stand, which makes testing of the different treatments on different stands the most convenient strategy. However, a strict experimental design comparing different treatments on separate stands should best adopt the whole stand as a single replication, and include a relatively large number of stands while trying to contain terrain, machine and operator variability. Even if such a design was applicable, it would be very complicated, costly and time-consuming. In our study, we have located a coppiced stand where shoots had been randomly reduced to one, two or three stems per stool, which allowed testing the effect of shoot density on harvester productivity. What is more, stools carrying one single shoot were approximately the same shape and size as planted stems, and could be used as a proxy for non-coppiced conventional plantations.

2 Material and methods

2.1 Machine and operation

A Sumitomo SH210 construction excavator was used for the test (Fig. 1). The excavator was powered by an lsuzu AJ-4HK1X engine delivering 117 kW of power, and had an operating weight of 20 000 kg. The excavator had undergone safety modifications such as the addition of roll over protection structures (ROPS), a steel bar windscreen protector and polycarbonate windows. The excavator was equipped with a Waratah HTH616C harvester head (Table 1).

Fig. 1. The excavator-based harvester used for the research.

| Table 1. Specifications of excavator-base and harvester head used in the study. | |

| Component | Specification |

| Base machine | |

| Make and model | Sumitomo SH210 |

| Weight | 20 000 kg |

| Power rating | 117.3 kW |

| Width | 2800 mm |

| Length (without boom) | 4810 mm |

| Height | 2960 mm |

| Ground clearance | 440 mm |

| Boom outreach | 8700 mm |

| Head | |

| Make | Waratah 616 C |

| Weight | 1680 kg |

| Max cutting capacity | 55 cm |

| Saw bar length | 75 cm |

| Number of feed-rollers | 3 |

| Feed-roller type | steel with angled bars |

| Number of knives | 2 fixed, 3 moving |

| Hydraulic fluid requirement | 320 – 360 l/min |

| Max hydraulic pressure requirement | 35 MPa |

| Source: Manufacturer specifications | |

To enable debarking, two retractable feed rollers converged towards the mainframe and against the third fixed feed roller, exerting pressure on the stem to break the bark-wood bond. The feed rollers, which were made of hard steel, were slightly angled and had sharp spiral ridges to grip the stem and make it rotate in the head. This spiraling motion allowed maximum feed roller contact with the stem to loosen the bark. The delimbing knives on the harvester head were designed to not only delimb the tree, but also to cut under the loosened bark to remove it. Like many harvester heads used for Eucalyptus debarking, the head had a short chassis to facilitate the passage of crooked stems.

In the standard configuration, the Waratah HTH616C uses two moving delimbing knives, situated above the feed rollers. To allow optimal debarking, an additional lower moving knife was also used. All three feed rollers had full hydraulic synchro-drive, which ensured that maximum tractive effort was applied to the stem and reduced roller slippage, so as to achieve optimal rotation of the stem and smooth stem feeding (Fig. 1). The harvester studied was new, with under 500 machines hours of operation. The cost of the machine was 130 € per scheduled hour, as reported by the owner.

For the purpose of the study, the same machine was used for the test, but two different operators alternated at its controls according to the standard shift schedule adopted by the harvesting contractor. The operators were between 30 and 40 years old, with operator A having more than 10 years’ experience, and operator B approximately one year.

2.2 Study site

The study was carried out in one compartment (Table 2) at Sappi Forests Venus Plantation, situated close to the town of Graskop in the Mpumalanga province of South Africa. The compartment coordinates were: 24°59´S, 30°56´E. The entire compartment consisted of E. grandis. Ground conditions and roughness were determined using the South African National Terrain Classification system (Erasmus 1994). The site contained all the main variables that may affect harvester productivity, such as tree size, tree form (straight or forked), terrain morphology, and the number of stems per stool (one or two – occasionally three).

| Table 2. Site description. | |

| Plantation | Sappi Venus |

| Compartment | A44 |

| Species | E. grandis (Coppiced) |

| Area (ha) | 42.0 |

| Age (yrs) | 11.0 |

| Average DBH (cm) | 21.0 |

| Average Height (m) | 33.7 |

| Spacing (m) | 2.4 × 2.4 |

| Trees per hectare (after mortality) | 1383 |

| Average tree volume (m3) | 0.466 |

| Removal per hectare (m3) | 645 |

| Original sample size (trees) | 769 |

| Ground roughness | Smooth |

| Slope | Level to Gentle (less than 20%) |

2.3 Experimental design

Data was collected on nine randomly located sample plots consisting of 100 trees each. In all plots there were one to three stems per stool, and stools carrying different numbers of stems were randomly distributed inside the plots. Operator A worked on all plots, except for plot 8, whereas operator B worked on plot 8 and on sections of plots 1 and 4 as well, since the shift change occurred when these two plots had not been completed. Operator A accounted for 82% of the number of valid observations, whereas operator B accounted for the remaining 18%. In the end, the valid dataset included 237 single stem records and 532 double (and rarely triple) stem records.

2.4 Measurements

The study consisted of a typical time and motion study (Magagnotti et al. 2013), and lasted four days, from July 6th to July 9th, 2015. The cutting (i.e. felling, delimbing, debarking and crosscutting) of one stem was assumed as the observation unit. Each valid record contained information about: tree diameter, operator, treatment type (one or two stems per stool) and cutting time.

Stem volume was determined with appropriate diameter-to-volume tables, and was obtained by measuring the diameter of each stem at the height of 1.37 m, according to South African standards. Diameter records were translated into volume records using a proprietary double-entry volume table, developed by the plantation owner for commercial purposes. The table returned volume under bark in cubic meters (m3 ub). A height-diameter curve for the test site was developed using 99 sample stems (11 per plot), which were evenly distributed across all diameter classes. Harvested stem diameter varied between 8 and 40 cm, and harvested stem height between 20 and 43 m. No form index values were attributed to the stems, since they were all relatively straight and clean from heavy branches or other malformations. After diameter measurement, each stem was identified with a number code, painted on its bark in highly visible colors so that individual stems could be identified from a safe distance and associated with the respective work time records.

The time taken to harvest each individual stem was recorded using Husky Hunter hand-held field computers running the dedicated Siwork3 time study software (Magagnotti et al. 2013). Productive time was separated from delay time (Björheden et al. 1995) and split into functional elements (Bergstrand 1987). In particular, felling time was separated from processing time in order to see which of the two main machine functions was most affected by the stem treatment on test (Table 3). Felling and processing never overlapped, so that priority recording was not an issue. In contrast, moving and felling occasionally overlapped, in which case priority was given to felling (i.e. overlap time was categorized as felling). The timing session lasted 19.8 hours and covered the harvesting of 769 stems. The study was deemed too short for providing a reliable estimate of delay time, and therefore measured delay time was replaced with a delay coefficient obtained from long-term studies. In this case, scheduled productivity was estimated after applying a 0.208 delay factor (Spinelli and Visser 2008).

| Table 3. Description of time elements of the cutting process. | |

| Time element | Description |

| Moving | Any time the tracks were rolling. |

| Felling | Positioning the harvester head around the standing tree, which began when the boom reached out; felling proper, which began when the chainsaw started advancing and ended when the tree started to fall and the head was horizontal, ready to process the tree. |

| Processing | Began when the head was horizontal and included delimbing, debarking and crosscutting. Ended when the last assortment had been processed. |

| Other work | Any other productive time (e.g., removing of obstacles, stacking logs etc.). |

| Delays | Non-productive time, including mechanical, operational and personal delays. |

2.5 Data analysis

Data were analysed with least squares regression techniques in order to check the statistical significance of any eventual differences between treatments. Indicator variables were used to represent different treatments (i.e. single stems vs. double stems) when exploring the relationship between time consumption and tree size (Olsen et al. 1998). Since the dataset contained twice as many double stem records as single stem records, balance was restored by randomly extracting enough records from the double stem pool to exactly match the single stem records for each diameter class. In this way, one obtained a balanced dataset with exactly the same diameter distribution for the two treatments. Indicator variables were also used for representing operator effect, although the imbalance between the two operator treatments was too large for restoring by random extraction. Fortunately, the use of indicator variables allows a general formulation that is more robust to unequal cell frequencies, compared with the alternative formulation where the same factors are expressed as categorical variables (Freund and Wilson 1998). Non-linear data were linearized through appropriate transformations before analysis. Different models were tested, and the final choice fell on those models that offered high significance, good correlation and a logical interpretation. Compliance with the statistical assumption was checked through the analysis of residuals. The elected significance level was α < 0.05.

Eventually, hourly machine cost was divided by productivity per scheduled hour, in order to estimate cost per unit product (€ per m3 ub).

3 Results

The mean cutting productivity recorded during the whole study was 24.8 m3 per productive machine hour (PMH), or 20.5 m3 per scheduled machine hour (SMH). This applied to the mix of single-, double- and (rare) triple-stem stools obtained from the nine experimental plots, and to the average stem size of 21.2 cm at breast height, or average merchantable volume of 0.466 m3. One should also consider that these figures have been calculated for a theoretical cutting height of 10 cm and a topping diameter of 5 cm, like in most other studies. In reality, increased cutting height and stem breakage are likely to generate some losses, and the actual productivity figures might be somewhat lower than the theoretical estimate.

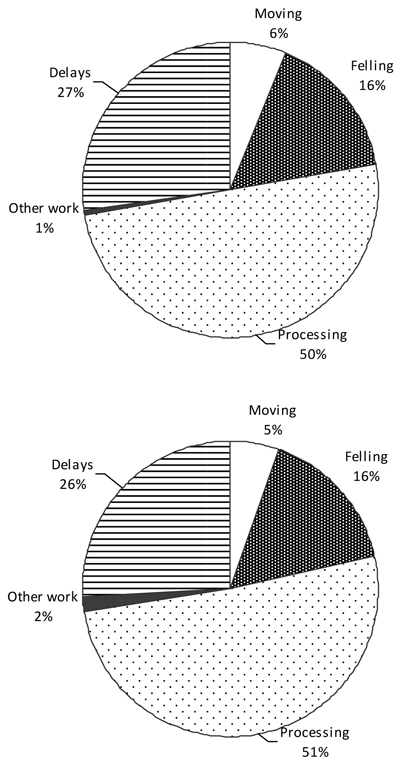

Regardless of treatment (single- or double-stem stools), the largest proportion of worksite time (57%) was spent processing, i.e. delimbing, debarking and cross-cutting (Fig. 2). Felling and processing together represented 75% of total worksite time.

Fig. 2. Breakdown of worksite time by activity type for single stems (above) and double stems (below).

Preliminary analysis of the dataset found that tree diameter, felling time, processing time and harvesting (felling + processing) time data were normally distributed and presented equal variances. Before analysis, tree diameter data were squared in order to linearize the time-diameter functions. Felling time data were still heavily skewed, and therefore regression analysis was conducted after cox-box transformation, for lambda = 0.

The results of the regression analysis conducted on the dataset balanced for stem treatment are reported in Table 3. The presence of more than one stem per stool determined a significant increase of processing and total cutting time when the machine was operated by operator B. In contrast, felling time was only affected by operator choice, but not by the number of stems per stool, or by the interaction of operator choice with the number of stems per stools. For this reason, the regression equation for felling time adopted into this study does not include any of the double-stem indicator variables (e.g. double-stem and double-stem × operator).

Expectedly, stem size had a very strong effect on felling, processing and total cutting time. In contrast, neither stem size nor treatment type had any effect on moving time or other work time. Moving and other work (e.g. brushing, stacking etc.) were not cyclic operations, but occurred every so many cycles and often supported the cyclic work conducted over more stems. Therefore, detecting any cyclic effects was neither possible nor theoretically justifiable. For this reason, a mean time per tree was adopted when it came to moving and other work.

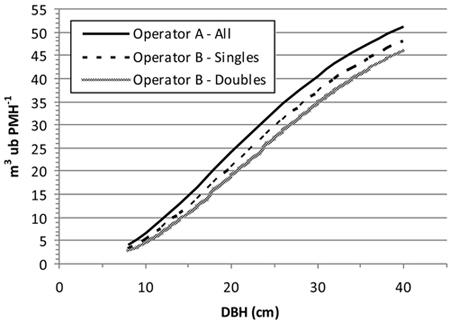

The functions in Table 4 were used to draw the graphs in Fig. 3, which relate net machine productivity with stem size, operator choice and stem number per stool (one or two). The graph shows that the less experienced operator B was between 6% and 20% less productive than the more experienced operator A, and that the productivity difference was inversely proportional to stem size. Furthermore, the experienced operator could handle single and double stems with equal proficiency, whereas the less experienced operator incurred a productivity loss between 5% and 15% when negotiating double-stem stools, compared with single-stem stools. In the specific case of the study stand, the additional cost incurred when deploying a less experienced operator could be estimated at 0.80 € per m3 ub (e.g. 6.6 vs. 5.8 € m–3 ub for the less experienced and the more experienced operator, respectively). If the less experienced operator was to harvest double stems, further costs would be incurred. These were estimated at 0.60 € per m3 ub (e.g 7.3 vs. 6.6 € m–3 ub for the double and the single stems, respectively). The additional cost could reach 1.40 € per m3 ub, if a less experienced operator – rather than a more experienced one – was tasked with cutting double stems.

| Table 4. Multiple regression models for time consumption. | ||||

| Moving | ||||

| T = | 5.147 | |||

| Felling | R2 adjusted = 0.428 | |||

| Ln T = a + b DBH^2 + c OPB | ||||

| Coeff | SE | T | P | |

| a | 2.149 | 0.031 | 68.635 | < 0.001 |

| b | 9.389 * 10–4 | 0.511 * 10–4 | 18.381 | < 0.001 |

| c | 0.217 | 0.048 | 4.526 | < 0.001 |

| Processing (= delimb, debark, cross cut) | R2 adjusted = 0.715 | |||

| T = a + b DBH^2 + c OPB + d OPB * DS | ||||

| a | 19.672 | 1.038 | 18.942 | < 0.001 |

| b | 0.057 | 0.002 | 33.871 | < 0.001 |

| c | 4.942 | 2.431 | 2.032 | 0.043 |

| d | 6.653 | 2.991 | 2.224 | 0.027 |

| Cutting (= felling + processing) | R2 adjusted = 0.750 | |||

| T = a + b DBH^2 + c OPB + d OPB * DS | ||||

| a | 26.516 | 1.227 | 21.612 | < 0.001 |

| b | 0.074 | 0.002 | 36.944 | < 0.001 |

| c | 9.038 | 2.863 | 3.157 | 0.002 |

| d | 7.295 | 3.521 | 2.072 | 0.039 |

| Other work | ||||

| T = | 1.168 | |||

| Delays | ||||

| (Moving + Cutting + Other work) * 0.208 | ||||

| Notations: T = time in s per stem; DBH = Stem diameter at breast height (1.37 m); OPB = Indicator variable for operator B (less experienced): 0 = operator A; 1 = operator B; DS = Indicator variable for double stems: 0 = single stem; 1 = double stem (i.e. stem growing from a stool that supports two stems) | ||||

Fig. 3. Harvester productivity as a function of tree size and treatment (single vs. double stem). DBH = Stem diameter at breast height (1.37 m).

4 Discussion

The productivity figures obtained from this study are within the range spanned by other studies conducted on the mechanized felling and processing of Eucalyptus plantations, despite the different work conditions in terms of stands, operators, work techniques and machine models. This corroborates the basic reliability of the experiment and may support cautious generalization of results. Once the values have been normalized to reflect the same tree size, the productivity figures recorded here are just 8%, 13% and 15% higher than those reported for South Africa and Europe by Ramantswana et al. (2013), Spinelli et al. (2002) and Magagnotti et al. (2011), respectively. In contrast, the same normalization exercise shows that the productivity figures in this study are 23%, 48% and 52% lower than those reported for Brazil by Martins et al. (2009), Tarnowski et al. (1999) and Dos Santos and Machado (1995), respectively. However, the Brazilian operations did not include debarking, which normally determines a significant productivity loss (Magagnotti et al. 2011).

The harvesting time model explains over 70% of the total variability in the dataset. Examining the models, one may query the indicator variables having a fixed effect on time consumption, regardless of tree size. In particular, some may postulate that the increase in time consumption when managing two-stem stools may be proportional to stem diameter, i.e. that the difficulty of handling these stems could be enhanced by their size. For instance, large adjacent stems may tend to shield each other, making it more difficult for the harvester head to single them out. Similarly, if the presence of two stems per stool requires selecting a sub-optimum felling direction, then it may be more difficult and time consuming to re-align a larger tree than a smaller one. In fact, the interaction variable “diameter × double stem indicator” was tested in the analysis, but its effect showed as not significant for any of the models. The same can be said for operator effect, which was fixed, rather than proportional to stem size. That may underline the difficulty for the less experienced operator with fixed-time, size-independent actions, such as approaching the stem to be felled, or re-grabbing it after being felled. Nevertheless, the current fixed-effect formulation was the only one offering models with high significance and good predictive qualities.

A closer look at the individual time consumption models can help understanding how a double stem exerts its effect on time consumption. Since it derives from stem crowding, the effect of double stems is expected to be most pronounced during the felling phase, as a result of a difficult approach to the target tree. Once the stem is on the ground and it is being processed, provenance from a single or a double-stem stool is expected to be irrelevant. However, the models obtained from this study indicate that the contrary is true, as the double stem indicator variable has a statistically significant effect on processing time, but not on felling time. The explanation could be that the real effect of stem crowding does not derive as much from hindering access to the target stems, as from imposing a limited angle of approach (the only free window), which may not correspond with the best angle for correct directional felling. As a result, many stems from crowded stems are laid down misaligned with the correct processing direction, which is about perpendicular to the harvester travel direction. The harvester must then spend additional time during the processing phase re-aligning felled stems with the correct processing direction to create sufficient space for the iterative feeding required by debarking, and to ensure that the log stacks created are correctly positioned and aligned.

Of course, this does not deny that stem crowding may hinder felling to some extent. However, the impact on felling time could have been variable enough to avoid detection from the simplest statistical tests. In future studies, expanding sample size may help capturing the effect of stem crowding on felling time, as well.

Furthermore, stem crowding might have an effect on value recovery, which was not investigated in this study. Stem crowding may force harvester operators to increase cutting height, leaving higher stumps. This may be more frequent with large stems, whose combined butt swell can exceed the harvester felling capacity. Then the actual productivity would be lower than predicted, due to the accumulation of fiber loss with increased work time. On a similar note, one may wonder if stem crowding had any effect on the extensive stem breakage observed during the study for both single and double stems. If stem crowding did affect tree fall direction, it could have affected the frequency and severity of stem breakage as well.

Finally, additional production losses could be expected due to smaller tree sizes, if stem crowding contributed to reduce the size of individual stems by subdividing the same growth potential between multiple individuals (Picchio et al. 2012). Then one should also consider the production losses derived from the many shoots that will not reach commercial size and will be cut to waste during the process.

The present study did not cover the indirect effects of stem crowding listed above. In contrast, at least part of their impact might have been reflected in the only other study on the subject conducted by Ramantswana et al. (2013), who used separate stands for gauging the effect of stem crowding. That may explain why that study reported a much larger productivity loss (38%) than found in this one (10%).

Comparison with Ramantswana et al. (2013) also raises the question of whether single coppice stems may provide a good proxy for single planted stems. The 2013 study offered a negative answer by determining large and significant productivity differences between single coppice stems and single planted stems. However, the study was conducted on two different plantations, and other factors may have determined such difference, including the different tree form of planted and coppice stems reported by the Authors. In any case, it may be difficult to explain a time consumption difference between single coppice stems and single planted stems from a pure work process viewpoint, if other factors do not concur to it. Of course, a correction should be made for the fiber losses derived from the increased cut height observed in coppice stands, if future studies showed that such cut height increase is statistically significant.

The study also highlights the importance of operator effect, which seems to mediate the effect of stem crowding and may determine substantial productivity differences. Finnish studies of harvester operators indicate productivity differences in the range of 20% (Ovasakinen et al. 2004), and up to 40% (Kärhä et al. 2004). Such figures are comparable with those found in this study, and actually hint at relatively small differences between the two operators tested in South Africa, since the productivity difference between them averaged 12%. In turn, that may indicate that it takes much experience to fully offset any stem crowding effects, and that only the best operators may handle single and double stems equally well. These considerations may justify investment in operator training, with the purpose of increasing overall proficiency levels (Mola-Yudego et al. 2015). This said, it is important to remember that the dataset used for this study suffered from a substantial cell imbalance when it came to operator selection, and therefore any statements about operator effect must be taken with some caution.

5 Conclusion

Harvester productivity is significantly impacted by stem crowding, but the magnitude of its impact is relatively moderate and productivity losses are contained below 10%. This holds true for direct impacts, affected by hindering accurate directional felling and causing time-consuming tree-handling during the stem processing phase. Further productivity losses could derive from poor value recovery if stem crowding resulted in a higher cutting height and more severe stem breakage than normally recorded for single stems. Anecdotal evidence seems to point in that direction, but no scientific studies have yet addressed the issue. Plantation managers can use the results of this study to make better informed decisions about the benefits of coppicing and of coppice stool reduction. In general, the direct cost derived from harvester production losses is moderate, which may support coppicing and/or a relatively weak stool reduction strategy. Operator experience may have a stronger effect than stem crowding, which suggests investments in operator training.

Acknowledgements

The authors would like to thank the following people for their assistance with the study: Kylle Schwegman, Cebolenkosi Hlongwane, Wandile Maseko, Sappi Forests, Can Do Timber Contractors. The study was supported by COST Action FP1301 “Eurocoppice” within the scope of its 4th STSM programme.

References

Bell J. (2002). Changes in logging injury rates associated with use of feller-bunchers in West Virginia. Journal of Safety Research. 33: 436–471. http://dx.doi.org/10.1016/S0022-4375(02)00048-8.

Bergstrand K. (1987). Planning and analysis of time studies on forest technology. The Forest Operations Institute of Sweden, Report no. 17. 58 p.

Björheden R., Apel K., Shiba M., Thompson M. (1995). IUFRO forest work study nomenclature. Swedish University of Agricultural Science, Department of Operational Efficiency, Garpenberg. 16 p.

Dos Santos S.L., Machado C.C. (1995). Analise técnico-economica do processamento de madeira de eucalipto em areas planas, utilizando o processador. [Technical and economical analysis of eucalypt tree processing in flat land, using a mechanical processor]. Revista Arvore Vol. 19(3): 346–357.

Erasmus D. (1994). National terrain classification for forestry. Institute for Commercial Forestry Research (ICFR). ICFR, Scottsville, Bulletin Series 11/94.

Evans J., Turnbull J. (2004). Plantation forestry in the tropics. 3rd ed. Oxford University Press, New York. 467 p.

Food and Agricultural Organisation (FAO) (2009). Responsible management of planted forests: voluntary guidelines – preparation for action – the country level methodology. FAO, Rome, Planted Forests and Tree Working Paper 45/E.

Food and Agricultural Organisation (2005). Global forest resources assessment 2005. FAO, Rome, Forestry Paper 147.

Forestry South Africa (2014). Abstract of South African forestry facts: for the year 2011/2012. Forestry South Africa. http://www.forestry.co.za/uploads/File/Industry%20News/2014/Sep%202014%20-%20Forestry%20Facts%20Pamphlet%202012.pdf. [Cited 14 July 2015].

Freund R., Wilson W. (1998). Regression analysis: statistical modelling of a response variable. Academic Press, Elsevier, Chestnut Hill, MA, USA. 444 p.

Godsmark R. (2014). The South African forestry industry’s perspective on forestry & forest products statistics. Forestry South Africa. http://www.forestry.co.za/statistical-data/. [Cited 14 July 2015].

Herbert M.A. (2012). Site requirements of commercial Eucalyptus and Corymbia species in Southern Africa. In: Bredenkamp B.V., Upfold S.J. (eds.). South African forestry handbook. Southern African Institute for Forestry. p. 51–58.

Kärhä K., Rönkkö E., Gumse S.I. (2004). Productivity and cutting costs of thinning harvesters. International Journal of Forest Engineering 15(2): 3–55.

Little K.M., McLennan L. (2000). Eucalypt coppice management. ICFR Technical Innovations 2000101. ICFR, Pietermaritzburg, South Africa.

Magagnotti N., Nati C., Pari L., Spinelli R., Visser R. (2011). Assessing the cost of stump-site debarking in eucalypt plantations. Biosystems Engineering 110(4): 443–449. http://dx.doi.org/10.1016/j.biosystemseng.2011.09.009.

Magagnotti N., Kanzian C., Schulmeyer F., Spinelli R. (2013). A new guide for work studies in forestry. International Journal of Forest Engineering 24: 249–253. http://dx.doi.org/10.1080/14942119.2013.856613.

Martins R., Seixas F., Stape J.L. (2009). Technical and economical evaluation of a harvester working under different spacing and planting arrangement conditions in eucalyptus plantations. Scientia Forestalis 83(37): 253–263.

Mola-Yudego B., Picchi G., Röser D., Spinelli R. (2015). Assessing chipper productivity and operator effects in forest biomass operations. Silva Fennica 49(5) article 1342. http://dx.doi.org/10.14214/sf.1342.

Olsen E., Hossain M., Miller M. (1998). Statistical comparison of methods used in harvesting work studies. Oregon State University, Forest Research Laboratory, Corvallis, OR, Research Contribution nr. 23. 31 p.

Ovaskainen H., Uusitalo J., Väätäinen K. (2004). Characteristics and significance of a harvester operators’ working technique in thinnings. International Journal of Forest Engineering 15(2): 67–77.

Ramantswana M., McEwan A., Pauw J. (2012). Determining the effect of tree size, bark-wood bond strength and tree form on the productivity of an excavator-based harvester in Acacia mearnsii in the KwaZulu-Natal forestry region of South Africa. Southern Forests: a Journal of Forest Science 74(3): 151–157. http://dx.doi.org/10.2989/20702620.2012.722823.

Siry J.P., Cubbage F.W., Ahmed M.R. (2005). Sustainable forest management: global trends and opportunities. Forest Policy and Economics 7(4): 551–561. http://dx.doi.org/10.1016/j.forpol.2003.09.003.

Spinelli R., Visser R. (2008). Analyzing and estimating delays in harvester operations. International Journal of Forest Engineering 19: 35–40.

Spinelli R., Owende P., Ward S. (2002). Productivity and cost of CTL harvesting of Eucalyptus globulus stands using excavator-based harvesters. Forest Products Journal 52(1): 67–77.

Spinelli R., Owende P., Ward S., Tornero M. (2004). Comparison of short-wood forwarding systems used in Iberia. Silva Fennica 38(1): 85–94. http://dx.doi.org/10.14214/sf.437.

Spinelli R., Ward S., Owende P. (2009a). A harvest and transport cost model for Eucalyptus spp. fast-growing short rotation plantations. Biomass and Bioenergy 33(9): 1265–1270. http://dx.doi.org/10.1016/j.biombioe.2009.05.010.

Spinelli R., Magagnotti N., Nati C. (2009b). Options for the mechanized processing of hardwood trees in Mediterranean forests. International Journal of Forest Engineering 20: 39–44.

Spinelli R., Hartsough B.R., Magagnotti N. (2010). Productivity standards for harvesters and processors in Italy. Forest Products Journal 60(3): 226–235. http://dx.doi.org/10.13073/0015-7473-60.3.226.

Suchomel C., Becker G., Pyttel P. (2011). Fully mechanized harvesting in aged oak coppice stands. Forest Products Journal 61(4): 290–296. http://dx.doi.org/10.13073/0015-7473-61.4.290.

Suchomel C., Spinelli R., Magagnotti N. (2012). Productivity of processing hardwoods from coppice forests. Croatian Journal of Forest Engineering 33: 39–47.

Tarnowsky C., Schneider P., Machado C. (1999). Productivity and costs of processor working in stands of Eucalyptus grandis (Hill. Ex. Maiden). Ciência Florestal 2(9): 103–115.

Zbonak A., Bush T., Grzeskowiak V. (2007). Comparison of tree growth, wood density and anatomical properties between coppiced trees and parent crop of six Eucalyptus genotypes. Improvements and culture of eucalypts, IUFRO conference 22–26 October 2007, Durban, South Africa.

Total of 32 references.