A crop tree release variant of precommercial thinning using a backpack mounted chain saw

Soucy M., Béland M. (2020). A crop tree release variant of precommercial thinning using a backpack mounted chain saw. Silva Fennica vol. 54 no. 3 article id 10205. https://doi.org/10.14214/sf.10205

Highlights

- Backpack mounted chain saws offer an opportunity to effectively cut larger stems in precommercial thinning treatments compared to conventional circular blade brushsaws

- Productivity in performing precommercial crop tree release (PCTR) in a hardwood stand using a backpack mounted chain saw varied between 0.22 to 0.47 ha h–1.

Abstract

Although crop tree release (CTR) in hardwood stands is an accepted variant of precommercial thinning (PCT), the lack of an affordable and feasible method hinders its adoption. CTR implies selecting between 150 and 500 trees ha–1 when trees are between 7 and 12 m high and cutting only stems competing with the target crop trees. We performed a field trial of a CTR variant of PCT in a 27.8 ha hardwood stand using a backpack mounted chain saw. A detailed time study was performed to document the trial over 13 days. Compared to conventional PCT performed earlier in the life of a stand, precommercial crop tree release required cutting larger stems, which showed to be feasible and productive using a backpack mounted chain saw. Productivity varied between 0.22 to 0.47 ha h–1 during the trial, Although productivity could vary with stand characteristics and worker, this proof of concept trial demonstrates some of the potential uses that this new saw configuration offers and sets the basis for an eventual larger scale deployment of this treatment.

Keywords

thinning;

hardwood;

spacing;

time study;

brushsaw;

motor-manual;

work performance

-

Soucy,

Université de Moncton, 165 boulevard Hébert, Edmundston, N.-B. Canada, E3V 2S8, (506) 737-5248

https://orcid.org/0000-0003-0531-5549

E-mail

michel.soucy@umoncton.ca

https://orcid.org/0000-0003-0531-5549

E-mail

michel.soucy@umoncton.ca

-

Béland,

Université de Moncton, 165 boulevard Hébert, Edmundston, N.-B. Canada, E3V 2S8, (506) 737-5248

https://orcid.org/0000-0001-8591-671X

E-mail

martin.beland@umoncton.ca

https://orcid.org/0000-0001-8591-671X

E-mail

martin.beland@umoncton.ca

Received 4 June 2019 Accepted 2 June 2020 Published 7 June 2020

Views 91405

Available at https://doi.org/10.14214/sf.10205 | Download PDF

1 Introduction

Thinnings are intermediate cuttings that are aimed at controlling the growth of stands to improve the quality of future yields while, when conditions permit, providing economic returns before final harvest (Smith et al. 1997). When the trees cut during thinning have commercial value and can be brought to mills in an efficient manner, the treatment is deemed “commercial”. When extraction costs exceed the revenues that can be obtained, it become preferable to leave the cut stems on the ground and the thinning is considered “precommercial”. The commercial status of thinning thus depends in part on regional market conditions such as demand for energy wood (Ahtikoski et al. 2004, 2008) and availability of subsidies, and not only on tree and stand characteristics. As such, the optimal stand management regime, including the choice of timing (Huuskonen and Hynynen 2006), intensity (Ahtikoski et al. 2004) and frequency of thinnings, is a complex and context-specific question (Pasanen et al. 2014). It is recognized that the timing and intensity of a precommercial thinning intervention will influence the size of trees removed and the profitability of the subsequent thinnings (Varmola and Salminen 2004; Heikkilä et al. 2009; Plamondon and Pitt 2013). However, changing the timing and intensity of precommercial thinning is not without consequences on the cost and feasibility of the treatment (Needham and Clements 1989; Groninger et al. 1998; Kaila et al. 2006; Lebel and Dubeau 2007).

In Canada, precommercial thinning (PCT) is widely used, with an average of 137 000 ha yr–1 treated between 1990 and 2015 (CCFM 2017). Its application was historically concentrated in regenerating softwood stands because of their dominance and because of the economic importance of softwood products. However, growing interest is shown towards actively managing shade-tolerant hardwood (such as sugar maple (Acer saccharum Marshall) and yellow birch (Betula alleghaniensis Britton)) stands for the production of high-quality sawlogs (Boulet and Pin 2015; NHRI 2019).

Precommercial thinning young dense shade-tolerant hardwoods for the production of high-quality sawlogs implies a few important differences compared to softwoods because of biological characteristics of these species (Lees 1995) and because of the challenges to make thinning profitable (McCauley and Marquis 1972; Dwyer et al. 1993; Groninger et al. 1998). First, it is recommended to delay thinning to promote better stem form and self-pruning (Marquis et al. 1984; Lamson and Smith 1987; von Althen et al. 1994, 1996; Leak and Solomon 1997; Collet et al. 1998; Dobner and Huss 2018). Second, it is recommended to use a crop tree release approach (CTR), where only a small number of high-quality crop trees are to be released (Smith and Lamson 1986; Lamson and Smith 1987; Voorhis 1986, 1990; Heitzman and Nyland 1991; von Althen et al. 1994, 1996).

Delaying precommercial thinning brings some operational challenges. The circular blade of the brushsaw, still the dominant tool used for PCT, is adapted to cutting small-diameter stems, surpassing the effectiveness of the chainsaw in the younger and denser stands (NSDNR 1992). With larger stems, brushsaw use results in significantly higher costs (NSDNR 1992; Kaila et al. 2006; Uotila et al. 2014). Worker productivity using a brushsaw is highly influenced by both stand density and stem size (Svensson 1971; Needham and Clements 1989; Needham and Hart 1991; Labbé 1995; Ligné et al. 2005; Lebel and Dubeau 2007; Uotila et al. 2014). While delaying thinning results in an increased size of trees to be cut, self-thinning reduces the number of stems (Kikuzawa 1988; Nilsson and Albrektson 1994; Wade 2018). Nonetheless, self-thinning is not sufficient to offset the negative effect of increased stem size on brushsaw performance.

Attempts have been made to mechanize PCT and move toward a more geometric thinning (in order to address labor shortages, low productivities, and difficulties in cutting larger, unmerchantable stems), but the motor-manual brushsaw remains the best option available (Ryans and Cormier 1994; Glöde and Bergkvist 2003; Ligné et al. 2005; Witzell et al. 2019). Hence, we still need to address the relatively low work productivity, labor shortages (Egan and Taggart, 2004) and high cost of PCT-treatments. Just like different patterns and methods were attempted to develop mechanized approaches to PCT, we might have to reconsider how the motor-manual approach is performed if significant improvements are to be found. Leader clipping (Bulley et al. 1997) and top-cutting (Karlsson and Albrektson 2000; Fällman et al. 2003) are such options, where competing stems are cut at a higher level, allowing for innovations in work techniques and tools (Ligné et al. 2005).

In this context, Ligné et al. (2005) explored a prototype of pole saw which showed promising results. Its productivity was reported to approach that of a conventional brushsaw for the biggest trees (4–6 cm diameter at the butt end) despite a much smaller engine and a chainsaw blade rather than a circular saw. Despite reservations, the pole saw configuration with a chain saw blade seemed advantageous for handling larger-diameter trees and for worker mobility in dense stands.

Recently, the Husqvarna 535FBx spacing saw, similar to the prototype tested by Ligné et al. (2005), was commercialized, but with a more powerful engine mounted on a backpack (also referred to as forestry clearing backpack chain saw, forestry clearing saw, or backpack clearing saw). The 1.6 kW engine coupled to a 33 cm chainsaw bar appears suited to cut the larger stems that would be encountered in a delayed precommercial thinning treatment of hardwood stands.

In addition to delaying PCT treatment in shade-tolerant hardwood stands destined for the production of high-quality sawlogs, the other important recommendation is to use a crop tree release approach (CTR). Precommercial crop tree release (PCTR) recommended in these hardwood stands involves selecting and releasing 125 to 500 crop trees per hectare instead of the systematic release of 1500 to 3000 stems ha–1 that is commonly performed in softwood stands. The treatment usually calls for only removing trees that compete in the top half of the crop tree’s crown in order to maintain some shade and protect the bole of the crop tree (Schütz 1990). This means leaving trees uncut near crop trees and untreated portions between crop trees. This complicates worker mobility and challenges worker orientation within the stand to ensure full coverage without overlap.

The objective of this study is to test the feasibility of using a “top-cutting” method with a backpack mounted chain saw to perform PCTR in a shade-tolerant hardwood stand.

2 Materials and methods

The precommercial crop tree release feasibility study was conducted using a Husqvarna 535FBx spacing saw (Fig. 1). It followed an explanatory mixed methods approach (concurrent nested strategy) (Terrell 2012; Creswell 2014). Data were collected through a time and motion study (Magagnotti and Spinelli 2012) and through GPS data files. This was complemented by filming portions of the thinning process and interviewing the worker daily to allow a posteriori analysis of work techniques and to broaden the perspective on the PCTR operation. To address the stand navigation challenges brought by the high-density residual stand, the use of a GPS, with and without the use of paint marks left by the worker, was tested.

Fig. 1. Worker performing precommercial crop tree release (PCTR) with the Husqvarna 535FBx spacing saw in the study stand. Green arrow points to a maple crop tree while red arrow points to a beech competitor about to be cut.

The trial lasted 13 days, in the period between November 8th and December 11th, 2016 and was limited to a single worker. The worker had more than 10 years’ experience in forestry jobs and 2 seasons using the new configuration of spacing saw in conventional precommercial thinning of younger stands. This kind of spacing saw being new in the country, we were not able to locate another experienced operator within a 1000 km radius.

2.1 Stand description

The field trial was located near Canterbury, New Brunswick, Canada (45°46´N, 67°34´W). The stand covered 27.8 ha and was dominated by naturally regenerated sugar maple and yellow birch 15 years following a clearcut. Characteristic of that region, the well regenerated portions of the stand were systematically interrupted by unregenerated sections corresponding to the extraction trails used during the previous harvest. The regenerated sections were 13.1 m wide on average, covering 18.3 ha of the block, divided by 6.8 m-wide unregenerated sections. This created distinct corridors to be treated that ranged between 200 and 375 m in length. Slope was less than 15% on solid ground with the presence of boulders (0.5 to 2 m in diameter) randomly distributed.

Species composition, density (stems ha–1), diameter at breast height (dbh) and average dominant height (m) per species were determined from sample plots systematically distributed every 50 m along the regenerated corridors. Sample locations consisted of a pair of plots: 1) a 2.82 m radius circular plot (25 m2) at the centre of the corridor and 2) a 2.82 m radius semi-circular plot (12.5 m2) at the edge of the corridor, alternating sides of corridor. This pairing of plots was done to capture any edge effect that the presence of the unregenerated trails could have on stand structure.

Crop trees were defined as dominant or codominant sugar maple, yellow birch or white ash (Fraxinus americana L.), having a minimum height of 4 m and an inclination of less than 10°. The first 2.5 m of the bole had to be free of defects affecting the quality of the first 2.44 m potential sawlog (crooks, forks, branches, holes). The tree should not show any signs of damage or poor vigour (more than 25% of crown dead; broken top; cankers). Presence of a crop tree in each plot was noted along with its species, dbh and height. Five meters between crop tree boles was aimed for, but crop trees as close as 3 m apart were accepted in sections of the stand with a lower stocking of crop trees. Crop trees identified pre-treatment were not marked, so the worker had no outside help finding them.

The stand had an average density of 8940 stems ha–1. The targeted desirable species, sugar maple and yellow birch made up 35% of the stems (3130 ha–1). American beech (Fagus grandifolia Ehrh.) (39%), white birch (Betula papyrifera Marshall) (23%), balsam fir (Abies balsamea (L.) Mill.) and white ash made up the rest of the stand. Crop trees were 251 ha–1, 5.5–9 m in height and averaged 6 cm dbh. Sugar maple made up 64% of the crop trees, yellow birch 32% and white ash 4%.

2.2 Treatment description and felling technique

Precommercial crop tree release (PCTR) consists of releasing up to 400 high-quality crop trees ha–1 in a 7- to 12-meter high hardwood stand by cutting only the trees that compete with the top half of crop tree’s crowns, leaving other trees uncut. This was respected except on a few occasions where the competitor was a large-diameter remnant tree that cutting would have slowed down the worker too much.

Unlike usual precommercial thinning requirements, the worker did not have to ensure that all cut stems lay on the ground. The requirements were 1) to protect crop trees from damage. This meant ensuring that cut stems did not lean against a crop tree or would not likely be pushed back against a crop tree, 2) to ensure a safe environment for workers. This meant ensuring that no large trees be left leaning above 1.5 m to prevent them from falling on someone.

Within the first days, a safe and productive cutting technique was chosen: stems less than 2 cm dbh were usually not competing with the crop trees. Nonetheless, many were cut near the ground to facilitate mobility and vision of the worker. Cutting these stems was done very quickly, often in swooping movements, cutting multiple stems in one pass as the worker moved. Stems between 2 and 6 cm dbh were cut either to release crop trees or to facilitate movement. They were mostly cut by specific, individual movement of the worker towards the stem. Height of cut varied greatly from near the ground all the way to the highest possible position (around 2.5 m). In general, the larger the diameter, the higher the cut. Two reasons motivated higher cuts: 1) higher cuts mean narrower stems, hence faster cut, 2) higher cuts allowed the top portion of the stem to drop vertically a distance long enough to ensure that the crown would untangle from that of its neighbours. This greatly facilitated and accelerated dropping cut stems away from the crop tree. For stems in the 8 to 12 cm dbh range, cuts were mostly made as high as possible to reduce diameter to cut and accelerate the fall. These trees, however, showed to sometimes fall very rapidly near the stump (vertical fall, stem still standing). The worker learned to recognize situations where cutting high could pose a risk and would adjust height of cut accordingly. In addition, the larger trees often required to be cut in rough 2.5-meter sections so they would not stay hung up dangerously in other trees, or lean against the crop tree. Directional felling techniques required to ensure the safe felling of larger trees (directional “V” notch followed by a back cut, leaving a hinge) was only used on the rare remnant trees that had a dbh over 12 cm.

The stand had an irregular distribution of crop trees. The worker was asked to work as if he was paid, and evaluated for the quality of the work, based on the data provided from his GPS using a combined method: 66.26 € for each hectare treated based on a 2.5 m buffer around the GPS tracking data and, 0.33 € per crop tree released based on the waypoints recorded on GPS. While the worker was paid a fixed hourly rate for the trial, he referred to these guidelines to gauge the relative effort he would put to cover more ground versus finding and releasing all potential crop trees.

2.3 Stand navigation

In regular precommercial thinning, the thinned portion of the stand is easily recognisable from an untreated portion; workers work through a stand along the treated section without having to make a significant effort to orient themselves. In PCTR, once a crop tree is identified, releasing it involves walking around it while focusing on identifying trees to cut and performing the cuts, hence the high risk of losing one’s sense of direction. This can be amplified when a stand is denser, leaves are still on, and when the distance to the last crop tree released increases.

A handheld GPS with stand boundaries and with a line at the centre of each regenerated corridor to be thinned was provided to help the worker find his bearings and efficiently navigate the stand. Real time tracking was activated to allow the worker to gauge where he was relative to the path in a block, and to ensure he did not miss sections.

The trial took place after the fall of the leaves which, combined with the narrow corridors to treat, allowed for good visibility and relatively easy navigation. However, it was understood from a prior undocumented trial that in a leaf-on context, navigation would be very difficult, and the sole use of a GPS would be insufficient. The worker had prior experience using light blue paint on crop trees and along his path, either on the ground or on trees, whenever required to maintain a quick reference point. The trial was divided in two main portions to understand the feasibility and time requirements of using paint marks: For the first six days of the trial, navigation was performed with the use of paint marks; for the remaining 7 days of the trial, paint marks were not used (Table 1).

| Table 1. Variants of work methods observed during the precommercial crop tree release (PCTR) trial. | ||

| Variant | Description | Duration |

| Paint and GPS | PCTR + Paint marks by the worker on crop trees to help navigate the stand + GPS waypoint of each crop tree | Days 1–6 of the trial |

| GPS only | PCTR + GPS waypoint of each crop tree | Day 7, 9, 11 and 13 |

| PCTR only | PCTR + GPS used for navigation purpose only | Day 8, 10 and 12 |

2.4 Productivity and cost determination

Area treated was determined in two different ways. The first, hereby called “tracking area”, is the area covered by a 2.5 m buffer on each side of the GPS tracking line (overlapping sections only considered once). The 2.5 m buffer corresponds to the prescribed 5 m spacing between crop trees. The second, called “corridor area”, is the area of the regenerated corridor (described in the stand description) covered by the worker, assuming adequate evaluation of crop tree presence in the rest of the regenerated area. This approach accounted for portions of the stand that were not within the 2.5 m buffer of tracking lines. Corridor area was determined by digitizing the contours from a high-resolution aerial photography. This method, while providing the accuracy required for this study, may not be realistically feasible at an operational scale.

The number and location of crop trees was recorded through GPS waypoints. Because this information is also deemed important in the context of large scale PCTR operations for quality control and for the payment scheme of workers, the task of recording the GPS waypoints was part of the worker’s job. To understand the impact of this task on productivity, on days 8, 10 and 12 of the trial, the worker did not take GPS waypoints of crop trees (hereby called the PCT only variant). In the PCT only variant, a technician followed the worker and took GPS waypoints of all crop trees for the benefit of the trial.

Time per tree released (cycle time) was calculated from the time stamp records in the GPS waypoints data files by determining the difference between two consecutive tree’s time stamps. This approach is similar to that used by Olivera et al. (2016) and by Strandgard et al. (2013) for estimating productivity from harvester StanForD data files. The subtraction of consecutive crop tree time stamps has the limitation that it is impossible to know whether there was a hidden delay. Delays were nonetheless accounted for by two means: 1) Detailed time and motion data were recorded by a technician on six of the 13 days of the trial. Cycles recorded by the technician were matched to those in the GPS files. Cycles that included breaks by the worker of more than one minute were removed. Occasional delays due to the chain bar getting stuck in a tree (pinched) were kept as part of what was considered productive time. 2) On days that did not have detailed time and motion data, the worker recorded the breaks he took so that the corresponding cycles could be removed. When processing the data, the few remaining cycles that were longer than three minutes were discussed with the worker and it was decided to keep them in the dataset.

Detailed time consumption was determined from continuous time and motion measurements collected on 6 of the 13 days of trial using the software TS-1000 (Gingras 2006), all taken by the same technician. The work cycle was divided into the following elements: Cutting; Moving; GPS; Paint; Delays (Table 2).

| Table 2. Definition of work cycle elements in time and motion study of the PCTR trial. | ||

| Cycle element | Description | Included in element |

| Cutting | Time required to release crop trees | When the chain is running or when working to bring trees down. This inevitably includes some movements of the worker and some time looking up to evaluate the presence of competing trees, especially when two crop trees are near one another. Cutting commonly ended when the worker stopped to either take out the GPS or the Paint container or, yelled “done” in the scenario without GPS. Small delays such as time taken to push on a tree that pinched the sawblade was included in this element. |

| Moving | Time required to search for crop trees, move between crop trees and evaluate the presence of competing trees | When the worker is walking, looking up and down at potential crop trees, but without the chain running on the saw or performing other tasks. Commonly started when the GPS or Paint container was put back in its holster. This element included limited saw use to cut small stems when the worker was walking through thick brush with no crop tree around. |

| GPS | Time dedicated to manipulating the GPS for entering crop tree waypoints | After releasing a crop tree, when worker had the GPS in hand and was not walking. The manipulation for waypoints was called out loud by the worker to distinguish from GPS manipulation for navigation purposes. This served as the end of cycle. |

| Paint | Time dedicated to marking crop trees with paint | When the worker had the paint container in hand. From the time it was taken out of the holster, until it was back in the holster. |

| Delays | Time resting or mechanical delays | When engine was turned off. Not considered as productive work time. |

The number of trees cut to release each crop tree was recorded during the time and motion data acquisition. The description of trees cut in terms of species and dbh was obtained as an average from the differences between pre- and post-treatment sample plots. Post-treatment sample plots were the same as for the pre-treatment. Post-treatment measurements included: presence of a crop tree not released; mention if a released tree met the criteria for crop trees; dbh and species of all residual stems in the plots. Damage to crop trees from the thinning treatment was not evaluated formally, but observations suggest that damage did not occur often, and usually consisted of minor cuts from the chainsaw. The strength of the relationship between time per crop tree released and number of stems cut per crop tree was evaluated with a Pearson correlation coefficient using the cor() function in R (R Core team 2017). The replicate for the correlation analysis is each of the 894 crop trees selected, tallied with the GPS and monitored during the time and motion study.

Cost estimates were derived from the 2016–2017 New Brunswick reimbursement rates for crown lands (Martin Noël. silviculture forester, New Brunswick Department of Energy and Resources Development, pers. comm. in 2016) using a costing tool for silviculture rate setting (St-Amour and Cormier 2012). Standard precommercial thinning assumes an average of 6.75 productive hours per day at a rate of 174.65 € (converted from CAD June 2019) per day paid to precommercial thinning workers for their time and equipment. This base rate was increased to 184.82 € day–1 to account for the extra cost of the backpack saw, for a GPS and batteries.

3 Results

Over the first 6 days of trial, the worker treated 7.9 ha in 35.3 productive hours while using paint marks and taking GPS waypoints of crop trees (Table 3). Based on the 2.5 m buffer around the GPS tracks (tracking method), only 5.6 ha were “walked”. Post treatment inventory of the 117 pairs of plots in the stand indicated that the worker had found and released just over 95% of the crop trees that were identified pre-treatment. Given that the areas not “walked” by the worker were deliberately skipped as a result of his visual analysis, they were deemed “treated”. Of the 35.3 productive hours, 19.1 were directly observed by a technician performing the time and motion study and counting the number of stems cut per crop tree. The number of crop trees entered in the GPS by the worker matched the number tallied by the technician during the time and motion study. Post-treatment plots showed no indication of differences in the quality of the work whether or not time and motion of the worker were being observed by a technician.

| Table 3. Summary of worker’s productivity in PCTR of a young hardwood stand in New Brunswick. For detailed data see Soucy and Béland (2018). | ||||||

| Average | ||||||

| Variant | Total productive time (h) | Crop trees released per hour | Area treated (ha h–1) (based on GPS buffer) | Area treated (ha h–1) (based on corridor area) | Crop trees ha–1 (based on GPS buffer) | Crop trees ha–1 (based on corridor area) |

| Paint and GPS | 35.3 | 47.1 | 0.16 | 0.22 | 297 | 211 |

| GPS only | 15.3 | 71.9 | 0.18 | 0.31 | 387 | 233 |

| PCTR only | 13.3 | 76.2 | 0.29 | 0.48 | 269 | 163 |

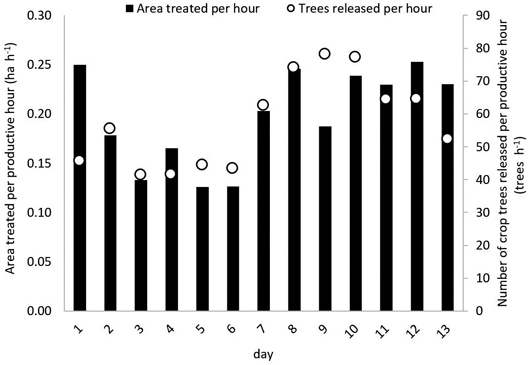

As can be expected, the GPS-only variant was more productive than the Paint-and-GPS variant (Table 3 and Fig. 2). Productivity was on average 0.31 ha h–1 (Table 3). For this variant, only 1.48 productive hours were observed by a technician for time and motion measurements. The PCTR-only variant showed to be even more productive than the GPS-only variant.

Fig. 2. Daily productivity of PCTR of a young hardwood stand observed in terms of area treated per productive hour (GPS based) and in terms of the number of crop trees released per productive hour.

Just like for area treated, the number of crop trees released per hour appeared to be influenced by the variant used. From an average of 47 trees h–1 in the Paint and GPS variant, it went up to an average of 76 trees h–1 for the PCTR only variant. Noteworthy is that for the last 7 days of the trial, 5 to 25 cm of snow covered the ground. This did not appear to significantly affect how work was performed nor its rate, but did cause the worker to occasionally trip over hidden obstacles.

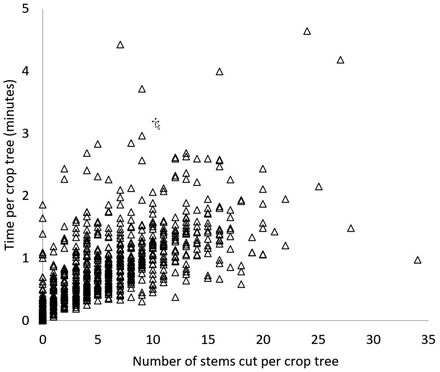

From the time and motion measurements, an average of 6.2 trees were cut for each crop tree released (Table 4). A few crop trees were free of competition, but others had up to 34 competitors cut. Trees requiring the largest number of stems to be cut tended to take more time to be released (Fig. 3, Pearson correlation coefficient r = 0.6772). Other factors causing long release times also included: 1) larger stems being cut requiring extra cuts, 2) cut stems tangled in crop tree, 3) saw blade pinched stuck in a stem.

| Table 4. Synthesis of time and motion measurements in PCTR of a young hardwood stand in New Brunswick. | ||||||||

| Average | ||||||||

| Variant | Duration (productive hours only) | Number of crop trees (CT) released | Trees cut per crop tree | Duration per crop tree (s) | Moving (s CT–1) | Cutting (s CT–1) | GPS (s CT–1) | Paint (s CT–1) |

| Paint & GPS | 19.07 | 954 | 6.1 | 72.0 | 20.6 | 43.9 | 3.9 | 3.5 |

| GPS only | 1.48 | 82 | 7.7 | 65.1 | 22.4 | 38.7 | 4.1 | - |

| PCTR only | 11.93 | 894 | 5.6 | 48.0 | 16.0 | 32.0 | - | - |

Fig. 3. Time consumption per crop tree in the PCTR only variant (Pearson correlation coefficient r = 0.6772).

Moving between trees and searching for the next crop tree systematically took approximately a third of the worker’s time (Table 4). Assuming a daily cost of 184.84 € for the worker’s salary and equipment, cost for walking the stand in search for crop trees thus varied from 19.22 to 35.12 € ha–1 in this trial (Table 5). The application of paint on trees to facilitate navigation took approximately 5% of the worker’s time. Taking a GPS waypoint of each crop tree took another 6% of the worker’s time. Overall, the total treatment cost estimate varied between 58.41 and 122.87 € ha–1.

| Table 5. Estimated cost of PCTR of a young hardwood stand for the worker and equipment in New Brunswick. | ||||

| Variant | 1Cost of walking and selecting trees (€ ha–1) | Cost of work on a crop tree (€) | Total cost per tree released | Total cost per area (€ ha–1) |

| Paint and GPS | 35.17 | 0.42 | 0.58 | 122.87 |

| GPS only | 30.51 | 0.25 | 0.38 | 88.83 |

| PCTR only | 17.29 | 0.24 | 0.36 | 58.41 |

| 1 Based on treated corridor area. | ||||

4 Discussion

This study’s main objective was to test the technical and financial feasibility of using a backpack mounted chain saw to perform precommercial crop tree release in shade-tolerant hardwoods. This proof of concept trial succeeded in providing results that are informative on some of the potential advantages that this new tool offers and for setting the basis for a larger scale deployment of this treatment. On the other hand, the trial had significant limitations that readers should keep in mind before attempting to generalize the results.

First, the trial was limited to a single worker and stand. Productivity of motor-manual worker in precommercial thinning is known to be highly variable between operators (Lebel and Dubeau 2007; Uotila 2017) mainly because of the high level of physical and mental strain it imposes (Gellerstedt 1997). It follows that the productivity reported in this study should not be generalized as an average productivity. Nonetheless, the productivities observed suggest that delayed PCTR in hardwood stands with a backpack mounted chainsaw is indeed feasible, and that gradual implementation can be considered to gain further understanding of its potential.

Second, thinning 10 to 15 m wide corridors separated by distinct unregenerated corridors created favorable conditions to navigate the stand and assess the presence of crop trees. While the worker effectively “zig-zagged” along the corridor, the visibility was often greater than the 2.5 m buffer making it possible to evaluate and notice the absence of a potential crop tree without having to actually walk into that area. Without clear unregenerated trails, it would have been necessary to rely more on the GPS to confirm that the entire section was effectively covered and it may not have been possible to determine the absence of crop trees as easily. The distinct unregenerated corridors, combined with the leaf-off condition, offered particularly good visibility and essentially rendered the use of paint marks unnecessary.

Third, the ability to produce “high stumps” during PCTR certainly played a great role in the high productivity observed. However, cutting 6 to 12 cm dbh stems at heights varying between 1 and 2.5 m raises a concern about possible negative effects on future harvesting operations. The high stumps could become obstacles during a first commercial thinning, especially for American beech (40% of all stems) when cut at 2.5 m in height. If the stumps manage to sprout and survive, they could greatly reduce visibility and accessibility in addition to potentially only grow into unmerchantable products by the time of commercial thinning. American beech being very shade tolerant, its sprouts may not only survive but grow well after PCTR. On the other hand, the presence of high stumps stocked with lots of sprouts around a crop tree could provide a physical barrier of protection against a premature harvest of those trees and against moose browsing, thus acting to protect the investment.

Finally, damage to crop trees from the thinning operation was not measured, but observations suggest there is little. This is in line with Ligné et al. (2005) who measured less damage from the chainsaw equipped pole saw (1.2–1.7% of stems) than from the conventional brushsaw (4.8% of stems). The reduction in damage from the pole saw can be explained by the reduction in kickbacks compared to a circular saw and the better visibility when cutting at a higher level.

It is clear that PCTR, as performed in this trial, is very different from conventional PCT. The significantly reduced number of stems cut combined with the possibility to cut stems higher proved to be a good fit for the backpack mounted polesaw. Similarily, PCTR could be a treatment well suited for testing the new electrical models of polesaw or brushsaw that are becoming available.

We do not know of publications on worker productivity performing an equivalent treatment, making a direct comparison of worker productivity impossible. Nonetheless, Miller (1984) reports on a CTR in young hardwoods using a chainsaw that averaged 8 hours per ha (0.125 ha h–1 to release 150 crop trees, which is in line with this trial, given the technology used. In an extensive study of PCT in Quebec, Lebel and Dubeau (2007) reported an average of 19.9 h required per hectare treated (standard deviation of 9.4 h ha–1) which is more time consuming than the 2.1 to 4.5 h ha–1 observed to perform PCTR in this pilot study. Accordingly, reimbursement rates for conventional, “early” precommercial thinning used on public lands in New Brunswick are based on an observed average stand density of 25 426 stems ha–1 where workers are expected to thin at 17.6 h ha–1. It’s notable that motor-manual PCTR, while a somewhat different silvicultural treatment than PCT in dense younger stands, was performed at a rate similar to that of mechanized options (Glöde and Bergkvist 2003). This further confirms that adaptation of when and how thinning is performed in respect to available labor and technologies may provide great cost-saving opportunities (Laitila et al. 2007; Laitila 2008; Laitila et al. 2010; Bergström and Fulvio 2014; Nuutinen and Björheden 2016; Ahnlund Ulvcrona et al. 2017).

In terms of treatment costs, a few side effects are expected. The required equipment, including a good GPS, results in an increased daily cost for the worker. More significant, but not measured in this trial, are the extra costs to manage the operation. The preparation and post-treatment processing of GPS files (grid, tracking and waypoints) would require time. On the other hand, we feel this GPS information would be beneficial when a treated stand is selected to be audited, for payment purposes, and to document stand stocking in high-quality trees.

A more complete financial analysis is required to evaluate the potential benefits of PCTR. The delay in thinning not only helps ensure that release is done on high-value trees, but might also decrease the time between PCT and a profitable harvest that will recoup the cost of the investment in PCT. Nonetheless, the treatment costs observed in this trial were much lower than the average of 452.55 € ha–1 being paid for conventional PCT on public lands in New Brunswick (pers. comm. May 2016. Martin Noël. silviculture forester, New Brunswick Department of Energy and Resources Development).

The success of such a treatment depends greatly on the stand’s response. Crop trees will be free to grow for several years before the stand closes back. Although a positive reaction of crop trees is not guaranteed (Caselas 2018; Gauthier and Tremblay 2018; Wotherspoon et al. 2018), the treatment is expected to stimulate crop tree value growth (Demchik et al. 2018) and might thus positively influence the rehabilitation of these degraded stands as was shown elsewhere (Ward 2013, 2017; Demchik et al. 2018). One might be concerned with an increase in large branches induced by the release, hindering the future maintenance of good tree quality (Reventlow et al. 2018). However, an old area-wide PCT in tolerant hardwoods of the area showed that sawlog yield potential is not decreased by even the largest spacings tested (Swift et al. 2017). It is likely that cutting stems at a higher level (Fällman et al. 2003), maintaining some small trees not competing with crop trees, and the presence of the untreated matrix should further help limit branch growth (Puhlick et al. 2018) and limit damage by ungulates (Boureima and Doyon 2010). Otherwise, other positive foreseeable effects of CTR relative to area-wide thinning may include increased presence of deadwood, and increased seed and mast production (Chhin 2018).

Our results also suggest that backpack mounted chainsaws could be considered to perform “late” or “delayed” precommercial thinnings. For instance, in a context where stands are at the stage for an “energy” thinning (Ahtikoski et al. 2008; Heikkilä et al. 2009; Laitila et al. 2010; Petty and Kärhä 2014; Bergström and Fulvio 2014; Karttunen et al. 2016; Sasatani et al. 2018) but where markets may not justify the extraction of the small stems, the stand could still be thinned to meet the stand tending objectives.

In conclusion, this study demonstrated that a precommercial crop tree release in shade-tolerant hardwoods is technically feasible. The use of a GPS to navigate the stand while selecting crop trees performed well. Compared to conventional PCT performed earlier in the life of a stand, PCTR required cutting larger stems, which showed to be feasible and productive using the chain saw configuration of the spacing saw. Results suggest that in New Brunswick conditions, time required to perform a PCTR can be significantly lower than to perform conventional PCT with a brushsaw, with equivalent cost reduction. Time spent and stems cut per crop tree averaged approximately 1 min and 6 stems respectively. Although these figures could vary with stand characteristics and worker, this proof of concept shows some of the potential advantages that this new tool offers and sets the basis for a larger-scale deployment of this treatment. Monitoring injury and survival of cut stems (mainly American beech) and response of released crop trees over the next few years will be useful in confirming the potential of this treatment in New Brunswick.

Acknowledgements

This work was financially supported by the Université de Moncton, the New Brunswick Department of Energy and Resource Development (NBERD), The National Research Council of Canada (NRC) and NB Wildlife Trust Fund.

We thank the staff from AV Group NB and NBERD for their field work support. We also thank Mr. Michel DesGagné and Jean Cyr of PPF Synergie for technical support. Finally, we thank the anonymous reviewers for their constructive comments.

References

Ahnlund Ulvcrona K., Bergström D., Bergsten U. (2017). Stand structure after thinning in 1–2 m wide corridors in young dense stands. Silva Fennica 51(3) article 1563. https://doi.org/10.14214/sf.1563.

Ahtikoski A., Päätalo M.-L., Niemistö P., Karhu J., Poutiainen E. (2004). Effect of Alternative Thinning Intensities on the Financial Outcome in Silver Birch (Betula pendula Roth) Stands: a Case Study Based on long-term Experiments and MOTTI Stand Simulations. Baltic Forestry 10(2): 46–55.

Ahtikoski A., Heikkilä J., Alenius V., Siren M. (2008). Economic viability of utilizing biomass energy from young stands—the case of Finland. Biomass and Bioenergy 32(11): 988–996. https://doi.org/10.1016/j.biombioe.2008.01.022.

Bergström D., Fulvio F.D. (2014). Evaluation of a novel prototype harvester head in early fuel-wood thinnings. International Journal of Forest Engineering 25(2): 156–170. https://doi.org/10.1080/14942119.2014.945697.

Boulet B., Pin D. (2015). Le portrait de la forêt feuillue et mixte à feuillus durs au Québec – Les perturbations et leur effet sur la dynamique forestière, [Portrait of the hardwood and mixed hardwood forest in Quebec – Disturbances and their effect on foresst dynamics]. Document d’information. Bureau du forestier en chef. Québec, Qc. 31 p.

Boureima I., Doyon F. (2010). Comparaison de la croissance et de la qualité externe et interne des tiges de feuillus nobles en Estrie après l’éclaircie précommerciale systématique et par puits de lumière, [Comparison of growth and of stem quality following systematic and crop tree release precommercial thinning]. Institut québécois d’Aménagement de la Forêt feuillue, Ripon, Québec. Rapport final. 40 p.

Bulley B., Bowling C., Niznowski G. (1997). Jack pine leader clipping trial: fifth-year results. Ontario Ministry of Natural Resources, Northwest Science and Technology, Thunder Bay, Ont. TR-106.

Caselas K. (2018). Evaluating the effectiveness of restoration treatments to enhance Oregon white oak systems within the Klickitat River Watershed. Master of Environmental Management Project Reports. https://doi.org/10.15760/mem.3.

[CCFM] Canadian Council of Forest Ministers. (2017). Silviculture: national tables: area of stand tending by ownership, treatment, and province/territory. National Forestry Database, Compendium of Canadian Forestry Statistics (online). Canadian Council of Forest Ministers, Ottawa, Ontario. http://nfdp.ccfm.org. [Cited 4 April 2017].

Chhin S. (2018). Managing red oak (Quercus rubra L.) reduces sensitivity to climatic stress. Journal of Forest and Environmental Science 34(4): 338-351. https://doi.org/10.7747/JFES.2018.34.4.338.

Collet C., Ningre F., Frochot H. (1998). Modifying the microclimate around young oaks through vegetation manipulation: effects on seedling growth and branching. Forest Ecology and Management 110(1–3): 249–262. https://doi.org/10.1016/S0378-1127(98)00284-9.

Creswell J.W. (2014). Research design: qualitative, quantitative, and mixed methods approaches. SAGE Publications inc. 273 p.

Demchik M.C., Conrad J.L., Vokoun M.M., Backes B., Schellhaass I., Demchik B.M. (2018). Crop tree release guidelines for 71- to 94-year-old oak stands based on height and financial maturity. Journal of Forestry 116(3): 217-221. https://doi.org/10.1093/jofore/fvx012.

Dobner M., Huss J. (2018). Crown thinning on Eucalyptus dunnii stands for saw- and veneer logs in southern Brazil. New Forests 50: 361–375. https://doi.org/10.1007/s11056-018-9661-5.

Dwyer J.P., Dey D.C., Kurtz W.B. (1993). Profitability of precommercial thinning oak stump sprouts. Northern Journal of Applied Forestry 10(4): 179–183. https://doi.org/10.1093/njaf/10.4.179.

Egan A., Taggart D. (2004). Who will log in Maine’s north woods? A cross-cultural study of occupational choice and prestige. Northern Journal of Applied Forestry 21(4): 200–208. https://doi.org/10.1093/njaf/21.4.200.

Fällman K., Ligné D., Karlsson A., Albrektson A. (2003). Stem quality and height development in a Betula-dominated stand seven years after precommercial thinning at different stump heights. Scandinavian Journal of Forest Research 18(2): 145–154. https://doi.org/10.1080/02827580310003713.

Gauthier M.-M., Tremblay S. (2018). Precommercial thinning as a silvicultural option for treating very dense conifer stands. Scandinavian Journal of Forest Research 33(5): 446–454. https://doi.org/10.1080/02827581.2017.1418422.

Gellerstedt S. (1997). Mechanised cleaning of young forest – the strain on the operator. International Journal of Industrial Engineering 20(2): 137–143. https://doi.org/10.1016/S0169-8141(96)00046-7.

Gingras J.F. (2006). (unpublished). Time study procedures using FERIC’s TS1000 program. Forest Engineering Research Institute of Canada. Pointe-Claire, Quebec. 14 p.

Glöde D., Bergkvist I. (2003). Mechanized cleaning down and out and back again? In: Iwarsson Wide M., Baryd B. (eds.). Proceedings Technique and Methods, 2nd Forest Engineering Conference. The Forestry Research Institute of Sweden, Arbetsrapport 535: 25–37.

Groninger J.W., Stein H.D., Zedaker S.M., Smith D.W. (1998). Growth response and cost comparisons for precommercial thinning methods of Appalachian oak stump sprouts. Southern Journal of Applied Forestry 22(1): 19–23. https://doi.org/10.1093/sjaf/22.1.19.

Heikkilä J., Sirén M., Ahtikoski A., Hynynen J., Sauvula T., Lehtonen M. (2009). Energy wood thinning as a part of stand management of Scots pine and Norway spruce. Silva Fennica. 43(1): 129–146. https://doi.org/10.14214/sf.220.

Heitzman E., Nyland R.D. (1991). Cleaning and early crop tree release in northern hardwood stands: a review. Northern Journal of Applied Forestry 8(3): 111–115. https://doi.org/10.1093/njaf/8.3.111.

Huuskonen S., Hynynen J. (2006). Timing and intensity of precommercial thinning and their effects on the first commercial thinning in Scots pine stands. Silva Fennica 40(4): 645–662. https://doi.org/10.14214/sf.320.

Kaila S., Kiljunen N., Miettinen A., Valkonen S. (2006). Effect of timing of precommercial thinning on the consumption of working time in Picea abies stands in Finland. Scandinavian Journal Forest Research 21(6): 496–504. https://doi.org/10.1080/02827580601073263.

Karlsson A., Albrektson A. (2000). Height development of Betula and Salix species following precommercial thinning at various stump heights: 3-year results. Scandinavian Journal Forest Research 15(3): 359–367. https://doi.org/10.1080/028275800447995.

Karttunen K., Laitila J., Ranta T. (2016). First-thinning harvesting alternatives for industrial or energy purposes based on regional Scots pine stand simulations in Finland. Silva Fennica. 50(2) article 1521. https://doi.org/10.14214/sf.1521.

Kikuzawa K. (1988). Intraspecific competition in a natural stand of Betula ermanii. Annals of Botany 61(6): 727–734. https://doi.org/10.1093/oxfordjournals.aob.a087611.

Labbé C. (1995). Influence des facteurs de terrain sur la productivité des travailleurs lors d’une éclaircie précommerciale (peuplement résineux). [Effect of terrain variables on worker productivity during precommercial thinning]. Ministère des Ressources naturelles, Direction de la recherche forestière, Sainte-Foy, Quebec. 13 p.

Laitila J. (2008). Harvesting technology and the cost of fuel chips from early thinnings. Silva Fennica 42(2): 267–283. https://doi.org/10.14214/sf.256.

Laitila J., Asikainen A., Nuutinen Y. (2007). Forwarding of whole trees after manual and mechanized felling bunching in pre-commercial thinnings. International Journal of Forest Engineering 18(2): 29–39. https://doi.org/10.1080/14942119.2007.10702548.

Laitila J., Heikkilä J., Anttila P. (2010). Harvesting alternatives, accumulation and procurement cost of small-diameter thinning wood for fuel in Central Finland. Silva Fennica 44(3): 465–480. https://doi.org/10.14214/sf.143.

Lamson N.I., Smith H.C. (1987). Precommercial treatments of 15- to 40-year-old northern hardwood stands. In: Nyland R.D. (ed.). Managing northern hardwoods. Silviculture Symposium Proceedings, June 23–25 1986. Society of American Foresters, Syracuse, New York. Publication no. 87-03. p. 160–175.

Leak W.B., Solomon D.S. (1997). Long-term growth of crop trees after release in northern hardwoods. Northern Journal of Applied Forestry. 14(3): 147–151. https://doi.org/10.1093/njaf/14.3.147.

Lebel L.G., Dubeau D. (2007). Predicting the productivity of motor-manual workers in precommercial thinning operations. Forestry Chronicle 83(2): 215–220. https://doi.org/10.5558/tfc83215-2.

Lees J.C. (1995). The growth, branchiness, and resprouting of sapling northern hardwoods after spacing. Canadian Forest Service – Maritimes Region. M-X-193E. 15 p.

Ligné D, Nordfjell T, Karlsson K. (2005). New techniques for pre-commercial thinning – time consumption and tree damage parameters. International Journal of Forest Engineering 16(2): 89–99. https://doi.org/10.1080/14942119.2005.10702518.

Lombardi F, Lella SD, Altieri V, Benedetto SD, Giancola C, Lasserre B, Kutnar L, Tognetti R, Marchetti M. (2018). Early responses of biodiversity indicators to various thinning treatments in mountain beech forests. IForest - Biogeosciences and Forestry 11(5): 609–618. https://doi.org/10.3832/ifor2733-011.

Magagnotti N., Spinelli R. (eds.) (2012). COST action FP0902 – good practice guideline for biomass production studies. CNR IVALSA, Florence, Italy. 41 p. ISBN 978-88-901660-4-4.

Marquis D.A., Ernst R.L., Stout S.L. (1984). Prescribing silvicultural treatments in hardwood stands of the Alleghenies. USDA, Forest Service General Technical Report-NE-96. 90 p.

McCauley O.D., Marquis D.A.. (1972). Investment in precommercial thinning of northern hardwoods. USDA, Forest Service. RP-NE-245. 13 p.

Miller G.W. (1984). Releasing young hardwood crop trees – use of a chain saw costs less than herbicides. USDA, Forest Service. RP-NE-550.

Needham T., Clements S. (1989). Stand factors affecting precommercial thinning productivity on small woodlots in New Brunswick. Faculty of Forestry, University of New Brunswick. 18 p. + figures.

Needham T., Hart D. (1991). Forest stand factors affecting precommercial thinning productivity. University of New Brunswick, Department of Forest engineering. 22 p.

[NHRI] Northern Hardwoods Research Institute. (2019). NHRI’s work plan – ongoing and upcoming projects for 2020 – working towards increasing timber volume and quality in northern hardwoods and mixed forests! The Leaflet vol. 1 issue 8. 23 p.

Nilsson U., Albrektson A. (1994). Growth and self-thinning in two young Scots pine stands planted at different initial densities. Forest Ecology and Management 68(2–3): 209–215. https://doi.org/10.1016/0378-1127(94)90046-9.

[NSDNR] Nova Scotia Department of Natural Resources. (1992). Worker productivity in pre-commercial thinnings. Forestry Branch, Forest research section, Truro, NS. 10 p.

Nuutinen Y., Björheden R. (2016). Productivity and work processes of small-tree bundler Fixteri FX15a in energy wood harvesting from early pine dominated thinnings. International Journal of Forest Engineering 27(1): 29–42. https://doi.org/10.1080/14942119.2015.1109175.

Olivera A., Visser R., Acuna M., Morgenroth J. (2016). Automatic GNSS-enabled harvester data collection as a tool to evaluate factors affecting harvester productivity in a Eucalyptus spp. Harvesting operation in Uruguay. International Journal of Forest Engineering 27(1): 15–28. https://doi.org/10.1080/14942119.2015.1099775.

Petty A., Kärhä K. (2014). Productivity and cost evaluations of energy-wood and pulpwood harvesting systems in first thinnings. International Journal of Forest Engineering 25(1): 37–50. https://doi.org/10.1080/14942119.2014.893129.

Pasanen K., Laitila J., Pykäläinen J., Anttila P. (2014). Using the ComBio decision support system to assess whether energy wood and/or pulpwood should be harvested in young forests. International Journal of Forest Engineering 25(1): 51–65. https://doi.org/10.1080/14942119.2014.903614.

Plamondon J., Pitt D.G. (2013). Effects of precommercial thinning on the forest value chain in northwestern New Brunswick: part 2 – efficiency gains in cut-to-length harvesting. Forestry Chronicle 89(4): 458–63. https://doi.org/10.5558/tfc2013-087.

Pitt D.G., Lanteigne L., Hoepting M.K., Plamondon J. (2013). Effects of precommercial thinning on the forest value chain in Northwestern New Brunswick: part 1 – roundwood production and stumpage value. Forestry Chronicle 89(4): 446–457. https://doi.org/10.5558/tfc2013-086.

Puhlick J.J., Kuehne C., Kenefic L.S. (2018). Crop tree growth response and quality after silvicultural rehabilitation of cutover stands. Canadian Journal of Forest Research 49(6): 670–679. https://doi.org/10.1139/cjfr-2018-0248.

R Core Team. (2017). R: a language and environment for statistical computing. R Foundation for Statistical Computing, Vienna, Austria. https://www.R-project.org/.

Reventlow D.O.J., Nord-Larsen T., Skovsgaard J.P. (2018). Pre-commercial thinning in naturally regenerated stands of European beech (Fagus sylvatica L.): effects of thinning pattern, stand density and pruning on tree growth and stem quality. Forestry: An International Journal of Forest Research 92(1): 120–132. https://doi.org/10.1093/forestry/cpy039.

Ryans M., Cormier D. (1994). A review of mechanized brush-cutting equipment for forestry. Forest Engineering Research Institute of Canada, Pointe-Claire, Quebec. SR-101. 36 p.

Sasatani D., Eastin I.L., Bowers C.T., Ganguly I. (2018). Public acceptance of pre-commercial thinning and energy and soil amendment products from post-harvest residues in western forests of the United States. Applied Engineering in Agriculture 34(1): 99–108. https://doi.org/10.13031/aea.12366.

Schütz J.-P. (1990). Sylviculture 1 : Principes d’éducation des forêts. [Principles of forest tending]. Collection Gérer l’environnement, Presses polytechniques et universitaires romandes.

Smith D.M., Larson B.C., Kelty M.J., Ashton P.M.S. (1997). The practice of silviculture: applied forest ecology. John Wiley and Sons, Inc. No. ed. 9 p. xvii + 537 p.

Smith H.C., Lamson N.I. (1986). Cultural practice in Appalachian hardwood sapling stands: if done, how to do them. In: Guidelines for managing immature Appalachian hardwood stands, Proceedings Workshop, Society of American Foresters. Publication 86-02. Society of American Foresters, Bethesda, Maryland. p. 46–61.

Soucy M., Béland M. (2018). Dataset – proof of concept: a crop tree release variant of precommercial thinning using a spacing saw designed for top spacing. Open Science Framework. https://doi.org/10.17605/OSF.IO/D2APY.

St-Amour M., Cormier D. (2012). Costing tools for silviculture rate setting. FPInnovations, Pointe-Claire, Quebec. CR-680. 34 p.

Strandgard M., Walsh D., Acuna M. (2013). Estimating harvester productivity in Pinus radiate plantations using StanForD stem files. Scandinavian Journal of Forest Research 28(1): 73–80. https://doi.org/10.1080/02827581.2012.706633.

Svensson S.A. (1971). Time functions for cleaning in young stands with brush saw. Forskningsstiftelsen (Logging Research Foundation), Stockholm, Sweden. 4 p.

Swift D.E., Knight W., Béland M., Boureima I., Bourque C.P.A., Meng F.-R. (2017). Stand dynamics and tree quality response to precommercial thinning in a northern hardwood forest of the Acadian forest region: 23 years of intermediate results. Scandinavian Journal of Forest Research 32(1): 45-59. https://doi.org/10.1080/02827581.2016.1186219.

Terrell S.R. (2012). Mixed-methods research methodologies. Nova southeastern University, Fort Lauderdale, Florida, USA. 254–280.

Uotila K. (2017). Optimization of early cleaning and precommercial thinning methods in juvenile stand management of Norway. Dissertationes Forestales 231. 42 p. https://doi.org/10.14214/df.231.

Uotila K., Saksa T., Rantala J., Kiljunen N. (2014). Labour consumption models applied to motor-manual pre-commercial thinning in Finland. Silva Fennica 48(2) article 982. https://doi.org/10.14214/sf.982.

Varmola M., Salminen H. (2004). Timing and intensity of precommercial thinning in Pinus sylvestris stands. Scandinavian Journal of Forest Research 19(2): 142–151. https://doi.org/10.1080/02827580310019545.

von Althen F.W., Wood J.E., Mitchell E.G., Hoback K. (1994). Effects of different intensities of yellow birch and sugar maple crop tree release. Canadian Forest Service – Sault Ste, Marie. TR-4. 13 p.

von Althen F.W, Wood J.E., Mitchell E.G., Hoback K. (1996). Recommendations for thinning yellow birch and sugar maple saplings in northeastern Ontario. Canadian Forest Service – Sault Ste, Marie. TR-18. 4 p.

Voorhis N.G. (1986). Sugarbush management in young stands: effects of crop tree thinning. Northern Journal of Applied Forestry 3(3): 106–108. https://doi.org/10.1093/njaf/3.3.106.

Voorhis N.G. (1990). Precommercial crop-tree thinning in a mixed northern hardwood stand. USDA Forest Service Research Paper. NE-640. 4 p. https://doi.org/10.2737/NE-RP-640.

Wade R.K. (2018). Models for plant self-thinning. Ecosphere 9(5) article e02219. 18 p. https://doi.org/10.1002/ecs2.2219.

Ward J.S. (2013). Precommercial crop tree release increases upper canopy persistence and diameter growth of oak saplings. Northern Journal of Applied Forestry 30(4): 156–163. https://doi.org/10.5849/njaf.13-017.

Ward J.S. (2017). Twenty-five year response of non-crop trees to partial release during precommercial crop tree management. Forest Ecology and Management 387: 12–18. https://doi.org/10.1016/j.foreco.2016.05.036.

Wischnewski A. (2018). Can late successional understory plants survive high intensity crop tree release? Master in Forest Conservation (MFC) Capstone Papers FOR3008H1. http://hdl.handle.net/1807/81244.

Wotherspoon A., Reicis K., Thiffault N., Houle D., Barrette M., Tremblay S. (2018). Interactions between pre-commercial thinning and climate in controlling black spruce productivity in two climate regimes of Québec, Canada. In: Proceedings from 20th EGU General Assembly, EGU2018, 4–13 April, Vienna, Austria. p. 11031. http://adsabs.harvard.edu/abs/2018EGUGA..2011031W.

Total of 80 references.