From useless thickets to valuable resource? – Financial performance of downy birch management on drained peatlands

Niemistö P., Kojola S., Ahtikoski A., Laiho R. (2017). From useless thickets to valuable resource? – Financial performance of downy birch management on drained peatlands. Silva Fennica vol. 51 no. 3 article id 2017. https://doi.org/10.14214/sf.2017

Highlights

- The most profitable management regimes for pulpwood and energy wood production in dense downy birch stands on drained peatlands include no thinnings, but final cutting at the stand age of 40–45 years as whole-tree harvesting, or as integrated harvesting of pulpwood and delimbed energy wood stems about 10 years later depending on applicable harvesting method

- A competitive management regime is early precommercial thinning at 4 m dominant height to a density of 2500 stems per hectare and production of pulpwood with a rotation of 55–65 years. Equal profitability is achieved with or without traditional first thinning, which can thus be included for other reasons, for example to improve regeneration of spruce.

Abstract

Downy birch (Betula pubescens Ehrh.) stands on drained peatlands are often considered useless because they typically do not yield good-quality sawn timber. However, covering an area of ca. 0.5 million hectares and with total yields of up to 250 m3 ha–1, downy birch stands on peatlands in Finland have a potential for pulpwood and/or energy wood production. We examined the financial performance of alternative management regimes (with or without thinnings, different thinning intensities, several rotation lengths) combined with alternative harvesting methods (pulpwood, energy wood, or integrated, energy wood being delimbed stems or whole trees). We used data from 19 experimental stands, monitored for 20–30 years. For harvesting removals we considered both actual thinning removals and final-cutting removals with alternative timings that were based on the monitoring data. We assessed the profitability as a combination of the net present value of the birch generation and the bare land value of future generations of Norway spruce (Picea abies (L.) Karst.). The most profitable management was growing without thinnings until whole-tree final cutting at the stand age of 40–45 years with an advanced multi-tree harvesting method. In contrast, the standard method in whole-tree final cutting resulted in the lowest profitability, and an integrated method with the energy wood as delimbed stems was the best of the standard methods. Thinnings were unprofitable especially when aiming to produce energy wood, whereas aiming for pulpwood, light precommercial thinning was competitive. Commercial thinning at the traditional “pulpwood stage” had little effect on profitability. The best stand age for final cutting was 40–65 years – earlier for very dense stands and whole-tree energy wood harvesting with advanced method, later for precommercially thinned stands and pulpwood harvesting.

Keywords

forest management;

Betula pubescens;

thinning;

energy wood;

pulpwood;

profitability;

final cutting

-

Niemistö,

Natural Resources Institute Finland (Luke), Management and Production of Renewable Resources, Kampusranta 9 C, 60320 Seinäjoki, Finland

E-mail

pentti.niemisto@luke.fi

- Kojola, Natural Resources Institute Finland (Luke), Management and Production of Renewable Resources, Latokartanonkaari 9, 00790 Helsinki, Finland E-mail soili.kojola@luke.fi

- Ahtikoski, Natural Resources Institute Finland (Luke), Management and Production of Renewable Resources, Paavo Havaksentie 3, 90014 University of Oulu, Finland E-mail anssi.ahtikoski@luke.fi

- Laiho, Natural Resources Institute Finland (Luke), Management and Production of Renewable Resources, Latokartanonkaari 9, 00790 Helsinki, Finland E-mail raija.laiho@luke.fi

Received 13 January 2017 Accepted 30 May 2017 Published 15 June 2017

Views 154877

Available at https://doi.org/10.14214/sf.2017 | Download PDF

1 Introduction

Downy birch (Betula pubescens Ehrh.) is one of the most common tree species in Northern Europe. In Finland, it represents about 12% of the total volume of the growing stock (Niemistö and Korhonen 2008). Downy birch tolerates moist conditions and thus grows well on wet soils, and as a pioneer tree species very easily forms dense stands on, e.g., drained peatlands (Keltikangas and Seppälä 1977; Saramäki 1977; Moilanen 1985). In Finland, where drainage of peatlands to improve forest growth has remarkably increased the area (ca. 5 million hectares; Metinfo 2014) and the annual harvesting potential (9–12 million m3 ha–1 a–1; Nuutinen et al. 2007) of peatland forests, downy birch stands have a notable role in forestry, especially regionally. Based on the Finnish National Forest Inventory data (NFI11, measured in 2009–2013), the total area of birch-dominated stands (proportion of birch at least 50% of stand volume) on drained peatlands representing “forest land” was 572 000 ha. These stands were most common in the northern parts of Finland, especially in Northern Ostrobothnia and south-western Lapland (Niemistö and Korhonen 2008; Kojola et al. 2015). There were further 29 000 ha of birch-dominated stands on “poorly productive forest land”.

The downy birch stands growing on drained peatlands are often considered useless thickets, without any reasonable forest management purpose. Yet, their wood-production potential is often good. When growing on well-productive site types, the total yield of downy birch stands may reach 250 m3 ha–1 (Niemistö 2013). In the NFI11, the total volume of the growing stock on birch-dominated drained peatlands was estimated to be close to 60 million cubic meters. Based on Niemistö and Korhonen (2008), approximately three quarters of that can be expected to be birch wood. Even if the sawn-timber yield may be low in birch-dominated peatland forests (Koivisto 1959; Fries 1964; Braastad 1967; Verkasalo 1997; Hynynen et al. 2010), the yield of pulpwood and especially biomass for energy can be notable. Profitable management of these stands calls for appropriate harvesting procedures (Fernandez-Lacruz et al. 2013; Jylhä and Bergström 2016), for which up-to-date guidelines are currently lacking.

Such guidelines are urgently needed, since the total area of young downy birch stands may be expected to increase in the near future. This is because presently or in the near future large areas of peatland stands are in the final-cutting stage due to the active period of drainage during 1960s and 1970s. In cases of failed or totally neglected forest regeneration, insufficient earlier care of sapling stands, or frost damages in spruce saplings, downy birch as a pioneer tree species (Hynynen et al. 2010) is likely to take dominance of the sites. For instance, as much as 29% of the planted peatland spruce stands (age under 20 years) in the Ostrobothnia, Kainuu, and Lapland regions have suffered from frost damages (NFI11, unpublished).

Until recently, the management of drained peatland forests has generally aimed at production of pulpwood and sawlogs. However, the current view is that some stands may be more suitable for energy wood production (Kojola et al. 2015). Because of the relatively small size and low quality of the stems for sawlogs or veneer logs, downy birch stands may be in more effective use when managed partly or totally for energy wood. The rapidly increased consumption of forest chips has increased the demand for wood biomass suitable for energy in general. In 2015, 7.3 million solid cubic meters of forest chips were used in heating and power plants in Finland (Natural Resources Institute Finland 2016), a major part of the raw material for the forest chips, 3.9 million cubic meters, being small-sized trees. Birch-dominated peatland stands would appear to make a suitable biomass reserve for this purpose.

The density of young stands dominated by downy birch is often very high, tens of thousands of stems per hectare (Ferm and Kauppi 1990; Ferm 1993). Management guidelines (Hyvän metsänhoidon… 2007) for pulpwood production have recommended tending young stands to 2000–2500 stems per hectare, and applying the first commercial thinning when stand dominant height has reached 13–15 meters. After thinning the basal area should be 12–13 square meters or density 1100 stems per hectare. However, downy birch has proved to respond only weakly to thinning (Niemistö 2013). Many low-diameter stems are also wasted in such management, and thus the growing capacity of the site is not fully used. Therefore, studies concerning alternative ways to manage downy birch stands are needed.

When comparing different harvesting methods, the resulting profitability values are bound to vary with the method and machinery used in harvesting. The common forestry practice is to harvest the energy wood, small stems with or without branches and tops, simultaneously with the pulpwood. This integrated harvesting generally reduces procurement costs of small-diameter wood (Rummukainen et al. 2003; Kärhä 2011; Petty and Kärhä 2014), and for instance Heikkilä et al. (2009) found the total stand management to be more profitable with integrated first thinning than with whole-tree first thinning in young pine or spruce stands. Whole-tree harvesting, where all trees including branches and tops are considered energy wood, may decrease the costs of cutting (no delimbing) but, on the other hand, increase the cost of forwarding due to the decreasing load size (Laitila et al. 2010; Laitila and Väätäinen 2012). Preliminary studies concerning downy birch stands on drained peatlands have also shown that whole-tree energy wood harvesting, especially, may have poor profitability (Kojola et al. 2015). In spite of the multi-tree method used, cutting of small stems is generally time-consuming (Laitila et al. 2016; Kärhä 2011; Petty and Kärhä 2014).

The aim of this study was to find out what kind of management regimes, that is, thinning intensities and rotation lengths, combined with different harvesting methods, would be the most productive for birch pulpwood and biomass, and the most profitable to be put into practice. The focus in our examination was in the time points, when management decisions for the rest of the rotation are made. The key question examined was whether the management should be focused on energy wood production rather than on traditional pulpwood production. This study is a sequel to the reports of Niemistö (1991, 2013) analyzing the stand dynamics and management of peatland birch stands.

2 Materials and methods

2.1 Experimental stands and their measurements

We utilized a set of 19 experimental downy birch stands treated with different thinnings that comprised a thinning experiment implemented by the Finnish Forest Research Institute (Metla; currently merged into the Natural Resources Institute Finland, Luke) in 1975–1990. The stands were located in Ostrobothnia and western Lapland (Table 1). A detailed description of the experimental design and measurements has been presented by Niemistö (2013). The drained peatland forest site types were MT2 (Vaccinium myrtillus type II) or HrT (Herb-rich type), Mtkg II and Rhtkg in the Finnish nomenclature (Laine et al. 2012; briefly in English in Westman and Laiho 2003), which represent relatively high levels of wood-production potential. The stands were pure downy birch stands and represented the first tree generation after the initial drainage of the peatlands. The stand ages varied from 10 to 52 years and from 30 to 83 years at the onset and at the end of the experiment, respectively.

| Table 1. Mean characteristics of the experimental stands at the onset of the experiment and the length of the study periods. Stand groups: Sapling stand stage (SS; H0 < 8 m), energy wood thinning stage (EW; 8 m < H0 < 11 m), and pulpwood thinning stage (PW; H0 > 12 m). Exp #: Code of the stands in Luke’s data archive. View in new window/tab. |

Most of the stands were measured 5–7 times in 5-year intervals. Based on the measurements, we knew the actual stand development during the 15–30 study years for each of the 245 plots within the 19 experimental stands (Table 1). For each single stand-measurement event the resulting data was used to estimate the volumes of pulpwood and small diameter stem wood in solid cubic meters ha–1 (Heinonen 1994) and the branch biomass in Mg ha–1 (Repola 2008), all separately for: the total tree stand, the natural removal, the harvesting removal, and the remaining stand. Transformation of branch biomass from Mg to solid cubic meters was made by the coefficient 2.0 according to branch density reported by Björklund and Ferm (1982).

We grouped the data based on the initial stage of the stands and, consequently, the first treatment applied at the onset of the experiment: sapling stand stage (SS stands; mean height 3–8 m; 9 experimental stands; precommercial thinning), energy wood thinning stage (EW stands; 8–11 m; 7 experimental stands; energy wood thinning), or pulpwood thinning stage (PW stands; 12–14 m; 3 experimental stands; pulpwood thinning). Following a randomized block design, each stand included 5–30 rectangular plots reaching from ditch to ditch, the area varying between 800 and 1400 square meters. The intensity of the first treatments on the plots varied, including: unthinned control plots; very light; light; moderate; and heavy thinning (Niemistö 2013). On an average, 40% of the basal area was removed in the heavy thinning of the PW, and 70–80% in the EW and SS stands. A second thinning was applied on 20% of the previously thinned plots (henceforth: twice-thinned stands). A light precommercial thinning to the density of 1900–2500 stems per hectare had been carried out before the initiation of the experiment in the PW stands (see Fig. 1 in Niemistö 2013).

2.2 Defining alternative management regimes and their removals for downy birch

We defined alternative management regimes as combinations of the first actual thinning treatments and ‘virtual’ final cuttings that were computed from the tree-level monitoring data for each measurement time (i.e., the different measurement times yielded the alternative timings for the final cuttings). Six different harvesting methods were considered (A–F; Table 2), of which F was applicable only in the SS and EW stands. As harvesting removals, these included only pulpwood (A); only energy wood, harvested as either whole trees including branches or delimbed stems (D–F); or pulpwood plus energy wood, harvested as whole trees or delimbed stems obtained with integrated harvesting (B–C). In the integrated harvesting, the branches from the pulpwood part of the stem are cut and dropped at the harvested area. We calculated the volume of this branch waste using a separate model (Laitila et al. 2014), and excluded it from the removals. In practice, some branches are still shed in whole-tree harvesting (Hytönen and Moilanen 2014), and we assumed the amount shed to be half of the branch waste estimated for integrated harvesting. We also produced computational thinning removals for SS stands to facilitate comparisons among the first treatments, but ignored them when calculating the total removals and profitability. Ditch network maintenance was not considered necessary before the final cutting in these relatively dense, highly-stocked birch stands. Thus, the alternative management regimes included altogether five intensity levels for the first treatments, six harvesting methods, and 4–7 rotation lengths. Henceforth, the total management regimes are referred to as A–F, according to the codes of the harvesting methods applied.

| Table 2. The alternative harvesting methods and the structure of the resulting removals (merchantable wood). | |||

| Harvesting method | Removal | Pulpwood component | Energy wood component |

| A. Pulpwood harvesting | Pulpwood | Pulpwood part of the stem 1) | – |

| B. Integrated harvesting | Pulpwood + energy wood as delimbed stems | Pulpwood part of the stem 1) | Top waste 2) + small stems 3) − tops 4) |

| C. Integrated harvesting | Pulpwood + energy wood as whole-tree | Pulpwood part of the stem 1) | Top waste 2) + small stems 3) + branches − branch waste 5) |

| D. Energy wood harvesting | Energy wood as delimbed stems | – | Large stems + top waste 2) + small stems 3) − tops 4) |

| E. Energy wood harvesting | Energy wood as whole-tree | – | Large stems + small stems 3) + branches − branch waste 5) |

| F. Advanced energy wood harvesting 6) | Energy wood as whole-tree | – | Large stems + small stems 3) + branches − branch waste 5) |

| 1) minimum top diameter of the pulpwood poles was 6.5 cm. 2) top waste = the part of the stem which is not pulpwood size. 3) small stems = stems smaller than pulpwood stems, diameter at breast height (d1.3) over 3.5 cm. 4) tops = the thinnest part of the stems cut away (diameter smaller than ~2 cm). 5) branch waste = branches that were dropped at the cutting area (see text for estimation). 6) for SS and EW stands. Similar to method E, but harvested by an accumulating felling head that is designed to be more efficient than regular multi-tree felling heads in dense stands with small stems (Jylhä and Bergström 2016) | |||

2.3 Estimating incomes, costs, and financial performance

We estimated the costs of all treatments as well as the harvesting incomes from both thinnings and final cuttings that would be applicable for each management regime and harvesting method. For harvesting incomes from the birch stands we used real roadside prices according to statistics (Metinfo 2014; Torvelainen 2014). Because of the generally poor quality of birch sawlogs from peatlands (Verkasalo 1997), all wood with a diameter ≥ 6.5 cm over bark was considered pulpwood, with the price of 30 € m–3. The energy wood price was 24 € m–3 and 21 € m–3 for delimbed stems and whole trees, respectively.

The harvesting costs for each harvesting method were estimated using the volumes and structures of the removals, published time-consumption models, and unit costs of the work. The time-consumption models were based on field studies utilizing defined machineries. We selected those models that we considered to be the most appropriate for each management regime and harvesting method. We further attempted to maintain the comparability of the models as good as possible, that is, as far as possible we used models from the same study. For the harvesting methods A–E (henceforth called “standard methods”), we used the models of Laitila et al. (2016). Since the method E does not fit well to the youngest and densest stands considered, we complemented the selection with the method F (henceforth called “advanced whole-tree harvesting method”) and the corresponding time-consumption model by Jylhä and Bergström (2016). The models used in the methods A–E were based on the use of a medium-size 6-wheel harvester (Komatsu 901.4), equipped with a harvester head capable of multi-tree handling (Komatsu 350.1). The model in the method F was based on a corresponding 6-wheel harvester (Valmet 911.3) with an accumulating biomass felling head (Bracke C16). Both the pulpwood and energy wood harvesting methods were thus based on multi-tree-handling in all regimes, but the number of small stems collected simultaneously in the felling head was much higher in the method F as compared to the others and only bunching onto the pile was needed. Further, in the method F, larger stems can be cut in two phases – the upper and lower parts separately. For the harvesting method F, we selected of the models of Jylhä and Bergström (2016) the one that was based on mean stem volume. Considering the tree size and the modelling data used for the time-consumption model in the method F, this method could be applied in all the measurement points of the SS stands, those up to the fourth measurement of the EW stands, and in none of the PW stands.

In calculations of forwarding costs we used the models of Kuitto et al. (1994) for the pulpwood, and Laitila et al. (2007) for the energy wood, respectively. The models are based on a medium-size forwarder. We specified the load size to 6 m3 for whole trees, and 9 m3 for stemwood (pulpwood and delimbed stems), respectively (Laitila et al. 2010; Laitila and Väätäinen 2011). To acquire the gross effective-time productivity (E15), we multiplied the effective-time productivity (E0) with 1.393 and 1.302 in harvesting and forwarding, respectively, as suggested by Laitila and Väätäinen (2011). For operating-hour costs, updated by the cost index (Statistics Finland 2013a), we used 95.4 € E15–1 and 68.9 € E15–1 for harvester and forwarder, respectively (Laitila and Väätäinen 2011).

In the SS stands the time consumption of precommercial thinning using a clearing saw was estimated as a function of the stem number and the mean diameter at stump height (estimated as 1.2 × mean DBH), based on the model of Kaila et al. (1999; 2001). A maximum time consumption of 60 h ha–1 was set for very dense sapling stands, where the model produced unrealistic values. We also included the cost of clearing in the harvesting costs in such cases, where only pulpwood was harvested in the final cutting (method A), and a lot of small stems would thus remain in the cutting area. Consequently, clearing is needed before soil preparation and stand regeneration. For the time consumption of clearing, we used the model of Fernandez-Lacruz et al. (2013). We used the unit cost of 35 € h–1 both for precommercial thinning and clearing.

When examining the financial performance of the alternative management regimes of downy birch, the considerably different regime-specific rotation time spans had to be made commensurable. This was done by combining the net present value (NPV, Eq. 1) of the birch rotation with the discounted bare land value (BLV, Eq. 2 and Eq. 3) of the management of future rotations of Norway spruce (Picea abies (L.) Karst.), assumed to be established right after the birch rotation. The costs and incomes of the birch rotation were discounted to the decision point, i.e., to the establishment of the experiment, which was the time point when the actual decision between alternative regimes was being made. In the discounting, we used the interest rates 1, 2, and 3%, and correspondingly, the NPVs are henceforth abbreviated as NPV1, NPV2, and NPV3. The NPV was calculated as:

where:

NPV = net present value at stand level in birch stand, € ha–1

Hi = income from thinning at time i, valued at roadside (i=0 denotes the decision point)

VT = income from final cutting at rotation T, valued at roadside

Ci = cost of thinning at time i

MT = cost of final cutting at rotation T

SCkl = cost of silvicultural operation k at time l (Note that l=i or l≠i)

r = rate of interest (here 1%, 2%, or 3%)

We chose Norway spruce management instead of downy birch management for the future stand generations since it generally provides better growth and yield as well as profitability than downy birch (Koivisto 1959; Saramäki 1977; Hökkä 1997). Furthermore, the onset of the experiments and, consequently, the decision points of our study occurred more or less in the middle of the birch rotation, and therefore, it was not possible to calculate the BLV according to the ongoing birch rotation without strong (speculative) assumptions concerning the early stages of the stands. The future rotations of Norway spruce management were based on the general management guidelines (Hyvän metsänhoidon… 2007), and a substantial mixture of downy birch was assumed to occur also in the Norway spruce stands, mainly because of summer-frost damages in the Norway spruce, which concurs with the findings in the NFI11 for western and northern Finland (unpublished). Technically, the Norway spruce management was simulated by the Motti-simulator (Hynynen et al. 2005; Salminen et al. 2005), which includes specific growth models for drained peatland stands (Hökkä et al. 1997; Hynynen et al. 2002; Hökkä and Salminen 2006). In brief, the simulated Norway spruce management included one intermediate thinning and a final cutting at the stand age of 95 years, producing a total yield of 295 m3 ha–1. In the financial calculations we applied average stumpage prices in real terms (average from 2011 to 2014, separately for first and later thinnings and final cuttings; Metinfo 2014, then nominal prices deflated by the cost-of-living index, Statistics Finland…2013b) and silvicultural costs in real terms for Northern Ostrobothnia and Southern Lapland (Metinfo 2014). The Norway spruce management included the following silvicultural measures: planting (500 € ha–1), tending of the sapling stand (350 € ha–1), or precommercial thinning (350 € ha–1) and a ditch network maintenance combined with mounding (300 € ha–1). In the calculations of the BLV (Chang and Gadow 2010; Chang 2014), we applied the Faustmann rotation model (Faustmann 1849). The BLV was calculated as:

where:

BLV = bare land value of a spruce stand, € ha–1

Ri = harvesting income in year i valued at stumpage, € ha–1

Cik = silvicultural cost k (k = 1, …, m) in year i

s = rotation length for spruce stand, years

r = rate of interest (here 1%, 2%, or 3%)

Because the examined time periods from the onset of the experiments to the final cuttings of the ongoing birch rotation varied, the BLV of the spruce generations had to be discounted to the decision point. This was done according to:

![]()

where:

T = rotation for the downy birch stand, in years

b = age of the downy birch stand at the onset of experiment, in years

Finally, we combined the NPV of the ongoing birch rotation and the discounted BLV of the future spruce generations by summing up the outcomes of Eq. 1 and Eq. 3 for each case. Henceforth, these combined values are referred to as CoV1, CoV2 and CoV3, the numbers indicating the discount rates 1%, 2% and 3%, respectively.

2.4 Comparisons between management regimes and harvesting methods

We analysed the differences in harvesting removals and profitability among management regimes through covariance analysis. We tested the effects of thinning intensities, with different harvesting methods, rotation lengths, and interest rates by a mixed model (Eq. 4), separately for the stand groups SS, EW and PW. The stand was included as a random block effect. We used the stand dominant height at the onset of the experiment as a covariate, because of the variation in tree height (development stage) within the stand groups. We adjusted the estimated removals and profitabilities on the basis of the overall means across the stand groups: Hdom: 7.45 m, 11.35 m, and 14.5 m in SS, EW and PW stands, respectively, to make the results comparable within stand groups. Because of the small variation in stand age within each stand group, we used the mean age of stands at each rotation length, not the exact age of the individual stands. The model was:

![]()

where:

Ysp = removal or profitability

µ = overall mean in the stand group (SS, EW, or PW)

δT = vector of treatment effects (thinning intensity, harvesting method, rotation length, interest rate)

β = coefficient of the covariate

Hdom1 = stand dominant height at the onset of the experiment

us = random term for experimental stand s

esp = residual term (stand and plot)

To simplify the presentation of our results that spanned over different time intervals, we calculated the means and variation of the parameters for one specific time point, 20 years after first thinning, i.e., at the time of the 4th (method F) or the 5th (other methods) measurement. We selected this time point, because the effects of the first thinning could thus be followed for as long as possible using data from all stands.

Because the financial performance was determined for the time point constituting the onset of the experiment, we finally modelled the effect of development stage (Hdom at the onset of the experiment) and site index (Hdom at the stand age of 50 years) on the CoVs using the harvesting method A. This allows for a general examination on how stand characteristics affect the financial performance. In this model (Eq. 5) we used all data across 20 years from the first thinning from all stand groups (SS, EW and PW) together:

where:

CoV = CoV1, CoV2, or CoV3 at 20 years after the onset of the experiment

treatment = thinning intensity: unthinned, very light, light, moderate, heavy, twice thinned

H50 = site index, stand dominant height at the age of 50 years

Hdom = stand dominant height at the onset of the experiment

ud, uds = random terms for stand group d, and experimental stand s

edsp = residual term

Restricted maximum likelihood (REML) estimation in the “Mixed linear” procedure for hierarchically structured data was used in these analyses (SPSS 16.0, PASW Statistics). Pairwise comparisons were performed through computing of generalised least-square means of the treatment effects.

3 Results

3.1 Harvesting removals

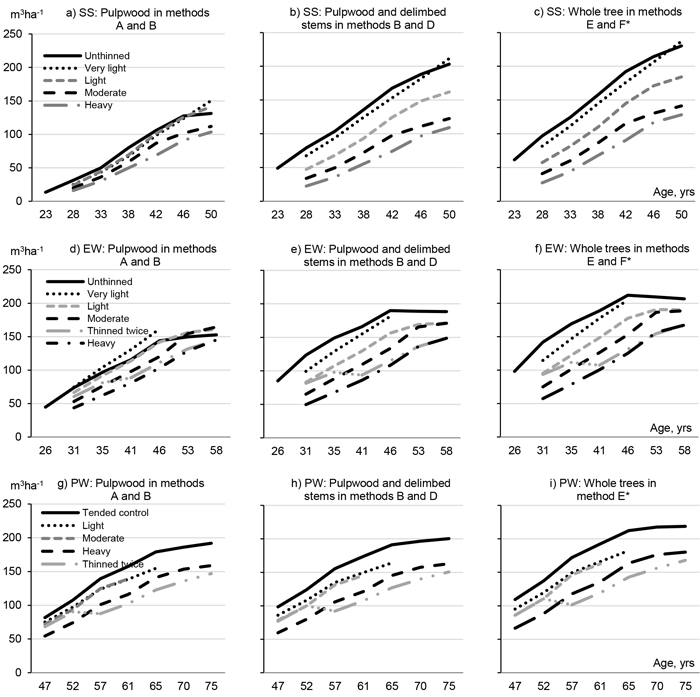

Thinning removals increased with thinning intensity, in the SS stands from 11 to 33 m3 ha–1 for very-light and heavy thinning, and in the EW and PW stands from 35 to 60 m3 ha–1 for light and heavy thinning, respectively (Fig. 1). Final-cutting removals generally depended negatively on thinning intensity, and increased from harvesting methods A and B to E and F (Fig. 2). The unthinned or very lightly thinned stands yielded the highest final-cutting removals in all cases except for pulpwood in the methods A and B for the EW stands at the highest stand ages (Fig. 2d). In the EW stands the number of observations in the category of very light thinnings after the stand age of 46 years was inadequate for giving reliable results. Yet, this treatment may surpass the unthinned stands at the stand age of 50 years also with the delimbed stems (Fig. 2e) and whole trees (Fig. 2f), since the final-cutting removals in the unthinned stands did not increase after that age due to increasing mortality.

Fig. 1. Thinning removals (m3 ha–1) in stand groups SS (sapling stand stage), EW (energy-wood thinning stage), and PW (pulpwood thinning stage) comprising of pulpwood and energy wood as delimbed stems. In SS stands, the first-thinning removal was computational and thus ignored later when calculating total removals and profitability. Error bars are standard errors of means for the total first-thinning removal and for the removal of two thinnings when the second thinning was also carried out.

Fig. 2. Estimates for final-cutting removals (m3 ha–1) as a function of stand age (yrs). Lines describe different intensities of thinnings done at the onset of the experiments. Letters A–F refer to different harvesting methods (described in Table 2). Top panels: sapling-stage stands (SS), middle panels: energy wood thinning stage stands (EW), lowest panels: pulpwood thinning stage stands (PW). *) = Method C is not shown, because the pulpwood + whole-tree energy wood components followed the same trends but with slightly lower values compared to methods E and F (on average 2.5 m3 ha–1).

In the SS stands, the reduction in pulpwood removal caused by thinning was 31% and 26% after the heavy and moderate thinnings, respectively, at the stand age of 46–50 years. When energy wood was cut as delimbed stems (D) or whole trees (E, F) these proportions were 47% and 41%, respectively. At the stand age of 46–50 years the final-cutting removals of the SS stands were evidently still increasing, except for the pulpwood removals in the unthinned stands (Fig. 2). In the EW stands, the reduction in pulpwood removals at the stand age of 46 years was 36% and 25% of the maximum obtained in the unthinned stands after the heavy and moderate thinnings, respectively. For the delimbed stems and whole trees these proportions were 42% and 29%, respectively. In the PW stands, the final-cutting removals after the light and moderate thinnings were quite similar, and 13–15% lower than the removals from the unthinned stands at the average stand age of 61–65 years.

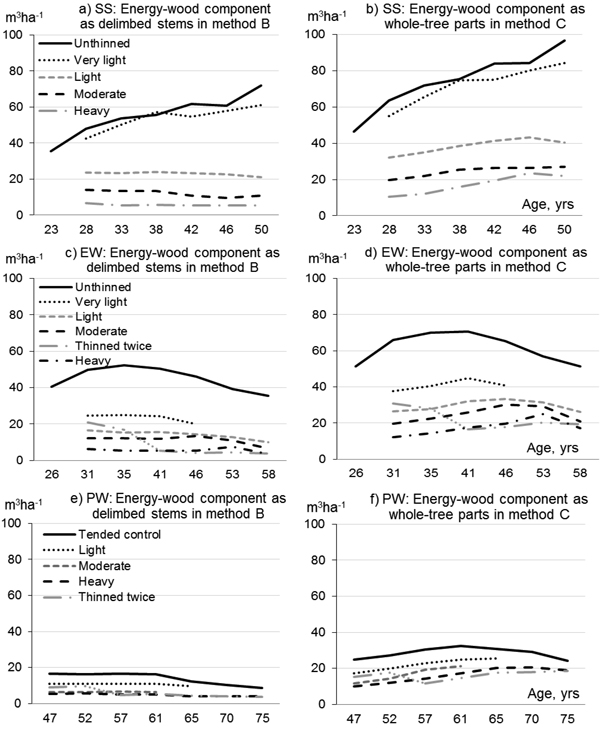

In the integrated harvesting, the maximal energy-wood components in the final-cutting removals were achieved in the unthinned stands (Fig. 3), although the very light thinning in the SS stands gave nearly similar results (Fig. 3ab). In the SS stands, the volume of the energy-wood component was still increasing at the end of the study period. In the EW stands, it culminated at the stand age of 35–40 years, and in the PW stands at 61–60 years (Fig. 3). In the PW stands, the volumes were much lower than in the SS and EW stands because of the tending of the PW stands at their young age.

Fig. 3. Energy-wood components of the estimated final-cutting removals (m3 ha–1) as a function of stand age (yrs) in integrated harvesting methods B (left) and C (right) (method descriptions are in Table 2). Lines describe the different intensities of thinnings done at the onset of the experiments. Top panels: sapling-stage stands (SS), middle panels: energy wood thinning stage stands (EW), lowest panels: pulpwood thinning stage stands (PW).

The total harvesting removals (thinnings + final cutting) examined 20 years after thinning did not differ significantly between the thinning intensities in the PW stands (Fig. 1 and 2). In the EW stands these removals were the largest in the very lightly thinned stands and the lowest in the heavily thinned stands. Correspondingly, the total removals in the SS stands were the highest in the unthinned stands and they decreased significantly with increasing thinning intensity, even for pulpwood.

3.2 Financial performance

3.2.1 Structure of incomes and costs

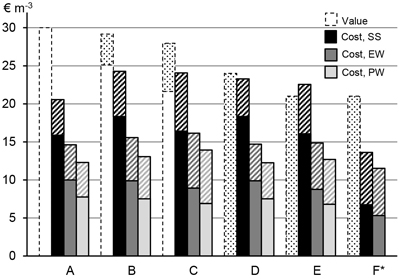

In the first thinning of the EW and PW stands the income (value of the removal) was, obviously, the higher the heavier the thinning was. On the other hand, the income from the final cutting at 20 years after the first thinning was consequently the highest in the unthinned stands and the lowest in the heavily thinned stands. Among the harvesting methods, the integrated methods B and C resulted in the most valuable final-cutting removals, due to the larger volume (both pulpwood and energy wood included) when compared to the method A, and the more valuable wood (pulpwood or delimbed stems) when compared to the methods D–F. The ‘unit value’ (€ m–3) of an average cubic meter of final-cutting removal was highest in method A (only pulpwood), decreasing with increasing proportions of energy wood (Fig. 4).

Fig. 4. Average value of final-cutting removals (€ m–3 at the roadside) and cost of harvesting (€ m–3) for each harvesting methods A–F at 20 years after first thinning. The selected time point represents average ages of 42, 46, and 65 years in stand groups SS (sapling stand stage), EW (energy wood thinning stage), and PW (pulpwood thinning stage), respectively. Value-bars are divided by proportions of pulpwood (blank part) and energy wood (dashed part). Cost-bars are divided by proportions of cutting (filled part) and haulage (dashed part) costs.

In the first thinning the harvesting costs were high, especially in the EW stands. On average in the EW stands, the harvesting costs varied from 60 € m–3 in the heavy to 68 € m–3 in the light first thinning, respectively. In the PW stands the corresponding costs had only small variations, being 18–19 € m–3. Forwarding represented around 12% and 27% of the costs in the EW and PW stands, respectively. The first treatment of the SS stands resulted in no income, whereas the cost of precommercial thinning varied greatly, from 200 to 2000 € ha–1. The cost of clearing of the remaining trees smaller than pulpwood, applied after final cutting by the method A, varied from 80 to 1020 € ha–1.

The average harvesting costs in the final cutting were the lower the heavier was the intensity of the first treatment, the differences being largest in the SS stands. When examining the final cutting at 20 years after the first thinning, the costs (€ m–3) were the highest in the SS stands and the lowest in the PW stands (Fig. 4), which logically reflects the differences in stand density, volume, and average stem size between the stand groups. Among the harvesting methods, the harvesting costs (€ m–3) were the highest in the integrated methods B and C and the lowest in the whole-tree method F (Fig. 4). The average cutting costs varied from 5 to 18 € m–3, and the forwarding costs from 5 to 8 € m–3. In the methods A, B, and D, including delimbed stems, about a third of the total harvesting costs resulted from forwarding, whereas in the whole-tree methods the proportion was 40–50% (Fig. 4).

Examined at 20 years after first thinning, the highest net incomes per cubic meter (= largest difference between wood price and harvesting costs) were reached with method A or F (Fig. 4). With constant prices, the harvesting costs should decrease by 15–30% or 40–70%, in the integrated and energy wood harvesting methods, respectively, to reach the net income level of method A. To reach the level of method F, the integrated harvesting costs should be on average 10–15% lower in the SS stands, whereas in the EW stands, integrated harvesting was already better than in the method F.

3.2.2 Profitability based on combined values of the current and future rotations

The CoV1 values (3000–6000 € ha–1) that arose from the BLV 1% of 4300 € ha–1 seemed unrealistically high for these sites. Since the CoV ranking of the management regimes based on thinning intensities or harvesting methods did not depend on the interest rate used, in the following we will focus on CoV2 (BLV 320 € ha–1) and CoV3 (BLV 0€ ha–1) only. With the interest rate of 3%, regeneration by spruce planting resulted in a negative BLV. Because the birch in our experimental stands showed a reasonable growing potential, we set the level of 0€ ha–1 for BLV 3%, which can be reached by naturally regenerating downy birch without costs. Furthermore, because of the clearly lowest profitability (income minus costs) of the harvesting methods D and E in all stand groups (Fig. 4), we will concentrate on the methods A–C and F.

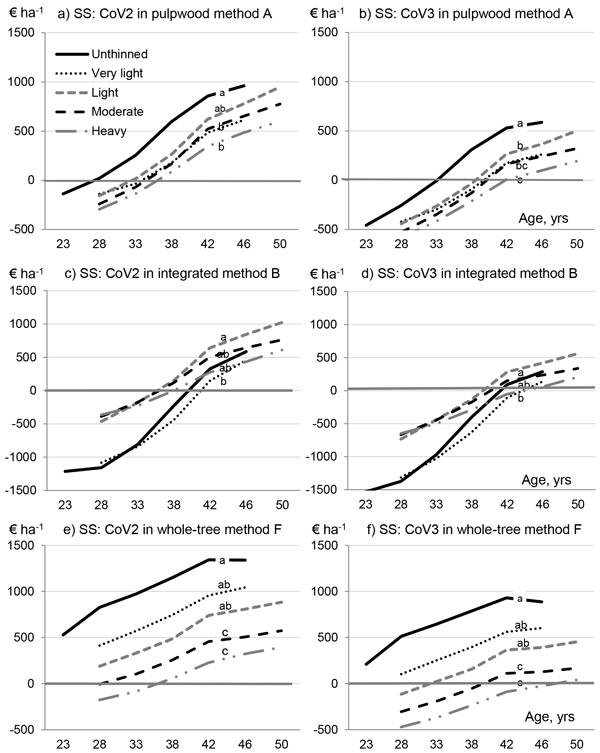

In the SS stands the best profitability in terms of CoV, 1340 € ha–1 (CoV2) or 930 € ha–1 (CoV3), was achieved by the advanced whole-tree harvesting method F in the unthinned stands at the stand age of 42 years (Fig. 5ef). The profitability of this method was the lower the heavier was the precommercial thinning intensity. A totally neglected thinning was more profitable than thinning also with the pulpwood method A (65–70% of the maximum of method F) (Fig. 5ab), for which the highest CoV and the most profitable final-cutting age had not been quite reached by the end of the study period. However, the most profitable timing seems to be achieved by 50 years or slightly later (Fig. 5ab). A light precommercial thinning was the second-best thinning option when method A was used, and heavy thinning was the least profitable. When the integrated method B or C was used (Fig. 5cd), the ranking of the precommercial thinning intensities was different, with light precommercial thinning yielding the best CoV. After light thinning, the maximum profitability of the integrated methods B and C was even higher than that of the pulpwood method A, and it was still increasing at the stand age of 46–50 years. In the unthinned or very lightly thinned SS stands the integrated methods were not competitive until the final-cutting ages of 42–46 years, when they reached the overall CoV levels of the other thinning intensities.

Fig. 5. Profitability, expressed as combined values (CoV, € ha–1) of net present value of the ongoing birch rotation and discounted bare land value of future spruce rotations, as a function of stand age (yrs) for sapling-stage (SS) stands. Lines describe the different thinning intensities and different panels show the harvesting methods A (top), B (middle), and F (bottom) (method descriptions are in Table 2). Discounting was done to the onset of the experiment with interest rates 2% (CoV2, left) and 3% (CoV3, right). Thinning intensities marked with the same letter were not significantly different within the harvesting method and interest rate (p > 0.05).

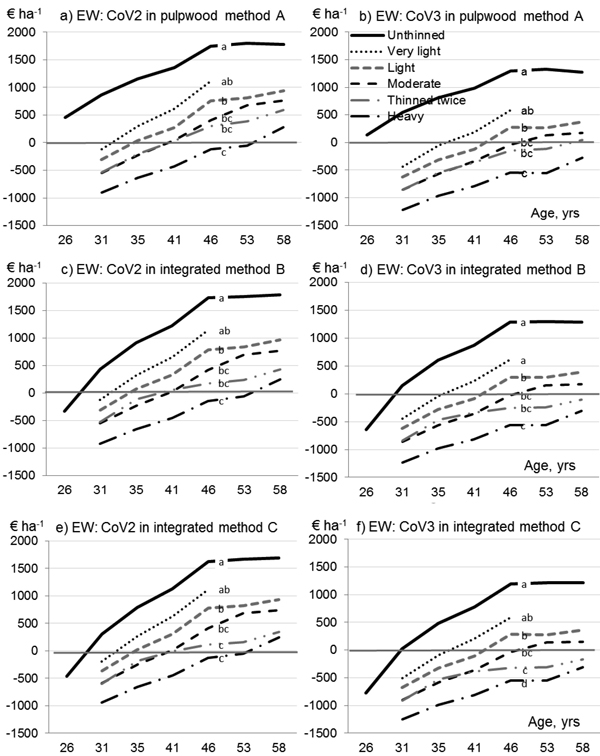

In the EW stands, the ranking of the thinning intensities was the same for all harvesting methods and interest rates (Fig. 6). The CoV was as its highest in the unthinned stands, and the lower the heavier the thinning was. The highest CoVs were achieved with the pulpwood method A and the integrated method B at the stand age of 46 years, being 1800 and 1300 € ha–1 with CoV2 and CoV3, respectively (Fig. 6abcd). For the method C the maximum was 110–130 € ha–1 lower. In the unthinned EW stands the profitability did not increase after the stand age of 46 years, but in thinned ones it continued increasing until the end of study period at the age of 58 years (Fig. 6). The differences in CoV caused by thinning intensity were almost equal with the interest rates of 2% and 3%, and by the methods A and B. By the methods A and B the CoV in the thinned stands was 700, 900, 1050, and 1550 € ha–1 below the maximum in the very light, light, moderate and heavy first thinnings, respectively. For the method C the CoV in unthinned stands was lower but in thinned stands almost equal to the methods A and B. In the EW stands the advanced whole-tree harvesting method F was also applicable until stand age of 40 years, when the stems had grown too thick for the energy-wood harvester used. In the unthinned EW stands CoV2 and CoV3 were positive from the onset of the study at the stand age of 26 years. At the age of 40 years, these values were outstanding in the unthinned EW stands, being 1660 and 1250 € ha–1 for CoV2 and CoV3, respectively. That is, the CoVs for the method F at the stand age of 40 years were close to the maxima reached with the methods A and B several years later.

Fig. 6. Profitability, expressed as combined values (CoV, € ha–1) of net present value of the ongoing birch rotation and discounted bare land value of future spruce rotations, as a function of stand age (yrs) for energy wood thinning stage (EW) stands. Lines describe the different thinning intensities and different panels show the harvesting methods A (top), B (middle), and C (bottom) (method descriptions are in Table 2). Discounting was done to the onset of the experiment with interest rates 2% (CoV2, left) and 3% (CoV3, right). Thinning intensities marked with the same letter were not significantly different within the harvesting method and interest rate (p > 0.05).

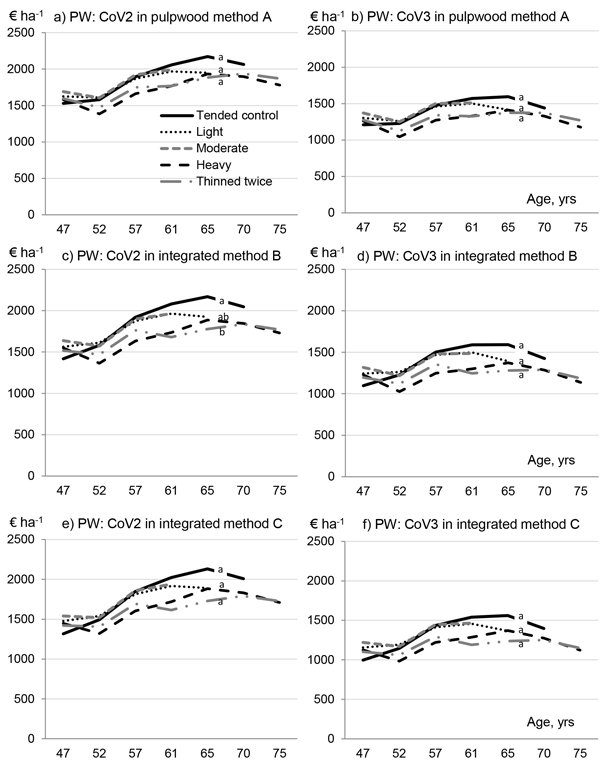

In the PW stands, the CoVs were positive for all methods and thinning intensities (Fig. 7). The CoVs were equal for the pulpwood method A and the integrated method B, except that in twice-thinned stands the method A outperformed method B (Fig. 7). For the integrated method C, CoV was only 30–50 € ha–1 lower than for methods A and B. The best profitability was reached in the unthinned stands (=early tended control) at the stand age of 65 years, being 2170 (CoV2) and 1600 € ha–1 (CoV3). For the other thinning intensities, CoV was 250–200 € ha–1 lower. However, the differences between thinning intensities were not statistically significant. Yet, a further argument in favor of management without thinning was that although the unthinned PW plots showed less profitable immediate final cutting than the thinned plots, i.e., by chance they had less valuable removals, after 20 years the final cutting resulted in higher CoVs in the unthinned plots. Regardless of the thinning intensity and harvesting method, the most profitable final-cutting age was 65 years for the PW stands, on average. After that age, the profitability decreased. For the PW stands, an immediate clearcutting was more profitable than applying thinning and growing the stands for 5 years (Fig. 7). The stands had to be grown for at least 10–15 years after thinning, depending on thinning intensity, before the profitability surpassed that of an immediate clearcut. However, growing of PW stands about 20 years without thinning was a profitable alternative.

Fig. 7. Profitability, expressed as combined values (CoV, € ha–1) of net present value of the ongoing birch rotation and discounted bare land value of future spruce rotations, as a function of stand age (yrs) for pulpwood thinning stage (PW) stands. Lines describe the different thinning intensities and different panels show the harvesting methods A (top), B (middle), and C (bottom) (method descriptions are in Table 2). Discounting was done to the onset of the experiment with interest rates 2% (CoV2, left) and 3% (CoV3, right). Thinning intensities marked with the same letter were not significantly different within the harvesting method and interest rate (p > 0.05).

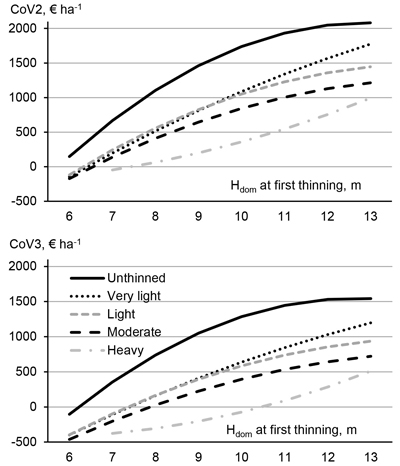

3.2.3 Effects of stand development stage and site index on the profitability

The expected CoVs calculated to the different development stages (defined by stand dominant height, Hdom) of unthinned downy birch stands by Eq. 5 (Table 3) indicated a fast value increase until a Hdom of 10 meters but with a slower increase afterwards (Fig. 8). On average, one meter increase in Hdom from 6 to 7 meters increased the CoV2 of unthinned stand by 519 € ha–1 and from 10 to 11 meters by 195 € ha–1 (Fig. 8). In the unthinned stands a one-unit change in site index (Hdom at the stand age of 50 years) corresponded to a change of 133 and 113 € ha–1 in CoV2 and CoV3, respectively (not shown).

| Table 3. Mixed model (Eq. 5) parameters concerning the whole data. Independent variables CoV2 and CoV3 when growing stands 20 years after the first thinning. | ||||

| CoV2: coeff. | CoV2: sig. | CoV3: coeff. | CoV3: sig. | |

| Intercept (a) | –6728.3 | <0.01 | –6180.2 | 0.00 |

| Twice thinned (b5) | 79.8 | 0.98 | –717.9 | 0.83 |

| Heavy (b4) | 4543.2 | <0.01 | 4436.9 | <0.01 |

| Moderate (b3) | 1850.9 | 0.06 | 1776.2 | 0.06 |

| Light (b2) | 1426.9 | 0.15 | 1467.9 | 0.11 |

| Very light (b1) | 1995.7 | 0.11 | 1858.2 | 0.11 |

| Unthinned (b0) | 0.0 | 0.0 | ||

| Covariates: | ||||

| H50 (c) | 133.3 | <0.01 | 113.0 | <0.01 |

| Hdom (d) | 1044.0 | <0.01 | 944.8 | <0.01 |

| Hdom2 (e) | –40.4 | <0.01 | –37.3 | <0.01 |

| Interactions: | ||||

| Twice * Hdom (f5) | –365.0 | 0.53 | –245.4 | 0.65 |

| Heavy * Hdom (f4) | –1121.6 | <0.01 | –1108.6 | <0.01 |

| Moderate * Hdom (f3) | –492.6 | 0.02 | –489.1 | 0.02 |

| Light * Hdom (f2) | –387.7 | 0.07 | –407.9 | 0.04 |

| Very light * Hdom (f1) | –556.4 | 0.06 | –520.9 | 0.06 |

| Unthinned * Hdom(f0) | 0.0 | 0.0 | ||

| Twice * Hdom2 (g5) | 22.8 | 0.34 | 18.7 | 0.40 |

| Heavy * Hdom2 (g4) | 52.9 | <0.01 | 52.9 | <0.01 |

| Moderate * Hdom2 (g3) | 21.8 | 0.06 | 22.3 | 0.04 |

| Light* Hdom2 (g2) | 17.6 | 0.11 | 19.1 | 0.06 |

| Very light * Hdom2 (g1) | 29.2 | 0.08 | 27.0 | 0.09 |

| Unthinned * Hdom2 (g0) | 0.0 | 0.0 | ||

Fig. 8. Expected combined values (CoV2 and CoV3, € ha–1) at 20 years from the onset of the experiments obtained with harvesting method A (see Table 2) for stands representing different dominant heights (Hdom, m, at the onset of the experiments) and overall mean site index (H50 = 15.5) (Eq. 5). Lines describe different thinning intensities.

4 Discussion

The total area of birch-dominated stands on drained peatlands, ca. 0.5 million hectares (Kojola et al. 2015), is a significant reserve of both pulpwood and energy wood in Finland. The structure, volume, and growth potential of the sites (Saramäki 1977; Keltikangas and Seppälä 1977; Niemistö 2013) enable application of different harvesting methods and management regimes so that the best possible gain may be reached.

4.1 Choosing the best management regime

Based on our results, the foremost three things to consider when deciding how to manage a downy birch stand are 1) management history, 2) production focus (whether pulpwood or energy wood production is emphasized), and 3) the harvesting machinery available. If the stand has not been managed earlier, there are no specific reasons to aim at pulpwood production, and if an effective multi-tree harvester for advanced whole-tree harvesting is available, the most profitable option clearly is to grow the stand untreated until final cutting as whole-tree energy wood at the stand age of 40–45 years. If such a machinery is not available, it is better to opt for integrated harvesting of both pulpwood and energy-wood poles at about ten years later. Producing only energy wood thus seems to be profitable only with a specific method (like method F in our study).

If the aim is to specifically produce pulpwood, applying a light precommercial thinning at 4–5 meter dominant height to the density of 2000–2500 stems per hectare is a competitive alternative. If precommercial thinning or early light thinning has already been done, the final cutting should be delayed until the stand age of 50–65 years, when pulpwood harvesting is the most profitable option. In that case, commercial thinning is not necessary but it is possible without any significant economic effect. Tending before 4 meters height is reached would be a cheaper operation, but, due to coppicing, may lead to the stand becoming even denser, with sprouts almost equal in size to the trees in unthinned sapling stands (Niemistö 2013).

In pulpwood production, rotation lengths shorter than 40–50 years, with or without thinnings, were economically inferior to longer rotations, due to the low removal and high harvesting costs of small stems. In unthinned stands the profitable final-cutting age seemed to be earlier than in lightly thinned stands. In spite of the increasing natural mortality, quite a long maturing period was competitive for the unthinned stands, because self-thinning was mostly selecting the smallest stems that are the most expensive to cut.

These choices are based on the estimated profitability only, but there may be other reasons also for thinning: regeneration through utilizing a Norway spruce understory that often appears in this kind of sites, producing saw logs or plywood in very high quality and fertile downy birch stands, or esthetic reasons only.

4.2 To thin or not to thin

Among the combinations of the five intensity levels of the first treatments, six harvesting methods, and several rotation lengths, the most profitable management in young and dense downy birch stands was growing without any thinnings to final cutting as whole-tree energy wood at the stand age of 40–45 years. The best profitability required, however, that it was possible to use an advanced whole-tree harvesting method specifically designed for small stems in the final cutting (Jylhä and Bergström 2016), whereas with the standard, non-specific, whole-tree method the profitability dropped drastically. As expected, the denser a birch-stand was grown, the higher was the production of small-diameter poles and branch biomass. A slightly unexpected result, in contrast, was that the pulpwood removal also was the highest in very dense stands, as Niemistö (2013) has already reported. Generally, opposite results, lower pulpwood yields in dense stands, have been observed (Scots pine: Ruha and Varmola 1997; Huuskonen and Hynynen 2006; silver birch: Niemistö 1995). The commonly held idea is that light thinning enables a maximal amount of stems to reach the size requirement for pulpwood, while in dense stands most stems remain too small. This seems not to be the case with downy birch, however, which thus seems to tolerate competition better than most species at the early stages of development.

Distinctively, applying energy wood thinning in dense downy birch stands with a mean height of 8–11 meters resulted in low overall profitability. The stem size in such thinnings is modest and the thinning removal tends to be low, resulting in an unprofitable operation. Getting larger removals by increasing thinning intensity causes growth losses (Niemistö 2013) that lead to decreasing total profitability of the final cutting, the more the heavier the thinning. In the SS and EW stage stands, these negative impacts will further increase with time. Regardless of the timing or method of final cutting the total profitability was the highest in the unthinned stands. In the absence of thinning, natural mortality takes care of removing the smallest stems for free, and thus, these will not lower the profitability of the final cutting. Applying a second thinning 10–15 years after the light first thinning, did not increase the profitability, either.

Precommercial thinning as well as energy wood thinning seemed to be unnecessary and expensive treatments. Thinning did not increase the value of the final-cutting removal. Moreover, it did not significantly decrease the harvesting costs per cubic meter of the final cutting, either, because natural mortality had removed the smallest trees during the rotation, without any cost. In all the studied rotation lengths and thinning treatments the total removals were lower in the SS and PW stands than in the EW stands. This was due to the precommercial thinning of the SS and PW stands which does not result in a merchantable removal, and the growth loss caused by early uncommercial thinning. This conclusion was proved in the unthinned SS stands, where the production of small diameter poles and branch biomass reached the same level as in the EW stands at the stand age of 55 years. The costs of late precommercial thinning or energy wood thinning were very high in dense birch stands and therefore the profitability of thinned sapling stands (SS) were higher than those of older EW stands, even if the rotation length was 55 years.

Even though thinnings were generally useless, applying a light precommercial thinning to the density of 2500–3500 stems per hectare was a competitive option when the aim of the stand management was to produce pulpwood (with or without energy wood). That was shown in the results of both young stands (SS) and more mature stands (PW). The traditional commercial thinning at the PW stage had a very small effect on total profitability. Due to this, the decision between to thin or not to thin may be based on other goals of forest management. For the sapling stands (SS), our study period was not long enough to produce final evidence to conclude, which of the two thinning intensities, unthinned or light, and two harvesting types, pulpwood or integrated, would be the most profitable. Obviously in pulpwood production the difference between the unthinned and lightly-thinned stands was small, whereas with integrated harvesting methods the light-thinning alternative was slightly better. In any case, final cutting for pulpwood was a proper method for the precommercially thinned more mature stands.

As to forest management in general, the thinnings are more profitable (or at least less unprofitable) when higher interest rates are used, due to the earlier incomes (Hyytiäinen and Tahvonen 2002; Ahtikoski et al. 2004). In the stands examined here, this was true only in early tended birch stands at the conventional first-thinning stage (PW), although the difference between thinned and unthinned stands even then was very small. The opposite effect of interest rate in dense downy birch stands stems from a combination of precommercial thinning causing costs and energy wood harvesting also often causing net costs or the net income being low without any subsidies. The higher interest rate was used, the more competitive the unthinned management regimes were. Because of the low value increment and low thinning response of downy birch (Niemistö 2013), the compensation of the costs of precommercial thinning or early thinning takes place very slowly, if at all. In addition, in a practical scale, the yield of valuable timber is nonexistent because of the low quality and small size of the stems.

Although our results showed low benefits of thinnings, the goals other than economic gain may be relevant reasons for them, such as regeneration of spruce via undergrowth (Niemistö and Poutiainen 2004; Niemistö et al. 2012) or landscaping or multiple use aspects. On the most nutrient-rich sites with a high production potential, when the quality of the downy birch stands is exceptionally high it may also be possible to produce saw or veneer timber besides pulpwood and energy wood. In such cases, different kinds of management regimes than those discussed in this study should most likely be applied.

4.3 Harvesting method

Our results showed that it was possible to significantly increase the productivity of final cutting in dense birch stands with small stems by using an advanced whole-tree harvesting method, which is more suitable for multi-tree harvesting of small stems than the standard whole-tree method. The gain of the advanced method used in our study (via productivity models) may be especially high in downy birch harvesting, where often bent and crooked stems are ill-suited to regular multi-tree harvesting, which uses feeding and delimbing harvester heads (Laitila et al. 2016). Further, the advanced method is capable of two-phase cutting of stems, which enables standard forwarding for up to even 15-m tall trees.

Generally, improving the productivity of forest forwarding also should be targeted for better profitability. Yet, the small size of whole-tree loads (6 m3 at a time) used in this study as model input may be an underestimate even for up-to-date forwarders in final cuttings of mature birch stands with a considerable amount of long stemwood logs.

In Finland, whole-tree harvesting solutions have thus far been mainly considered from thinning operations points of view. Elsewhere, whole-tree harvesting is used in final cuttings, but the target is usually single larger, sawn-timber sized trees. Multi-tree treatment of smaller-sized trees in final cuttings is still a novel and rare approach, and the methodologies have been little developed or studied. Because of new bio-refineries and an increasing use of forest energy it seems that the need and, consequently, development of this kind of machinery will increase in the future.

4.4 Methodological considerations

The results of this study were based on 19 experimental stands that included a wide range of thinning intensities and a wealth of growth data from sapling stands to mature stands. These stands covered well the variation existing in the most common peatland site types of downy birch dominated stands, as well as their frequency in western and northern Finland. According to NFI11 46%, 39%, and 18% of the downy birch dominated stands were situated at HrT, MT2, and MT1 sites (Herb-rich type and V. myrtillus type II and I; see Westman and Laiho 2003), and more than half of the total area was found in the regions where our experimental stands were located (Kojola et al. 2015).

The long-time trial with several stands and carefully planned experimental design allowed us to study a wide range of treatments, stand densities and rotation periods. All the stand data have earlier been cross-checked and analyzed by Niemistö (2013), giving a reliable starting point for this study. Thanks to the accurate measurement data we were able to augment the data further to extra assortments, like small energy wood stems and branch biomass.

With models, we were able to compare many types of harvesting methods simultaneously. Of course, such calculations are based on several assumptions that were made already at the development phase of the models. The harvesting models of Laitila et al. (2016) have been developed to be applicable on similar types of peatland birch stands as used in this study and for harvesting of delimbed stems. Furthermore, the models distinguish between thinning and clear cutting, thus resulting in more accurate estimates in different cases. Therefore, those models were easily adapted to the circumstances of our study stands for harvesting of pulpwood or delimbed stems. However, even for whole-tree harvesting, the volume of delimbed stems is used as an input for the model, which may cause a small overestimation in harvesting cost. The method and model of Jylhä and Bergström (2016) gave us the advanced whole-tree harvesting alternative. To ensure the functioning of the model in our stands, its use was carefully restricted only to data matching the modelling data. The model of Kuitto et al. (1994) for forwarding costs was for pulpwood. Therefore we also used the models of Laitila et al. (2007) for the delimbed stems and whole-tree, to get more exact results. However, the load size may still be debatable.

Comparing the results obtained with productivity models from different studies, which involve different operators, whose impact on productivity may be great (Laitila et al. 2016), involves some risk. Here, the method F was derived from a different study than the others. However, we did not consider the differences that we got between the whole-tree methods E and F, where the method of multi-tree handling but also the operator changed, to be overly dependent on the latter. Since the method F involves a very different approach to the whole operation than method E, the experience of the operator with the method in question may be of more importance than utilizing a “standard” operator. Also, the difference obtained for these two methods in downy birch stands, especially, is quite logical, as pointed out in the previous section.

Unit prices and costs are important variables when profitability is discussed. We set the levels according to statistics. However, especially the price of energy wood is difficult to specify since it fluctuates in the market. In our study the energy wood price considered was a subsidized price, resulting in a relatively high value when compared to that of pulpwood.

In the current forestry context, it was not reasonable to assume that several downy birch generations would be repeatedly managed. Instead, we assumed that the main species would be changed to Norway spruce after the ongoing birch rotation, although at least some birch will then appear as mixture. The spruce generation was used as a representative management regime for assessing the bare land value, BLV, enabling us to compare the different final-cutting times for birch. Due to the great variation in final-cutting times for birch, the discounted BLV of the future spruce generations needed to be included in the financial analyses in order to commensurate the alternative management regimes of the ongoing birch rotation in a theoretically solid manner (Amacher et al. 2009). In general, the stands of this study were located on such site types and climatic conditions where forestry on peatlands can be considered profitable also in the future based on their BLV (Hyvän metsänhoidon… 2007), if the required rate of return and the regeneration costs remain moderate. On the other hand, Niemistö (2013) has shown that the productivity of the downy birch may be very high in the sites in question. Because of the difficulties related to the establishment of spruce stands, like frost damages, it may be questioned if the regeneration for spruce is always the best alternative.

This study focused on pure downy birch stands in central and northern Finland that were assumed to be regenerated to spruce after final cutting. Further research is still needed concerning the management of downy birch-dominated mixed forests and two-storied birch-spruce stands. Also, while the challenges and risks related to regeneration of the highly productive peatlands are well known (Hånell 1993; Moilanen et al. 2011), there is insufficient scientific information to support the valuation of the alternative regeneration methods. In southern Finland, downy birch stands may yield valuable logwood on both peatland and mineral-soil sites of high production potential, which should be considered when making decisions on their management. Thus, unthinned thickets are not the only feasible management option in downy birch stands, even though these resulted in the best profitability in this study that only examined production of pulpwood and energy wood.

Acknowledgements

Markus Hartman (English revision), Antti Ihalainen (National Forest Inventory), Paula Jylhä (harvest models), Juha Laitila (harvest models), Eero Poutiainen & Jorma Issakainen (field works and basic computations).

References

Ahtikoski A., Päätalo M.-L., Niemistö P., Karhu J., Poutiainen E. (2004). Effect of alternative thinning intensities on the financial outcome in silver birch stands: a case study based on long-term experiments and MOTTI stand simulations. Baltic Forestry 10(2): 46˗55. http://www.balticforestry.mi.lt/bf/PDF_Articles/2004-10[2]/46_55%20Ahtikoski%20et%20al.pdf.

Amacher G.S., Ollikainen M., Koskela E. (2009). Economics of forest resources. The MIT Press, Cambridge. 448 p.

Björklund T., Ferm A. (1982). Pienikokoisen koivun ja harmaalepän biomassa ja tekniset ominaisuudet. Summary: Biomass and technical properties of small-sized birch and grey alder. Folia Forestalia 500. 37 p. [In Finnish, with English summary].

Braastad H. (1967). Produksjonstabeller for bjørk. [Yield tables for birch]. Meddelelser fra det Norske Skogforsøksvesen 22: 265–365. [In Norwegian].

Cameron A.D., Dunham R.A., Petty J.A. (1995). The effects of heavy thinning on stem quality and timber properties of silver birch (Betula pendula Roth). Forestry 68(3): 275–285. https://doi.org/10.1093/forestry/68.3.275.

Chang S.J. (2014). Forest valuation under the generalized Faustmann formula. Canadian Journal of Forest Research 44(1): 56–63. https://doi.org/10.1139/cjfr-2013-0298.

Chang S.J., Gadow K.V. (2010). Application of the generalized Faustmann model to uneven-aged forest management. Journal of Forest Economics 16(4): 313–325. https://doi.org/10.1016/j.jfe.2010.06.002.

Faustmann M. (1849). Berechnung des Werthes, welchen Waldboden, sowie noch nicht haubare Holzbestände für die Waldwirthscaft besitzen. [Calculation of the value which forest land and immature stands possess for forestry]. Allegemeine Forst und Jagd Zeitung 15: 441–455.

Ferm A. (1993). Birch production and utilization for energy. Biomass and Bioenergy 4(6): 391–404. https://doi.org/10.1016/0961-9534(93)90061-8.

Ferm A., Kauppi A. (1990). Coppicing as a means for increasing hardwood biomass production. Biomass 22(1–4): 107–121. https://doi.org/10.1016/0144-4565(90)90010-H.

Fernandez-Lacruz R., Di Fulvio F., Bergström D. (2013). Productivity and profitability of harvesting power line corridors for bioenergy. Silva Fennica 47(1) article 904. https://doi.org/10.14214/sf.904.

Fries J. (1964). Summary: Yield of Betula verrucosa Ehrh. in Middle Sweden and southern North Sweden. Studia Forestalia Suecica 14. 303 p.

Hånell B. (1993). Regeneration of Picea abies forests on highly productive peatlands – clearcutting or selective cutting? Scandinavian Journal of Forest Research 8(1–4): 518–527. https://doi.org/10.1080/02827589309382798.

Heikkilä J., Sirén M., Ahtikoski A., Hynynen J., Sauvula T., Lehtonen M. (2009). Energy wood thinning as a part of stand management of Scots pine and Norway spruce. Silva Fennica 43(1): 129–146. https://doi.org/10.14214/sf.220.

Heinonen J. (1994). Koealojen puu- ja puustotunnusten laskentaohjelma KPL – käyttöohje. Summary: Computer programme package for computing stand and single tree characteristics from sample plot measurements. Finnish Forest Research Institute Research Papers 504. 80 p. [In Finnish with English summary].

Hökkä H. (1997). Models for predicting growth and yield in drained peatland stands in Finland. The Finnish Forest Research Institute, Research Papers 651. 45 p.

Hökkä H., Salminen H. (2006). Utilizing information on site hydrology in growth and yield modeling: peatland models in the MOTTI stand simulator. In: Hydrology and Management of Forested Wetlands: Proceedings of the International Conference 8–12 April 2006, New Bern, NC, American Society of Agricultural and Biological Engineers (ASABE), St. Joseph, MI. p. 302–309.

Hökkä H., Alenius V., Penttilä T. (1997). Individual-tree basal area growth models for Scots pine, pubescent birch and Norway spruce on drained peatlands in Finland. Silva Fennica 31(2): 161–178. https://doi.org/10.14214/sf.a8517.

Huuskonen S., Hynynen J. (2006). Timing and intensity of precommercial thinning and their effects on the first commercial thinning in Scots pine stands. Silva Fennica 40(4): 645–662. https://doi.org/10.14214/sf.320.

Hynynen J., Ojansuu R., Hökkä H., Salminen H., Siipilehto J., Haapala P. (2002). Models for predicting stand development in MELA system. Finnish Forest Research Institute, Research Papers 835. 116 p.

Hynynen J., Ahtikoski A., Siitonen J., Sievänen R., Liski J. (2005). Applying the MOTTI simulator to analyse the effects of alternative management schedules on timber and non-timber production. Forest Ecology and Management 207(1–2): 5–18. https://doi.org/10.1016/j.foreco.2004.10.015.

Hynynen J., Niemistö P., Viherä-Aarnio A., Brunner A., Hein S., Velling P. (2010). Silviculture of birch (Betula pendula Roth and Betula pubescens Ehrh.) in northern Europe. Forestry 83(1): 103–119. https://doi.org/10.1093/forestry/cpp035.

Hytönen J., Moilanen M. (2014). Effect of harvesting method on the amount of logging residues in the thinning of Scots pine stands. Biomass and Bioenergy 67: 347–353. https://doi.org/10.1016/j.biombioe.2014.05.004.

Hyvän metsänhoidon suositukset turvemaille (2007). [Guidelines for best management practices in silviculture on drained peatlands]. Finnish Forest Development Centre, Tapio. Metsäkustannus Oy, Helsinki. 50 p. [In Finnish].

Jylhä P., Bergström D. (2016). Productivity of harvesting dense birch stands for bioenergy. Biomass and Bioenergy 88: 142–151. https://doi.org/10.1016/j.biombioe.2016.03.016.

Kaila S., Poikela A., Strandström M. (1999). Raivaussahantyön tuottavuus ja palkanmääritys.[Payment and productivity of forest cleaning with clearing saw]. Metsätehon raportti 78. 43 p. [In Finnish].

Kaila S., Poikela A., Strandström M. (2001). Henkilökohtaiseen tuottavuustavoitteeseen perustuva raivaussahatyön palkkausjärjestelmä. Osa 2. Tulokset vuoden 1999 kokeiluista. [Payroll system for clearing saw based on personal productivity targets. Part 2. Results from 1999 experiments]. Metsätehon raportti 99. [In Finnish]. http://www.metsateho.fi/wp-content/uploads/2015/02/metsatehon_raportti_099_osa_2.pdf.

Keltikangas M., Seppälä K. (1977). Ojitusalueiden koivikoiden kasvatus taloudellisena vaihtoehtona. Summary: The economics of growing birch stands on drained peatlands. Silva Fennica 11(1): 49–68. [In Finnish, with English summary]. https://doi.org/10.14214/sf.a14813.

Koivisto P. (1959). Kasvu- ja tuottotaulukoita. Summary: Growth and yield tables. Communicationes Instituti Forestalis Fenniae 51(8). 49 p. [In Finnish, with English summary].

Kojola S., Niemistö P., Ihalainen A., Laiho R. (2015). Birch-dominated stands on drained peatlands. In: Kojola S., Niemistö P., Salminen H., Lehtonen M., Ihalainen A., Kiljunen N, Soikkeli P., Laiho R. (eds.). Synthesis report on utilization of peatland forests for biomass production. Cleen Oy Research report no D 2.1.2. ISBN 978-952-5947-79-3. p. 5–20. http://urn.fi/URN:NBN:fi-fe2016091523781.

Kuitto P.-J., Keskinen S., Lindroos J., Oijala T., Rajamäki J., Räsänen T., Terävä J. (1994). Puutavaran koneellinen hakkuu ja metsäkuljetus. Summary: Mechanized cutting and forest haulage. Metsäteho raportti 410. 38 p. [In Finnish, with English summary].

Kärhä K. (2011). Integrated harvesting of energy wood and pulpwood in first thinnings using the two-pile cutting method. Biomass and Bioenergy 35(8): 3397–3403. https://doi.org/10.1016/j.biombioe.2010.10.029.

Laine J., Vasander H., Hotanen J.-P., Nousiainen H., Saarinen M., Penttilä T. (2012). Suotyypit ja turvekankaat – opas kasvupaikkojen tunnistamiseen. [Site types of mires and drained peatland forests – a guide for identification]. Metsäkustannus Oy, Helsinki. 160 p. ISBN 978-952-5694-89-5. [In Finnish].

Laitila J., Väätäinen K. (2011). Kokopuun ja rangan autokuljetus ja haketustuottavuus. [Truck transportation and chipping productivity of whole trees and delimbed energy wood poles]. Metsätieteen aikakauskirja 2/2011: 107–126. https://doi.org/10.14214/ma.6635.

Laitila J., Väätäinen K. (2012). Truck transportation and chipping productivity of whole trees and delimbed energy wood in Finland. Croatian Journal of Forest Engineering 33(2): 199–210. http://hrcak.srce.hr/116817.

Laitila J., Asikainen A., Nuutinen Y. (2007). Forwarding of whole trees after manual and mechanized felling bunching in pre-commercial thinnings. International Journal of Forest Engineering 18(2): 29–39.

Laitila J., Heikkilä J., Anttila P. (2010). Harvesting alternatives, accumulation and procurement cost of small-diameter thinning wood for fuel in Central Finland. Silva Fennica 44(3): 465–480. https://doi.org/10.14214/sf.143.

Laitila J., Niemistö P., Väätäinen K. (2014). Hieskoivikoiden avo- ja harvennushakkuun tuottavuus aines- ja energiapuun yhdistetyssä korjuussa joukkokäsittelymenetelmällä. Working Papers of the Finnish Forest Research Institute 285. ISBN 978-951-40-2462-7. [In Finnish]. http://www.metla.fi/julkaisut/workingpapers/2014/mwp285.pdf.

Laitila J., Niemistö P., Väätäinen K. (2016). Productivity of multi-tree cutting in thinnings and clear cuttings of young downy birch- (Betula pubescens) dominated stands in the integrated harvesting of pulpwood and energy wood. Baltic Forestry 21(1): 116–131. http://www.balticforestry.mi.lt/bf/PDF_Articles/2016-22[1]/e-Baltic%20Forestry%202016.1_116-131%20psl.pdf.

Metinfo (2014). Searchable online database provided by METINFO Services. Finnish Forest Research Institute, Helsinki. http://www.metla.fi/metinfo/.

Moilanen M. (1985). Lannoituksen ja harvennuksen vaikutus hieskoivun kasvuun ohutturpeisilla ojitetuilla rämeillä. Summary: The effect of fertilization and thinning on the growth of birch Betula pubescens on the drained mires with thin peat layer. Folia Forestalia 629. 29 p. [In Finnish, with English summary]. http://urn.fi/URN:ISBN:951-40-0712-3.

Moilanen M., Issakainen J., Vesala H. (2011). Metsän uudistaminen mustikkaturvekankaalla – luontaisesti vai viljellen? Working Papers of the Finnish Forest Research Institute 192. [In Finnish]. http://www.metla.fi/julkaisut/workingpapers/2011/mwp192.pdf.

Natural Resources Institute Finland (2016). Wood in energy generation 2015. Official Statistics of Finland (OFS). http://stat.luke.fi/en/wood-energy-generation-2015_en.

Niemistö P. (1991). Hieskoivikoiden kasvatustiheys ja harvennusmallit Pohjois-Suomen turvemailla. Summary: Growing density and thinning models for Betula pubescens stands on peatlands in northern Finland. Folia Forestalia 782. 36 p. [In Finnish, with English summary]. http://urn.fi/URN:ISBN:951-40-1185-6.

Niemistö P. (1995). Influence of initial spacing and row-to-row distance on the growth and yield of silver birch (Betula pendula). Scandinavian Journal of Forest Research 10(3): 245–255. https://doi.org/10.1080/02827589509382890.

Niemistö P. (2013). Effect of growing density on biomass and stem volume growth of downy birch stands on peatland in Western and Northern Finland. Silva Fennica 47(4) article 1002. https://doi.org/10.14214/sf.1002.

Niemistö P., Korhonen K.T. (2008). Koivuvarat ja kasvu. [Birch resources and growth]. In: Niemistö P., Viherä-Aarnio A., Velling P., Heräjärvi H., Verkasalo E. (eds.). Koivun kasvatus ja käyttö. [Production and utilization of birch]. Metla and Metsäkustannus. ISBN 978-952-5694-12-3. p. 175–181. [In Finnish].

Niemistö P., Poutiainen E. (2004). Hieskoivikon käsittelyn vaikutus kuusialikasvoksen kehitykseen Keski- ja Pohjois-Pohjanmaan viljavilla ojitusalueilla. [Impacts of different treatments of downy birch stands on the development of Norway spruce undergrowth on the fertile drainage areas in Northern Ostrobothnia]. Metsätieteen aikakauskirja 4/2004: 441–459. [In Finnish]. https://doi.org/10.14214/ma.5664.

Niemistö P., Korpunen H., Laurén A., Salomäki M., Uusitalo J. (2012). Impact and productivity of harvesting while retaining young understorey spruces in final cutting of downy birch (Betula pubescens). Silva Fennica 46(1): 81–97. https://doi.org/10.14214/sf.67.

Nuutinen T., Hirvelä H., Salminen O., Härkönen K. (2007). Alueelliset hakkuumahdollisuudet valtakunnan metsien 10. inventoinnin perusteella, maastotyöt 2004–2006. [Regional felling possibility estimates based on the tenth National Forest Inventory, field data from 2004–2006]. Metsätieteen aikakauskirja 2B/2007: 215–248. [In Finnish]. https://doi.org/10.14214/ma.6218.

Petty A., Kärhä K. (2014). Productivity and cost evaluations of energy-wood and pulpwood harvesting systems in first thinnings. International journal of forest engineering 25(1): 37–50. https://doi.org/10.1080/14942119.2014.893129.

Repola J. (2008). Biomass equations for birch in Finland. Silva Fennica 42(4): 605–624. https://doi.org/10.14214/sf.236.

Ruha T., Varmola M. (1997). Precommercial thinning in naturally regenerated Scots pine stands in northern Finland. Silva Fennica 31(4): 401–41. https://doi.org/10.14214/sf.a8537.

Rummukainen A., Heikkilä J., Sikanen L., Aarnio J., Mäkinen P., Tahvanainen T. (2003). Puunhankinnan tienviitat. Tutkimustarpeet muuttuvassa toimintaympäristössä. [Signposts for wood procurement. Research needs in the changing operational environment]. Finnish Forest Research Institute Research Papers 896. 80 p.

Salminen H., Lehtonen M., Hynynen J. (2005). Reusing legacy FORTRAN in the MOTTI growth and yield simulator. Computers and Electronics in Agriculture 49(1): 103–113. https://doi.org/10.1016/j.compag.2005.02.005.

Saramäki J. (1977). Development of white birch (Betula pubescens Ehrh.) stands on drained peatlands in Northern Central Finland. Communicationes Instituti Forestalis Fenniae 91(2). 59 p.

Statistics Finland (2013a). Cost index of forest machinery and vehicles. (Metsäalan kustannusindeksit MEKKI). [In Finnish]. http://tilastokeskus.fi/til/mekki/tau.html.

Statistics Finland (2013b). Consumer and cost-of-living indexes 2013. Appendix table 2, Cost-of-living index 1951:10=100. Official Statistics of Finland (OSF). http://www.stat.fi/til/khi/2013/12/khi_2013_12_2014-01-14_tau_002_en.html.

Torvelainen J. (2014). Energiapuun kauppa, tammi-maaliskuu 2014. [Energy wood trade, January–March 2014]. Metsätilastotiedote 25/2014. 6 p. [In Finnish]. http://www.metla.fi/metinfo/tilasto/julkaisut/mtt/2014/energiapuu14_1-3.pdf.