Vibration and noise assessment of tractor-trailer and truck-mounted chippers

Rottensteiner C., Tsioras P., Neumayer H., Stampfer K. (2013). Vibration and noise assessment of tractor-trailer and truck-mounted chippers. Silva Fennica vol. 47 no. 5 article id 984. https://doi.org/10.14214/sf.984

Highlights

- Truck-mounted chippers were associated with higher vibration values, while tractor-trailer chippers had higher noise level

- Chipping hardwood produced higher vibration magnitudes than softwood

- Vibration and noise values in most cases did not exceed the exposure limit values set by the European Union.

Abstract

During chipping, machine operators are exposed to whole-body vibration and noise bearing a risk to health. Vibration on the operator’s seat and noise inside the chipper cab was measured and analyzed. The factorial design considered two setup variants (tractor-trailer and truck-mounted) of two chipper models from different manufacturers during chipping of softwood and hardwood tree species. Furthermore, exposure to noise was measured during chipping of hardwood. Vibration and noise during chipping, driving between wood piles, and operational delays were measured separately. The results associated truck-mounted chippers with higher vibration values and tractor-trailer chippers with higher noise levels. The highest vibration levels were recorded while driving on the forest road from one log pile to another and the second highest during chipping. On the contrary, the lowest vibration levels were measured during operational delays with the chipper in idling condition. Chipping hardwood produced higher vibration magnitudes than softwood. Exposure to noise was significantly higher during chipping compared to driving and operational delays. Vibration and noise data were combined with time studies data, for the calculation of eight-hour energy equivalent total values, both for vibration and noise. In all cases, the exposure limit values set by the European Union were not exceeded, with the exception of truck-mounted chippers, which are likely to exceed the exposure action value for vibration.

Keywords

chippers;

noise;

whole-body vibration;

exposure limit values

-

Rottensteiner,

University of Natural Resources and Life Sciences Vienna, Institute of Forest Engineering, Peter Jordan Straße 82, 1190 Wien, Austria

E-mail

christian.rottensteiner@boku.ac.at

- Tsioras, Aristotle University, P.O. Box 227, GR-541 24 Thessaloniki, Greece E-mail ptsioras@for.auth.gr

- Neumayer, Specialist in Occupational Medicine, Wörndlestraße 10, 6020 Innsbruck, Austria E-mail heinz.neumayer@die-arbeitsmedizin.at

- Stampfer, University of Natural Resources and Life Sciences Vienna, Institute of Forest Engineering, Peter Jordan Straße 82, 1190 Wien, Austria E-mail karl.stampfer@boku.ac.at

Received 23 August 2013 Accepted 25 November 2013 Published 16 December 2013

Views 174030

Available at https://doi.org/10.14214/sf.984 | Download PDF

1 Introduction

Energy from biomass is increasingly gaining in importance and its utilization has increased multifold in the last few decades (Kühmaier and Stampfer 2012). Comminution is an essential element of all modern energy wood supply chains, because the size reduction of biomass from its initial form into finer particles allows increased load density and improves transport economy, and is essential when feeding biomass boilers. The most common option is comminution at the forest roadside, which is followed by transportation of the chips (Junginger et al. 2005; Stampfer and Kanzian 2006). A large variety of chippers is currently available and used all over the world (e.g. Eschlböck 2013; Mus-max 2013; Vermeer 2013), which with their different characteristics and specifications are oriented toward the different needs of the forest biomass producers. Two main chipper setup categories can be identified: the ones that are permanently mounted on a truck; and chippers mounted on a trailer that can be attached to a tractor.

One of the problems that came up along with the mechanization of forest operations is exposure of machine operators to whole-body vibration (WBV) (Bovenzi et al. 1991; Axelsson 1998). Occupational exposure to WBV is clearly connected to an increased risk for lower back pain, sciatic pain and lumbar intervertebral disc disorders (Bovenzi and Hulshof 1999; Lings and Leboeuf-Yde 2000; Gallais and Griffin 2006), as well as to musculoskeletal symptoms in the neck and shoulder regions (Viikari-Juntura et al. 1994; Axelsson 1998; Rehn et al. 2002; Rehn et al. 2005). Long-term WBV exposure has been also associated with an increased risk of disturbances of the central nervous system (CNS), and possibly damage to the digestive and genital/urinary systems (Bovenzi and Hulshof 1999; Neitzel and Yost 2002).

Excessive noise represents another source of occupational health problems. It affects the health condition of the workforce in various ways, in the form of elevated blood pressure, reduced performance, sleeping difficulties, annoyance and stress (Nelson et al. 2005). Exposure to excessive levels of noise may lead to noise induced hearing loss (NIHL). NIHL still counts for 57% of all incidents of occupational diseases reported in Austria and is the number-one job-related disease (AUVA 2013).

Efforts to reduce occupational exposure to WBV and noise have increased substantially over recent decades. In this context, risk estimations due to exposure to WBV as well as to noise exposure, can be achieved by comparison of the vibration magnitudes and duration of exposure with the occupational exposure limits, described in the European Union Directive 2002/44/EC for vibration (European Union 2002) and 2003/10/EC for noise (European Union 2003).

Previous research efforts have examined the WBV exposure levels of various types of forest machines (Rummer and Rummer 1990; Neitzel and Yost 2002), the influence of forest machine function on WBV transmission to its operator (Sherwin et al. 2004a) and possible ways for WBV reduction (Sherwin et al. 2004b). However, limited literature is available with a focus on WBV exposure of chipper operators (Suchomel et al. 2011) and information is restricted to reports from National Safety Agencies (e.g. Brereton 2005).

Exposure of forest workers to noise during forest operations has been the subject of investigation during different types of equipment, such as chainsaws (Humann et al. 2012), harvesters and/or forwarders (Ljungberg and Neely 2007; Gerasimov and Sokolov 2013) and tractors (Franklin et al. 2006; Bilski 2013). However, no studies report values of noise exposure during the chipping process.

Although it is the manufacturers’ obligation (European directive on machinery 2006/42/EC) to publish the exposure levels of vibration and noise in the machine instructions (European Union 2006), this information is mostly unavailable. This fact, in combination with the increased interest in wood chip production as a renewable source of energy was the main drivers behind the present study.

Therefore, the objectives of this study were a) to determine the WBV exposure levels on operators of various truck-mounted and tractor-attached wood chippers b) to examine the impact of wood species on vibration exposure and c) determine the level of noise exposure during wood chipping. The results are analyzed and evaluated against the occupational exposure limits for vibration and noise set by the European Union.

2 Material and methods

2.1 Experimental design

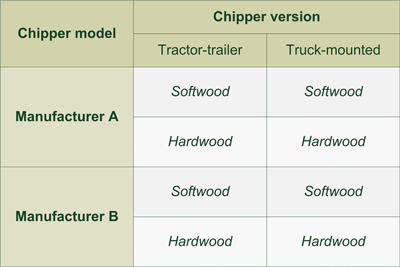

Measurements were carried out in order to investigate potential impacts of various chipper setup variants on the magnitude of vibration and noise emission. The factorial layout (Fig. 1) considered two chipper models of different manufacturers (Eschlböck and Jenz), each with two setup variants (tractor-trailer and truck-mounted) during the chipping of softwood and hardwood. Consequently, the experimental design included eight (2x2x2) different treatments.

Fig. 1. Study layout.

2.2 Data collection

Field data collection was conducted under real working conditions. The data set included 10 measurements for each of the eight different chipping constellations. More specifically, independent measurement samples with a duration of five minutes were taken during the chipping process whereas the sampling duration for driving between piles and operational delays has been determined to one minute to achieve the same number of measurement samples (delays and driving were less frequent and of shorter duration than chipping). The wood species chipped were poplar and, in one case spruce, in the case of softwood, while oak trees were chipped in the case of hardwood. Three operational modes were analyzed: chipping, driving, and operational delays. Chipping was distinguished according to wood material, in contrast to driving between wood piles and operational delays. Finally, during breaks, machine maintenance or other operational modes when the operator is not in the machine’s cab, only noise assessment was done for calculating the total exposure over an eight-hour day.

Wood samples were collected for the estimation of wood density. Fresh and oven-dry density were calculated by dividing the fresh mass and the oven-dry mass of the specimens by their volumes. Fresh weight was measured immediately after chipping by using a scale. The oven-dry mass was determined on the same samples in the laboratory, according to the oven-dry method (CEN/TS 14774-1:2004). Specimen volume was measured by dip-coating using Archimedes’ principle, according to which the upward force of a body immersed in water is equal to the weight of the amount of water the body displaces. Considering the fact that the specific gravity of water is 10 N/dm³, one can directly get the volume by reading the measurement result on a scale. The water content was calculated by comparing the sample’s fresh mass with its oven-dry mass. Additionally, control samples of wood-chips were dried using the oven-dry method.

2.3 Characteristics of chipping equipment, operators and raw material

Both manufacturers offer the same chipper model in tractor-trailer and truck-mounted versions. The truck-mounted versions are characterized by a higher power-output (Table 1). It should be noted that the drum speed (rotations per minute) is identical for the tractor-trailer and the truck-mounted models of same manufacturer. All chipper models are operated inside a cab.

| Table 1. Chipper characteristics and operators’ weight. | ||||

| Chipper # | 1 | 2 | 3 | 4 |

| Manufacturer | A | A | B | B |

| Type | Tractor | Truck | Tractor | Truck |

| Power [kW] | 286 | 397 | 217 | 353 |

| Drum speed [rpm] | 600 | 600 | 560 | 560 |

| Mass tractor/ truck [kg] | 10 830 | 26 000 | 10 450 | 26 820 |

| Mass chipper [kg] | 17 500 | Included in truck’s weight | 16 000 | Included in truck’s weight |

| Total setup mass [kg] | 28 330 | 26 000 | 26 450 | 26 820 |

| Year of construction | 2012 | 2011 | 2008 | 2011 |

| Operating hours [PSH15] | 170 | 970 | 4741 | 3280 |

| Seat suspension | Mechanical | Mechanical | Mechanical | Mechanical |

| Weight of operator [kg] | 90 | 93 | 103 | 70 |

All operators were experienced professionals, who had worked on their chippers or on similar models for a period of two up to ten years, chipping softwood and hardwood (Table 2).

| Table 2. Raw material characteristics per chipper model and wood species. | ||||||||

| Species | Poplar | Spruce | Poplar | Poplar | Oak | Oak | Oak | Oak |

| Chipper model | A1 | A2 | B3 | B4 | A1 | A2 | B3 | B4 |

| Fresh density [kg/m3] | 644 | 650 | 680 | 621 | 950 | 866 | 869 | 817 |

| Oven-dry density [kg/m3] | 411 | 438 | 483 | 431 | 673 | 658 | 641 | 616 |

| Water content [%] | 36 | 33 | 29 | 31 | 29 | 24 | 26 | 25 |

| Diameter (Mean ± Sd) [cm] | 25 ± 11 | 15 ± 5 | 15 ± 7 | 25 ± 10 | 20 ± 8 | 25 ± 10 | 17 ± 6 | 23 ± 9 |

2.4 Vibration and noise measurements

A Bruel & Kjaer 4515 cubic triaxial piezoelectric accelerometer was used for simultaneous vibration measurements in three mutually perpendicular directions on the chippers’ seat. The accelerometer’s weight including the seat pad was 345 g and its sensitivity was 10 mV/ms-² for each of the three axes. The orientation of the measurement axes was done as recommended in ISO 2631-1 (2007).

Vibration data was recorded with a Bruel & Kjaer LAN-XI 6-channel input module (Type 3050) for the frequency range from 0to 51.2 kHz, for which a dynamic of 160 dB was used. The portable data logger was driven by an accumulator; data was stored on a SD (Secure Digital) memory card for post-processing. The accelerometer was calibrated before each measurement with a Bruel & Kjaer 4294 calibration exciter producing an acceleration signal of 10 m/s² at the frequency of 159.2 Hz.

Noise measurements were carried out using a Bruel & Kjaer 2230 precision integrating sound level meter equipped with a capacitor microphone of type 4155. The sound level calibrator Bruel & Kjaer 4230, producing a signal of 94 dB at the frequency of 1000 Hz, was used for the calibration of the sound level meter before each measurement. The sound level meter was mounted on a tripod behind the operator so that the microphone’s position was 0.8 m ± 0.05 m above the seat according to ISO 9612 (2009). That is more or less in the vicinity of the ears of the operators. Sound pressure level measurements were done as recommended in ISO 9612 (2009) for field measurements. EN 13525 (2005) was not applied because this standard was more suitable for noise measurements under well-defined conditions (e. g. standardized logs) for comparison of different machines.

2.5 Data analysis

The collected vibration data was analyzed using the Bruel & Kjaer PULSE LabShop 14.1 software. The root-mean-square (rms) acceleration at one-third octave bands for each axis, in the frequency range between 0.5 and 80 Hz, was used for calculating the weighted rms accelerations (awx, awy and awz). Weighting factors and axes-weighting were applied according to ISO 2631-1 (2007). Frequency weighting is done because the risk of damage to the body is not equal all over the frequency range. This kind of correction applied to vibration measurements is comparable to sound-weighting filters for equal-loudness curves for the human ear. From frequency weighted acceleration values of three axes the total vibration value aw was calculated (Eq. 1).

![]()

Noise was expressed in decibels (dB) as equivalent continuous sound pressure level Lp,A,eq,Te applying A-weighing according to ISO 9612 (2009) and ISO 1999 (1990), respectively. The peak sound pressure level Lp,C,peak was calculated using C-weighing.

Average values (mean) and standard deviation (Sd) of the measurement samples were calculated and the corresponding minimum (Min) and maximum (Max) values were recorded.

The analysis of variance (ANOVA) module of the software package PASW Statistics 18 was used for a) the comparison of the vibration and noise data during the various operational modes and configurations, and b) for examining the effect of the chipper model, the setup-type, and wood material, on the operator’s exposure to vibration and noise. Before calculating the tables of variance, the data was checked for normality and homogeneity of variance. The significance level for all tests was set to 5%.

The assessment of the level of exposure to whole-body vibration is based on the calculation of the daily vibration exposure value A(8) according to Directive 2002/44/EC (European Union 2002). The action value is set to 0.5 m/s² and the limit value to 1.15 m/s². Daily exposure values are normalized to an eight-hour reference period, expressed as the rms acceleration of frequency weighted acceleration of the three orthogonal axes. These axes represent the eight-hour energy equivalent of total vibration exposure during the working day. For the calculation of daily vibration exposure, A(8) values, the partial vibration awi and the corresponding time Ti (Eq. 2) are needed.

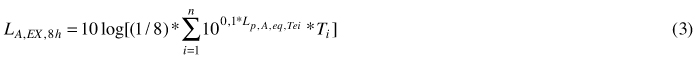

The same time elements Ti are used for calculating daily noise exposure levels according Directive 2003/10/EC (European Union 2003) using Eq. 3. Lp,A,eq,Te are the noise levels of the respective working elements.

For noise there exists a lower exposure action value of 80 dB(A) and an upper exposure action value of 85 dB(A) expressed as energy-equivalent values. Additionally, there are C-weighted peak values that must not be exceeded. The corresponding peak values are 135 dB(C) and 137 dB(C), respectively. The exposure limit value is set to an energy-equivalent value of 87 dB(A) and a peak value of 137 dB(C).

The calculation of A(8) values was done on the basis of the following assumptions for time consumption during chipping, as described in recent studies (Spinelli and Hartsough 2001; Affenzeller and Stampfer 2007; Kühmaier et al. 2007; Spinelli and Visser 2008; Sauerzapf 2010): For every working day of 8 hours chipping was performed for 4.8 hours, driving accounted for 0.4 hours, delays and idling time lasted for 2 hours, while during the remaining 0.8 hours no exposure to vibration occurred. During that time the operator was not operating the machine. Regardless of whether the machinist is operating the machine or stands outside the cab the corresponding sound level is not zero. Thus the sound level for such times was set at 55 dB(A) after Norton and Karczub (2003).

3 Results

3.1 Vibration acceleration evaluation

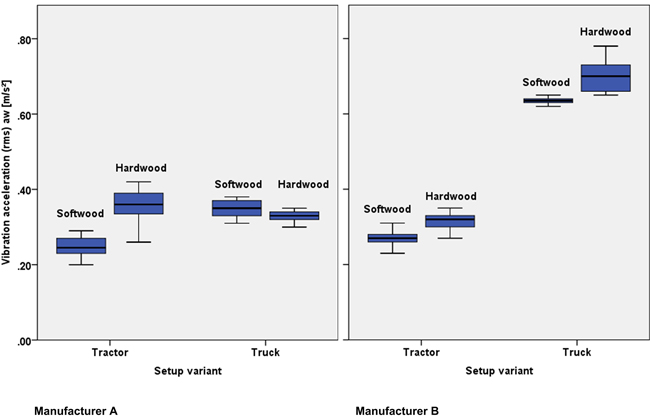

The measurements revealed that vibration values during chipping were higher on the truck-mounted chipper models (Fig. 2). Analysis of variance revealed no differences between the tractor versions of both manufacturers. On the contrary, the vibration value of the truck-mounted chipper of Manufacturer B was significantly higher than in the similar model of Manufacturer A. One-way ANOVA revealed that the vibration magnitude during chipping hardwood was higher than during chipping softwood. However, in the case of the truck-mounted version of manufacturer A, the vibration value for chipping softwood exceeded the value for hardwood (Fig. 2). The difference between the vibration magnitude of hardwood and softwood was 14% on average.

Fig. 2. Vibration during chipping per setup variant, manufacturer and wood type. The bottom and top of the box represent the first (25%, lower end) and third (75%, upper end) quartiles. The black strip in the middle is the median. The brackets outline maximum deviations in both directions.

It should be stressed that in three out of the four cases vibration values for the working element of chipping were measured below the exposure action value of 0.5 m/s² (Table 3 and Table 4). Statistical analysis showed that vibration during driving from one wood pile to another exceeded the vibration occurring during chipping and vibration exposure during driving of tractors was higher than that of trucks. On the contrary, no significant differences between the investigated chipper models were evident for operational delays. Least vibration occurred during delays when the engine was in idling condition, which proved to be statistically significant.

| Table 3. Frequency-weighted vibration acceleration (rms) in m/s² – Manufacturer A. | |||||||||

| Working element | Wood type | Tractor | Truck | ||||||

| Mean | Sd | Min | Max | Mean | Sd | Min | Max | ||

| Chipping | Soft | 0.25 | 0.03 | 0.20 | 0.29 | 0.35 | 0.02 | 0.31 | 0.38 |

| Hard | 0.35 | 0.04 | 0.26 | 0.39 | 0.33 | 0.01 | 0.30 | 0.34 | |

| Driving | Soft/Hard | 0.64 | 0.05 | 0.58 | 0.68 | 0.60 | 0.09 | 0.50 | 0.77 |

| Delays | Soft/Hard | 0.11 | 0.04 | 0.07 | 0.17 | 0.06 | 0.01 | 0.04 | 0.07 |

| Table 4. Frequency-weighted vibration acceleration (rms) in m/s² – Manufacturer B. | |||||||||

| Working element | Wood type | Tractor | Truck | ||||||

| Mean | Sd | Min | Max | Mean | Sd | Min | Max | ||

| Chipping | Soft | 0.27 | 0.02 | 0.23 | 0.31 | 0.63 | 0.02 | 0.58 | 0.65 |

| Hard | 0.31 | 0.03 | 0.27 | 0.35 | 0.70 | 0.04 | 0.65 | 0.78 | |

| Driving | Soft/Hard | 0.84 | 0.17 | 0.53 | 1.08 | 0.50 | 0.12 | 0.24 | 0.64 |

| Delays | Soft/Hard | 0.05 | 0.02 | 0.02 | 0.08 | 0.13 | 0.02 | 0.10 | 0.14 |

Vibration in the direction of the z-axis (longitudinal axis of the human body) was predominant for all working tasks performed, followed by x- (thorax-dorsum direction) and y-axes (lateral axis of the human body). For driving and operational delays there was no statistical difference found for the x- and the z-axes. In those cases the least vibration occurred in y-axis.

3.2 Noise level evaluation

Noise analysis focuses on the A-weighted noise levels because they are considered as energy-equivalent action and limit values according legislation set by the European Union (2003). Additionally there exists a peak sound pressure level Lp,C,peak that has not to be exceeded. It might be that the energy-equivalent value over the working day (A-weighing) is below the limit but exceeds the peak sound pressure level (C-weighing). In the present study that was never the case.

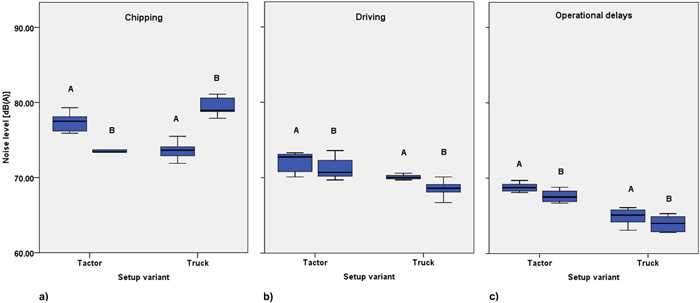

The noise level during chipping was significantly higher than during driving and operational delays. For the operational mode chipping no differences were found between the tractor- and truck-mounted variants (Fig. 3a).

Fig. 3. Noise level for various working elements separated for setup variant, for manufacturer A and B. The bottom and top of the box represent the first (25%, lower end) and third (75%, upper end) quartiles. The black strip in the middle is the median. The brackets outline maximum deviations in both directions.

Calculating ANOVA separately for both manufacturers shows obvious differences between tractor- and truck-mounted models. But neither power output, nor the number of operating hours could explain why the tractor variant of manufacturer A had higher noise levels, while for manufacturer B that incidence was found for the truck-mounted version (Table 5 and Table 6).

| Table 5. Noise level for various working elements during chipping hardwood – Manufacturer A. | |||||||||

| Working element | Machine type | Lp,A,eq,Te [dB(A)] | Lp,C,peak [dB(C)] | ||||||

| Mean | Sd | Min | Max | Mean | Sd | Min | Max | ||

| Chipping | Tractor | 77.4 | 1.1 | 75.9 | 79.3 | 102.3 | 1.2 | 100.1 | 103.9 |

| Truck | 73.5 | 1.0 | 71.9 | 75.5 | 101.4 | 1.2 | 99.7 | 103.2 | |

| Driving | Tractor | 72.1 | 1.2 | 70.1 | 73.3 | 99.9 | 0.8 | 98.8 | 100.8 |

| Truck | 70.0 | 1.0 | 68.5 | 72.3 | 99.1 | 0.8 | 97.9 | 100.1 | |

| Delays | Tractor | 68.8 | 0.5 | 68.1 | 69.7 | 93.1 | 0.6 | 92.4 | 94.4 |

| Truck | 64.9 | 1.0 | 63.1 | 66.1 | 90.4 | 0.5 | 89.7 | 91.2 | |

| Table 6. Noise level for various working elements during chipping hardwood – Manufacturer B. | |||||||||

| Working element | Machine type | Lp,A,eq,Te [dB(A)] | Lp,C,peak [dB(C)] | ||||||

| Mean | Sd | Min | Max | Mean | Sd | Min | Max | ||

| Chipping | Tractor | 73.6 | 0.9 | 71.9 | 74.9 | 100.6 | 1.4 | 98.1 | 102.4 |

| Truck | 79.4 | 1.2 | 77.9 | 81.1 | 100.7 | 1.1 | 99.7 | 102.3 | |

| Driving | Tractor | 71.2 | 1.3 | 69.7 | 73.6 | 100.2 | 0.9 | 98.7 | 101.7 |

| Truck | 68.3 | 1.2 | 65.9 | 70.1 | 99.6 | 0.9 | 97.9 | 100.7 | |

| Delays | Tractor | 67.6 | 0.7 | 66.7 | 68.8 | 90.6 | 0.8 | 89.1 | 92.1 |

| Truck | 63.9 | 1.0 | 62.8 | 65.3 | 90.5 | 0.6 | 89.7 | 91.7 | |

During driving and operational delays (Fig. 3b and 3c) tractor-based models were associated with significantly higher noise levels than the truck-mounted ones.

3.3 Comparison to exposure limits

Over an eight-hour working shift none of the chippers exceeded the exposure limit A(8) of 1.15 m/s² (Table 7) and only in one case the exposure action value is surpassed. With chipper models A1, A2 and B3 one could work more than 20 hours without reaching the action value. On the contrary, the action value for model B4 is reached after six hours and 20 minutes of work.

| Table 7. Total vibration and A(8) values during the chipping of hardwood. | |||||

| Task | Time [hours] | Total vibration value aw [m/s²] | |||

| Chipper A1 | Chipper A2 | Chipper B3 | Chipper B4 | ||

| Chipping | 4.8 | 0.35 | 0.33 | 0.27 | 0.70 |

| Driving | 0.4 | 0.64 | 0.60 | 0.84 | 0.50 |

| Delays | 2.0 | 0.11 | 0.06 | 0.05 | 0.13 |

| Maintenance and breaks (no exposure to vibration) | 0.8 | 0 | 0 | 0 | 0 |

| A(8) | 8.0 | 0.31 | 0.29 | 0.28 | 0.56 |

All chippers had noise levels below the lower action value of 80 dB(A) set by the European Union (European Union 2003) (Table 8). One forest worker could work with chipper B4 for 15 hours and with chipper A1 for 22 hours and 25 minutes until the lower action value is reached. With chipper A2 and model B3 one cannot exceed the action value within 24 hours of continuous work. The lowest noise level was found for the truck-mounted chipper of manufacturer A, while the highest noise level was measured on the truck-mounted variant of manufacturer B. On the contrary, the tractor-trailer model of manufacturer A emitted more noise than the model of manufacturer B.

| Table 8. Sound level per task and total exposure values during the chipping of hardwood. | |||||

| Task | Time [hours] | Sound level Lp,A,eq,Te [dB(A)] | |||

| Chipper A1 | Chipper A2 | Chipper B3 | Chipper B4 | ||

| Chipping | 4.8 | 77.4 | 73.5 | 73.6 | 79.4 |

| Driving | 0.4 | 72.1 | 70.0 | 71.2 | 68.3 |

| Delays | 2.0 | 68.8 | 64.9 | 67.6 | 63.9 |

| Maintenance and breaks (machine not operating) | 0.8 | 55.0 | 55.0 | 55.0 | 55.0 |

| Total (LA,EX, 8h) | 8.0 | 75.5 | 71.7 | 72.0 | 77.3 |

4 Discussion

This paper provides data on exposure to vibration and noise during wood chipping operations with two different chipper types. According to the European Directive 89/391/EC (European Union 1989), the employer is obliged to assess the exposure levels of mechanical vibration and noise. Therefore, knowledge of these exposure levels is crucial, as it can facilitate the choice of machinery with less detrimental effects on the health of the workers.

Over an eight-hour working shift none of the chippers exceeds the exposure limit for noise and vibration, a finding similar to other scientific results. Suchomel et al. (2011) measured an A(8)-value of 0.44 m/s² for a chipper attached on a tractor, while Brereton (2005) reported values in the range of 0.50–0.60 m/s² on forwarder-mounted chippers. Operating truck- or forwarder-mounted chippers are more likely to lead to higher vibration exposure levels, and are therefore more likely to exceed the action value set by the European Union.

The noise level in all investigated chipper models was below the lower action value of 80 dB(A) (energy-equivalent value) and of 135 dB(C) (peak value), respectively. Vibration, as well as noise levels, during driving between different wood piles in the forest was higher in the tractor-mounted variants than in truck-mounted ones. Similar findings have been reported by various authors (Kumar 2004; Franklin et al. 2006; Pitts 2007; Scarlett et al. 2007; Scarlett et al. 2009; Nitti and De Santis 2010; Smets et al. 2010; Bilski 2013), not for chippers but for agricultural tractors and trucks used in off-road transport.

As driving takes only 5% of the total operating time compared to 60% for chipping, it is safe to conclude, that the total daily exposure to both vibration and noise are mainly determined by the chipping process. For vibration, the A(8)-value was found to be higher for truck-mounted chippers, while the energy-equivalent noise level was higher in tractor-mounted models. Anyway, with a tractor-trailer chipper the vibration, as well as the noise level, is likely to be below the corresponding action values. Considering that the majority of industrial chippers are of the tractor-trailer type (Spinelli and Hartsough 2001), this finding can be only positively regarded. Operators working inside a chipper’s cab are less affected by vibration and noise (Brueck 2008; Aybek et al. 2010) as well as less exposed to wood dust (Magagnotti et al. 2012). However, regardless of the existence of a cab or not, staying close to the chipper while the engine is in operation has to be avoided for both chipper operators and bystanders like truck drivers.

Chipping hardwood was connected with higher vibration magnitudes than chipping softwood. In general, vibration of chippers seems to bear low risk to health. Nevertheless, it remains to be clarified if other chipper models behave like model B4 that produced vibration magnitudes twice as high compared to the other machines. Brueck (2008) found that noise depends on the type of material being processed. In the present study, noise was measured only in hardwood operations. Further research would be recommended in order to clarify the influence of the chipped material (roundwood vs. residual branches), as well as those of chipper model characteristics (e.g. drum speed), on vibration and noise behavior of the chipping equipment.

References

Affenzeller G., Stampfer K. (2007). Energieholzbereitstellung mit Traktor und Kran-anhänger mit Fallbeilklingenaggregat. [Energy wood harvesting using a guillotine-shear mounted on a tractor trailer]. Institute of Forest Engineering of the University of Natural Resources and Life Sciences, Vienna. 29 p.

AUVA (2013). Auszug aus der Statistik 2012. Ausgabe 2013. [Statistical summary 2012. Issue 2013]. Allgemeine Unfallversicherungsanstalt. [Austrian Workers’ Compensation Board]. 34 p. Information retrieved from: http://www.auva.at/mediaDB/981608_Auszug_aus_Statistik_2012.pdf.

Axelsson S.A. (1998). The mechanization of logging operations in Sweden and its effect on occupational safety and health. Journal of Forest Engineering 9(2): 25–31.

Aybek A., Kamer H.A., Arslan S. (2010). Personal noise exposures of operators of agricultural tractors. Applied Ergonomics 41(2): 274–281. http://dx.doi.org/10.1016/j.apergo.2009.07.006.

Bilski B. (2013). Exposure to audible and infrasonic noise by modern agricultural tractors operators. Applied Ergonomics 44(2): 210–214. http://dx.doi.org/10.1016/j.apergo.2012.07.002.

Bovenzi M. & Hulshof C.T. (1999). An updated review of epidemiologic studies on the relationship between exposure to whole-body vibration and low back pain (1986–1997). International Archives of Occupational and Environmental Health 72(6): 351–365. http://dx.doi.org/10.1007/s004200050387.

Bovenzi M., Zadini A., Franzinelli A., Borgogni F. (1991). Occupational musculoskeletal disorders in the neck and upper limbs of forestry workers exposed to hand-arm vibration. Ergonomics 34(5): 547–562. http://dx.doi.org/10.1080/00140139108967336.

Brereton P. (2005). Update on research into HAV, WBV and noise in forestry and agriculture. Health and safety executive. Information retrieved from: http://www.hse.gov.uk/aboutus/meetings/iacs/aiac/afag/091105/noiseforestry.pdf.

Brueck L. (2008). Noise emissions and exposure from mobile woodchippers. Health and Safety Laboratory UK, Derbyshire. 43 p.

CEN/TS 17774-1. (2004). Solid biofuels – Methods for determination of moisture content – Oven dry method – Part 1: Total moisture – Reference method. European Committee for Standardization, Brussels. 10 p.

EN 13525. (2005). Forestry machinery. Wood chippers. Safety. European Committee for Standardization, Brussels. 39 p.

Eschlböck (2013). Information retrieved from the site: http://www.eschlboeck.at/en.

European Union (1989). Directive 89/391/EEC of 12 June 1989 on the introduction of measures to encourage improvements in the safety and health of workers at work. Official Journal of the European Communities L 183. p. 1–8.

European Union (2002). Directive 2002/44/EC of the European Parliament and of the Council of 25 June 2002 on the minimum health and safety requirements regarding the exposure of workers to the risks arising from physical agents (vibration) (sixteenth individual Directive within the meaning of Article 16(1) of Directive 89/391/EEC. Official Journal of the European Communities L 177. p. 13–19.

European Union (2003). Directive 2003/10/EC of the European Parliament and of the Council of 6 February 2003 on the minimum health and safety requirements regarding the exposure of workers to the risks arising from physical agents (noise) (seventeenth individual Directive of Directive within the meaning of Article 16(1) of Directive 89/391/EEC. Official Journal of the European Communities L 42. p. 38–44.

European Union (2006). Directive 2006/42/EC of the European Parliament and of the Council of 17 May 2006 on machinery, and amending Directive 95/16/EC. Official Journal of the European Communities L 157. p. 24–86.

Franklin R.C., Depczynski J., Challinor K., Williams W., Fragar L.J. (2006). Factors affecting farm noise during common agricultural activities. Journal of Agricultural Safety and Health 12(2): 117–125. http://dx.doi.org/10.13031/2013.20388.

Gallais L., Griffin M. (2006). Low back pain in car drivers: a review of studies published 1975 to 2005. Journal of Sound and Vibration 298(3): 499–513. http://dx.doi.org/10.1016/j.jsv.2006.06.012.

Gerasimov Y., Sokolov A. (2013). Ergonomic evaluation and comparison of wood harvesting systems in Northwest Russia. Applied Ergonomics. [In press].

Hummann M.J., Sanderson W.T., Gerr F., Kelly K.M., Merchant J.A. (2012). Effects of common agricultural tasks on measures of hearing loss. American Journal of Industrial Medicine 55(10): 904–916. http://dx.doi.org/10.1002/ajim.22077.

ISO 1999. (1990). Acoustics – Determination of occupational noise exposure and estimation of noise-induced hearing impairment. International Organization for Standardization, Geneva. 17 p.

ISO 2631-1. (2007). Mechanical vibration and shock – Evaluation of human exposure to whole-body vibration – Part 1: General requirements. International Organization for Standardization, Geneva. 31 p.

ISO 9612. (2009). Acoustics – Determination of occupational noise exposure – Engineering method. International Organization for Standardization, Geneva. 51 p.

Junginger M., Faaij A., Björheden R., Turkenburg W.C. (2005). Technological learning and cost reductions in wood fuel supply chains in Sweden. Biomass and Bioenergy 29(6): 399–418. http://dx.doi.org/10.1016/j.biombioe.2005.06.006.

Kühmaier M.& Stampfer K. (2012). Development of a multi-criteria decision support tool for energy wood supply management. Croatian Journal of Forest Engineering 33(2): 181–198.

Kühmaier M., Kanzian C., Holzleitner F., Stampfer K. (2007). Wertschöpfungskette Waldhackgut. Optimierung von Ernte, Transport und Logistik. [Value added chain for woodchips. [Optimization of harvesting, transportation and logistics]. Institute of Forest Engineering of the University of Natural Resources and Life Sciences, Vienna. 283 p.

Kumar S. (2004). Vibration in operating heavy haul trucks in overburden mining. Applied Ergonomics 35(6): 509–520. http://dx.doi.org/10.1016/j.apergo.2004.06.009.

Lings S., Leboeuf-Yde C. (2000). Whole-body vibration and low back pain: a systematic, critical review of the epidemiological literature 1992–1999. International Archives of Occupational and Environmental Health 73(5): 290–297. http://dx.doi.org/10.1007/s004200000118.

Ljungberg J., Neely G. (2007). Stress, subjective experience and cognitive performance during exposure to noise and vibration. Journal of Environmental Psychology 27(1): 44–54. http://dx.doi.org/10.1016/j.jenvp.2006.12.003.

Magagnotti N., Spinelli R., Nannicini C., Sciarra G. (2012). Determining the exposure of chipper operators to wood dust. In: Proceedings of the 45th International Symposium on Forestry Mechanisation. October 8–12 2012, Dubrovnik (Cavtat), Croatia.

Mus-max (2013). Information retrieved from the site: http://www.mus-max.at.

Neitzel R., Yost M. (2002). Tasks-based assessment of occupational vibration and noise exposures in forestry workers. American Industrial Hygiene Association Journal 63(5): 617–627. http://dx.doi.org/10.1080/15428110208984748.

Nelson D.I, Nelson R.Y., Concha-Barrientos M., Fingerhut M. (2005). The global burden of occupational noise-induced hearing loss. American Journal of Industrial Medicine 48(6): 446–458. http://dx.doi.org/10.1002/ajim.20223.

Nitti R., De Santis P. (2010). Assessment and prediction of whole-body vibration exposure in transport truck drivers. Industrial Health 48(5): 628–637. http://dx.doi.org/10.2486/indhealth.MSWBVI-24.

Norton M.P., Karczub D.G. (2003). Fundamentals of noise and vibration for engineers. Cambridge University Press, Cambridge. 652 p. http://dx.doi.org/10.1017/CBO9781139163927.

Pitts P.M. (2007). Whole-body vibration exposure in forestry. In: Proceedings of the 42nd United Kingdom Conference on Human Responses to Vibration, September 10–12 2007, Southampton, England.

Rehn B., Lundström R., Nilsson T., Bergdahl I.E., Ahlgren C., From C. et al. (2002). Musculoskeletal symptoms among operators of all-terrain vehicles. Journal of Sound and Vibration 253(1): 21–29. http://dx.doi.org/10.1006/jsvi.2001.4247.

Rehn B., Lundström R., Nilsson L., Liljelind I., Järvholm B. (2005). Variation in exposure to whole-body vibration for operators of forwarder vehicles – aspects on measurement strategies and prevention. International Journal of Industrial Ergonomics 35(9): 831–842. http://dx.doi.org/10.1016/j.ergon.2005.03.001.

Rummer D.I., Rummer R.B. (1990). Measuring whole-body vibration of forest equipment operators with a digital data acquisition system. Computers and Electronics in Agriculture 5(3): 213–222. http://dx.doi.org/10.1016/0168-1699(90)90012-E.

Sauerzapf F. (2010). Vollmechanisierte Bereitstellung von Waldhackgut im Laubholz – Kosten, Energie- und CO2-Bilanz. [Fully-mechanized supply with hardwood-chips – costs, energy and CO2 balance]. Master’s thesis. Institute of Forest Engineering of the University of Natural Resources and Life Sciences, Vienna. 75 p.

Scarlett A.J., Price J.S., Stayner R.M. (2007). Whole-body vibration: evaluation of emission and exposure levels arising from agricultural tractors. Journal of Terramechanics 44(1): 65–73. http://dx.doi.org/10.1016/j.jterra.2006.01.006.

Scarlett A.J., Price J.S., Semple D.A. (2009). Whole-body vibration on agricultural vehicles: evaluation of emission and estimated exposure levels. Health and Safety Laboratory UK, Derbyshire. 231 p.

Sherwin L.M., Owende P.M.O., Kanali C.L., Lyons J., Ward S.M. (2004a). Influence of forest machine function on operator exposure to whole-body vibration in a cut-to-length timber harvester. Ergonomics 47(11): 1145–1159. http://dx.doi.org/10.1080/00140130410001702141.

Sherwin L.M., Owende P.M.O., Kanali C.L., Lyons J., Ward S.M. (2004b). Influence of tyre inflation pressure on whole-body vibrations transmitted to the operator in a cut-to-length timber harvester. Applied Ergonomics 35(3): 253–261. http://dx.doi.org/10.1016/j.apergo.2004.02.002.

Smets M.P.H., Eger T.R., Grenier S.G. (2010). Whole-body vibration experienced by haulage truck operators in surface mining operations: a comparison of various analysis methods utilized in the prediction of health risks. Applied Ergonomics 41(6): 763–770. http://dx.doi.org/10.1016/j.apergo.2010.01.002.

Spinelli R., Hartsough B. (2001). A survey of Italian chipping operations. Biomass and Bioenergy 21(6): 433–444. http://dx.doi.org/10.1016/S0961-9534(01)00050-2.

Spinelli R., Visser R. (2008). Analyzing and estimating delays in wood chipping operations. Biomass and Bioenergy 33(3): 429–433. http://dx.doi.org/10.1016/j.biombioe.2008.08.003.

Stampfer K., Kanzian C. (2006). Current state and development possibilities of wood chip supply chains in Austria. Croatian Journal of Forest Engineering 27(2): 135–145.

Suchomel J., Belanova K., Vlckova M. (2011). Evaluation of vibration in the chipping process. Report 15. Commission on Agricultural, Forestry and Veterinary Sciences. Polish Academy of Arts and Sciences. 10 p.

Vermeer (2013). Information retrieved from the site: http://www2.vermeer.com/Vermeer/NA/en/N/equipment/brush_chippers.

Viikari-Juntura E., Riihimäki H., Tola S., Videman T., Mutanen P. (1994). Neck trouble in machine operating dynamic physical work and sedentary work: a prospective study on occupational and individual risk factors. Journal of Clinical Epidemiology 47(12): 1411–1422. http://dx.doi.org/10.1016/0895-4356(94)90085-X.

Total of 51 references