Climate change mitigation through alternative uses of Norwegian forest resources

Kallio A. M. I., Strîmbu V. F., Gobakken H., Gobakken T. (2025). Climate change mitigation through alternative uses of Norwegian forest resources. Silva Fennica vol. 59 no. 1 article id 23066. https://doi.org/10.14214/sf.23066

Highlights

- Climate effects of Norwegian forests under various policies were examined under parametric uncertainty

- Shifting some of wood use to high-emission-saving wood products, climate benefits from Norwegian forests can be increased without increasing harvests

- Only in the short-term it is possible to increase the climate benefits by increasing harvest

- Investments to bioethanol production likely decrease climate benefits of forests.

Abstract

The carbon substitution and storage effects related to Norwegian forests and the forest sector were compared under three potential roundwood harvest scenarios: maintaining harvests at 2021 levels, increasing harvests by 20% due to policies aimed at maximizing economic benefits from the forest sector, and reducing harvests by 20% due to biodiversity concerns. For harvested wood products, both the current product structure and hypothetical alternatives were considered. The carbon stock development in forests was projected using a forestry simulation tool for Norway. Many uncertainties in carbon storage, substitution parameters, and data have been addressed using Monte Carlo simulations. Shifting a portion of pulpwood use to produce wood-based insulation materials and textile fibres was found to increase the climate benefits from the Norwegian forest sector. In contrast, the shift to bioethanol production had only a marginal effect compared to the current production structure. The analysis spanned the next two decades, which is a period relevant to the investment and operational lifespan of industrial facilities. The results suggest that during this time, smarter use of harvested roundwood for HWPs with high carbon substitution benefits can be an effective means of climate change mitigation. However, in the long term, enhancing forest carbon sinks by reducing harvests may be more beneficial for the climate, provided that global efforts to reduce emissions from energy production are successful and lead to a decrease in emissions associated with the production of various materials.

Keywords

harvested wood products;

forest sector;

biofuels;

greenhouse gas emissions;

bioeconomy;

carbon sink

-

Kallio,

Norwegian University of Life Sciences, Faculty of Environmental Sciences and Natural Resource Management, P.O.Box 5003, NO-1432 Ås, Norway

https://orcid.org/0000-0002-5393-761X

E-mail

maarit.kallio@nmbu.no

https://orcid.org/0000-0002-5393-761X

E-mail

maarit.kallio@nmbu.no

-

Strîmbu,

Norwegian University of Life Sciences, Faculty of Environmental Sciences and Natural Resource Management, P.O.Box 5003, NO-1432 Ås, Norway

https://orcid.org/0000-0002-0588-2036

E-mail

victor.strimbu@nmbu.no

https://orcid.org/0000-0002-0588-2036

E-mail

victor.strimbu@nmbu.no

- Gobakken, Norwegian University of Life Sciences, Faculty of Environmental Sciences and Natural Resource Management, P.O.Box 5003, NO-1432 Ås, Norway E-mail helle.ross.gobakken@nmbu.no

-

Gobakken,

Norwegian University of Life Sciences, Faculty of Environmental Sciences and Natural Resource Management, P.O.Box 5003, NO-1432 Ås, Norway

https://orcid.org/0000-0001-5534-049X

E-mail

terje.gobakken@nmbu.no

https://orcid.org/0000-0001-5534-049X

E-mail

terje.gobakken@nmbu.no

Received 31 October 2023 Accepted 17 December 2024 Published 2 January 2025

Views 46965

Available at https://doi.org/10.14214/sf.23066 | Download PDF

1 Introduction

In most European countries, managed forests sequester more carbon dioxide (CO2) from the atmosphere than they release in the form of various greenhouse gases (GHG), in terms of CO2 equivalents. Therefore, they offset some GHG emissions from other sources. Moreover, harvested wood products (HWP) contribute to climate change mitigation through two mechanisms: carbon storage and substitution. Concerning carbon storage, HWPs function as a post-harvest repository for carbon that is initially sequestered into trees (IPCC 2019). A net increase in carbon within an HWP reservoir acts as a carbon sink and, thus, appends the sink in managed forest land. Substitution effects arise when the utilization of an HWP in an end-use, for example, in wooden furniture, results in lower GHG emissions throughout the product’s lifecycle compared to products made from alternative materials that serve the same function (Sathre and O’Connor 2010; Eriksson et al. 2012; Smyth et al. 2017; Leskinen et al. 2018; Myllyviita et al. 2021). Hence, substitution benefits can also be described as emissions avoided by replacing wood with other materials. Not all applications of HWPs provide substitution benefits; however, in some cases, these benefits can be substantial.

A growing body of literature assesses the magnitude of the carbon storage and/or substitution effects of HWPs at different geographical scales. For instance, Hurmekoski et al. (2020) considered the substitution benefits coupled to wood harvests in Finland and found possibilities for increasing them by changing the market structure to accommodate production of textiles and wood-plastic composites and harvesting more wood for construction use. Braun et al. (2016) considered avoided emissions in alternative scenarios for forest industry in Austria. Suter et al. (2017) considered the overall average climate effects of wood use in Switzerland. Several studies have also accounted for the conflict between the decreased forest carbon sinks and increased carbon storage and substitution benefits in HWPs, when the latter are attained by increasing the harvest volume in a country (Werner et al. 2010; Kallio et al. 2013; Smyth et al. 2014, 2018; Braun et al. 2016; Matsumoto et al. 2016; Soimakallio et al. 2016, 2021; Heinonen et al. 2017; Valade et al. 2018; Jonsson et al. 2021; Schulte et al. 2022; Hurmekoski et al. 2023). The question of whether the increased harvest and production of HWPs is beneficial from a climate change mitigation perspective depends on several factors, among which the structure of forests in the region and the products assumed to be produced from the increased harvests are important. For example, in the scenarios of Jonsson et al. (2021) for the European Union, the substitution and storage benefits of HWPs were offset by the reduction in forest carbon sinks from increased roundwood harvests by 2030. Matsumoto et al. (2016) suggest that, in Japan, enhancing carbon sinks in forests is more effective for climate change mitigation than increasing the production of wood-based energy and construction materials. For Finland, Seppälä et al. (2019) calculated that, to compensate for the reduction of 1 Mg of forest carbon sinks, the emission savings from wood products should be at least 2 Mg carbon. Soimakallio et al. (2021) and Hurmekoski et al. (2023) suggest that increasing harvests in Finland would result in an increase in the net flow of GHG to the atmosphere. The former considers emissions over a 50-year period, while the latter examines them for the next 100 years. Several previous studies (Lecocq et al. 2011; Kallio et al. 2013; Soimakallio et al. 2016; Suter et al. 2017), indicate that if harvests are increased to produce heat, power, or biofuels, the substitution benefits gained do not offset the reduction in forest carbon sinks within a timeframe relevant to meeting Paris Agreement targets (United Nations 2024).

For Norway at the national level, a comparative evaluation of the combined climate effects of forests and forest products is lacking, and this study aims to address this gap. Such an analysis is particularly important given the Norwegian government’s goals to achieve climate change mitigation by increasing or initiating the production of wood-based biofuels for transport (The Government of Norway 2023). Meanwhile, the issue of reducing harvests for biodiversity reasons has recently gained prominence in the political agenda (Stortinget 2023). While examining parametric data suitable for analysing the climate effects of HWPs in Norway, Kallio et al. (2023) observed that the substitution effects from Norway’s domestic forest industry production in 2020 could range from 2.9 to 7.7 Tg CO2, with an average of 5.3 Tg CO2. This wide range of estimates highlights the uncertainty related to the substitution parameters and end use of the materials. Gobakken (2023) explored alternative HWP production schedules based on industrial roundwood from Norway, considering the uncertainty in the carbon substitution parameters. In addition to uncertainties related to substitution effects, uncertainties related to the carbon sinks of forests and HWPs also exist.

This study compares the climatic effects of Norway’s forests and forest sector under different harvest levels – current, increased, and decreased – based on national policy goals. It accounts for various uncertainties in carbon substitution and storage parameters. Alternative production options for forest industries are explored to identify pathways that enhance climate benefits and those that may be less favourable. This study considers climate change mitigation effects and potential in the medium term, looking up to 25 years ahead. This timeframe is particularly relevant for industries planning investments in new operations or considering extending the lifespan of existing ones, as well as for achieving the targets of the Paris Agreement (United Nations 2024).The study addresses key issues in current Norwegian forest and climate policies, including the goals of investing in biofuels for transport and forest protection. These results will be valuable for policymakers and industrial stakeholders.

2 Material and methods

Carbon substitution and storage effects for Norwegian forests and forest sector were calculated for seven alternative production settings discussed in Section 2.1. The calculation of the substitution effects and data used are discussed in Section 2.2. The method employed for calculating carbon storage in HWPs follows that used by Norway for UNFCC reporting (IPCC 2019). This method and the choice of the relevant parameters are described in Section 2.3. Carbon sinks in forests were calculated using the GAYA 2.0 forest simulation tool (Strimbu et al. 2023), as discussed in Section 2.4.

Significant uncertainty exists regarding the data and assumptions that impact the assessment of the climate effects of the forest sector. Regarding HWPs, these uncertainties concern end-uses, materials substituted by wood products, wood input coefficients in production of HWPs, GHG emissions related to the production and consumption of alternative products, and lifetimes and end of life (EoL) destinies of products in their various uses. Sawnwood provides a good example. For instance, we only have a rough idea of the share of sawnwood production used for making furniture, and, further, for alternative types of furniture. Furthermore, it is not possible to determine which type of furniture the customer would have selected if the wooden options were not available. Thereafter, the question of how long wooden furniture will last in use before disposal, and what happens to it afterward, remains uncertain. Similar issues arise when examining the use of sawnwood in construction. In forestry, alongside numerous uncertainties surrounding carbon sequestration in managed forest areas, forests can be managed in various alternative ways, each with differing impacts on forest carbon sequestration.

Monte Carlo simulations were used to account for uncertainties. Seven forest sector production settings were designed and compared in a space consisting of 15 000 equally likely states of nature. These states of nature aim to address the uncertainties in parameters affecting the calculations of forest carbon sinks, HWP carbon sinks, and substitution effects. For consistency, some parameters in the states of nature were shared between the calculations of substitution benefits and the carbon sinks of HWPs. The states of nature were created by drawing the data from their assumed plausible distributions, which were assumed to be uniform. These choices are discussed below.

2.1 Production alternatives considered

The seven cases for which the climate effects were calculated differed in roundwood harvests and forest industry production, as presented in Tables 1 and 2, respectively. The climate impacts of the HWPs assumed to be made of wood of Norwegian origin were considered. Thus, in addition to the domestic production of HWPs, foreign production, based on Norwegian net exports of roundwood and wood chips, was included in the calculations. Domestic forest industry production was maintained at least at its current level in all cases, but the use of wood exports and the potentially increased or decreased harvests varied across cases. Among the HWPs, we consider only products manufactured from wood biomass removed from the forests and used for the first time. Hence, paper products made of recycled paper and panels made of recycled wood were excluded. Instead, sawmill chips and sawdust used for pulp and panels were included, because that represents the first-time use of these raw materials. The current forest sector production in Norway was defined based on statistics for 2021, using FAOSTAT database (FAO 2023) as the primary data source. Additional data on the production of ethanol, pellets, and insulation materials were collected from producers’ websites. Data from Statistics Norway (2023a) supplemented the wood export data.

| Table 1. Harvests and net exports of wood in seven production alternatives considered for Norway. iH2021: harvest and forest industry production as in 2021. iH2021Fibr: as iH2021 but with pulpwood exports used for textile fibre and insulation materials production instead of paper pulp. iH2021Fuel: as iH2021 but with pulpwood exports used for transportation biofuels. iH2021-20%: industrial roundwood harvests are 20% lower than in 2021. Forest industry production based on exported wood is cut down. iH2021+20%: industrial roundwood harvests are 20% higher than in 2021. Production increases in existing product categories. iH2021+20%Fibr: as iH2021+20% but production of textile and insulation materials increase. iH2021+20%Fuel: else as iH2021+20% but production of transportation biofuels increases. | ||||||||

| Harvest, Mm3 | Net exports, Mm3 | Side product from sawlog net exports and changes in domestic sawnwood production, Mm3 | ||||||

| Fuelwood | Sawlogs | Pulpwood | Total | Sawlogs | Pulpwood | Wood chips and particles | Wood chips and particles | |

| iH2021 | 2.1 | 6.9 | 4.6 | 13.6 | 1.7 | 1.9 | 0.2 | 0.6 |

| iH2021Fibr | 2.1 | 6.9 | 4.6 | 13.6 | 1.7 | - | - | 0.6 |

| iH2021Fuel | 2.1 | 6.9 | 4.6 | 13.6 | 1.7 | - | - | 0.6 |

| iH2021-20% | 2.1 | 5.5 | 3.7 | 11.3 | 0.3 | 0.9 | 0.2 | 0.1 |

| iH2021+20% | 2.1 | 8.2 | 5.6 | 15.9 | 3.0 | 2.8 | 0.6 | 1.1 |

| iH2021+20%Fibr | 2.1 | 8.2 | 5.6 | 15.9 | 1.7 | - | - | 1.1 |

| iH2021+20%Fuel | 2.1 | 8.2 | 5.6 | 15.9 | 1.7 | - | - | 1.1 |

| Table 2. Production of forest industry products in the seven cases considered for Norway. Abbreviations: SaW = sawnwood, MeP = mechanical pulp, ChP = chemical pulp, DiP = Dissolving pulp, ParB = particleboard, FiB = fibreboard, WhP = white pellets, BlP = black pellets, TeF = textile fibre, InsM = insulation materials, BE = bioethanol. Wood inputs for textile fibre and ethanol were randomized between 4.9–5.3 m3 Mg–1 and 6.0–7.3 m3 m–3, respectively. Notation [min, max] gives the resulting minimum and maximum production levels that appeared in the 15 000 states of nature. Mg refers to tonne, and Tg to millions of tonnes. For short description of the cases, see Table 1. | |||||||||||

| SaW | MeP | ChP | DiP | ParB | FiB | WhP | BlP | TeF | InsM | BE | |

| Mm3 | Tg | Tg | Tg | Mm3 | Mm3 | Tg | Tg | Tg | Tg | Mm3 | |

| iH2021 | 3.73 | 0.90 | 0.53 | 0.15 | 0.32 | 0.18 | 0.15 | 0.07 | 0.00 | 0.04 | 0.02 |

| iH2021Fibr | 3.73 | 0.90 | 0.12 | 0.15 | 0.32 | 0.18 | 0.15 | 0.07 | [0.29, 0.35] | 0.20 | 0.02 |

| iH2021Fuel | 3.73 | 0.90 | 0.12 | 0.15 | 0.32 | 0.18 | 0.15 | 0.07 | 0.00 | 0.04 | [0.28, 0.38] |

| iH2021-20% | 2.97 | 0.90 | 0.24 | 0.15 | 0.32 | 0.18 | 0.15 | 0.07 | 0.00 | 0.04 | 0.02 |

| iH2021+20% | 4.49 | 0.90 | 0.82 | 0.15 | 0.32 | 0.18 | 0.15 | 0.07 | 0.00 | 0.04 | 0.02 |

| iH2021+20%Fibr | 4.49 | 0.90 | 0.12 | 0.15 | 0.32 | 0.18 | 0.15 | 0.07 | [0.48, 0.59] | 0.31 | 0.02 |

| iH2021+20%Fuel | 4.49 | 0.90 | 0.12 | 0.15 | 0.32 | 0.18 | 0.15 | 0.07 | 0.00 | 0.04 | [0.47, 0.65] |

2.1.1 Production settings assuming harvests remaining at their 2021 levels

In the case, hereafter called iH2021, the annual roundwood harvests were set to remain at 13.2 Mm3 as they were in 2021 (Table 1). Domestic forest industry production was set to replicate the production in 2021 (Table 2). Net exports were 3.5 Mm3 for roundwood and 0.2 Mm3 for wood chips and particles obtained as by-products of the forest industries (Table 1). Sawlog net exports were assumed to be used for sawnwood production abroad. Net exports of pulpwood and chips were assumed to be used for making chemical pulp for printing and writing papers (50%) and paperboard (50%). Sawnwood production from Norwegian sawlogs abroad was also taken to generate chips and particles of Norwegian origin (Table 1). These were also used for paper pulp production. Production of one cubic meter of sawnwood was assumed to require 1.8 m3 of sawlogs (under bark). That figure was obtained by calibrating the input factor with statistics on apparent sawlog consumption and sawnwood production in Norway for the years 2016–2020 (Statistics Norway 2023a, FAO 2023). Amount of chips suitable for pulp production obtained as side product was assumed to be 63% of sawnwood volume. These figures align well with the input factors used in forest sector models for sawnwood production in Norway (Mustapha 2016; Kallio 2021). In addition to chips, the sawnwood production provides sawdust used as an input for instance in pellets and particle board production. For chemical pulp production abroad, wood input 4.9 m3 (u.b.) per 1000 kg of pulp was assumed.

Two alternative forest industry production structures were considered under the 2021 harvest level. Instead of using net exports of pulpwood and chips for production of chemical pulp for paper and paperboard, they were assumed to be used for biofuels (ethanol) in case iH2021Fuel and for textiles fibres and insulation materials in case iH2021Fibr (Table 2). The production could take place in Norway given investments into production capacity. Production of bioethanol was chosen, because several investment projects for bioethanol and other biofuels have been under discussion (Prosess2021 2021) and the increase in the use of bioenergy and biofuels for transport is in the agenda of the Government of Norway (2023). Production of textile fibres and insulation materials were taken into consideration based on a pre-study by Kallio et al. (2023) proposing that these products could lead to increased substitution benefit for Norway. Favourable climate impact of textile fibres had been shown by Shen and Patel (2010), Shen et al. (2010), Rüter et al. (2016), and Spinnova (2022). Wood-based insulation materials are still a niche product but have the potential to become significant. In Norway, new production capacities for wood-based insulation materials have recently been established, and further expansion could be more manageable for companies that already have market knowledge.

2.1.2 Production settings where industrial roundwood harvests are 20% higher than in 2021

In the past decade, roundwood harvests in Norway have consistently fallen well below the annual increment in forests (Nibio 2019). Recognizing the economic potential of increasing harvests, the Norwegian government set a target of approximately 15 Mm3 for annual harvests in its forest strategy “SKOG22” (The Government of Norway 2015). This target was maintained when the Norwegian government established the LULUCF forest reference levels for 2021–2030, selecting from various scenario paths for forests (Nibio and Miljødirektoratet 2019; The Government of Norway 2019). This policy target formed the basis for three cases in our analysis: iH2021+20%, iH2021+20%Fibr, and iH2021+20%Fuel (Tables 1 and 2). In these cases, where industrial roundwood harvests were assumed to be 20% higher than in 2021, the increase in sawlog harvests was assumed to be used for additional sawnwood production either domestically or abroad. The increase in pulpwood and sawmill chips production was assumed to be exported for paper pulp production in iH2021+20%. In the other two cases, increased pulpwood and sawmill chips production and the volume of pulpwood and chips that were net exported in iH2021 were used to make bioethanol (iH2021+20%Fuel) or textile and insulation materials (iH2021+20%Fibr) in Norway. Fuelwood harvests obtained from Statistics Norway (2023b) were kept at the 2021 level of 2.1 Mm3 in all the cases (Table 1). Statistics on fuelwood production are estimated based on sample surveys among households and are not as reliable as those of officially registered industrial roundwood harvests. Although this study focuses on the industrial use of wood, fuelwood harvests are included due to their impact on forest carbon stocks.

2.1.3 Production settings where industrial roundwood harvests 20% lower than in 2021

The need for increased forest protection has been debated in Norway in recent years. The Energy and Environmental Committee of the Norwegian Parliament (The Energy and Environmental Committee 2024) recently supported a proposal to protect all natural and old-growth forests in Norway. This aligns with the EU Biodiversity Strategy for 2030 (European Commission 2020), which calls for increasing protected land areas and strict protection of all primary and old-growth forests. Norway often follows EU legislation through the European Economic Area Agreement. Storaunet and Rolstad (2020) estimate that 30% of Norway’s productive forests could be classified as natural forests in 2016. Some of these forests are likely to be in areas of difficult accessibility, where harvests would not yield significant economic gains. Therefore, protecting these areas would likely not impact the overall harvest levels. In case iH2021-20%, it was assumed that sawlog and pulpwood harvests would decrease by 20% from the 2021 levels and affect the net exports of roundwood and, consequently, the volumes of sawnwood, sawmill chips, and paper pulp produced from the exported quantities (Tables 1 and 2). However, whether domestic or foreign production adjusts to reduced wood availability in Norway is not critical to the results. Additionally, it was assumed that the fuelwood harvest remains unchanged.

2.2 Avoided emissions owing to the use of wood products

As discussed above, there is considerable uncertainty regarding the end-uses of HWPs, materials they replace, and GHG emissions avoided owing to such replacements. Table 3 displays the ranges of the carbon displacement factors (DFs) applied to create the states of nature for substitution effects. The data are provided separately for the production stage of HWPs and EoL use for energy. Various data sources were used, and key references are listed in Table 3. When applicable, Table 3 provides the assumed ranges of end-use shares for semi-finished products and wood inputs. Among the HWPs currently produced in Norway, sawnwood has the highest contribution to carbon storage and substitution, and it was examined by end use. Treindustrien (2021) reports that 75% of the sawnwood produced in Norway is used as building material. Leskinen et al. (2018) considered that 50% of sawnwood is used as construction materials which was here interpreted to refer to structural construction. Previous studies by Hurmekoski et al. (2020) and Sandberg et al. (2014) were examined when defining end-use share ranges for furniture, packaging materials, and other sawnwood products. In Norway, mechanical pulp is solely used for production of newsprint and other printing and writing papers. Chemical softwood pulp that was assumed to be produced abroad from Norwegian wood was assumed to be used equally for printing and writing papers, and for packaging paper and paperboard (Table 3). Considering that paperboard production is growing, and printing and writing paper production is decreasing (FAO 2023), the share of paperboard, which has been suggested to provide higher substitution effects than printing papers, can be considered conservative.

| Table 3. Carbon displacement factors (DFs) for 2030, end uses, and other assumptions made on harvested wood products (HWPs) originating from Norwegian wood. Unless otherwise mentioned, unit for DF is MgC per unit of finished product expressed in MgC stored in it. For the parameters varying across the 15 000 states of nature, the ranges used in defining these states by random draw are indicated either by [lowest value, highest value] or by a default value with a 30% percentage variation around it. Thus e.g., 0.9 + 30% could also be written [0.63, 1.17]. | |||

| HWP | Variation in end-use share or wood input & other assumptions | DF, Production | DF, End-of-Life |

| Sawnwood for | |||

| Construction: | [70%, 80%] of sawnwood (1) | ||

| -Structural | [60%, 73%] of construction (2), (3) | 0.9 + 30% (2) | 0.55 + 30% |

| -Non-structural | Rest of construction | 1.2 + 30% (2) | 0.55 + 30% |

| Furniture | [2%, 4%] of sawnwood (4), (5) | 0.9 + 30% (4) | 0.55 + 30% |

| Packaging | [81%, 91%] of what is left after construction and furniture. Mean 19%. (4), (5) | 1.1 + 30% (4) | 0.55 + 30% |

| Other uses | What is left from all other uses. Mean 3%. (4), (5) | 0 (4) | 0.55 + 30% |

| Fibreboard | Various end-uses | [–0.16, 0.33] (6), (7) | 0.55 + 30% |

| Particleboard | Various end-uses | [0.26–1.60] (2), (6), (7), (8), (15) | 0.55 + 30% |

| Insulation materials | |||

| Blow in | [40%, 60%] (3) | [2.9, 3.8] (9), (10), (11) | 0.55 + 30% |

| Board form | Rest of insulation materials | [1.5, 3.8] (9), (10), (11) | 0.55 + 30% |

| Mechanical pulp | Used for newsprint and magazine papers | 0 | 0.55 + 30% |

| Wood-based textile fibres | Substituting oil-based fibre. Wood input [4.9, 5.3] m3 per Mg of pulp (3) | [2.5, 3.7] (12), (13), (14) | 0.55 + 30% |

| Chemical pulp made from exported wood | |||

| Printing and writing papers | 50% end-use share (3) | 0 (4) | 0.55 + 30% |

| Paperboard replacing plastics | 50% end-use share (3) | 1.3 + 30% (8) | 0.55 + 30% |

| Pellets (white) | Substituting [heating oil, coal] | - | [0.35, 0.43] MgC per Mg of pellets (3) |

| Pellets (black) | Substituting coal | - | [0.45, 0.49] MgC per Mg of pellets (3) |

| Bioethanol | Substituting gasoline. Wood input [6, 7.3] m3 per m3 of fuel (3) | - | [0.35, 0.44] MgC per m3 of fuel (3) |

| Fuelwood | Household fuelwood | - | [0.10, 0.60] (3) |

| Sources: 1) Treindustrien 2021. 2) Leskinen et al. 2018. 3) Calculated or assumed by authors, 4) Hurmekoski et al. 2020. 5) Sandberg et al. 2014. 6) Suter et al. 2017. 7) Trømborg and Sjølie 2011, 8) Knauf et al. 2015. 9) Kallio et al. 2023, 10) Hunton 2017, 2020a, 2020b, 11) Schulte et al. 2021, 12) Shen et al. 2010, 13) Rüter et al. 2016, 14) Spinnova 2022. 15) Brunet-Navarro et al. 2021. | |||

When it was necessary to convert units of forest industry production in cubic meters or tonnes (Mg) to grammes of carbon, the following carbon contents, cf, were applied: 0.225 MgC m–3 for sawnwood, 0.269 MgC m–3 for panel products, 0.4 MgC Mg–1 for pulp for paper and textiles, 0.44 MgC Mg–1 for insulation materials. The IPCC default value for sawnwood carbon content is 0.229 MgC m–3, but a slightly lower value was used here because Norway mostly produces coniferous sawnwood, which has a lower carbon density than hardwood. The same values were used for the carbon stock calculations discussed in section 2.3.

At the end of their life, most wood products can be recovered and incinerated for energy. Other materials replaced by wood products could also be used for energy, but such energy is often not renewable. Cotton is an exception, but we assumed wood-based textile fibres to replace fossil fuel-based fibres. Despite rapidly increasing demand for textile materials, cotton production has stagnated or grown very slowly, while the use of wood-based and oil-based textile fibres has been growing rapidly (Kallio 2021).

We assumed that the EoL DF ranges between 0.4 and 0.7 MgC MgC–1 (0.55 + 30%) up to 2030. Unless stated otherwise, this and other figures in Table 3 refer to Mg of fossil carbon avoided per Mg wood carbon remaining in the product. This allows for a consistent EoL DF unit across all forest industry products, assuming a similar rate of energy recovery, which simplifies calculations and enhances transparency. Regarding other studies, we could note that Leskinen et al. (2018) found a mean EoL DF for all HWPs at 0.4 MgC MgC–1 across the studies reviewed, and Hurmekoski et al. (2020) chose to employ 0.7 MgC MgC–1 for Finland. However, these DFs referred to the fossil carbon avoided per unit of wood carbon used in the production of wood product. Converting them to carbon saved per unit of carbon remaining in the product would yield higher figures. Brunet-Navarro et al. (2021) used a figure for EU that was in various applications above 0.4 MgC per MgC contained in a product, which is comparable to many of the EoL DFs applied by Rüter et al. (2016) for 2030.

The assumption on DF for fuelwood does not affect the comparison of the production cases (Table 2), as fuelwood production was kept fixed at 2.1 Mm3 a–1 (0.48 Tg C). The DF for fuelwood was set in the range of 0.1–0.6 MgC MgC–1 (Table 3). In Norway, fuelwood is mainly used by private households for heating (Statistics Norway 2023c). Fossil fuel-based heating applications are now forbidden in Norway, and the main plausible alternatives for fuelwood are direct electric heating or electricity driven heat pumps. Using the statistics of production of heat and the electricity use by heat pumps in Norway, GHG content of Norwegian electricity (Norwegian Ministry of Energy, 2024), and assuming 85% efficiency of heat production if fuelwood is used, DF of circa 0.06 MgC MgC–1 would results. The figure is low because electricity produced in Norway is almost 100% renewable. However, Norway is an important exporter of clean electricity to European markets. In 2021, the net exports of electricity were 17.6 TWh (Norwegian Ministry of Energy 2024). Electricity not used in Norway can be exported, helping the more emission intensive countries to decarbonize and balance their electricity production, particularly in the winter times when the demand for heating is high. Considering the average emission intensity of electricity in the main importer countries for Norwegian electricity, Denmark, Germany, Sweden, and the United Kingdom in 2021 (European Environment Agency 2024, Government UK 2024), DF would be 0.41, 0.66, or 1.14 MgC MgC–1 using the figures for Denmark, the UK, and Germany, respectively, whereas DF for Sweden would be at the Norwegian level. Hence, there is large variability of potential and relevant substitution benefits. Since heat pumps are not always a practical alternative to direct electric heating, these examples of DFs can be regarded as conservative.

Emission savings achieved by producing and using HWPs compared to products made from alternative materials, as well as savings from the EoL of HWPs, are expected to decrease as energy sectors in many countries gradually decarbonize. This trend is acknowledged in several studies (Rüter et al. 2016; Hurmekoski et al. 2020; Brunet-Navarro et al. 2021), but accurately predicting how much the DFs should decline over time is complex. The EU aims to reduce emissions by 90% from 1990 levels by 2040 and to achieve climate neutrality by 2050. Although some GHG emissions from industries and energy supply will remain in 2050, these should be counterbalanced by removals including forest sinks (European Commission 2024). Wood-based bioenergy, whose emissions are accounted for in changes to forest carbon stocks, plays a role in the EU’s decarbonization strategies. Without it, additional costly measures would be needed to replace fossil fuels. However, if we base assumptions about future DFs solely on the EU’s climate goals, we might overlook the fact that many significant global producers of alternative materials, such as concrete, steel, plastics, and polyester, are not European. For example, China and India – two major users of coal, crucial for electricity generation in steel and cement production – have no plans to phase out coal by 2035 and have not provided a timeline for doing so beyond that (International Energy Agency 2024). China and India are leading producers of steel and cement, with China being the largest and India the fourth-largest exporter of PET, a plastic material used in many applications competing with paperboard and wood-based textiles (The Observatory of Economic Complexity 2024; World Cement Association 2024; World Steel Association 2024). If we assume that DFs decline in line with the EU’s climate goals – owing to HWPs produced in Europe becoming more climate-friendly – we risk overlooking the possibility that the emissions associated with the materials we compare these HWPs to may not necessarily decrease at the same rate, if at all. In some rare instances, the emissions gap between some alternative materials could even widen. As to the EoL DFs, it is also relevant to consider that as Norway and the EU export HWPs to non-EU countries, where the incineration or reuse of these HWPs also will occur. This presents significant potential for emission savings when these countries realise the value in waste recovery, if not doing so already.

Acknowledging the challenge of making perfect assumptions about the evolution of DFs, and without claiming to have resolved it, we incorporated some decline in the DFs over time, while trying to keep in mind the previously discussed points: that Norway and the EU do not produce all alternative materials to HWPs; that Norway and the EU export HWPs also outside of Europe; and that bioenergy remains the most suitable renewable alternative for replacing fossil fuels in some cases even in the EU. We assumed that all DF’s, both production and EoL, would decrease over time – by 30% by 2040 and by 50% by 2050 – relative to the DFs in Table 3. Each state of nature was adjusted accordingly over time with a constant ratio. For the range of EoL DF between 0.4 and 0.7 MgC MgC–1, a 50% reduction would result in a DF ranging between 0.2 and 0.35 MgC MgC–1 in 2050. The same assumptions were applied to bioethanol, despite the EU’s plan to ban the sale of new petrol and diesel cars in 2035 (European Parliament 2022). Some such vehicles will still be on the European roads in 2050, and biofuels can be used for fuelling remaining vehicles, including those used in heavy transportation and aviation.

2.3 Carbon sink of harvested wood products

Carbon sinks or sources in HWP pools, i.e., increases or decreases, respectively, in the volume of carbon stored in these products, were calculated by applying the first order decay function as proposed by the Intergovernmental Panel on Climate Change (IPCC 2006). Following IPCC, the carbon stock C(i) and its change ΔC(i) in a particular HWP category in year i were calculated using Eqs. 1 and 2:

![]()

where:

C(i) is carbon stock (kt C) in the beginning of year i;

k is rate at which carbon is removed from the pool (first order decay rate);

cf is carbon content of the HWP considered (MgC per unit of product);

Qi is production volume of the HWP considered;

ΔC(i) is carbon stock change (kt C) in year i.

The decay rate, k, is defined as k = ln(2) / HL, where HL is the half-life. HL is the number of years it takes to lose half of the material currently in the pool. It is calculated from the mean lifetime ML of an HWP as HL = ln(2) × ML. The initial carbon stock C(i = 0) for the HWP category was based on the average inflow of carbon to the pool from 1961 to 1965.

Carbon sinks were calculated for sawnwood, panel products, paper pulp, and textile fibres. The half-lives of these products were randomized for 15 000 states of nature. In each state of nature, HL was kept fixed during the entire calculation (1960–2050). The resulting mean of the HLs deviates only slightly from the default values used in IPCC (2014): 2 years for paper, 35 years for sawnwood, and 25 years for panels. Table 4 displays the ranges of the mean lifetimes (ML) and corresponding half-lives (HL). Since there are several alternative uses for sawnwood and panels, the HLs used in the carbon stock calculation for a given state of nature were determined by taking the weighted average of the HLs across these, with the end-use shares serving as weights. For ensure consistency, the end-use shares in the states of nature were the same as those used in the calculation of the substitution factors.

| Table 4. Assumptions used for calculating the carbon sinks in Norway for harvested wood products (HWP) with half-life of 2 years or more. The half-life values vary across the 15 000 states of nature, and ranges used in defining these states by random draw are indicated by [lowest value, highest value]. Lifetime data are based on various sources reviewed and indicated in Kallio et al. (2023, p. 260). | ||

| HWP | Mean lifetime (ML). Years. | Half-life range used in sampling. HL = ln(2) × ML. [Min, Max] years. |

| Sawnwood | Weighted average over the uses in Table 3 | [20, 50] |

| -Structural construction | 52–100 | [36, 69] |

| -Non-structural construction | 10–60 | [7, 42] |

| Furniture | 13–43 | [9, 30] |

| Packaging | 0–9 | [0, 6] |

| Other uses of sawnwood | 0–9 | [0, 6] |

| Particleboard | Weighted average of various uses: [40%, 50%] for furniture with ML of 13–43 years, rest [50%, 60%] for non-structural construction, with ML of 10–60 years. | [8, 37] |

| Insulation materials | [28, 42] | |

| Paper pulp | 2 | |

| Pulp for textiles | 3 | |

To calculate the HWPs carbon sink, the initial carbon stock must be estimated from the past data. In addition, because only HWPs whose production is based on wood produced in Norway are considered, net trade in wood must be accounted for. In the past, Norway has sometimes been a net importer of wood, whereas it has been a net exporter in recent years. This issue was addressed by adjusting sawnwood and chemical pulp production in 1961–2021 by the shares of domestic wood material of the total apparent use of sawlogs and pulpwood, respectively. The results are not sensitive to these adjustments because they only slightly affect the starting volume of the HWP carbon stock in 2022. Net exports of pulpwood and sawlogs were collected from FAOSTAT for the years 1960–1987 (FAO, 2023). Data from SSB (Statistics Norway 2023a) were available and used from 1988 onwards.

2.4 Carbon sinks of forests

A scenario analysis software tool, GAYA 2.0, was used to calculate the carbon sinks of the forests in Norway. Strimbu et al. (2023) provide a description of the tool and show how it can be used to predict and project carbon balance in a region based on national forest inventory sample plots. The reader is referred to that article, but the details essential for this study are briefly described below.

The GAYA 2.0 simulations were initialized using 9691 plots measured by the Norwegian NFI over a complete 5-year cycle from 2015 to 2019. Projections were made over a planning horizon of 50 years, with forest simulations conducted for 10 five-year periods, extending the projections up to 2070 and beyond the timeframe examined in this study. Treatments were timed at the beginning of each period. An abbreviated treatment list is provided in Strimbu et al. (2023) supplementary file S2. Forest owners were assumed to maximize net present value (NPV) of roundwood production using a 3% yearly discount rate. The silvicultural treatment options are standard for Norwegian management.

To compare the different harvest intensities, the harvests of each industrial wood category were constrained to remain at the level observed for 2021 (Alternatives iH2021, iH2021Fuel, and iH2021Fibr), 20% below that level (iH2021-20%), or 20% above that level (iH2021+20%, iH2021+20%Fuel, iH2021+20%Fibr). An exception was made for birch harvest levels for which only total harvested volume was set as a constraint. This was necessary as birch is seldom the dominant species in Norwegian forest stands and is largely used for fuelwood, a category that is not accounted for by the harvest statistics. Fuelwood harvests were kept same in all the cases. Furthermore, by default, GAYA 2.0 predicts ideal wood categories, prioritizing saw logs over pulpwood logs. To avoid infeasibility, calibration factors were used to increase the proportion of the pulpwood logs. These factors were approximated at county level using levels based on the saw logs and pulpwood logs proportions observed in 2021. While the objective of maximizing NPV drives the decision of stand treatments, the fixed harvest level constraint is an important determinant in harvest decisions. GAYA 2.0 uses the JLP22 (Lappi 2022) optimizer. The average prices for sawlogs and pulpwood were obtained from Statistics Norway (2023b).

In this study, GAYA 2.0 was used to calculate carbon in living biomass, litter, and soil. Biomass carbon predictions are based on biomass models for different tree components (Marklund 1988), assuming a 50% carbon content. Litter and soil carbon were predicted using the Yasso20 model (Viskari et al. 2022). The climate data necessary for the soil carbon model was retrieved from Norwegian Meteorological Institute (2023) and consisted in county-level precipitation and temperature measurements over 5 years (May 2018 – June 2023).

When building the states of nature for uncertainty analysis, it was assumed that the actual forest carbon sinks could vary within +30% of the value projected by GAYA 2.0. This uncertainty was judged plausible after examining the variations in carbon sinks across the projections calculated for Norway as background material for preparation of the Norwegian Forest Reference Levels (Nibio and Miljødirektoratet 2019) and, also, when comparing those results to those given by GAYA 2.0. There are also other relevant reasons for allowing variation in the sink estimates, regardless of the model’s accuracy in projecting the impacts of the assumed harvest on the forest carbon sink. First, the impact of harvests on carbon sinks was not considered when making harvest decisions in the GAYA simulations, as forest owners are not compensated for carbon. Hence, it is possible to find harvest alternatives that would provide higher carbon sinks at the expense of forest owners’ income. Second, it is also possible to allocate harvests in a manner that reduces the carbon sink more than the harvest decisions chosen by the model. There are many forest owners, who differ in their preferences and decision alternatives available to them. Third, future harvests could be allocated differently among counties. An uncertainty range of 30% was considered to capture these aspects as well.

The carbon stock in forest was calculated in the beginning of each 5-year period, while in the result section we mainly discuss the years 2030 and 2050. The carbon sink for 2030 was calculated from the change in forest carbon stock from the beginning of the year 2025 to the beginning of the year 2035 divided by 10. For 2050, the sink refers to the respective change in forest carbon stock during 2045–2055.

3 Results

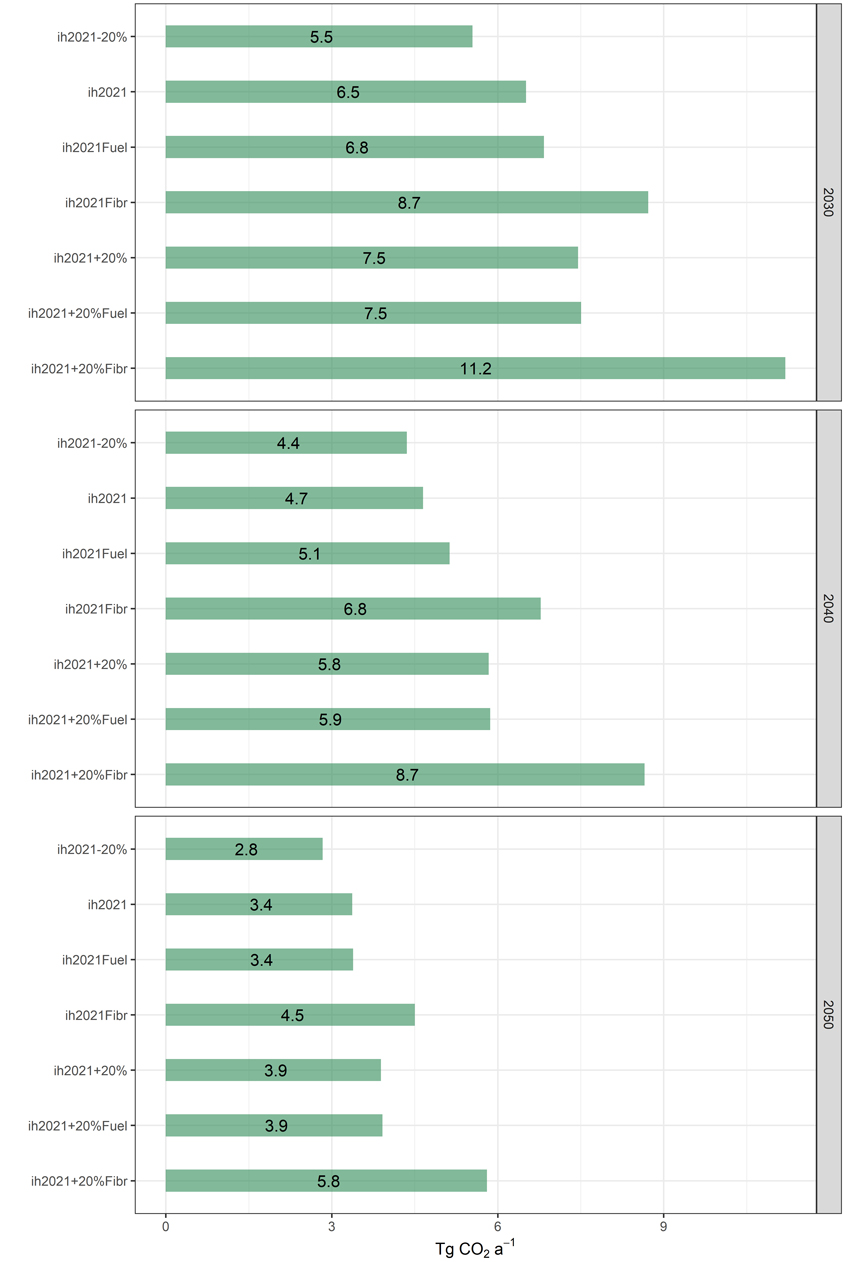

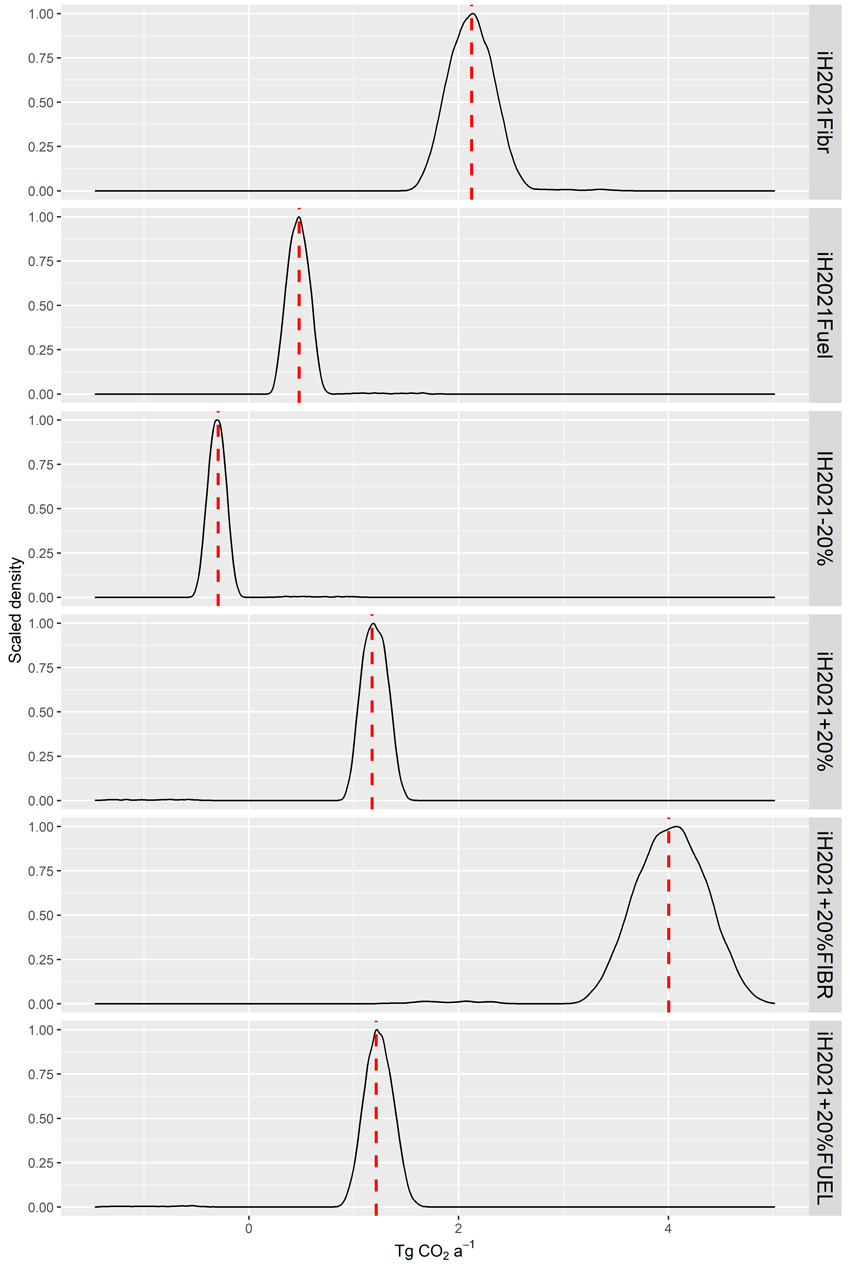

Fig. 1 presents the mean substitution effects in the seven production alternatives evaluated in 2030, 2040, and 2050. The values shown in the figure are total substitution benefits compared to a counterfactual with no HWP production. Fig. 2 shows the distribution of the substitution effect differences of other production alternatives compared to iH2021, which is used as a reference case. iH2021 assumes that harvest levels and production structure remain as in 2021.

Fig. 1. Mean substitution effects of Norwegian forests for seven production alternatives evaluated in 2030, 2040, and 2050, Tg CO2 a–1. The figures are calculated for total production quantities, as in Table 2. The cases are arranged in the order of increasing substitution effects. The production alternatives are explained in Tables 1 and 2, and Section 2.1.

Fig. 2. Probability distributions of the difference in avoided emissions (substitution effects) among six production alternatives for Norway compared to the iH2021 case, evaluated across 15 000 states of nature in 2040, Tg CO2 a–1. See Tables 1 and 2 in Section 2.1 for the explanations of the production alternatives.

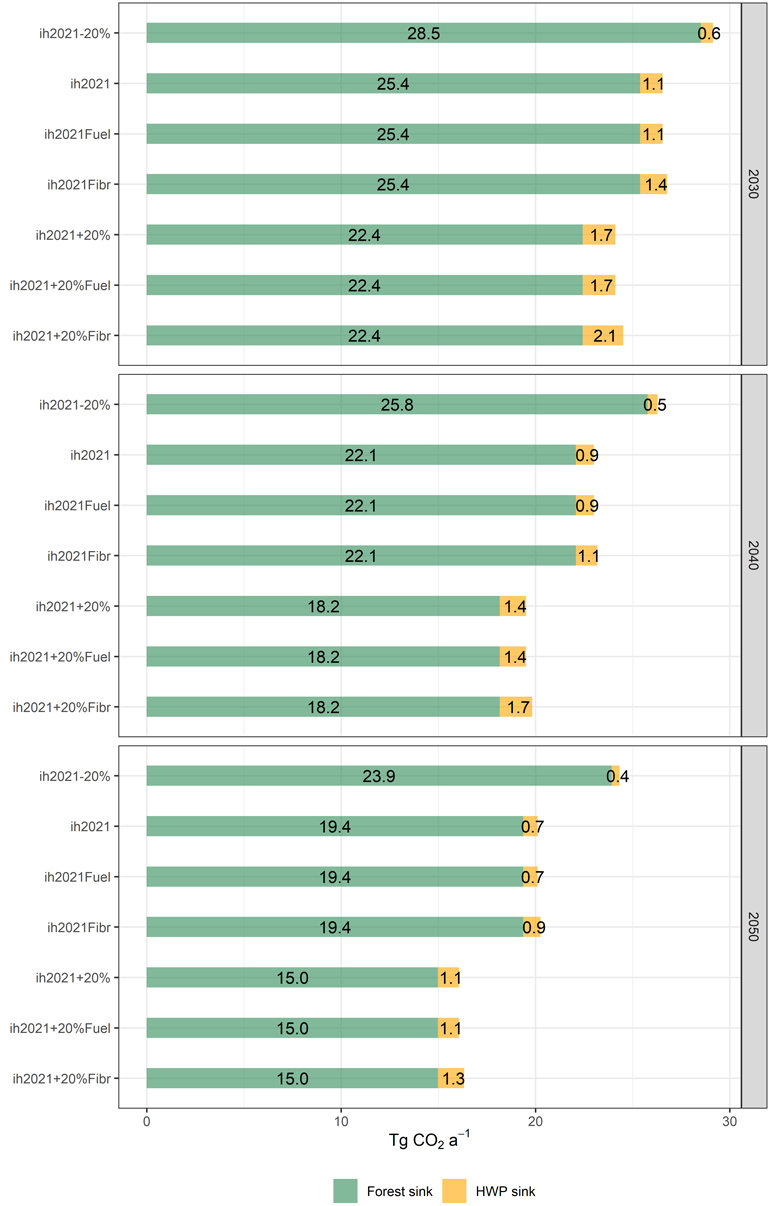

Fig. 3 illustrates the projected carbon sinks in forests and wood products for the production alternatives in 2030, 2040, and 2050. The values shown in Fig. 3 indicate the actual development of the sinks, rather than their development relative to a counterfactual. The sinks are not compared to the same counterfactual as the substitution effects in Fig. 1, as the development of the forest sink without harvests was not calculated in this study.

Fig. 3. Mean carbon sinks in forests and harvested wood products related to Norwegian forests for seven cases evaluated in years 2030, 2040, and 2050, Tg CO2 a–1. The cases are arranged in the order of declining carbon sinks. The cases are explained in Tables 1 and 2, and Section 2.1.

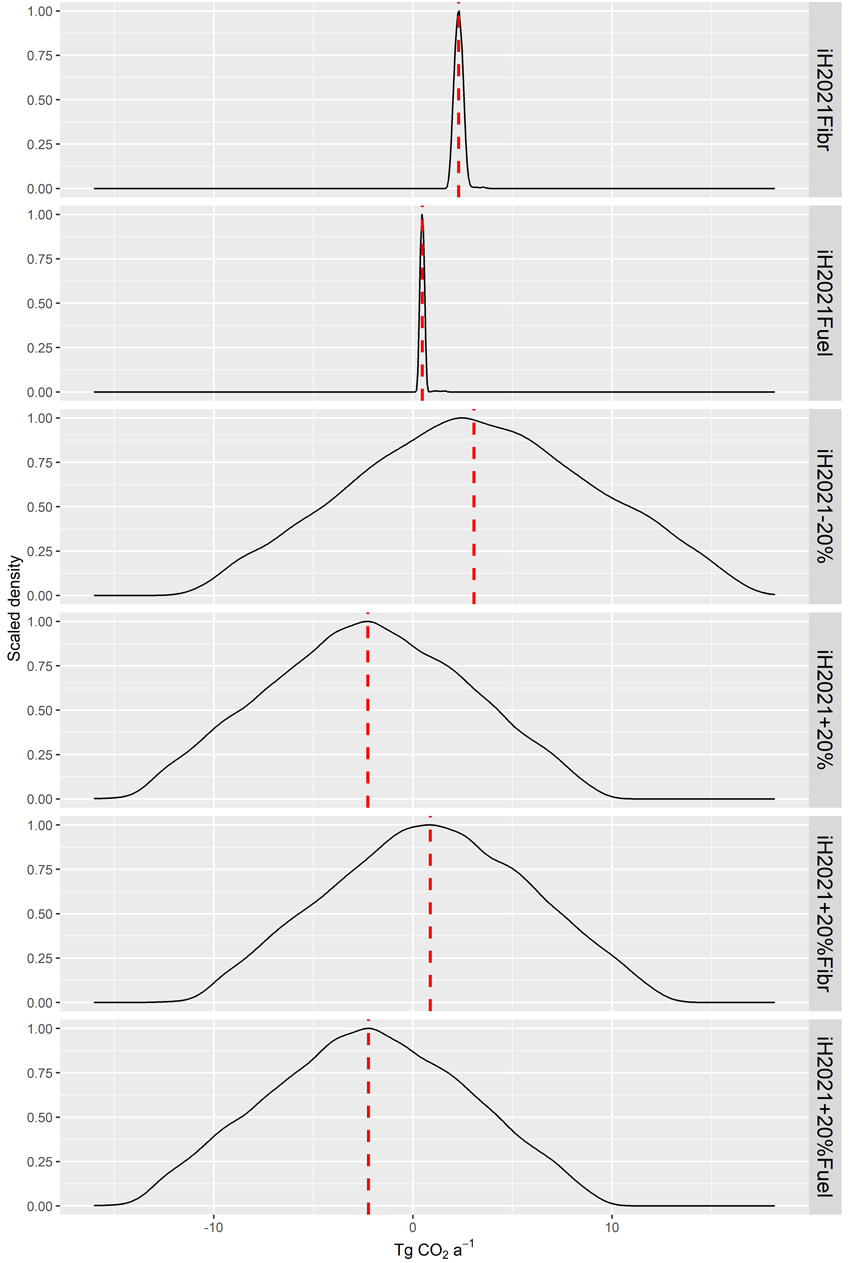

Fig. 4 shows the difference in the level of the combined substitution and sink effects of the six other production alternatives compared to iH2021. Notably, adding the differences in the substitution effects (Fig. 1, Fig. 2) and sink effects (Fig. 3) is possible, as the differences in the levels of the effects (compared to the reference case, iH2021) are the same regardless of whether the effects (in Fig. 1 and Fig. 3) are initially expressed relative to the same counterfactual or not. Fig. 4 allows comparing and ranking the cases.

Fig. 4. Probability distributions of the difference in climate effects among six production alternatives for Norway compared to the iH2021 case, evaluated across 15 000 states of nature in 2040. The effects compared include the carbon sinks of forests and harvested wood products and avoided emissions resulting from the use of harvested wood products, Tg CO2 a–1. See Tables 1 and 2 in Section 2.1 for the explanations of the production alternatives.

In 2030, the cases in which some pulpwood and chips are redirected from paper pulp production to the manufacturing of insulation materials and textile fibres (iH2021Fibr, iH2021+20%Fibr) yield the most favourable climate change mitigation outcome in the Norwegian forest sector across the alternatives considered. As expected, the forest carbon sink is larger in the iH2021Fibr compared to the iH2021+20%Fibr (Fig. 3), due to higher harvest level in the latter. However, the greater substitution effects in iH2021+20%Fibr (Fig. 1) make it the most favourable option for the climate among the alternatives considered in the short term.

By 2040, the option of reducing harvests (iH2021-20%) generally outperforms the other alternatives in terms of climate effects (Fig. 4). This is primarily due to the anticipated decline in substitution factors resulting from the assumed decarbonization of global energy sectors. In 55% of the 15 000 states of nature, iH2021-20% is superior to the next best alternative, iH2021Fibr. However, the average difference in climate effects between iH2021-20% and iH2021Fibr in 2040 is only 0.6 Tg CO2 a–1. The cumulative climate effects during 2025–2040 are not necessarily higher in iH2021-20% when compared to iH2021Fibr, where some of the pulpwood use is shifted to production of HWPs with greater climate benefits. Notably, this gap could have been reduced further if we had considered the possibility that both mechanical and chemical pulps might end up in paperboard replacing plastic packaging instead of newsprint and magazine paper in the future.

In 2050, the difference in climate effects in the favour of case iH2021-20% becomes more pronounced. iH2021-20% case now outperforms iH2021Fibr in 65% of the states of nature. The three scenarios that align with the policy target of increased harvests (iH2021+20%, iH2021+20%Fibr, iH2021+20%Fuel) generally provide lower climate benefits compared to maintaining harvest levels at their 2021 level. However, when examining the simulated outcomes, the iH2021+20%Fibr scenario still surpasses iH2021 in 38% of the cases in 2050.

The option of increasing harvests to produce biofuels for transportation (iH2021+20%Fuel) is not advantageous from a climate perspective. It offers minimal improvement in substitution effects compared to the current production structure, iH2021+20% (Fig. 2), while the higher harvest levels would reduce the forest carbon sink (Fig. 3).

It’s important to note that the differences in climate effects among the cases iH2021, iH2021Fibr, and iH2021Fuel, as well as among iH2021+20%, iH2021+20%Fibr, and iH2021+20%Fuel, are solely due to the reallocation of some pulpwood and chips to produce ethanol or textile fibres and insulation materials (Fig. 4). Despite some year-to-year differences across the cases in the volumes of HWPs with longer lifetimes reaching their EoL stage and contributing to energy substitution, the substitution effects in 2050 are approximately half of those in 2030 (Fig. 1). Because substitution effects do not impact carbon sinks, they can be scaled upward or downward if one wishes to explore the impact of alternative rates of decline in the DFs on the results, rather than the 50% rate applied in this study. The dominance of the forest sink effect flattens the distributions of differences across the cases (Fig. 4), given the assumption that the forest sink varies uniformly by ±30% around the values obtained from GAYA 2.0 simulations. HWP sinks play a smaller role compared to avoided emissions and forest sinks (Fig. 3).

4 Discussion

In the simulations using the GAYA 2.0 forest model, forest carbon sinks decline over time across all considered harvest levels. Much of Norway’s forests are relatively mature and have passed their period of most rapid growth. Harvesting shifts forests from mature age classes to younger ones, which sequester little carbon in the first few decades after harvesting. Even with an immediate 20% reduction in harvests from current levels, the simulations suggest that Norway’s forest carbon sink in 2030–2050 will be significantly lower than that observed today. In addition to the measures that might be taken within forestry, for example, allocating harvests differently across the forest stands, which was not considered in this study, a feasible alternative for increasing the climate benefits of forests is to change the consumption and thus production of forest industry products. Increased consumption of wood-based textile fibres and insulation materials as a substitute for other materials would provide positive climate effects. However, there may also be other products with potential for climate benefits which were not considered in this study.

When harvest volumes increase, the forest sink is lower than that in the alternative case without the increase. This difference in sinks between these cases tends to persist over time, at least for some decades, as was also the case in this study. A carbon balance indicator (CBI) can be calculated by comparing carbon sinks at different harvest levels (Soimakallio et al. 2022). The CBI measures the difference in sink in relation to the difference in harvests (decrease in forest sink in MgC per increase in harvests in MgC) over a period. For increased roundwood harvests to provide positive climate effects, the carbon sink and substitution benefits from additional HWP production should be higher than CBI. Such threshold values obtained from comparing annual forest sinks of iH2021+20% to iH2021 and iH2021 to iH2021-20% are 1.3 and 1.6 MgC MgC–1, respectively in 2030, and 1.2 and 2.3 MgC MgC–1 in 2050. The figures are close to the mean CBI of 1.6 MgC MgC–1 reported in the meta-analysis by Soimakallio et al. (2022) for temperate and boreal forests. However, their analysis considered a longer time perspective of over 100 years.

When comparing CBI with the DFs in Table 3, it is important to note that the latter refer to substitution effects per unit of finished product and exclude the wood inputs consumed during production. Interpreting a CBI of 1.3 MgC MgC–1 in terms of the coniferous wood usage means that for each 1 m3 of wood (assuming cf of approximatively 0.2 tC m–3), the avoided emissions need to exceed 0.26 MgC to gain climate benefits. If we consider the highest avoided fossil emission benefit employed in this study for ethanol substituting gasoline, 0.44 MgC m–3, the wood input for that could be at most 0.33 MgC for CBI of 1.3 in 2030 to yield climate benefits that surpass the loss in forest carbon sink. That is clearly not a sufficient wood input (in terms of carbon) for producing 1 m3 of ethanol. Respectively, the highest value assumed for avoided emissions by consumption of one MgC of textile fibre pulp was 3.7 + 0.55 MgC MgC–1 in 2030 (Table 3). Considering the carbon content 0.4 MgC MgC–1 of such pulp, one tonne (Mg) of pulp could provide substitution benefits of 1.6 MgC. For not to exceed the CBI 1.3, at most 1.2 MgC of wood could be used, which is more than the typical wood input. It is worth noting that the highest CFs for textile fibres are to be attained with the novel technologies with the lowest wood use (Spinnova 2022). The examples for ethanol and textile pulps did not consider carbon sinks in the HWP pools, but for some other products they would be relevant.

Non-market-driven, exogenous changes in harvest levels and forest industry production in one region cause shifts in consumption and production in other regions. These impacts should be considered when evaluating the climate effects of such policy-driven changes. The phenomenon of harvest leakage has been recently examined by Kallio and Solberg (2018) for Norway, as well as by Päivinen et al. (2022) and Di Fulvio et al. (2024) for the EU and Norway. These studies, which agree on the magnitude of leakage effects resulting from policy-induced harvest changes in Europe, are relevant in the context of this study. Kallio and Solberg (2018) suggest that if roundwood harvests in Norway were reduced by 10–30%, at least 80% of the reduced volume would be compensated by increased harvests elsewhere in the world. A similar but opposite effect would occur if harvests were increased. For example, if the production alternative iH2021 is used as a market-based reference point, a shift to iH2021-20% with reduced harvests would represent a policy-driven exogenous change. Based on the 80% harvest leakage, a rough interpretation is that if Norway’s annual forest carbon sinks increased by 3.0 Tg CO2 in 2030 and 4.3 Tg CO2 in 2050 due to a 20% reduction in industrial roundwood harvests (iH2021-20%), at least 80% of this increase could be offset by a corresponding decrease in carbon sinks elsewhere in the world. The mean difference in forest carbon sinks between cases iH2021 and iH2021-20% might decrease to approximately 0.6 Tg CO2 in 2030 and 0.9 Tg CO2 in 2050. The corresponding differences between cases iH2021 and iH2021+20%, after accounting for the leakage effect, would be approximately 0.5 Tg CO2 in 2030 and 2050. However, harvest leakage is driven by the market demand for harvested wood products (HWPs) and adjustments made by industries. This means that while the substitution benefit from producing HWPs from Norwegian roundwood decreases by 1.5 Tg CO2 when we shift from iH2021 to iH2021-20% in 2030, perhaps 80% of that lost in avoided emission is also compensated by HWP production from non-Norwegian wood that wasn’t harvested under the iH2021 scenario. Expanding the analysis beyond Norway’s borders would narrow the difference in climate effects between the iH2021 and iH2021-20% cases. From a climate perspective, the difference between these two production alternatives would not be remarkable. Although iH2021-20%, with its higher carbon sink, would appear more favourable in Norway’s carbon accounting, it would be less economically advantageous.

Kallio et al. (2023) suggest that when increased harvests are used to produce emerging HWPs that are transitioning from niche to mainstream markets and have a significant substitution factor, the leakage impact – whether sectoral or cross-sectoral (Howard et al. 2021) – could be less pronounced. If the iH2021+20%Fibr production alternative was adjusted so that the entire increase in harvests was directed solely toward wood-based textile fibres and insulation materials (Table 2), the leakage impact would be reduced. It is also noteworthy that there is a declining trend in the consumption of newsprint and magazine papers (FAO 2023), whereas this study assumed that mechanical pulp and half of the chemical pulp production would continue to supply these products in the future (Table 3). Further decline in the production of these products could release additional pulpwood and chips for new HWPs. However, the effects of market interactions on climate outcomes require further investigation. Properly addressing this issue requires a forest sector model or, ideally, a model that includes additional sectors to comprehensively capture global market developments.

The carbon stored in HWPs is gradually released into the atmosphere, when the products are disposed at the end of their lifetimes. The only way to prevent the HWP sink from declining is to keep increasing the amount of carbon transferred from forests to HWPs, i.e., increasing the production of HWPs. A practical approach to preventing or at least delaying the decline of the HWP sink, which was not addressed in this assessment, is to extend the lifetime of HWPs. Instead of incineration or landfilling materials at the end of their lifetime, they could be increasingly reused for new products beyond just energy commodities. Reducing waste incineration delays the end-of-life substitution of HWPs. If and how much the increased material recycling would increase the avoided emissions owing to HWPs in their production stage depends not only on the technologies used for HWPs, but also on the advances in the recycling and recyclability of competing materials. The EU’s waste legislation (The European Parliament and the Council 2018) enforces increased recycling, recovery, and recycling of municipal waste, including wood materials and packaging. Furthermore, technologies where the textiles fibre could be recycled repeatedly are also under development (Ioncell 2023).

While maintaining increased carbon storage in HWP pools over the long term is challenging, the cases compared in this study demonstrate that it is possible to temporarily enhance the HWP sink by shifting forest industry production towards products with longer lifetimes. For example, the iH2021+20%Fibr case (which includes more sawnwood and insulation materials than iH2021) shows an increase of 0.6 Tg C per year in 2050 compared to iH2021, while the iH2021Fibr case (which contains more insulation materials than iH2021) shows an increase of 0.1 Tg C per year. However, without significant changes in the production structure, a substantial portion of Norway’s harvests is used for energy, including industrial processes for manufacturing HWPs. According to Kallio et al. (2023, p. 259), only 54% of the carbon in industrial roundwood harvests used in domestic production in Norway in 2020 was stored in industrial products, including short-lived products such as pellets and paper.

The DFs used in this study for Norway were sourced from the literature. Given Norway’s nearly emission-free electricity supply (Norwegian Ministry of Energy 2024), one might argue that they are too low. Our choice was based on the reasoning discussed earlier regarding fuelwood. Norway can export surplus low-carbon electricity, for instance, to the UK or Germany. Another factor that could justify the use of higher DFs than those used in this study for some HWPs is their potential for material reuse. For example, textile fibres can be reused multiple times with appropriate collection and recycling systems. While systems for recycling are not yet widespread in all countries and HWPs, they could become more common in the future. Such cascading use has been considered by Rüter et al. (2016) and Brunet-Navarro et al. (2021). Nevertheless, the uncertainty ranges applied in this study may be sufficient to address this aspect.

5 Conclusions

This study compared seven production alternatives for using wood from Norway, varying based on potential harvest levels influenced by Norwegian forest and environmental policies, and forest industry production structures. The findings highlight the familiar trade-off between the reduction in forest carbon sink due to increased harvests and the potential increase in carbon sinks and substitution benefits from harvested wood products. They also indicate that it is possible to increase climate benefits by reallocating the use of wood to produce HWPs with high carbon substitution benefits. Wood-based textile fibres and insulation materials, in addition to sawnwood, were used as examples of such products in this study. Whether this also holds in the case of increasing roundwood harvests and beyond 2040 depends on the success of mitigation efforts in the energy sector globally. As noted in previous studies, if the energy sector is efficiently decarbonized, with most production relying on emission-free or low-emission energy, the differences in energy intensities among alternative materials and their substitution effects will become less significant over time. In such a case, enhancing forest carbon sinks might be considered as a potential climate change mitigation measure for Norway. However, its cost-effectiveness relative to other measures remains uncertain and was not assessed in this study. Such a policy is also susceptible to the leakage phenomenon, which should be considered.

Reallocating wood from paper pulp production to produce transportation fuel does not enhance the climate benefits of the forest sector. Moreover, increasing roundwood harvests for bioethanol production would be harmful to climate change mitigation efforts.

International trade in forest products and their non-wood alternatives, along with energy scenarios in the producer countries, including those beyond the EU, plays a vital role in analyzing the climate effects of HWPs. Adequately accounting for these factors, both for the Norwegian forest sector and globally, will require further analysis, ideally using global multi-sectoral models.

Authors contribution

MK: Conceptualization, Methodology, Data curation, Formal analysis, Investigation, Writing-original draft, Funding acquisition, Project administration, Resources; VS: Methodology (forest simulation tool), Data (forest carbon sinks), Text review and commentary; HG: Data curation, Text review and commentary; TG: Methodology (forest simulation tool), Visualization, Text review and commentary.

Funding

This research obtained funding form the Research Council of Norway: The grant agreement NR 302701 (Climate Smart Forestry Norway).

Data availability

The data are available on request from the corresponding author.

References

Braun M, Fritz D, Weiss P, Braschel N, Büchsenmeister R, Freudenschuß A, Gschwantner T, Jandl R, Ledermann T, Neumann M, Pölz W, Schadauer K, Schmid C, Schwarzbauer P, Stern T (2016) A holistic assessment of greenhouse gas dynamics from forests to the effects of wood products use in Austria. Carbon Manag 7: 271–283. https://doi.org/10.1080/17583004.2016.1230990.

Brunet Navarro B, Jochheim H, Cardellini G, Richter K, Muys B (2021) Climate mitigation by energy and material substitution of wood products has an expiry date. J Clean Prod 303, article id 127026. https://doi.org/10.1016/j.jclepro.2021.127026.

Di Fulvio F, Snäll T, Lauri P, Forsell N, Mönkkonen M, Burgas D, Blattert C, Eyvindson K, Toraño Caicoya A, Vergarechea M, Antón-Fernández C, Klein J, Astrup R, Lukkarinen JP, Pitzén S, Primmer E (2024) Impact of the EU biodiversity strategy for 2030 on the EU wood-based bioeconomy. Preprint. SSRN. https://dx.doi.org/10.2139/ssrn.4718363.

Eriksson LO, Gustavsson L, Hänninen R, Kallio M, Lyhykäinen H, Pingoud K, Pohjola J, Sarhtre R, Solberg B, Svanaes J, Valsta L (2012) Climate change mitigation through increased wood use in the European construction sector – towards an integrated modelling framework. Eur J For Res 131: 131–144. https://doi.org/10.1007/s10342-010-0463-3.

European Commission (2020) EU biodiversity strategy for 2030. COM(2020) 380 final. https://eur-lex.europa.eu/resource.html?uri=cellar:a3c806a6-9ab3-11ea-9d2d-01aa75ed71a1.0001.02/DOC_1&format=PDF.

European Commission (2024) 2040 climate target. https://climate.ec.europa.eu/eu-action/climate-strategies-targets/2040-climate-target_en. Accessed 21 June 2024.

European Environment Agency (2024) Greenhouse gas emission intensity of electricity generation in Europe. https://www.eea.europa.eu/en/analysis/indicators/greenhouse-gas-emission-intensity-of-1. Accessed 9 July 2024.

European Parliament (2022) EU ban on the sale of new petrol and diesel cars from 2035 explained. https://www.europarl.europa.eu/topics/en/article/20221019STO44572/eu-ban-on-sale-of-new-petrol-and-diesel-cars-from-2035-explained. Accessed 27 August 2024.

FAO (2023) FAOSTAT data base. Forestry production and trade. https://www.fao.org/faostat/en/#data/FO. Accessed 1 August 2023.

Gobakken H (2023) Carbon substitution and storage benefits from harvested wood products in the Norwegian forest sector. Master’s thesis, 30 ECTS. Norwegian University of Life Sciences, Faculty of Environmental Sciences and Natural Resource Management (MINA). https://hdl.handle.net/11250/3078998.

Government UK (2024) Estimated carbon dioxide emissions from electricity supplied. https://assets.publishing.service.gov.uk/media/66a7dacaa3c2a28abb50d91e/DUKES_5.14.xlsx. Accessed 18 December 2024.

Heinonen T, Pukkala T, Mehtätalo L, Asikainen A, Kangas J, Peltola H (2017) Scenario analyses for the effects of harvesting intensity on development of forest resources, timber supply, carbon balance and biodiversity of Finnish forestry. For Pol Econ 80: 80–98. https://doi.org/10.1016/j.forpol.2017.03.011.

Howard C, Dymond CC, Griess VC, Tolkien-Spurr D, van Kooten GC (2021) Wood product carbon substitution benefits: a critical review of assumptions. Carbon Bal Manage 16, article id 9. https://doi.org/10.1186/s13021-021-00171-w.

Hunton Fiber AS (2017) Isolere fornybart og lagre CO2. [Isolate renewably and store CO2]. https://www.hunton.no/wp-content/uploads/2018/08/isolereoglagreco2_web.pdf. Accessed 15 December 2021.

Hunton Fiber AS (2020a) Environmental product declaration. Trefiberisolasjon Innblåst. https://www.epd-norge.no/getfile.php/1324547-1702295674/EPDer/Byggevarer/Isolasjon/NEPD-2286-1041_Hunton-Trefiberisolasjon-Innblast---%281%29.pdf. Accessed 15 December 2021.

Hunton Fiber AS (2020b) Environmental product declaration. Wood fibre insulation board. https://www.epd-norge.no/getfile.php/1322787-1645783834/EPDer/Byggevarer/Isolasjon/NEPD-2287-1041_Hunton-Trefiberisolasjon-Plate---_en_1.pdf. Accessed 15 December 2021.

Hurmekoski E, Myllyviita T, Seppälä J, Heinonen T, Kilpeläinen A, Pukkala T, Mattila T, Hetemäki L, Asikainen A, Peltola H (2020) Impact of structural changes in wood-using industries on net carbon emissions in Finland. J Ind Ecol 24: 899–912. https://doi.org/10.1111/jiec.12981.

Hurmekoski E, Kunttu J, Heinonen T, Pukkala T, Peltola H (2023) Does expanding wood use in construction and textile markets contribute to climate change mitigation? Renew Sust Ener Rev 174, article id 113152. https://doi.org/10.1016/j.rser.2023.113152.

IPCC (2006) IPCC guidelines for national greenhouse gas inventories – a primer, chapter 12: harvested wood products. IGES, Japan.

IPCC (2014) Revised supplementary methods and good practice guidance arising from the Kyoto Protocol.

IPCC (2019) Calvo Buendia E, Tanabe K, Kranjc A, Baasansuren J, Fukuda M, Ngarize S, Osako A, Pyrozhenko Y, Shermanau P, Federici S (eds) 2019 Refinement to the 2006 IPCC guidelines for national greenhouse gas inventories.

Ioncell (2023) Enter the new era of textile production. https://ioncell.fi/. Accessed 30 October 2023.

Jonsson R, Rinaldi F, Pilli R, Fiorese G, Hurmekoski E, Cazzaniga N, Robert N, Camia A (2021) Boosting the EU forest-based bioeconomy: market, climate, and employment impacts. Technol Forecast Soc Change 163, article id 120478. https://doi.org/10.1016/j.techfore.2020.120478.

Kallio AMI (2021) Wood-based textile fibre market as part of the global forest-based bioeconomy. For Pol Econ 123, article id 102364. https://doi.org/10.1016/j.forpol.2020.102364.

Kallio AMI, Salminen O, Sievänen R (2013) Sequester or substitute – consequences of increased production of wood based energy on the carbon balance in Finland. J For Econ 19: 402–415. https://doi.org/10.1016/j.jfe.2013.05.001.

Kallio AMI, Solberg B (2018) Leakage of forest harvest changes in a small open economy: case Norway. Scand J For Res 33: 502–510. https://doi.org/10.1080/02827581.2018.1427787.

Kallio AMI, Houtmeyers S, Aza A (2023) On carbon substitution and storage benefits for harvested wood products in the context of climate change mitigation in the Norwegian forest sector. Environ Clim Technol 27: 254–270. https://doi.org/10.2478/rtuect-2023-0020.

Knauf M, Köhl M, Mues V, Olschofsky K, Frühwald A (2015) Modeling the CO2-effects of forest management and wood usage on a regional basis. Carbon Bal Manage 10, article id 13. https://doi.org/10.1186/s13021-015-0024-7.

Lappi J (2022) Jlp22 GitHUB repository. https://github.com/juhalappi/Jlp22. Accessed 30 March 2023.

Lecocq F, Caurla S, Delacote P, Barkaoui A, Sauquet A (2011) Paying for forest carbon or stimulating fuelwood demand? Insights from the French forest sector model. J For Econ 2: 157–168. https://doi.org/10.1016/j.jfe.2011.02.011.

Leskinen P., Cardelline G, González-García S, Hurmekoski E, Sathre R, Seppälä J, Smyth C, Stern T, Verkerk PJ (2018) Substitution effect of wood-based products in climate change mitigation, From Science to Policy 7, European Forest Institute. https://efi.int/sites/default/files/files/publication-bank/2019/efi_fstp_7_2018.pdf. Accessed 30 March 2023.

Matsumoto M, Oka H, Mitsuda Y, Hashimoto S, Kayo C, Tsunetsugu Y, Tonosaki M (2016) Potential contributions of forestry and wood use to climate change mitigation in Japan. J For Res 21: 211–22. https://doi.org/10.1007/s10310-016-0527-4.

Marklund LG (1988) Biomass functions for pine, spruce and birch in Sweden. Report 45, Swedish University of Agricultural Sciences, Department of Forest Survey.

Mustapha W (2016) The Nordic Forest Sector Model (NFSM): data and model structure. INA fagrapport 38, Norwegian University of Life Sciences. https://hdl.handle.net/11250/2648132.

Myllyviita T, Soimakallio S, Judl J, Seppälä J (2021) Wood substitution potential in greenhouse gas emission reduction – review on current state and application of displacement factors. For Ecosyst 8, article id 42. https://doi.org/10.1186/s40663-021-00326-8.

Nibio (2019) Volum og tilvekst gjennom 100 år. [Volume and growth over 100 years]. https://www.nibio.no/tema/skog/skog-og-miljoinformasjon-fra-landsskogtakseringen/N%C3%B8kkeltall/volum-og-tilvekst-gjennom-100-ar. Accessed 7 April 2024.

Nibio and Miljødirektoratet (2019) Notat. Alternative referansebaner for forvaltet skog: Oppdaterte beregninger. [Note: Alternative reference scenarios for the managed forest: updated calculations]. https://www.regjeringen.no/contentassets/03fc087f1c3b4351b236e2493a746f9f/besvarelse-pa-oppdrag_oppdatert_finland-08022019_final.pdf. Accessed 19 December 2024.

Norwegian Meteorological Institute (2023) SeNorge. https://www.senorge.no/. Accessed 1 June 2023.

Norwegian Ministry of Energy (2024) Energy facts Norway. https://energifaktanorge.no/en/norsk-energibruk/energibruken-i-ulike-sektorer/. Accessed 9 July 2024

Päivinen R, Kallio AMI, Solberg B, Käär L (2022) EU forest reference levels: the compatible harvest volumes compiled and assessed in terms of forest sector market development. For Pol Econ 140, article id 102748. https://doi.org/10.1016/j.forpol.2022.102748.

Prosess21 (2021) Biobasert prosessindustri. Prosess21 ekspertgrupperapport. [Prosess21 Expert Group Work]. https://www.prosess21.no/. Accessed 15 August 2023.

Rüter S, Werner F, Forsell N, Prins C, Vial E, Levet A-L (2016) ClimWood2030 – climate benefits of material substitution by forest biomass and harvested wood products: perspective 2030. Johann Heinrich von Thünen-Institut, Braunschweig.

Sandberg D, Vasiri M, Trischler J, Öhman M (2014) The role of the wood mechanical industry in the Swedish forest industry cluster. Scand J For Res 29: 352–359. https://doi.org/10.1080/02827581.2014.932005.

Sathre R, O’Connor J (2010) Meta-analysis of greenhouse gas displacement factors of wood product substitution. Environ Sci Pol 13: 104–114. https://doi.org/10.1016/j.envsci.2009.12.005.

Schulte M, Lewandowski I, Pude R, Wagner M (2021) Comparative life cycle assessment of bio-based insulation materials: environmental and economic performances. GCB Bioenergy 13: 979–998. https://doi.org/10.1111/gcbb.12825.

Schulte M, Jonsson R, Hammar T, Stendahl J, Hansson P-A (2022) Nordic forest management towards climate change mitigation: time dynamic temperature change impacts of wood product systems including substitution effects. Eur J For Res 141: 845–863. https://doi.org/10.1007/s10342-022-01477-1.

Seppälä J, Heinonen T, Pukkala T, Kilpeläinen A, Mattila T, Myllyviita T, Asikainen A, Peltola H (2019) Effect of increased wood harvesting and utilization on required greenhouse gas displacement factors of wood-based products and fuels. J Environ Manage 247: 580–587. https://doi.org/10.1016/j.jenvman.2019.06.031.

Shen L, Patel M (2010) Life Cycle Assessment of man-made cellulose fibres. Lenzinger Berichte 88: 1–59.

Shen L, Worrell E, Patel MK (2010) Environmental impact assessment of man-made cellulose fibres. Resour Conserv Recy 55: 260–274. https://doi.org/10.1016/j.resconrec.2010.10.001.

Smyth CE, Stinson G, Neilson E, Lempri`ere TC, Hafer M, Rampley GJ, Kurz WA (2014) Quantifying the biophysical climate change mitigation potential of Canada’s forest sector. Biogeosciences 11, article id 3515. https://doi.org/10.5194/bg-11-3515-2014.

Smyth CE, Kurz WA, Rampley W, Lempri`ere TC, Schwab O (2017) Climate change mitigation potential of local use of harvest residues for bioenergy in Canada. GCB Bioenergy 9: 817–832. https://doi.org/10.1111/gcbb.12387.

Smyth CE, Smiley BP, Magnan M, Birdsey R, Dugan AJ, Olguin M, Mascorro VS, Kurz WA (2018) Climate change mitigation in Canada’s forest sector: a spatially explicit case study for two regions. Carbon Bal Manage 13, article id 11. https://doi.org/10.1186/s13021-018-0099-z.

Soimakallio S, Saikku L, Valsta L, Pingoud K (2016) Climate change mitigation challenge for wood utilization – the case of Finland. Environ Sci Technol 50: 5127–5134. https://doi.org/10.1021/acs.est.6b00122.

Soimakallio S, Kalliokoski T, Lehtonen A, Salminen O (2021) On the trade-offs and synergies between forest carbon sequestration and substitution. Mitig Adapt Strateg Glob Chang 26, article id 4. https://doi.org/10.1007/s11027-021-09942-9.

Soimakallio S, Böttcher H, Niemi J, Mosley F, Turunen S, Hennenberg KJ, Reise J, Fehrenbach H (2022) Closing an open balance: the impact of increased tree harvest on forest carbon. GCB Bioenergy 14: 989–1000. https://doi.org/10.1111/gcbb.12981.

Spinnova (2022) Spinnova helps brands tackle climate change: SPINNOVA® production saves more CO2 emissions than it emits. Press release 26.04.2022. https://spinnovagroup.com/releases/spinnova-helps-brands-tackle-climate-change-spinnova-production-saves-more-co2-emissions-than-it-emits/.

Statistics Norway (2023a) Imports and exports of timber. https://www.ssb.no/450972/imports-and-exports-of-timber.cubic-metres. Accessed 1 August 2023.

Statistics Norway (2023b) Commercial roundwood removals. https://www.ssb.no/jord-skog-jakt-og-fiskeri/skogbruk/statistikk/skogavvirkning-for-salg. Accessed 1 August 2023.

Statistics Norway (2023c) Lavere strømforbruk, men mer bruk av ved i 2022. [Less use of electricity, but more use of fuelwood in 2022]. https://www.ssb.no/energi-og-industri/energi/statistikk/produksjon-og-forbruk-av-energi-energibalanse-og-energiregnskap/artikler/lavere-stromforbruk-men-mer-bruk-av-ved-i-2022. Accessed 19 December 2024.

Storaunet KO, Rolstad J (2020) Naturskog i Norge. En arealberegning basert på bestandsalder i Landsskogtakseringens takstomdrev fra 1990 til 2016. [An area calculation based on stand age in the National Forest Inventory’s assessment cycles from 1990 to 2016.] NIBIO Rapport 6(44). https://nibio.brage.unit.no/nibio-xmlui/bitstream/handle/11250/2650496/NIBIO_RAPPORT_2020_6_44.pdf. Accessed 12 July 2024.

Stortinget (2023) Proposal to protect natural forests and old-growth forests. Representantforslag 63. https://www.stortinget.no/no/Saker-og-publikasjoner/Publikasjoner/Representantforslag/2023-2024/dok8-202324-063s/. Accessed 12 July 2024.

Strîmbu VF, Eid T, Gobakken T (2023) A stand level scenario model for the Norwegian forestry – a case study on forest management under climate change. Silva Fenn 57, article id 23019. https://doi.org/10.14214/sf.23019.

Suter F, Steubing B, Hellweg S (2017) Life cycle impacts and benefits of wood along the value chain: the case of Switzerland. J Ind Ecol 21:874–886. https://doi.org/10.1111/jiec.12486.