A survey of the Finnish mechanized tree-planting industry in 2013 and its success factors

Laine T., Kärhä K., Hynönen A. (2016). A survey of the Finnish mechanized tree-planting industry in 2013 and its success factors. Silva Fennica vol. 50 no. 2 article id 1323. https://doi.org/10.14214/sf.1323

Highlights

- In 2013, 31 planting machines were operated by 22 businesses and planted 4.7 million seedlings on 2663 hectares in Finland

- Critical success factors included expertise of planting machine operators, high quality planting, adequate amount of work, stoniness, and removal of slash

- Growth of the industry will depend on improved cost-efficiency, appropriate worksites, marketing, development of planting machines.

Abstract

The aim of the study was to update the information pertaining to mechanized tree-planting activity in Finland in 2013 and its success factors. All businesses providing a mechanized tree-planting service were interviewed and asked to describe their equipment and activities, identify critical success factors (CSFs), and suggest areas for improvement. In 2013, 31 planting machines (18 Bracke P11.a, 11 M-Planter and 2 Risutec) operated by 22 businesses planted approximately 4.7 million seedlings on 2663 hectares. CSFs included expertise of planting machine operators, high quality planting, adequate amount of work, stoniness, and removal of slash. Based on the survey, some recommendations for improving mechanized planting work can be made. Firstly, improving the cost-efficiency of mechanized planting is necessary to enhance businesses’ profitability. Secondly, worksite selection is crucial as stoniness, stumps and slash debris diminish productivity. Lastly, the popularity of mechanized planting in the future will benefit from more marketing. Many businesses were unwilling to increase the area of service, invest in new equipment, or increase the volume of planting work but they believed that mechanized planting will become more popular in the near future.

Keywords

regeneration;

boreal;

forestry;

silviculture;

mechanization;

planting machines;

critical success factors (CSFs)

-

Laine,

Natural Resources Institute Finland (Luke), Management and Production of Renewable Resources, Juntintie 154, FI-77600 Suonenjoki, Finland

E-mail

tiina.laine@luke.fi

- Kärhä, Stora Enso Wood Supply Finland, P.O. Box 309, FI-00101 Helsinki, Finland E-mail kalle.karha@storaenso.com

- Hynönen, University of Eastern Finland, Faculty of Science and Forestry, P.O. Box 111, FI-80101 Joensuu, Finland E-mail hynonena@gmail.com

Received 4 March 2015 Accepted 17 February 2016 Published 24 February 2016

Views 99765

Available at https://doi.org/10.14214/sf.1323 | Download PDF

1 Introduction

Highly-automated and continuously-advancing planting machines such as the Swedish Silva Nova and the Finnish Serlachius were first developed in the 1970s. As they were rather specialized machines restricted to planting work, they were considered too expensive in comparison to manual techniques (Kaila 1984; Hallonborg et al. 1995). By the end of 1980s, these planting machines were succeeded by the first boom-mounted planting device; the Öje-Planter or the Bracke P11.a as it is known today (von Hofsten 1993; Hallonborg et al. 1997; Ersson 2010). Currently, the planting machines used in Finland (i.e., Bracke, M-Planter and Risutec) perform the steps of forming mounds and planting seedlings in a smooth sequence. Most planting devices are attached to excavator booms and the operator determines planting points individually. Seedlings are fed from one or two seedling cassettes which are manually refilled as required from a seedling storage rack attached to the excavator (Rantala et al. 2009; Ersson 2010; Rantala and Laine 2010).

In 2013, just over 80% of the 121 000 hectares (ha) of regenerated forestland were regenerated artificially in Finland (Juntunen and Herrala-Ylinen 2014). Silviculture has a highly seasonal demand for labour, and most planting takes place during one month in spring. Manual planting in Finnish private forests requires 650 person-years each year; this translates to a standing labour pool of approximately 4300 people (Alatalo et al. 2011; Hallongren et al. 2012). Mechanized planting requires 22% fewer human resources and offers a more efficient use of time and resources compared to separate soil preparation and manual planting (Hallongren et al. 2014). Mechanized planting can also ameliorate the problems associated with seasonal demand for labour and provide year-round employment for operators that use the base excavator for other work outside the planting season (Rantala and Saarinen 2006; Strandström et al. 2009; Hallongren et al. 2014). Biologically planting is possible from May to the end of September with seedlings grown for use during this time period (Luoranen et al. 2005; Luoranen et al. 2006).

Mechanized tree planting is expected to become more popular in the near future for several reasons. Firstly, the supply of forest labour continues to shrink in Finland, as forest workers are aging and forest owners are less able and eager to do the planting work themselves. Industrial-scale service providers are needed to provide the planting service effectively with a minimal workforce (Karppinen et al. 2002; Alatalo et al. 2011). Secondly, there is a need to decrease silvicultural costs in order to maintain profitability (Uotila 2005) and motivate private forest owners for forestry (Harstela 2006). Thirdly, the recovery of slash (also known as logging residues), stumps and rootwood as bioenergy will improve and further increase the amount of forestland suitable for mechanized planting (Saarinen 2006). Seedlings planted with machines perform as well or better than those planted manually (Luoranen et al. 2011; Ersson and Petersson 2013), so it is unlikely that work quality represents a limiting factor in the application of planting machines.

The mechanical planting chain involves several constituents with different set of responsibilities. The planting machine business, or contractor, is responsible for operational work, i.e., planting the seedlings and managing its quality. From the point of view of the planting machine contractor, a typical client is a large silviculture and forest industry enterprise [SFIE], a local forest owners association [FOA] or a non-industrial private [NIP] forest owner. A client can be regarded as a service provider with responsibility to plan the mechanized planting activities, ordering the seedlings from the nursery and selecting worksites suitable for the mechanized planting. NIP forest owners usually buy a planting service from SFIE or FOA rather than employ the planting machine contractor themselves. It is the nurseries responsibility to grow, prepare and deliver seedlings suitable for mechanized planting to depots or worksites.

The aim of the study was to survey mechanized planting activity and the mechanical planting chain in Finland in 2013. The most recent survey was carried by Metsäteho Ltd. in 2003 (Vartiamäki 2003) and the current number of tree-planting machines actively employed in Finland is currently unknown. Also, a set of critical factors for the success of planting machine businesses are provided. Suggestions made by planting machine contractors with respect to developing and optimizing mechanized planting activities are provided.

2 Material and methods

All registered businesses that provided a mechanized tree planting service in Finland during 2013 were interviewed in person by two interviewers in March and April 2014. The survey contained both open and structured questions. Two open questions asked the respondent to describe the seedling material used in 2013 and how to develop and improve the efficiency of mechanized planting in the future. The structured questions were divided into 14 sections.

Firstly, background information concerning the respondent and their business was obtained before proceeding to the second section which asked about the work carried out in 2013, the machinery and equipment, the amount of time (years [yr]) the business had performed mechanized planting, and the portion of annual revenue from mechanized planting (%). The market was addressed in the third section in which questions aimed to reveal how many clients the business had in 2013, to which group they could be assigned (i.e., SFIEs, FOAs or NIP forest owners), and if there were any notable changes in their client base 2010–2013. A fourth section focused on the reach of each business, i.e., the average, minimum and maximum distance [km] at which the service is provided. A fifth section dealt with the type of planting device and base machine, as well as the length of the planting season (start and end dates), work-shift structure (1, 1.5, 2 shifts, or alternative work-shift structure), stoppages during the planting season (weeks) and other non-planting tasks to which excavators were applied outside the 2013 season.

The sixth section concentrated on the utilization of planting capacity (ha yr–1) in 2013 and the target for 2014, as well as the potential for 2014 and what respondents saw as the main obstacles to achieving it. A seventh section asked about the average, minimum and maximum area of worksites (ha) in 2013, as well as the share of sites where slash and stumps have been recovered, and how worksites were divided according to stoniness, i.e., %-distribution to low, normal, and high. Activity during the planting period was also investigated, i.e., %-distribution of worksites conducted in spring, summer, and autumn. Finally, the respondents were asked to estimate the proportion of worksites that required supplementary manual planting (%).

Sections 8–12 dealt with seedling quality and logistics, characteristics of the worksites, machine relocation, and quality of the planting work:

- tree species planted in 2013 (i.e., % Norway spruce [Picea abies (L.) Karst.], Scots pine [Pinus sylvestris L.] and silver birch [Betula pendula Roth.])

- main delivery route for seedlings from nursery to worksites

- proportion of worksites unsuitable for mechanized planting (%) and the main reason(s) for their rejection

- who was responsible for the route planning of worksites and what were the main factors influencing the decision-making process of that

- how far in advance route planning was done (weeks)

- average distance between worksites (km)

- if machine relocations were performed with owned or hired vehicles

- how the quality of planting work was controlled

Section 13 aimed to determine critical success factors (CSFs). First, respondents were asked to evaluate 12 factors (low stoniness, slash harvested, high skill of machine operator, adequate worksite area [ha site–1], high quality planting, adequate amount of worksites [ha yr–1], high quality seedling material, stumps harvested, proper seedling storing, good worksite route planning, clear responsibilities in planting process, good logistics of seedling deliveries) in terms of their importance and impact on the productivity and cost-efficiency of mechanized planting in general. Next, respondents evaluated how these 12 factors were realized in 2013 based on their perceptions. For example, the importance of low stoniness to the productivity and cost-efficiency of mechanized planting was asked first and then, where worksites really stony or not. With this, it can be seen what needs to be improved and taken into account, because it is irrelevant to pay attention to something that is unimportant even though the realization of that factor would be poor. Evaluations were made on a five-level Likert scale (importance: 1 = unimportant, 2 = of little importance, 3 = moderately important, 4 = important, 5 = very important, and realization in 2013: 1 = very poor, 2 = poor, 3 = fair, 4 = good, 5 = very good).

In the final section of the interview, nine statements of the future of the mechanized planting were stated and the respondents were asked to express the extent to which they agreed (1 = strongly disagree, 2= disagree, 3 = neither disagree nor agree, 4 = agree, 5 = strongly agree) with the statements.

At the beginning of 2014, a total of 28 businesses were identified as operating a mechanized tree-planting service, of which 22 were active during 2013. Two did not participate in a full interview, but a non-response analysis covering the key questions concerning machinery and equipment in use, as well as the amount of mechanized planting work in 2013 was completed. Their data were merged with those obtained from the full interviews and some analyses were conducted on this (20 + 2) dataset.

For statistical analyses, mean values (arithmetic means) and standard deviations (SD) were calculated. Site-specific variables were calculated as means weighted with the total area planted by the contractor. Due to a small data set and relatively slight differences in the population, a deeper statistical analysis was not possible. A gap analysis methodology was used to compare the 2013 performance of CSFs with their perceived importance. This involved the comparison of actual performance (realization) with the importance of the factor in question. The gap was calculated as follows (Eq. 1):

where

Gi = gap of the success factor i

Ri = realization of the success factor i in 2013

Ii = importance of the success factor i.

3 Results

3.1 State of the industry

3.1.1 Businesses and their characteristics

According to the survey, 22 businesses operated 31 planting machines in Finland during the 2013 planting season. Most businesses had one planting machine (63.6%), about one third had two (31.8%) and one business had three (4.6%). The most common planting device was the Bracke P11.a, 18 of which were in use in 2013 along with 11 M-Planters and 2 Risutecs. Most of the planting devices were mounted on the booms of 14–21-ton excavators (93.5%), but two devices were harvester-based (6.5%). At the time of the survey (2014), base machines and planting devices were on average 6.0 (SD 4.0) and 7.2 years old (SD 5.6), respectively.

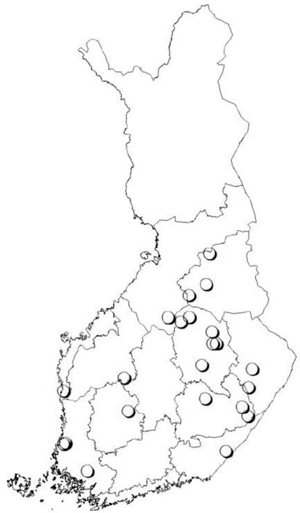

The average age of a business owner was 47.1 years (SD 9.1) varying from 32 to 63 years in 2014 (Table 1). The average age of the company (i.e., years since foundation) was 29.3 years (SD 15.4). Almost half (45.5%) of businesses have been providing a mechanized planting service for less than 4 years, 36.3% for 4–10 years, and 18.2% for more than 10 years, the average being 6.2 years (SD 6.0) in 2014. Most of the businesses operated in eastern Finland, and the service was unavailable in northern Finland (Fig. 1).

| Table 1. Characteristics of the Finnish planting machine businesses during the 2013 planting season. | ||||||

| Parameter | Unit a) | N | Average | Min. | Max. | SD |

| Age of owner of the business | yr | 20 | 47.1 | 32 | 63 | 9.1 |

| Foundation of the business | yr | 20 | 29.3 | 3 | 52 | 15.4 |

| Providing mechanized planting services | yr | 22 | 6.2 | 1 | 21 | 6.0 |

| Number of machines owned | pcs | 20 | 9.3 | 3 | 22 | 5.3 |

| Number of excavators owned | pcs | 20 | 3.0 | 0 | 8 | 2.0 |

| Share of annual revenue due to planting | % | 22 | 18.7 | 3 | 90 | 19.1 |

| Number of clients | pcs | 22 | 1.7 | 1 | 3 | 0.8 |

| a) pcs = pieces; yr = year | ||||||

Fig. 1. Distribution of mechanized planting businesses (n=22) in 2013. Copyright Karttakeskus Ltd, L11040/14.

Besides mechanized planting, 95.0% of businesses also provided soil preparation services, 65.0% ditching, 65.0% industrial roundwood/energy-wood cutting/forest haulage, 45.0% earthmoving, and 40.0% harvesting stumps. Businesses owned on average 9.3 machines (SD 5.3), of which 32.3% were excavators, 23.7% harvesters and 22.0% forwarders (Table 1). The relative contribution of mechanized planting to annual revenue varied from 3 to 90% (average 18.7% [SD 19.1]). For 59.1% of companies, mechanized planting contributed less than 20% of annual revenue.

Planting machine businesses had on average 1.7 clients (SD 0.8) varying from one (45.5%) to three (18.2%) (Table 1). The largest client group (86.2%) was SFIEs (e.g., Stora Enso Wood Supply Finland, Tornator, UPM Forest). Local FOAs represented 8.1% of clients and NIP forest owners 5.7%. Most companies (85.0%) had a similar client base from 2010 to 2013.

3.1.2 Performance

Mostly, the planting season started at the beginning of May (weeks 18–20). One business began planting in April, whereas four started during the first weeks of June. Most or all planting was complete by mid-October (weeks 40–42), with one contractor planting until the end of October. Thus, the average length of planting season was 19.8 weeks (i.e., 138 days or 4.9 months) (Table 2). During the planting season, 41.4% of machines had a planting-work stoppage for an average period of 1.2 weeks (0–8 weeks), and 41.7% of those were employed in other tasks (e.g., soil preparation, ditching, forest-road construction and stump lifting) during those periods. Base machines performed these tasks for 0–8 weeks with an average of 0.8 weeks per machine. Consequently, the length of the planting season excluding idle periods and/or time when the base machine was employed in other tasks was 18.6 weeks on average (i.e., 130 days or 4.7 months). Outside the planting season, base machines remained in operation (e.g., wood cutting, soil preparation, ditching, and stump lifting) for an average 2.9 months, varying from 0–8 months.

| Table 2. The extent of Finnish mechanized planting operations during the 2013 planting season. | ||||||

| Parameter | Unit a) | N | Average | Min. | Max. | SD |

| Planting season | w | 29 | 19.8 | 13.1 | 24.9 | 3.19 |

| Stoppage | w | 29 | 1.2 | 0 | 8 | 1.97 |

| Other work during planting season | w | 29 | 0.8 | 0 | 8 | 1.93 |

| Planting season excluding stoppages | w | 29 | 18.6 | 11.1 | 24.8 | 3.60 |

| Other work outside the planting season | m | 29 | 2.9 | 0 | 8 | 1.92 |

| Planted area | ha | 31 | 85.9 | 25.0 | 177.0 | 39.9 |

| Planted seedlings | pcs | 31 | 151 242 | 45 000 | 320 000 | 69 979.7 |

| a) ha = hectares; m = months; pcs = pieces; w = number of weeks | ||||||

The survey estimated that 4.7 million seedlings were planted mechanically on 2663 ha during 2013. Each planting machine planted an average of 151 242 seedlings (SD 69 979) on an average area of 86 ha (SD 39.9) (Table 2). Planting machines working in a single shift planted an average of 63 ha (113 727 seedlings), and those in two shifts planted an average of 104 ha (180 577 seedlings). Of planting machines in operation during 2013, 37.9% were used in a single shift-, 44.8% in a double shift-, and 13.8% in a 1.5 shift-system. One (3.4%) used an alternative work-shift structure. Assuming a 5-day workweek, the average productivity of the mechanized planting was 0.92 ha and 1614 seedlings per work day.

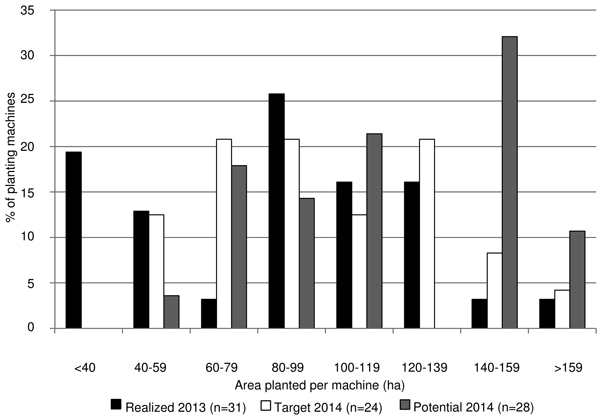

Respondents estimated that the 2014 target for planting area would be 40–180 ha per planting machine, being an average of 96 ha (SD 34.8), and the potential could be up to 120 ha (SD 50.7) (Fig. 2). The most important factors limiting that potential from being reached were as follows: lack of suitable worksites within the operational range; worksite stoniness; lack of skilled operators; general weaknesses of worksites; poor operational planning; and worksite size and inclination.

Fig. 2. Number of realized hectares planted by machine in 2013 compared to the target and potential area for 2014. Target is the realistic amount of planting work for 2014 and potential is a theoretical maximum that could be planted. At the time of the interview, some respondents could not evaluate the target for planting work in 2014.

3.1.3 Working conditions

The average distance between the worksite and depot was 61.5 km, varying 5–125 km. The shortest distance to a worksite was 0.5 km and the furthest was 250 km. The average worksite area was 4.7 ha, varying from 2.0 to 10.0 ha (SD 1.8). The largest single worksite was 31 ha and the smallest was 0.3 ha. Slash was harvested from 61.9% of worksites, and stumps from 32.9% of worksites. Stoniness was low at 28.1% of worksites and high at 21.4% of worksites. Of the worksites, 31.1% were planted during the spring (from the beginning of the planting season to late-June), 30.4% during the summer (from late-June to the end of July), and 38.6% in autumn (from the beginning of August till end of the planting season in mid-October). Only on 1.6% of worksites supplementary manual planting was conducted due to unsuitable working conditions such as stoniness or steep terrain. Of the worksites, 2.9% were rejected mainly due to stoniness, soft soil or steep terrain.

The route planning of worksites was mostly (60.0%) carried out by the contractor in 2013. One quarter of the route planning was done in conjunction with the client and 15.0% were specified entirely by the client. Route planning was completed on average 10.6 (2–22) weeks ahead. Seventy percent of the respondents stated that the most important factor in the route planning of worksites was the need to minimize the frequency of and distance between machine relocations. Additional factors included client preferences (40% of respondents), timing of stump harvesting at the worksite (25% of respondents) and soil type (20% of respondents). The average machine relocation distance between worksites was 22.2 km (SD 16.5) and most of the relocations were performed by the contractors’ own relocation trucks.

3.1.4 Seedlings and quality management

Of all mechanically planted seedlings in 2013, 90.0% were Norway spruce and 10.0% were Scots pine. Most respondents were satisfied with seedling quality in 2013. Minor problems were mentioned in that some seedlings were over-grown or under-sized for mechanized planting, and that root plugs were loose or had grown together.

In most cases (77.3%), seedlings were transported from the nursery to the worksite via a contractor’s depot, 9.1% were transported to client depot, and 13.6% of seedlings were transported directly to the worksite, mostly when the worksite was close to the nursery.

All but one of the contractors performed self-control as quality control methods during planting. Most contractors (70.0%) returned at a later date to check planting quality at some or all worksites, and all but one reported that their clients had also visited the site after planting work was complete at some or all worksites of 2013.

3.2 Critical success factors

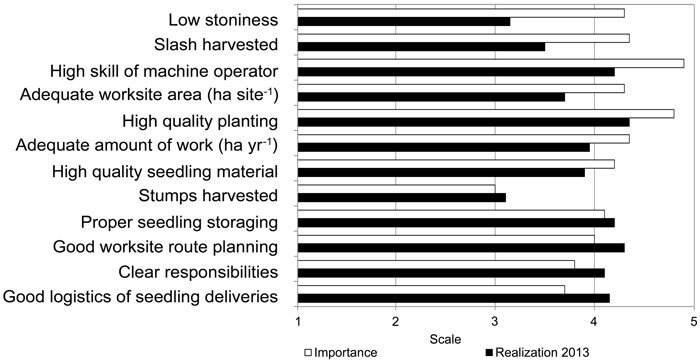

Respondents considered the most important factor affecting productivity and cost-efficiency of mechanized planting to be a high machine operator skill-level (importance: 4.90), high quality planting work (importance: 4.80), adequate amount of work for each planting machine (4.35), and harvesting of slash from worksites (importance: 4.35) (Fig. 3). Respondents felt the least important factors among the 12 listed were harvesting of stumps (importance: 3.00) and good logistics of seedling deliveries (importance: 3.7). The realization of these 12 listed factors in 2013 was highest for high quality planting work (realization: 4.35) and route planning for the worksite (realization: 4.30). Realization was poorest on worksites that were stony (realization: 3.15) and where no slash (realization: 3.50) or stumps (realization: 3.11) had been removed.

Fig. 3. Impact and importance of 12 factors affecting the productivity and cost-efficiency of mechanized planting as well as how these 12 factors were realized in 2013. Evaluations were made on a five-level Likert scale (importance: 1 = unimportant, 2 = of little importance, 3 = moderately important, 4 = important, 5 = very important, and realization: 1 = very poor, 2 = poor, 3 = fair, 4 = good, 5 = very good).

The greatest gap between the realization and importance concerned site stoniness (gap: –1.15), removal of slash (gap: –0.85), and expertise of planting machine operators (gap: –0.70) (Fig. 3). These are the factors that respondents considered important but performance of the factors in 2013 was poor. The greatest positive gap concerned good logistics of seedling deliveries (gap: +0.45), clear responsibilities in the planting process (gap: +0.30), and route planning (gap: +0.30).

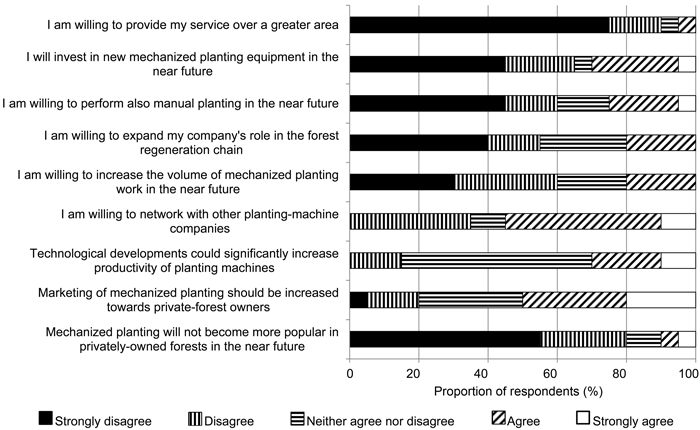

3.3 Future prospects

Many planting machine contractors were unwilling to increase the area over which they offered their planting service (90% disagreed or strongly disagreed with the statement), invest in new planting machines in the next few years (65% disagreed or strongly disagreed with the statement), or increase the volume of mechanized planting work in the near future (60% disagreed or strongly disagreed with the statement) (Fig. 4). Few businesses were willing to offer manual planting (60% disagreed or strongly disagreed with the statement), expand their role in the forest regeneration chain (55% disagreed or strongly disagreed with the statement), and the majority of businesses were unsure if productivity could be significantly increased by technological developments (55% neither disagreed nor agreed with the statement). However, many were willing to network with other planting machine contractors (55% agreed or strongly agreed with the statement), stated that mechanized planting will become more popular among NIP owned forests in the near future (80% agreed or strongly agreed with the statement), and 50% of the respondents agreed or strongly agreed with the statement that better marketing of mechanized planting would improve demand (Fig. 4).

Fig. 4. Response of respondents (n=20) to nine statements concerning the future of mechanized planting in Finland. Responses were made on a five-level Likert scale (importance: 1 = strongly disagree, 2 = disagree, 3 = neither agree nor disagree, 4 = agree, 5 = strongly agree).

Responses to the open questions can be categorized under the following four main development and rationalization topics: 1) education and marketing; 2) development of machines and maintenance of existing machinery; 3) the efficiency of and collaboration among the entire regeneration chain; and 4) selection of worksites. The contractors realize that informing NIP forest owners and forestry professionals about the benefits of mechanized planting (e.g., by organizing work demonstrations) will facilitate feedback and improve demand. Respondents suggested that developing existing devices and making them more reliable could also enhance productivity, and that the entire regeneration chain from nursery to outplanting could be better integrated. Worksite selection plays a critical role in efficiency of mechanized planting and selection should be considered more carefully.

Respondents explained that increasing the worksite area, making machine relocations more efficient, employing highly-skilled operators, and improving the care of seedlings during transport and temporary storage could increase the productivity of mechanized planting. Respondents also believed that NIP forest owners and local FOAs in particular represent an underdeveloped market for the mechanized tree-planting industry.

4 Discussion

The results of the study can be considered reliable in that only two of the 22 businesses active in 2013 did not fully participate in the survey. The pooled data set represents the entire population of planting machine businesses active in Finland. However, it remains possible that authors did not identify all businesses providing a mechanized planting service. The questionnaire was extensive and covered the main aspects of mechanized planting and respondents answered according to their knowledge. However, it should be kept in mind that responses were opinions based on the perspectives and perceptions of the respondents own business rather than an objective analysis of accurate data.

Tree-planting with excavator-based machines is more common in Finland than in other countries. In Sweden, the estimated number of planting machines is less than ten, and all of them are excavator boom-mounted Bracke devices (Ersson 2014). Most of the planted seedlings are Norway spruce planted on mesic and moist sites. Risutec Ltd. have designed a new planting device and Bracke has modified P11.a-planting device to plant hardwoods, such as eucalyptus, especially in plantations (Bracke 2016; Risutec 2016), but there are no available data concerning the use or performance of these machines. Data on the use of planting machines outside Finland are also unavailable, but there have been some trials in UK (Drake-Brockman 1998), Ireland (Nieuwenhuis and Egan 2002) and Latvia (Liepiņš et al. 2011). There could be potential for mechanized planting in other boreal countries such as Canada and Norway.

In 2003, there were 14 businesses operating with 16 planting machines: ten Bracke, two Ecoplanter, and four Lännen FP-160 planting devices (Vartiamäki 2003) (Table 3). These planting devices were attached to six harvesters, seven excavators and three forwarders. Even in 2013, Bracke remains the most popular planting device. The use of harvesters and forwarders has dwindled as excavators have become the preferred base machine. The main reason for this shift is that all planting machines in use today also carry out mounding (i.e., the Ecoplanter and Lännen planting devices do not mound), and an excavator boom is more suitable for digging than other forest machines (cf. Kärhä and Peltola 2004).

| Table 3. Comparison of the Finnish mechanized tree-planting industry in 2003 (Vartiamäki 2003) and 2013. | ||||

| Parameter | Unita) | 2003 | 2013 | Difference to 2003 (%) |

| Number of planting devices | pcs | 16 | 31 | 93.8 |

| Number of businesses | pcs | 14 | 22 | 57.1 |

| Planting machines per business | pcs | 1.14 | 1.41 | 23.7 |

| Number of planting devices | pcs | 16 | 31 | 93.8 |

| Bracke | 10 | 18 | 80.0 | |

| Lännen | 4 | 0 | - | |

| Ecoplanter | 2 | 0 | - | |

| M-Planter | 0 | 11 | - | |

| Risutec | 0 | 2 | - | |

| Amount of work | ha | 1420 | 2663 | 87.5 |

| Planted seedlings | million pcs | 2.5 | 4.7 | 88.0 |

| Relocation distance | km | 25b) | 22.2 | –11.2 |

| Working range | km | 100 | 62 | –38 |

| a) ha = hectares; km = kilometers; pcs = pieces b) 20–30 km in literature | ||||

There has been rather high variability among businesses, because less than a fifth of contractors provided a mechanized planting service ten years ago. However, during the past ten years, new contractors have entered the market. The average number of planting machines owned by a business has risen slightly in ten years (Table 3). There is no accurate information concerning the reasons that businesses ceased operating, but poor performance and low profitability are likely involved.

The planting area has almost doubled in 10 years: 1420 ha were planted mechanically on 2003 which accounted for 1.6% of all plantings, while in 2013 the equivalent numbers were 2663 ha and 3.5%, respectively. Most seedlings planted in 2003 were Norway spruce (80%), with the remaining 20% being Scots pine, similar to today. In 2003, some businesses also tried to plant birch (Vartiamäki 2003). In 2013, the area of artificial regeneration was unexpectedly low; only 98 000 ha (Juntunen and Herrala-Ylinen 2014). The area of forest regeneration was lower than this only during the 1950s and the early 1960s. In 2003, the area of artificial regeneration was approximately 119 000 ha (Västilä 2004). Since 2003, mounding has been become the most popular soil preparation method in Finland. In 2003, the share of mounding was 29.7% (35 249 ha) of all artificial regeneration, while in 2013 the same number was 66.6% (65 512 ha) (Västilä 2004; Juntunen and Herrala-Ylinen 2014). The increased use of mounding as a soil preparation method is reflected by today’s planting machines which use this method prior to planting.

Contractors suggested the most important CSFs affecting the productivity and cost-efficiency of mechanized planting were the expertise of planting machine operators, high quality planting, adequate amount of work for each planting machine, and harvesting slash from worksites. CSFs also include site stoniness and expertise of planting machine operator because these factors had the greatest gap between realization and importance, i.e., respondents considered them important but their performance in 2013 was poor. Site stoniness has been reported to significantly decrease the productivity of planting work whereas collecting slash has a lower effect on productivity (Rantala et al. 2009; Rantala and Laine 2010). Thus, worksite selection is an important factor. Expertise and skill of the planting machine operator is crucial, because without a proper operator the machine will remain idle and productivity can differ by up to 65% across operators (Laine and Rantala 2010). Operators already familiar with a base machine learned to use a planting device more rapidly. Consequently, proper training is important since it increases the likelihood that work is done cost-effectively and to a high standard. Also, experienced operators attain high productivity which can reduce the cost of mechanical planting to the extent that it is cheaper than manual techniques (Hallongren et al. 2014).

Based on our survey, some recommendations for improving mechanized planting work can be made. Firstly, improving the cost-efficiency of mechanized planting is necessary in order to enhance contractor’s profitability. One third of machines planted less than 60 ha yr–1, the overall average was less than 90 ha yr–1, and more than one third of machines were used for a single shift. Based on these findings, planting machines were clearly under-utilized in 2013 and this negatively affects their cost-efficiency. In order to be cost-effective, a Finnish planting machine’s annual planting capacity should be 130–150 ha. However, increasing the annual capacity might create some disadvantages in the form of greater relocation distances, poorer worksite conditions and difficulty finding competent operators. The cost-efficiency of mechanized planting can also be improved by developing new and existing machines in order to enhance productivity. It is expected that as technology improves, the role of the operator will become less important as robust machines carry out an increasingly automated processes.

A second recommendation would be that a careful appraisal of worksite suitability for mechanized planting is important because stoniness, stumps and slash debris significantly diminish productivity (Saarinen 2006; Rantala et al. 2009; Rantala and Laine 2010; Laine and Rantala 2013; Ersson 2014). Also, by avoiding small worksites and optimizing the number of and distance between machine relocations, mechanized planting can become more efficient (Rantala et al. 2009; Hallongren et al. 2014). Lastly, the popularity of mechanized planting will benefit from more marketing, particularly targeting NIP forest owners and forestry professionals. By making mechanized planting more common, it is possible to operate on smaller, more densely-distributed worksites that will improve productivity and profitability.

Our survey showed limited interest of current planting machine contractors in acquiring new machinery or offering planting services over a larger area. This apparent lack of interest is likely due to low profitability. However, most contractors believed that mechanized planting will become more popular in the future as the labour pool in silvicultural works shrinks, especially in privately-owned forests. There is a large potential to increase the mechanized planting industry in Finland, because almost all sites that are presently mounded by excavators and manually planted can also be regenerated mechanically. In 2013, 65 500 of the 107 000 ha of forested land prepared in Finland were mounded (Juntunen and Herrala-Ylinen 2014). As our survey results show, only 2663 ha was planted with machines, so their share could increase substantially. It has been estimated that the technological potential of mechanized planting could be about 90%, representing approximately 180 units that are employed at the current productivity level (Strandström et al. 2009). According to Rantala and Saarinen (2006), the demand for planting machines in Finland would be approximately 225 units on the assumption that 50% of regeneration sites > 0.75 ha are planted mechanically. Although the cost of mechanized planting remains higher than manual methods in Finland (Hallongren et al. 2014) and in Sweden (Ersson 2014), a demand for better and more uniform quality favours mechanized planting in both countries.

This study profiled the Finnish mechanized planting industry in 2013. Although the industry has not changed significantly in the ten-year period (2003–2013) between surveys, contactors expect machines to become more popular as commercial forestry enterprises require silviculture services at increasingly large scales. Growth of the industry will depend on improved cost-efficiency, appropriate worksites, marketing and co-operation among all members of the mechanized planting chain. There is also room for the development of existing as well as entirely-new planting machines in order to enhance productivity and decrease the industry’s dependency on highly-skilled operators.

Acknowledgement

Our analysis is based on the report published by Metsäteho. Authors of this article would like to thank co-authors: M.Sc. (Agr. & For.) Markus Strandström, Mr. Kyösti Sipilä, Professor Teijo Palander, and Business Development Manager Pekka T. Rajala. The original report “Koneellinen metsänistutus ja sen tehostaminen Suomessa” (Mechanized planting and improving its efficiency in Finland), Metsäteho Report 233, is available in Finnish at: http://www.metsateho.fi/wp-content/uploads/2015/02/Raportti_233_Koneellinen_metsanistutus_ja_sen_tehostaminen_kk_ym.pdf. Mr. Hynönen made his master thesis based on the data. The manuscript text was checked and edited by Dr. Michael Hardman of Lucidia Tieteellisten Julkaisujen Editointipalvelut (lucidia.fi).

References

Alatalo J., Räisänen H., Tuomaala M. (2011). Työvoimatilanne metsäalan ammateissa. [Labor force situation in forestry related occupations]. Ministry of Employment and the Economy, Analyses 30/2011. 59 p.

Bracke (2016). http://www.brackeforest.com/parser.php?did=344:3469. [Cited 13 Feb 2016].

Drake-Brockman GR. (1998). Evaluation of the Bracke Planter on UK restock sites. Dumfries, Technical Development Branch, Forestry Commission, Technical Note 7/98. 10 p.

Ersson B.T. (2010). Possible concepts for mechanized tree planting in southern Sweden – an introductory essay on forest technology. Sveriges lantbruksuniversitet, Institutionen för skoglig resurshushållning, Arbetsrapport 269. 51 p.

Ersson B.T. (2014). Concepts for mechanized tree planting in southern Sweden. Doctoral thesis. Swedish University of Agricultural Sciences, Acta Universitatis Agricultural Sueciae 2014:76. 78 p.

Ersson B.T., Petersson M. (2013). Återinventering av 2010 års maskinplanteringar – 3-års uppföljning. [Three-year follow-up of 2010’s mechanically planted seedlings]. Skoglig service, Södra Skog, Rapport S048. 5 p.

Hallonborg U., von Hofsten H., Mattsson S., Hagberg J., Thorsén Å., Nyström C., Arvidsson H. (1995). Maskinell plantering med Silva Nova: nuvarande status samt utvecklingsmöjligheter i jämförelse med manuell plantering [Mechanized planting with the Silva Nova tree planter – recent state and feasibility compared with manual planting]. Skogforsk, Redogörelse 6. 95 p.

Hallonborg U., von Hofsten H., Mattsson S., Thorsén Å. (1997). Planteringsmaskiner i skogsbruket – en beskrivning av metoder och maskiner. [Forestry planting machines – a description of the methods and the machines]. Skogforsk, Redogörelse 7. 24 p.

Hallongren H., Laine T., Juntunen M.-L. (2012). Metsänhoitotöiden koneellistamisesta ratkaisu metsuripulaan? [Is mechanization of silvicultural work a solution for labour shortage?]. Metsätieteen aikakauskirja 2/2012: 95–99.

Hallongren H., Laine T., Rantala J., Saarinen V.-M., Strandström M., Hämäläinen J., Poikela A. (2014). Competitiveness of mechanized tree planting in Finland. Scandinavian Journal of Forest Research 29(2): 144–151. http://dx.doi.org/10.1080/02827581.2014.881542.

Harstela P. (2006). Kustannustehokas metsänhoito. [Cost-efficient silviculture]. Gravita Ky. 126 p.

Juntunen M.-L., Herrala-Ylinen H. (2014). Metsänhoito. [Silviculture]. In: Peltola A. (ed.). Finnish statistical yearbook of forestry 2014. Finnish Forest Research Institute. p. 105–146.

Kaila S. (1984). G.A. Serlachius Oy:n istutuskone. [The G.A. Serlachius planting machine. Test report to the machine]. Metsäteho Review 9/1984. 6 p.

Kärhä K., Peltola J. (2004). Metsäkoneiden monikäyttöisyys. [Versatility of forest machines]. Metsäteho Report 181. 17 p.

Karppinen H., Hänninen H., Ripatti P. (2002). Suomalainen metsänomistaja 2000. [Finnish forest owner 2000]. Finnish Forest Research Institute, Research Papers 852. 83 p.

Laine T., Rantala J. (2013). Mechanized tree planting with an excavator-mounted M-Planter planting device. International Journal of Forest Engineering 24(3): 183–193. http://dx.doi.org/10.1080/14942119.2013.844884.

Liepiņš K., Lazdiņa D., Lazdiņš A. (2011). Productivity and cost-effectiveness of the M-Planter tree planting machine in Latvian conditions. Baltic Forestry 17(2): 308–313.

Luoranen J., Rikala R., Konttinen K., Smolander H. (2005). Extending the planting period of dormant and growing Norway spruce container seedlings to early summer. Silva Fennica 39(4): 481–496. http://dx.doi.org/10.14214/sf.361.

Luoranen J., Rikala R., Konttinen K., Smolander H. (2006). Summer planting of Picea abies container-grown seedlings: effects of planting date on survival, height growth and root egress. Forest Ecology and Management 237(1–3): 534–544. http://dx.doi.org/10.1016/j.foreco.2006.09.073.

Luoranen J., Rikala R., Smolander H. (2011). Machine planting of Norway spruce by Bracke and Ecoplanter: an evaluation of soil preparation, planting method and seedling performance. Silva Fennica 45(3): 341–357. http://dx.doi.org/10.14214/sf.107.

Nieuwenhuis M., Egan D. (2002). An evaluation and comparison of mechanised and manual tree planting on afforestation and reforestation sites in Ireland. International Journal of Forest Engineering 13(2): 11–23.

Rantala J., Laine T. (2010). Productivity of the M-Planter tree-planting device in practice. Silva Fennica 44(5): 859–869. http://dx.doi.org/10.14214/sf.125.

Rantala J., Saarinen V-M. (2006). Istutuskoneinvestointi alueyrittäjän näkökulmasta. [Economic evaluation of investing in tree-planting device – machine contractor’s viewpoint]. Metsätieteen aikakauskirja 3/2006: 343–352.

Rantala J., Harstela P., Saarinen V-M., Tervo L. (2009). A techno-economic evaluation of Bracke and M-planter tree planting devices. Silva Fennica 43(4): 659–667. http://dx.doi.org/10.14214/sf.186.

Risutec (2016). http://www.risutec.fi/en/products/hardwood. [Cited 6 Jan 2016].

Saarinen V.-M. (2006). The effects of slash and stump removal on productivity and quality of forest regeneration operations – preliminary results. Biomass & Bioenergy 30(4): 349–356. http://dx.doi.org/10.1016/j.biombioe.2005.07.014.

Strandström M., Hämäläinen J., Pajuoja H. (2009). Metsänhoidon koneellistaminen: visio ja T&K-ohjelma. [Mechanization of silviculture: vision and R&D-programme]. Metsäteho Report 206. 24 p.

Uotila E. (2005). Yksityismetsien hakkuuarvo ja metsänomistajien sijoitustuotto 1983–2003. [Stumpage price value and return on investment in private forests 1983–2003]. Metsätieteen aikakauskirja 1/2005: 57–65.

Vartiamäki T. (2003). Koneellinen metsänistutus vuonna 2003 – kyselytutkimuksen tulokset. [Mechanical planting in year 2003 – results of survey research]. Metsäteho Report 154. 14 p.

Västilä S. (2004). Metsien hoito. [Silviculture]. In: Peltola A. (ed.). Finnish statistical yearbook of forestry 2004. Finnish Forest Research Institute. p. 99–147.

von Hofsten H. (1993). Hög kvalitet även på högkvaliteten med Öje-Planter. [The Öje-Planter machine - good performance at a competitive cost]. Skogforsk, Resultat 3/1993. 4 p.

Total of 31 references.