Cost analysis of seedling supply systems adapted for mechanized tree planting: a case study from southern Sweden

Ersson B. T., Sundblad L.-G., Manner J. (2022). Cost analysis of seedling supply systems adapted for mechanized tree planting: a case study from southern Sweden. Silva Fennica vol. 56 no. 2 article id 10663. https://doi.org/10.14214/sf.10663

Highlights

- The total cost of cardboard box concepts that increase the productivity of tree planting machines is higher than of the cultivation tray system (5–49% in the basic scenario)

- Increasing the boxes’ packing densities and/or the planting machines’ hourly cost increases the boxes’ cost-competitiveness

- Packing density is a key factor in achieving highly cost-efficient seedling supply systems for mechanized tree planting.

Abstract

Because today’s tree planting machines do a good job silviculturally, the Nordic forest sector is interested in finding ways to increase the planting machines’ productivity. Faster seedling reloading increases machine productivity, but that solution might require investments in specially designed seedling packaging. The objective of our study was to compare the cost-efficiency of cardboard box concepts that increase the productivity of tree planting machines with that of today’s two most common seedling packaging systems in southern Sweden. We modelled the total cost of these five different seedling packaging systems using data from numerous sources including manufacturers, nurseries, contractors, and forest companies. Under these southern Swedish conditions, the total cost of cardboard box concepts that increase the productivity of intermittently advancing tree planting machines was higher than the cost of the cultivation tray system (5–49% in the basic scenario). However, the conceptual packaging system named ManBox_fast did show promise, especially with increasing primary transport distances and increased planting machine productivities and hourly costs. Thus, our results show that high seedling packing density is of fundamental importance for cost-efficiency of cardboard box systems designed for mechanized tree planting. Our results also illustrate how different factors in the seedling supply chain affect the cost-efficiency of tree planting machines. Consequently, our results underscore that the key development factor for mechanized tree planting in the Nordic countries is the development of cost-efficient seedling handling systems between nurseries and planting machines.

Keywords

logistics;

silviculture;

reforestation;

tree planting machine;

containerized seedling;

seedling handling;

system analysis

-

Ersson,

SLU, School of Forest Management, SE-739 21 Skinnskatteberg, Sweden

https://orcid.org/0000-0003-2442-7482

E-mail

back.tomas.ersson@slu.se

https://orcid.org/0000-0003-2442-7482

E-mail

back.tomas.ersson@slu.se

- Sundblad, Skogforsk, Uppsala Science Park, SE-751 83 Uppsala, Sweden E-mail lars-goran.sundblad@skogforsk.se

-

Manner,

Skogforsk, Uppsala Science Park, SE-751 83 Uppsala, Sweden

https://orcid.org/0000-0002-4982-3855

E-mail

jussi.manner@skogforsk.se

https://orcid.org/0000-0002-4982-3855

E-mail

jussi.manner@skogforsk.se

Received 23 November 2021 Accepted 8 March 2022 Published 11 March 2022

Views 47038

Available at https://doi.org/10.14214/sf.10663 | Download PDF

1 Introduction

The Nordic forest sector is striving to mechanize silviculture (Strandström et al. 2009; Nilsson et al. 2010; Ersson et al. 2018; Ramantswana et al. 2020). Since the 1970s, tree planting machines have existed as a more or less commercial alternative to manual tree planting in Nordic forestry (Ersson 2014; Laine 2017). The planting machines that are used today in Sweden plant containerized stock, comprise generally an excavator with a crane-mounted planting device, and produce high-quality regenerations (Luoranen et al. 2011; Ersson and Petersson 2013; Ersson 2014). However, the productivity of these tree planting machines is low, which leads to poor cost-efficiency.

One important reason why productivity is low is the high proportion of seedling reloading time (Ersson et al. 2014). Seedling reloading is slow chiefly because today’s seedling supply systems were developed solely for manual tree planting. Thus, productive planting time is lost when operators have to spend substantial amounts of time handling seedlings and reloading the machines with seedlings one-by-one. Machine-specific seedling packaging helps decrease the operators’ seedling handling time and increase planting machine uptime (Ersson et al. 2011). Therefore, machine-specific packaging is probably an important innovation that needs to be developed in order to create efficient seedling supply systems for tree planting machines (Laine 2017). Nowadays, the hourly cost of intermittently advancing tree planting machines has increased substantially since 2010 when Ersson et al. (2011) last studied machine-specific seedling packaging.

Seedling supply systems for mechanized tree planting has been studied by Ersson et al. (2011). That study analyzed two machine-specific packaging systems, and concluded, among things, that the cost-efficiency of machine-specific packaging is strongly dependant on sufficient demand. If there are not enough tree planting machines, there is little incentive for investing in seedling supply systems for mechanized planting. The first studied packaging system was the PLS system, in which linked pots could be formed as belts/chains (Hallonborg 1997; Ersson 2010). This concept was invented to automate seedling feeding on the Silva Nova planting machine. It was also possible to cultivate seedlings at the nursery in these linked pots. The PLS system, however, suffered from poor cost-efficiency and low mechanical availability (Ersson 2010), and proved too expensive also for today’s planting machines (Ersson 2014). Normark and Norr (2002) reported results from the EcoBandPak system, a concept which entailed seedlings being band-mounted at the nursery and then shipped to the EcoPlanter tree planting machine. This seedling supply concept showed promise; however, it also showed to be too expensive for today’s planting machines (Ersson 2014).

Ersson et al. (2014) and Laine and Saarinen (2014) studied seedling feeding systems for crane-mounted planting devices (Bracke Planter and Risutec) that did not require machine-specific seedling packaging. These innovative feeding systems (seedling carousels), however, suffered from low mechanical availability and were subsequently cost-inefficient.

A special aspect of seedling supply for mechanized tree planting relates to the physiological state (actively growing or dormant/frozen-stored) that the seedlings are in when planted. Many studies have shown the superiority of planting frozen-stored/dormant seedlings during spring planting (Luoranen et al. 2005; Landis 2010). However, it is not possible to deliver dormant seedlings today unless they are packed in boxes or enclosed in some type of container. This limitation precludes the use of seedling supply systems based on cultivation trays during springtime if the customer (forest owner) wants to plant dormant seedlings.

One important attribute for seedling supply systems adapted for mechanized tree planting is the systems’ capability of delivering seedlings in defined positions. However, this capability is generally in conflict with the requirement for high seedling packing density (Österström et al. 1974). Minimizing this conflict is of fundamental importance for the development of cost-efficient mechanized tree planting.

Skogforsk (Sundblad and Bergkvist 2018) has studied, under southern Swedish conditions, a packaging concept with seedlings in defined positions. These seedlings were packed in cardboard boxes with an internal cardboard grid or matrix (herein named MechBox). The system has the potential to speed up seedling reloading onto planting machines, but the concept needs to be developed for higher seedling packing densities. Foldable matrixes similar to the Paperpot solutions used in many gardening and agricultural applications (Robb et al. 1994) might be one solution to this problem of low packing densities.

The objective of this study was to analyze cardboard box concepts that increase the productivity of tree planting machines by comparing the concepts’ cost-efficiency with that of today’s two most common seedling packaging systems in southern Sweden.

2 Materials and methods

2.1 Dataset and general assumptions

This study comprised a holistic analysis of alternative seedling supply systems for tree planting machines. The supply chain consists of: 1) packing seedlings at the nursery; 2) seedling transport from the nursery, via the contractor’s depot, to the planting site (i.e. roadside landing); 3) loading onto planting machine and subsequent reloading of the planting device; and 4) handling of empty packaging. The study is based on data from south Swedish conditions. Nonetheless, the figures and results are relevant also for forestry throughout the Nordic region and to some extent even for North America.

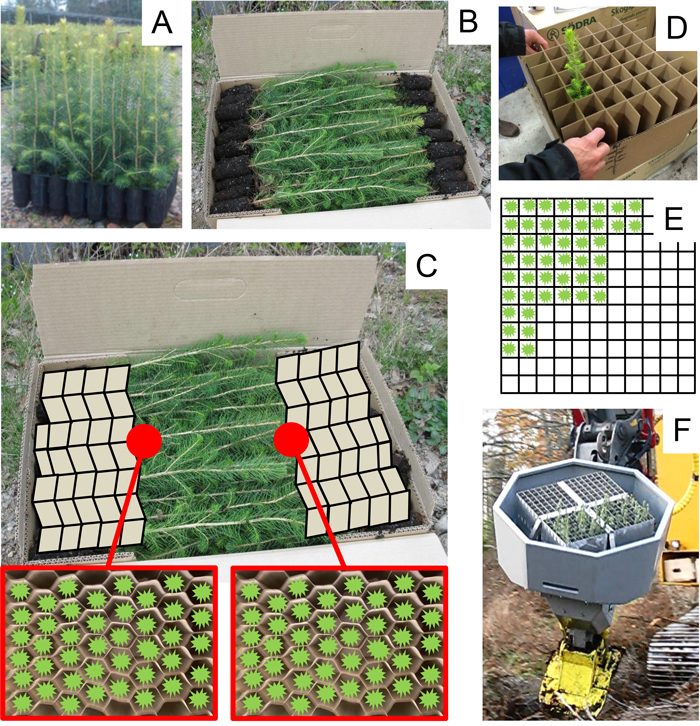

Five seedling packaging systems were modelled and analyzed. Two were existing packaging systems originally developed for manual tree planting, and three were conceptual cardboard box systems designed specifically to increase the productivity of today’s excavator-based tree planting machines (Fig. 1; Table 1).

Fig. 1. Hiko v93 cultivation trays were the starting point for all systems. The Hiko supply system uses cultivation trays also as the seedling packaging (A). ManBox is today’s standard seedling supply system (B). The ManBox_fast system is conceptual and uses similar cardboard boxes as ManBox, but the novelty of ManBox_fast is that the seedlings are placed singly within the cells of two collapsible, compressible paper grid spacers (C). In the MechBox_49 (D) and MechBox_121 (E) systems, seedlings are packed into square cardboard boxes while standing upright within individual cells created by a carton grid spacer. The difference between the two MechBox systems is the grid spacers resulting in two different cell densities. ManBox_fast and both MechBox systems require a tree planting device equipped with a high-capacity seedling carousel (F) matching the geometry of the seedling packaging’s grid spacers.

| Table 1. Overview of the five seedling (Picea abies) packaging systems that were compared in the cost analysis from southern Sweden. | |||||

| Packaging system | Intended use | Developmental stage | Seedling position / description | Number of seedlings per handling unit (pl) | End point |

| Hiko (plastic cultivation trays) | Manual planting | Operational use in southern Sweden since the 1970s | Standing upright within individual tray cells/cavities | 40 | Reuse by nursery |

| ManBox (simple divisible cardboard box) | Manual planting | Operational use in southern Sweden since 2010 | Lying down, stems intertwined, in one large open space | 165 | Recycling |

| ManBox_fast (same box as in ManBox but with a collapsible, compressible paper grid spacer within the box) | Mechanized planting | Conceptual | Lying down, stems intertwined, but seedlings mounted in individual pockets of paper strips | 149 | Recycling |

| MechBox_49 (cardboard box with removable 7×7 carton grid spacer) | Mechanized planting | Existing prototype | Standing upright within individual cells created by the grid spacer | 49 | Recycling |

| MechBox_121 (cardboard box with removable 11×11 carton grid spacer) | Mechanized planting | Conceptual | Standing upright within individual cells created by the grid spacer | 121 | Recycling |

| Seedlings are abbreviated pl. | |||||

We based our comparative cost analysis on the models of Ersson et al. (2011). Just like in Ersson et al. (2011), today’s standard Hiko v93 cultivation tray was the starting point for all systems, and the end point was after outplanting when the packaging had either been recycled (cardboard box systems; Fig. 1; Table 1) or returned to the nursery for reuse (Hiko system). The Hiko system entailed seedling handling in the cultivation trays between the nursery and planting machine, while the other four systems involved transferring seedlings from cultivation trays to system-specific cardboard boxes for transport to the planting machine. See Ersson et al. (2011) for further details on general system assumptions, theories, methods, cost calculation models, and equations.

Data (time consumption values, costs, measurements, materials, work tasks, capacities, productivities, etc.) were acquired during 2015 from manufacturers, nursery personnel, researchers, contractors, and southern Swedish transportation and forest companies. Costs were collected in Swedish krona (SEK) but converted to Euro according to the long-term average exchange rate of 10 SEK per Euro. We assumed an interest rate of 10% for nursery investments and 6% for contractor investments. The higher interest rate for the nursery investments was justified by the higher risk and longer depreciation periods that nursery investments bring forth. In the present study, all time consumption and productivity figures are given using productive work hours (PWh) including interruptions up to 15 minutes (PWh15) unless otherwise stated. This applies irrespective of the used time unit (second, minute, or hour).

2.2 Costing model and system descriptions

2.2.1 Seedling packing at the nursery

We assumed the seedlings in the analysis to be Picea abies (L.) Karst. grown in copper-painted Hiko v93 trays for circa 20 months at a midsized nursery (annual production of 15 million seedlings) in southern Sweden. For all systems, the assumed target mass, stem heights, and stem base diameters of an individual seedling at the nursery were 65 g, 32 cm, and 4 mm, respectively. The root plug volumes, lengths, and diameters were 93 cm3, 87 mm, and 41 mm, respectively.

Because the seedling (pl) cultivation process is similar for all five systems, it was excluded from the comparison. However, the Hiko supply system uses cultivation trays also as the seedling packaging. Using cultivation trays also as seedling packaging requires increasing the total number of seedling trays in use by up to 50% (Saarinen et al. 2013). Moreover, this use causes extra wear on the cultivation trays. According to Ersson et al. (2011), this extra wear equals 10% additional annual tray loss, whereas according to Saarinen et al. (2013) the corresponding figure is 5%. In the present study, we estimated the extra wear, based on Ersson et al. (2011), to be 10%. Hiko’s total packing cost (CPack) consisted only of this extra material cost. Beyond this assumption, Hiko was free from other packing related costs (such as machinery investments, extra facilities, cardboard boxes, freezer storage, etc.).

The ManBox system uses today’s standard packing line in which seedlings are automatically lifted from Hiko cultivation trays and packed into standard cardboard boxes designed for manual tree planting. In this analysis, a standard seedling cardboard box contains 165 seedlings, and comprises ManBox’s handling unit. The cardboard boxes are then stacked onto Euro-pallets and shrink-wrapped together; these pallets comprise ManBox’s shipping units (Table 2). Altogether, the total packaging material for ManBox comprised boxes, pallets, and shrink-wrap. The packaging material cost, together with labour and facility costs, resulted in an overall packing cost (CPack) of 55.00 Euro (1000 pl)–1. All systems except Hiko required freezer/cooler storage. The ManBox system’s freezer/cooler cost (CFreezer) was 17.00 Euro (1000 pl)–1 including labour, facilities, etc.

| Table 2. Cost factors for the five seedling (Picea abies) supply systems’ packaging materials. The total material cost is that of the basic scenario. | ||||||

| Intended use | Cost factor | Hiko | ManBox | ManBox_fast | MechBox_49 | MechBox_121 |

| Handling unit | Capacity (pl) | 40 | 165 | 149 | 49 | 121 |

| Dimensions (cm) | 22×35×40 | 60×40×28 | 60×40×28 | 40×40×45 | 40×40×45 | |

| Mass when loaded with seedlings (kg) | 3 | 11 | 10.5 | 4 | 9.5 | |

| Shipping unit | Capacity (pl) | 40 | 2640 | 2384 | 1176 | 2904 |

| Dimensions (cm) | 22×35×40 | 80×120×130 | 80×120×130 | 80×120×194 | 80×120×194 | |

| Mass when loaded with seedlings (kg) | 3 | 200 | 192 | 120 | 252 | |

| Total material cost (Euro (1000 pl)–1) | 15.58 | 10.00 | 31.20 | 59.80 | 24.20 | |

| Seedlings are abbreviated pl. | ||||||

The ManBox_fast system is conceptual and uses similar cardboard boxes as today’s ManBox system does (Fig. 1; Table 1). But the novelty of ManBox_fast is that the seedlings are placed singly within the cells of a collapsible, compressible paper grid spacer. This grid spacer reduces time consumption when reloading seedlings onto the planting device (as explained in section 2.2.3). A nursery worker fills the paper grid spacer with seedlings and then places two filled grid spacers lying down, stems intertwined, within a standard cardboard box. We assumed the average productivity of this packing work to be 1500 seedlings h–1 and that the nursery worker’s labour costs were 23 Euro h–1 (equalling a total labour cost for packing of 15.33 Euro (1000 pl)–1). Because the paper grid spacers occupy some space within the cardboard box, we assumed the seedling packing density of ManBox_fast system to be 10% lower than today’s ManBox system. Hence, a ManBox_fast cardboard box accommodated 149 seedlings. The unit cost of one ManBox_fast paper grid spacer was 1.50 Euro (two grid spacers per box = 3.00 Euro per cardboard box). Altogether, ManBox_fast’s packaging material cost was 212% higher than ManBox’s (Table 2). Due to the lower packing density, ManBox_fast’s freezer/cooler unit cost (CFreezer, including labour, facilities, etc.) was 18.80 Euro (1000 pl)–1, circa 11% higher than that of ManBox.

In the MechBox_49 and MechBox_121 systems, seedlings are packed into square cardboard boxes while standing upright within individual cells created by a carton grid spacer (Fig. 1). The difference between the two MechBox systems is the grid spacers resulting in two different cell densities. MechBox_49 (the low-density variant) provides enough cell space (5.3 cm×5.3 cm = 28.1 cm2) to allow the seedlings to glide out of the grid spacer with ease during seedling reloading of the planting device. Meanwhile, MechBox_121 (the high-density variant) assumes the theoretical minimum cell space for seedlings grown in Hiko v93 cultivation trays: 41 mm which is equal to the diameter of the peat root plug. This theoretical minimum cell space (4.1 cm×4.1 cm = 16.8 cm2) would allow the seedlings to be inserted into the grid spacer without squeezing out water from the root plug, but would in turn hamper easy seedling extraction during seedling reloading of the planting device. Hence, MechBox_121 points to the maximum theoretical potential for cost-efficiency of cardboard boxes with upright standing seedlings.

The MechBox systems’ packing process was assumed to be automated, and to use ManBox’s existing standard packing line. However, because the MechBox systems’ cardboard boxes are of different sizes than ManBox’s (Table 2), both MechBoxes required an investment in a new box erector, taping machine, 20 m2 of floor space, additional conveyor belts, and programming. We assumed the total investment in the additional packing machines and floor space to be 60 000 Euro and 12 000 Euro respectively, the depreciation period to be 10 years for both, and the salvage value to be 10% for both. We assumed the total investment in the additional conveyor belts and programming to be 105 000 Euro, the depreciation period to be 10 years, and the salvage value to be null. The additional packing line’s productivity was assumed to be 10 000 pl h–1. During the investment’s lifetime, >6 million seedlings in total are assumed to be packed in the basic scenario. These investments also generate variable operating costs including labour, heating, electricity, maintenance, etc. In total, the overall packing costs (CPack) in the basic scenario for MechBox_49 and MechBox_121 were 91.50 and 88.90 Euro (1000 pl)–1 respectively.

Both MechBox systems use a similar cardboard box (Table 2), and we assumed the unit price for the box and carton grid spacer to be 2.70 Euro for both systems. Other packaging material for the MechBox systems included pallets and shrink-wrap. We assumed that the nursery’s overall freezer/cooler storage cost (CFreezer, including labour, electricity, facilities, etc.) is constant/fixed. This means that the total unit cost per seedling for freezer/cooler storage increases linearly with decreasing number of stored seedlings per m3 of freezer/cooler space. Consequently, the freezer/cooler storage cost of MechBox_49 was 147% higher than that of MechBox_121 (61.3 vs 24.8 Euro (1000 pl)–1).

2.2.2 Seedling transport

All five supply systems assumed primary transport from the nursery/freezer storage to a contractor depot (equipped with some type of roofed shelter with space for circa 8000 seedlings), and secondary transport from the depot to the roadside landings. In the basic scenario, the distance to the depot from the nursery was set to 100 km for all systems.

The Hiko system’s primary transportation vehicle, a courier truck, delivers in the basic scenario 7000 seedlings (175 trays) once in a week from the nursery to the contractor’s depot. Cultivation trays is the handling unit. We assumed that the courier truck driver loads the trays unaided at the nursery onto shelves in the trucks’ cargo hold using a front-end loader. The courier truck’s fixed and variable costs were 30.12 Euro h–1 and 0.39 Euro km–1, respectively. Because we assumed the courier truck to be commissioned solely for a sole seedling delivery at a time, the courier transporter invoices for each seedling delivery according to a two-way principle. Hence, Hiko’s tariff (linear cost function comprising fixed and variable costs; Table 3) for the total transport cost (CTotalTrans) in the basic scenario was:

15.48 Euro (1000 pl)–1 + 0.255 Euro (1000 pl)–1 km–1× 200 km = 66.5 Euro (1000 pl)–1.

| Table 3. Tariff (linear cost function; the total transport cost CTotalTrans = fixed cost + variable cost × invoiced distance in km) in the basic scenario for the primary transport of one week’s demand of seedlings from the nursery to the contractor’s depot (100 km one-way) for the five seedling (Picea abies) supply systems. The tariff gives the total transport cost (CTotalTrans) per 1000 seedlings including loading and unloading of seedlings in handling units of: i) cultivation trays for Hiko; and ii) stacked cardboard boxes shrink-wrapped together on Euro-pallets for the four cardboard box systems. | ||||

| Packaging system | Weekly consumption of seedlings (pl week–1) | Fixed cost (Euro (1000 pl)–1) | Variable cost (Euro (1000 pl)–1 km–1) | Invoiced distance (km) |

| Hiko | 7000 | 15.48 | 0.255 | 200 |

| ManBox | 6735 | 3.86 | 0.520 | 100 |

| ManBox_fast | 7780 | 3.67 | 0.449 | 100 |

| MechBox_49 | 7485 | 4.82 | 1.408 | 100 |

| MechBox_121 | 7870 | 3.31 | 0.622 | 100 |

| Seedlings are abbreviated pl. | ||||

With Hiko, the planting machine operator must water the seedlings daily, which required on average a total of 16 minutes in the basic scenario. These minutes reduce each day’s planting time, hence directly reducing the planting machine’s daily production. In contrast, the four cardboard box systems involve frozen or cooler-stored seedlings, and hence no watering was required. In the end, the watering cost for Hiko (CWater) was the product of the planting machine’s hourly cost, the average time needed to water seedlings (we assumed 1 min (1000 pl)–1), and the number of seedlings at the depot that needed to be watered per shift.

The four cardboard box systems use general groupage delivery truck as their mode of primary transportation. The handling unit is stacked cardboard boxes shrink-wrapped together on Euro-pallets. In contrast to the courier truck, the groupage delivery truck was assumed to deliver many other shipments apart from seedlings during one trip. Thus, the groupage delivery truck invoices according to a one-way principle. The groupage delivery truck’s fixed and variable costs (including independent loading at the nursery, and unloading at the depot with a truck-mounted forklift at a cost of 11.50 Euro per delivery) were 33.79 Euro h–1 and 1.03 Euro km–1, respectively. Each delivery equalled one week’s consumption of seedlings. All together, the fixed costs for the groupage delivery truck in the basic scenario were lower than those for Hiko’s courier truck, while the variable costs were generally higher (Table 3).

The planting machine operator’s workday always started at the depot (assumed adjacent to the operator’s residence) where he loads the estimated daily seedling consumption onto his personal vehicle (light pickup truck or alternatively cargo van) and drives to the planting site. At the end of workday, he drives back to the depot (with empty packaging). Because of the systems’ different number of seedlings per handling unit, the time consumption to load and unload seedlings from the secondary transport vehicle varied between the packaging systems. In the end, the loading personal vehicle cost (CV.Load) was the product of the planting machine’s hourly cost, the time consumption per handling unit, and the number of handling units handled per shift.

2.2.3 Loading onto planting machine, outplanting, and planting device reloading

For all five systems, we assumed that seedlings were loaded onto the planting machine at the landing each day by the operator. A shift’s worth of handling units (Table 4) were loaded into the planting machine’s storage box directly from the operator’s personal vehicle. The loading planting machine cost (CPM.Load) was the product of the planting machine’s hourly cost, the time consumption per handling unit, and the number of handling units handled per shift.

| Table 4. Outplanting cost (COutplant) factors in the cost analysis of seedling supply systems from southern Sweden. The values are those of the basic scenario. | ||||||

| Packaging system | Handling units handled per shift | Time consumption for reloading seedlings (s pl–1) | Planting machine productivity (pl h–1) | Production per shift (pl shift–1) | Planting machine hourly cost (Euro h–1) | Additional investments required by the contractor |

| Hiko | 35 | 2.6 | 200 | 1400 | 85.0 | - |

| ManBox | 9 | 3.3 | 192 | 1347 | 85.0 | - |

| ManBox_fast | 11 | 0.8 | 222 | 1556 | 86.9 | Conceptual 296 seedling carousel |

| MechBox_49 | 31 | 1.45 | 214 | 1497 | 87.4 | Existing 196 seedling carousel + modified seedling storage box |

| MechBox_121 | 14 | 0.6 | 225 | 1574 | 87.4 | Conceptual 484 seedling carousel + modified seedling storage box |

| Seedlings (Picea abies) are abbreviated pl. | ||||||

Irrespective of seedling supply system, the planting machine consisted of 18 tonne Volvo tracked excavator equipped with a Bracke Planter planting device. This type of planting machine prepares the soil via spot mounding and plants a seedling during the same work cycle. The planting machine was assumed to work 135 single shifts per year, 7 PWh per shift, totalling 945 PWh per year. Similar to Ersson et al.’s (2011) analysis, we assumed more seedlings to be planted per year when productivity increased, instead of the planting machine working fewer hours per year (and vice-versa for decreased productivity).

The total hourly cost of the planting machine when using either the Hiko or ManBox system was 85 Euro (Table 4). As according to Ersson et al. (2014), manually reloading seedlings onto the Bracke Planter planting device from the Hiko cultivation tray was assumed to average 2.6 s pl–1, while mounding and planting together average 15.4 s pl–1. Hence, 200 seedlings are planted during one PWh. And because one working shift equalled 7 working hours, 1400 seedlings were planted during one shift when using Hiko in the basic scenario. The corresponding figures for ManBox were: reloading seedlings onto the Bracke Planter planting device 3.3 s pl–1; mounding and planting 15.4 s pl–1; and productivities of 192 pl h–1 or 1347 pl shift–1. Because seedlings are reloaded manually onto the existing version of the Bracke Planter planting device, neither Hiko nor ManBox require the planting machine contractor to make any extra investments.

In contrast, ManBox_fast and both MechBox systems require the planting machine contractor to invest an additional 10 000 Euro in new high-capacity seedling carousels for the Bracke Planter (the existing 196 seedling carousel for MechBox_49, and conceptual 298 and 484 seedling carousels for ManBox_fast and MechBox_121 respectively). All three high-capacity seedling carousels were assumed to have the same purchase price, be used 945 h year–1, and to have a 7-year depreciation period and 10% salvage value. Because of the taller cardboard boxes and there being more of them, the MechBox systems also require a modified seedling storage box on the base machine. This modification was assumed to cost 2000 Euro, and to have a 5-year depreciation period and no salvage value.

These extra investments result in slightly higher planting machine hourly costs compared to the Hiko and ManBox systems (Table 4). The extra investments allowed for higher outplanting productivity because of notably reduced seedling reloading times. Based on various time studies, reloading seedlings onto the high-capacity carousels was assumed to average 0.8 s pl–1, 1.45 s pl–1, and 0.6 s pl–1 for ManBox_fast, MechBox_49, and MechBox_121 respectively. The time needed for mounding and planting was assumed the same (15.4 s pl–1) irrespective of the packaging system. Hence, in the basic scenario, the outplanting productivities and number of planted seedlings per shift of ManBox_fast and the MechBox systems were higher than of Hiko and ManBox.

2.2.4 Empty packaging handling

Irrespective of the packaging system, the planting machines operator returns empty packaging to the contractor’s depot after each shift. The stacks of empty Hiko cultivation trays are returned to the nursery from the depot by a returning courier truck twice a year. Hence, a courier truck might transport both full trays to the depot and empty trays to the nursery. Returning empty trays (CReturns) is therefore assumed to generate only additional loading and unloading (but not transport) costs. Regarding the cardboard box systems (CRecycling), the planting machine operator flattens empty cardboard boxes and grid spacers and deposits them in a rented recycling container at the contractor’s depot. After that, the cardboard material is picked up and recycled by a cardboard recycling company without generating any other costs.

2.2.5 Sensitivity analysis

In the basic scenario, we applied mean values reflecting actual southern Swedish conditions in 2015. However, for our study to be relevant for other regions, and because environmental, societal, and technological conditions change over time, a sensitivity analysis was essential, especially since MechBox_49 was only a prototype and MechBox_121 and ManBox_fast were only conceptual. The sensitivity analysis helped us test how different input values affect the relative cost-efficiency of the packaging systems.

We varied the input values of eight different variables as according to Table 5. The minimum and maximum values reflect realistic extremes of the variables. For example, as in Ersson et al. (2011), –40% in mean planting time excluding seedling handling reaches the theoretical limit of the Bracke Planter. The same goes for –50% in planting device reloading time. Meanwhile, the 298 and 484 values for the planting device’s carousel capacity reflect how many seedlings would be reloaded per occasion if the carousel could hold two and four entire boxes of ManBox_fast and MechBox_121 respectively.

| Table 5. The extent of the sensitivity analysis of the five seedling (Picea abies) packaging systems in southern Sweden. The last two columns show the change in cost variables from the basic scenario. | |||

| Variable | Basic scenario | Sensitivity analysis | |

| Minimum | Maximum | ||

| Primary transport distance (distance between nursery and depot) | 100 km | 0 km | 400 km |

| Mean planting time excluding seedling (Picea abies) handling | 15.4 s pl–1 | –40% | +40% |

| Yearly demand for mechanically planted seedlings | 500 000 pl year–1* | –0% | +1000% |

| Planting machine’s hourly cost | 85.0–87.4 Euro** | –8% | +70% |

| Planting device reload time | 0.6–3.3 s pl–1** | –50% | +30% |

| Number of seedlings per box of ManBox_fast | 149 pl | –45% | +10% |

| Planting device’s carousel capacity (for Hiko and ManBox only) | 70 pl | 70 pl | 484 pl |

| Interest rate, for contractor and nursery respectively | 6 and 10% | 3% | 12% |

| Seedlings are abbreviated pl. *See Table 3. **See Table 4. | |||

To explore ManBox_fast’s potential, we also fashioned a best case scenario from ManBox_fast’s point-of-view. This best case scenario assumed a few realistic increases in the following four variables: 30% increase in the planting machine’s total hourly cost (to 111–114 Euro h–1); 400% increase in the yearly demand for mechanically planted seedlings (to 2 million pl year–1); 20% increase in the planting machine’s productivity (to 230–270 pl h–1); and 10% increase in the number of seedlings per ManBox_fast cardboard box (to theoretic the maximum of 165 pl box–1).

3 Results

In the basic scenario, the assumed increase in planting machine productivity provided by the cardboard box concepts could not offset their higher total costs. Instead, Hiko was 5% (versus ManBox_fast) to 49% (versus MechBox_49) more cost-efficient than all the other seedling packaging systems (Table 6, CTotal). A comparatively low packaging cost (CPack) was the main reason for Hiko’s cost-superiority. Meanwhile, ManBox_fast seemed to offer a cost-saving of 4% compared to ManBox despite the former’s higher packing and freezer-storage costs. Because of comparatively low packing densities, both MechBox concepts suffered from the highest packing, freezer-storage, recycling, and – ultimately – total costs of all five systems.

| Table 6. Aggregated costs per activity in the basic scenario for the five seedling (Picea abies) packaging systems in southern Sweden. Costs are given as Euro per thousand planted seedlings (Euro (1000 pl)–1) excluding the seedling purchase price. | |||||

| Packaging system | |||||

| Activity (cost variable) | Hiko | ManBox | ManBox_fast | MechBox_49 | MechBox_121 |

| Packing at the nursery (CPack) | 15.6 | 55.0 | 89.7 | 151.3 | 113.5 |

| Freezer storage (CFreezer) | - | 17.0 | 18.8 | 61.3 | 24.8 |

| Primary seedling transport (Total transport; CTotalTrans)* | 66.5 | 55.0 | 48.0 | 142.9 | 64.6 |

| Watering (CWater) | 6.2 | - | - | - | - |

| Loading secondary transport vehicle (CV.Load) | 6.8 | 3.4 | 3.5 | 8.1 | 4.1 |

| Loading planting machine (CPM.Load) | 7.7 | 4.2 | 4.3 | 8.7 | 4.8 |

| Outplanting seedlings (COutplant)** | 425.0 | 441.9 | 391.0 | 408.7 | 388.8 |

| Returning cultivation trays (CReturns) | 7.8 | - | - | - | - |

| Recycling cardboard boxes (CRecycling) | - | 8.4 | 8.3 | 17.4 | 9.5 |

| Total (i.e. aggregated) cost (CTotal) | 535.5 | 584.9 | 563.6 | 798.4 | 610.1 |

| Seedlings are abbreviated pl. * Including loading at the nursery and unloading at the depot. ** Including reloading planting device. | |||||

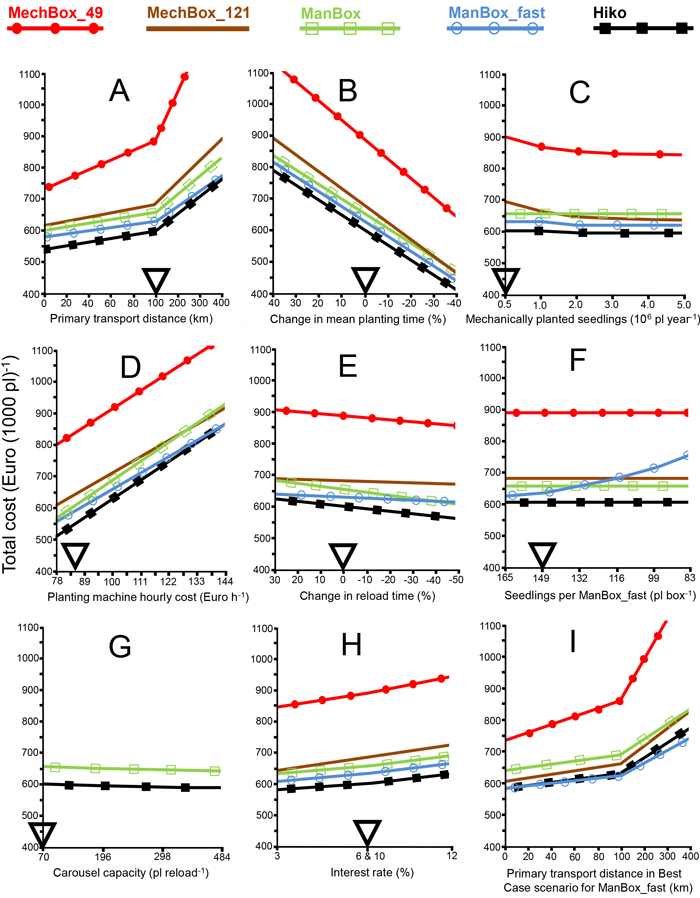

Generally, altering the input values within realistic confines changed very little the packaging systems’ relative order of cost-efficiency. Again, because of low packing densities, the MechBox concepts were weakened the most by long distances between the nursery and the planting machine’s depot (Fig. 2A). Conversely, both MechBox systems benefitted the most from faster mean planting time excluding seedling handling and higher demand for mechanically planted seedlings (both which helped to lower the per seedling cost of MechBoxes’ extra nursery investments, Fig. 2B and C, respectively). Meanwhile, increasing the planting machines’ hourly cost helped both ManBox_fast and MechBox increase their competitiveness (so much so that ManBox_fast supplants Hiko above 140 Euro h–1, Fig. 2D), while quicker seedling reloading (in relative terms without any other changes to the packaging systems) enhanced Hiko and ManBox the most (Fig. 2E). ManBox_fast was very sensitive to its seedling packing density, although it never became more cost-efficient than Hiko even when assuming the same seedling density as ManBox (165 pl box–1, Fig. 2F). Increasing the seedling carousel capacity for Hiko and ManBox or changing the interest rate had relatively little effect on CTotal (Fig. 2G and H respectively). Even in its best case scenario did ManBox_fast only become the most cost-efficient packaging system once primary transport distances exceeded 60 km (Fig. 2I).

Fig. 2. The effect on the total cost of the studied seedling (Picea abies) packaging systems per thousand seedlings (pl) when varying the distance between nursery and depot (A), the mean planting time excluding seedling handling (B), the yearly demand for mechanically planted seedlings (C), the planting machine’s hourly cost (D), the relative planting device reload time (E); the number of seedlings per box of ManBox_fast (F), the planting device’s carousel capacity (for Hiko and ManBox only (G), the interest rate (H), and the primary transport distance during a best case scenario from ManBox_fast’s point-of-view (I). The triangles on the x-axes denote the default values used in the basic scenario.

4 Discussion

Our calculation model suggested that the Hiko tray system was the most cost-efficient seedling supply system for southern Swedish conditions. This result agrees with that of Ersson et al. (2011), in which the enhanced planting machine productivity offered by machine-specific seedling packaging could not offset its higher packaging costs. In both studies, the lack of additional costly nursery activities made Hiko cost-superior; here, however, only up until high planting machine hourly costs (above circa 140 Euro h–1).

Today’s excavator-based planting machines generally cost less than 100 Euro h–1 (cf. Ersson et al. 2014; Laine and Saarinen 2014; Guerra et al. 2019), although the highly productive, forwarder-based Silva Nova planting machine of the 1990s had a much higher hourly cost than that (Hallonborg et al. 1995). Machine-specific seedling packaging can’t be dismissed entirely though, because it’s likely that future tree planting machines’ hourly cost will become equally expensive (because of continuous advancement like today’s Plantmax prototype, or productivity enhancing innovations like e.g. multi-headed planting devices; Ersson 2014; Tysklind 2021).

According to our results, the packing density of any new cardboard box concept must be high (i.e. low volume per packed seedling) to achieve cost-efficiency. This correlation is necessary because the costs of the box itself and the nursery’s extra packing activities are substantial. Low packing densities are especially detrimental when shipping distances are long (Berner 1922). High packing densities can be achieved in different ways; for example by overlaying tops / intertwining the seedlings’ stems (Österström et al. 1974). ManBox uses this space-saving solution, and any cost-efficient MechBox would most probably have to as well. Besides overlaying the tops, achieving high packing densities with real-life versions of ManBox_fast probably requires using a box-internal, collapsible paper grid of cells. Perhaps these grids should be similar to the chain pots used by the Paperpot system (cf. Sundström 1992). Other solutions might be foldable trays made of paper similar in design to the Spencer-Lemaire fold-up plug tray (Cayford 1972), but where the paper grids are removed prior to planting. The crux, of course, would be to find robust solutions for swift removal of these paper grids.

In comparison to the Hiko tray system in Ersson et al. (2011), we now assumed lower transport costs because the courier truck in this study is optimized for 7000–10 000 seedlings per trip. Also, we now assumed more time-efficient loading of Hiko at the nursery (we assumed in this study that the nursery uses a front-end loader with a hydraulic spacer fork so that loading could be performed by a single operator). Moreover, we now assumed a lower time consumption for loading the seedling carousel (which lowers CPM Load) with Hiko than what was assumed in Ersson et al. (2011). All three of these new assumptions translate into a smaller window of opportunity for machine-specific seedling packaging.

There are existing solutions to further cut costs with today’s two existing packaging systems (Hiko and ManBox). For example, Bracke Planter’s new seedling carousel holds 196 (instead of 70–72) seedlings. The total cost of mechanized planting can be reduced by 1–2% with this larger carousel (Fig. 2G). Also, practical experience has shown that “serving platters” (simple trays onto which seedlings can be emptied and quickly oriented in the same direction; the operator thus avoids having to pick seedlings one-by-one from the boxes) can allow for faster seedling loading from ManBox. This “platter” solution is especially advantageous with high capacity carousels.

Similar to Ersson et al. (2011), the strengths of this study include: 1) its theoretical and comprehensive nature; and 2) the absence of operator effects and different technical maturity levels found in e.g. field studies. However, some of the study’s weaknesses include: 1) the absence of planting machine relocations (which in reality according to e.g. Rantala et al. (2009) lowers the positive effect of higher planting machine productivity) on the ManBox_fast and MechBox concepts); and 2) that we did not analyze the effect of larger or smaller seedlings on the packaging systems’ comparative advantage.

Using real-life data in cost analyses, as we did in our case study, has its strength and weaknesses. Our real-life data describes the existing state of mechanized tree planting quite a well from a microeconomic perspective. Understanding the existing situation is necessary to comprehend the barriers to launching seedling supply system adapted for mechanized planting. However, using real-life data in long-term strategical analyses is seldom advisable because markets never work perfectly (Wickens 2012). Therefore, using biased market prices in cost analyses often leads to inefficient outcomes, which in turn are harmful for the business sector as a whole. Hence, the results of our study should not be used for long-term planning of mechanised tree planting in Swedish forestry. Instead, the results should be considered as descriptive figures that describe the challenges of today’s mechanized tree planting in Sweden and other similar countries.

Because Nordic foresters and researchers keep predicting future growth in mechanized tree planting (Strandström et al. 2009; Järlesäter and Jönsson 2013; Laine 2017; Ersson et al. 2018), further studies of machine-specific seedling packaging are warranted. For example, since the hourly cost of future planting machines will probably increase (cf. the assumed hourly planting machine cost of 55 Euro h–1 in Ersson et al. (2011) versus 85 Euro h–1 in this study), the development of a ManBox_fast concept is justified. Parallel to such development work, studies on freezer storage of Hiko trays should be performed, since the performance of frozen-stored seedlings is superior to actively growing ones during spring planting in Fennoscandia (Luoranen et al. 2005). But the Hiko system assumed hot-lifted seedlings because there is presently no operational method of freezer storing seedlings in Hiko v93 cultivation trays. For example, to avoid desiccation, maybe frames of cultivation trays can be wrapped in plastic and stored in loader-accessible freezers. In any case, it is important that any novel storage or packing solutions do not significantly weaken the vitality or potential performance of the seedlings (Luoranen et al. 2019).

The need to develop and implement mechanized tree planting in Nordic forestry is important because of decreasing supply of manual labour (Laine 2017). To increase the cost-efficiency of mechanized planting, streamlined seedling supply systems between nurseries and mechanized planting machines must be developed. This development should take into account biological, technological, logistical, and cost-efficiency aspects. For example, is the seedling supply system intended for intermittently advancing versus continuously advancing tree planting machines? Should the nursery’s design and production system be integrated with the needs of the planting machines? If so, should adaptations be made at several existing nurseries, or should there be a specialized nursery for mechanized planting? Almost 20 forest nurseries are in operation in Sweden, should e.g. one of them in the future be designated and converted to supply seedlings to all of Sweden’s tree planting machines? Moreover, this developmental process should also consider the potential for future remote-controlled and/or autonomous planting machine systems. In the present study, we focused mainly on logistical and cost-efficiency aspects.

5 Conclusions

Cultivation trays (Hiko v93) was in this study the most cost-efficient packaging system for today’s tree planting machines. Because of low packing densities, systems like the MechBox concepts do not seem to show any promise for the future. Indeed, to save on transport and packaging material costs, seedlings in boxes should be shipped lying down with intertwined stems/green parts. And as long as the hourly cost of mechanized tree planting is relatively low (because of low-tech planting machines) and primary transport distances are short (because of few contracted planting machines), even the proposed ManBox_fast cardboard box concept seems to be cost-inefficient. However, if continuously advancing and highly productive planting machines are developed in the future (Manner and Ersson 2021), then the cost-competitiveness of systems like the ManBox_fast concept (and even high-packing-density variants of the MechBox system) will increase.

Declaration of openness of research materials, data, and code

The dataset is available upon request from the corresponding author.

Authors’ contributions

Back Tomas Ersson and Lars-Göran Sundblad initiated the study. Back Tomas Ersson collected the data. Back Tomas Ersson did all the calculations and analyses. Back Tomas Ersson and Jussi Manner wrote the manuscript with help from Lars-Göran Sundblad. All authors revised the manuscript.

Acknowledgements

We acknowledge Urban Bergsten for initial guidance in planning the study.

Funding

Thanks to Södra’s forskningsstiftelse for funding the study, and to SLU and Skogforsk for funding the writing of the manuscript.

References

Berner N (1922) En ny klimpplanteringsmetod. [A new method of planting seedlings with root plugs]. Svenska skogsvårdsföreningen. Skogen, Häfte 5–6: 161–170.

Cayford J H (1972) Container planting systems in Canada. For Chron 48: 235–239. https://doi.org/10.5558/tfc48235-5.

Ersson BT (2010) Possible concepts for mechanized tree planting in southern Sweden – an introductory essay on forest technology. Swedish University of Agricultural Sciences, Arbetsrapport 269. https://pub.epsilon.slu.se/4540/.

Ersson BT (2014) Concepts for mechanized tree planting in southern Sweden. Acta Uni Agric Suec 2014:76. https://pub.epsilon.slu.se/11522/.

Ersson BT, Petersson M (2013) Återinventering av 2010 års maskinplanteringar – 3-års uppföljning. [Three-year follow-up of 2010’s mechanically planted seedlings]. Skoglig service, Södra Skog Rapport S048.

Ersson BT, Bergsten U, Lindroos O (2011) The cost-efficiency of seedling packaging specifically designed for tree planting machines. Silva Fenn 45: 379–394. https://doi.org/10.14214/sf.108.

Ersson BT, Bergsten U, Lindroos O (2014) Reloading mechanized tree planting devices faster using a seedling tray carousel. Silva Fenn 48, article id 1064. https://doi.org/10.14214/sf.1064.

Ersson BT, Laine T, Saksa T (2018) Mechanized tree planting in Sweden and Finland: current state and key factors for future growth. Forests 9, article id 370. https://doi.org/10.3390/f9070370.

Guerra SPS, Soler RR, Sereghetti GC, Oguri G (2019) An evaluation of the economics and productivity of fully mechanised tree seedling planting in Brazil. South For 81: 281–284. https://doi.org/10.2989/20702620.2019.1615225.

Hallonborg U (1997) Aspects of mechanized tree planting. Acta Universitatis Agriculturae Sueciae, Silvestria 29.

Hallonborg U, von Hofsten H, Mattson S, Hagberg J, Thorsén Å, Nyström C, Arvidsson H (1995) Maskinell plantering med Silva Nova -nuvarande status samt utvecklingsmöjligheter i jämförelse med manuell plantering. [Mechanized planting with the Silva Nova tree planter -recent state and feasibility compared with manual planting]. Skogforsk Redogörelse nr 6.

Järlesäter M, Jönsson A (2013) Skogsbolags och entreprenörers attityder till mekaniserad plantering och röjning. [Forest companies’ and contractors’ attitudes towards mechanized tree planting and pre-commercial thinning]. Swedish University of Agricultural Sciences, Kandidatarbeten i skogsvetenskap 2013:23. https://stud.epsilon.slu.se/6544/.

Laine T (2017) Mechanized tree planting in Finland and improving its productivity. Diss For 239. https://doi.org/10.14214/df.239.

Laine T, Saarinen V-M (2014) Comparative study of the Risutec Automatic Plant Container (APC) and Bracke planting devices. Silva Fenn 48, article id 1161. https://doi.org/10.14214/sf.1161.

Landis TD (2010) Chapter 6: outplanting. In: Landis TD, Tinus RW, MacDonald SE. Barnett JP (eds) The container tree nursery manual. Volume 7. Agric. Handbook 674. USDA Forest Service, Washington D.C., pp 147–192.

Luoranen J, Rikala R, Konttinen K, Smolander H (2005) Extending the planting period of dormant and growing Norway spruce container seedlings to early summer. Silva Fenn 39: 481–496. https://doi.org/10.14214/sf.361.

Luoranen J, Rikala R, Smolander H (2011) Machine planting of Norway spruce by Bracke and Ecoplanter: an evaluation of soil preparation, planting method and seedling performance. Silva Fenn 45: 341–357. https://doi.org/10.14214/sf.107.

Luoranen J, Pikkarainen L, Poteri M, Peltola H, Riikonen J (2019) Duration limits on field storage in closed cardboard boxes before planting of Norway spruce and Scots pine container seedlings in different planting seasons. Forests 10, article id 1126. https://doi.org/10.3390/f10121126.

Manner J, Ersson BT (2021) Mechanized tree planting in Nordic forestry: simulating a machine concept for continuously advancing site preparation and planting. J For Sci 67: 242–246. https://doi.org/10.17221/203/2020-JFS.

Nilsson U, Luoranen J, Kolström T, Örlander G, Puttonen P (2010) Reforestation with planting in northern Europe. Scand J For Res 25: 283–294. https://doi.org/10.1080/02827581.2010.498384.

Normark E, Norr M (2002) EcoPlanter – sammanställning av ett utvecklingsprojekt. [EcoPlanter – a compilation of the development project]. Skogsvårdsavdelningen, Holmen Skog.

Österström L-O, Hultén H, Mattsson A (1974) Från plantskola till odlingsobjekt – en analys av några planttransportsystem. Del 1 Huvudresultat. [From nursery to clearcut – an analysis of seedling transportation systems]. Royal College of Forestry, Department of Reforestation, Research Notes Nr 52.

Ramantswana M, Guerra SPS, Ersson BT (2020) Advances in the mechanization of regenerating plantation forests: a review. Curr For Rep 6: 143–158. https://doi.org/10.1007/s40725-020-00114-7.

Rantala J, Harstela P, Saarinen V-M, Tervo L (2009) A techno-economic evaluation of Bracke and M-Planter tree planting devices. Silva Fenn 43: 659–667. https://doi.org/10.14214/sf.186.

Robb JG, Smith JA, Wilson RG, Yonts CD (1994) Paperpot transplanting systems – overview and potential for vegetable production. Horttechnology 4: 166–171. https://doi.org/10.21273/HORTTECH.4.2.166.

Saarinen V-M, Hyyti H, Laine T, Strandström M (2013) Kohti jatkuvatoimista koneistutusta. [Towards continuously operating planting machines]. Metsäteho report 227.

Strandström M, Hämäläinen J, Pajuoja H (2009) Metsänhoidon koneellistaminen – Visio ja T&K-ohjelma. [The mechanization of silviculture – Vision and R&D program]. Metsäteho report 206.

Sundblad L-G, Bergkvist I (2018) New solutions for seedling supply chain and enhancement in planting devices; technical report- development and innovations. EFFORTE, Natural Resources Institute Finland (Luke).

Sundström E (1992) Effects of removal of the paperpot container on growth and development of black spruce seedlings on a drained peatland clearcut in northeastern Ontario. Forestry Canada, Great Lakes Forestry Centre, Information Report O-X-418.

Tysklind L (2021) Mechanized tree planting with the Plantma X planting machine – the impact of terrain factors on planting quality. Swedish University of Agricultural Sciences. Department of Forest Biomaterials and Technology, Report 2021:7. https://stud.epsilon.slu.se/17291/.

Wickens M (2012) Macroeconomic theory: a dynamic general equilibrium approach 2nd edition. Princeton University Press, Princeton, New Jersey, United States. ISBN 9780691152868.

Total of 31 references.