First-thinning harvesting alternatives for industrial or energy purposes based on regional Scots pine stand simulations in Finland

Karttunen K., Laitila J., Ranta T. (2016). First-thinning harvesting alternatives for industrial or energy purposes based on regional Scots pine stand simulations in Finland. Silva Fennica vol. 50 no. 2 article id 1521. https://doi.org/10.14214/sf.1521

Highlights

- Small-diameter delimbed wood from Scots pine stands delivered directly for energy use was the most cost-efficient option in terms of the total supply-chain cost in comparison with corresponding industrial use or a whole-tree supply chain for energy use

- Forest-management and harvesting decisions influenced the removal of forest biomass and stumpage price as well as the total supply-chain costs for forest biomass

- The greatest cost-reduction potential (10.0%, 4.00 € m–3) was achieved for the delimbed energy wood’s supply chain in the regional case of South Savo in eastern Finland.

Abstract

Combining research into forest management stand conditions and wood supply chain processes has been missing from earlier forestry studies. There is a clear need to develop more cost-efficient small-diameter wood production, harvesting and transportation methods from first thinning, which could be used for either industrial or energy wood purposes. This study considers the total cost for small-diameter wood originating from young Scots pine (Pinus sylvestris L.) dominated stands. Pine pulpwood is the most harvested and most used roundwood assortment, use of which is expected to rise following new pulp-mill investments in Finland. In addition, utilisation of small-diameter trees directly for energy purposes has been increasing steadily in recent years. The aim of the study was to determine the cost-reduction potential of alternative forest management options and supply chains for small diameter-wood in the regional case of South Savo in eastern Finland. The total costs of three distinct scenarios were studied on the basis of forest management, first-thinning harvesting methods, and transportation: 1) industrial wood, 2) delimbed energy wood, and 3) whole trees for energy purposes. The cost-reduction potential for energy-wood supply chains from first thinning was compared to the industrial supply chain. Small-diameter delimbed wood delivered straight for energy purposes was found to be the most cost-efficient as far as the total cost of the supply chain is concerned. More cost-efficient small-diameter wood processes can be found by linking forest stand simulations with supply chain analysis.

Keywords

harvesting;

energy wood;

stand simulation;

stumpage price;

small-diameter wood

- Karttunen, Lappeenranta University of Technology, LUT School of Energy Systems, Laboratory of Bioenergy, Lönnrotinkatu 7, FI-50100 Mikkeli, Finland E-mail kalle.karttunen@lut.fi

- Laitila, Natural Resources Institute Finland (Luke), Bio-based business and industry, P.O. Box 68, FI-80101 Joensuu, Finland E-mail juha.laitila@luke.fi

-

Ranta,

Lappeenranta University of Technology, LUT School of Energy Systems, Laboratory of Bioenergy, Lönnrotinkatu 7, FI-50100 Mikkeli, Finland

E-mail

tapio.ranta@lut.fi

Received 13 November 2015 Accepted 9 March 2016 Published 16 March 2016

Views 181834

Available at https://doi.org/10.14214/sf.1521 | Download PDF

1 Introduction

Forest biomass is the most important source of renewable energy in Finland, which goes either straight from forests for energy purposes or through processing. Most forest-based bioenergy is generated from by-products of the forest industry (black liquor, bark, and sawdust). The rest of the wood-based energy is generated from forests directly for energy use (by means of firewood and forest chips). In 2014, solid wood fuels, consisting of industrial by-products (bark and sawdust) and direct energy use of forest chips, were used to generate 35.9 TWh of energy in Finland, from 18.7 million cubic metres of material (Ylitalo 2015). Consumption of forest chips, which are currently the country’s most used solid wood fuel, came to 8.2 million (M) m3, from heating and power plants (7.5M m3) and from small buildings (0.7M m3) (Ylitalo 2015). Small-diameter wood accounted for the largest proportion of forest-based chips (3.7M m3) (Ylitalo 2015). In addition, approximately 6.7 million cubic metres of firewood is estimated to be burnt in small fireplaces each year (Torvelainen 2009). Young Scots pine (Pinus sylvestris L.) stands represents the biggest source of small-diameter energy wood (2.5–5M m3 year–1) in Finland (Anttila et al. 2013). However, it must be noted that the harvesting potential depends on the quality requirements and dimensions for industrial roundwood. In addition, pine pulpwood is the most harvested and most used sort of timber in Finland, with 15.9M m3 utilised in 2012; it represented 46% of total pulpwood use (36.7M m3) and 26% of all timber used (61.5M m3) (Ylitalo 2013). The Finnish national strategy for renewable energy specifies using 13.5 million cubic metres of forest-based chips annually by 2020 (Finnish Ministry of Employment and the Economy 2010). The material streams of small-diameter wood from first thinning for either the industrial use of chemical pulping or as forest chips for energy purposes constitute an interesting issue for study because, in line with demand, this material has been used for both purposes in recent years.

Cutting has proved to be the largest cost component in the supply chain, and stem size has been the factor explaining cost-efficiency (Laitila et al. 2010). The cost of cutting depends on stem size, defined either as tree diameter at breast height (DBH), expressed in centimetres, or as volume (in litres), whereas supply-chain costs from stand to mill are usually presented as a function of distance or procurement volume (Laitila et al. 2010; Jylhä et al. 2010; Nivala et al. 2015). Profitable mechanised energy-wood harvesting comes about through having a large enough stem size and thinning removal, which also increases the proportion of commercial wood (Jylhä et al. 2011; Pasanen et al. 2014; Petty and Kärhä 2014).

Single-grip harvester heads equipped with multi-tree handling equipment capable of cutting whole trees and multi-stem delimbed stemwood (Belbo 2011; Laitila et al. 2010) have proved to be the most competitive and flexible solution for harvesting young stands (Kärhä et al. 2009; Laitila and Väätäinen 2012; Petty 2014). A single-grip harvester head that is able to perform single- and multi-tree handling enables cutting trees into various assortments in accordance with market prices and product specifications, and this can increase the value of material recovered at the stand (Nurminen et al. 2009; Iwarson-Wide 2011; Spinelli and Magagnotti 2010; Tolan and Visser 2015). Cutting of whole trees costs less, but the cost difference diminishes as a function of tree size. The productivity of forwarding, transportation, and chipping is significantly higher for delimbed energy wood than for whole trees (Laitila and Väätäinen 2012). In addition, delimbed material produces uniform fuel stock devoid of needles and branches. This may be a benefit especially at some power plants with restricted ability to handle high levels of chlorine and alkali metals contained in the branch material (Nurmi and Hillebrand 2007). Bundling technology has been developed in order to rationalise the harvesting of small-diameter thinning wood and reduce transport costs via load compaction (Jylhä 2011; Jylhä and Laitila 2007; Laitila et al. 2009; Nuutinen et al. 2011; Nuutinen and Björheden 2015), but cost calculations have shown that bundling of whole trees displays poor cost-competitiveness (Jylhä 2011; Jylhä et al. 2010; Kärhä et al. 2009; Laitila and Väätäinen 2012).

There is great potential to increase the cost-efficiency of wood harvesting by improving harvesting conditions and methods (Oikari et al. 2010; Bergström and Di Fulvio 2014). The two-pile cutting method has been used in integrated harvesting to separate industrial and energy-wood fractions in forests. Though integrated harvesting is an interesting way to decide between industrial and energy wood, the harvesting costs have been higher (Karttunen and Laitila 2015). One reason for this is the additional forwarding cost created in conveying the respective timber assortments to different piles (Kärhä 2011). At the same time, the optimal choice of harvesting and supply chain is strongly influenced by harvesting conditions, such as stem size, as indicated by DBH (Laitila 2008; Petty 2014). Using the method of gross-profit analysis, Petty (2014) found a delimbed-energy-wood supply chain to be the most profitable with stem sizes of 7–15 cm DBH when stationary chipping was utilised, whereas pulpwood production was the most profitable in operations with stem sizes greater than 15 cm.

Many harvesting, transportation and supply chain methods for small-diameter wood from first thinning have been studied and can currently be found in practical harvesting operations. The profitability of producing forest biomass for energy purposes, however, has been less studied (Ahtikoski et al. 2008; Heikkilä et al. 2009; Karttunen 2006). Forest-management opportunities should be considered in the innovation process for all aspects of forest-biomass supply chains, to reveal the cost-reduction potential (Karttunen 2015). The aim of the study was to find the most cost-efficient process for small diameter wood, which was determined by using the following three aspects: 1. Forest stand simulation and supply-chain analyses were linked, 2. The harvesting and transportation of industrial and energy wood from first thinning were compared, 3. Accurate stands from the regional case from South Savo (and South Karelia) in eastern Finland were used and compared to other regions of Finland.

2 Material and methods

2.1 Scenarios and formulas

Three alternative scenarios were studied on the basis of harvesting methods from first thinning (Table 1). The first scenario (Scenario 1), which was the baseline for the study, was based on industrial roundwood used for chemical pulping and sawn wood. Other scenarios were based on energy wood harvesting from first thinning, with the second (Scenario 2) representing harvesting of delimbed energy wood and the third (Scenario 3) representing whole trees used for energy purposes. The scenarios varied in their cutting diameter and moisture content at first thinning removal. In addition, forest growth differences were determined for each scenario.

| Table 1. Main scenarios of the study. | |||

| First thinning removal | Min. top diameter of wood, cm | Moisture content, % | |

| Scenario 1 | industrial wood | 6 | 55 |

| Scenario 2 | delimbed energy wood | 4 | 35 |

| Scenario 3 | whole trees for energy | 0 | 45 |

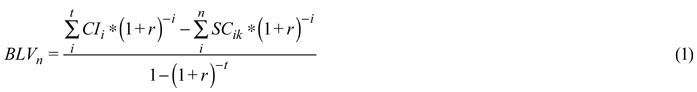

The cost-calculation procedure has been used in an earlier study by Karttunen and Laitila (2015). In this study, alternative data, cases and scenarios were determined. Firstly, the bare land value (BLV) for alternative forest-management regimes was measured for all plots, with the income from first thinning in scenarios 2 and 3 set to produce the same BLV as the baseline (Scenario 1) (Eq. 1).

BLV = NPV∞ (t)

where:

BLVn = bare land value at stand level for Scenario 1, Scenario 2, and Scenario 3, € ha–1

CIi = cutting income at stand age i, € ha–1

t = final cutting

SCik = silvicultural cost for activity k at stand age i, € ha–1

k1 = cost of forest regeneration (year 0)

k2 = cost of pre-commercial thinning (year 10 if not known)

n = time of pre-commercial thinning

i = time in years elapsed since the start of the simulation

r = interest rate, 3%

Secondly, cutting, forwarding and truck transportation were included in the supply chain analysis, in a manner consistent with earlier studies and formulas (Table 2). Finally, the cost-reduction potential of the other scenarios was compared to the baseline (Scenario 1) (Eq. 2).

| Table 2. Productivity (PMH15 = Productive machine hour excluding delays longer than 15 minutes), payload (m3 = solid cubic meter) and cost parameters (€ h–1) used in the study scenarios. | |||

| Average productivity (m3 h–1, PMH15) | Payload (m3) | Cost (€ h–1) | |

| Cutting | |||

| Scenario 1 | 8.2 m3 h–1 | 102.30 € h–1 | |

| Scenario 2 | 8.7 m3 h–1 | 102.30 € h–1 | |

| Scenario 3 | 9.7 m3 h–1 | 102.30 € h–1 | |

| Forwarding | |||

| Scenario 1 | 12.2 m3 h–1 | 11 m3 | 81.00 € h–1 |

| Scenario 2 | 12.1 m3 h–1 | 10 m3 | 81.00 € h–1 |

| Scenario 3 | 8.5 m3 h–1 | 6 m3 | 81.00 € h–1 |

| Truck transportation | |||

| Scenario 1 | 12.8 m3 h–1 (100 km) | 57 m3 | 72 € h–1 |

| Scenario 2 | 14.7 m3 h–1 (100 km) | 67 m3 | 72 € h–1 |

| Scenario 3 | 6.6 m3 h–1 (100 km) | 30 m3 | 66 € h–1 |

where:

Cost – reduction (%)jn = cost-reduction percentage for the first thinning related to scenario j (j = 2 or 3) and management plot n (n = 1,2,3, …, 18) relative to Scenario 1 (baseline, BL)

Cost reduction (%)jn < 0indicates absence of cost reduction for jn

Cost reduction (%)jn > 0indicates presence of cost reduction for jn

C = share cost, € m–3

i = share of estimated stumpage price, harvesting cost, and transportation cost

2.2 Stand data and simulation

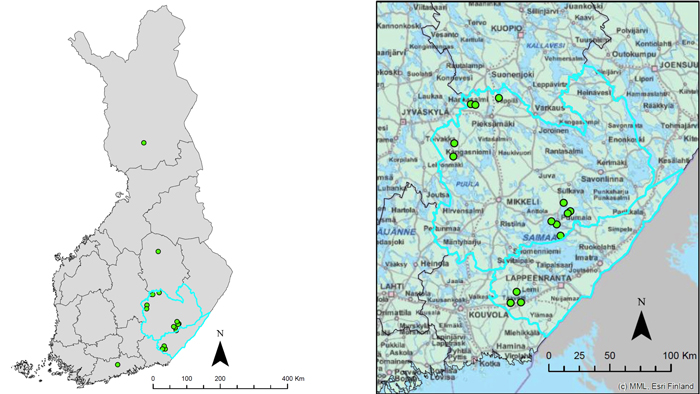

The study focused on 15 original stands representative of typical Scots pine stands in the regional case of South Savo (and South Karelia) in eastern Finland. These provided ‘the regional case’ supply data. Stand data for the regional case came from an accurate plot measurement made in the 11th National Forest Inventory (2009–2013) and plots were selected according to the young Scot´s pine pure or dominated stands before first thinning, with a density between 1000 and 5000 trees per hectare. In addition, the study examined three average stands (with a density of 3000 trees ha–1) from southern (1300 dd. ‘day degrees’), central (1100 dd.), and northern Finland (900 dd.) (Fig. 1, Table 3). The day degrees (dd.) calculation is the growing days multiplied by the average temperature of each day. For all stands, the site type was dryish heath (VT, Vaccinium vitis idaea), and the density of trees varied between 1140 and 4900 trees per hectare.

Fig. 1. The data points from the study, with highlighting for areas in the regional case of South Savo (and South Karelia) in eastern Finland.

| Table 3. Stand characteristics of plots in the alternative areas of Finland (‘Regional case’ = South Savo and South Karelia), with different stand density classes. N = number of stems per hectare, G = stand basal area (m2 ha–1), Dg = mean diameter at breast height (cm), Hg = mean height (m), T = age (years), and V = volume (m3). | ||||||||

| Area | Stand density class, N | Plot number | T | G | N | Dg | Hg | V |

| Regional case | < 3000 | 1 | 28 | 21.7 | 1140 | 16.8 | 13.8 | 149.7 |

| 2 | 25 | 21.3 | 1218 | 15.3 | 12.5 | 135.3 | ||

| 3 | 19 | 11.0 | 1847 | 9.4 | 7.6 | 46.9 | ||

| 4 | 17 | 17.8 | 1886 | 11.9 | 9.5 | 89.7 | ||

| 5 | 22 | 18.5 | 2240 | 11.2 | 9.6 | 95.0 | ||

| 6 | 17 | 9.2 | 2502 | 7.5 | 6.2 | 34.0 | ||

| 7 | 26 | 16.0 | 2515 | 9.7 | 9.3 | 80.1 | ||

| 8 | 33 | 29.7 | 2633 | 13.0 | 11.3 | 174.3 | ||

| 9 | 15 | 11.9 | 2802 | 8.6 | 6.8 | 46.8 | ||

| > 3000 | 10 | 16 | 11.1 | 3002 | 8.1 | 6.6 | 42.0 | |

| 11 | 35 | 36.8 | 3065 | 13.3 | 13.5 | 241.5 | ||

| 12 | 31 | 9.5 | 3803 | 6.9 | 7.9 | 41.8 | ||

| 13 | 13 | 10.7 | 4500 | 5.8 | 4.3 | 30.1 | ||

| 14 | 11 | 4.6 | 4900 | 3.5 | 4.2 | 13.7 | ||

| 15 | 34 | 30.8 | 4794 | 10.9 | 10.7 | 168.4 | ||

| southern Finland | 3000 | 16 | 23 | 12.7 | 3000 | 9.3 | 6.3 | 46.5 |

| central Finland | 3000 | 17 | 27 | 12.1 | 3000 | 9.2 | 6.0 | 43.4 |

| northern Finland | 3000 | 18 | 34 | 13.0 | 3000 | 9.5 | 6.2 | 47.1 |

The MOTTI forest-stand simulator was used in the study. The MOTTI simulator has been designed to simulate and analyse stand development for alternative forest-management regimes in various growth conditions with all major tree species in Finland (Hynynen et al. 2005). It has been implemented via multi-language programming that includes the coupling of models for predicting forest growth with integrated process-based models (Salminen et al. 2005). The input to MOTTI can be either tree- or stand-level data, with each stand simulated separately. The simulation period can be defined as one to five years. Growth and yield models in MOTTI are reliable only in Finnish or similar conditions, but upon construction of a new set of models, the system could be adapted for application elsewhere (Salminen et al. 2005). This simulator’s performance with young Scots pine stands has been assessed by Ahtikoski et al. (2004), Huuskonen (2008), and Huuskonen and Ahtikoski (2005), and in mixed stands by Hynynen et al. (2002). Mäkinen et al. (2005) evaluated the reliability of its growth predictions for intensively managed Scots pine stands, with the results indicating that the MOTTI simulator can be applied as an analysis tool to compare stand-management alternatives in Finnish conditions.

In this study, the growth of young pine-dominated stands with alternative growth and density conditions was modelled for the whole rotation. The MOTTI application, version 3.2 (see http://www.metla.fi/metinfo/motti/), was used in line with silvicultural recommendations (Äijälä et al. 2014; Hyvän metsänhoidon… 2006); thinnings were based on basal area models, and regeneration was based on mean diameter or age. The simulation began with a stand age that varied between 11 and 35 years for stands in the regional case and averaged 23 (southern), 27 (central), and 34 (northern) years for the other region-level assessment. The starting point adopted for the simulation represented the number of trees after pre-commercial thinning but before first thinning. In young stands with more than 4000 trees per hectare, pre-commercial harvesting to 3500 trees a hectare was implemented at the beginning of the simulation. Pre-commercial thinning was assumed to be done in the tenth year in the regional case (when there was no evidence to the contrary) and in southern Finland, in the 15th year in central Finland, and in the 20th year in northern Finland. There were 45 simulations (three scenarios × 15 plots) based on the stands from the area of the regional case and nine (three scenarios × 3 plots) based on the other average region-level. The average region level stands were based on the earlier study results (Karttunen and Laitila 2015), with the exception of novel whole-tree simulations.

The profitability of forest management as a silvicultural system was examined through comparisons of the discounted net revenues and costs associated with various management regimes. The discount interest was kept constant at 3%. Average stumpage price was arrived at via an index-based increase from actual stumpage prices for a statistically relevant time period, with stumpage prices broken down among first thinning, other thinnings, and final cutting (2011–2014) in the regional case, whilst the trend price for 2013 was used for southern, central, and northern Finland. The latter was based on real stumpage prices for an intermediate time period (1995–2012).

For all areas, the average soil-preparation cost was 194 € ha–1 and the regeneration cost 210 € ha–1 (for sowing) at the start of the rotation (year 0) and the cost of pre-commercial thinning was set at 399 € ha–1 (Metsätilastotiedote 2013). There was assumed to be no difference in operations between alternative scenarios before first thinning.

2.3 Supply-chain analysis

The average costs were presented relative to distance and categorised by stand density: above or below 3000 trees per hectare before first thinning. The average costs for the first-thinning supply chains were presented in euros per solid cubic metre. Minimum tree length for cutting was set to 3 m, and the other basic dimensions were determined by the MOTTI stand simulator. For average-cost analysis, the extent of long-distance transportation was set to 100 km, but distances of 10–150 km were shown in cost curves. The supply chain process for each scenario was kept constant: cutting of first thinning, forwarding to roadside, and truck transportation to the plant terminal. The chipping cost associated with energy wood was not considered in this study.

The main difference between the supply-chain scenarios lies in the removals and the functioning of operations, wherein industrial wood must be transported fresh to the end-use facility, while energy wood is usually dried by the roadside. Wood weight was assumed to vary between scenarios, which may have an influence on transportation payload and costs. The basic density for Scots pine in the study was set to 400 kg m–3 (Lindblad and Verkasalo 2001). The average moisture content assumed for small-diameter delimbed energy wood was 35% (615 kg m–3), for whole trees 45% (727 kg m–3), and for industrial wood 55% (889 kg m–3) at the roadside before long-distance transportation. The moisture content of fresh pine wood in practice has varied with the month of cutting and has been, on average, between 55% and 57% (Gislerud 1974; Hakkila 1962; Hillebrand and Nurmi 2001; 2007; Kärkkäinen 1976; Nurmi 1999; Nurmi and Lehtimäki 2011). Normally, the moisture content of energy wood varies greatly with the drying time, seasonal differences (Lindblad et al. 2013), and storage conditions (Nurmi and Hillebrand 2007). In our study, the moisture content of small-diameter wood, which influences the payload in transportation, was kept constant across the individual scenarios. The assumed moisture content of whole trees and delimbed energy wood used in the study was not based on exactly measured data.

The productivity assumed for cutting of industrial roundwood, delimbed stemwood, and whole trees by means of the multi-tree processing technique was based on a study by Laitila and Väätäinen (2013). In the multi-stem cutting time-consumption model, productivity was explained in terms of tree/stem volume (dm3) and harvesting intensity (stem or tree number per hectare). The effective forwarding productivity for industrial roundwood and delimbed enegywood were calculated via the model of Kuitto et al. (1994) and the functions of Laitila et al. (2007) were applied for forwarding of whole trees. The total length of the strip-road network at the stands was assumed to be 600 m ha–1, based on an average strip-road spacing of 20 m (Niemistö 1992). The forwarding distance was 300 m (e.g., Kärhä et al. 2009; Laitila 2012; Laitila and Väätäinen 2012). The forwarder payload was set to 11 m3 for industrial wood, 10 m3 for delimbed energy wood, and 6 m3 for whole trees. The effective time productivities of cutting and forwarding were converted into gross effective time productivities with the coefficients 1.393 and 1.302 (Jylhä et al. 2010; Laitila and Väätäinen 2012). The hourly-cost data for forest machines were obtained from a study by Laitila et al. (2015). The following operating hourly costs were used: 102.30 € h–1 (0% VAT) for a harvester equipped with multi-tree handling accessories and 81.00 € h–1 (0% VAT) for a forwarder.

Multi-stem-harvested industrial wood and delimbed energy wood were transported by a timber truck with a trailer having a 76-tonne maximum legal weight (Anttila et al. 2012), for a maximum payload of 51 tonnes when the weight of an empty truck was set to 25 tons. The road-transport times were composed of driving without a load, driving with the load, and the terminal times (incl. loading, unloading, waiting, and ‘auxiliary time’). The time consumption of driving, with full and empty loads both, was calculated as a function of transportation distance in line with the speed functions of Nurminen and Heinonen (2007). Whole trees were transported by truck, with the payload set to 30 m3 (Laitila and Väätäinen 2012). The payload of the 5–5.5 meter long industrial roundwood and delimbed energy wood were set to 57 m3 and 67 m3 (Korpilahti 2013) respectively. The data for vehicles’ hourly operating costs came from the study by Laitila et al. (2015): a timber truck’s hourly use cost was 72.00 € h–1 (0% VAT), and a whole-tree truck’s was 66.00 € h–1 (0% VAT).

3 Results

3.1 Total supply-chain cost and cost-reduction potential

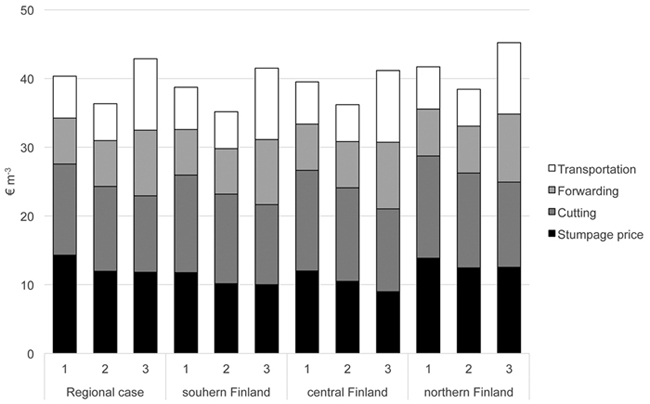

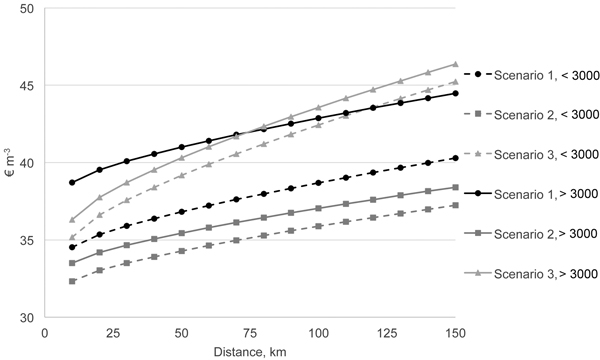

The total cost of the supply chain was, on average, 40.40 € m–3 in Scenario 1; 36.30 € m–3 in Scenario 2; and 42.90 € m–3 in Scenario 3 in the regional case (Fig. 2), while the total supply chain cost for southern, central, and northern Finland averaged 38.70 € m–3, 39.50 € m–3, and 41.70 € m–3, respectively, in Scenario 1; 35.20 € m–3, 36.20 € m–3, and 38.40 € m–3 in Scenario 2; and 41.50 € m–3, 41.10 € m–3, and 45.20 € m–3 in Scenario 3.

Fig. 2. Total supply-chain costs, in € m–3, with a transport distance of within 100 km (chipping cost is not included). Scenario 1: industrial wood, Scenario 2: delimbed energy wood, Scenario 3: whole trees for energy. ‘Regional case’ = South Savo (and South Karelia).

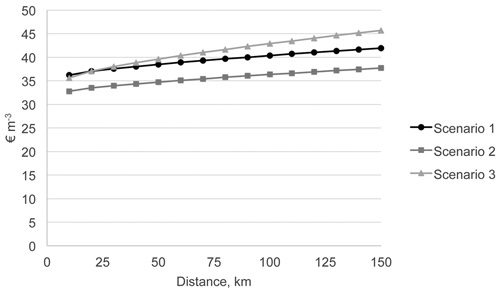

The delimbed-energy-wood supply chain (Scenario 2) had the highest cost-reduction potential, coming to, on average, 10.0% (4.00 € m–3) relative to the baseline in the regional case. The cost-reduction potential of the delimbed-energy-wood supply chain showed a decrease in the analysis of the three regions with transfer from south to north as follows: southern Finland 9.1% (3.50 € m–3), central Finland 8.4% (3.30 € m–3), and northern Finland 7.8% (3.30 € m–3). Total costs in the various scenarios are presented in relation to distance (Fig. 3). Scenario 2, using delimbed energy wood, represented the lowest total cost in every scenario and area examined.

Fig. 3. Average supply-chain costs, in € m–3, in relation to distance in the regional case (South Savo and South Karelia) (chipping cost is not included).

The forest-stand plots of the regional case were grouped by stand density: under 3000 or over 3000 trees per hectare (Fig. 4). One can see that delimbed-energy-wood supply chains (Scenario 2) had the lowest total cost, and that cost did not depend on stands’ density as much as seen in the other scenarios. The cost-reduction potential from denser forests (>3000 trees/ha) is 4.3% (1.60 € m–3), on average, when Scenario 2 is compared to the baseline (Scenario 1) with a traditional forest-management stand density (<3000 trees/ha). If Scenario 2 for denser forests is compared to the baseline (Scenario 1) for denser forests, the cost-reduction potential is 13.6% (5.80 € m–3).

Fig. 4. Average total supply-chain costs in the regional case of South Savo (and South Karelia) (chipping cost is not included) plotted against distance and the density of the stand (>3000 trees ha–1 and <3000 trees/ha, in € m–3).

3.2 Removal of forest biomass from first thinning

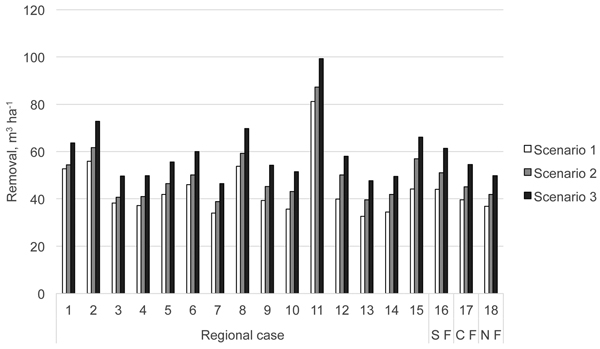

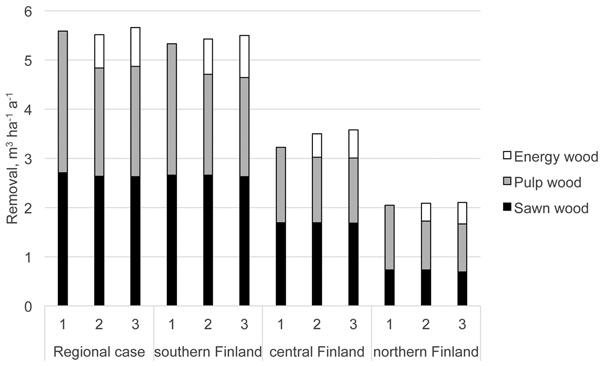

Removal of forest biomass varied according to plots and scenarios. Whole trees removed from the first thinning constituted 59.6 m3 ha–1, on average (Scenario 3), and the delimbed-energy-wood scenario produced, on average, 50.4 m3 ha–1 (Scenario 2), whereas the scenario for industrial wood (Scenario 1) had the lowest average removal, 44.5 m3 ha–1 in the regional case (Fig. 5). The average removal volumes for scenarios 1, 2, and 3, were 44.1, 51.0, and 61.3 m3 ha–1, respectively, in southern Finland; 39.6, 45.1, and 54.6 m3 ha–1 in central Finland; and 36.8, 41.8, and 49.8 m3 ha–1 in northern Finland. Forest management with whole-tree harvesting (Scenario 3) had the highest annual removal rate, at 5.7 m3 ha–1 year–1 in the regional case, with the other figures being 5.5 m3 ha–1 year–1 for southern Finland, 3.6 m3 ha–1 year–1 for central Finland, and 2.1 m3 ha–1 year–1 for northern Finland (Fig. 6). The annual removal rate refers to the total cutting removals of forest biomass divided by the rotation period.

Fig. 5. Total first thinning removal of scenarios (Scenario 1: Industrial wood; Scenario 2: Delimbed energy wood; Scenario 3: Whole tree) and plots (plot number 1–18) in the regional case of South Savo (and South Karelia), and in the other regional areas of Finland (S F = southern Finland, 1300 dd., C F = central Finland, 1100 dd., N F = northern Finland, 900 dd.).

Fig. 6. Total annual removal of sawn wood, pulp wood, and energy wood from the whole forest rotation (m3 ha–1 a–1) in the alternative scenarios studied in the regional case of South Savo (and South Karelia), and in the other areas of Finland.

3.3 Estimated stumpage price of small-diameter trees

The estimated stumpage price demanded by forest owners so as to achieve the same economic result as at baseline (Scenario 1) for first-thinning removal varied by case and scenario, as shown in Table 4. Average energy-wood stumpage prices were lower (1.30–3.00 € m–3, 9–25%) than at baseline (Scenario 1) in every alternative case. Estimated stumpage prices in the energy-wood scenarios (Scenarios 2 and 3) in the regional case were lower, but featured more variation than with the baseline scenario. It is notable that the minimum stumpage price of energy-wood scenarios (Scenarios 2 and 3) was 6.70–7.50 € m–3, which is around half (47–52%) the average stumpage price at baseline (Scenario 1) in the regional case.

| Table 4. Estimated average stumpage prices for each scenario and area (‘Regional case’: = South Savo and South Karelia, ‘Regional areas’: ‘S F’ = southern Finland, ‘C F’ = central Finland, ‘N F’ = northern Finland). Minimum (min) and maximum (max) values of stumpage prices has been presented in the regional case. | ||||||

| Regional case | Regional areas | |||||

| mean | min | max | S F | C F | N F | |

| Scenario 1 | 14.3 | 14.0 | 16.4 | 11.7 | 12.0 | 13.9 |

| Scenario 2 | 12.0 | 6.8 | 15.9 | 10.1 | 10.5 | 12.4 |

| Scenario 3 | 11.8 | 7.7 | 15.4 | 10.0 | 9.0 | 12.6 |

4 Discussion and conclusions

The study determined alternative supply chains for small-diameter wood from Scots pine stands in Finland. The goal was to find the most cost-efficient way of producing and delivering small-diameter wood in the regional case area of South Savo (and South Karelia) in eastern Finland. Forest stand simulations were combined with supply chain analysis to determine the option with the most potential for first thinning harvesting and transportation of young Scot´s pine stands. The study showed that delimbed small-diameter wood supplied for energy purposes was more cost-efficient than for industrial wood or corresponding energy use of whole trees in all areas and transport distances of Finland, as indicated by the total supply-chain costs.

The economics of forest-resource systems should be studied comprehensively and site-dependently in relation to biomass use, to enable an assessment of the optimal use of forest biomass. Forest-stand location is an important cost element, especially if the forests are far from user sites. Energy wood can usually be used locally, while the user facilities of industrial wood can be situated further away. The average long-distance transport of roundwood by truck is 108 km in Finland (Strandström 2014). Nonetheless, the total supply-chain cost curve produced in our study showed lower costs for delimbed energy wood than with the industrial-wood supply chain at all distances especially due to lower moisture content, which enabled bigger payloads.

The study showed that energy wood from first thinnings can be produced cost-effectively even at around half the stumpage price compared to traditional industrial wood in the regional case. If energy wood is cost-efficient to grow at a considerable lower cost than industrial wood, it can change the optimal way of managing forests and the use of wood. Competitiveness and the ability to pay for energy wood will define the potential use compared with either industrial wood or other fuels, such as fossil fuels. However, the additional costs of energy wood may have an effect on cost-competitiveness. It must be taken into consideration that we did not factor into the study the costs of drying energy wood, further storage, and interest costs, or the cost of dry-material losses for raw material, or the chipping cost of wood material.

It must be noted that it is not only the profitability of forest management and supply-chain costs that matter; the price level at the user-site gate is important too. Comparable gate-price estimates should be subjected to gross-profit-margin analysis (Petty 2014) or examination of the ability to pay for wood (Jylhä et al. 2010). Regrettably, the gate price paid at the user site for industrial wood is not available as statistical data and is seldom presented even at a theoretical level. The current plant prices for forest chips, on the other hand, are available as statistics. However, forest chips have been supported by the state compared to fossil fuels, which make it difficult to compare with other uses. In this study, the stumpage price of energy wood from first thinning was estimated in relation to industrial wood prices and the baseline of traditional forest management so as to redress the effects of statistical unavailability for longer periods. Also, subsidies paid for small-diameter-wood supply from early thinnings have led to confusion surrounding the stumpage prices of energy wood.

The study involved a comparison of the economic results for given plots producing industrial vs. energy wood from first thinning. Two aspects must be separated when analysing the results. Firstly, we explored forest management and its profitability over a time horizon. Secondly, we studied alternative first thinning harvesting methods in constant time. Usually, the larger the removal at first thinning, the lower the net stumpage price needed for the same economic effect in constant time. But when analysing the profitability of alternative forest management regimes over a time horizon, the harvesting method can significantly influence results. Unless whole-tree harvesting yielded the largest removal in this study, removing this forest biomass out of the forest stand influenced later forest growth and decreased the profitability of forest management and further increased the stumpage price. The reason for decreased profitability is due to nutrient loss from whole tree harvesting (Palviainen and Finér 2012), which is already included in the MOTTI stand simulator´s growth models. In addition, the whole-tree supply chain was, in fact, the most expensive option of the alternative supply chains, because of the low bulk density of forwarding and transporting whole trees.

Acknowledgements

The work was implemented under the ongoing strategic research consortium project FORBIO (3500010200), for which funding from the Strategic Research Council of the Academy of Finland is acknowledged. We also want to thank the regional development project of South Savo (12617), funded by The European Agricultural Fund for Rural Development, for being able to finish the work.

References

Ahtikoski A., Heikkilä J., Alenius V., Siren M. (2008). Economic viability of utilizing biomass energy from young stands – the case of Finland. Biomass & Bioenergy 32(11): 988–996. http://dx.doi.org/10.1016/j.biombioe.2008.01.022.

Ahtikoski A., Päätalo M.-L., Niemistö P, Karhu J., Poutiainen E. (2004). Effect of alternative thinning intensities on the financial outcome in silver birch (Betula pendula Roth) stands: a case study based on long-term experiments and MOTTI stand simulations. Baltic Forestry 10(2): 46–55.

Äijälä O., Koistinen A., Sved J., Vanhatalo K., Väisänen P. (eds.). (2014). Metsänhoidon suositukset. [Forest management recommendations]. Metsätalouden kehittämiskeskus Tapion julkaisuja. [In Finnish].

Anttila P., Korpilahti A., Väätäinen K. (2012). Puutavaran maantiekuljetusten kehittämispyrkimyksiä Suomessa ja Ruotsissa. [Development efforts of timber road transportation in Finland and Sweden]. Tieteen tori. Metsätieteen aikakauskirja 3/2012: 179−186. http://www.metla.fi/aikakauskirja/full/ff12/ff123179.pdf. [In Finnish].

Anttila P., Nivala M., Laitila J., Korhonen K.T. (2013). Metsähakkeen alueellinen korjuupotentiaali ja käyttö. [The regional harvesting potential and use of forest chips]. Metlan työraportteja 267. 24 p. http://www.metla.fi/julkaisut/workingpapers/2013/mwp267.pdf. [In Finnish].

Belbo H. (2011). Efficiency of accumulating felling heads and harvesting heads in mechanized thinning of small diameter trees. Linnaeus University Dissertations 66/2011.

Bergström D., Di Fulvio F. (2014). Evaluation of a novel prototype harvester head in early fuel-wood thinnings. International Journal of Forest Engineering 25(2): 156–170. http://dx.doi.org/10.1080/14942119.2014.945697.

Finnish Ministry of Employment and the Economy (2010). Suomen kansallinen toimintasuunnitelma uusiutuvista lähteistä peräisin olevan energian edistämisestä direktiivin 2009/28/EY mukaisesti. [The Finnish national strategy for enhancing energy from the renewable sources according to the directive 2009/28/EY]. [In Finnish].

Gislerud O. (1974). Heltreutnyttelse. II. Biomasse og biomasseegenskaper hos tynningsvirke av gran, furu, bjork og or. [Biomass characteristics of thinnings of spruce, pine, birch and alder]. Norsk Institutt for skogforskning, Rapport 6: 1–59. [In Norwegian].

Hakkila P. (1962). Polttohakepuun kuivuminen metsässä. [Drying of wood for chips at the forest stand]. Communicationes Instituti Forestalis Fenniaie 54(4). 82 p. [In Finnish].

Heikkilä J., Sirén M., Ahtikoski A., Hynynen J., Sauvula T., Lehtonen M. (2009). Energy wood thinning as a part of the stand management of Scots pine and Norway spruce. Silva Fennica 43(1): 129–146. http://dx.doi.org/10.14214/sf.220.

Huuskonen S. (2008). The development of young Scots pine stands – precommercial and first commercial thinning. Dissertationes Forestales 62. 61 p. [In Finnish]. http://dx.doi.org/10.14214/df.62.

Huuskonen S., Ahtikoski A. (2005). Ensiharvennuksen ajoituksen ja voimakkuuden vaikutus kuivahkon kankaan männiköiden tuotokseen ja tuottoon. [Impact of timing and strength of the first thinning on the yield and profitability of dryish heath pine stands]. Metsätieteen aikakauskirja 2/2005: 99–115. [In Finnish].

Hynynen J. Ojansuu R., Hökkä H., Salminen H., Siipilehto J., Haapala P. (2002). Models for predicting stand development in MELA System. Finnish Forest Research Institute, Research Paper 835. 116 p.

Hynynen J., Ahtikoski A., Siitonen J., Sievänen R., Liski J. (2005). Applying the MOTTI simulator to analyse the effects of alternative management schedules on timber and non-timber production. Forest Ecology and Management 207(1–2): 5–18. http://dx.doi.org/10.1016/j.foreco.2004.10.015.

Hyvän metsänhoidon suositukset (2006). [Forest management recommendations]. Metsätalouden kehittämiskeskus Tapio. Metsäkustannus Oy, Helsinki. 100 p. [In Finnish].

Iwarson-Wide M. (2011). Var går gränsen? Massaved och/eller energiuttag i klen gallring. [Where is the breakpoint ? Extraction of pulp wood and/or energy wood in thinning of small-dimension stands]. Resultat från Skogforsk 9/2011. 4 p. [In Swedish].

Jylhä P. (2011). Harvesting of undelimbed Scots pine (Pinus sylvestris L.) from first thinnings for integrated production of kraft pulp and energy. Dissertationes Forestales 133. 73 p. http://dx.doi.org/10.14214/df.133.

Jylhä P., Laitila J. (2007). Energy wood and pulpwood harvesting from young stands using a prototype whole-tree bundler. Silva Fennica 41(4): 763–779. http://dx.doi.org/10.14214/sf.470.

Jylhä P., Dahl O., Laitila J., Kärhä K. (2010). The effect of supply system on the wood paying capability of a kraft pulp mill using Scots pine harvested from first thinnings. Silva Fennica 44(4): 695–714. http://dx.doi.org/10.14214/sf.454.

Jylhä P., Dahl O., Laitila J., Kärhä K. (2011). Efficiency of wood procurement systems of small-diameter Scots pine based on the wood paying capability of a kraft pulp mill. In: Ackerman P., Ham H., Gleasure E. (eds.). Proceedings of 4th forest engineering conference: innovation in forest engineering - adapting to structural change. 5–7 April 2011, Stellenbosch University, South Africa. p. 126–128. ISBN 978-0-7972-1284-8.

Kärhä K. (2011). Integrated harvesting of energy wood and pulpwood in first thinings using two-pile cutting method. Biomass and bioenergy 35(18): 3397–3403. http://dx.doi.org/10.1016/j.biombioe.2010.10.029.

Kärhä K, Laitila J, Jylhä P, Nuutinen Y, Keskinen S. (2009). Kokopuun paalaus -tuotantoketjun tuottavuus ja kustannukset. [Productivity and costs of a supply chain based on whole-tree bundling]. Metsäteho Report 211. 60 p. + 6 app. [In Finnish].

Kärkkäinen M. (1976). Puun ja kuoren tiheys ja kosteus sekä kuoren osuus koivun, kuusen ja männyn oksissa. [Density and moisture of the wood and bark and bark proportion of birch, spruce and pine branches]. Silva Fennica 10(3): 212–236. [In Finnish]. http://dx.doi.org/10.14214/sf.a14794.

Karttunen K. (2006). Energiapuuharvennus osana metsänkasvatusta ja ilmastonmuutoksen hillitsemistä. [Energy wood thinning as a part of forest management and mitigating of climate change]. Pro gradu. Helsingin yliopisto. [In Finnish].

Karttunen K. (2015). Added-value innovation of forest biomass supply chains. Dissertationes Forestales 186. 78 p. http://dx.doi.org/10.14214/df.186.

Karttunen K., Laitila J. (2015). Forest management regime options for integrated small-diameter wood harvesting and supply chain from young Scots pine (Pinus sylvestris L.) stands. International Journal of Forest Engineering 26(2): 124–138. http://dx.doi.org/10.1080/14942119.2015.1083749.

Korpilahti A. (2013). Puutavara-autot mitta- ja massamuutoksen jälkeen. [The new physical dimensios of timber trucks according to the new statute]. Metsätehon tuloskalvosarja 11/2013. 24 p. [In Finnish].

Kuitto P.-J., Keskinen S., Lindroos J., Oijala T., Rajamäki J., Räsänen T., Terävä J. (1994). Puutavaran koneellinen hakkuu ja metsäkuljetus. [Mechanized cutting and forest haulage]. Metsäteho Report 410. 38 p. [In Finnish].

Laitila J. (2008). Harvesting technology and the cost of fuel chips from early thinnings. Silva Fennica 42(2): 267–283. http://dx.doi.org/10.14214/sf.256.

Laitila J., Väätäinen K. (2011). Kokopuun ja rangan autokuljetus ja haketustuottavuus. [Chipping productivity and transportation of whole trees and delimbed stem wood]. Metsätieteen aikakauskirja 2/2011: 107–126. [In Finnish].

Laitila J, Väätäinen K. (2012). Truck transportation and chipping productivity of whole trees and delimbed energy wood in Finland. Croatian Journal of Forest Engineering 33(2): 199–210.

Laitila J, Väätäinen K. (2013). The cutting productivity of the excavator-based harvester in integrated harvesting of pulpwood and energy wood. Baltic Forestry 19(2): 289–300.

Laitila J. Asikainen A., Nuutinen Y. (2007). Forwarding of whole trees after manual and mechanized felling bunching in pre-commercial thinnings. International Journal of Forest Engineering 18(2): 29–39.

Laitila J., Kärhä K., Jylhä P. (2009). Time consumption models and parameters for off- and on-road transportation of whole-tree bundles. Baltic Forestry 15: 105–114.

Laitila J., Heikkilä J., Anttila P. (2010). Harvesting alternatives, accumulation and procurement cost of small-diameter thinning wood for fuel in Central Finland. Silva Fennica 44(3): 465–480. http://dx.doi.org/10.14214/sf.143.

Laitila J., Ranta T., Asikainen A., Jäppinen E., Korpinen O.J. (2015). The cost competitiveness of conifer stumps in the procurement of forest chips for fuel in Southern and Northern Finland. Silva Fennica 49(2) article 1280. http://dx.doi.org/10.14214/sf.1280.

Lindblad J., Verkasalo E. (2001). Teollisuus- ja kuitupuuhakkeen kuiva-tuoretiheys ja painomit-tauksen muuntokertoimet. [Conversion factors of dry-green density and weighting for industry and pulp chip]. Metsätieteen aikakauskirja 3/2001: 411–431. [In Finnish].

Lindblad J., Äijälä O., Koistinen A. (2013). Energiapuun mittaus. [Measurement of energy wood]. Metsätalouden kehittämiskeskus Tapio ja Metla. 32 p. [In Finnish].

Mäkinen H., Hynynen J., Isomäki A. (2005). Intensive management of Scots pine stands in southern Finland: first empirical results and simulated further development. Forest Ecology and Management 215(1–3): 37–50. http://dx.doi.org/10.1016/j.foreco.2005.03.069.

Metsätilastotiedote (2013). Metla. http://www.metla.fi/metinfo/tilasto/julkaisut/mtt/2013/mhmpk12.pdf. [Cited 19 Aug 2015].

Niemistö P. (1992). Runkolukuun perustuvat harvennusmallit. [Thinning models based on the number of stems]. Finnish Forest Research Institute, Research Papers 432. 18 p. [In Finnish].

Nivala M., Anttila P., Laitila J. (2015). A GIS-based comparison of long-distance supply of energy wood for future needs from young forests to the coast of Finland. International Journal of Forest Engineering 26(3): 185–202.

Nurmi J. (1999). The storage of logging residue for fuel. Biomass and Bioenergy 17(1): 41–47. http://dx.doi.org/10.1016/S0961-9534(99)00023-9.

Nurmi J., Hillebrand K. (2007). The characteristics of wholetree fuel stocks from silvicultural cleanings and thinnings. Biomass and Bioenergy 31(6): 381–392. http://dx.doi.org/10.1016/j.biombioe.2007.01.010.

Nurmi J., Lehtimäki J. (2011). Debarking and drying of downy birch (Betula pubescens) and Scots pine (Pinus sylvestris) fuelwood in conjunction with multi-tree harvesting. Biomass and Bioenergy 35(8): 3376–3382. http://dx.doi.org/10.1016/j.biombioe.2010.08.065.

Nurminen T., Heinonen J. (2007). Characteristics and time consumption of timber trucking in Finland. Silva Fennica 41(3): 471–487. http://dx.doi.org/10.14214/sf.284.

Nurminen T., Korpunen H., Uusitalo J. (2009). Applying the activity-based costing to cut-to-length timber harvesting and trucking. Silva Fennica 43(5): 847–870. http://dx.doi.org/10.14214/sf.177.

Nuutinen Y., Björheden R. (2015). Productivity and work processes of small-tree bundler Fixteri FX15a in energy wood harvesting from early pine dominated thinnings. International Journal of Forest Engineering 27(1): 29–42. http://dx.doi.org/10.1080/14942119.2015.1109175.

Nuutinen Y., Kärhä K., Laitila J., Jylhä P., Keskinen S. (2011). Productivity of whole-tree bundler in energy wood and pulpwood harvesting from early thinnings. Scandinavian Journal of Forest Research 26: 329–338. http://dx.doi.org/10.1080/02827581.2011.568952.

Oikari M., Kärhä K., Palander T., Pajuoja H., Ovaskainen H. (2010). Analyzing the views of wood harvesting professionals related to the approaches for increasing the cost-efficiency of wood harvesting from young stands. Silva Fennica 44(3): 481–495. http://dx.doi.org/10.14214/sf.144.

Palviainen M., Finér L. (2012). Estimation of nutrient removals in stem-only and whole-tree harvesting of Scots pine, Norway spruce, and birch stands with generalized nutrient equations. European Journal of Forest Research 131(4): 945–964. http://dx.doi.org/10.1007/s10342-011-0567-4.

Pasanen K., Laitila J., Pykäläinen J., Anttila P. (2014). Using the ComBio decision supportsystem to assess whether energy wood and/or pulpwood should be harvested in young forests. International Journal of ForestEngineering 25(1): 51–65. http://dx.doi.org/10.1080/14942119.2014.903614.

Petty A. (2014). Opportunities for cost mitigation and efficiency improvements through rationalization of small-diameter energy wood supply chains. Dissertationes Forestales 175. 47 p. http://dx.doi.org/10.14214/df.175.

Petty A., Kärhä K. (2014). Productivity and cost evaluations of energy-wood and pulpwood harvesting systems in first thinnings. International Journal of Forest Engineering 25(1): 37–50. http://dx.doi.org/10.1080/14942119.2014.893129.

Salminen H., Lehtonen M., Hynynen J. (2005). Reusing legacy FORTRAN in the MOTTI growth and yield simulator. Computers and electronics in agriculture 49(1): 103–113. http://dx.doi.org/10.1016/j.compag.2005.02.005.

Spinelli R., Magagnotti N. (2010). Comparison of two harvesting systems for the production of forest biomass from the thinning of Picea abies plantations. Scandinavian Journal of Forest Research 25(1): 69–77. http://dx.doi.org/10.1080/02827580903505194.

Strandström M. (2014). Puunkorjuu ja kaukokuljetus vuonna 2013. [Harvesting and long-distance transportation 2013]. Metsätehon katsaus 50. 4 p. [In Finnish with English summary].

Tolan A., Visser R. (2015) The effect of the number of log sorts on mechanized log processing productivity and value recovery. International Journal of Forest Engineering 26(1): 36–47. http://dx.doi.org/10.1080/14942119.2015.1011404.

Torvelainen J. (2009). Pientalojen polttopuun käyttö 2007/2008. [The use of firewood in one-family houses 2007/2008]. Metsätilastotiedote (SVT Maa-, metsä-ja kalatalous) 26. [In Finnish].

Ylitalo E. (2013). Puun energiakäyttö 2012. [The use of wood for energy 2012]. Metsätilastotiedote (SVT Maa-, metsä-ja kalatalous) 15. [In Finnish].

Ylitalo E. (2015). Puun energiakäyttö 2014. [The use of wood for energy 2014]. http://stat.luke.fi/puun-energiakaytto. [In Finnish].

Total of 62 references.

Send to email