The effect of forked trees on harvester time consumption in a Pinus contorta final-felling stand

Manner J., Lundström H. (2024). The effect of forked trees on harvester time consumption in a Pinus contorta final-felling stand. Silva Fennica vol. 58 no. 4 article id 24039. https://doi.org/10.14214/sf.24039

Highlights

- For forked trees, codominant stems double harvester time consumption per tree, while double crowns have only minor impacts on harvester time consumption

- Forked trees should be removed during thinning when they can still be time-efficiently multi-tree handled

- Dealing with forked trees at a later rotation age, when they are too large for multi-tree handling, becomes excessively time-consuming.

Abstract

The consensus on the factors affecting harvester productivity is generally widely acknowledged in the discipline. However, research results regarding the effect of forking on productivity are diverse. Some studies show that harvester productivity is halved when harvesting double stems compared to single-stem trees, while other studies indicate that forking does not necessarily decrease harvester productivity. These differences in study results can depend on what is considered forking. In our study, the forking occurred above the breast-height level. We defined codominant stems as forked trees too large to be multi-tree handled. In contrast, we defined double crowns as forked trees that could be multi-tree handled. The objective of our study was to analyse how the presence of codominant stems and/or double crowns affects harvester time consumption. The study was conducted in Sweden in 2022, involving two operators and two large harvesters. The 45-year-old Pinus contorta Douglas ex Loudon-dominated stand was clearcut during the study. We found that the presence of codominant stems doubles harvester time consumption per tree, while double crowns had only a minor impact on harvester time consumption. Additionally, total time consumption increased linearly with increasing diameter at breast height. Based on these findings, we recommend that forked trees be removed already during thinning when they can still be time-efficiently multi-tree handled. Dealing with forked trees later during the rotation cycle, when they are too large for multi-tree handling, is excessively time-consuming.

Keywords

productivity;

stem quality;

stem defect;

lodgepole pine;

cut-to-length logging;

double stem;

forking

-

Manner,

Skogforsk, Uppsala Science Park, 751 83 Uppsala, Sweden

https://orcid.org/0000-0002-4982-3855

E-mail

jussi.manner@skogforsk.se

https://orcid.org/0000-0002-4982-3855

E-mail

jussi.manner@skogforsk.se

- Lundström, Skogforsk, Uppsala Science Park, 751 83 Uppsala, Sweden E-mail hagos.lundstrom@skogforsk.se

Received 14 June 2024 Accepted 20 August 2024 Published 29 August 2024

Views 21337

Available at https://doi.org/10.14214/sf.24039 | Download PDF

Supplementary Files

1 Introduction

Harvester productivity increases rapidly with increasing stem volume until it starts to plateau after a certain saturation point (Nuutinen et al. 2010; Purfürst and Erler 2011; Visser and Spinelli 2012; Ramantswana et al. 2013; Manner et al. 2023; Pohjala et al. 2024). Although productivity is strongly related to stem volume, other influential factors also exist. Harvesting time consumption increases with the number of bucked logs per stem (Nuutinen et al. 2010; Suchomel et al. 2011; Strandgard and Mitchell 2017). Moreover, stem quality issues such as large branches, crooks, and decay negatively impact productivity (Suchomel et al. 2011; Labelle et al. 2016; Kärhä et al. 2019). Harvester productivity also varies between different tree species (Nuutinen et al. 2010; Labelle et al. 2019; Manner et al. 2023). However, some of these factors are likely to correlate with each other, such as stem properties and tree species. Despite these nuances, the consensus on the factors affecting harvester productivity is generally widely acknowledged within the discipline. That said, research results regarding the effect of forking on productivity are more diverse.

According to Acuna et al. (2017), forking explains 7% of the variation in productivity when harvesting a Eucalyptus globulus Labill. plantation. Moreover, Labelle et al. (2016) found that the presence of a fork can reduce harvesting productivity by 15–20% in a hardwood-dominated stand. According to Danilović et al. (2011), forked stems reduce harvester productivity by 30% when operating in a Populus euramericana (Dode) Guinier plantation. Ramantswana et al. (2013) found that harvester productivity is halved when harvesting coppiced double stems compared to planted single-stem trees in a Eucalyptus grandis W. Hill ex Maiden plantation.

In contrast, some studies indicate that forking does not necessarily decrease harvester productivity. For instance, Hartsough and Cooper (1999) found that the additional time spent dealing with forks is at most only a few seconds per tree when harvesting a short-rotation Eucalyptus viminalis Labill. plantation. Suchomel et al. (2011) found that the time consumption for harvesting a tree from a multiple-stem group was not significantly higher than harvesting a single tree during logging operations in a Quercus L. coppice stand. In the study by Suchomel et al. (2011), the operator grasped and felled each stem individually from the stools with multiple stems. However, such a working method requires that there is sufficiently space between the stems. That said, it is debatable whether such a case genuinely involves forking (i.e., double stems) or just two or more stems growing close to each other.

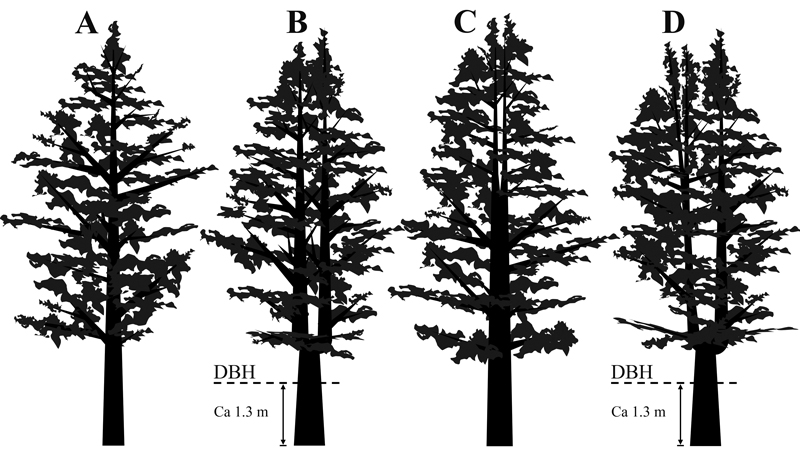

Thus, the differences in study results probably depend on how forking is defined. To clarify this, we define forking and related terminology based on the studies of Labelle et al. (2016) and Drénou et al. (2020). Hereafter, we use the term “codominant stems” to specifically describe situations where the involved tree section (i.e., double stems) is too large to be multi-tree handled. In contrast, we define forking as a “double crown” if the involved tree section can be multi-tree handled. Multi-tree handling means that more than one stem is delimbed, bucked, and measured at one time, thus treated as a single stem (Magagnotti et al. 2021). Moreover, either of the codominant stems can later split into a double crown, meaning a tree can have more than two crowns in total (Fig. 1). In our study, the forking occurred above breast height. Thus, for instance, coppicing per se does not meet this criterion.

Fig. 1. From left to right: (A) a defect-free tree with neither codominant stems nor a double crown; (B) a tree with codominant stems; (C) a tree with a double crown; (D) a codominant stem that has split into a double crown. Diameter at breast height (DBH) was measured by the harvester during the field study. Consequently, breast height is approximately 1.3 m above ground level. The forking always occurred above the breast-height level in our study.

The objective of our study was to analyse how the presence of codominant stems and/or double crowns affects harvester time consumption.

2 Material and methods

The field study was conducted in Hammarstrand, Jämtland County, northern Sweden, in the spring of 2022. The 45-year-old study stand was dominated by planted lodgepole pine (Pinus contorta Douglas ex Loudon). In addition to the lodgepole pine, there were small numbers of naturally regenerated Scots pines (Pinus sylvestris L.), birches (Betula spp.), and Norway spruces (Picea abies (L.) H. Karst.). The stand had been thinned once, and the number of trees per ha prior to the study was 825. The dominant height was approximately 22 m. The stand was clearcut during the study.

Participating operators were in their early 20s and 30s and had 1–2 years’ working-life experience on harvester work. Operators are hereafter referred to as operator A and B. Two large John Deere 1470G harvesters (operating mass: 24 tons) were used in the study. The machines were equipped with a rotating and levelling cabin and a CH9 crane (reach: 10 m). The older machine was equipped with an H415 harvester head, while the newer one had an H425. When using the newer machine, operators had a boom-tip control system (product name: IBC) activated at all times. The older machine had only a conventional crane-control system installed.

2.1 Recording work elements and stem defects

We divided harvester work into two work elements: crane-out and processing. Crane-out started simultaneously as the crown of the previously processed stem was dropped on the ground. Crane-out ended and processing started simultaneously as the harvester head was within ca 0.5 m of the next tree to be felled. And then again, processing ended simultaneously as crane-out started. Thus, roughly speaking, all work when the harvester head was holding a stem/log was included in the work element processing. While crane-out included driving events (i.e., machine re-positionings) and work when the harvester head was not holding any stem/log. Additionally, we summed crane-out and processing times to calculate the total time per tree.

We recorded potential stem defects, specifically the presence of codominant stems (yes or no) and/or double crowns (yes or no), to analyse their effect on time consumption. Time-consumption observations included only productive time, excluding all delays. Diameter at breast height (DBH) was recorded from the harvester’s onboard display. All other data, except descriptive statistics, were recorded manually using a handheld computer.

2.2 Descriptive statistics, study design and statistical analyses

We divided the study stand into four blocks. In block 1, operator A drove the old machine, while in block 2 he drove the new machine. In block 3, operator B drove the old machine, while in block 4 he drove the new machine. According to harvester measurements, the block-wise mean stem volumes were: 0.429 m3 (block 1), 0.351 m3 (block 2), 0.418 m3 (block 3), and 0.378 m3 (block 4). The total numbers of harvested trees from block 1 to block 4 were: 618, 435, 216, and 399. Because trees with codominant stems were lodgepole pines, we removed Scots pines, birches, and Norway spruces from the dataset. After the removal, the final dataset consisted of 1503 lodgepole pines, of which 339 trees had codominant stems and/or a double crown (Table 1). The unit of observation was a tree (i.e., stem).

| Table 1. Random effect (i.e., block) estimates (s tree–1) from the linear mixed model (LMM) analysis for the dependent variables. Diameter at breast height (DBH) is provided in cm. The number of trees (n) in the final dataset was 1503. All trees were lodgepole pines (Pinus contorta Douglas ex Loudon). | ||||||||

| Dependent variable | Mean DBH (a | n | ||||||

| Total time | Crane-out | Processing | ||||||

| Estimate | p-value | Estimate | p-value | Estimate | p-value | |||

| Block 1: operator A, old machine | 0.097 | 0.947 | 0.118 | 0.799 | –0.023 | 0.983 | 25.8 | 579 |

| Block 2: operator A, new machine | –3.269 | 0.026 | –1.239 | 0.008 | –1.971 | 0.071 | 23.0 | 391 |

| Block 3: operator B, old machine | 3.565 | 0.018 | 0.673 | 0.164 | 2.824 | 0.012 | 25.1 | 191 |

| Block 4: operator B, new machine | –0.393 | 0.790 | 0.448 | 0.340 | –0.830 | 0.449 | 23.6 | 342 |

| a) The dataset’s overall mean DBH was 24.5 cm. | ||||||||

During the study typically 2–3 trees were harvested in each machine position without needing to drive the machine, either forward or backward. Thus, roughly every other tree was randomly affected by a driving event, which took extra time that was not linked to the stem defects. Although driving might occur simultaneously with the work element crane-out, it is still likely to increase time consumption. The presence of a driving event was treated as a binary variable (levels: yes and no). Similarly, the presence of stem defects, specifically codominant stems and/or double crown, was treated as a binary variable.

We used a linear mixed model (LMM) to analyse the effect of factors on time consumption. The presence of stem defects and the occurrence of a driving event were entered as fixed effects, while block was included as a random effect. Additionally, DBH was included as a covariate in the LMM. All statistical analyses were conducted using SAS 9.4, with the significance level set at 5%.

3 Results

The presence of codominant stems increased the harvester time consumption by 31.31 s tree–1, rising from 28.5 to 59.8 s tree–1 at the study’s mean DBH (Tables 1 and 2). For trees with a double crown, the increase was 1.81 s tree–1, corresponding to an increase from 28.5 to 30.3 s tree–1. Thus, codominant stems resulted in a 110% increase in time consumption per tree, whereas a double crown resulted in a 6% increase.

| Table 2. Fixed effect estimates (s tree⁻¹) from the LMM analysis for the dependent variables. The machine was either repositioned during the crane-out work element or not (driving: yes/no). Driving and processing did not occur simultaneously. The covariate DBH should be provided in cm. | ||||||

| Dependent variable | Effect | Estimate | Standard error | t-value | p-value | |

| Total time | Intercept | 46.03 | 2.25 | 20.43 | <0.001 | |

| DBH | 0.80 | 0.05 | 17.46 | <0.001 | ||

| Codominant stems: | No | –31.31 | 0.96 | –32.47 | <0.001 | |

| Yes | 0 | |||||

| Double crown: | No | –1.81 | 0.58 | –3.14 | 0.002 | |

| Yes | 0 | |||||

| Driving: | No (a | –6.94 | 0.44 | –15.84 | <0.001 | |

| Yes | 0 | |||||

| Crane-out | Intercept | 13.43 | 0.87 | 15.52 | 0.001 | |

| DBH | 0.00 | 0.02 | 0.07 | 0.941 | ||

| Codominant stems: | No | –1.29 | 0.41 | –3.14 | 0.002 | |

| Yes | 0 | |||||

| Double crown: | No | 0.01 | 0.25 | 0.05 | 0.956 | |

| Yes | 0 | |||||

| Driving: | No (a | –6.80 | 0.19 | –36.40 | <0.001 | |

| Yes | 0 | |||||

| Processing | Intercept | 32.50 | 1.83 | 17.80 | <0.001 | |

| DBH | 0.80 | 0.04 | 20.21 | <0.001 | ||

| Codominant stems: | No | –30.03 | 0.83 | –36.08 | <0.001 | |

| Yes | 0 | |||||

| Double crown: | No | –1.83 | 0.50 | –3.67 | <0.001 | |

| Yes | 0 | |||||

| a) In the results section’s example calculations, we used estimates –6.94 × 0.564 and –6.80 × 0.564, where 0.564 was the probability of a tree being unaffected by a driving event during the field study. | ||||||

Codominant stems only marginally (1.29 s tree–1) increased the time consumption during the work element crane-out (Table 2). This increase corresponds to a 16% rise, from 8.3 to 9.6 s tree–1. The presence of a double crown did not significantly affect the time consumption during the work element crane-out (Table 2).

The presence of codominant stems increased the processing time by 30.03 s tree–1, from 20.1 to 50.2 s tree–1 at the study’s mean DBH (Tables 1 and 2). For trees with a double crown, the increase was 1.83 s tree–1, corresponding to an increase from 20.1 to 22.0 s tree–1. Consequently, the presence of codominant stems increased the processing time per tree by 149%, while a double crown increased it by 9.1%.

Thus, most of the increase in total time consumption caused by stem defects occurred during processing. Additionally, total time consumption and processing time increased linearly with increasing DBH (Table 2). Given that the increase (s tree–1) caused by stem defects is constant, the relative impact of stem defects on time consumption decreases with increasing DBH. In contrast, DBH did not significantly affect the work element crane-out (Table 2).

4 Discussion

Lodgepole pine has been a relatively common and economically meaningful tree species in Sweden for decades (Hagner 1983; Elfving et al. 2001; Backlund 2013). However, studies on harvester time consumption in lodgepole pine stands in Sweden are scarce. According to a follow-up study by Eriksson and Lindroos (2014), harvester productivity during thinning operations decreases when harvesting lodgepole pine stands. It is unknown whether this decrease is due to stem defects or other factors. The stands included in the study by Eriksson and Lindroos (2014) were in the same region of Sweden as our study stand.

There are Nordic studies on the impact of stem defects on harvester time consumption, but current studies specifically addressing forked trees are from North America, Africa, and southern and central Europe (see Introduction). Due to significant differences in regional conditions and practices, the results of these studies should be applied to the Nordic context with caution. Nonetheless, the results of our study are very similar, for instance, to those of Ramantswana et al. (2013) from South African plantation logging operations.

To align with current literature, we considered a forked tree as a single tree, which was also the unit of observation in our study. Furthermore, we modelled time consumption based on DBH, a relatively common approach in the discipline (Nakagawa et al. 2007; Labelle et al. 2018; Ackerman et al. 2022). Although the objective was solely to determine the extra time required by stem defects, the lack of stem volumes and hence the inability to model productivity is a limitation of our study. Therefore, in future studies, replacing DBH with volume should be considered. That said, defining volume is not a straightforward process. The harvester does not record the volume of the stem’s first section unless the minimum log length is reached. Consequently, the stem’s physical volume and its merchantable (i.e., measured) volume might differ notably and randomly, complicating productivity comparisons. In contrast, DBH is measured consistently regardless of the possible presence of stem defects (Fig. 1). This consistency is a strength of the methodology we employed in our study.

Statistically significant differences were observed between the blocks (Table 1). In blocks 2 and 4, where the newer machine equipped with IBC was used, time consumption was generally lower than in blocks 1 and 3, where the older machine was used. Moreover, operator A (blocks 1 and 2) consumed slightly less time than his colleague (blocks 3 and 4). Although absolute time consumption varied between the operators, the relative effect of stem defects on harvester time consumption remained consistent. For instance, codominant stems require, regardless of the operator’s skill level, that each stem is separately reached, grasped, felled, and bucked into logs. This finding provides sufficient grounds to generalize the main conclusion of our study: the presence of codominant stems doubles the harvester time consumption per tree.

To summarize, we suggest that forked trees be removed during thinning when they can still be time-efficiently multi-tree handled. Dealing with forked trees later during the rotation cycle, when they are too large for multi-tree handling, becomes excessively time-consuming. Additionally, significant roundwood volume, i.e., the stem’s thickest section, goes to waste if the butt log does not meet the minimum length requirements. Our suggestion is also justified from a silvicultural perspective. Removing trees with stem defects creates space for high-quality stems to grow and produce valuable sawlogs. The remaining trees can efficiently adjust to improved water supply, nutrition, and light conditions, even though quality-weighted tree selection can occasionally lead to slightly uneven spatial distributions (Bowering et al. 2006; Wallentin and Nilsson 2011; Stempski et al. 2021).

Declaration of openness of research materials, data, and code

Dataset and SAS codes used for analysing the data can be found at: https://doi.org/10.5281/zenodo.13333123.

Authors’ contributions

Hagos Lundström initiated the study and collected the data. Jussi Manner analysed the data and wrote the manuscript. Both authors revised the final manuscript.

Funding

This study was financed by Skogforsk.

Acknowledgements

We thank the participating harvester operators and other staff at the Swedish forest company SCA. In addition, we acknowledge Back Tomas Ersson (SLU) for his assistance in revising the English.

References

Ackerman SA, Talbot B, Astrup R (2022) The effect of tree and harvester size on productivity and harvester investment decisions. Int J For Eng 33: 22–32. https://doi.org/10.1080/14942119.2021.1981046.

Acuna M, Strandgard M, Wiedemann J, Mitchell R (2017) Impacts of early thinning of a Eucalyptus globulus Labill. pulplog plantation in Western Australia on economic profitability and harvester productivity. Forests 8, article id 415. https://doi.org/10.3390/f8110415.

Backlund I (2013) Cost-effective cultivation of lodgepole pine for biorefinery applications. Acta Univ Agric Suec 81. ISBN 978-91-576-7900-0.

Bowering M, LeMay V, Marshall P (2006) Effects of forest roads on the growth of adjacent lodgepole pine trees. Can J For Res 36: 919–929. https://doi.org/10.1139/x05-300.

Danilović M, Tomašević I, Gačić D (2011) Efficiency of John Deere 1470D ECOIII harvester in poplar plantations. Croat J For Eng 32: 533–548.

Drénou C, Restrepo D, Slater D (2020) Demystifying tree forks: vices and virtues of forks in arboriculture. J Bot Res 3: 100–113. https://doi.org/10.36959/771/566.

Elfving B, Ericsson T, Rosvall O (2001) The introduction of lodgepole pine for wood production in Sweden – a review. Forest Ecol Manag 141: 15–29. https://doi.org/10.1016/S0378-1127(00)00485-0.

Eriksson M, Lindroos O (2014) Productivity of harvesters and forwarders in CTL operations in northern Sweden based on large follow-up datasets. Int J For Eng 25: 179–200. https://doi.org/10.1080/14942119.2014.974309.

Hagner S (1983) Pinus contorta: Sweden’s third conifer. Forest Ecol Manag 6: 185–199. https://doi.org/10.1016/S0378-1127(83)80002-4.

Hartsough BR, Cooper DJ (1999) Cut-to-length harvesting of short-rotation Eucalyptus. Forest Prod J 49: 69–75.

Kärhä K, Räsänen M, Palander T (2019) The profitability of cross-cutting practices in butt-rotten Picea abies final-felling stands. Forests 10, article id 874. https://doi.org/10.3390/f10100874.

Labelle ER, Soucy M, Cyr A, Pelletier G (2016) Effect of tree form on the productivity of a cut-to-length harvester in a hardwood dominated stand. Croat J For Eng 37: 175–183.

Labelle ER, Breinig L, Sycheva E (2018) Exploring the use of harvesters in large-diameter hardwood-dominated stands. Forests 9, article id 424. https://doi.org/10.3390/f9070424.

Labelle ER, Windisch J, Gloning P (2019) Productivity of a single-grip harvester in a beech dominated stand: a case-study under Bavarian conditions. J For Res-JPN 24: 100–106. https://doi.org/10.1080/13416979.2019.1566995.

Magagnotti N, Spinelli R, Kärhä K, Mederski PS (2021) Multi-tree cut-to-length harvesting of short-rotation poplar plantations. Eur J Forest Res 140: 345–354. https://doi.org/10.1007/s10342-020-01335-y.

Manner J, Karlsen T, Ersson BT (2023) A pilot study of continuous cover forestry in boreal forests: decreasing the harvest intensity during selection cutting increases piece size, which in turn increases harvester productivity. J For Sci 69: 172–177. https://doi.org/10.17221/22/2023-JFS.

Nakagawa M, Hamatsu J, Saitou T, Ishida H (2007) Effect of tree size on productivity and time required for work elements in selective thinning by a harvester. Int J For Eng 18: 24–28. https://doi.org/10.1080/14942119.2007.10702547.

Nuutinen Y, Väätäinen K, Asikainen A, Prinz R, Heinonen J (2010) Operational efficiency and damage to sawlogs by feed rollers of the harvester head. Silva Fenn 44, article id 165. https://doi.org/10.14214/sf.165.

Pohjala J, Vahtila M, Ovaskainen H, Kankare V, Hyyppä J, Kärhä K (2024) Effect of prior tree marking on cutting productivity and harvesting quality. Croat J For Eng 45: 25–42. https://doi.org/10.5552/crojfe.2024.2213.

Purfürst FT, Erler J (2011) The human influence on productivity in harvester operations. Int J For Eng 22: 15–22. https://doi.org/10.1080/14942119.2011.10702606.

Ramantswana M, McEwan A, Steenkamp J (2013) A comparison between excavator-based harvester productivity in coppiced and planted Eucalyptus grandis compartments in KwaZulu-Natal, South Africa. South For 75: 239–246. https://doi.org/10.2989/20702620.2013.858213.

Stempski W, Jabłoński K, Jakubowski J (2021) Effects of strip roads in a pine tree stand (Pinus sylvestris L.) on the diameter growth and pith eccentricity of trees growing along them. Forests 12, article id 1414. https://doi.org/10.3390/f12101414.

Strandgard M, Mitchell R (2017) Impact of number of stems per stool on mechanical harvesting of a Eucalyptus globulus coppiced plantation in south-west Western Australia. South Forests 80: 137–142. https://doi.org/10.2989/20702620.2017.1292448.

Suchomel C, Becker G, Pyttel P (2011) Fully mechanized harvesting in aged oak coppice stands. Forest Prod J 61: 290–296.

Visser R, Spinelli R (2012) Determining the shape of the productivity function for mechanized felling and felling-processing. J For Res 17: 397–402. https://doi.org/10.1007/s10310-011-0313-2.

Wallentin C, Nilsson U (2011) Initial effect of thinning on stand gross stem-volume production in a 33-year-old Norway spruce (Picea abies (L.) Karst.) stand in southern Sweden. Scand J Forest Res 26: 21–35. https://doi.org/10.1080/02827581.2011.564395.

Total of 26 references.