The effect of mechanization level and harvesting system on the thinning cost of Mediterranean softwood plantations

Spinelli R., Lombardini C., Magagnotti N. (2014). The effect of mechanization level and harvesting system on the thinning cost of Mediterranean softwood plantations. Silva Fennica vol. 48 no. 1 article id 1003. https://doi.org/10.14214/sf.1003

Highlights

- Whole-tree harvesting is 40–50% cheaper than cut-to-length harvesting

- Mechanization reduced thinning cost by a factor 4

- Between 1.5 and 6% of the residual trees were damaged

- Mechanized cut-to-length harvesting allows controlled biomass release

- Mechanized whole-tree harvesting is the cheapest option for energy chip production.

Abstract

The study compared motor-manual cut-to-length (CTL) harvesting, motor-manual whole-tree (WT) harvesting, mechanized CTL harvesting and mechanized WT harvesting as applied to the production of energy chips from the second thinning of Mediterranean pine plantations in flat terrain. Mechanization increased productivity between 6 and 20 times, depending on process step. It also allowed reducing thinning cost by a factor 4. Shifting from CTL to WT harvesting resulted in a reduction of harvesting cost between 40 and 50%. Fuel consumption was between 40 and 100% higher for CTL harvesting than for WT harvesting. Mechanization entailed a reduction of fuel consumption between 10 and 40%. Stand damage was generally low, between 1.5 and 6%. Mechanized CTL harvesting resulted in the lowest incidence of wounding, and the difference between mechanized CTL and manual WT harvesting was statistically significant. Soil compaction was absent or very small, depending on treatment. Mechanized thinning may produce larger increases of soil bulk density, compared to motor-manual thinning, but the difference is small, although significant. CTL harvesting leaves a larger amount of biomass on the soil, which relieves possible concerns about soil nutrient depletion. On the other hand, heavy residue loads may increase fire risk especially in sensitive Mediterranean environments.

Keywords

chipping;

biomass;

logging;

compaction;

stand damage

-

Spinelli,

CNR IVALSA,Via Madonna del Piano 10, Sesto Fiorentino (FI), Italy

E-mail

spinelli@ivalsa.cnr.it

- Lombardini, CNR IVALSA,Via Madonna del Piano 10, Sesto Fiorentino (FI), Italy E-mail lombardini@ivalsa.cnr.it

- Magagnotti, CNR IVALSA,Via Biasi 75, S. Michele all’Adige (TN), Italy E-mail magagnotti@ivalsa.cnr.it

Received 21 September 2013 Accepted 20 January 2014 Published 13 February 2014

Views 188446

Available at https://doi.org/10.14214/sf.1003 | Download PDF

1 Introduction

The need for mobilizing increasingly large amounts of energy biomass has revived interest for thinning operations, which cannot offer conventional assortments at competitive cost (Kärhä et al. 2003). In fact, small trees from thinning operations represent an abundant resource (Kinoshita et al. 2009; Malinen et al. 2001), which can be profitably tapped to supplement other biomass streams and prevent harmful competition between new forest energy users and the traditional consumers of wood fibre (Lundmark 2006).

Among the many harvesting systems applied to thinning operations, the most popular are whole-tree (WT) and cut-to-length (CTL) harvesting. Whole-tree harvesting consists of felling trees and extracting them whole (stem, top and branches) to the landing, where they are eventually processed into commercial assortments (Stokes et al. 1989). This system offers the advantage of simplified in-forest handling. First documented in the US (Kammenga 1983), the application of WT harvesting in thinning operations is often associated to whole-tree chipping, and its basic set-up has proven so effective to remain virtually unchanged and appreciated until our days (Mitchell and Gallagher 2007). CTL harvesting in thinning favours a more articulated product strategy, leading to increased value recovery (Harstela 1999). By producing logs directly at the stump site, CTL facilitates wood extraction, potentially decreasing stand damage (Han and Kellogg 2000). What is more, in-stand tree processing results in lower organic matter removals, compared to WT harvesting. That is especially desirable on poorer sites, where organic fertility may represent a serious issue (Jacobson et al. 2000; Smolander et al. 2010). Processing at the stump site allows removing branches and needles, which detract from chip quality. As a result, biomass recovery is lower than for WT harvesting, but product quality is better, which may be rewarded with a higher price (Spinelli and Magagnotti 2010).

Both WT and CTL harvesting can be deployed with different levels of mechanization. In the motor-manual version, trees are felled or felled and processed with chainsaws, and the product is extracted with skidders, forwarders or forestry fitted farm tractors (Kellogg et al. 1993). Motor-manual harvesting is especially suited to self-employed forest owners and small contractors, with limited investment capacity (Lindroos et al. 2005). At the other end of the scale, mechanized WT harvesting is applied with feller-bunchers and grapple skidders, while mechanized CTL harvesting with harvesters and forwarders. The intersection of systems and mechanization levels results in four possible combinations, as follows: motor-manual WT, motor-manual CTL, mechanized WT and mechanized CTL. In all cases, extracted biomass can be chipped at the landing site with a mobile in-woods chipper.

The goal of this study was to compare these four systems in terms of: 1) productivity; 2) production cost; 3) site impact and 4) residue biomass loads. To our knowledge, no other studies have yet produced such a comprehensive comparison, and especially not in the Mediterranean region, which is characterized by dry climate and mineral soils. In particular, Mediterranean softwoods present a heavy branching, which makes harvesting system especially relevant to soil fertility and fire hazard.

2 Materials

A comparative trial was carried out in a pine plantation located near Pisa, Italy, inside the Regional Park of San Rossore, which encloses a surface of about 3000 ha and is covered for a large part by pine.

Trials were conducted in the second thinning of a 15-hectare tract, consisting of a 21-year-old umbrella pine (Pinus pinea L.) plantation, originally planted in rows with 2.5 x 2.5 m spacing. The first thinning was conducted 10 years earlier and removed alternate rows, so that current spacing at the time of second thinning was 5 x 2.5 m. Pine plantations are very common along the Tuscan coastline, where they have been established and managed for many centuries (Barbero et al. 1998). The mainstream silvicultural prescription is clear-cutting, followed by replanting or by re-naturalization, if the quality of the hardwood understory is good (Zerbe 2002). Two to four thinnings are performed before the final cut. In the experiment, the local forester marked the trees to be preserved as the final crop (candidate trees) and prescribed the removal of any other trees potentially interfering with their future development (Carrasquinho et al. 2010). Selection of removal trees was left to the logger, whose main task was to create enough space around candidate trees. Soil was a loamy sand, developed over a quaternary dune just few kilometres from the present coastline. Site and thinning characteristics are reported in Table 1.

| Table 1. Description of the test site. | |||||

| Placename | San Rossore | ||||

| Northing | 43°41’33.08ˮN | ||||

| Easting | 10°18’30.44ˮE | ||||

| Slope | % | 2 | |||

| Species | Pinus pinea L. | ||||

| Age | years | 21 | |||

| DBH | cm | 23.1 | |||

| Height | m | 10.7 | |||

| Operation | 2nd thinning | ||||

| Criteria | Selection of candidates | ||||

| Removal | % trees | 35–40 | |||

| Mechanization | level | Manual | Mechanized | ||

| System | type | WT | CTL | WT | CTL |

| Removal | trees ha–1 | 251a | 244a | 221a | 251a |

| Removal | t ha–1 | 51a | 29.6b | 53.9a | 33.5b |

| Tree size | kg tree–1 | 203a | 122b | 244a | 133b |

| Wood moisture content | % | 45.8a | 47.3a | 48.2a | 43.5a |

| Notes: Different letters in superscript indicate that the differences between the mean values presented on the same row are statistically significant at the 5% level according to Scheffe’s multiple comparison test; DBH = diameter at breast height; WT = whole-tree harvesting; CTL = cut-to-length harvesting; Tree size = the mass of the mean tree as it is extracted, i.e with top and branches for WT and without top and branches for CTL. | |||||

In the motor-manual treatments, trees were felled with two chainsaws (Husqvarna 357XP, 3.2 kW) by two professional operators and skidded to the roadside landing with a forestry-fitted farm tractor (Valtra 6400, 75 kW), equipped with a forestry winch (Fig. 1a). When motor-manual CTL was applied, trees were also delimbed and crosscut into random lengths (4 to 7 m) before skidding, by the same crew and using exactly the same equipment. Minimum top diameter was 3 cm: tops and branches were left inside the plantation. In the mechanized WT harvesting treatment, pine trees were felled and bunched with a 27-t tracked feller buncher (JD759 J, 164 kW) and skidded to the roadside with a rubber-tired grapple skidder (JD460 G, 127 kW). The two machines are shown in Figs. 1b and 1c. Finally, in the mechanized CTL harvesting treatment, trees were felled, delimbed and crosscut to random lengths (4 to 7 m) with a 14-t four-wheel harvester (JD870 B,114 kW), while logs were extracted to roadside with a 10-t capacity forwarder (JD1110 B, 121 kW) (Fig. 1d and 1e). Again, minimum top diameter was 3 cm: tops and branches were left in the forest. None of the extraction machines used tyre chains or bogie tracks. In all cases, whole trees and logs were chipped at the roadside landing with a forwarder-mounted drum chipper (Erjo 12/90), powered by a 370 kW independent engine (Fig. 1f). The technical characteristic of all machines (except for the chainsaws) are presented in Table 2. All teams in each system worked independently, which avoided interaction delays. System balance issues were solved by adjusting the hours spent on site by each team. Chipping was performed about four months after harvesting and extraction, and chips were discharged directly into chip vans. Due to logistical reasons, the four treatments were applied at different times, often with several months passing between individual tests. Overall, felling and extraction were performed between February and July 2012, whereas chipping was conducted in October of the same year.

Fig. 1. Farm tractor (a); Feller-buncher (b); Skidder (c); Harvester (d); Forwarder (e); Chipper (f).

| Table 2. Technical charecteristics of the machines in the test. | |||||||

| System | WT | WT | CTL | CTL | WT/CTL | WT/CTL | |

| Mechanization | level | Mechanized | Mechanized | Mechanized | Mechanized | Motor-manual | Both |

| Machine | type | Feller-buncher | Skidder | Harvester | Forwarder | Tractor | Chipper |

| Make | John Deere | John Deere | John Deere | John Deere | Valtra | Erjo | |

| Model | 759J | 460D | 870B | 1110B | 6400 | 12/90 | |

| Power | kW | 164 | 127 | 114 | 121 | 75 | 370/129 |

| Weight | t | 27770 | 12770 | 13800 | 13670 | 4170 | 30350 |

| Width | mm | 3050 | 2880 | 2510 | 2710 | 2340 | 2890 |

| Length | mm | 4410 | 7345 | 5435 | 10310 | 4440 | 10400 |

| Clearance | mm | 759 | 598 | 570 | 605 | 435 | 600 |

| Head make | John Deere | - | John Deere | - | - | - | |

| Head model | FR21B | - | 746C | - | - | - | |

| Cut capacity | mm | 508 | - | 500 | - | - | - |

| Notes: Chainsaws are not included in the table; Chipper size data refer to the complete forwarder-mounted unit; Chipper power figures are provided for both the chipper engine and the forwarder engine, in this order; WT = whole-tree harvesting, CTL = cut-to-length harvesting. | |||||||

All machines were operated by experienced professionals, who had run them for at least 5 years. No attempt was made to normalize individual performances by means of productivity ratings (Scott 1973), recognizing that all kinds of normalization or corrections can introduce new sources of errors and uncontrolled variation in the data material (Gullberg 1995). On the other hand, the skills of study operators were considered representative of the region and were very similar between them, supporting the comparative character of the study.

3 Methods

Each of the four treatments was replicated on three study plots, for a total of twelve plots. Plot size varied from 2500 to 12 000 m2, with an average value of 5000 m2. Individual plot size depended on available block size, and on the need to contain work time within manageable bounds (≤ 3 days per plot). For this reason, motor-manual plots were generally smaller than mechanized plots. The average surface area was 3200 and 7600 m2 for the motor-manual and the mechanized plots, respectively. Plots were randomly distributed on a very uniform stand, so that the main differences could be safely attributed to treatments.

Product output was determined by accumulating all the biomass extracted from each plot in a separate pile and weighing separately the chips obtained from each pile. When a chipvan received chips from more than one pile, partial loads were weighed by interrupting the chipping operation when the first pile was exhausted and driving the van on a set of portable scales. The operation would then be repeated when the load had been completed with material coming from the second pile. Figures obtained with portable scales were validated by taking all loads to a certified weighbridge available just at the exit of the estate. When needed, partial load figures determined with the portable scales were corrected using the certified weighbridge values. Moisture content was determined according to the European standard CEN/TS 14774-2, on one 500-g chip samples per load. These samples were obtained from the reduction of larger 3 L samples collected at different places within the same load.

Time input was determined with a time-motion study (Magagnotti and Spinelli 2012). Each work cycle was timed individually, using Husky Hunter hand-held field computers running the dedicated Siwork3 time study software (Kofman 1995). Productive time was separated from delay time (Björheden et al. 1995), in order to calculate appropriate delay factors (Spinelli and Visser 2008) for each machine type. Delay factors were calculated as the average delay to productive time ratio recorded on all three plots for each given machine. Then, individual time input per plot was calculated as the actual productive time recorded on each plot, corrected by the appropriate delay factor. This allowed controlling the effect of delay time, which is typically erratic and may confound results (Spinelli and Visser 2009). Study delays were excluded from the study, but all other delay types were included.

Fuel input was determined by refilling all machine tanks at the end of each working day, and recording the amount of fuel used during that day. This figure was divided by stopwatch hours and prorated to each plot based on the hours actually needed to harvest it.

Stand damage was determined by inspecting all trees left on each plot after harvest, according to the method described by Meng (1978). Wounds with an exposed surface smaller than 10 cm2 were not recorded, as they had little consequences on tree health or wood quality (Whitney 1991). To describe wound severity, the authors used the total wound surface.

Soil compaction was determined from undisturbed cores, collected before and after harvest. Cores were collected in rings of thin-walled stainless steel tubing, with an internal diameter of 8 cm and a height of 5 cm, corresponding to a volume of 250 cm3. Rings were pushed into the soil down to a 5-cm depth, after removing the litter layer. Rings were then removed from the soil, for trimming the sample and placing it into a sealed plastic bag. Bags were taken to the laboratory and weighed before and after oven-drying at 105°C for 48 hours. These data were used to calculate the bulk density (BD) and the gravimetric water content of each sample. Researchers collected 40 cores per plot, 20 before and 20 after harvesting. Cores collected after harvesting were obtained from inside the machine tracks. Each core was considered as an individual observation. The depth of the observations seemed to be appropriate, as the main impacts of wood extraction are generally concentrated within the first 10 cm layer (Ampoorter et al. 2009), especially in Mediterranean and sub-Mediterranean soils (Makineci et al. 2007). Unfortunately, soil moisture was only determined at the time of core sampling, about 8 weeks after harvesting.

The amount of retained biomass was determined on forty 1 x 1 m sample plots, randomly spread over the whole experimental area in the number of 20 per harvesting system. Before locating the samples, the sample area was divided in two strata according to residual biomass load, in order to reflect the systematic slash accumulation pattern derived from trafficking every other inter-row.

Machine costs were calculated with the harmonized method developed within the scope of European COST Action FP0902 (Forest Energy Portal 2013). Data about utilization, maintenance and value recovery were obtained directly from the machine owners, and matched published figures (Spinelli et al. 2010; Spinelli et al. 2011a). Main assumption and results are shown in Table 3.

| Table 3. Costing assumptions and machine rates. | ||||||||

| Unit | Chainsaw | Tractor | Feller | Skidder | Harvester | Forwarder | Chipper | |

| Utilization | % | 46 | 72 | 81 | 90 | 90 | 90 | 83 |

| Investment | Euro | 1500 | 55 000 | 320 000 | 180 000 | 300 000 | 240 000 | 500 000 |

| Resale | Euro | 450 | 16 500 | 96 000 | 54 000 | 90 000 | 72 000 | 150 000 |

| Service life | years | 2 | 10 | 10 | 10 | 10 | 10 | 10 |

| Utilization | SMH year–1 | 1000 | 1000 | 1600 | 1600 | 1600 | 1600 | 1600 |

| Interest rate | % | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| Depreciation | € year–1 | 525 | 3850 | 22 400 | 12 600 | 21 000 | 16 800 | 35 000 |

| Interests | € year–1 | 50 | 1507 | 8768 | 4932 | 8220 | 6576 | 13 700 |

| Insurance | € year–1 | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 |

| Fuel | € year–1 | 2700 | 4500 | 47 840 | 31 408 | 27 040 | 27 040 | 72 800 |

| Lubricant | € year–1 | 270 | 450 | 4784 | 3141 | 2704 | 2704 | 7280 |

| Repairs | € year–1 | 263 | 1925 | 11 200 | 6300 | 10 500 | 8400 | 17 500 |

| Total | € SMH–1 | 6 | 15 | 61 | 38 | 45 | 40 | 93 |

| Crew | n. | 2 | 1 | 1 | 1 | 1 | 1 | 1 |

| Labour | € SMH–1 | 32 | 16 | 20 | 20 | 20 | 20 | 20 |

| Overheads | € SMH–1 | 8 | 6 | 16 | 12 | 13 | 12 | 23 |

| Total rate | € SMH–1 | 46 | 37 | 97 | 70 | 78 | 72 | 136 |

| Notes: Cost in Euro (€) as on Sept.18, 2013. 1 € = 1.33 US$; SMH = Scheduled Machine Hours, inclusive of delays; Utilization is the incidence of work time over total work site time: the remaining time is represented by delays. The utilization rates reported in the table were actually measured during the study. | ||||||||

Data were analyzed with the Statview advanced statistics software (SAS 1999). Differences between plot characteristics were tested with the Kruskal-Wallis non-parametric test, because the distribution of data was skewed and it did not met the normality assumption. If this test detected significant differences between treatments, the data pool was tested again with the Scheffe’s multiple comparison test, in order to pinpoint differences. Differences between unit cost figures and specific fuel consumption were tested with standard analysis of variance (ANOVA) because the data met all standard assumptions. The analysis of variance allowed to separately gauge the effect of harvesting system and mechanization level. Again, Scheffe’s multiple comparison test was used to pinpoint specific differences between treatments.

Overall, the test covered 6.47 ha, from which 1558 trees were harvested, yielding 262 tonnes of oven-dry chips. The time study sessions covered a total of 227 observation hours.

4 Results

Table 1 shows the absence of any significant differences between treatments for what concerns the number of trees removed per unit surface and wood moisture content at the time of chipping. In contrast, mass removals (per unit surface and per tree) differed significantly between the WT and CTL treatments, with WT harvesting yielding 66% more biomass than CTL harvesting, regardless of mechanization level.

Felling and extraction productivity were significantly different between treatments, whereas chipping productivity was not (Table 4). Mechanization allowed a dramatic increase of labour productivity. With mechanization, felling-processing productivity increased 8 times, and felling-bunching productivity 20 times. Extraction productivity increased from 6 to 8 times. Shifting from CTL to WT resulted in productivity increases between 40% and 270%, depending on work step and mechanization level. Gains were highest when replacing mechanized felling-processing with mechanized felling-bunching. The table also shows that extraction distances did not differ significantly between treatments, whereas mean payloads did. Larger mechanized units were able to carry larger payloads.

| Table 4. Productivity by treatment and work phase. | |||||

| Mechanization | Manual | Mechanized | |||

| System | type | WT | CTL | WT | CTL |

| Felling | odt SMH–1 | 0.9a | 0.6b | 18.2c | 4.9d |

| Extraction | odt SMH–1 | 2.3a | 0.6b | 13.5c | 6.9d |

| Chipping | odt SMH–1 | 18.7a | 16.7a | 15.5a | 17.5a |

| Extraction distance | m | 233a | 140a | 189a | 174a |

| Load size | odt | 0.410a | 0.212b | 0.958c | 3.845d |

| Notes: Different letters in superscript indicate that the differences between the mean values presented on the same row are statistically significant at the 5% level according to Scheffe’s multiple comparison test; SMH = Scheduled Machine Hours, inclusive of delays; odt = oven-dry tonnes; WT = whole-tree harvesting, CTL = cut-to-length harvesting. | |||||

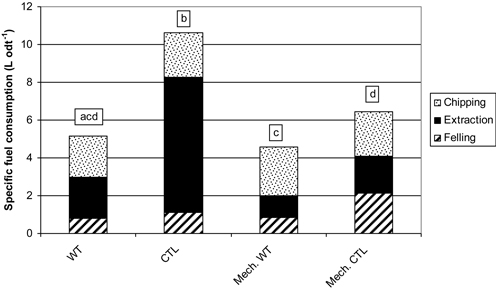

Specific fuel consumption ranged from 4.6 to 10.6 L per tonne of oven-dry chips (Fig. 2). Consumption was between 40 and 100% higher for CTL harvesting than for WT harvesting. Mechanization entailed a reduction of fuel consumption between 10 and 40%. Shifting from mechanized CTL to manual WT harvesting allowed reducing fuel consumption by 19%. Differences were statistically significant between motor-manual CTL harvesting and all other treatments, as well as between mechanized CTL and mechanized WT harvesting. In contrast, there was no statistically significant difference between the mean fuel consumption incurred by manual WT harvesting and by the two mechanized treatments.

Fig. 2. Specific fuel consumption per unit product by treatment and work phase. Notes: Different letters over different bars indicate that the difference between the mean fuel consumption values are statistically significant at the 5% level according to Scheffe’s multiple comparison test; WT = motor-manual whole-tree harvesting; CTL = motor-manual cut-to-length harvesting; Mech. WT = mechanized whole-tree harvesting; Mech CTL = mechanized cut-to-length harvesting; Felling also includes delimbing and crosscutting in the case of CTL harvesting operations.

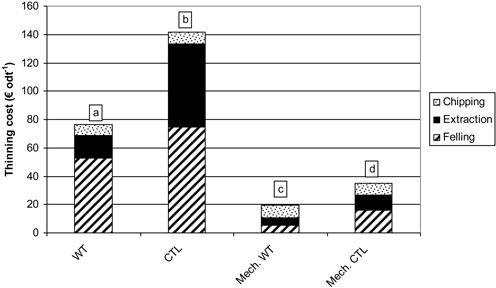

Harvesting cost varied between 19 and 142 € per tonne of oven-dry chips (Fig. 3). Mechanized WT harvesting offered the lowest harvesting cost, allowing a 40% saving over the next best option (mechanized CTL). In both cases, mechanization allowed reducing harvesting cost by a factor 4. Shifting from CTL to WT harvesting resulted in a reduction of harvesting cost between 40 and 50%. All these differences were statistically significant. Table 5 shows the results of the ANOVA, indicating that the effect of mechanization was stronger than the effect of harvesting system for what concerned harvesting cost. The contrary was true for fuel consumption.

Fig. 3. Thinning cost by treatment and work phase. Notes: Different letters over different bars indicate that the difference between the mean total cost values are statistically significant at the 5% level according to Scheffe’s multiple comparison test; WT = motor-manual whole-tree harvesting; CTL = motor-manual cut-to-length harvesting; Mech. WT = mechanized whole-tree harvesting; Mech CTL = mechanized cut-to-length harvesting; Felling also includes delimbing and crosscutting in the case of CTL harvesting operations.

| Table 5. Anova table for the effect of mechanization level and harvesting system on unit cost and fuel consumption. | |||||

| Thinning cost (€ odt–1) | |||||

| Effect | DF | SS | η2 | F-Value | P-Value |

| Mechanization | 1 | 20003 | 0.71 | 113.034 | <0.0001 |

| System | 1 | 4863 | 0.17 | 27.479 | 0.0008 |

| Interaction | 1 | 1861 | 0.07 | 10.515 | 0.0118 |

| Residual | 8 | 1416 | 0.05 | ||

| Specific fuel consumption (L odt–1) | |||||

| Effect | DF | SS | η2 | F-Value | P-Value |

| Mechanization | 1 | 17.452 | 0.22 | 13.529 | 0.0062 |

| System | 1 | 40.853 | 0.52 | 31.668 | 0.0005 |

| Interaction | 1 | 10.155 | 0.13 | 7.872 | 0.0230 |

| Residual | 8 | 10.32 | 0.13 | ||

| Notes: odt = oven-dry tonnes. | |||||

Between 1.5 and 15% of the residual trees presented wounds larger than 10 cm2 (Table 6). However, the 15% figure recorded for motor-manual CTL was considered dubious and excluded from the comparison (see discussion), resulting in an actual wounding frequency range between 1.5 and 6%. Therefore, only three treatments were compared, and namely motor-manual WT, mechanized WT and mechanized CTL. Among them, mechanized CTL resulted in the lowest incidence of wounding, and the difference between mechanized CTL and manual WT was statistically significant. Mechanized WT was in between, with no statistically significant differences with respect to the other two treatments. The differences in wound size had no statistical significance, so one could not safely state that any of the treatments caused more severe wounding than the others.

| Table 6. Site impact for the four treatments on test. | |||||

| Mechanization | Manual | Mechanized | |||

| System | type | WT | CTL | WT | CTL |

| Wounding | % trees | 6.0a | 15.7 | 2.5ab | 1.5b |

| Wound size | cm2 | 433a | 407a | 106a | 431a |

| Soil density untrafficked | g cm–3 | 1.30a | 1.18a | 1.25a | 1.21a |

| Soil density trafficked | g cm–3 | 1.28a | 1.28a | 1.28a | 1.36a |

| Difference | % | –1.2 | 8.8 | 2.5 | 11.9 |

| t test | p-value | 0.3462 | <0.0001 | 0.2332 | <0.0001 |

| Notes: Different letters in superscript indicate that the differences between the mean values presented on the same row are statistically significant at the 5% level according to Scheffe’s multiple comparison test; p-values in the last row refer to the comparison between untrafficked and trafficked soil density within each treatment; WT = whole-tree harvesting, CTL = cut-to-length harvesting. | |||||

Only the CTL treatments caused a significant increase of soil bulk density, which is indicative of soil compaction. However, such increase was very low, ranging from 8 to 10% of the original value. The density increase recorded for the mechanized CTL treatment was significantly higher than for the manual CTL treatment (p-value = 0.0032).

After harvesting, the amount of biomass released in the stand as forest residue amounted to 4.6 (standard error = 1.3) and 34.0 (standard error = 1.3) oven-dry tonnes per hectare for the WT and the CTL treatments, respectively. This difference was highly significant (p-value < 0.0001 according to the Mann-Whitney test). Summing the amounts of biomass removed and released for the two harvesting systems gave consistent results, confirming the general validity of our estimates.

5 Discussion

The comparison presented in this study is truly innovative because at the same time a) it is conducted under typical Mediterranean conditions, b) it includes different mechanization levels and c) it concurrently explores productivity, financial performance, site impact and biomass release. However, this study not is the first one to compare the performance of WT and CTL harvesting. In the early 1990s, the appearance of commercial CTL technology prompted a number of comparison studies in North America. In following years, system comparison studies have been produced sporadically but regularly, both in North America and in Europe. As a consequence, we now have a relatively large body of references for checking our results.

The better financial performance of WT harvesting is matched by several papers, which report cost savings between 20 and 40% (Adebayo 2007; Spinelli et al. 2009; Bisson et al. 2013). However, other studies report of no significant cost difference between the two systems (Lanford and Stokes 1996; Benjamin et al. 2012). That can be explained with the fact that the latter studies compared the two systems when applied to the production of pulpwood logs, which made delimbing and crosscutting necessary for both systems. In that case, WT harvesting did not avoid delimbing and crosscutting, as occurred in our study. Cost seems to depend more on the number of process steps than on their sequence, unless a different sequence allows increasing the level of mechanization. In general, the financial advantages of WT harvesting are maximized if the system allows multi-tree harvesting (Oikari et al. 2010) and process simplification (Spinelli and Magagnotti 2010). Anyway, no study has ever suggested that WT harvesting may incur a higher production cost than CTL harvesting, for the same level of mechanization and when producing chips. In the specific case of this study, the heavy branching of umbrella pine trees may have hindered delimbing, thus increasing the gap between the two systems.

Concerning mechanization, the results of our study may deserve some comments. It is clear that mechanization introduces substantial cost reductions, but the differences we observed were twice as large as reported in previous studies (Laitila 2008; Spinelli and Magagnotti 2011). Such result may partly depend on different operator proficiency. While all operators in the study were trained professionals, motor-manual crews were more flexible and performed many different forestry jobs depending on opportunity. In contrast, mechanized operators were much more specialised in their respective tasks, and therefore they were more likely to achieve top performance in their individual jobs. Further evidence of different operational capacity is offered by the use of a winch rather than a forestry trailer for extracting logs, under the motor-manual CTL treatment. A forestry trailer would have been more appropriate, but the company did not have one available and decided to use their simple winch instead. On the other hand, different specialization is an inherent characteristic of the two mechanization levels, which is becoming more pronounced as mechanization develops, and specialized logging companies abandon motor-manual technology.

The selection thinning of Mediterranean forests often results in a higher damage frequency than recorded in our experiment. This can range between 14% (Picchio et al. 2011) and 20 % (Tsioras and Liamas 2010) of the residual stand. Previous studies confirm that CTL harvesting may result in lower residual stand damage compared to WT harvesting (Camp 2002; Lanford and Stokes 1995; Waters et al. 2004), and that mechanized operations may cause less damage than motor-manual operations (Koŝir 2008). Easy handling is the key to stand damage reduction. Whole trees are unwieldy, which increases the potential for hitting the residual stand. Handling is made much easier after size reduction at the stump site, as occurs with CTL harvesting. The better performance of mechanized operations is explained by the higher capacity of mechanical equipment for controlled tree handling (Magagnotti et al. 2012).

That is also true for our study, if we accept removing the data obtained for the motor-manual CTL treatment. Stand damage for this treatment was unusually high, and we assumed that it was the result of post-harvest mulching, occurred before data collection. With motor-manual CTL harvesting, tops and branches were left in windrows, to the side of the extraction trails. As a result, slash was not trampled by the tractor and remained quite thick, interfering with the recreational use of the forest. For this reason, the forest manager decided to mulch the slash windrows in the motor-manual CTL plots immediately after harvest. That was not necessary for all other treatments, because branches were either removed and chipped or crushed to the ground by the harvester and forwarder team. Mulching involved further in-stand traffic and the projection of wood particles at relatively high speeds, with a significant potential for tree damage. When mulching is necessary, its cost should be added to total harvesting cost, which would further expand the gap between mechanization levels and harvesting systems.

Post-harvest traffic occurred on alternate inter-rows and did not interfere with the measurement of soil bulk density, because the inter-rows trafficked by the extraction units were those left free from slash. However, harvesting occurred at different times for the two harvesting systems, which prevents us from making any conclusive statements about their relative performance with respect to soil compaction. Different soil moisture content at the time of harvest may explain why one system (CTL) resulted in a significant increase of soil bulk density while the other (WT) did not. On the other hand, motor-manual and mechanized variations of the same system were tested at about the same time, which supports the validity of comparisons between mechanization levels. Apparently, mechanization does not increase the soil impact of WT harvesting, but it does result in higher compaction when CTL harvesting is applied. This result can be explained in several ways. It is possible that soil moisture at the time of WT harvesting was so low that neither motor-manual harvesting nor mechanized harvesting had any effect on soil bulk density. Furthermore. Mechanized WT harvesting was performed by a tracked swing-to-tree feller-buncher and a grapple skidder, both of which would exert a relatively low ground pressure. Mechanized CTL equipment was heavier and had a smaller ground contact area, resulting in higher ground pressure and potentially heavier soil impact, especially if soil moisture content was near critical levels.

In any case, the post-harvest increase in soil bulk density recorded for CTL harvesting is much below the values found in literature, which range between 15 and 30 % (Froehlich et al. 1986). That is explained by the resistance of sandy soils to compaction (Wästerlund 1985), especially when their initial density is near the 1.4 g cm–3 threshold (Powers et al. 2005). Mediterranean pine plantations seem less susceptible to disturbance than similar hardwood stands (Gondard et al. 2003).

Obviously, the release of organic matter is much higher for CTL than for WT harvesting, which relieves possible concerns about soil nutrient depletion and consequent growth losses (Nord-Larsen 2002). On the other hand, heavy residue loads may increase fire risk especially in sensitive Mediterranean environments (Graham et al. 1999). In this respect, mechanized CTL harvesting is the best option, because it allows releasing relatively large amounts of slash while crushing it to the soil as the result of trampling.

Finally, readers must notice that product quality is very different for the two harvesting systems. WT harvesting offers whole-tree chips, which contain a larger proportion of needles and twigs compared to the chips obtained from CTL harvesting. In this study, we did not determine chip quality in terms of ash and fiber content, or particle size distribution. Therefore, we cannot make any conclusive statements about chip quality. However, whole-tree chips are likely less suitable for use in small-scale residential heating systems, which may entail a lower sale price (Spinelli et al. 2011b)

6 Conclusions

The results of this study can be extended to similar stands, characterized by simple even-aged structure and growing on flat terrain. Under these conditions, both mechanized treatments achieve high productivity and low harvesting cost, when producing forest chips. In contrast, motor-manual harvesting is too expensive for cost-effective thinning, regardless of harvesting system. WT harvesting allows a dramatic reduction of harvesting cost, as long as it allows simplifying the harvesting process. Fuel consumption is also lower for WT harvesting, compared to CTL harvesting. WT harvesting offers higher product yields, but a higher risk for soil nutrient depletion. All treatments result in very low site impact. If soil fertility is not a problem, mechanized WT harvesting is the preferable option.

Acknowledgements

The research leading to these results has received funding from the European Union Seventh Framework Programme (FP7/2012-2015] under grant agreement n°311881 (INFRES Project).

References

Adebayo A., Han H., Johnson L. (2007). Productivity and cost of cut-to-length and whole-tree harvesting in a mixed-conifer stand. Forest Products Journal 57: 59–69.

Ampoorter E., Verheyen K., Hermy M. (2009). Soil damage after skidding: results of a meta-analysis. Proceedings of the 32nd Annual meeting of the Council on Forest Engineering, Kings Beach, California, USA.

Barbero M., Loiser R., Quezel P., Richardson D., Romane F. (1998). Pines of the Mediterranean basin. In: Richardson D. (ed.). Ecology and biogeography of Pinus. Cambridge University Press, Cambridge, UK. p. 153–170.

Benjamin J., Meacham E., Seymour R., Wilson J. (2012). Early commercial thinning in Maine’s spruce-fir forests. Proceedings of the 35th Annual meeting of the Council on Forest Engineering, New Bern, North Carolina, USA.

Bisson J., Han S., Han H.S., Zhang J., Montgomery T. (2013). Comparing whole tree to tree-length fuel reduction thinning operations: cost and actual amounts of biomass removal. Proceedings of the 36th Annual Meeting of the Council on Forest Engineering, Missoula, Montana, USA.

Björheden R., Apel K., Shiba M., Thompson M.A. (1995). IUFRO forest work study nomenclature. Swedish University of Agricultural Science, Department of Operational Efficiency, Garpenberg. 16 p.

Camp A. (2002). Damage to residual trees by four mechanized harvest systems operating in small-diameter, mixed-conifer forests on steep slopes in Northeastern Washington: a case study. Western Journal of Applied Forestry 17: 14–22.

Carrasquinho I., Freire J., Rodrigues A., Tomé M. (2010). Selection of Pinus pinea L. plus tree candidates for cone production. Annals of Forest Science 67 814. http://dx.doi.org/10.1051/forest/2010050.

Forest Energy Portal. (2013). Machine cost calculation model. http://www.forestenergy.org/pages/costing-model---machine-cost-calculation/. [Cited 14 Sep 2013].

Froehlich H.A., Miles D., Robbins R. (1986). Growth of young Pinus ponderosa and Pinus contorta on compacted soil in central Washington. Forest Ecology and Management 15: 285–294. http://dx.doi.org/10.1016/0378-1127(86)90165-9.

Gondard H., Romane F., Aronson J., Shater Z. (2003). Impact of soil surface disturbances on functional group diversity after clear-cutting in Aleppo pine (Pinus halepensis) forests in southern France. Forest Ecology and Management 180: 165–174. http://dx.doi.org/10.1016/S0378-1127(02)00597-2.

Graham R.T., Harvey A.E., Jain T.B., Tonn J.R. (1999). The effects of thinning and similar stand treatments on fire behavior in western forests. USDA Forest Service, Pacific Northwest Research Station, General Technical Report PNW-GTR-463. 27 p.

Gullberg T. (1995). Evaluating operator-machine interactions in comparative time studies. International Journal of Forest Engineering 7: 51–61.

Jacobson S., Kukkola M., Mälkönen E., Tveite B. (2000). Impact of whole-tree harvesting and compensatory fertilization on growth of coniferous thinning stands. Forest Ecology and Management 129: 41–51. http://dx.doi.org/10.1016/S0378-1127(99)00159-0.

Han H.S., Kellogg. L. (2000). Damage characteristics in young Douglas-fir stands from commercial thinning with four timber harvesting systems. Western Journal of Applied Forestry 15: 27–33.

Harstela P. (1999). The future of timber harvesting in Finland. Journal of Forest Engineering 10: 33–36.

Kammenga J. (1983). Whole-tree utilization system for thinning young Douglas-fir. Journal of Forestry 4: 220–224.

Kärhä K., Jouhiaho A., Mutikainen A., Mattila S. (2003). Mechanized energy wood harvesting from early thinnings. International Journal of Forest Engineering 16: 23–36.

Kellogg L., Bettinger P., Studier D. (1993). Terminology of ground-based mechanized logging in the pacific northwest. Research Contribution 1. Forest Research Laboratory, Oregon State University, Corvallis, OR, USA. 12 p.

Kinoshita T., Inoue K., Iwao K., Kagemoto H., Yamagata Y. (2009). A spatial evaluation of forest biomass usage using GIS. Applied Energy 86: 1–8. http://dx.doi.org/10.1016/j.apenergy.2008.03.017.

Kofman P. (1995). Siwork 3: user guide. Danish Forest and Landscape Research Institute, Vejle, Denmark. 37 p.

Koŝir B. (2008). Modelling stand damage and comparison of two harvesting methods. Croatian Journal of Forest Engineering 29: 5–14.

Laitila J. (2008). Harvesting technology and the cost of fuel chips from early thinnings. Silva Fennica 42: 267–283.

Lanford B., Stokes B. (1995). Comparison of two thinning systems. Part 1. Stand and site impacts. Forest Products Journal 45: 74–79.

Lanford B., Stokes B. (1996). Comparison of two thinning systems. Part 2. Productivity and costs. Forest Products Journal 46: 47–53

Lindroos O., Lidestav G., Nordfjell T. (2005). Swedish non-industrial private forest owners: a survey of self-employment and equipment investments. Small-scale Forest Economics, Management and Policy 4: 409–425.

Lundmark R. (2006). Cost structure and competition for forest-based biomass. Scandinavian Journal of Forest Research 21: 271–280. http://dx.doi.org/10.1080/02827580600688251.

Magagnotti N., Spinelli R., Güldner O., Erler J. (2012). Site impact after motor-manual and mechanised thinning in Mediterranean pine plantations. Biosystems Engineering 113: 140–147. http://dx.doi.org/10.1016/j.biosystemseng.2012.07.001.

Magagnotti N., Spinelli R. (eds.). (2012). COST action FP0902 – good practice guideline for biomass production studies. CNR IVALSA. Florence, Italy. 41 p. ISBN 978-88-901660-4-4.

Makineci E., Demir M., Comez A., Yilmaz E. (2007). Chemical characteristics of the surface soil, herbaceous cover and organic layer of a compacted skid road in a fir (Abies bornmulleriana Mattf.) forest. Transportation Research, Part D 12: 453–459. http://dx.doi.org/10.1016/j.trd.2007.06.001.

Malinen J., Pesonen M., Määttä T., Kajanus M. (2001). Potential harvest for wood fuels (energy wood) from logging residues and first thinnings in Southern Finland. Biomass and Bioenergy 20: 189–196. http://dx.doi.org/10.1016/S0961-9534(00)00075-1.

Meng W. (1978). Baumverletzungen durch Transportvorgänge bei der Holzernte – Ausmaß und erteilung, Folgeschäden am Holz und Versuch ihrer Bewertung. Schriftenreihe der LFV Baden- Württemberg, Band 53. 159 p.

Mitchell D., Gallagher T. (2007). Chipping whole trees for fuel chips: a production study. Southern Journal of Applied Forestry 4: 176–180

Nord-Larsen T. (2002). Stand and site productivity response following whole-tree harvesting in early thinnings of Norway spruce. Biomass and Bioenergy 23: 1–12. http://dx.doi.org/10.1016/S0961-9534(02)00032-6.

Oikari M., Kärhä K., Palander T., Pajuoja H., Ovaskainen H. (2010). Analyzing the views of wood harvesting professionals related to the approaches for increasing the cost-efficiency of wood harvesting from young stands. Silva Fennica 44: 481–495.

Picchio R., Neri F., Maesano M., Savelli S., Sirna A., Blasi S., Baldini S., Marchi E. (2011). Growth effects of thinning damage in a Corsican pine (Pinus laricio Poiret) stand in central Italy. Forest Ecology and Management 262: 237–243. http://dx.doi.org/10.1016/j.foreco.2011.03.028.

Powers R., Scott A., Sanchez F., Voldseth R., Page-Dumroese D., Elioff J., Stone D. (2005). The North American long-term soil productivity experiment: findings from the first decade of research. Forest Ecology and Management 220: 31–50. http://dx.doi.org/10.1016/j.foreco.2005.08.003.

SAS Institute Inc. (1999). StatView reference. SAS Publishing, Cary, NC. ISBN-1-58025-162-5.

Scott A. (1973). Work measurement: observed time to standard time. In: Wittering W. (ed.). Work study in forestry. Forestry Commission Bulletin 47: 26–39.

Smolander A., Kitunen V., Tamminen P., Kukkola M. (2010). Removal of logging residue in Norway spruce thinning stands: long-term changes in organic layer properties. Soil Biology and Biochemistry 42: 1222–1228. http://dx.doi.org/10.1016/j.soilbio.2010.04.015.

Spinelli R., Magagnotti N. (2010). Comparison of two harvesting system for the production of forest biomass from the thinning of Picea abies plantation. Scandinavian Journal of Forest Research 25: 69–77. http://dx.doi.org/10.1080/02827580903505194.

Spinelli R., Magagnotti N. (2011). The effects of introducing modern technology on the financial, labour and energy performance of forest operations in the Italian Alps. Forest Policy and Economics 13: 520–524. http://dx.doi.org/10.1016/j.forpol.2011.06.009.

Spinelli R., Visser R. (2008). Analyzing and estimating delays in harvester operations. International Journal of Forest Engineering 19: 35–40.

Spinelli R., Visser R. (2009). Analyzing and estimating delays in wood chipping operations. Biomass and Bioenergy 33: 429–433. http://dx.doi.org/10.1016/j.biombioe.2008.08.003.

Spinelli R., Owende P., Ward S. (2009). A harvest and transport cost model for Eucalyptus spp. fast-growing short rotation plantations. Biomass and Bioenergy 33: 1265–1270. http://dx.doi.org/10.1016/j.biombioe.2009.05.010.

Spinelli R., Magagnotti N., Picchi G. (2010). Deploying mechanized cut-to-length technology in Italy: fleet size, annual usage, and costs. International Journal of Forest Engineering 21: 23–31.

Spinelli R., Magagnotti N., Picchi G. (2011a). Annual use, economic life and residual value of cut-to-lenght harvesting machines. Journal of Forest Economics 17: 378–387. http://dx.doi.org/10.1016/j.jfe.2011.03.003.

Spinelli R., Ivorra L., Magagnotti N., Picchi G. (2011b). Performance of a mobile mechanical screen to improve the commercial quality of wood chips for energy. Bioresource Technology 102: 7366–7370. http://dx.doi.org/10.1016/j.biortech.2011.05.002.

Stokes B., Ashmore C., Rawlins C., Sirois D. (1989). Glossary of terms used in timber harvesting and forest engineering. General Technical Report SO-73. USDA, Forest Service, Southern Forest Experimental Station, New Orleans, LA, USA. 33 p.

Tsioras P. Liamas D. (2010). Hauling damages in a mixed beech-oak stand. Proceedings of FORMEC 2010 “Forest Engineering: Meeting the Needs of the Society and the Environment”, July 11–14, 2010, Padova, Italy.

Wästerlund I. (1985). Compaction of till soils and growth tests with Norway spruce and scots pine. Forest Ecology and Management 11: 171–189. http://dx.doi.org/10.1016/0378-1127(85)90025-8.

Waters I., Kembel S., Gingras J.F., Shay J. (2004). Short-term effects of cut-to-length versus full-tree harvesting on conifer regeneration in jack pine, mixedwood, and black spruce forests in Manitoba. Canadian Journal of Forest Research 34: 1938–1945. http://dx.doi.org/10.1139/x04-064.

Whitney R. (1991). Quality of eastern white pine 10 years after damage by logging. Forestry Chronicle 67: 23–26.

Zerbe S. (2002). Restoration of natural broad-leaved woodland in Central Europe on sites with coniferous forest plantations. Forest Ecology and Management 167: 27–42. http://dx.doi.org/10.1016/S0378-1127(01)00686-7.

Total of 53 references