The effect of feedstock, knife wear and work station on the exposure to noise and vibrations in wood chipping operations

Anton P., Spinelli R., Magagnotti N., Mihelic M. (2018). The effect of feedstock, knife wear and work station on the exposure to noise and vibrations in wood chipping operations. Silva Fennica vol. 52 no. 1 article id 7003. https://doi.org/10.14214/sf.7003

Highlights

- Exposure to noise and vibration is higher when chipping branches rather than logs

- Noise levels are higher in the separate cab, especially at some frequencies

- Vibration is higher for the Z axis in the separate cab, for the X axis in the truck

- Noise is higher when working with blunt knives, rather than new knives

- Knife wear has no significant effect on exposure to whole-body vibration.

Abstract

Industrial chipping is becoming increasingly popular, as the result of a growing demand for woody biomass. Industrial chippers are large, powerful machines that generate much noise and vibration. This study explored some factors that may affect exposure to noise and vibration, namely: feedstock type (branches vs. logs), work station characteristics (truck cab vs. separate cab) and knife wear (new knives vs. blunt knives). Exposure to noise was significantly affected by all three factors, and it was higher for branch feedstock, separate cabs and blunt knives. The higher exposure levels recorded for the separate cab were especially insidious, because they were below and above the hearing threshold and would elude immediate perception. Exposure to whole-body vibration (WBV) was significantly higher for branch feedstock and for the separate cab. Knife wear seemed to determine an increase in WBV, but this effect had no statistical significance and the result could not be taken as conclusive. Among the three factors studied, work station characteristics had the strongest effect. Further studies may extend the comparison to a wider range of options, as well as explore the use of exposure variation for machine diagnostics.

Keywords

biomass;

fuelwood;

ergonomics;

safety

- Anton, University of Ljubljana, Dept. of Forestry and Renewable Resources, Večna pot 83, 1000 Ljubljana, Slovenia E-mail anton.poje@bf.uni-lj.si

-

Spinelli,

CNR IVALSA, Via Madonna del Piano 10, I-50019 Sesto Fiorentino, Italy; AFORA, University of the Sunshine Coast, Locked Bag 4, Maroochydore DC, Queensland, 4558 Australia

http://orcid.org/0000-0001-9545-1004

E-mail

spinelli@ivalsa.cnr.it

http://orcid.org/0000-0001-9545-1004

E-mail

spinelli@ivalsa.cnr.it

- Magagnotti, CNR IVALSA, Via Madonna del Piano 10, I-50019 Sesto Fiorentino, Italy; AFORA, University of the Sunshine Coast, Locked Bag 4, Maroochydore DC, Queensland, 4558 Australia E-mail magagnotti@ivalsa.cnr.it

- Mihelic, University of Ljubljana, Dept. of Forestry and Renewable Resources, Večna pot 83, 1000 Ljubljana, Slovenia E-mail matevz.mihelic@bf.uni-lj.si

Received 18 March 2017 Accepted 9 January 2018 Published 10 January 2018

Views 90325

Available at https://doi.org/10.14214/sf.7003 | Download PDF

1 Introduction

Wood chipping is an essential element of all forest-to-energy chains, which have become extremely popular across the European Union as a results of the Union’s strong commitment to develop the renewable energy sector (Stupak et al. 2007). The increasing demand for fuel chips has resulted in a rapid development of industrial chipping operations, based on powerful chippers in order to obtain large daily outputs (Spinelli and Magagnotti 2014a). These machines have already raised some concern for the exposure of operators to wood dust (Magagnotti et al. 2013) and noxious chemical compounds (Magagnotti et al. 2014), due to their large outputs and engines. For the same reasons, one may suspect that exposure to noise and vibration is also significant, and recent studies confirm such concerns (Rottensteiner et al. 2013; Nuutinen et al. 2014). While they agree on high exposure levels, these studies often disagree about whether these levels exceed legal limits or not (Poje et al. 2015). In fact, the exact exposure levels are likely to depend on a number of factors, and especially the characteristics of the chipped material (Suchomel et al. 2011) and of the work station (Brueck 2008). Since small differences will cause exposure to exceed legal limits, it is crucial to develop a better understanding of the main influencing factors, which can be manipulated in order to guarantee compliance with present regulations.

Feedstock and work station have just been mentioned as important influencing factors, and therefore it may be worth exploring the effect of the main existing alternatives currently faced by chipper operators, so that they can ponder the pros and cons of different strategies. Concerning feedstock, the two extremes are logs and branches. Productivity, fuel use and product quality are significantly different depending on whether logs or branches are being chipped, and one may assume that differences may also be encountered for what concerns exposure to noise and vibration (Spinelli et al. 2011). As to work station, industrial chippers come in many different configurations, but the most popular machines are currently truck-mounted chippers (Kärhä 2011). These machines offer two options for the work station: in a separate cab mounted on the loader, or in the truck’s own cab, after minor modifications. The former option is more common, as it enables a better visibility of the work area; the latter is less widespread but is becoming increasingly popular, because it allows for a lighter and smaller machine (Spinelli et al. 2015).

Finally, a further factor that may affect exposure to noise and vibration is knife wear. As they process the wood, chipper knives lose their sharpness, which decreases productivity and fuel efficiency (Facello et al. 2013). Knives are changed after producing variable amounts of chips, depending on wood species and contamination levels (Spinelli and Magagnotti 2014b). There are no fixed schedules for knife replacement, contrary to motor oil or other wear parts. Operators replace worn knives based on their subjective perception of performance decay, and many claim that they can “hear” when the knives need replacement, because the machine “sounds” differently (Spinelli and Hartsough 2001). That obviously hints at an effect on noise exposure, and makes knife wear a factor worth including in this study.

Therefore, the goals of this study were to determine if and how much exposure to noise and vibration during chipping work was affected by: 1) feedstock type (i.e. logs vs. branches), 2) position of the operator cab (i.e. separate cab on the loader vs. truck’s own cab and 3) knife wear (i.e. new knives vs. blunt knives).

2 Materials and methods

The study consisted of three separate trials, one for each of the questions asked in the study goals (Table 1).

| Table 1. Experiment description. | |||

| Test # | 1 | 2 | 3 |

| Effect probed | Feedstock | Work station | Knife wear |

| Place name | Cuneo | Envie | Envie |

| Machine 1 | PTH 1200/820 | PTH 1200/820 | - |

| Machine 2 | - | PTH 800/820 | PTH 800/820 |

| Cab machine A | Truck | Truck | - |

| Cab Machine B | - | Separate | Separate |

| Feedstock A | Chestnut logs | Chestnut logs | Chestnut logs |

| Feedstock B | Poplar branches | - | - |

| Knife conditions A | New | New | New |

| Knife conditions B | - | - | Blunt |

| Repetitions factor A | 9 | 9 | 8 |

| Repetitions factor B | 13 | 8 | 8 |

| The letters A and B refer to the two factors compared in any of the three paired Experiments, i.e. Cab A (truck) vs. Cab B (separate); Feedstock A (chestnut logs) vs. Feedstock B (poplar branches); Knife conditions A (new) vs. Knife condition B (blunt); Marked in bold are the individual factors represented in each column (e.g. Test #1: Effect probed = Feedstock; Feedstock A = Chestnut logs, Feedstock B = Poplar branches; Repetitions for Factor A = 9, for factor B = 13) | |||

The effect of feedstock type was tested at a log yard in Cuneo (north-western Italy), using two different raw material types: branches with a maximum end diameter of 10 cm, and 2-m long logs with a diameter between 10 and 30 cm. Branch material consisted of hybrid poplar (Populus × euramericana Guinier), whereas log material consisted of chestnut (Castanea sativa L.). The moisture content of the selected feedstock types was not measured, but it was estimated at 40% (wet basis) from previous experience of the same materials and work sites (Spinelli et al. 2013a). The basic density of sweet chestnut and poplar was estimated at 550 kg m–3 and 400 kg m–3, respectively (Giordano 1983). These raw materials were chosen because they were widely available in the area and represented the main feedstock used for chip production. Both materials were chipped with the same machine: a 382 kW Pezzolato PTH 1200/820 drum chipper, in the chipper truck configuration. The machine was equipped with new knives before starting the trial. Materials were alternated at random during the chipping trial.

The effect of workstation was gauged through a second comparative trial conducted at a log yard in Envie (north-western Italy), using different chippers: the same Pezzolato PTH 1200/820 used in the previous test and a truck-mounted 316 kW Pezzolato PTH 800/820. Both machines featured 6-cylinder engines and two-bladed 820 mm diameter drums, but the PTH 1200/820 was equipped with a stronger engine and with a wider drum than the PTH 800/820. Most importantly, the operator of the PTH 1200/820 operated the loader from inside the truck cab, whereas the operator of the PTH 800/820 sat in a separate cab installed on the loader column. Both machines were fed with the same feedstock: fresh chestnut (C. sativa) logs, with a length of 2 m, a diameter between 10 and 30 cm and a moisture content around 40% (wet basis). Both machines were equipped with new knives before starting the trial.

The effect of blade wear was also tested at the same log yard in Envie, using the same chestnut log feedstock and the same Pezzolato PTH 800/820 chipper used before, alternatively equipped with a set of new knives and a set of blunt (worn out) knives.

Overall, the trials lasted 27 hours, including actual measurements, preparation for the measurements and moving between test sites.

Both machines used for the test were factory-made, type-approved and in good shape. The year of manufacture was 2010 for both of them, so that they were 5 years old at the time of testing. Both machines were fitted with the same chip discharge system, and namely: a mechanical blower that pushed chips through a curved spout with an adjustable directional flap on its tip.

Two operators were involved with the study, one per machine type. Both were informed about the methods and the purpose of the experiment, and gave their written consent to participate. The operators were experienced professionals, with good knowledge of chipping techniques and technology. As to anthropometrics, both operators were mesomorphic adult males, with an age between 30 and 40 years. All these characteristics can be taken as representative of the Italian logging workforce (Spinelli et al. 2013b).

Exposure to noise and whole body vibration (WBV) was recorded during chipping time only, because: 1) this is the activity that generates the highest noise and vibration levels and 2) feedstock and knife wear exert their effect when the machine is actually chipping, and not during other activities (i.e. manoeuvring, parking, downtime etc.).

Noise levels were measured with a Brüel & Kjær model 2250 sound level meter, equipped with a 4189 model microphone. This was mounted inside the cab, on the left side of the windshield and at the same level as the operator’s head. The distance from the operator’s head was about 50 cm and was the same for both machine types. The exponential time weighting was set to fast and the recording interval to 1 second. Therefore, every second the instrument acquired the following records: equivalent continuous A-weighted sound pressure level (LAeq); maximum value of the C-weighted instantaneous sound pressure (LpCpeak); full sound frequency spectrum in 1/3 octave bands (LAeq), as suggested by Goelzer et al. (2001). The sound meter was verified with a Brüel & Kjær model 4231 acoustic calibrator before and after the measurements.

Whole body vibration levels were measured with a Brüel & Kjær model 4447 human vibration analyzer, equipped with a 4524 model accelerometer installed in a model 4515B rubber seat pad. The accelerometer recorded root-mean-squares (RMS) and vibration dose values (VDV) in the three directions (X, Y and Z), as well as the vibration total value (VTV). Data were recorded at 1 s intervals. Vibration dose values were referred to an 8-working hours day, to allow comparison with current action values (i.e. the legal limits beyond which corrective action must be taken).

Exposure to noise and vibration was evaluated according to current ISO standards (ISO 2009; ISO 1997). The observational unit corresponded to a 5 minutes uninterrupted record, containing 300 single data points for each of the measured parameters (i.e. LAeq; LpCpeak; RMS X,Y and Z; RMS VTV; VDV X, Y and Z; VDV VTV). Each record covered the processing of about 10 grapple loads, and therefore the cyclic nature of the operation was well represented within each individual record.

Preliminary statistical analysis included: descriptive statistics; distribution tests (Kolmogorov-Smirnov and Shapiro-Wilks); homogeneity of variance test (Levene’s test). Depending on data distribution and variance characteristics, the equality of means was tested with a classic one-way ANOVA or with the Welch test. Post-hoc tests were conducted with either Tukey’s HSD or Tamhane’s T2 techniques. All statistical analyses were conducted with the IBM SPSS 21 software package. The elected significance level was α < 0.05.

3 Results

3.1 Feedstock effect

Noise exposure (LAeq) was higher when chipping branches than when chipping logs. The difference was small – 0.19 dB(A) – but was highly significant. In contrast, no significant difference was detected for peak sound pressure, which was the same regardless of feedstock type (Table 2). The action value set by the European Union for LAeq noise exposure was 80 dB(A) and it was exceeded under both treatments (European Union 2003). In contrast, the 135 dB(C) action value set by the same directive for peak pressure was never exceeded.

| Table 2. Comparison between feedstock types (i.e. logs vs. branches). | ||||||||||

| Exposure parameters | Unit | Action value | Log (n = 9) | Branch (n = 13) | Analysis of variance (ANOVA) | |||||

| Mean | SD | Mean | SD | df1 | df2 | F | p-value | |||

| Noise | ||||||||||

| LAeq | dB(A) | 80 | 81.51 | 0.12 | 81.70 | 0.15 | 1 | 20 | 10.986 | 0.003** |

| LpCpeak | dB(C) | 135 | 109.07 | 0.79 | 109.05 | 0.54 | 1 | 20 | 0.005 | 0.942 |

| Whole-body vibration | ||||||||||

| RMSX | m s–2 | 0.50 | 0.31 | 0.03 | 0.29 | 0.04 | 1 | 20 | 0.362 | 0.554 |

| RMSY | m s–2 | 0.50 | 0.18 | 0.01 | 0.18 | 0.02 | 1 | 20 | 0.13 | 0.722 |

| RMSZ | m s–2 | 0.50 | 0.19 | 0.01 | 0.18 | 0.01 | 1 | 20 | 8.795 | 0.008** |

| RMSVTV | m s–2 | 0.50 | 0.40 | 0.04 | 0.39 | 0.06 | 1 | 20 | 0.337 | 0.568 |

| VDVX | m s–1.75 | 9.1 | 6.22 | 0.66 | 6.13 | 1.20 | 1 | 20 | 0.018 | 0.896 |

| VDVY | m s–1.75 | 9.1 | 3.43 | 0.13 | 3.81 | 0.89 | 1 | 20 | 0.781 | 0.387 |

| VDVZ | m s–1.75 | 9.1 | 3.38 | 0.20 | 3.19 | 0.19 | 1 | 20 | 5.228 | 0.033* |

| VDVVTV | m s–1.75 | 9.1 | 7.99 | 0.83 | 8.04 | 1.94 | 1 | 20 | 0.006 | 0.941 |

| LAeq = A-weighted equivalent continuous sound pressure level in dB(A); LCpeak = C-weighted peak sound pressure level in dB(C); SD = Standard Deviation; df = Degrees of freedom; RMSX,Y,Z = Root mean squared amplitude of the vibration in the X, Y, Z direction; VTV = Vibration total value; VDV X,Y,Z = Vibration dose value in the X,Y,Z direction, VDVVTV = Vibration dose value, total (X, Y and Z directions); * = significant; ** = highly significant | ||||||||||

Vibration levels (RMS and VDV) were highest in the X direction. Both RMS and VDV exposure levels were significantly higher for the log treatment in the Z direction only. In no case vibration levels exceeded the action values set by EU (European Union 2002).

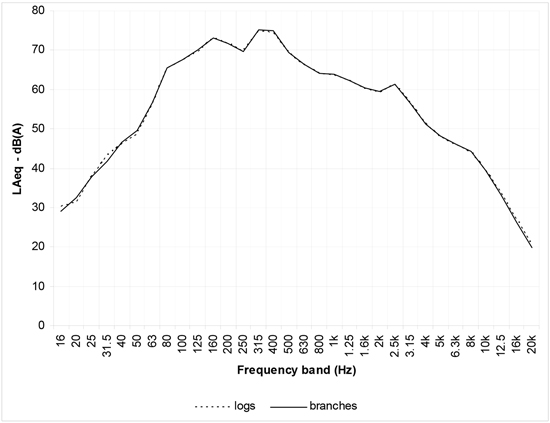

Spectral analysis of the noise records clearly showed the fundamental frequency levels generated by the rotation of the drum (50 rad s–1) and the engine (167 rad s–1). These corresponded to the peaks recorded at 16 Hz, 80 Hz and their multiples (Fig. 1). The shape of noise frequency spectra recorded when chipping log and branch feedstock were almost identical. However, the noise recorded during branch chipping was up to 0.9 dB(A) higher than the noise recorded during log chipping. That was true across the whole spectrum, except for very high (10–20 kHz) and very low (16Hz and 31.5 Hz) frequency bands. Differences between treatments were evident for the following bands: 16, 20, 31.5, 63, 100, 125, 400, 630 and 1600 Hz. Noise was higher at the 16 and 31.5 Hz bands for log chipping, and at the other bands for branch chipping.

Fig. 1. Noise frequency spectrum: logs vs. branches.

3.2 Work station effect

Both LAeq noise exposure and peak pressure were higher in the separate cab (PTH 800/820) than in the truck cab (PTH 1200/820). However, differences were only significant for peak pressure, not for LAeq noise exposure. Again, action values were exceeded for LAeq noise exposure but not for peak pressure, regardless of work station (Table 3).

| Table 3. Comparison between work stations (i.e. truck cab vs. separate cab). | ||||||||||

| Exposure parameters | Unit | Action value | Truck cab (n = 9) | Separate cab (n = 8) | Analysis of variance (WELCH) | |||||

| Mean | SD | Mean | SD | df1 | df2 | F | p-value | |||

| Noise | ||||||||||

| LAeq | dB(A) | 80 | 81.51 | 0.12 | 81.94 | 0.73 | 1 | 7.309 | 2.700 | 0.143 |

| LpCpeak | dB(C) | 135 | 109.07 | 0.79 | 122.79 | 0.81 | 1 | 14.651 | 1250.086 | 0.000** |

| Whole-body vibration | ||||||||||

| RMSX | m s–2 | 0.50 | 0.31 | 0.03 | 0.59 | 0.07 | 1 | 9.199 | 68.289 | 0.000** |

| RMSY | m s–2 | 0.50 | 0.18 | 0.01 | 0.59 | 0.08 | 1 | 7.091 | 111.925 | 0.000** |

| RMSZ | m s–2 | 0.50 | 0.19 | 0.01 | 0.65 | 0.08 | 1 | 7.198 | 249.636 | 0.000** |

| RMSVTV | m s–2 | 0.50 | 0.40 | 0.04 | 1.06 | 0.13 | 1 | 7.879 | 181.013 | 0.000** |

| VDVX | m s–1.75 | 9.1 | 6.22 | 0.66 | 12.89 | 1.73 | 1 | 8.802 | 53.684 | 0.000** |

| VDVY | m s–1.75 | 9.1 | 3.43 | 0.13 | 13.76 | 2.15 | 1 | 7.045 | 94.122 | 0.000** |

| VDVZ | m s–1.75 | 9.1 | 3.38 | 0.20 | 15.85 | 2.30 | 1 | 7.095 | 233.411 | 0.000** |

| VDVVTV | m s–1.75 | 9.1 | 7.99 | 0.83 | 25.26 | 3.67 | 1 | 7.641 | 169.558 | 0.000** |

| LAeq = A-weighted equivalent continuous sound pressure level in dB(A); LCpeak = C-weighted peak sound pressure level in dB(C); SD = Standard Deviation; df = Degrees of freedom; RMSX,Y,Z = Root mean squared amplitude of the vibration in the X, Y, Z direction; VTV = Vibration total value; VDV X,Y,Z = Vibration dose value in the X,Y,Z direction, VDVVTV = Vibration dose value, total (X, Y and Z directions) ; * = significant; ** = highly significant | ||||||||||

Whole body vibration levels were much higher (2–3 times) for the separate cab, compared with the truck cab. All differences were statistically significant. Vibration levels were highest in the Z direction for the separate cab, and in the X direction for the truck cab. Action values were exceeded in the separate cab, but not in the truck cab.

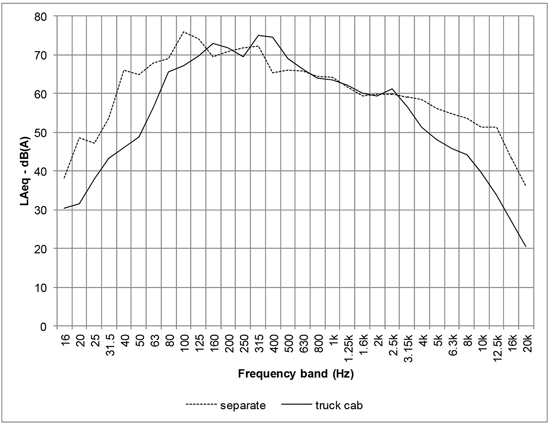

Spectral analysis showed that the noise level differences were highest in the frequency bands below 200 Hz and above 3.15 kHz (Fig. 2). Differences were smallest between 630 Hz and 2 kHz. At 2 kHz the differences between treatments were minor, contrary to the differences recorded for all other frequency bands. The highest noise levels were reached at 100 Hz in the separate cab, and at 315 Hz in the truck cab.

Fig. 2. Noise frequency spectrum: separate cab vs. truck cab.

3.3 Knife wear effect

As an average, both LAeq noise exposure and peak pressure were lower (1.06 dB(A) and 1.60 dB(C), respectively) for the new knife treatment, compared with the blunt knife treatment (Table 4). As before, action values were exceeded for LAeq noise exposure but not for peak pressure, regardless of treatment.

| Table 4. Comparison between knife conditions (i.e. new vs. blunt). | ||||||||||

| Exposure parameters | Unit | Action value | New (n = 8) | Blunt (n = 8) | Analysis of variance (ANOVA) | |||||

| Mean | SD | Mean | SD | df1 | df2 | F | p-value | |||

| Noise | ||||||||||

| LAeq | dB(A) | 80 | 81.94 | 0.73 | 83.00 | 0.42 | 1 | 14 | 17.168 | 0.001** |

| LpCpeak | dB(C) | 135 | 122.79 | 0.81 | 124.39 | 2.09 | 1 | 14 | 7.993 | 0.013* |

| Whole-body vibration | ||||||||||

| RMSX | m s–2 | 0.50 | 0.59 | 0.07 | 0.65 | 0.05 | 1 | 14 | 2.281 | 0.153 |

| RMSY | m s–2 | 0.50 | 0.59 | 0.08 | 0.62 | 0.07 | 1 | 14 | 0.413 | 0.531 |

| RMSZ | m s–2 | 0.50 | 0.65 | 0.08 | 0.68 | 0.08 | 1 | 14 | 1.937 | 0.186 |

| RMSVTV | m s–2 | 0.50 | 1.06 | 0.13 | 1.17 | 0.10 | 1 | 14 | 1.913 | 0.188 |

| VDVX | m s–1.75 | 9.1 | 12.89 | 1.73 | 14.28 | 1.74 | 1 | 14 | 1.704 | 0.213 |

| VDVY | m s–1.75 | 9.1 | 13.76 | 2.15 | 14.67 | 1.99 | 1 | 14 | 0.388 | 0.543 |

| VDVZ | m s–1.75 | 9.1 | 15.85 | 2.30 | 16.47 | 2.76 | 1 | 14 | 1.902 | 0.189 |

| VDVVTV | m s–1.75 | 9.1 | 25.26 | 3.67 | 28.57 | 3.19 | 1 | 14 | 2.551 | 0.133 |

| LAeq = A-weighted equivalent continuous sound pressure level in dB(A); LpCpeak = C-weighted peak sound pressure level in dB(C); SD = Standard Deviation; df = Degrees of freedom; RMSX,Y,Z = Root mean squared amplitude of the vibration in the X, Y, Z direction; VTV = Vibration total value; VDV X,Y,Z = Vibration dose value in the X,Y,Z direction, VDVVTV = Vibration dose value, total (X, Y and Z directions) ; * = significant; ** = highly significant | ||||||||||

Whole body vibration levels were 4–13% higher for the blunt knife treatment, but differences were deprived of statistical significance. Vibration levels were highest in the Z direction for both treatments, which was likely related to the position of the cab (on the loader column). Action values were exceeded in all direction and treatment combinations, for all calculation methods (RMS and VDV).

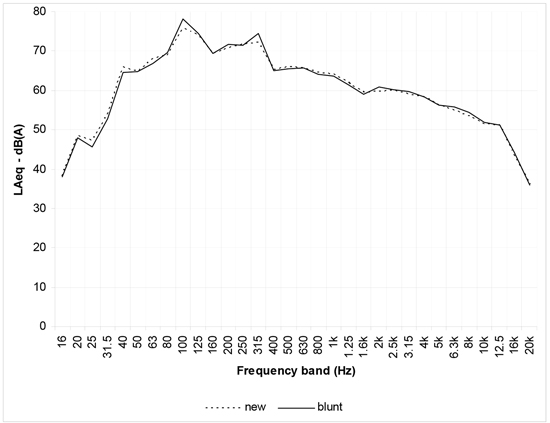

Spectral analysis showed four clear peaks at 20, 40, 100 and 315 Hz, which corresponded to the fundamental frequencies generated by the drum and the engine (Fig. 3). The drum produced the first two peaks as it rotated at 62 rad s–1, whereas the engine produced the third and fourth peaks as it ran at 209 rad s–1. Noise levels were higher for the blunt knife treatment at the 100, 125, 200, 315 Hz and the 10 and 16 kHz bands. In contrast, they were lower for this treatment at the 800 and 1000 Hz bands. Differences were highest (2.3 and 2.2 dB(A)) at the 100 and 315 Hz bands.

Fig. 3. Noise frequency spectrum: new knives vs. blunt knives.

4 Discussion

First of all, it is important to stress that the figures reported in this study refer to pure chipping time only. That represents a highly variable proportion of the work day, estimated between 13% (Mihelic et al. 2015) and 77% (Magagnotti et al. 2016). Daily exposure must account for other work tasks, which normally generate lower emission levels compared with chipping proper (Poje et al. 2015). As a result, actual daily exposure is likely lower than reported here for chipping alone, and that must be considered when matching recorded values with legal limits. The fact that legal limits were exceeded for chipping does not imply that operators would be exposed to excessive noise and vibration levels along an actual working day, due to the effect of the considerable proportion of worksite time spent in other activities than chipping. There are at least three good reasons why our study focused on chipping time. First, chipping is the task generating the highest emission levels, and therefore it is the strongest functional contributor to daily exposure (Rottensteiner et al. 2013). Second, at least two of the factors explored in this study (i.e. feedstock type and knife wear) exert their effect during chipping, only. Third, the proportion of chipping time over a given period is highly variable, which would blur any comparisons conducted using total worksite time as the reference. Since it was impossible to contain such variability, it was decided to isolate chipping time, and work on that alone. Therefore, the LAeq figures estimated in this study are theoretical values used to compare different chipping conditions, rather than to estimate actual risk. In any case, noise is recognized as a psychophysical stressor capable of affecting human health at lower levels than 85 dB(A). Compliance with existing standards does not automatically exclude extra-aural effects (Babisch 2004), and therefore one should implement all available strategies to reduce noise exposure, even when exposure levels are below current legal limits. The knowledge produced in this study may contribute to a further reduction of noise exposure, which may minimize the risk of extra-aural health effects (Bilski 2013).

An additional general remark concerns the experimental environment. The tests were conducted under real work conditions, not under standardized ones. Therefore, one could not exclude the effect of reflection or moderate background noise. However, these are common conditions for chipping operations, often deployed in constrained space settings (Spinelli et al. 2015). In any case, the comparisons were conducted under even conditions for all treatment pairs on test, and they remain valid.

4.1 Feedstock effect

The higher noise exposure recorded for branches is counterintuitive, as one may expect that impact against harder logs would generate higher noise levels. That is actually the case, because noise is higher for the log treatment at 16 and 31 Hz, which are the frequency bands generated by drum rotation. However, standard measurements integrate noise pressure along the whole process, and log chipping incurs more interruptions than branch chipping. These interruptions are mostly micro-stops derived from the activation of the no-stress device – a system that interrupts wood feeding when the rotational speed of the engine falls below a certain threshold, in order to avoid stalling the engine. Feeding is then resumed when the engine regains its target speed. Logs are harder and larger than branches, and they put a heavier strain on the engine, which results in the no-stress engaging more often (Spinelli et al. 2016). Eventually, micro-stops add up and the time when log chipping generates higher noise levels is offset by the time when the drum is turning idle and the machine generates lower noise levels. Therefore, the effect of feedstock type is dependent on no-stress setting, which is normally adjusted by the operator in order to achieve productivity targets. Different settings may produce different results, and further studies should explore the potential of machine tuning, as well as the effect of other species than poplar and chestnut.

4.2 Work station effect

The two machines on test were not exactly the same. The Pezzolato PTH 800/820 (separate cab) had a shorter drum and a weaker engine, compared with the Pezzolato PTH 1200/820 (truck cab). For this reason, the PTH 800/820 ran its engine and drum at a higher speed than the PTH 1200/800, which explains the higher fundamental frequency bands. However, the PTH 1200/820 had higher overall power, which was expected to generate higher energy and pressure levels. Therefore, any base machine bias would have dampened the differences recorded in the experiment, not magnified them. That also excludes that the differences reported in this study are due to the base machine and not to the work station. At worst, use of different base machines may have blurred our results, but it certainly did not cause them.

The two work stations present similar noise exposures in the frequency bands to which humans are most sensitive (Scharf 2010), and the higher exposure recorded for the separate cab only occurs at very low or very high frequency bands. For this reason, operators may not immediately perceive the difference between the two options. However, exposure to sound below the hearing threshold may cause nervousness and weariness (Leventhall 2003), whereas exposure to ultrasonic sound may cause headache, tinnitus, fatigue and nausea (Lawton 2001; Smagowska and Pawlaczyk-Łuszczyńska 2013). That makes the additional risk incurred with the separate cab especially insidious, and gives special value to the experiment that disclosed it.

The effect of different work stations is also visible in the dominance of different vibration axes. With the separate cab, vibration was highest along the Z axis because the cab was mounted on a stilt and it was one with the loader column. That made it less stable, and prone to bounce up and down as the loader picked up its loads and dropped them on the chipper feeding table. On the other hand, being placed on the fulcrum of the loader, the separate cab suffered less from the momentum the loader generated along the X and Y axes. In contrast, the truck cab was located on the machine nose, at a considerable distance from the loader column. That would magnify any oscillations generated by loader work along the X axis, which is consistent with the vibration records. In fact, the operator lodged in the truck cab did make some remarks about the unusual rocking motion, which he did not experience when he was working in a separate cab. These different vibration dynamics may confirm that different exposure levels are an inherent characteristic of the two work station alternatives, disclosing a general trend that is independent from individual makes and models.

In any case, previous studies conducted on other equipment types confirm that exposure to vibration is strongly affected by the position and the characteristics of both cab (Tiemessen et al. 2007) and seat (Patil and Palanichamy 1985).

In that regard, it is important to mention a third work station option. Separate cab and truck cab are the main options if the work station is installed on the chipper itself, but one may also operate the chipper from a detached work station. This might be a self-propelled loader, a forestry-fitted farm-tractor or a modified excavator, parked alongside the chipper. Operators claim that such option offers many benefits, and it would be more widespread if it did not make relocation more expensive (Spinelli and Hartsough 2001). Operators on a detached machine would certainly avoid the vibration caused by the chipper, although they would still be exposed to its noise. Further research may address this third option, and explore its possible variations (i.e. different machine types, different positions with regard to the chipper etc.).

4.3 Knife wear effect

The study indicates that knife wear has a significant effect on noise exposure, but this effect is weak and secondary to the effects of feedstock type and work station. For this reason, knife wear effects might be a minor concern in terms of operator health. On the other hand, noise variations are significant and they might be exploited for preventive diagnostic, possibly after selecting proper frequency bands (Vardhan and Adhikari 2006). If one might associate progressive variation of noise levels in certain frequency bands to advancing knife wear, one could install cheap noise sensors to inform the operator when it is time to change knives. In current practice, operators replace knives when the chipper cannot perform any longer – that is, when productivity losses are high enough to be clearly visible and product quality is clearly degraded (Spinelli et al. 2014). By then, the point of minimum cost has been exceeded. It would be far more efficient to change knives early on, before the incremental chipping cost derived from knife wear offsets the savings accrued from extended knife service. Unfortunately knife wear is erratic, and one cannot developed reliable schedules for knife replacement. What is needed is an early warning system, informing the operator that wear is reaching the critical level. Variations in noise levels might provide such indicator, and their potential should be explored in further studies.

5 Conclusions

Exposure to noise and vibration in chipping operation is significantly affected by work station, feedstock type and knife wear. The latter has a secondary effect, but it remains a factor, nonetheless. Furthermore, knife wear and work station can be manipulated better than feedstock type, unless one decided to turn down those jobs offering less attractive feedstock types. Industrial chipping contractors aim at maximizing machine utilization, and are unlikely to renounce specific jobs just for their effect on exposure levels. In contrast, one can easily improve knife replacement schedules and work station characteristics. Different noise and vibration levels associated with different configurations may affect operator preference when deciding between alternative products. Therefore, the results of this study might be of significant interest to machine manufacturers, when planning their product strategies. Future studies should address the effect of other feedstock and work station options that could not be included in this experiment, as well as the effect of other additional factors, such as chip discharge system (i.e. blower or conveyor), moisture content and density of the wood being chipped, and position of the engine within the machine structure.

Acknowledgments

The research leading to these results has received support from the Regione Piemonte within the scope of project MCV2, and was funded with EU structural funds (PSR 2007–2013, Misura 124.2). The Authors wish to tank Sergio Cottura (Mombracco Energy Srl) and Daniele Bertoglio (Pezzolato SpA) for their assistance with the trials.

References

Babisch W. (2004). Health aspects of extra-aural noise research. Noise Health 22: 69–81.

Bilski B. (2013). Exposure to audible and infrasonic noise by modern agricultural tractors operators. Applied Ergonomics 44(2): 210–214. https://doi.org/10.1016/j.apergo.2012.07.002.

Brueck L. (2008). Noise emissions and exposure from mobile woodchippers. Health and Safety Executive. Research Report RR618. Norwich, UK. 54 p.

European Union (2002). Directive 2002/44/EC of the European Parliament and of the Council of 25 June 2002 on the minimum health and safety requirements regarding the exposure of workers to the risks arising from physical agents (vibration) (sixteenth individual Directive within the meaning of Article 16(1) of Directive 89/391/EEC. Official Journal of the European Communities L 177. p. 13–19.

European Union (2003). Directive 2003/10/EC of the European Parliament and of the Council of 6 February 2003 on the minimum health and safety requirements regarding the exposure of workers to the risks arising from physical agents (noise) (seventeenth individual Directive of Directive within the meaning of Article 16(1) of Directive 89/391/EEC. Official Journal of the European Communities L 42. p. 38–44.

Facello A., Cavallo E., Magagnotti N., Paletto G., Spinelli R. (2013). The effect of knife wear on chip quality and processing cost of chestnut and locust fuel wood. Biomass and Bioenergy 59: 468–476. https://doi.org/10.1016/j.biombioe.2013.07.012.

Giordano G. (1983). Tecnologia del Legno. [Wood Technology]. Ed. III, Vol. II. UTET, Turin, Italy. 1618 p.

Goelzer B., Hansen H., Sehrndt G. (2001). Occupational exposure to noise: evaluation, prevention and control. World Health Organization, Dortmund, Germany. 336 p.

ISO 2631-1 (2007). Mechanical vibration and shock – evaluation of human exposure to whole-body vibration – part 1: general requirements. International Organization for Standardization, Geneva. 31 p.

ISO 9612 (2009). Acoustics – determination of occupational noise exposure – engineering method. International Organization for Standardization, Geneva. 51 p.

Kärhä K. (2011). Industrial supply chains and production machinery of forest chips in Finland. Biomass and Bioenergy 35(8): 3404–3413. https://doi.org/10.1016/j.biombioe.2010.11.016.

Lawton B.W. (2001). Damage to human hearing by airborne sound of very high frequency or ultrasonic frequency. Health and Safety Executive, Sudbury, UK. 86 p.

Leventhall G. (2003). A review of published research on low frequency noise and its effects. Department for Environment, Food and Rural Affairs, London, UK. 89 p.

Magagnotti N., Nannicini C., Sciarra G., Spinelli R., Volpi D. (2013). Determining the exposure of chipper operators to inhalable wood dust. Annals of Occupational Hygiene 57: 784–792.

Magagnotti N., Picchi G., Sciarra G., Spinelli R. (2014). Exposure of mobile chipper operators to diesel exhaust. Annals of Occupational Hygiene 58: 217–226.

Magagnotti N., Spinelli R., De Francesco F., Lombardini C. (2016). A versatile terrain and roadside chipper for energy wood production in plantation forestry. Baltic Forestry 22: 107–115.

Mihelic M., Spinelli R., Magagnotti N., Poje A. (2015). Performance of a new industrial chipper for rural contractors. Biomass and Bioenergy 83: 152–158. https://doi.org/10.1016/j.biombioe.2015.09.010.

Nuutinen Y., Laitila J., Rytkönen E. (2014). Grinding of stumps, logging residues and small diameter wood using a CBI 5800 grinder with a truck as a base machine. Baltic Forestry 20: 176–188.

Patil M.K., Palanichamy M.S. (1985). Minimization of human body responses to low frequency vibration: application to tractors and trucks. Mathematical Modelling 6(5): 421–442. https://doi.org/10.1016/0270-0255(85)90063-6.

Poje A., Spinelli R., Magagnotti N., Mihelic M. (2015). Exposure to noise in wood chipping operations under the conditions of agro-forestry. International Journal of Industrial Ergonomics 50: 151–157. https://doi.org/10.1016/j.ergon.2015.08.006.

Rottensteiner C., Tsioras P., Neumayer H., Stampfer K. (2013). Vibration and noise assessment of tractor-trailer and truck-mounted chippers. Silva Fennica 47(5) article 984. https://doi.org/10.14214/sf.984.

Scharf B. (2010). Loudness. In: Crocker M.J. (ed.). Handbook of acoustics. Wiley, New York. p. 1181–1195.

Smagowska B., Pawlaczyk-Łuszczyńska M. (2013). Effects of ultrasonic noise on the human body: a bibliographic review. International Journal of Occupational Safety and Ergonomics 19(2): 195–202. https://doi.org/10.1080/10803548.2013.11076978.

Spinelli R., Hartsough B. (2001). A survey of Italian chipping operations. Biomass and Bioenergy 21(6): 433–444. https://doi.org/10.1016/S0961-9534(01)00050-2.

Spinelli R., Magagnotti N. (2014a). Determining long-term chipper usage, productivity and fuel consumption. Biomass and Bioenergy 66: 442–449. https://doi.org/10.1016/j.biombioe.2014.04.016.

Spinelli R., Magagnotti N. (2014b). Using disposable chipper knives to decrease wood fuel processing cost. Fuel Processing Technology 126: 415–419. https://doi.org/10.1016/j.fuproc.2014.05.026.

Spinelli R., Magagnotti N., Paletto G., Preti C. (2011). Determining the impact of some wood characteristics on the performance of a mobile chipper. Silva Fennica 45(1): 85–95. https://doi.org/10.14214/sf.33.

Spinelli R., Cavallo E., Eliasson L., Facello A. (2013a). Comparing the efficiency of drum and disc chippers. Silva Fennica 47(2) article 930. https://doi.org/10.14214/sf.930.

Spinelli R., Magagnotti N., Facchinetti D. (2013b). A survey of logging enterprises in the Italian Alps: firm size and type, annual production, total workforce and machine fleet. International Journal of Forest Engineering 24(2): 109–120. https://doi.org/10.1080/14942119.2013.838376.

Spinelli R., Glushkov S., Markov I. (2014). Managing chipper knife wear to increase chip quality and reduce chipping cost. Biomass and Bioenergy 62: 117–122. https://doi.org/10.1016/j.biombioe.2014.01.007.

Spinelli R., De Francesco F., Eliasson L., Jessup E., Magagnotti N. (2015). An agile chipper truck for space-constrained operations. Biomass and Bioenergy 81: 137–143. https://doi.org/10.1016/j.biombioe.2015.06.017.

Spinelli R., Eliasson L., Magagnotti N. (2016). Increasing wood fuel processing efficiency by fine-tuning chipper settings. Fuel Processing Technology 151: 126–130. https://doi.org/10.1016/j.fuproc.2016.05.026.

Stupak A., Asikainen A., Jonsel M., Karltun E., Lunnan A., Mizaraitė D., Pasanen K., Pärn H., Raulund-Rasmussen K., Röser D., Schroeder M., Varnagirytė I., Vilkriste L., Callesen I., Clarke N., Gaitnieks T., Ingerslev M., Mandre M., Ozolincius R., Saarsalmi A., Armolaitis K., Helmisaari H.-S., Indriksons A., Kairiukstis L., Katzensteiner K., Kukkola M., Ots K., Ravn H.P., Tamminen P. (2007). Sustainable utilisation of forest biomass for energy – possibilities and problems: policy, legislation, certification, and recommendations and guidelines in the Nordic, Baltic, and other European countries. Biomass and Bioenergy 31: 666–684. https://doi.org/10.1016/j.biombioe.2007.06.012.

Suchomel J., Belanova K., Vlckova M. (2011). Evaluation of vibration in the chipping process. Commission on Agricultural, Forestry and Veterinary Sciences, Polish Academy of Arts and Sciences, Warsaw, Poland. Report 15. 10 p.

Tiemessen I.J., Hulshof C.T., Frings-Dresen M.H. (2007). An overview of strategies to reduce whole-body vibration exposure on drivers: a systematic review. International Journal of Industrial Ergonomics 37(3): 245–256. https://doi.org/10.1016/j.ergon.2006.10.021.

Vardhan H., Adhikari G.R. (2006). Development of noise spectrum based maintenance guideline for reduction of heavy earth moving machinery noise. Noise Control Engineering Journal 54(4): 236–244. https://doi.org/10.3397/1.2219894.

Total of 36 references.