Primary forest fuel supply chain: assessing barriers and drivers for the modal shift from truck to train

Wolfsmayr U. J., Rauch P. (2014). Primary forest fuel supply chain: assessing barriers and drivers for the modal shift from truck to train. Silva Fennica vol. 48 no. 5 article id 1217. https://doi.org/10.14214/sf.1217

Highlights

- For combined heat and power plants in Austria procuring forest fuels, the most competitive transport mode is road transport using walking-floor trucks

- The main barriers for a modal shift are the plant managers’ negative experiences with the railroad

- Rail transport has its benefits, when high volumes are needed and transport distances are long.

Abstract

Multimodal primary forest fuel (PFF) transport using the railroad for main haulage has been quite uncommon to present, although it could provide considerable advantages in terms of economical, ecological and social parameters. Accordingly, the objective of this paper is to assess barriers and drivers for the modal shift from truck to train. As methodological tool, we are using the concept of Quality Function Deployment (QFD) with the House of Quality (HoQ) – an approach that has not been used in forest management so far. As the most important barriers for the modal shift from truck to train in PFF transport in Austria, the following were identified: (i) bioenergy plant managers have a negative opinion and negative experience regarding the railroad in terms of high prices, a lot of bureaucracy, etc.; (ii) absence of rail sidings or relatively short rail sidings not suitable for block trains; and (iii) unwillingness to invest in new supply or unloading systems. On the contrary, the most important drivers for a modal shift are: (i) multimodal PFF supply chains using trains can provide high volumes; (ii) increasing catchment areas for larger CHP plants result in increasing transport distances; and (iii) rail transport has less negative environmental and social impact than road transport.

Keywords

biomass;

multimodal transport;

train transport;

quality function deployment;

house of quality

Received 30 June 2014 Accepted 6 November 2014 Published 31 December 2014

Views 143424

Available at https://doi.org/10.14214/sf.1217 | Download PDF

1 Introduction

Biomass is a renewable source for energy, and it is steadily growing in importance due to a rising demand for energy, the awareness of climate change, and the environmental dilemma caused by fossil and nuclear energy systems. Additionally, fossil resources are getting more difficult to exploit and rising prices have lead to increasing energy trade deficits in Europe, which is dependent on imports. In 2013 Austria paid over 13 billion euro for importing fossil energy – more than ever in history, additionally since the late 90’s there has been a tremendous increase in prices for fuel oil in contrast to forest fuel per unit of energy (Austrian Biomass Association 2013). Biomass for bioenergy, however, is available on the domestic market and will play a major role in the future renewable energy mix. Among different types of biomass for bioenergy, primary forest fuel (PFF) plays a major role. Traditionally, PFF is used in small-scale applications, and residential heating with wood is popular and increasingly used, but district heating systems and combined heat and power (CHP) plants have also gained in importance in recent years throughout Europe. Due to scale effects, the cost per unit of the produced bioenergy decreases with plant size (see e.g. Jenkins 1997; Dornburg and Faaij 2001). In contrast, the influence of transport costs increases with the plant size due to increasing feedstock draw areas (Dornburg and Faaij 2001). The biggest CHP plant fired entirely with PFF in Austria, apart from industrial sites, is the 66 MW plant in Simmering (Vienna). Larger plants can be found e.g. in Jakobstad, Finland; “Alholmens Kraft” produces 240 MW electricity plus 60 MW heat and 100 MW steam, burning a feedstock of approximately 45% wood-based fuels, 45% peat and 10% coal (Alholmens Kraft Ab 2012). These plants using reasonable volumes of PFF are often located in densely populated, but sparsely forested areas. This results in the requirement for long-distance transport, where train transport can become competitive.

An overview on PFF assortments, procurement systems, transport modes and supply chain management can be found in (Wolfsmayr and Rauch 2014). Due to available infrastructure and the geographically dispersed origin of PFF in the forests, an initial road transport is necessary in most cases. Furthermore, short transport distances, flexibility and low average PFF volume per logging site, as well as the low demand for small and medium-scale heating plants, make unimodal road transport advantageous (Hamelinck et al. 2005). For longer transport distances, multimodal transport is possible, where the initial haulage by truck is followed by main haulage on a train. Introducing multimodal transport chains in the bioenergy sector is becoming increasingly important, since truck transport has undesirable effects on the public welfare, such as noise and air pollution, congested roads, or traffic accidents (Behrends 2012), but mainly because increasing plant size results in greater distances between the sites of origin and use of PFF.

The application of multimodal transport in the design of supply chains for solid biofuels, e.g. PFF, has rarely been studied until present. Studies on multimodal PFF supply chains provide calculations for supply costs (Mahmudi and Flynn 2006; Searcy et al. 2007; Karttunen et al. 2013; Korpinen et al. 2013), greenhouse gas emissions (Jäppinen et al. 2014b) or both (Kanzian et al. 2013). Recently, Xie et al. (2014) studied the integration of multimodal transport into a biofuel supply chain in California (corn stover and forest residues) and applied a multistage, mix-integer programming model. They compared unimodal truck transport with single railcar and block train transport and conclude that “the multimodal solution makes the supply chain more adaptive to feedstock seasonality, more cost effective, and more capable handling policies on distance limits for biomass truck deliveries” (Xie et al. 2014).

In Northern Europe the use of rail transport within the PFF supply chain has become relatively common. Enström (2011) reports that in Sweden there are regular train transports of wood chips in containers, and volumes correspond to 1 TWh annually. A calculation tool for making economic analyses of various train transport options in Sweden has been developed. Thereby, factors that influence costs were identified as follows: (i) number of deliveries that a train unit makes per time unit; (ii) utilization of load capacity; (iii) transport distance; (iv) terminal handling (loading and unloading); (v) conditions for train shunting at terminal points (Enström 2011).

When comparing rail and road transport costs, we see that distance variable costs, which directly depend on transport distance, are much lower for train transport. In contrast, time-dependent costs are higher for train transport. They are independent of travel distance and include the costs of loading and unloading, inter alia. Without doubt the use of both road and rail leads to additional transhipment processes connected with additional costs.

Subsequently, the railroad is more competitive in terms of costs only above a certain minimum transport distance. Train transport can be found favourable for distances exceeding 100 km (Hamelinck et al. 2005). Accordingly, for a 30 MW CHP plant in Basel (Switzerland), rail transport is competitive for distances well beyond 100 km, whereas for short distances transhipment costs are too high (Madlener and Vögtli 2008). Consequently, the procurement area of power plant “Alholmens Kraft” covers distances, within 200 km, and train transport bridges longer transport distances (Eriksson and Gustavsson 2010). In contrast, based on PFF transport costs for a 66 MW CHP plant in Vienna, multimodal transport (truck–train) outperforms truck transport above 96 km in terms of energy requirements and above 250 km in terms of cost-effectiveness (Madlener and Bachhiesl 2007). Compared to multimodal transport, transporting PFF by truck only results in higher total transport costs at distances of more than 200 km (Tahvanainen and Anttila 2011). For roundwood transport in Germany, Chesneau et al. (2012) compared unimodal road transport with multimodal road-rail transport and estimated a break-even point of 330 km for the multimodal alternative to become competitive.

In any case, numerous factors, e.g. energy costs, pre-treatment (unchipped, chipped or baled), moisture content, and plant size, influence the economical transport distance, which thus cannot be fixed in general (Junginger et al. 2001; Gronalt and Rauch 2007; Rauch and Gronalt 2011).

In addition to cost efficiency over longer distances, rail transport using electricity from renewable resources has a lower global-warming potential, and negative impacts on the environment are thus reduced (Lindholm and Berg 2005). Accordingly, Jäppinen et al. (2014b) show that the greenhouse gas emissions from large-scale forest fuel supply can be effectively reduced by using multimodal road-rail transport. However, savings of CO2 emissions achievable in the supply chain are only a fraction of those achievable in energy production by substituting fossil fuels (Gustavsson et al. 2011; Jäppinen et al. 2014a).

At present, road transport is the dominant mode for transporting PFF. However, a modal shift from truck to train or ship would make the PFF supply less dependent on distance and more environmentally friendly, whereby both energy consumption and transport costs could be kept lower for longer distances (Börjesson and Gustavsson 1996; Ranta and Rinne 2006).

Why multimodal PFF transport has been rarely used to present, although it provides considerable advantages in terms of economical, ecological and social aspects, has not yet been examined with scientific rigour Accordingly, the objective of this paper is to assess barriers and incentives for the modal shift from truck to train for long distance PFF transport using the concept of ‘Quality Function Deployment’ (QFD), focussing on the actual supply situation in Austria.

2 Definitions

Primary Forest Fuel (PFF): “Forest fuel is produced directly from forest wood by a mechanical process” (FAO 2004 p. 35). PFF is solid biofuel and includes, e.g., low quality roundwood, logging residues or traditional firewood. The European standard EN 14961-1:2010 (EN 14961-1:2010) uses the term “Forest, plantation and other virgin wood” and subsumes different assortments.

Unimodal transport: For transportation only one mode is used, e.g. logging truck from forest landing to sawmill.

Multimodal transport: the mode of transport changes, e.g., woodchips produced at the forest landing are transported on trucks to a train terminal and then transhipped on trains and delivered to a CHP plant.

Bioenergy: Energy (electricity and/or heat and/or cooling) produced from biofuel, such as PFF

Bioenergy plant: produces bioenergy, for example heating plants for district heating and/or process heat, CHP, etc.

3 Material and methods

When searching for barriers and incentives for the modal shift from truck to train, we first considered the best method for structuring and analysis based on practical input. The SWOT (Strengths, Weaknesses, Opportunities and Threats) analysis is well-known and widely applied as an instrument of strategic planning, which surveys internal strengths and weaknesses on the one hand and opportunities and threats to the environment on the other hand. Moreover, it provides a framework for deriving strategies based on promising combinations of strengths, weaknesses, opportunities or threats (Rauch 2007). Within the science of forestry, the SWOT method has been used to analyse the whole forest sector in a certain region in order to find strategies for business development (Oswald et al. 2004). Furthermore, it has been used to map out timber mobilisation strategies (Rauch 2007). Recently, a hybrid method of SWOT and analytic network process framework was applied to assess further development of bioenergy production in Kentucky (Catron et al. 2013).

Pairwise comparisons of analytic hierarchy process technique in SWOT analysis was applied to a strategic decision-making situation of certifying a nonindustrial private forest holding in Finland (Kurttila et al. 2000). A similar method was used to evaluate the suitability of community-based management for a forest reserve in Rwanda (Masozera et al. 2006).

Quality Function Deployment (QFD) is an overall concept, which ascertains and classifies the customer demands and preferences for translation into corresponding technical requirements (see e.g. Chan and Wu 2002). Since QFD originated in the late 1960s, a great volume of corresponding literature has been published (Chan and Wu 2002). The concept is not only applicable in product development; it has also been used to develop services, software and processes, as well as for strategic development and other applications (Carnevalli and Miguel 2008). However, no application of the QFD concept in the field of forestry or forest fuel transport could be found in the relevant sources.

Within QFD, different methods were developed and applied, although, there is one common component: the House of Quality – HoQ (Lager 2005). Accordingly, it is the most important tool within the QFD concept, and many applications restrict QFD to the HoQ (Carnevalli and Miguel 2008). For analysing the PFF supply chain, the QFD concept with the adapted HoQ tool facilitates analysing customer demands, comparing the multimodal supply chain with competing technologies, and defining quality characteristics for further development of the analysed supply chain.

The SWOT-approach provides more general and strategic outcomes, while QFD/HoQ offers decision support for both the strategic and the operational level, and it can be used for deriving specific characteristics for products and processes. Although QFD/HoQ is more formalistic and time consuming, compared with the SWOT-approach, we decided to use the QFD method, since the outcomes are more technical and precise.

3.1 QFD-Analysis using HoQ

The basis of the HoQ is the assumption that products, services or processes have to be designed to meet customer demands (Temponi et al. 1999). HoQ is a matrix scheme, which illustrates the dependencies of customer demands and service or product properties (Hauser and Clausing 1988; Saatweber 2011; Klein 2012). “The idea is that in this way desires of customers can be translated into target values for the engineering characteristics and in priorities for improving certain engineering characteristics” (Van de Poel 2007, p. 22).

Fig. 1 shows the scheme of the HoQ. The horizontal axis illustrates the customer or market perspective, while the vertical axis shows the technical or internal point of view. The central part shows the relationship between both. The HoQ gives answers to the following questions: (1) What do customers want? (2) Why do we need improvements (comparison with competitors)? (3) How do we meet the requirements? (4) How much do we want to achieve (target values of the ‘whys’)?

Fig. 1. Scheme of the House of Quality (HoQ). Author’s drawing.

Initially, a qualitative investigation of the customer perspective is necessary and includes identifying and maybe clustering the customers of the observed product or service, diverse ways of gathering information and procedures for dealing with data (Saatweber 2011). The building of the HoQ is a stepwise procedure (see e.g. Hauser and Clausing 1988; Temponi et al. 1999; Bottani and Rizzi 2007; QFDonline 2012):

- Customer demands (perception of the market) are listed in the rows on the left side of the house and give concrete statements that describe the desired quality.

- The degree of importance of the customer demands is provided as a rating from 1 to 10 (low importance to high importance) and as relative weight calculated as a ratio of the rating value for a specific demand and sum of rating values for all demands.

- To compare one company’s products or services with competing companies, customer evaluations are listed on the right side of the house, opposite to the customer demands. This competitive analysis shows how existing products/services fulfil single demands on an integer scale from 0 (worst) to 5 (best). Based on customer perception, this sub-matrix “provides a natural link from product concept to a company’s strategic vision” (Hauser and Clausing 1988, p. 6).

- For the purpose of developing new products or services, customer demands must be translated into measurable attributes, quality characteristics that should be either maximised or minimised, that are listed in the columns.

- The centre of the HoQ is the relationships matrix. The correlation between customer demands and quality characteristics is given as a strong, moderate or weak relationship, expressed with graphic symbols and reflected by the numerical values 9, 3 or 1, respectively. A specific customer demand may affect more than one quality characteristic. The absence of symbols means absence of relationships.

- The “roof” of the house, the correlation matrix, shows positive or negative dependencies between quality characteristics, if such exist. Dependencies between quality characteristics are assessed as Strong Positive Correlation, Positive Correlation, Negative Correlation or Strong Negative Correlation.

- In the “cellar” of the house, there are target values for each quality characteristic and a rating for the difficulty of its achievement. The weight/importance is calculated as the weighting in the customer importance rating and the relationship matrix section. Subsequently, the relative weight is calculated. Quality characteristics with considerable influence on customer satisfaction attain the highest importance (i.e. high values). In the case study the values in the HoQ are shown with one decimal place, but the calculation in the background includes more decimal places – this leads to rounding of differences.

Finally, the knowledge gained by systematically translating the customer demands into quality characteristics of the product or service is summarized by the assembled HoQ, which enables complex correlations to be visualised and supports decision-making.

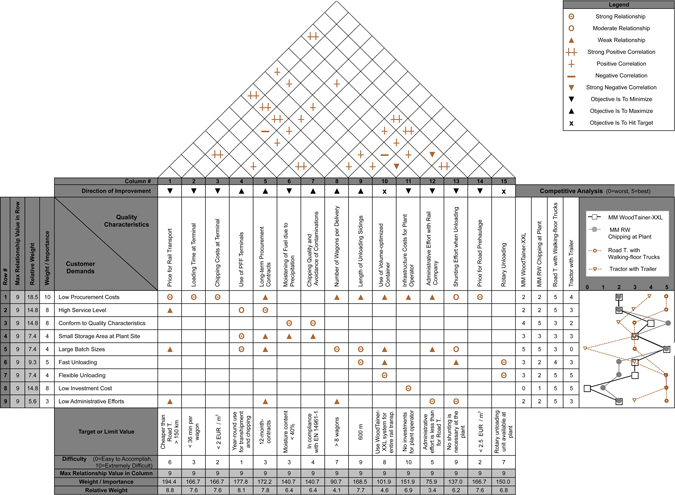

A vast amount of literature can be found on how to build the HoQ; thus, details might vary in different descriptions (e.g., numerical values for expressing strong, moderate or weak relationship or specific elements within the matrix). For the present study, we used a template provided by QFD online – see Fig 2 (QFDonline 2012).

3.2 Common transport systems versus multimodal alternative

In Austria, rail transport is currently applied in CHP plants for low quality roundwood (partly originating from neighbouring countries), which is chipped at the plant site. Consequently, for this case study, relevant customers are large-scale CHP plants in Austria, since small and medium-scale heating plants in Austria are mainly supplied on a regional or local level, and thus rail transport is not an alternative due to short distances.

At the moment, almost no containers are used in Austria for multimodal PFF transport, but only for delivering high quality chips from sawmills to pulp and chipboard mills in Austria. On the other hand, in Sweden, Poland, Italy and the Czech Republic, container systems are also used for delivering chipped PFF to bioenergy plants. There were a few trials in Austria and Finland, but no regular use has yet been established (Hannes Pichler, Innofreight Speditions GmbH, pers. comm. in 2013).

A key system for implementing multimodal PFF transport with containers is the WoodTainer-XXL system. Therefore, we will focus on this container system, since it is well recognised and easily available in Austria. At the starting point of the multimodal supply chain PFF is transported via truck from forest landings to a terminal. There the material is stored, chipped and loaded in containers on train wagons. The WoodTainer-XXL system is based upon a volume-optimized 20 ft container with a dead weight of 2.9 tonnes, which is specially designed for transporting light to moderately heavy bulk cargo. The container volume (48 m3) is higher compared with a 20 ft ISO-standard container and allows an optimal usage of a 60 ft container wagon. Furthermore, the applied container system enables efficient unloading by means of rotary unloading with a forklift equipped with a rotator, which allows 360° rotation during the unloading process (Innofreight 2013).

Altogether, three currently widely used transport systems can be identified as competitors of the WoodTainer-XXL system: (i) unimodal road transport using walking-floor trucks with a load capacity of 90 m3, a commonly used system for bulk customers; (ii) unimodal local road transport using tractors with trailers (the volume depends on the type of trailer, but is normally much less than that of trucks); hence, tractors are used for PPF originating from small-scale forests of surrounding areas; (iii) multimodal rail transport of low quality roundwood; prehauling by truck to a terminal is followed by rail transport over a longer distance. The CHP plant needs a roundwood storage capacity, as well as a chipper, either stationary or mobile.

3.3 Assessing customer demands for QFD/HoQ

The objective of QFD is to translate customer demands into quality characteristics with target values, and the first step required is to survey the customers’ points of view. A central part of QFD is to investigate the relevant customer demands and to determine their relative importance (Van de Poel 2007). Depending on the individual case, several mainly qualitative methods might be useful, e.g. interview or focus groups (Temponi et al. 1999).

We decided to carry out expert interviews as a structured discussion, which enable gathering of qualitative information. Additionally, personal communication provided useful insight into practical application.

The observed customers, large-scale bioenergy CHP plants, were located all over Austria. Interviewees were either the purchasing manager or the executive director (if responsible for procurement). Prior to the conversations with plant managers the “Austrian association for biomass heating plants” (Arbeitsgemeinschaft Biomasse-Nahwärme) was consulted and the results of the expert panel were also included in the analysis.

Basically, all considered plants use predominantly PFF, one plant additionally uses waste wood and residues from landscaping. Three plants were located at wood industry plants, but one plant firing only bark from their own sawmill showed no specific PFF transport and was therefore excluded from the study. Finally, we included the opinions of managers responsible for 22 CHP plants with at least 10 MW capacity each, of which 10 have direct rail connections, in the QFD/HoQ. The total number of bioenergy plants in Austria has been established by the Chamber of Agriculture: there are 73 CHP plants with over 10 MW (Herbert Haneder, Lower Austrian Chamber of Agriculture; pers. comm. in January 2014).

The interviews with the customers were made in German and were structured as follows: Before starting the interview the research setting was explained. The first question asked for basic data of the individual plant (boiler capacity, raw material, storage method, procurement area, current use and experiences with transport modes, availability of rail sidings). Moreover the manager was asked for some economic facts and about the production of bioenergy (i.e. district heating, process heat, electricity) and costumers. Thus, we could expand our previously gathered knowledge of the individual plants.

The second question asked for the relevant demands related to the transport chain from the manager’s point of view (open questioning). The third question was to indicate the importance of the previously notified demands. Additionally, we asked for the importance of further relevant characteristics, mentioned by other plant managers. The importance of customer demands was rated from 1 (low importance) to 10 (high importance). Calculating the means (rounded to integer numbers) resulted in the customer importance rating.

The fourth question was how four different transport systems can fulfil the customer demands, expressed as a rating from 0(worst) to 5 (best). Again, means were calculated and resulted in the competitive analysis. Now the customer demands were well assessed and the horizontal axis of the HoQ could be built.

When all interviews were completed and the gathered information was condensed using the HoQ, it was necessary to connect customer demands with the technical point of view to complete the matrix. Here, important input came from the company producing and marketing the WoodTainer-XXL system (Innofreight Speditions GmbH) during a workshop and regular collaboration. Finally, customer demands were translated into quality characteristics and target values.

4 Results

According to the interviews, experts expressed and ranked the general requirements on PFF supply chains for CHP plants as follows:

- Procurement cost is the dominant factor in customer demand and is significantly influenced by the prices for the respective transport modes. To analyse the supply chain, we must focus on procurement costs, which in the case of the WoodTainer system include prehaulage from forest landing to a terminal, chipping and loading, rail transport and unloading. When evaluating prices for rail transport, those surveyed rely on the information provided by rail companies (e.g., “Rail Cargo Austria” in Austria). However, this price information is not transparent, since pricing is highly dependent on volume handled, but only standard prices are publicly available. Therefore, prices from official price tables do not have a high impact, in reality.

- Service level, i.e. percentage of PFF orders supplied on time and in accordance with specified quantity criteria. Experts mentioned that during winter, when fuel demand is highest, periods with reduced PFF availability are unpredictable, due to non-passable forest roads, and plants need to store large stocks to compensate. Most of the plant managers indicated a high priority for the service level. However, if the bioenergy plant is located at a sawmill, the basic supply with PFF is provided by bark from the debarking process, and the availability of special fuel assortments is less important.

- Fuel quality: the dominant quality criterion is the heating value, which directly depends on moisture content. Other relevant quality characteristics are particle size distribution, amount of contamination and wood species. Individual fuel requirements depend on the combustion technology. Homogenous particle size distribution is most relevant in fluidised bed combustion, whereas oversized particles can be accepted in grate firing. The amount of contamination should be kept low, since inorganic material does not provide heat, increases the weight of the inbound fuel and is left over as ash for disposal. Heating value of PFF relating to mass does not vary much between the different wood species, but relative to volume, it varies to a larger extent. Thus, hardwood species, such as oak or beech have a higher wood density and require less storage volume compared with softwood – in some cases this needs to be considered. Lower quality is generally compensated with a reduced price, and thus even fuel of the lowest quality is used as long as technical utilisation is possible. However, quality is generally indicated as a high priority.

- Storage capacity at plant site: Some plants have limited storage capacity on their site, and a system that maintains low storage requirements at the plant site is preferable. Only a few CHP plants have space to store a year’s PFF demand or more. The indicated level of importance varies from not at all to moderate importance. In any case, the plant managers’ average conviction is that there is no difference between the four observed transport systems.

- Large batch size: Single shipments with high volumes are preferable for large-scale plants, since this reduces administrative efforts. Additionally, regular supplies increase supply process knowledge and reduce administration and unloading time due to routine, as well as learning-curve effects. The level of importance ascertained by the plant managers varies from low to moderate.

- Efficient unloading has basically three requirements: speed, flexibility and low investment cost for unloading equipment (as given in the HoQ, Fig. 2). The unloading of trucks is flexible: chips are dumped beside the chip piles and a wheel loader is used for stacking, if necessary. In contrast, train transport requires additional unloading equipment. If WoodTainer XXL is used, the rotary unloading system is fast and flexible, but investment costs are high. Additionally, if unloading sidings are available, they are often quite short and shunting is necessary (e.g., a maximum number of 8 wagons can be unloaded at the CHP plant in Vienna).

- Low administrative effort: Besides the above-mentioned restrictions, a further reason for the low volume of PFF transported by train is posed by difficulties in communication with rail companies. Potential customers in the bioenergy sector complain about the lack of customer orientation in rail companies resulting in high costs for administration, although the high transport volumes would suggest the opposite. Administrative costs also depend on the method used to measure inbound material: measuring of volumes is imprecise and difficult, if changing vehicle types are used (i.e. different types of trailers); measuring weight is easier, but when delivering woodchips in containers, woodchip samples need to be taken from each container to analyse the moisture content. Additionally, delivery on time reduces administrative efforts, but all plant managers complain about inconsistent railroad deliveries.

Fig. 2 shows the HoQ; the template has been provided by QFD online (www.QFDOnline.com). The horizontal axis illustrates the perspective of plant managers; their requirements are described above in answer to the question: ‘What do the customers want?’ Most important are procurement costs, followed by service level, fuel quality and low investment cost for unloading equipment. In order to compare the WoodTainer system with competing transport systems, we look at the competitive analysis (right side of the HoQ). Road transport using walking-floor trucks generally proves to be the best system for bioenergy plants. However, volumes of single shipments are highest for the two multimodal transport systems. Additionally, delivery of roundwood via train with chipping at the plant site, provides the highest chip quality. Interestingly, plant managers think chips delivered in WoodTainers have a higher quality than chips delivered on trucks. Moreover, they state that inappropriate material is mainly shipped by smaller tractors. Nevertheless, plant managers have a negative perception of rail transport in terms of price, service level, fast and flexible unloading (mainly due to shunting), administrative efforts and especially investment cost.

Fig. 2. House of Quality (HoQ) for the PFF supply chain evaluating the modal shift from truck to train. Abbreviations in the HoQ: MM (multimodal), Road T. (road transport), RW (roundwood). View larger in new window/tab.

To improve multimodal supply chains, customer demands have to be translated into quality characteristics, relating to the quality in demand. The relationships between customer demand and quality characteristics are given in the central part of the HoQ.

The “roof” of the house shows positive or negative dependencies between quality characteristics. A minor negative correlation can be found between chipping costs at the terminal and chipping quality. Infrastructure costs for the plant operator have a highly negative correlation with other characteristics that require improvements in infrastructure. However, this is a main barrier for rail transport of PFF. In the “cellar” of the house, there are target values for each quality characteristic and a rating for the difficulty of achieving it. The weight/importance ratio is calculated from the weighting process in the customer importance rating and the relationship matrix section; quality characteristics with higher values have a greater influence on customer satisfaction.

Important quality characteristics are:

Reduce price for rail transport. This highly depends on the willingness and cost structure of the rail company. However, if transport by rail is cheaper than by road above a 150 km distance, this would lead to an increasing use of train transport.

Increase year-round use of terminals. Existing loading sidings could provide adequate quantities and allow transhipments (Wolfsmayr et al. 2014).

Increase long-term procurement contracts. The target of 12-month contracts ensures availability and provides the basis for regular train service. However, both plant managers and forest owners have concerns about long-term contracts. Nevertheless, some long-term contracts are known to exist.

Increase the length of unloading sidings up to 600 meters to enable unloading a block train without shunting. This would increase the batch size, speed up the unloading process and reduce shunting costs. Nevertheless, this quality characteristic is highly contrary to the unwillingness to invest in infrastructure.

Reduce loading time at the terminal. The WoodTainer system allows loading times of less than 36 min per wagon (ca. 144 m3), which helps to keep procurement costs low (Wolfsmayr et al. 2014).

Reduce chipping costs at the terminal to under EUR 2 m–3 loose. There may be a slight negative effect on chip quality.

Reduce price for road prehaulage. This is necessary to reduce overall procurement costs and much easier to realise than the reduction of rail prices.

5 Discussion

In this research the QFD/HoQ method was used to evaluate the customer demands, to develop quality characteristics to be improved and to figure out barriers and drivers for the modal shift from truck to train. The HoQ provided detailed answers in the competitive analysis part for these issues.

The competitive analysis in the HoQ reflects the customers’ views on the observed multimodal PFF supply chain using WoodTainer XXL in comparison with other relevant PFF supply chains: (i) road transport using walking-floor trucks; (ii) local road transport using tractors with trailers; (iii) rail transport of roundwood. The tractor-trailer-system is limited in transport distances and, in addition, large volumes cannot be transported efficiently. However, some 10 MW bioenergy plants in rural regions obtain up to one third of their fuel via the tractor-trailer-system; and some hauliers use special trailers with volumes up to 60 m3. Nevertheless, this system restricts the area to locally available PFF. The advantage of rail transport for roundwood is the use of stationary chippers, increasing both chip quality and chipping efficiency. Apart from that, the container system can be competitive. Train transport perfectly meets the requirement for large supply quantities, but inflexibility of the train companies and a lack of railway sidings at plants are the main barriers for its utilisation. Concluding, the competitive analysis reveals the plant managers’ negative perception of railroad as a main barrier for multimodal PFF transport. Nevertheless, the most competitive transport system under the current Austrian circumstances is still transport with walking-floor trucks comprising a current modal split share of about 86% (Rauch and Gronalt 2011).

The introduction of a multimodal supply chain is a strategic decision. However, quality characteristics provide the link to measures on the operational level, and individual characteristics might be subject to further operational improvements. As the HoQ illustrates, some of the most important quality characteristics, which must first be improved to introduce a multimodal PFF transport, rely on the railway company. This definitely includes the price for rail transport, as well as the establishment of terminals (since wood loading sidings are normally owned by the railway company) and – at lower priority – the administrative efforts related to train transport. Implementation of long-term contracts depends on both plant owner and forest owner. The conflicting quality characteristics are basically dependent on the plant owner: the unwillingness to invest in infrastructure versus increasing efficiency due to new unloading facilities. Further important quality characteristics could be on the agenda of a professional haulier providing the gateway between forest, bioenergy plant, prehaulier and main haulier, thus organising transport, transhipment, chipping and partially even unloading. However, any of the other players could take on this role, as well.

Although the HoQ does not highlight it explicitly (quality characteristics: increase length of unloading sidings), currently unloading sidings at bioenergy plants are often absent or quite short. As long as the sidings remain short, the unloading of block trains requires more shunting efforts, time, etc. resulting in extra handling costs and a barrier for rail transport. Additionally, there is an unwillingness to invest in infrastructure.

On the one hand, target values related to train transport are very ambitious, but on the other hand difficulties observed are high. Reluctance to invest in infrastructure at CHP plants turns out to be a major barrier against the implementation of a multimodal PFF supply chain. Overcoming it would require other stakeholders to pay for these investments, such as the government in the form of subsidies for environmentally friendly transport or the rail company (also public owned), but both would seem to be very unrealistic, due to the current fiscal situation. However, if road transport increases in price, due to rising diesel prices or CO2 taxes, investments in rail transport will pay off more quickly. Based on a MILP model of the PFF supply to Austrian CHP plants, it was demonstrated that a 20% increase in energy costs would result in a significant increase of ship transport, while the share of rail transport would remain stable. Immediately following a further 20% increase in energy costs, rail transport would gain significant market share by nearly doubling the transported PFF volume (Rauch and Gronalt 2011). This model only considers CHP plants with existing rail sidings for direct railway supplies. For all others additional truck transport from the nearest rail terminal to the CHP plant was assumed. A comparison with Sweden seems interesting, because a lot of PFF is consumed in large scale CHP plants in densely populated areas, in part far away from forests; therefore rail transport is used more regularly. However, only 6 of 44 plants in Sweden using over 100 GWh PFF annually have a direct rail connection, yet 20 have nearby rail sidings. Therefore a multimodal transport combination truck–train–truck is utilised (Skogforsk 2010).

Generally, plant managers have a negative perception of the railroad, particularly the Austrian federal railroad company (ÖBB), due to bad experiences. Therefore, even if rail sidings are available, these are not used. The main reasons given in explanation are: unrealistic prices, especially for short transport distances; inflexibility; tardiness; high administrative costs; and even literally ‘customer adverseness’. To our surprise, one plant manager stated that when he invited the railroad company to offer container wagons with ACTS containers (from German Abrollcontainer Transportsystem, standardised roll-on/roll-off containers) to implement a multimodal supply chain, his request was simply ignored. Moreover, in recent times dozens of small rail terminals in remote areas have been shut down, and freight traffic on branch lines has been stopped. These infrastructural adjustments turn out to be counterproductive, especially for transport of wood products, due to their geographically dispersed origin.

Based on our research, currently only the CHP plant in the city of Linz regularly receives reasonable volumes of low quality roundwood via train. If a block train is used, the owner of the plant, who is the regional energy supplier, can provide his own locomotive and personnel for shunting, keeping administration with the railroad company low.

Madlener and Vögtli (2008) state that for the 30 MW CHP plant in Basel (Switzerland), the railway should be used for transport, even if it is considerably more expensive than by road. Train transport, which should provide half of the fuel needed, was a main requirement for obtaining the construction permit for the site located directly in the city, due to environmental concerns. Currently, the operating plant obtains 17% of its fuel via train. The main reason is that the catchment area is much smaller than originally expected (radius of 20 – 50 km around Basel). Nevertheless, current transport by train is more expensive than by road, due to short distances (Stefan Vögtli, Raurica Wald AG, pers. comm. in 2014).

Summing up, we identify the most important barriers for the modal shift from truck to train in PFF transport in Austria as follows: (i) bioenergy plant managers have a negative opinion and negative experience with the railroad mainly in terms of high prices, high bureaucracy and inaccuracy, (ii) absence of rail sidings or short rail sidings not suitable for block trains, and (iii) unwillingness to invest in new supply or unloading systems.

In contrast, the most important drivers for the modal shift proved to be the following: (i) multimodal PFF supply chains using trains can provide high volumes; (ii) increasing plant sizes, as well as raw material competition, led to increasing catchment areas, at least for periods with higher demands or temporary undersupply situations, as during spring thaw when PFF storage sites in the forest cannot be accessed; and (iii) rail transport has less negative environmental and social impact than road transport. However, the latter point relies on environmental policy and not on the company operating the bioenergy plant, as indicated according to the example of the CHP plant in Basel. When asking for customer demands with an open question, the interviewees did not demand environmental compatibility (see HoQ). In contrast, environmental aspects are repeatedly quoted in the literature as important driver for modal shift (see e.g. Börjesson and Gustavsson 1996; Ranta and Rinne 2006; Behrends 2012).

6 Conclusions

In summary the analysis points out that for an efficient use of PFF rail transport, investments in infrastructure at the CHP plants are necessary, in particular with regard to unloading sidings. Advantages of the container system are fast and flexible unloading, as well as savings of roundwood storage capacity and a stationary chipper. However, forklifts for rotary unloading are necessary. Only some CHP plants feature sufficient rail infrastructure. The transhipment point in a multimodal PFF supply chain is a PFF terminal. While in Northern Europe large rail terminals are used for PFF storage and transhipment, these are more or less absent in Austria. Nevertheless, existing loading sidings could be used as PFF terminals. Recently, transported volumes, storage needs, inbound logistics, chipper use, and bottlenecks have been simulated, and the possibilities of such transhipments points have been illustrated (Wolfsmayr et al. 2014). Subsequently, transhipment quantities of more than 150 000 m3 per year are realistic for adapted Austrian rail sidings.

The actual trend of increasing plant sizes in bioenergy production results in larger catchment areas, further stimulating raw material competition, at least for periods with higher demands or temporary undersupply situations. Both results in correspondingly longer transport distances and that is when rail transport becomes more attractive.

In contrast, road transport is the most economically competitive, and plant managers are unwilling to invest in unloading infrastructure as a prerequisite for rail transport. The HoQ shows the quality characteristics, which are required to establish a multimodal PFF transport system. Obviously, the most important quality characteristics are dependent on the railway company and the plant owners. The HoQ clearly reveals the trade-offs between different quality characteristics, such as a highly negative relationship between minimising investment costs (no investment costs) and other quality characteristics. However, the specific situation at the CHP plant must be considered to make a strategic decision on transport mode mix.

The setting of the customer survey as structured discussion provided more information than necessary to create the HoQ. Valuable insight in the praxis were gained connecting scientists better to the bioenergy business. Thus, it enables researchers to figure out further research questions as well as contacts for upcoming collaboration. The HoQ tool provides a possibility to transform qualitative information from discussions with customers into technical characteristics.

However, QFD/HoQ was experienced as a method, which is difficult to explain to interviewees within a short time. Therefore, the HoQ matrix was not shown at the interviews, but the questions explicitly asked for the customer demands and the importance of the individual demands as well as for the perception of the different transport chains. Undoubtedly, it is not the sense of QFD to use the HoQ matrix as a form for customer interviews, but it provides a good structure for further development. The strength of the HoQ is to derive planning targets based on evaluated, major customer demands.

We conclude that the HoQ can be used to evaluate important issues of forest based industry respective bioenergy producers, because it offers a strategic as well as an operative point of view. It provides an excellent frame for structuring customer surveys and for improving processes or products.

However, the plant managers did not demand environmental compatibility, but it is discussed in the literature as important driver for modal shift (see e.g. Börjesson and Gustavsson 1996; Ranta and Rinne 2006; Behrends 2012). We conclude that plant managers are very focused on their day-to-day business where ecological aspects of transportation are not important and thus the possible driver relies on environmental policy. Subsequently, ecological or social aspects should be subject to policy making; for example increased taxation for fossil fuels could introduce a modal shift.

Future research should address the impact of rising energy prices, as well as increasing diesel prices, on transport mode shares in the bioenergy sector, including decisions on investment in rail sidings at CHP plants. Due to higher fuel demand in winter, it might be possible to combine PFF transport using container wagons with other seasonal commodities, such as sugar beets or grain, thus enabling year-round capacity utilisation of the WoodTainer system.

References

Alholmens Kraft Ab (2012). http://www.alholmenskraft.com. [Cited 10 July 2013].

Austrian Biomass Association (2013). Basisdaten Bioenergie 2013.Vienna.

Behrends S. (2012). The significance of the urban context for the sustainability performance of intermodal road-rail transport. Procedia – Social and Behavioral Sciences 54: 375–386. http://dx.doi.org/10.1016/j.sbspro.2012.09.757.

Börjesson P., Gustavsson L. (1996). Regional production and utilization of biomass in Sweden. Energy 21: 747–764. http://dx.doi.org/10.1016/0360-5442(96)00029-1.

Bottani E., Rizzi A. (2007). An analytical methodology to estimate the potential volume attracted by a rail-road intermodal terminal. International Journal of Logistics Research and Applications 10: 11–28. http://dx.doi.org/10.1080/13675560600819668.

Carnevalli J.A., Miguel P.C. (2008). Review, analysis and classification of the literature on QFD – types of research, difficulties and benefits. International Journal of Production Economics 114: 737–754. http://dx.doi.org/10.1016/j.ijpe.2008.03.006.

Catron J., Stainback G.A., Dwivedi P., Lhotka J.M. (2013). Bioenergy development in Kentucky: A SWOT-ANP analysis. Forest Policy and Economics 28: 38–43. http://dx.doi.org/10.1016/j.forpol.2012.12.003.

Chan L.-K., Wu M.-L. (2002). Quality function deployment: a literature review. European Journal of Operational Research 143: 463–497. http://dx.doi.org/10.1016/S0377-2217(02)00178-9.

Chesneau J.-B., Net E., Berg S. (2012). A transport tool to evaluate sustainability impacts of transport processes within the Forest Wood Chain. European Journal of Forest Research 131: 73–80. http://dx.doi.org/10.1007/s10342-011-0530-4.

Dornburg V., Faaij A.P.C. (2001). Efficiency and economy of wood-fired biomass energy systems in relation to scale regarding heat and power generation using combustion and gasification technologies. Biomass and Bioenergy 21: 91–108. http://dx.doi.org/10.1016/s0961-9534(01)00030-7.

EN 14961-1:2010 Solid biofuels – fuel specifications and classes – part 1: general requirement.

Enström J. (2011). Increased railway transport of forest fuel. In: Thorsén Å., Björheden R., Eliasson L. (eds.). Efficient forest fuel supply systems, composite report from a four year R&D programme 2007–2010. Skogforsk, Uppsala. p. 78–79.

Eriksson L., Gustavsson L. (2010). Comparative analysis of wood chips and bundles – costs, carbon dioxide emissions, dry-matter losses and allergic reactions. Biomass and Bioenergy 34: 82–90. http://dx.doi.org/10.1016/j.biombioe.2009.10.002.

FAO (2004). Unified bioenergy terminology UBET. 50 p.

Gronalt M., Rauch P. (2007). Designing a regional forest fuel supply network. Biomass and Bioenergy 31: 393–402. http://dx.doi.org/10.1016/j.biombioe.2007.01.007.

Gustavsson L., Eriksson L., Sathre R. (2011). Costs and CO2 benefits of recovering, refining and transporting logging residues for fossil fuel replacement. Applied Energy 88: 192–197. http://dx.doi.org/10.1016/j.apenergy.2010.07.026.

Hamelinck C.N., Suurs R.A.A., Faaij A.P.C. (2005). International bioenergy transport costs and energy balance. Biomass and Bioenergy 29: 114–134. http://dx.doi.org/10.1016/j.biombioe.2005.04.002.

Hauser J.R., Clausing D. (1988). The House of Quality. Harvard Business Review 66: 63–73.

Innofreight (2013). http://www.innofreight.com/. [Cited 3 Sep 2013].

Jäppinen E., Korpinen O.-J., Laitila J., Ranta T. (2014a). Greenhouse gas emissions of forest bioenergy supply and utilization in Finland. Renewable and Sustainable Energy Reviews 29: 369–382. http://dx.doi.org/10.1016/j.rser.2013.08.101.

Jäppinen E., Korpinen O.-J., Ranta T. (2014b). GHG emissions of forest-biomass supply chains to commercial-scale liquid-biofuel production plants in Finland. GCB Bioenergy 6: 290–299. http://dx.doi.org/10.1111/gcbb.12048.

Jenkins B.M. (1997). A comment on the optimal sizing of a biomass utilization facility under constant and variable cost scaling. Biomass and Bioenergy 13: 1–9. http://dx.doi.org/10.1016/s0961-9534(97)00085-8.

Junginger M., Faaij A., van den Broek R., Koopmans A., Hulscher W. (2001). Fuel supply strategies for large-scale bio-energy projects in developing countries. Electricity generation from agricultural and forest residues in Northeastern Thailand. Biomass and Bioenergy 21: 259–275. http://dx.doi.org/10.1016/s0961-9534(01)00034-4.

Kanzian C., Kühmaier M., Zazgornik J., Stampfer K. (2013). Design of forest energy supply networks using multi-objective optimization. Biomass and Bioenergy 58: 294–302. http://dx.doi.org/10.1016/j.biombioe.2013.10.009.

Karttunen K., Lättilä L., Korpinen O.-J., Ranta T. (2013). Cost-efficiency of intermodal container supply chain for forest chips. Silva Fennica 47(4) article 1047. http://dx.doi.org/10.14214/sf.1047.

Klein B. (2012). QFD – Quality Function Deployment.Expert Verlag, Renningen. 169 p. ISBN 978-3-8169-3088-4.

Korpinen O., Jäppinen E., Ranta T. (2013). A geographical-origin–destination model for calculating the cost of multimodal forest-fuel transportation. Journal of Geographic Information System 5: 96–108. http://dx.doi.org/10.4236/jgis.2013.51010.

Kurttila M., Pesonen M., Kangas J., Kajanus M. (2000). Utilizing the analytic hierarchy process (AHP) in SWOT analysis – a hybrid method and its application to a forest-certification case. Forest Policy and Economics 1: 41–52. http://dx.doi.org/10.1016/S1389-9341(99)00004-0.

Lager T. (2005). The industrial usability of quality function deployment: a literature review and synthesis on a meta-level. R&D Management 35: 409–426. http://dx.doi.org/10.1111/j.1467-9310.2005.00398.x.

Lindholm E.-L., Berg S. (2005). Energy requirement and environmental impact in timber transport. Scandinavian Journal of Forest Research 20: 184–191. http://dx.doi.org/10.1080/02827580510008329.

Madlener R., Bachhiesl M. (2007). Socio-economic drivers of large urban biomass cogeneration: Sustainable energy supply for Austria’s capital Vienna. Energy Policy 35: 1075–1087. http://dx.doi.org/10.1016/j.enpol.2006.01.022.

Madlener R., Vögtli S. (2008). Diffusion of bioenergy in urban areas: A socio-economic analysis of the Swiss wood-fired cogeneration plant in Basel. Biomass and Bioenergy 32: 815–828. http://dx.doi.org/10.1016/j.biombioe.2008.01.006.

Mahmudi H., Flynn P. (2006). Rail vs truck transport of biomass. Applied Biochemistry and Biotechnology 129: 88–103. http://dx.doi.org/10.1385/abab:129:1:88.

Masozera M.K., Alavalapati J.R.R., Jacobson S.K., Shrestha R.K. (2006). Assessing the suitability of community-based management for the Nyungwe Forest Reserve, Rwanda. Forest Policy and Economics 8: 206–216. http://dx.doi.org/10.1016/j.forpol.2004.08.001.

Oswald K., Riechsteiner D., Thees O., Lemm R. (2004). Reorganisation of wood production for improved performance: a swiss forest district case study. Small-scale Forest Economics, Management and Policy 3: 143–160. http://dx.doi.org/10.1007/s11842-004-0011-4.

QFDonline (2012). http://www.qfdonline.com/. [Cited 5 June 2012].

Ranta T., Rinne S. (2006). The profitability of transporting uncomminuted raw materials in Finland. Biomass and Bioenergy 30: 231–237. http://dx.doi.org/10.1016/j.biombioe.2005.11.012.

Rauch P. (2007). SWOT analyses and SWOT strategy formulation for forest owner cooperations in Austria. European Journal of Forest Research 126: 413–420. http://dx.doi.org/10.1007/s10342-006-0162-2.

Rauch P., Gronalt M. (2011). The effects of rising energy costs and transportation mode mix on forest fuel procurement costs. Biomass and Bioenergy 35: 690–699. http://dx.doi.org/10.1016/j.biombioe.2010.10.015.

Saatweber J. (2011). Kundenorientierung durch Quality Function Deployment.Symposion Publishing GmbH, Düsseldorf. 537 p. ISBN 978-3-86329-429-8.

Searcy E., Flynn P., Ghafoori E., Kumar A. (2007). The relative cost of biomass energy transport. Applied Biochemistry and Biotechnology 137–140: 639–652. http://dx.doi.org/10.1007/s12010-007-9085-8.

Skogforsk 2010. Skogen – en växande energikälla. Sammanfattande rapport från Effektivare Skogsbränslesystem 2007–2010. Uppsala.

Tahvanainen T., Anttila P. (2011). Supply chain cost analysis of long-distance transportation of energy wood in Finland. Biomass and Bioenergy 35: 3360–3375. http://dx.doi.org/10.1016/j.biombioe.2010.11.014.

Temponi C., Yen J., Amos Tiao W. (1999). House of quality: a fuzzy logic-based requirements analysis. European Journal of Operational Research 117: 340–354. http://dx.doi.org/10.1016/S0377-2217(98)00275-6.

Van de Poel I. (2007). Methodological problems in QFD and directions for future development. Research in Engineering Design 18: 21–36. http://dx.doi.org/10.1007/s00163-007-0029-7.

Wolfsmayr U., Merenda R., Rauch P., Longo F., Gronalt M. (2014). Using simulation for evaluating the use of primary forest fuel rail terminals.Unpublished working paper, Boku, Vienna.

Wolfsmayr U.J., Rauch P. (2014). The primary forest fuel supply chain: a literature review. Biomass and Bioenergy 60: 203–221. http://dx.doi.org/10.1016/j.biombioe.2013.10.025.

Xie F., Huang Y., Eksioglu S. (2014). Integrating multimodal transport into cellulosic biofuel supply chain design under feedstock seasonality with a case study based on California. Bioresource Technology 152: 15–23. http://dx.doi.org/10.1016/j.biortech.2013.10.074.

Total of 48 references

Send to email