Estimation of conversion factors for wood stacks in landings and their influencing parameters: a comprehensive literature review for America and Europe

de Miguel-Díez F., Purfürst T., Acuna M., Tolosana-Esteban E., Cremer T. (2023). Estimation of conversion factors for wood stacks in landings and their influencing parameters: a comprehensive literature review for America and Europe. Silva Fennica vol. 57 no. 1 article id 22018. https://doi.org/10.14214/sf.22018

Highlights

- Midpoint diameter, stacking quality, crookedness, log length, delimbing quality and bark thickness strongly influence the conversion factors

- In Europe and America, a total of 48 methods were developed to estimate the conversion factors of wood stacks

- The conversion factors should be estimated for each wood assortment and tree species.

Abstract

In commercial transaction of stacked roundwood, the estimation of the stack net volume plays a key role. One generalized method to determine the net volume is using conversion factors that relate the gross and net volumes. In this literature review the developed methods to estimate the conversion factors as well as their influencing parameters were analyzed based on 153 references from America and Europe. According to the results, 48 different methods (including their variants) for estimating the conversion factors were developed. The newest methods enabled their accurate determination inexpensively, e.g., photo-optical methods or 3D simulation models. The analyzed references revealed that 30 parameters influence the conversion factors. Based on this comprehensive review, each stakeholder involved in the roundwood supply chain can know which method is used for estimating the conversion factors in the analyzed territories and which influencing parameters should be considered when purchasing roundwood in order to accurately assess the solid wood content in the stacks.

Keywords

log properties;

roundwood measurement;

roundwood purchase;

stack properties;

wood supply chain

-

de Miguel-Díez,

Eberswalde University for Sustainable Development, Department of Forest Utilization and Timber Markets, Eberswalde, Germany; University of Freiburg, Chair of Forest Operations, Freiburg, Germany

https://orcid.org/0000-0002-3800-7449

E-mail

felipe.diez@hnee.de

https://orcid.org/0000-0002-3800-7449

E-mail

felipe.diez@hnee.de

-

Purfürst,

University of Freiburg, Chair of Forest Operations, Freiburg, Germany

https://orcid.org/0000-0001-9661-0193

E-mail

thomas.purfuerst@foresteng.uni-freiburg.de

https://orcid.org/0000-0001-9661-0193

E-mail

thomas.purfuerst@foresteng.uni-freiburg.de

- Acuna, University of the Sunshine Coast, Forest Research Institute, Sunshine Coast, Queensland, Australia E-mail macuna@usc.edu.au

-

Tolosana-Esteban,

Universidad Politécnica de Madrid, E.T.S.I. Montes, Forestal y del Medio Natural, Madrid, Spain

https://orcid.org/0000-0003-2561-0342

E-mail

eduardo.tolosana@upm.es

https://orcid.org/0000-0003-2561-0342

E-mail

eduardo.tolosana@upm.es

-

Cremer,

Eberswalde University for Sustainable Development, Department of Forest Utilization and Timber Markets, Eberswalde, Germany

https://orcid.org/0000-0001-7866-944X

E-mail

Tobias.Cremer@hnee.de

https://orcid.org/0000-0001-7866-944X

E-mail

Tobias.Cremer@hnee.de

Received 10 November 2022 Accepted 31 March 2023 Published 20 April 2023

Views 129975

Available at https://doi.org/10.14214/sf.22018 | Download PDF

1 Introduction

The worldwide commercialization of industrial roundwood (destined generally to manufacture pulpwood and paper) is very diverse, considering specific factors such as the local conditions, tree species and legislation in each country. As this kind of assortment tends to have smaller diameters (Williams 1968; Hamilton 1975), shorter lengths (no longer than 6 m) and be of a lower quality, the measurement should not generally be costly. Thus, there are usually two options to estimate the industrial roundwood volume to be acquired in stacks: weight or volumetric measurement (Hamilton 1975; Batista and Zarate do Couto 2002). The advantages and disadvantages of each of these alternatives to measure the roundwood volume have been analyzed in former research studies. These deem the weight measurement more suitable, mainly because the application of this method is quick and does not require special handling nor human judgment entering the picture. The weight measurement is typically more efficient concerning the precision per unit cost, because of the large quantities and greater objectivity. Moreover, the volumetric measurement cannot be fair to the stakeholders involved in the commercialization process since this method is influenced by several parameters such as diameter, length or quality. However, the weight measurement does have notable disadvantages such as the inability to weigh the roundwood in the forest where it is usually purchased, i.e., due to inaccessibility of the weighbridges (Smith 1979) and the weight differences (Taras 1956). Furthermore, using the volumetric measurement, greater precision per unit cost can be achieved for more moderate quantities if the logs are uniform and straight and the stacking quality is also high (Taras 1956; Hamilton 1975; Smith 1979).

Nowadays, there are some countries, such New Zealand, where weight measurement is generally used for commercial and trading purposes (Ellis 1993). In contrast, the volumetric measurement of stacked roundwood has traditionally been used either at storage sites or at the roadside, e.g., Germany (RVR 2020) or USA (Briggs 1994); or loaded on trucks, e.g., Norway (Norsk Virkesmåling 2015a,b). In several South American countries, the stacked roundwood is volumetrically measured by scaling each stacked log, applying generally the Smalian or Huber formula or the Doyle rule (Ministerio del Ambiente de Ecuador 2001; Instituto Nacional de Bosques - INAB- 2004; Ammour et al. 2012; Ministerio de Desarrollo Agrario y de Riego. Servicio Nacional Forestal y de Fauna (SERFOR) 2021). However, conversion factors are applied for roundwood on trucks as a faster option to the individual measurement of the logs’ volumes. This fact is explicitly indicated so in the measurement guidelines or research efforts conducted in Venezuela (González et al. 2010), Peru (Ministerio de Desarrollo Agrario y de Riego. Servicio Nacional Forestal y de Fauna (SERFOR) 2021), Colombia (Gutierrez Rodriguez et al. 2013), Costa Rica (Meza-Montoya and Simón 2005; Ammour et al. 2012) and Ecuador (Ministerio del Ambiente de Ecuador 2001). In some countries volumetric measurement methods are even used as standard for commercializing industrial wood depending on the roundwood properties (e.g., midpoint diameter). Examples include Lithuania (Lietuvos Respublikos Aplinkos Ministro 2002, 2010), Latvia (Latvijas valsts meži 2022) and Rumania (Guvernul României 2020). In most countries, the measurement process for this roundwood type takes place in landings (at storage sites or in roadsides in the forests), where the logs are stacked and sold by the stack volume (Baró y Zorrilla 1948; Hamilton 1975; Smith 1979; Maa- ja metsätalousministeriö 1997; Edwards 1998; Purser 1999; Rondeux 1999; Jänes 2001; Batista and Zarate do Couto 2002; Lietuvos Respublikos Aplinkos Ministro 2002; Schulting 2002; Fonseca 2005; Environment and Sustainable Resource Development - Government of Alberta 2006; Fachverband der Holzindustrie Osterreichs der Wirtschaftskammer Osterreichs 2006; United States Department of Agriculture. Forest Service 2006; Nova Scotia Natural Resources 2007; Barros et al. 2008; González et al. 2010; Romahn de la Vega and Ramírez Maldonado 2010; British Columbia Ministry of Forests, Lands and NRO 2011; Lindblad 2011; Ljubojević et al. 2011; Meyen and O´Connel 2012; Ministério do Meio Ambiente 2012; New Brunswick Forest management branch natural resources 2012; Russian state scientific center of the timber industry complex 2013; Câmpu et al. 2015; Podkorytov 2015; Forest Service of Newfoundland and Labrador 2016; Luonnonvarakeskus 2017; Witkowska and Jodłowski 2018; FCBA Institut Technologique 2019; Manitoba sustainable development 2019; Biometria 2020; Ontario Ministry of Natural Resources and Forestry 2020; RVR 2020; Saskatchewan Ministry of Environment 2021; WaldSchweiz et al. 2021; Moskalik et al. 2022).

With the purpose of determining the cubic volume occupied, which is known as gross volume, stacked volume or frame volume, the width, length and height of the stack are measured and multiplied (Diéguez Aranda et al. 2003; Fonseca 2005; Lindblad 2011; Russian state scientific center of the timber industry complex 2013; Podkorytov 2015). The most common units to express the stack volume are the cord (principally used in the USA) (Williams 1968; Briggs 1994; Batista and Zarate do Couto 2002; Fonseca 2005; United States Department of Agriculture. Forest Service 2006) and the stere (generally used outside of the USA) (Baur 1879; Huffel 1919; Rondeux 1999; Batista and Zarate do Couto 2002; Schulting 2002; Wabo 2002; FEDEMAR. Federation belge des exploitants forestiers et des marchands de bois de mine et de papeterie 2005; Fonseca 2005; Barros et al. 2008). The stere is defined as being a unit of measure of stacked wood occupying the space of 1m3 and therefore it is equivalent to the cubic meter stacked (m3 stacked) (Baur 1879; Huffel 1919; Baró y Zorrilla 1948; Cailliez 1980; Wabo 2002; Fonseca 2005; Environment and Sustainable Resource Development - Government of Alberta 2006; Nova Scotia Natural Resources 2007; New Brunswick Forest management branch natural resources 2012; Junta de Comunidades de Castilla-La Mancha et al. 2013). In countries where the metric system is used, the stere is considered the standard measured for stacked roundwood (Briggs 1994). There are other units used in further territories that are equivalent to the stere and whose application has traditionally been implemented. Examples include the stacked cubic meter (st m3) in Canada (Ontario Ministry of Natural Resources and Forestry 2020) and the cubic meter (m3) in Ireland (Purser 1999). In contrast, the cord is defined as being a unit of measure of stacked wood which occupies a space of 218 ft3 (Fonseca 2005; United States Department of Agriculture. Forest Service 2006). Another measuring unit is the metro ruma (mr), which is defined as being a unit of measure of stacked wood which occupies a space of 2.44 m3 (Emanuelli et al. 1997; Cogolludo Agustín 2012). The metro ruma is used in some countries of South America such as Chile and Venezuela (González et al. 2010). Furthermore, there are other units with different volumes used in other regions or countries such as metro Biobio or metro Masisa in Chile (Emanuelli et al. 1997; Prodan et al. 1997).

The real wood quantity in a stack is known as solid wood content or solid wood cubic volume and generally measured under bark, although in several countries, such as Finland, it is considered over bark as well (Lindblad 2011). The solid wood cubic volume does not correspond to its stacked volume, since not only wood is contained in a stack but also bark and air spaces between the logs (also known as cracks, gaps or voids) (Smith 1979; Rondeux 1999; Batista and Zarate do Couto 2002; Fonseca 2005; Forest Service of Newfoundland and Labrador 2016; Ontario Ministry of Natural Resources and Forestry 2020). Other materials that can also comprise the stack include snow, ice, dirt, stones, soil, and foreign matter (Batista and Zarate do Couto 2002), which can adhere to and become part of the wood stack as it is built (Smith 1979; Fonseca 2005; Foelkel 2015; Biometria 2020). Due to this fact the proportion of solid wood in a stack can vary between 60 % and 70%, in some extreme cases these values reach between 45% and 80% (Rondeux 1999; Fonseca 2005; Biometria 2020). There are general guidelines that indicate roughly similar proportions of the main components in a stack, concretely: solid wood 66.67% (66% or 66.667%), bark 11.46% (12% or 11.458%) and air 21.87% (22% or 21.875%) (Fonseca 2005; Manitoba sustainable development 2019; FAO et al. 2020; Ontario Ministry of Natural Resources and Forestry 2020). Even though a few references provide these proportions based on data collected, e.g., data from 50 000 cords by a pine (Pinus spp. L.) mill located in the south of the United States showed 59.92% of wood, 12.65% of bark and 27.43 % of air spaces (Williams 1968).

These proportions can vary since several parameters influence the net stack volume. Further measurement guidelines indicate that although the stack gross volume may occasionally be used in sales (Hamilton 1975; Smith 1979; Barros et al. 2008), it is common to convert the stack gross volume to net volume by applying a suitable conversion factor (Hamilton 1975; Bertola et al. 2003; Câmpu et al. 2015). These conversion factors relate the gross and net volumes (o.b. or u.b) (Reinhold 1951), and help to estimate the solid wood content in a stere, metro ruma, or cord (Briggs 1994; Emanuelli et al. 1997; Da Crislei Silva 2003). Conversion factors are also known as stack density (Asikainen et al. 2009). Conversion factors are also defined according to Ciubotaru (1998) as the real volume occupied by wood in a cube with a dimension of 1 m × 1 m × 1 m (1 m3). In this way, the conversion factor is defined as a sub-unitary value that indicates the volume occupied by wood in a gross volume of 1 m3 (Câmpu et al. 2015). The conversion factors range between 0and 1, usually between 0.45 and 0.80 (Cailliez 1980; Rondeux 1999). These factors are average values (Emanuelli et al. 1997; Batista and Zarate do Couto 2002) and are generally highly biased (Emanuelli et al. 1997); therefore, they are deemed valid only in specific regions. Thus, the conversion factors are applied to quantify the commercial value of the roundwood based on a price per unit solid volume (Hamilton 1975).

In general, conversion factors are calculated by dividing the net stack volume (or solid wood content) by the gross stack volume (Batista and Zarate do Couto 2002; Diéguez Aranda et al. 2003). Another way to calculate them consists of dividing the sum of the face areas (circles) by the spatial cross-section. This method is based on the assumption that all logs have the same length (Reinhold 1951). Other authors developed regression models for that purpose (Palo 1969). However, the existing methods to determine the conversion factors are different depending on the territory, showing a historical variation over the years. Furthermore, from several research efforts (Barros et al. 2008; González et al. 2010) and documents of international organizations (Fonseca 2010; FAO et al. 2020) the need to regularly update the conversion factors can be deduced, being even indicated explicitly due to the changes occurred in the forest sector, e.g., increasing mechanization when harvesting and preparing the logs.

Conversion factors are not only admittedly estimations (Barret et al. 1941) but also they must be applied in order to obtain the net stack volume according to measurement guidelines currently in use either after being derived from the gross stack volume (Environment and Sustainable Resource Development - Government of Alberta 2006; Nova Scotia Natural Resources 2007; New Brunswick Forest management branch natural resources 2012; Russian state scientific center of the timber industry complex 2013; Forest Service of Newfoundland and Labrador 2016; Ontario Ministry of Natural Resources and Forestry 2020) or directly to the measured stack volume such as in Bosnia and Herzegovina (according to the former Yugoslavia’s national standards) (Ljubojević et al. 2011), in Brazil (Bertola et al. 2003; Barros et al. 2008), in Estonia (Keskkonnaministri 2006; Riigimetsa Majandamise Keskuse (RMK) 2021), in Guatemala (Instituto Nacional de Bosques - INAB- 2004), in the Italian regions of South Tyrol and Turin (Landesbetrieb für Forst- und Domänenverwaltung et al. 2006; Camera di Commercio Industria Artigianato e Agricoltura di Torino 2009), in Mexico (Romahn de la Vega and Ramírez Maldonado 2010; Galán Larrea et al. 2014), in the Netherlands (Schulting 2002), in Poland (Witkowska and Jodłowski 2018; Jodłowski and Witkowska 2019; Director General of the State Forests 2019; Moskalik et al. 2022), in the Canadian region of Québec (Gouvernement du Québec 2021), in Romania (Guvernul României 2020), in Spain, where the conversion factors are usually indicated in the contract specifications (Gobierno de Navarra. Servicio de gestión forestal 2016), in Ukraine (Podkorytov 2015) or in the United States of America (Briggs 1994). In the measurements guidelines or framework agreement for roundwood trade, some conversion factors are given as reference. However, those guidelines explicitly indicate that the given conversion factors may not be used for billing, e.g., in Germany (Bundesministerium für Ernährung, Landwirtschaft und Forsten 1983; RVR 2020).

As well as the net stack volume, the conversion factors vary as per a series of influencing log and stack parameters such as taper or crookedness. Over the last centuries, several authors from different countries analyzed those parameters considering their effects on different tree species and using different research methods (Huffel 1919; Barret et al. 1941; Keepers 1945; Baró y Zorrilla 1948; Mountain 1949; Briggs 1994; Bertola et al. 2003; Barros et al. 2008; Dos Santos Lisboa et al. 2009; Vera Solis 2010; Ljubojević et al. 2011; Foelkel 2015). In addition, the effect of some influencing parameters has been included in the measurement guidelines used in several countries such as the United Kingdom (Hamilton 1975), Ireland (Purser 1999), the Netherlands (Schulting 2002), Sweden (Biometria 2020) or some Canadian provinces (Environment and Sustainable Resource Development - Government of Alberta 2006; New Brunswick Forest management branch natural resources 2012; Forest Service of Newfoundland and Labrador 2016; Saskatchewan Ministry of Environment 2021).

To conclude, the aim of this literature review is to gather information about different methods to estimate conversion factors (and thus, the solid wood content in a stack) used for industrial roundwood stacks in several countries in Europe and America; these methods are described both in the measurement guidelines and previous research efforts. In particular, this literature review is focused on the roundwood measurement process performed in the forest (either at roadsides or at storage sites). In those places, conversion factors are used since there is no access to weighbridges. Weight differences can be produced for various reasons but specially because of the seasonal variation of the moisture content. In the present literature review, conversion factors are considered as those figures that relate the gross stack volume over bark to the net stack volume under bark. In addition, this review aims to compile the influence of every identified log and stack parameter on the conversion factors based on the found references. Since the first documented study addressed this literature review´s issues in 1765, numerous studies have been reported and methods developed in several countries to estimate conversion factors and analyze their influencing parameters. Even though some authors could gather diverse methods or influencing parameters (e.g., Pardé and Bouchon in 1988 and Zon in 1903), a comprehensive literature review that had compiled all methods and findings has not been conducted in the selected territories so far. Thus, the present literature review was conducted with the purpose of filling this historical gap. It is expected to provide stakeholders in the roundwood supply chain and researchers alike with a solid basis for understanding this issue, reviewing their methods for estimating the conversion factors (and the solid wood content) and facilitating the measurement and acquisition operations in the territories analyzed.

2 Method

2.1 Databases

The present literature review was undertaken by systematically searching measurement guidelines, research works, theses and related internet documents on “Google Scholar” and websites of the regional and national organizations in the analyzed territories. The scope of the literature review was not limited to the documents classed as ‘articles’ or ‘papers’; it also included relevant data found in official documents such as the regional or national guidelines for roundwood measurements. Thus, the references included in the study were classified in five different document types: guidelines, articles, handbooks, final theses, and internet documents.

- The term “guidelines” refers to official documents such as regulations, scaling manuals or framework agreements for roundwood trade. From those documents, the methods to estimate the conversion factors used in the respective countries can be gleaned. Furthermore, the effect of several influencing parameters is explicitly described in those documents or can be deduced from their content. In some countries, the method or methods to estimate the conversion factors can be described in a single national guideline; also, it is possible to find several regional guidelines in the same country with different variants for one specific method. The German framework agreement for roundwood trade or the Canadian regional log scaling manuals are examples of the documents included in this category.

- An article is considered as any research effort conducted and published, such as papers, conferences papers, etc. Due to the particularities of the analyzed topic, every research effort, which was published in English or the respective mother tongue, was analyzed. Articles that were not peer-reviewed, were also considered in order to encompass a broader spectrum of the knowledge in each territory.

- Final theses were also considered for performing this literature review. They provided additional and deeper information about the methods to estimate the conversion factors and the influence of the respective parameters.

- Handbooks (books and/or chapter of book) were also considered in the present review. In the documents included in this category, the authors either compiled several methods and described the effect of selected influencing parameters, or described their research efforts comprehensively.

- Lastly, internet documents considered in the present literature review included relevant information about the topics. They were not included in the mentioned categories since these were obtained from online sources, and/or were not published in a scientific journal or by an editorial (e.g., learning materials, presentations at conferences, user manuals of devices or software, etc.).

2.2 Research strategy

The literature review process included selected keywords in English and the respective languages of each country related to the main topics. These terms were then searched for in different parts of each document including the title, abstract and keywords. In the case of the guidelines or regulations, the search was conducted on those sections of the document related to the measurement of stacked roundwood. The selected terms in English and in the respective languages of the most relevant countries are displayed in the Table 1.

| Table 1. Selected terms to perform the literature review concerning the estimation of conversion factors and their influencing parameters in the respective languages of the relevant forestry countries. | ||||

| Terms | Language | |||

| Danish | Dutch | Estonian | Finnish | |

| Roundwood measurement | Måling af rundtræ | Meten van rondhout | Puidumõõtmine | Puutavaran mittaus |

| Stack/pile | Rundtræ stak | Stapel | Virna | Pino/muodostelma |

| Stack gross volume | Stak bruttovolumen / stakkens fysiske volumen | Stapel volume | Virna kubatuuriga | Kehystilavuus |

| Stack net volume | Stak nettovolumen | Werkelijk houtvolume | Virna mahtu | Kiintotilavuus |

| Conversion factors | Omregningsfaktorer / fastmasseprocent | Conversiefactoren / Stapelfactor | Virnatäiuse koefitsient | Pinotiheystekijä/ Pinotiheyskerroin/ Pinotiheysprosentti |

| Terms | Language | |||

| French | German | Italian | Lithuanian | |

| Roundwood measurement | Cubage des bois ronds | Rundholzvermessung | Misurazione del legname tondo (tronco) | Apvaliosios medienos matavimo tūrio |

| Stack/pile | Pile | Polter | Catasta | Medienos rietuvės |

| Stack gross volume | Volume apparent | Bruttoraummaß | Volume della catasta | Rietuvės tūris |

| Stack net volume | Volume plein | Festmaß | Volume reale | Medienos tūris rietuvėje |

| Conversion factors | Coefficient d’empilage | Umrechnungsfaktoren | Coefficiente Stereometrico del Legno in catasta | Perskaičiavimo koeficientas |

| Terms | Language | |||

| Norwegian | Polish | Portuguese | Romanian | |

| Roundwood measurement | Tømmermåling | Pomiar drewna okrągłego | Medição da Madeira | Măsurarea lemnului rotund |

| Stack/pile | Tømmerlunne | Stos drewna | Pilha | Stiva, Gramada, Lemn asezat in figuri |

| Stack gross volume | Løsvolumet | Objętość stosu drewna | Volume empilhado | Volumul aparent |

| Stack net volume | Fastvolum | Miąższość drewna | Volume sólido | Volumul real |

| Conversion factors | Fastmasseprosent | Współczynniki zamienne | Fator de cubicação | Factor de cubaj |

| Terms | Language | |||

| Russian | Spanish | Swedish | Ukrainian | |

| Roundwood measurement | измерений объема круглых лесоматериалов | Medición de madera | Virkesmätning | Вимірювання деревини в круглому вигляді |

| Stack/pile | штабеля бревен | Pila | Trave | Штабель |

| Stack gross volume | складочный объем | Volumen aparente | Travens virkesvolym | Об’єм штабеля у складовій мірі |

| Stack net volume | плотный объем | Volumen real | Virkesvolymen | Об’єм штабеля у щільній мірі |

| Conversion factors | Коэффициент полнодревесности лесоматериалов | Coeficiente de apilado/apilamiento | Vedvolymprocent | Коефіцієнт повнодеревності |

Every document was analyzed as per their relevance and suitability with the topic and scope established for the literature review. Those documents that addressed the methods to estimate the conversion factors from roundwood on trucks were not considered. Likewise, research papers and measurement guidelines dealing with the commercialization of roundwood by weight and conversion factors from weight to volume were discarded. It is worth noting that it was not always possible to find every type of document in all the selected countries (e.g., guidelines or final theses) since these were not accessible online.

2.3 Data structure

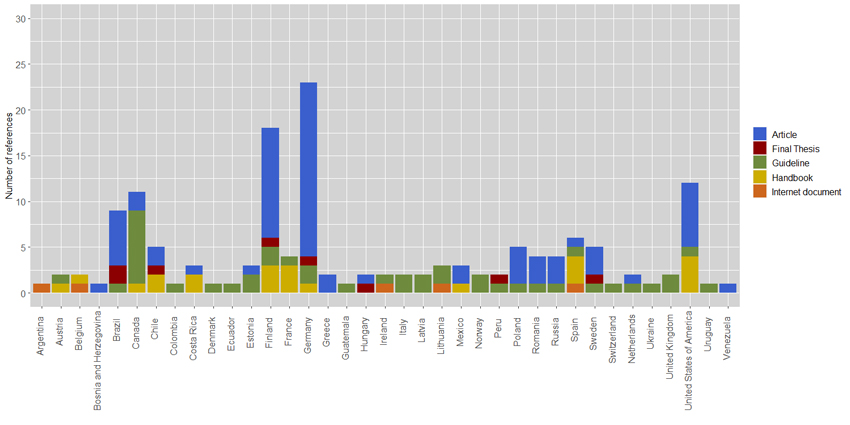

A total of 153 documents were selected and analyzed. According to the assigned categories 72 articles (including conference papers), 43 guidelines used in 28 countries, 8 final theses, 5 internet documents and 25 handbooks were analyzed. Fig. 1 presents this distribution by country and type of document.

Fig. 1. Number of published references concerning the estimation of conversion factors and their influencing parameters categorized by (i) type of document and (ii) country. View larger in new window/tab.

Most articles gathered in the study were published in Germany, Finland, the United States of America (USA), and Brazil. Official documents such as guidelines, regulations, or framework agreements for the roundwood trade were found in 28 of the 38 analyzed countries. Canada had more documents of this type since most Canadian provinces have their own guidelines, known as log scaling manuals.

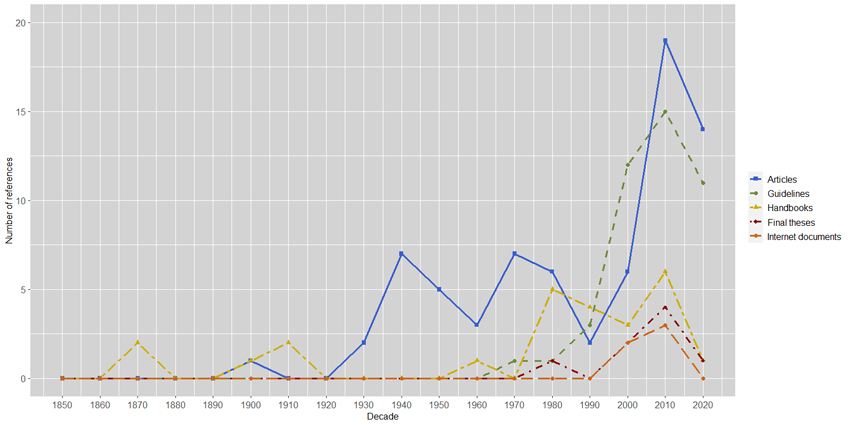

The literature research revealed the first studies on the estimation of solid wood content, the conversion factors, and the effect of the influencing parameters date from 1765, with Germany being the country that reports the first studies on this topic (von Seckendorff-Gudent 1878; Graves 1906; Schnur 1932). However, the first reliable results were obtained only as from second half of the 19th century (Graves 1906; Schnur 1932). During the following decades, this issue has drawn the attention of a considerable number of researchers from many countries. In those papers, the methods used in the first studies were applied again in order to identify new influencing parameters and determine the solid wood content and the conversion factors for new tree species. The latest studies have analyzed the influence of selected parameters using 3D simulation models, which additionally allows estimating conversion factors for specific roundwood assortments. The analysis of the decennial sum of all references showed that this issue was deeply studied by a few researchers in the 19th century and the beginning of the 20th century (Fig. 2). The low number of studies conducted in that period can be due to the high required costs and time involved to analyze the effect of the influencing parameters and the methods applied for that purpose. After the 1930s the number of studies increased gradually, a trend that was driven by the considerable amount of wood used by the pulp and paper industry at the start of the 20th century. At that time, both the selection of the roundwood and its efficient use were of great importance. This trend was further intensified by the decreasing supply of preferable pulpwood species and its growing demand for other purposes (Keepers 1945). A century later, financial considerations still drive the research in this area, particularly nowadays as roundwood is used at an industrial scale (Bäucker et al. 2014a). The implementation of modern technologies has facilitated that this issue can be studied more deeply; this has allowed time and cost reductions due to the implementation of modern sensing technologies.

Fig. 2. Decennial sum of the published references about the estimation of conversion factors and their influencing parameters categorized by type of document. View larger in new window/tab.

It is worth noting that the use of the developed methods to estimate the conversion factors was regulated just after the decade of 1970; this is quite late compared to the high number of research studies reported and published in previous years. Those regulations, represented by guidelines, legislations or framework agreements for the roundwood trade, have increased gradually; thus, since the first decades of the 21st century, either the measurement methods have been regulated or the regulations have been updated and renewed.

3 Methods to estimate the conversion factors from gross volume to net volume

In the analyzed references, two general groups could be identified:

- Methods to estimate solid wood content (and conversion factors) in the first group can be classified into two different categories: 1) direct and 2) indirect. The direct methods aim to determine the logs’ volumes directly whereas the indirect methods aim to estimate the voids’ volumes in a stack (von Seckendorff-Gudent 1878).

- Methods in the second group can be classified into two categories: exact and approximate methods. According to this classification, the exact methods are: 1) the xylometric method, 2) the hydrostatic method and 3) the gravimetric method, whereas the approximate methods are: 1) the diagonal method, 2) the network method, 3) the photographic method and 4) the Bitterlich or angle-gauge method (Câmpu et al. 2015).

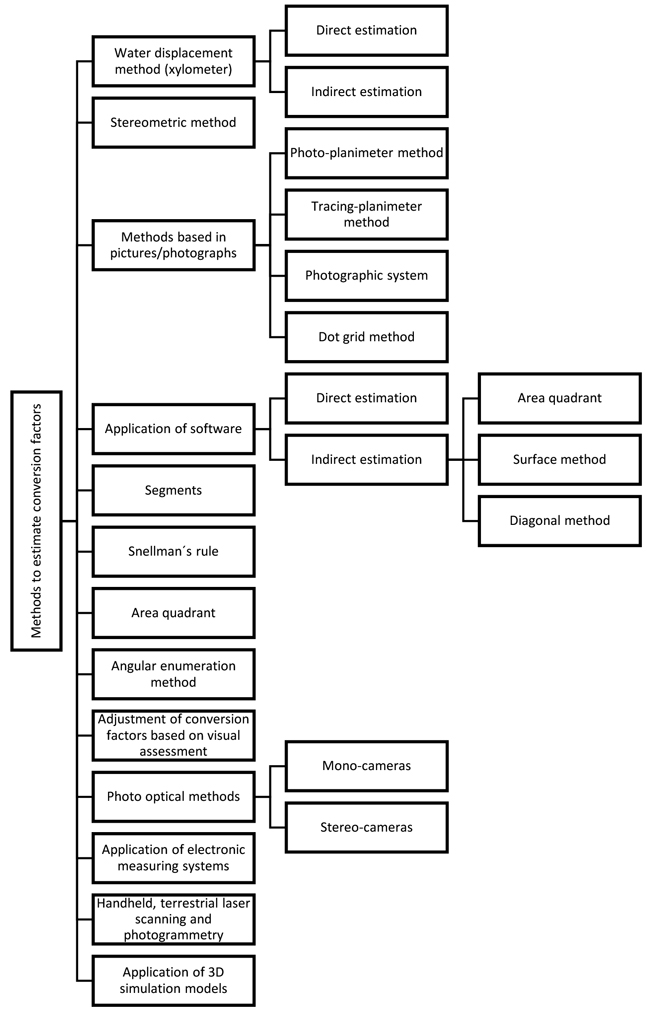

However, the references, which were found in this literature review, reflected a broader spectrum of developed methods to estimate the conversion factors or the solid wood content. That spectrum encompasses more methods than those that were included in the previous two groups identified. Thus, a new classification, which includes all found methods, is suggested in the current literature review (Fig. 3).

Fig. 3. Classification of the found methods to estimate conversion factors.

3.1 Water displacement or xylometric method

3.1.1 Direct estimation

The xylometric method was one of the first used to estimate solid wood content and determine conversion factors (von Seckendorff-Gudent 1878; Baur 1879; Graves 1906; Huffel 1919; Schnur 1932; Keepers 1945; Mountain 1949). There are several possibilities to achieve that goal with this method:

- By immersing the logs in a xylometer and measuring the water volume displaced (or the increase of the water level) (Huffel 1919; Keepers 1945; Diéguez Aranda et al. 2003; González et al. 2010; Romahn de la Vega and Ramírez Maldonado 2010; Ljubojević et al. 2011);

- By introducing the logs in the xylometer, filling it with water up to a determined level, then extracting the logs and measuring how much the water level has decreased (Ljubojević et al. 2011);

- By measuring the increase in weight after placing the logs inside the xylometer or the decrease in weight of the xylometer by extracting the logs and converting the weight variation into a variation in water volume (Ljubojević et al. 2011).

The xylometric method is deemed one of the most accurate ways (Emanuelli et al. 1997) or probably the most accurate way to measure the logs’ volume in a stack (Keepers 1945). This method has disadvantages when the logs or stacks are too big (Bertola et al. 2003). Moreover, this method is not extensively used for measuring large quantities since it requires using costly equipment and the transport of the roundwood to the location where this equipment is installed. Numerous conversion factors, which are included in various measurement guidelines, have been determined using this method in several previous research studies (von Seckendorff-Gudent 1878; Baur 1879; Emanuelli et al. 1997; Batista and Zarate do Couto 2002; Ljubojević et al. 2011; Câmpu 2012; Câmpu et al. 2015).

3.1.2 Indirect estimation

Indications about this method could be found in references from the 19th century; it consists in placing the logs in a closed container after measuring the gross volume of the stack made up of them. Afterwards, water or dry sand was poured into the container until it was full and all spaces between logs filled. Finally, the volume of water or dry sand was measured, so the net stack volume could be calculated (von Seckendorff-Gudent 1878; Baur 1879).

3.2 Stereometric method

This method was used to estimate the net stack volume applying a pre-determined formula and dividing the stack’s net volume by the gross volume. The first studies that used this method comprised preparing the logs with determined dimensions and their assembly near heavy frames designed to hold a specific stack volume (von Seckendorff-Gudent 1878) or a half unit of 5-foot wood (Barret et al. 1941). Like in the first studies, individual log scaling is currently advised in several measurement guidelines (Hamilton 1975; Cailliez 1980; Edwards 1998).

The method consists in measuring the log diameters at both ends and/or at the midpoint and calculating the volume by applying the Newton formula, the Smalian formula (Barret et al. 1941; Emanuelli et al. 1997; Edwards 1998; Barros et al. 2008; Ljubojević et al. 2011), the Huber formula (Emanuelli et al. 1997; Batista and Zarate do Couto 2002; González et al. 2010; Ljubojević et al. 2011), or Rieckes formula (Ljubojević et al. 2011). By applying this method, conversion factors (over and under bark) can be obtained depending on measuring those diameters under or over bark. Generally, this method is costly and time-consuming since it entails scaling each log individually, with results that do not differ significantly from those obtained using water displacement method (Keepers 1945; Emanuelli et al. 1997). Nevertheless, some exceptions can occur when the diameter and length measurements are rounded (down) (Ljubojević et al. 2011).

When scaling large quantities, it is necessary to select samples representing the whole roundwood measured (Keepers 1945). Moreover it must be pointed out that the application of the Newton formula still requires that many measurements are taken, making this process very laborious (Cailliez 1980). Thus, measuring the diameter at both ends of the log and applying the Smalian formula is recommended. This step is repeated forsome stacks; the conversion factor is then calculated by dividing the total volume of the individually measured logs by the stack volume comprised ofthe measured logs (Cailliez 1980).

The stereometric method has also been used to determine conversion factors for practical use in various research studies as well as to analyze the influence that log and stack parameters have on the conversion factors (Frothingham 1912; Barret et al. 1941; Keepers 1945; Emanuelli et al. 1997; Batista and Zarate do Couto 2002; Barros et al. 2008; González et al. 2010). Moreover, further developed methods are currently available. According to a Brazilian source, the traditional approach to estimate the conversion factors is based on cutting trees and preparing logs from representative areas and forest conditions (age, local quality, the distance between trees, etc.). The logs are stacked, and the stack volumes are measured (both gross and net volume) to obtain the average conversion factor from all built stacks (Bertola et al. 2003).

Further, three variants of this method have also beenfound in the English forest mensuration handbook, the research effort conducted by Smith in 1979 and the New Brunswick (Canada) scaling manual.

- The method outlined in the English forest mensuration handbook consists in dismantling the stack and measuring the volume of the individual logs, and from there, the stack volume (Hamilton 1975). Each log’s volume is scaled considering the specified length and the diameter at the midpoint of the specified length, measured from the butt end. Usually, the net stack volume may be estimated by measuring the solid volume of a sample of logs. The sample size depends on the number of logs in a stack. The stack volume is computed as the sample volume multiplied by the total number of logs and divided by the number of logs in the sample. The number of stack samples required to estimate the conversion factor depends on the precision required (Hamilton 1975).

- Another variant to estimate the solid wood content is the cube-scale method. This method is outlined in the section 5.3.2. of the document “Scaling roundwood”, published by the Canadian Standards Association (1977). It involves the measurement of the top diameter of all logs on one stack’s side. The logs’ volumes are then calculated by applying the formula of a cylinder’s volume with the same diameter as the log’s diameter and assuming the same length for all logs. Once deductions are made, all calculated logs’ volumes are added up to estimate the net stack volume. Afterwards, the stack volume is measured according to the method outlined in chapter 7 of the “Scaling Roundwood” report (Canadian Standards Association 1977). Once the solid-wood volume and the volume of a sample of stacks have been calculated for a logging area or shipment, the solid wood (stacked volume ratio or conversion factor) is finally calculated by dividing all logs’ volumes by all measured gross stack volumes (Smith 1979).

- The last found variant is a similar procedure to the previous method. It is described in the log scaling manual of New Brunswick (Canada). Firstly, the volume of every stacked log is calculated. For that purpose, the diameter of the end of a stack’s face is measured under bark by consistently holding the scale stick. In the case of quite oval logs, an average diameter is calculated, while in logs with butt swell, the small butt diameter must be recorded. When the diameters of every half log, on both stack’s faces have been measured, they are added up by diameter class and multiplied by the volume per log in order to estimate the total volume by diameter class. These volumes are totaled to calculate the net stack volume. Afterwards, a “taper adjustment” must be applied to the calculated net stack volume to account for the log taper associated with butt logs featuring buttressing. For that purpose, it is necessary to calculate a taper adjustment factor (taper adjusted solid content). Afterwards, the gross stack volume is calculated. Finally, the conversion factor is calculated by dividing the taper adjusted solid content of the stack by the figure resulting from subtracting the volume of voids to the gross tack volume (New Brunswick Forest management branch natural resources 2012).

3.3 Methods based on photos

3.3.1 Photo-planimeter method

This is the first method that used photos to quantify the solid wood content in a stack and estimate the conversion factors. This method consists in photographing both sides of a stack. Next, a scale with a white background and a 100-square-inch black square on top is set in the same vertical plane as the ends of the logs. Using this scale in each picture and outlining all the log ends with a white piece of chalk, it is possible to measure the end areas of each log on the photograph. Thus, by taking the area of the photographed scale as a reference, the actual end areas in square inches are calculated (Barret et al. 1941).

3.3.2 Tracing-planimeter method

This method consisted in disassembling a stack and tracing both ends of each log on heavy, oiled tracing paper. Afterwards, the areas of these tracings are used to measure the final area of each log’s end in square inches (Barret et al. 1941).

3.3.3 Photographic system

C. Keepers developed the first method of this category as another approach to estimate the solid wood content. This system emerged due to the need to accelerate the measurement processes, mainly when a large amount of roundwood arrived at the production facilities in a short time window, causing a high degree of yard congestion. Its development was possible through photographs of the stacks (Keepers 1945). The original method measured, on a picture, the proportion of air space to the wood area and the air space on a number of equidistant, parallel lines across the face of a stack. In addition, an optical instrument was designed specifically to make the necessary measurements. This method was tested, and the values obtained by the photographic method came closer to the results obtained with the xylometer than the values resulted from the stereometric method (Keepers 1945). The measurement process was demonstrated to be fast, reasonably accurate and inexpensive. The method did not require much experience and the calculations were reduced to simple arithmetic operations. Furthermore, all individual measurements of stacks or logs and potential resulting errors were removed. In this regard, this method constituted an excellent option for purchasing roundwood on a sound, scientific basis and made it possible to keep the photographic records for future reference (Keepers 1945).

3.3.4 Dot grid method of scaling

This method, which Mountain first described in 1949, is outlined in several handbooks, e.g., the scaling manual of the Canadian province of Nova Scotia (Nova Scotia Natural Resources 2007), other handbooks (Diéguez Aranda et al. 2003; Romahn de la Vega and Ramírez Maldonado 2010) and several research studies (Mountain 1949; Emanuelli et al. 1997; Batista and Zarate do Couto 2002; Bertola et al. 2003; González et al. 2010). It uses a rectangular piece of clear plastic with dots spaced on a grid to represent a determined number of volume units. Notably, several variants have been developed during the last decades, e.g., the method developed in Finland by Keltikangas-Ahonen or the one developed by the forest technician Heinonen (Aro 1958). Its principle is to find the relation between the solid wood and the voids and bark in a stack of rough pulpwood. This method, which is fast and accurate (Mountain 1949; Emanuelli et al. 1997), was used initially to measure the gross stack volume (Nova Scotia Natural Resources 2007). However, as can be deduced from some references, the solid wood content can also be obtained this way (Mountain 1949; Romahn de la Vega and Ramírez Maldonado 2010).

The process is carried out as follows: the grid is placed vertically on the picture against the stack’s face beginning at one end and ensuring that the grid covers all wood on the extremity of the stack. A trace of the stack can also be used (Romahn de la Vega and Ramírez Maldonado 2010). Afterwards, the dots falling on the end surface of the stack are counted. Moreover, the dots that fall on the interstices between logs are also counted to estimate the stack’s face section. Should the grid not cover the whole stack, an edge of the grid in the stack’s face with a lumber crayon is marked, later moving the grid to the new position with the grid’s edge lined up with the mark. In doing so, the grid’s edge indicates the previous position. This step must be repeated as much as necessary in order to cover the whole stack (Nova Scotia Natural Resources 2007). Garland (1968) however demonstrated that it is not necessary to sample the entire face of the picture since a sample of only 20% of the stack’s face would be enough (Garland 1968; Bertola et al. 2003).

The spacing of the dots on the grid represents their volume. The volume is calculated by multiplying the total number of dots by the volume represented by each dot. The volume obtained in this way is gross scale and deductions corresponding voids and defects must then be calculated as described in the manual (Nova Scotia Natural Resources 2007; Romahn de la Vega and Ramírez Maldonado 2010). Finally, the conversion factor is estimated by dividing the number of dots within the face section of the logs by the number of dots within the stack’s face section (Romahn de la Vega and Ramírez Maldonado 2010).

Some research studies concluded that estimating the solid wood content through this method is as accurate as the measurement in situ (Mountain 1949; Emanuelli et al. 1997; Kallio et al. 1973) or the water displacement method (Mountain 1949). Other authors could specify that the deviation in solid wood content obtained when applying this method is smaller than 2% compared to the measured solid wood content (Emanuelli et al. 1997). In contrast, Rezende (1988) in Brazil found that this method tended to underestimate the conversion factors for stacks made up of eucalyptus logs. Those underestimates would increase in stacks with large-sized logs (Rezende 1988; Bertola et al. 2003).

A similar method developed in Chile, known as Método red-400 (grid-400 method), consists in counting the dots distributed systematically on an area to be evaluated. This method uses a dot grid built in a frame of 1m2 (1 m by 1 m). Each dot is obtained in the intersection of the cords placed every 5 cm on the frame. The number of dots that fall in the logs (solid wood) determines the surface occupied by the wood in each sample. The dots’ density and the design of the grid-400 enable a perfect compensation of the border effect. The surface covered by the log faces (m2) is calculated by multiplying 0.0025 (i.e., the surface that represents each dot on the solid wood in m2) by the number of dots that fall in the log faces (Emanuelli et al. 1997; Cancino et al. 1997).

3.4 Application of software

The use of software recently developed in Brazil and Russia enables direct or indirect estimation of the conversion factors. In this study, existing software used for estimating conversion factors was classified into two categories:

- Direct estimation, i.e., the software providing the conversion factors directly.

- Indirect estimation, i.e., the software is used to edit pictures to estimate conversion factors by measuring specific areas in the pictures, e.g., log end area.

3.4.1 Direct estimation

With the development of the IT-technology, the methods based on pictures to determine conversion factors became obsolete, giving place to the development of the first programs, such as Digitora (Bertola et al. 2003). Digitora could estimate conversion factors and, in some cases, the net stack volume from pictures taken from the front and rear sides of the stacks. Based on real measurements, the evaluation of this software demonstrated its accuracy when providing conversion factors (Bertola et al. 2003). Kruglov developed another program that models the logs in 3D from pictures of the stack’s faces. Using log pile photogrammetry, this algorithm deviated from the measurement manual piece-by-piece method by less than 9.2%. (Kruglov and Shishko 2017). Although it is possible to estimate conversion factors using this software, it was not the primary purpose of its development. Recently, Artificial Neural Networks have been implemented to estimate conversion factors, e.g., the software NeuroDIC 2.0. This software was developed in JAVA and allows importing pictures of the stack faces. Afterwards, several filters can be applied to facilitate sample selection. Next, the variables are defined to obtain training data and implement the Artificial Neural Networks. Consequently, it is possible to estimate the stack volume as well as the proportion of voids and wood in a stack (Silva Silva 2019).

3.4.2 Indirect estimation

3.4.2.1 Area quadrant method by editing pictures digitally

This method involves taking pictures of stack sides (front/rear) with a commercially available camera. The faces of the log ends are manually recorded, and the digital images are binarized. Afterwards, pictures analysis is performed to calculate the proportion of wood and voids. Finally, the conversion factor was computed as the average value of the proportion of the areas of the logs’ ends without the representative bark share measured for each stack (Bäucker et al. 2014a,b).

3.4.2.2 Surface method

The surface method is based on setting an area quadrant on a picture of stack faces (Câmpu et al. 2015). This quadrant comprises a quadrilateral figure of known dimensions set on the image of the photographed stack faces. The pictures are taken perpendicularly to each stack face, and then processed using a CAD tool. The conversion factor is determined as the ratio between the sum of the surfaces of the log ends and the surface of a quadrilateral figure that contains the logs in the picture (Câmpu et al. 2015). A variant of this method was developed in Russia (Knyaz and Maksimov 2014), with a similar approach to estimate the conversion factors to that developed by Câmpu et al. (2015).

3.4.2.3 Diagonal method

This method applies to stacks with rectangular form and consists of drawing two diagonal lines on the stack faces (front/rear) from the top left corner to the right bottom corner and from the top right corner to the left bottom corner. The segments that overlap the log ends are measured, and their lengths added up. The conversion factor is then calculated by dividing the total of all overlapped segments by the sum of the diagonals lengths (Câmpu 2012; Câmpu et al. 2015).

3.5 Segments

When applying this method, a line is drawn on the face of the stack. The conversion factor is then estimated by dividing the sum of the segments that cover the log ends by the line length. A variant of this method involves nailing a bar (e.g., 2 m or 3 m long) on the face of the stack. After that, the segments covering the logs’ ends are measured and added up. The conversion factor is estimated by dividing that result by the length of the the bar. (Slangen and van Boven 1981).

3.6 Snellman´s rule

This method involves setting a 1 m rule (graduated in cm) on the face of the stack. The conversion factors is then estimated by dividing the number of marks in each centimeter that falls on the wood area of the log ends by 100. This process must be repeated several times, setting the rule on different positions to obtain an average value (Diéguez Aranda et al. 2003).

3.7 Area quadrant

Estimating the conversion factors by using an area quadrant is a very common and widely-used method. Consequently, this method presents several variants in its application. Specifically, ten similar methods were found in the analysis of the references of seven different countries: Ireland, the United Kingdom, Canada, Mexico, Spain (two variants), Uruguay, Poland and Chile (two variants).

- According to the Irish references the measurement process using this method consists of fixing an area quadrant to the face (front/rear) of the stack. Next, the diameter of all log ends falling within the quadrant is measured. These measurements must be recorded over bark to the nearest whole centimeter using a tape or small ruler. This step must be repeated at regular intervals on the front and rear sides of the stack and along the length of the stack. The number of the samples taken depends on the stack’s size and the variation in the log and stacking quality. Afterwards, a count or tally of the logs in each end diameter class from all samples must be made. Each count is multiplied by the surface area associated with that diameter class in order to calculate the total surface area per diameter class. These sums are added to compute the total surface area of the log ends from all quadrants. The total area of the stack surface sample is calculated by multiplying the area of the quadrant used by the number of samples taken. Finally, the total surface area of log ends from all quadrants divided by the total area of stack surface sampled provided the conversion factor to be applied to obtain the net stack volume from the previously measured gross stack volume (Purser 1999; Meyen and O´Connel 2012).

- In the United Kingdom, the application of this method involves calculating the area on the side (front/rear) of a stack occupied by the log ends per unit of total area on the stack’s sides. For that purpose, a rectangular grid or dot grid is placed against the stack face. Afterwards, the number of intersections or dots falling on log ends counted relative to the number of intersections or dots falling on both log and gaps provides a quick easy estimation of the conversion factors (Hamilton 1975).

- In the scaling standard of the Canadian region of Saskatchewan, a specific conversion factor for the stack is determined by painting a required number of 1 m by 1m squares on the stack’s face. The number of squares is determined by multiplying the area of the stack face times 10%, rounding the result to the nearest whole number. The calculated number of squares is then randomly painted across the face of the stack so as to represent the log size distribution and defect distribution. Afterwards, the solid wood content of the squares is determined by scaling the diameters to the nearest 1 cm and the logs’ length is the average pile width. All diameters where the face is more than halfway into the sample must be considered part of the sample. The conversion factor for the stack is defined by dividing the gross solid wood volume of the samples by the gross stacked volume of the 1m by 1m samples. The solid volume is finally estimated by multiplying the stack volume times the conversion factor (Saskatchewan Ministry of Environment 2021).

- A comparable method, which is used in Oaxaca (Mexico), consists of making a wooden quadrant or square with a surface of 1 m by 1 m (1 m2) and gridded with separations every 10 cm, into which thread fastened with nails was placed. In doing so, a uniform mesh with 81 interior points (and totally 100 points) was formed. The conversion factor was then determined by dividing the number of points falling in the logs by the total number of points (Galán Larrea et al. 2014).

- One Spanish variant of this method consists of setting a wooden quadrant (1 m2) on the stack faces (front/rear), one or more times, and deducing first the number of logs and the approximate total of logs that form the stack. Next, the average of the area of the log ends within the quadrant is calculated. Finally, the rate is obtained as well as the percentage that must be applied to obtain the solid wood content (Baró y Zorrilla 1948). Another variant of this method involves using a wooden quadrant with a metallic square net. This quadrant is set on the stack face, and the number of quadrant vertices falling on the wood surfaces of the log ends are counted. The conversion factor is then calculated by dividing the number of vertices that fall on the wood surfaces by the total number of vertices of the wooden quadrant (Diéguez Aranda et al. 2003).

- In Uruguay, a quadrant, whose sides are 1 m, is set on one stack face. The logs whose end face center falls within the quadrant is identified and its diameter measured. The areas of the log ends are calculated and totaled. The result of that addition is the conversion factor for that stack. This process should be repeated in different places of the stack face. Afterwards the average value of all calculated conversion factors corresponds to the conversion factor for that stack (Acquarone et al. 2021).

- In Poland, a quadrant is drawn on the stack face. The quadrant sides are 1 m. For the measurements, a diagonal is drawn on the quadrant, crossing the sections of the logs. To get the conversion factor of the stack, the diagonal lengths on the log ends are added up, and that result is then divided by the whole length of the drawn diagonal (Michalec and Wąsik 2020).

- In Chile, two variants of this method could be found:

a. Método marco simple (simple frame method): the simple frame method consists of measuring the log end diameter (under bark) and estimating later the section which is based on the fraction of the diameter included in the unit (values are to be extracted from a table). In the logs placed on the vertexes, that fraction is determined based on the shortest distance between the log and the sample’s border (Emanuelli et al. 1997).

b. Método marco CEM (CEM frame method): the CEM frame method, consists of calculating the real surface fraction included in the logs placed in the sample’s border. This method involves measuring the log end diameter under bark; two distances: first, between the log’s center and the samples’ border in those logs placed in the vertexes of the sample; and second, between the logs placed in other points of the sample’s border. This method enables to determine accurately the log surface contained in the sample (Emanuelli et al. 1997).

3.8 Angular enumeration method

This method allows a direct determination of the conversion factors. This method is based on the angular enumeration principle of Bitterlich. This method involves rotating an angle from a point on a stack’s face and counting all the log top ends that are not fully overlapped by the angle to a predetermined distance from that point. The construction of that angle and radius defines a constant of proportionality between the number of log top ends counted and the ratio of the surface of the log top ends and the area of the circle formed by rotating the angle. The conversion factor is then calculated by multiplying a constant by the number of top logs counted. Bitterlich (1984) suggested a constant equal to 1/100. An instrument able to generate this constant only requires an angle with a radius five times the aperture angle at the radius end (Batista and Zarate do Couto 2002).

3.9 Adjustment of the conversion factor based on visual assessment

Similar methods have been developed to estimate the conversion factors in situ in the northern European countries of Sweden, Lithuania, Latvia, Estonia, Denmark and Finland. The conversion factors start with an initial value which is adjusted based on a visual assessment of the stack considering different log and stack parameters until a final figure is obtained and applied to estimate the solid wood content. The starting value in Sweden, Denmark, Estonia, Latvia and Lithuania depends on the tree species (Keskkonnaministri 2006; Danske skoves handelsudvalg 2008; Ladusāns and Buļs 2010; Lietuvos Respublikos Aplinkos Ministro 2010; Tebėra 2019; Biometria 2020), while in Finland, the starting value depends on the log length (Asikainen et al. 2009; Lindblad 2011; Luonnonvarakeskus 2017). The net volume estimation is obtained by multiplying the calculated conversion factor by the measured gross volume (Lietuvos Respublikos Aplinkos Ministro 2002; Asikainen et al. 2009; Fonseca 2010; Ladusāns and Buļs 2010; Lindblad 2011; Luonnonvarakeskus 2017; Biometria 2020; FAO et al. 2020).

The accuracy of this method in Finland has been analyzed and revised in previous studies (Heiskanen 1973; Heiskanen and Salmi 1975). While some improvements have been performed, e.g. the addition of some classes for the parameters crookedness or diameter (Heiskanen and Salmi 1975), the results reported in the other studies indicated that the assessment of the solid wood content were reliable enough for all tree species (Heiskanen 1973). Furthermore, the stacking method and the human factor played an important role. Studies revealed that the training provided to the people did not reduce the deviation of the results, although it reduced the error compared to the correct evaluation (Heiskanen 1973). It is also worth noting that adequate supervision and control systems had to be established to prevent the application of this method could tend to favor the employer (Heiskanen 1973). Later studies showed that this method’s measurement accuracy is very poor when using it in practice (Asikainen et al. 2009). For instance, Lehtimäki (2001), who is cited by Asikainen et al. in 2009, estimated a standard deviation in the measurement error from 7 to 8% for pulp logs with a length of 3 m. Likewise Sairanen (1995) estimated a standard deviation of the measurement error from 3 to 13% for pulp logs with a length exceeding 3.5 m. The errors could also reach standard deviations ranging from 20% to 25% for volumes lower than 20 m3. The tree species considered in the studies conducted by Lehtimäki (2001) and Sairanen (1995) were pine (Pinus sylvestris L.), spruce (Picea abies (L.) H. Karst.) and birch (Betula pendula Roth). Those errors were generally caused by the technical difficulties and the human influence when measuring the stack volume. This resulted in the subjective evaluation and successive generalizations of the respective influencing parameters when estimating the solid wood content (Asikainen et al. 2009).

3.10 Photo-optical methods

These methods are classified into a new category and separated from methods based on pictures and those using some software. This is due to two important factors: 1) these methods use machine learning and artificial intelligence in order to automatically recognize the log ends without printing the images and applying grids such as the methods included in the section 4.3. and 2) generally, computer use is not needed as field results can be obtained using a tablet or a smartphone in contrast to the methods included in the section 4.4.

For the last ten years, the determination of the conversion factors has been able to be computed by apps, which are usually used for measuring the stack gross and net volumes by applying photo-optical methods. Examples include tools such as TIMBETER (TIMBETER Ltd.) in Estonia or Trestima Stack in Finland (Kärhä et al. 2019; Trestima Ltd.). These apps are drawing increasing attention in the forest sector (Opferkuch et al. 2017), and are currently used by many companies (TIMBETER Ltd.) in numerous countries (Berendt et al. 2021b). Their use is mainly applied for quality control. However, two of them have also been certified as calibrated methods: sScale and LogStackPro developed respectively by DRALLE Ltd. and the HEIDEGESELLSCHAFT, Forstprodukte und – geräte Ltd.

Currently, there are two possibilities for taking the pictures using photo-optical methods: mono and stereo cameras. While the latter ones are normally mounted onto a car, do not need a reference and are officially calibrated, the former ones usually apply these methods with tablets or smartphones and do need a reference (either the length of the stack or a pattern set on a stack`s face). These methods are based on artificial intelligence (machine learning) and techniques that enable processing images in order to recognize the log ends and measuring their surface and/or the surfaces of the front and rear sides of the stacks and measuring these as well.

In scaling the gross volume of a stack, the app recognizes the stack faces (front/rear) and traces a contour that delimits the faces. Where required, post-processing of the contour is traced by the app. Subsequently, the app measures the surface of the stack`s face and multiplies this by the logs` length (order length). The resulting total is the stack gross volume, measured in m³ (st) or steres depending on the country. For computing the net stack volume, another variant of this process recognizes and measures the area of the log ends, multiplying the sum of all measured areas by the order length. Furthermore, several apps can directly estimate the conversion factors (known in some apps as the density factor) (TIMBETER Ltd.) or implement the conversion factors outlined in the measurement guidelines used in the respective countries, e.g., iFOVEA (SDP Digitale Produkte GmbH) or AFoRS (Scheller Technology GmbH).

3.11 Application of electronic measuring systems

A recent research study has used a 3D-system in the production facility to measure the logs’ volumes individually after measuring the gross volume of the stacks in the forest; it used the sectional volumetric measurement method outlined in the German framework for roundwood trade (Heinzmann 2017; RVR 2020). The conversion factors are then obtained by dividing the sum of every log’s volume by the gross stack volume (Heinzmann and Barbu 2017). The calibrated roundwood measurement system of the class JORO-3D was used. This kind of device could take the following measurements: log length (m), diameters at both ends and at midpoint (cm), taper (cm/m), crookedness (%) and log ovality (%) (Heinzmann and Barbu 2017). The measurement of the log’s volume using this kind of device is deemed the most accurate. However, its implementation has not yet been spread everywhere (Witkowska and Jodłowski 2018).

3.12 Application of handheld laser scanning and simultaneous localization and mapping (SLAM) technology, photogrammetry and terrestrial laser scanning

Recent publications have shown methods to estimate the volume of logs of industrial wood with high accuracy using handheld laser scanning and simultaneous localization and mapping (SLAM) technology (De Miguel-Díez et al. 2021b, 2022c). Moreover, further methods have been developed using such devices and technology to estimate the gross stack volume (Borz and Proto 2022; Purfürst et al. 2022). The combined application of these developed and tested methods could also lead to the estimation of reliable conversion factors considering the successfully proven high accuracy of these developed methods. Nevertheless, it is worth noting based on the analysis of results of this literature review that the operational application of these methods could still be costly.

Notably, similar methods which involve photogrammetry or terrestrial laser scanning have recently been or are currently being developed (Forsman 2016; Purfürst et al. 2022). These methods could also lead to estimate conversion factors accurately in the near future.

3.13 Application of 3D Simulation models

Recently, 3D simulation models have been developed to determine conversion factors and analyze the influence of stack and log parameters (De Miguel-Díez et al. 2021a,c,d; Miesner 2021; De Miguel-Díez et al. 2022a,b). This approach has numerous advantages: 1) the estimation of the conversion factors is automatically performed, 2) reduced costs and time involved in data collection and 3) the analyses of the influence exerted by the log and stack parameters resulted in solid statements based on broad statistical bases.

The first 3D simulation model was successfully developed in 2017 to measure roundwood stacks’ volume (Kruglov and Shishko 2017). However, that simulation model did not allow the analysis of the influencing parameters on the conversion factors. In 2021, a similar simulation model was developed, but this 3D simulation model enabled to analyse the influence of log parameters on the conversion factors based on a comprehensive statistical basis. However, this model had important shortcomings, such as it was not able to generate the logs thoroughly virtually, e.g., it could not simulate the bark. Moreover, the results provided by that 3D simulation model were not validated with real measurements (Miesner 2021; De Miguel-Díez et al. 2022a). In contrast, another 3D simulation model was developed and evaluated based on real measurements. The validation results showed its high accuracy in virtually generating and stacking the logs and estimating the stack gross and net volumes (De Miguel-Díez et al. 2022a). This simulation model was specifically designed and developed to estimate conversion factors, analyze the influence of the log and stack parameters on the conversion factors, and determine stack volume and solid wood content on a statistical basis. Based on the inputted data (real data and/or data defined by the user), the model can simulate as many stacks as required by the user. The simulation results are the stack volume, the solid wood content, the conversion factors, and the bark share in the stack. The simulation model can accurately reproduce three different measurement methods: 1) the sections volumetric measurement method outlined in the German framework for roundwood trade (RVR) (RVR 2020), 2) the photo-optical and 3) the polygonal line methods, which delimits the surface of the stack sides (front/rear). The use of the 3D simulation model allows for specific conversion factors (drawn from large databases) for each assortment and tree species, saving time in the process (De Miguel-Díez et al. 2022a). Determining these specific conversion factors was suggested as the best solution in some of the sourced identified (Fonseca 2005).

4 Influencing parameters on the conversion factors

Considering the references analyzed, the influencing parameters can be classified into three categories: 1) log parameters, 2) stack parameters and 3) external parameters. These categories can be deduced from several current measurement guidelines used in different countries and previous research studies, e.g., Nikkilä et al. (1974) divided the influencing parameters into three categories: 1) pulpwood properties, 2) stack qualities and 3) parameters related to the measurement. In addition, a new category, the external parameters, had to be separately categorized to include those parameters that are not dependent on the roundwood or the stack features but the environment or the related preparation operations. These parameters are not outlined in most measurement guidelines nor in the majority of the previous research works. The effect of some parameters is limited to some countries or regions, while others depend on specific aspects of the roundwood supply chain in the country or region.

This review considers the log parameters crookedness, taper, delimbing quality and irregularities separately. This is opposed to previous studies that have treated these parameters together (Zon 1903; Mountain 1949; Wabo 2002; Meza-Montoya and Simón 2005). However, it has been clearly indicated that the logs form has an important influence on the conversion factors. Notably, it has been indicated that the straighter and smoother the logs, the fewer air spaces in between, and consequently, the higher the solid wood content. Moreover, it is worth clarifying that the statements about the effect of the influencing parameters described below are focused on their individual effect, although in combination, they can also influence the conversion factors (and the solid wood content). Moreover, it must be pointed out that diverse statements concerning the respective influencing parameters are compiled and described below. These considerations differ from each other depending on the data and studies analyzed.

4.1 Log parameters

4.1.1 Midpoint diameter

The vast majority of the references confirm that this parameter strongly influences the conversion factors. Research outcomes have shown that the solid wood content increases as the midpoint diameter of the logs increases, i.e., the conversion factors increase if the midpoint diameter does it too (von Seckendorff-Gudent 1878; Baur 1879; Zon 1903; Frothingham 1912; Huffel 1919; Schnur 1932; Schmidt 1940; Barret et al. 1941; Keepers 1945; Reinhold 1951; Makkonen 1960; Williams 1968; Nikkilä et al. 1974; Pita Carpenter 1984; Sairanen 1987; Zarate do Couto and Magalhães Bastos 1988; Briggs 1994; Bertola et al. 2003; Diéguez Aranda et al. 2003; Meza-Montoya and Simón 2005; González et al. 2010; Ljubojević et al. 2011; Bäucker et al. 2014a,b; Foelkel 2015; Forest Service of Newfoundland and Labrador 2016; Heinzmann and Barbu 2017; Witkowska and Jodłowski 2018; Jodłowski and Witkowska 2019; De Miguel-Díez et al. 2021a, 2022b). This statement is also endorsed by several roundwood measurement guidelines (Schulting 2002; Environment and Sustainable Resource Development - Government of Alberta 2006; New Brunswick Forest management branch natural resources 2012; Forest Service of Newfoundland and Labrador 2016; Biometria 2020; Acquarone et al. 2021; Saskatchewan Ministry of Environment 2021).

Although research studies have demonstrated the above relationship, there is a disparity in the current measurement guidelines used in different countries. The Swedish and Finnish guidelines for timber measurement confirm the strong influence of this parameter, in the case of the Swedish guidelines with a variation of 17 percentage points (pp) in the solid wood content have been reported for a mean diameter range from 4 cm to over 80 cm (Biometria 2020) and in the case of the Finnish guidelines, a total variation in the conversion factors of 9 pp for conifers and of 12 pp for hardwood species has been reported for a mean diameter ranging from 9 cm to over 25 cm (Luonnonvarakeskus 2017). This statement is also supported by references from the United States of America, where, e.g., the solid wood contents of stacks made up of straight, smooth logs can vary from less than 6 inches and more than 12 inches between 10.5% (Loblolly pine - Pinus taeda L.) and 11.9% and (Longleaf pine - Pinus palustris Mill.). These variations can even be greater (Longleaf pine - Pinus palustris - 18.2% and loblolly pine - Pinus taeda - 20.7%) if the stacks are made up of crooked, rough and knotty logs (Williams 1968). A recently study conducted using a 3D simulation model reported a variation in solid wood content of 17.8% for Norway spruce (Picea abies) (De Miguel-Díez et al. 2022b).

Other previous research studies demonstrated a strong influence of this parameter on the conversion factors. Carrillo et al. (1985), cited by Dos Santos Lisboa et al. (2009), found a deviation of as much as 64% when applying a conversion factor that was not appropriate for a determined diameter class. On the other hand, the English forest mensuration handbook and the Irish timber measurement manual state that this parameter has little impact on the conversion factor (Hamilton 1975; Purser 1999). In addition, the English forest mensuration handbook indicates that the value of the mean diameter in the stack is unimportant (Hamilton 1975). A research work conducted in Poland endorsed the statement of the English and Irish measurement guidelines about the relation between the conversion factors and the average diameter to be insignificant (Witkowska and Jodłowski 2018), especially when considering the tree species.

From previous research studies, it could be deduced that the relationhip described above occurs due to the effect of three parameters: 1) the number of logs in a stack, 2) the effect of crookedness and 3) the bark share in a stack:

- Number of logs in a stack. According to the articles of Zon (1903) and Schmidt (1940) , the number of stacked logs is higher for stacks with the same gross volume but made up of small-diameter logs. This causes the number of voids in the stack to increase, which decrease the solid wood content. Specifically, the difference in solid wood content in two stacks with the same gross volume can be as high as 13% when one of these is made up of logs whose diameter are double the logs of the other stack. This difference can reach up to 25% if the logs’ diameters of one stack are four times those of the other stack (Zon 1903). Baur’s research indicated different variations of the solid wood content depending on the tree species. For a variation from 17.27 cm (6.8 inches) to 8.89 cm (3.5 inches), Baur reported a variation of 29.0% for hardwoods, 12.7% for softwoods and 21.2% for stacks made up of hardwoods and softwoods logs (Baur 1879; Zon 1903). Further found references supported this relationship, reporting that an increase in the number of logs increases the air space in the stack (Forest Service of Newfoundland and Labrador 2016) and thus the conversion factors decrease (Ljubojević et al. 2011; Foelkel 2015).

- Effect of crookedness. Previous research has confirmed that the crookedness in thin logs substantially influences the conversion factors (Reinhold 1951; Bäucker et al. 2014b). Consequently, voids are present with higher frequency as a stack is made up of thinner logs, resulting in smaller conversion factors (Forest Service of Newfoundland and Labrador 2016).

- Bark share. According to research studies from the middle of the 20th century, the stack’s bark share decreases as the stacked logs’ midpoint diameter increases (Reinhold 1951; Vorreiter 1954). Studies report this relation for Scots pine (Pinus sylvestris) and oak (Quercus spp.) since the bark share of the logs remains constant regardless of the midpoint diameter of the stacked logs (Bäucker et al. 2014a; Berendt et al. 2021a). Nevertheless, Chilean handbooks show that the bark share in a stack made up of radiata pine (Pinus radiata D.Don) logs increases as the mean diameter of the stacked logs increases. Consequently, the conversion factors from gross volume (o.b.) to net volume (u.b) remained constant. These documents show that the proportion of air space in the stack decreased as the mean diameter of the stacked logs increased and the number of logs in the stack decreased (Peters Nario et al. 1985; Vidaurre Echeverría et al. 1987). This effect usually leads to higher conversion factors; however, it is compensated by the increased bark share, which leads to reduced conversion factors (Peters Nario et al. 1985; Vidaurre Echeverría et al. 1987). However, this fact is probably only applied to that tree species.