The effects of the EU’s forest-related policies on harvesting costs in Finland

Ahtikoski A., Väätäinen K., Anttila P., Laitila J., Mutanen A., Lindblad J., Sikanen L., Routa J. (2024). The effects of the EU’s forest-related policies on harvesting costs in Finland. Silva Fennica vol. 58 no. 3 article id 23018. https://doi.org/10.14214/sf.23018

Highlights

- The EU’s forest-related policies set direct and indirect limitations on the harvesting operations and operating environment

- The effect on harvesting costs of Directives and Regulations depends on the magnitude of policy implementation

- In a high-impact scenario, harvesting costs could increase by as much as 18% from the current level of costs.

Abstract

The EU’s influence on national forest policies is growing, and the implementation of forest-related policies proposed by the Commission will affect the practice of forestry in Europe. For instance, the Nature Restoration Law sets concrete areal goals for restoring forest ecosystems and for conservation, the Deforestation Regulation requires meticulous tracking of wood’s origin, and the renewed Renewable Energy Directive (RED III) sets new criteria to sustainable forest biomass procurement. So far there have been no studies that have looked into the impacts from the economic and operational point of view. In this study, structural systems analysis was first performed to discover the relevant variables (and their functioning) associated with the roundwood harvesting operations and the operating environment. A scenario approach was then applied to capture the potential levels of implementation of the EU’s forest-related policies. Finally, using different scenarios (low-, moderate- and high-impact) and a systems analysis framework, the impact of alternative levels of implementation was quantified in terms of harvesting costs, measured in € m–3. The results indicate that with the low- and moderate-impact scenarios the harvesting costs would increase by less than 10% from the current levels in three different regions in Finland. Such an increase (less than 10%) could be tolerated over a period of a few years, but a sudden increase is likely to lead to challenges to the running of businesses. With the high-impact scenario the harvesting costs would increase by between 15% and 18%, depending on the region. This magnitude of increase (of approximately a sixth) corresponds to a severe change in the roundwood harvesting operations and operating environment.

Keywords

forests;

scenario approach;

harvesting costs;

directives and regulations;

EU legislation;

structural systems analysis

-

Ahtikoski,

Natural Resources Institute Finland (Luke), Tekniikankatu 1, FI-33720 Tampere, Finland

https://orcid.org/0000-0003-1658-3813

E-mail

anssi.ahtikoski@luke.fi

https://orcid.org/0000-0003-1658-3813

E-mail

anssi.ahtikoski@luke.fi

-

Väätäinen,

Natural Resources Institute Finland (Luke), Yliopistonkatu 6, FI-80100 Joensuu, Finland

https://orcid.org/0000-0002-6886-0432

E-mail

kari.vaatainen@luke.fi

https://orcid.org/0000-0002-6886-0432

E-mail

kari.vaatainen@luke.fi

-

Anttila,

Natural Resources Institute Finland (Luke), Latokartanonkaari 9, FI-00790 Helsinki, Finland

https://orcid.org/0000-0002-6131-392X

E-mail

perttu.anttila@luke.fi

https://orcid.org/0000-0002-6131-392X

E-mail

perttu.anttila@luke.fi

- Laitila, Natural Resources Institute Finland (Luke), Yliopistonkatu 6, FI-80100 Joensuu, Finland E-mail juha.laitila@luke.fi

-

Mutanen,

Natural Resources Institute Finland (Luke), Yliopistonkatu 6, FI-80100 Joensuu, Finland

https://orcid.org/0000-0003-0533-9356

E-mail

antti.mutanen@luke.fi

https://orcid.org/0000-0003-0533-9356

E-mail

antti.mutanen@luke.fi

-

Lindblad,

Natural Resources Institute Finland (Luke), Yliopistonkatu 6, FI-80100 Joensuu, Finland

https://orcid.org/0009-0003-6766-6587

E-mail

jari.lindblad@luke.fi

https://orcid.org/0009-0003-6766-6587

E-mail

jari.lindblad@luke.fi

- Sikanen, Natural Resources Institute Finland (Luke), Yliopistonkatu 6, FI-80100 Joensuu, Finland E-mail lauri.sikanen@luke.fi

-

Routa,

Natural Resources Institute Finland (Luke), Yliopistonkatu 6, FI-80100 Joensuu, Finland

https://orcid.org/0000-0001-7225-1798

E-mail

johanna.routa@luke.fi

https://orcid.org/0000-0001-7225-1798

E-mail

johanna.routa@luke.fi

Received 31 March 2023 Accepted 9 April 2024 Published 11 April 2024

Views 41463

Available at https://doi.org/10.14214/sf.23018 | Download PDF

1 Introduction

The EU has no common, comprehensive, and statutory forest policy because it remains within the competence of the Member States. However, the EU has a forest strategy, and, more importantly, the forest sector is affected by several of the EU’s sectoral policies, such as the climate, energy, environment, and agricultural policies, which are in the sphere of the EU’s supranational competence. Historically, European forest policy can be divided into three eras: emergence (1958 to 1960s), expansion (1970s to late 1990s), and stabilisation (late 1990s to now) (Pülzl et al. 2018). However, one may argue that a second phase of expansion can be observed today (Gordeeva et al. 2022).

The current Commission’s European Green Deal (COM(2019) 640 final) and the related documents prioritise forest preservation, forest restoration, and afforestation as ways to tackle two global crises at the same time: climate change and biodiversity loss. Forests’ contribution to climate change mitigation, as carbon sinks, was already highlighted in the 2030 Climate and Energy Framework (COM(2014) 15 final). Moreover, a regulatory framework for calculating the contribution of forests towards climate change objectives, as well as national forest reference levels and legally binding objectives for the land use sector, was set by the EU Land Use, Land Use Change, and Forestry (LULUCF) Regulation ((EU) 2018/841).

More recently, the European Climate Law ((EU) 2021/1119) and the proposals of the Commission’s Fit for 55 Package (COM(2021) 550 final) such as the revision of the LULUCF Regulation (COM(2021) 554 final), further emphasise the need to enhance carbon sequestration by forests and to maintain and increase forests’ carbon stocks.

The Green Deal and its core document, the EU Biodiversity Strategy for 2030 (COM(2020) 380 final) place biodiversity goals firmly alongside the EU’s climate goals. In the numerous forest-related policy proposals published by the Commission between 2020 and 2023, the objectives of the Biodiversity Strategy, such as avoiding negative impacts on biodiversity, soil, and the health and productivity of forests, are strongly present. A transition from voluntary measures to legally binding regulation is evident.

Further, the New EU Forest Strategy (COM(2021) 572 final) aims to strengthen forest conservation in accordance with the targets of the Biodiversity Strategy, while encouraging sustainable forestry on the territory of the European Union. Along with facilitating the cascade principle and the principle of the circular economy and launching the concept of closer-to-nature forest management and a related certification framework, the Forest Strategy strives for a new European definition of sustainable forest management (Lier et al. 2022).

To implement the strategies that set these goals, the Commission has published several proposals for revising the existing legislation and bringing in totally new legislation, which will affect forestry in practice. Firstly, the proposal for Nature Restoration Law (COM (2022) 304 final) sets targets for the restoration and re-establishment of the ecosystems listed in the Habitats Directive (Council Directive 92/43/EEC), on the volume of dead wood, the amount of continuous cover forestry (CCF), forest connectivity, the common forest bird index, and the stocks of organic carbon in forests. Secondly, the revision of the Renewable Energy Directive (RED III) (COM (2021) 557 final) tightens the sustainability criteria for forest biomass by, for example, limiting harvesting on vulnerable soils and the extraction of dead wood, as well as restricting the size of clear cuts. In addition to the increased time consumption in actual harvesting operations, these requirements may increase the harvesting costs due to more detailed planning of harvesting sites, monitoring of operations, and related administrative work. Finally, the new EU Deforestation Regulation (Regulation (EU) 2023/1115) sets targets for matters such as tracking (i.e., geolocation reporting) of harvesting operations, by requiring the exact coordinates of a particular operation that has taken place and by linking the place and the harvested raw wood to the end-products made from that wood.

The EU Taxonomy requires that any taxonomy aligned activity must promote at least one of six environmental goals without causing significant harm (the DNSH rule) to other goals. The minimum requirements for a taxonomy-aligned economic activity are defined in the technical screening criteria. The first set of screening criteria concerning climate targets was published in 2021 (COM (2021) 2800 final). In the case of forestry promoting climate goals, these include, for example, a climate benefit analysis, the reduced use of pesticides, the minimal use of fertilisers, the promotion of biodiversity-friendly practices, and the maintenance and enhancement of the quality of the soil. The technical screening criteria for forestry promoting biodiversity were proposed by the Platform on Sustainable Finance has published its proposal (Platform on Sustainable Finance: Technical Working Group 2021, 2022a, 2022b). Considering even-aged forests with mixed native species, the proposed criteria include;

-a minimum proportion for set aside forest areas (20%),

-a minimum number and volume of retention trees (100 pcs, 10% of standing volume),

-the accumulation of dead wood (30 m3 ha–1 broadleaf and mixed forest, 20 m3 ha–1 conifer forest),

-a maximum clear-cut area (1 ha in broadleaf and mixed forests, 3 ha in conifer forests) and riparian buffer zones (at least 30 m on both sides of water courses).

Due to differing views and political sensitivity of the issue, the Commission decided not to include forestry in its latest delegated acted concerning technical screening criteria of the last four environmental goals of the Taxonomy. However, as the activities included and the technical screening criteria are constantly being reassessed, the criteria for biodiversity promoting forestry may be proposed in the future.

The above-mentioned strategies and new legislation form only a part of the current EU forest-related policy environment. The EU has ambitious climate and biodiversity goals and, understandably, sustainability and tracing requirements on value chains from the practical forest management practises to the end use of wooden products are increasing. However, in the official impact analyses, neither the magnitude of actual changes in forest management practises required nor the economic or social impacts of the proposals on the forest sector are rarely discussed. In addition, the academic studies on the economic impacts of recent policy changes are few. Schier et al. (2022) found that the effect in the EU of the implementation of the Biodiversity Strategy on harvesting volumes and the production of wood products may be substantial, and the leakage effects large. Thus, there is a great need for a better understanding and an evaluation of the possible consequences of the policy changes in the forest sector.

The new strategies accompanied with proposed new legislation, and changes in previous legislation (i.e., EU´s forest related policies) set either directly or indirectly limitations on forest owners, entrepreneurs, companies, and communities in terms of timber production, the potential to make profits, and socio-economic aspects such as employment, income, and rural development in relation to current practises (Köhl et al. 2021). In this study, the focus is on at the upstream of value chain in Finland. The aim is to analyze, how the EU’s forest-related policies might affect harvesting operations and harvesting costs. The study includes three phases: 1) a systems analysis is introduced to describe the relevant (key) variables and their functioning in the Finnish roundwood harvesting operations and operating environment, 2) a scenario approach is applied to capture different levels of implementation associated with the EU’s forest-related policies, and finally 3) the impact of these different levels on harvesting costs is quantified. In addition, a sensitivity analysis on the relevant (key) variables of the systems analysis, such as the number of harvesting weeks, the proportion of CCF-cuttings and the size of the average harvesting site is conducted. The main aim of this study is to provide valid estimates of harvesting costs when new elements of EU forest-related policies come into force.

2 Material and methods

2.1 Systems analysis

In this study, a structural systems analysis (Manzano-Solís et al. 2019) was performed. A system is a group of interrelated elements, and the structure of a system is the network of the relationships between its components (Godet 1994). A structural systems analysis can be described as a systematic method of analysis of the relationships between the constitutive variables of the studied system and of its explanatory environment. This method has the objective of highlighting the main influential and dependent variables and, as a consequence, the variables essential to the evolution of the system (Godet 2009). Delgado-Martínez and Pantoja-Timarán (2015) stated that structural systems analysis is used to identify the key variables of the system in order to achieve two goals. The first goal is to contribute towards decision making. The second goal in brief is to inform the prospective process and to identify the key variables that would configure those scenarios. In principle, there are two phases of structural systems analysis: 1) an inventory of the variables and 2) a description of the relationships between the variables (Godet and Durance 2011). In the inventory phase, a list of the internal and external variables characterising the system is produced (Manzano-Solís et al. 2019). The second phase (the description of the relationships between the variables) then involves the determination of the relationships among the identified variables, which are further analysed and discussed, and ultimately a consensus on these relationships is established (Manzano-Solís et al. 2019).

2.2 Cut-to-length (CTL) harvesting by a two-machine system (TMS)

Many previous studies have been conducted on the effects of alternative operational conditions, harvesting system setups and business models for cut-to-length (CTL) harvesting. Static methods have been used to assess harvesting costs for different harvesting system setups in CTL-harvesting (Kärhä et al. 2018; Triplat and Krajnc 2020; Ahtikoski et al. 2021; Jonsson et al. 2023). Dynamic and stochastic analyses have mostly been utilized for the comparison of, for example, different harvesting systems and operating models, where the temporal variation in the system and environment have been taken into account (Asikainen 2001; Talbot et al. 2003; Väätäinen et al. 2021). Calculations based on spreadsheets do not take temporal system variation into account, and typically the analysis is deterministic (that is, without any randomness in the system or in the parameters). Fast model building, systems analysis tools that are often shareable, and the enhanced transparency of the data and the model construction used have supported the use of such static methods.

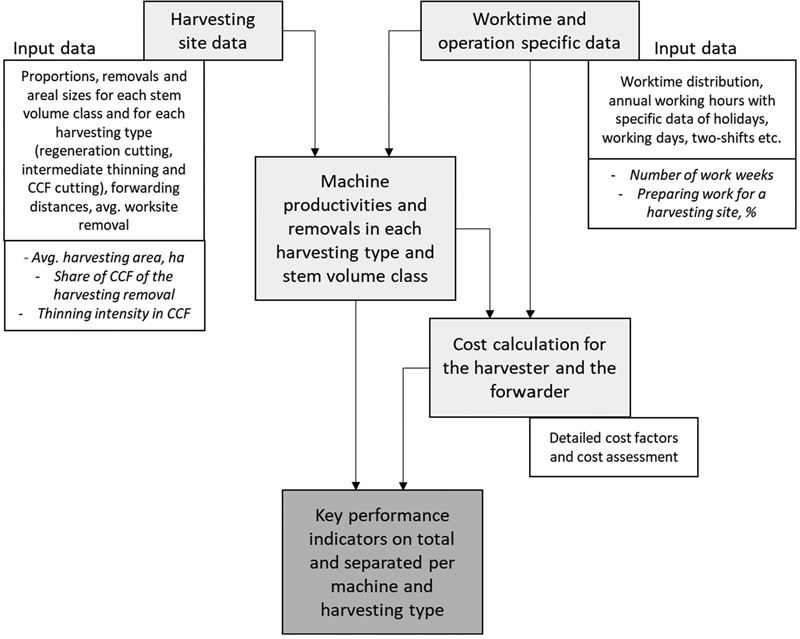

In this study, a detailed and extensive static systems analysis model (SA-model) for CTL-harvesting by TMS was formulated by constructing a spreadsheet program. The SA-model included various variables (elements) consisting of mathematical formulations and models describing the modules of the entity (Fig. 1). The systems analysis covers one calendar year. The resulting harvesting performance indicators are calculated with several parameters within each main section of the spreadsheet calculus. These sections are termed a) harvesting sites, b) worktime and operation specifications, c) machine productivities and removals, and d) machine cost calculations for a harvester and a forwarder (Fig. 1).

Fig. 1. A flowchart of the systems analysis model framework applied for CTL-harvesting. The parameters subject to particular focus (i.e., the key variables) are presented in italics.

The TMS consisted of a harvester and a forwarder typically found in the Nordic regions. The SA-model balanced the productivity difference of the machines.The model enabled the average daily worktime of the forwarder to match the annual production of the harvester. Therefore, the annual worktime of the forwarder could vary even if the worktime of the harvester was fixed for all runs. Historical harvesting site data from the years 2003–2007 of the central part of Finland (Väätäinen et al. 2007, 2008, 2010) was employed in the study. Three regions were defined: Region 1 (consisting of the provinces of Ostrobothnia, South Ostrobothnia and Central Ostrobothnia), Region 2 (Central Finland province) and Area 3 (South Savo, South Karelia and Kymenlaakso province). The regional harvesting site data were first aggregated and divided into harvesting types and within them the division was done for the average stem size classes. The harvesting type division was conducted for final cutting, thinning and CCF-cutting types. Divisions for each class (for harvesting type and stem size class) were based on the cutting removals of the original harvesting site data. The forwarding distance was determined as the averaged value for each harvesting type. To match the removal of each harvesting type on an average worksite, the model used the aggregated site data and the defined static value of the average worksite of each case/scenario.

Regarding the worktime and operation specifications for the full year (base scenario), both the harvester and the forwarder operators had 235 working days, 34 holidays and 11 days of non-scheduled machine lay-down. Machines were running 23 weeks in one-shift and 20 weeks in two shifts, totalling 43 working weeks. As regards weekends, 20 Saturdays were operated with one shift. In the SA-model, worktime was broken down into repairs and maintenance, operator and planning delays, machine relocations, preparatory (non-productive) work and productive machine use. Moreover, the first two categories were fixed for all scenario runs. In the base scenario, the annual worktime of the harvester operator was 2881 hours, whereas the forwarder operator’s worktime was adjusted to balance the annual productions of both machines. The operational worktime distribution in Region 2 (see Section 2.4 for the definition of the regions) is depicted in Table 1.

| Table 1. Worktime distributions and working hours of a harvester and a forwarder for a calendar year on a current level (base scenario) for Central Finland province. The shares in percents for each element is calculated against the worktime (i.e., workplace time). | ||

| Harvester | Forwarder | |

| Repairs and maintenance, % | 11.0 | 7.0 |

| Delays due to the operator and planning, % | 4.0 | 4.0 |

| Machine relocations (incl. waiting for relocations), % | 3.0 | 3.1 |

| Preparatory (non-productive) work, % | 2.5 | 0.9 |

| Machine utilization (MUE0) for the productive machine time (E0), % | 79.5 | 85.0 |

| Delays of less than 15 mins, % | 6.0 | 4.0 |

| Machine utilization (MUE15) for the productive machine time* (E15), % | 85.5 | 89.0 |

| Worktime (i.e., workplace time), h | 2881 | 2734 |

| Productive machine time, h15 | 2462 | 2435 |

| Productive machine time, h0 | 2289 | 2326 |

| * Including delays, which duration is less than 15 minutes | ||

The productivity functions of m3 PMh–1 for both the harvester and the forwarder were derived from a study conducted by Eriksson and Lindroos (2014). The productivity models used were linear regression models (Table 2 and 3). The productivity formulas were compared and adjusted to match the harvester’s and forwarder’s productivity figures (PMh) from Finland taken from the harvester’s data produced by Jylhä et al. (2019) and Liski et al. (2020), and the forwarder’s data produced by Äijälä (2022). Therefore, the model for the harvester productivity (PMh) was corrected by a coefficient of 0.86, and the model for the forwarder by a coefficient of 0.9. In the forwarder’s productivity model the mean load capacity in volume under bark (solid under bark, sub) was set to 13.5 m3 for the final cutting, and 10 m3 for thinning and CCF-cutting. Respective volumes over bark (solid over bark, sob) were 15.1 m3 and 11.4 m3. For all harvesting types, parameter values of 2 were used both for the terrain roughness and the slope.

| Table 2. Harvester productivity models of Eriksson & Lindroos (2014) used in the systems analysis model of CTL harvesting. Models are for Ln(y), where y = productivity in m3 PMh–1. (RMSE2)/2 is required to add to the model when estimating y. | ||

| Variable | Parameter estimates | |

| Final cutting | Thinning & CCF-cutting | |

| Intercept | 3.135 | 3.592 |

| Ln(Mean stem size) | 0.378 | 0.693 |

| Ln(Total harvested volume) | 0.066 | 0.037 |

| Ln(Harvested volume per ha) | 0.056 | 0.039 |

| (Ln(Mean stem size))2 | –0.072 | - |

| (RMSE2)/2 | 0.0365 | 0.0313 |

| Table 3. Forwarder productivity models of Eriksson & Lindroos (2014) used in the SA-model of CTL harvesting. Models are for Ln(y), where y = productivity in m3 PMh–1. (RMSE2)/2 is required to add to the model when estimating y. MFD = Mean forwarding distance. | ||

| Variable | Parameter estimates | |

| Final cutting | Thinning & CCF-cutting | |

| Intercept | 0.641 | 2.318 |

| (Ln(MFD))2 | –0.056 | –0.028 |

| Ln(Mean stem size) | 0.176 | 0.259 |

| Ln(MFD × Load capacity) | 0.435 | 0.149 |

| Ln(Total harvested volume) | 0.058 | 0.046 |

| Ln(Harvested volume per ha) | 0.094 | 0.074 |

| Ln(Terrain roughness × Slope) | –0.074 | –0.050 |

| (RMSE2)/2 | 0.0392 | 0.0365 |

As the volume-based parameters in Eriksson and Lindroos’s (2014) productivity formulas for the harvester and the forwarder were based on volumes under bark, a correction model (1) between volume over bark and under bark was applied (Hakkila et al. 2020).

![]()

where y is the stem volume m3(sub) and x is volume m3(sob).

Machine relocations were set so that 70% of all relocations occurred during the machine operators’ worktime, and the average time for a relocation (including loading, driving while loaded, unloading, auxiliary time) and waiting for the relocation was set at 1.8 hours. Ninety percent of all the machine relocations were carried out by using the relocation truck and the rest were self-propelled by the machines. The SA-model calculated the number of logging sites and machine relocations on annual basis with the average size of the harvesting site (i.e., average removal per site) of each scenario run. The initial values for the relocation distance and the trip distance of a relocation truck were 25 km and 80 km, respectively. Correspondingly, the work trip distance (return) was 85 km. For the start of each worksite, fixed times of 0.6 hours and 0.25 hours for the typical non-productive preparatory work at the site were defined for the harvester and the forwarder, respectively. These work activities included planning the work, reading the worksite instructions and preparing site-specific settings for IT systems.

2.3 Cost assessment

The machine-specific costings for the harvester and the forwarder were calculated using the cost accounting spreadsheets of the SA-model. The price values for the costings were mostly derived from Väätäinen et al. (2021), with the price-index correction published by Finn Stat – MEKKI to convert the prices into the average price levels for 2022. The main costing parameters and values for the harvester and forwarder are presented in Table 4.

| Table 4. Main costing parameters and values for the harvester and forwarder in the systems analysis model of CTL-harvesting. | ||

| Harvester | Forwarder | |

| Investment costs and capital factors | ||

| Base machine (excluding equipment), € | 421 000 | 336 000 |

| Soft soil gear, € | 52 000 | 52 000 |

| Harvester head, € | 60 000 | |

| Other equipment, € | 9000 | 14 000 |

| Working capital, € | 30 000 | 20 000 |

| Life span (base machine; fixed), years | 5 | 7 |

| Life span (equipment; varying), hours | 7000 | 7000 |

| Annual depreciation, % | 15 | 15 |

| Labour costs | ||

| Wage cost for base shift, €/h | 17.0 | 15.3 |

| Wage cost for weekend/extended shift, €/h | 25.5 | 22.9 |

| Indirect wage cost, % | 53.25 | 53.25 |

| Kilometre allowance for machine operators, €/km | 0.53 | 0.53 |

| Daily allowance for machine operators, €/day on average | 6 | 6 |

| Operational factors and costs | ||

| Fuel, l/h (consumption) - €/l (price) | 16.0–1.29 | 13.0–1.29 |

| Engine oil, l/h (consumption) - €/l (price) | 0.1–2.50 | 0.1–2.50 |

| Ad-blue, l/h (consumption) - €/l (price) | 0.7–1.29 | 0.6–1.29 |

| Gear oil, l/h (consumption) - €/l (price) | 0.1–3.06 | 0.1–3.06 |

| Hydraulic oil, l/h (consumption) - €/l (price) | 0.2–3.06 | 0.2–3.06 |

| Chainsaw oil, l/h (consumption) - €/l (price) | 0.57–1.77 | - |

| Colour mark, l/h (consumption) - €/l (price) | 0.3–1.77 | - |

| Rot-stop fluid, l/h (consumption) - €/l (price) | 0.56–1.77 | - |

| Chainsaw, pc./h (consumption) - €/kpl (price) | 0.06–16.94 | - |

| Sawbar, pc./h (consumption) - €/kpl (price) | 0.020–52.42 | - |

| Machine relocation, €/km | 2.35 | 2.35 |

| Fixed costs | ||

| Interest rate, % | 4 | 4 |

| Insurances, €/year, a | 2600 | 1800 |

| Real estate expenses, €/a | 4000 | 4000 |

| Administration and maintenance, €/a | 4000 | 4000 |

| Supervision of work and site visits, €/a | 6000 | 3500 |

| Operating margin, % | 5 | 5 |

2.4 The scenario approach

Having established the structural systems analysis according to CTL harvesting by TMS, the next step was to apply a scenario approach to discover the impact of the different EU’s forest-related policies on harvesting costs. Since direct links between the Directives and Regulations and the quantitative values of the key variables (see Fig. 1) cannot be constructed because of the lack of scientific information (or of any information, for that matter), a scenario approach was applied here. In the scenario approach alternative, the values for the key variables are assumed to hold in the future (Campi et al. 2021). There is a question about how plausible these values are, but the more important thing is that they are based on argumentation which is at least transparent. Further, some of the key variables (Fig. 1) have a more essential impact on the harvesting costs than others. In this study, structural systems analysis was applied to identify the four key variables most sensitive to Directives and Regulations: 1) the size of the average harvesting site (expressed in cubic metres, m3), 2) share of CCF over total operating volume (expressed as a percentage and primarily calculated according to the cutting volumes of CCF and rotation forestry, RF), 3) number of working weeks per annum (expressed in number of weeks) and 4) total of non-productive preparatory work at a harvesting site (expressed as a percentage of the total working time, %).

The average size of the harvesting site relates to the constraining factors: the fewer the limitations on forest management, the higher the cutting removals that are achievable (and therefore the higher the average harvesting site removal). In other words, with high legislative pressure one might assume there are more constraints on timber production (such as buffer zones near to water courses and conservation reserves) resulting in a smaller average harvesting area and less removal per site. In such a case the fixed costs tend to increase too much in relation to the variable costs, possibly resulting in efficiency losses (Begg et al. 2005). In the scenario calculations, the same percentual changes, as for the size of the harvesting site, were used to reduce the harvesting removal per site in each stem size distribution class and in each harvesting type (see classes in Table 1). Moreover, it was assumed that the annual operating area of the TMS would remain unchanged, even though the size of the harvesting sites would decrease. At the same time, it was assumed that the average commuting distance of the machine operators and the average relocation distance of the machines between the work sites remained unchanged in the different scenarios. The reduction in the size of the harvesting site increased the number of work sites, which increases the number of machine relocations during the year.

Increasing the share of CCF then corresponds to increasing the number of harvesting sites with less cutting removal per unit of forest land area (m3 ha–1 or 1000 m3 km–2), compared to RF. This is particularly the case within the next, say, 10–15 years, when some of the mature stands are converted into the CCF-system by executing the first selection cuttings. Jonsson (2015) found that selection cutting promoting the transformation from rotational forest management to CCF followed the established standards for time consumption in thinning so closely that these standards may also be used for predicting time consumption in selection cutting. It is noteworthy that an increase in CCF simultaneously with a decrease in both RF and in the area of a harvesting site combine to reduce the timber removal from the average harvesting area.

The number of working weeks per year is directly linked to annual productivity: the higher the number of working weeks, the lower the fixed costs per unit produced (Begg et al. 2005). A decrease in the working weeks could be due, for instance, to the conservation of wild birds (Directive 2009/147/EC) which sets temporary protection schedules. Finally, more preparatory work for a harvesting site is needed (in terms of, for example, administrative actions and the monitoring of environmental issues) if Directives and Regulations are fully enforced.

In the analysis, the decrease in working weeks was targeted at the late spring and summer. Thus, each lay-down week reduced the production of the TMS corresponding to the average harvesting performance of five working days in the one-shift mode. In the scenarios, as the number of working weeks decreased, there was compensation for the gap in removal by additional harvesting in the late summer and autumn. This increased the two-shift working time up to a maximum of five weeks. Thus, in the Low-impact scenario, there could be full compensation for the reduction in harvesting weeks, but in the Moderate-impact and High-impact scenarios, there could not be complete compensation. Therefore, the annual worktime and performance of the TMS decreased in those scenarios compared to the current state.

In the scenario approach the four key variables mentioned above were changed according to a specific matrix in which three potential levels of impact were classified. These levels were designated the Low-impact, Moderate-impact and High-impact levels. The rationale for the impact levels was that they enabled the quantification in economic terms (harvesting costs) of how EU Directives and Regulations might affect the operating environment of harvesting entrepreneurs in Finland. Table 5 shows the scenarios associated with the numeric values of the four key variables. For instance, in the Low-impact scenario, the average size of the harvesting site is decreased by 10% (compared to the present situation), the share of CCF is increased from a 2% to a 10% share, corresponding a 400% increase, the number of working weeks is reduced by 7% (from 43 to 40), and the total preparatory work for a harvesting site is increased by 50%. Furthermore, proportionate changes in the four key variables take place simultaneously within a particular scenario, indicating a clear ranking between the three scenarios (Low < Moderate < High) with respect to the severity of the combined impact of Directives and Regulations on the harvesting operations and operating environment.

| Table 5. Proportionate changes (%) in the four key variables in the three impact scenarios of EU’s forest-related policy changes on the operating environment of harvesting entrepreneurs (Low-, Moderate- and High-impact). Proportions are expressed as relative to the status quo, %. Negative values indicate a decrease and positive values an increase relative to the current level. For the share of CCF, the percentages illustrate the level, not a proportionate change. | |||

| Key variable | Low | Moderate | High |

| Size of an average harvesting site1) | –10% | –20% | –30% |

| share of CCF-cutting2) | 10% | 20% | 30% |

| number of working weeks3) | –7% | –15% | –21% |

| total preparatory work for a harvesting site4) | +50% | +100 % | +150% |

| 1) expressed in cutting volume, m3, 2) the share of CCF is currently ca. 2% of total cutting removals (the increase from the 2% level to 10% corresponds to a 400%, from 2% to 20% a 900% and from 2% to 30% a 1400% proportionate increase). The change in this variable will have an additional effect on the removal of harvesting site, 3) current level is 43 weeks, and 7% decrease corresponds to 40, 15% decrease to 37 and 21% decrease to 34 weeks, 4) preparatory work consists of e.g., administrative actions and checking environmental issues on site (note that current level of preparatory work represents 1.0% of the total working time of the harvester and 0.2% of the forwarder). | |||

Further, the scenario approach was applied to three different regions of Finland. The three regions represent approximately 33% of the annual total cutting volumes in Finland (Natural Resources Institute Finland 2022). The rationale was to look at potential regional differences related to harvesting costs. Initially, there are some differences between the regions in stand structures (e.g., mean stem size distribution, proportion of harvesting types, mean forwarding distances and mean harvesting site removal) and thus in harvesting conditions (Table 6). For instance, in the Region 1 the average magnitude of a harvesting site was considerably smaller (approximately 20–30% less) than in Region 2 and 3 (Table 6).

| Table 6. Regional differences in harvesting conditions, Regions 1, 2 and 3. | |||

| Region 1 | Region 2 | Region 3 | |

| Share of total accumulation by harvesting types1), %; | 70-28-2 | 63-36-2 | 65-33-2 |

| Average stem size, dm3 | 168 | 198 | 242 |

| Average removal, m3 ha–1 | 104 | 109 | 108 |

| Average forwarding distance in RF, m | 287 | 265 | 297 |

| Average forwarding distance in thinning and CCF-cutting, m | 321 | 286 | 364 |

| Average stand size, m3 | 484 | 628 | 580 |

| Average harvesting site removal, m3 | 411 | 534 | 493 |

| 1) RF – thinning - CCF. For instance, in Region 1, 70% of total accumulated removal was from final cuttings, 28% from thinnings and 2% from CCF-cuttings. | |||

2.5 Sensitivity analysis

Since the proportionate changes in the key variables (see Table 5) were based on experts’ opinions and sophisticated estimates rather than actual measured (observed) values, it is essential to apply a sensitivity analysis to these changes in the key variables. In the sensitivity analysis the effect of a single key variable on harvesting costs was evaluated by changing its value while keeping the other key variables intact. The idea was to assess how significant the changes in variable values are with respect to the total harvesting cost. The range of parameter values associated with each key variable is presented in Table 7.

| Table 7. Alternative parameter values associated with the key variables in the sensitivity analysis of the systems analysis model of CTL-harvesting. | ||

| Key variable | Current variable value | Alternative variable values |

| Size of the average harvesting site1) | 411–534 m3 | –10%, –20%, –30% and –40% |

| share of CCF2) | 2% | 5%, 10%, 20%, 40% and 60% |

| harvesting intensity in CCF3) | 50% | 30%, 40%, 60% and 70% |

| number of working weeks | 43 weeks | 31, 34, 37 and 40 weeks |

| Increase in preparatory work for a harvesting site4)5) | 1% for a harvester 0.2% for a forwarder | +50%, +100% and +150% |

| 1) average harvesting site removal relative to present level; note that the absolute harvesting site varies between the three regions and that size represents an average working site including one relocation of logging machines, 2) proportion of total cutting volume (m3), %, 3) harvesting intensity expressed as number of removed stems per hectare compared to removed stems in final cutting in RF, %, 4) expressed in proportionate increase relative to current parameter value, %. 5) In each SA-model run, 0.6 h and 0.25 h per each harvested worksite was added to the preparatory work presented above for the harvester and forwarder, respectively. | ||

3 Results

All annual performance indicator values of the TMS decreased steadily when the values of the policy scenarios were compared with the corresponding values of the current state (Table 8). For example, in the High-impact scenario, the annual productivity of the TMS decreased by 14.6% compared with the current state. The machine utilization rate (MU) of the harvester and the forwarder decreased by 5.2% and 3.1%, respectively. The change in utilization rates was influenced by both the increase in machine relocations and the increase in the proportion of auxiliary time. Changes in operating conditions were significant. For instance, in the High-impact scenario, the timber removal of the average logging site decreased by 42.4% compared with the current state, and the number of logging sites increased by almost 51%. The changes were similar for all performance indicator values in the three regions, although absolute values differed due to the differences in site characteristics.

| Table 8. Annual performance indicator values of the two-machine system (TMS) derived from the systems analysis model of CTL-harvesting for all scenarios (Current state, Low-, Moderate- and High-impact). Presented values are averages of the scenario analysis from the three regions. | ||||

| Annual performance indicators | Current state | Low | Moderate | High |

| Production, m3 | 40 448 | 39 342 | 37 506 | 34 525 |

| Productive machine hours, E15* | ||||

| - harvester | 2446 | 2410 | 2332 | 2180 |

| - forwarder | 2483 | 2460 | 2396 | 2255 |

| Machine utilization (MUE15), % | ||||

| - harvester | 84.9 | 83.6 | 82.2 | 80.5 |

| - forwarder | 88.6 | 87.9 | 87.0 | 85.9 |

| Average productivity, m3/hE15–2* | ||||

| - harvester | 16.5 | 16.3 | 16.1 | 15.8 |

| - forwarder | 16.3 | 16.0 | 15.6 | 15.3 |

| Total harvesting area, ha | 377 | 385 | 389 | 378 |

| Average removal of a logging site, m3 | 479 | 407 | 337 | 276 |

| Number of logging sites | 85 | 98 | 113 | 127 |

| * E15-time corresponds productive machine time (PMh-time) including delays, which duration is less than 15 minutes. | ||||

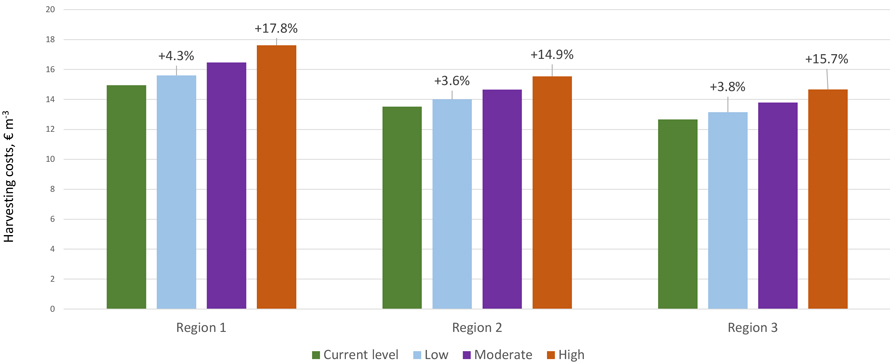

In general, based on the scenarios, the effect of the planned legislation on harvesting costs was similar in all three regions (Fig. 2). For instance, when a Low-impact scenario (see Table 5) was assumed, the harvesting costs increased by between 3.6% and 4.3% approximately (compared to the current level of harvesting costs), depending on the region (Fig. 2). Further, in the High-impact scenario the increase in harvesting costs was between 14.9% and 17.8% depending on the region (Fig. 2). The current level of harvesting costs fluctuated considerably between the regions, by approximately 18% (Fig. 2: Current level bars). This is mostly due to differences in the main site characteristics between the regions, particularly in average stem size (see Table 6).

Fig. 2. Harvesting costs according to alternative scenarios and current level of legislation in three different regions of Finland: Region 1 (consisting of the provinces of Ostrobothnia, South and Central Ostrobothnia), Region 2 (Central Finland province) and Region 3 (provinces of South Savo, South Karelia and Kymenlaakso), € m–3. Percentages above the bars illustrate proportionate changes to current level. View larger in new window/tab.

3.1 Sensitivity analysis

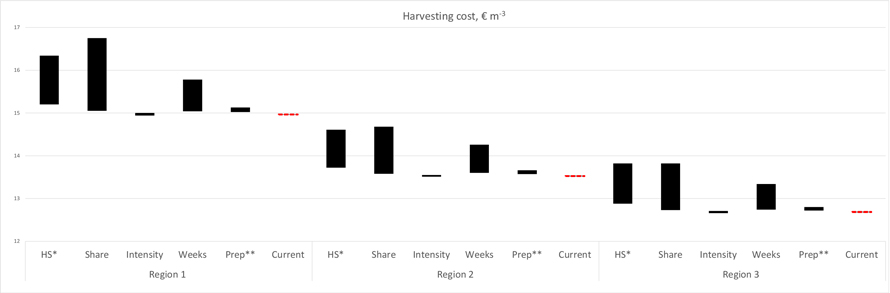

The sensitivity analysis revealed that changes in the size of a harvesting site, share of CCF and the number of work weeks would have considerable impacts on harvesting costs, depending on the region (Fig. 3). However, the sensitivity analysis was based on altering the variable values according to the experts’ opinions to create a plausible range, rather than on structural analysis which would, for example, apply identical proportionate changes in the variable values associated with the key variables. Thus, this should be borne in mind when interpreting the results of the sensitivity analysis.

Within the sensitivity range of the size of the harvesting site-parameter, the relocation cost itself represented roughly 40% of the whole cost change. The rest of this (~60%) was based on the machine operation costs, wherein both the decreasing operating time and the lowering productivities for both the harvester and the forwarder were the rest of the factors influenced by the lowered size of the harvesting site. The effects on harvesting costs of the thinning intensity of CCF-cutting and increasing the preparatory work for a harvesting site were minuscule, indicating an absolute change of harvesting costs of between 0.04 and 0.11 € m–3 (depending on the region; Fig. 3). These absolute values correspond to less than a 1% relative change in harvesting costs, which can be considered insignificant.

Fig. 3. Results of the sensitivity analysis of the systems analysis model of CTL-harvesting in Region 1, 2 and 3. The floating bars represent the variation according to the alternative variable values presented in Table 7. Red dotted lines illustrate harvesting cost associated with the current level of the key variables in each Region. HS stands for Harvesting site, Share for share of CCF, Intensity for intensity of CCF, Weeks for Working weeks, Prep for Preparatory work and Current for current level. [*Decrease in harvesting site, %, and ** increase in preparatory work – see Table 7 for details]. View larger in new window/tab.

4 Discussion

Various EU Directives (see Pettersson and Keskitalo 2013) contain legislative obligations which in turn lead to limitations on timber production, among other things (Köhl et al. 2021). To date these limitations have not been constructively assessed with respect to the different agents involved in the forestry sector, except the forest owners (Nichiforel et al. 2020). This study attempted to estimate the effect of the implementation of EU Directives and Regulations on timber harvesting costs in Finland. A scenario approach was used in which the magnitude of implementation was categorized into alternative impact levels, and these levels were constructed according to a structural systems analysis of timber harvesting. To our knowledge this is the first attempt to quantify the effect of EU Directives and Regulations in monetary terms from the entrepreneur’s point of view. We have used a report by Väätäinen et al. (2023) as a background material. Methodology and scientific framework are described more detailed in the article enabling peer review of the selected approach and evaluation of the relevance of presented outcomes. Moreover, presented results of this article are based on scenario runs with updated productivity models for the harvester, and thereby results will differ from Väätäinen et al. (2023). This had an effect especially in the scenario and sensitivity runs, where the size of the average harvesting site was varying.

There are a few issues that need to be raised in order to avoid misinterpretations of the results. First, because of various uncertainties in the processes of EU regulation and politics related to timing (how fast policies are brought into force) and severity (how intensively the proposed changes will be realised in practice), three varying future scenarios were assessed and calculated in this study. Moreover, the short time horizon of 10–15 years applied here was partly chosen because of the increase in the uncertainty about the level of implementation of policies and the outcomes of these for harvesting practices, particularly the share of CCF, over a longer perspective. On the other hand, the machine technology, machine performance and prices of cost factors will be expected to change in 10–15 years. Thereby, the results of the impact of EU-regulations on CTL-harvesting are valid in technology, productivity and price levels of the present state. Second, the systems analysis framework applies at an annual level, with a year being divided into two operating seasons: autumn and winter predominantly operated in a two-shift working mode and spring and summer in a one-shift mode. Within each operating season, daily productivities were averaged. Moreover, because of the limitations of the static spreadsheet approach, the operational conditions were even throughout the year, indicating e.g., even productivity and fuel consumption of the machines.

If the share of CCF grows, this will most probably increase the seasonality by forcing more pressure on wintertime operations. In summer, there is a limit, particularly for selection cutting operations (e.g., CCF and thinning cuttings), because of the higher risk of damage to the soil and the remaining trees, particularly on peatlands and forests with fine-grained soils and in wet terrain. This, on the other hand might bring about capacity issues since more labour (e.g., forest machinery operators) and machinery would be needed at the time of year when the capacity is already reaching its limits. Such capacity restrictions are not taken into account in this study. However, the required capacity increase has been estimated to be approximately 15% for machinery and harvester operators in the high-impact scenario in Finland (Väätäinen et al. 2023). In particular, the need for new harvester operators (skilled labour) will cause a bottleneck, since even now there are regional shortages of operators.

The relatively short time period of the scenarios is also supported by the scenario assumption related to the type of CCF-cuttings. During the time period used in this study, almost all CCF-cuttings would be so-called conversion phase cuttings, where the even-aged forest stands would be selected and harvested for conversion to CCF. After 10–15 years of conversion phase cuttings, the structure of the CCF forests would be significantly different and the steady-state CCF-cuttings would take over. The conversion versus steady-state comparison relates to the different diameter distributions and lower cutting volumes for CCF, and probably leads to higher harvesting costs (see Jonsson (2015) for such an increase demonstrated with steady-state removals). More importantly, the current systems analysis framework does not apply to steady-state cuttings. Finally, besides the cost estimates (increases in harvesting costs) calculated in this study, there are other cost items, which might create pressure on harvesting costs. Namely, it is likely that seasonality causes more maintenance operations for the road network and for wood procurement (including logistics). At a large scale, long-distance transport costs have been estimated to increase by about 12% because of the cost effects related to EU legislation (Väätäinen et al. 2023).

Compared to Väätäinen et al. (2023) report of potential effects of EU-regulations on harvesting costs, our results differed primarily in the scenarios and sensitivity results, where the size of the harvesting site was changing. For example, the scenarios of Low-impact, Moderate-impact and High-impact resulted in 0.3, 0.8 and 1.3 percent unit higher harvesting costs in this study than in Väätäinen et al. (2023). This was due to the different cutting productivity models used in scenario runs of the SA-model. The harvester productivity model of Liski et al. (2020) was replaced by the model of Eriksson and Lindroos (2014). The latter includes the parameters i) size of harvesting site, and ii) removal intensity, which are missing in Liski’s model.

Since there are vast temporal and system variations in machine operations, with fluctuations, for example in operating conditions, machine productivity and delays in Nordic CTL-harvesting methods, a word of caution is addressed: this study was based on a static structural systems analysis for a Finnish case. To attain more generic results, one should apply dynamic simulation methods such as a discrete-event simulation within the systems analysis framework, to improve the accuracy of the modelling and thus achieve more general results on harvesting costs for Nordic CTL-harvesting (see e.g., Asikainen 2001; Talbot et al. 2003; Väätäinen et al. 2021).

In addition to wood harvesting, there will potentially be cost effects of EU policies on the entire wood procurement and procurement logistics systems. Major changes in wood procurement logistics are caused by the increase in the seasonality of wood harvesting, especially if harvesting operations are halted during late spring and summer due to nesting time and because of the large increase in CCF-cuttings and the protection of forest soils. The closed period for harvesting in the late spring and summer requires that the corresponding amount of wood is harvested during autumn and winter and stored to fulfil the forest industry’s demand for wood during the closed period. This will increase the costs associated with increased and prolonged timber storage, such as capital, timber quality loss and quality maintenance costs.

From the forest owners’ point of view, two main aspects both affecting the timber sales revenue, can be highlighted. First, in accordance with the decrease of timber removal of a harvesting site (i.e., both the size of the site and the removal intensity are decreased), also the sales revenue of timber will reduce. Another issue affecting sales revenue is lowered stumpage price due to the increased harvesting costs per harvested cubic meter. Thus, changes in EU-regulation on forestry have a direct impact on profitability of private forestry as well.

The wood processing industry has been making large investments in Finland in recent years by upgrading the current mill production capacity and establishing big new biorefineries. Some older mills have been closed, but timber demand may even increase a little because of the capacity increase and stopped import of sawlogs, pulpwood and chips from Russia. The potential changes in EU policy and their resulting impacts on forestry, including increased difficulties in timber accessibility will hamper domestic timber procurement by the forestry industries.

According to the scenario runs, the High-impact scenario will require a 16% larger total harvesting area than in the current state to obtain the same timber removal. This is because of the decrease in RF, which is compensated by a simultaneous increase in CCF-cutting with lower timber removal per hectare than in RF. Moreover, as the areas and removals of harvesting sites will decrease, it will result in roughly a 70% increase in the number of harvesting sites in the High-impact scenario compared to the current state scenario. This is a result of a combined effect of both the smaller logging site areas and the larger CCF share in logging removals. These potential changes in the operating environment may be inherent in the difficulties that must be tackled in the Finnish forestry practices and timber procurement. For this reason, it is crucial to fine-tune and re-adjust domestic timber procurement by following best business practices. These involve contracting with several clients to optimise the operational areas, having bigger harvesting site reserves, and improving the potential to have efficient clusters of harvesting sites which minimise machine relocations (Väätäinen et al. 2008; Öhman and Eriksson 2010; Väätäinen et al. 2021). In addition, a reduction in the size of the harvesting sites and an increase in the number of individual harvesting sites will probably increase the transaction costs of wood procurement, requiring cost-efficient practices and models to be found for wood buying activities. Matching these opposing effects of EU policies on the demands on forest industry and timber procurement will ultimately be highly challenging.

The main results of this study demonstrate that in the High-impact scenario there will be a considerable increase in harvesting costs (between ca. 15% and 18%, depending on the Region), which clearly diminishes the potential profits for entrepreneurs unless the cost increase is compensated for by adjusted contract fees. The magnitude of the increase corresponds to an approximate doubling of the fuel price (Väätäinen et al. 2023). In the Low- and Moderate-impact scenarios the increase in harvesting costs (< 10%) is tolerable, but if it occurs suddenly that would also cause downturns in business. The relevant question is whether the High-impact scenario is more probable than the Low- and Moderate-impact scenarios. This question, however, cannot be answered until the new elements of EU forest legislation, that is, the Directives and Regulations, are implemented in full. In the meantime, the results of this study will contribute to adjusting the harvesting operations and harvesting methods of the future.

Declaration of openness of research materials, data, and code

Data are available upon request from the corresponding author (anssi.ahtikoski@luke.fi)

Authors contribution

AA: Conceptualization, Investigation, Methodology, Writing-original draft, Editing the final draft

KV: Conceptualization, Data curation, Formal analysis, Investigation, Methodology, Writing-review &editing

PA: Conceptualization, Data curation, Formal analysis, Investigation, Methodology, Writing-review &editing

JL: Formal analysis, Methodology, Writing-review & editing

AM: Conceptualization, Methodology, Writing-review & editing

JLi: Formal analysis, Project administration, Writing-review & editing

LS: Resources, Methodology, Writing-review & editing

JR: Resources, Funding acquisition, Methodology, Writing-review & editing

Acknowledgements

The authors thank Simo Jaakkola from Koneyrittäjät ry and steering group of the project from Ministry of Agriculture and Forestry for their support and comments to the manuscript.

Funding

This work was supported by Ministry of Agriculture and Forestry of Finland, Development of a model for machine cost accounting-effects of EU policies and other identified factors on costs-project (VN/13509/2022).

References

Aggestam F, Giurca A (2021) The art of “green” deal: policy pathways for the EU Forest Strategy. Forest Policy Econ 128, article id 102456. https://doi.org/10.1016/j.forpol.2021.102456.

Ahtikoski A, Laitila J, Hilli A, Päätalo ML (2021) Profitability of the first commercial thinning, a simulation study in northern Finland. Forests 12, article id 1389. https://doi.org/10.3390/f12101389.

Äijälä J (2022) Puunkorjuuyritysten hiilijalanjälki. [Carbon footprint of a harvesting entrepreneur]. Pro-gradu -tutkielma, Metsätieteiden maisteriohjelma, Helsingin yliopisto. https://helda.helsinki.fi/handle/10138/354553.

Asikainen A (2001) Simulation of logging and barge transport of wood from forests on islands. Int J For Eng 12 43–50. https://doi.org/10.1080/14 942119.2001.10702445.

Begg D, Fischer S, Dornbusch R (2005) Economics, 8th edition. McGraw-Hill, Berkshire, UK.

Campi MC, Carè A, Garatti S (2021) The scenario approach: a tool at the service of data-driven decision making. Ann Rev Control 52: 1–17. https://doi.org/10.1016/j.arcontrol.2021.10.004.

COM(2014) 15 final. A policy framework for climate and energy in the period from 2020 to 2030. https://www.eea.europa.eu/policy-documents/com-2014-15-final.

COM(2019) 640 final. The European Green Deal. https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:52019DC0640.

COM(2020) 380 final. EU Biodiversity Strategy for 2030. https://eur-lex.europa.eu/resource.html?uri=cellar:a3c806a6-9ab3-11ea-9d2d-01aa75ed71a1.0001.02/DOC_1&format=PDF.

COM(2021) 550 final. “Fit for 55”: Delivering the EU’s 2030 Climate Target on the way to climate neutrality. https://eur-lex.europa.eu/legal-content/EN/ALL/?uri=COM:2021:550:FIN.

COM(2021) 554 final. Amendment of Regulations (EU) 2018/841 as regards the scope, simplifying the compliance rules, setting out the targets of the Member States for 2030 and committing to the collective achievement of climate neutrality by 2035 in the land use, forestry and agriculture sector, and (EU) 2018/1999 as regards improvement in monitoring, reporting, tracking of progress and review. https://opac.oireachtas.ie/Data/Library3/Documents%20Laid/2021/pdf/DECCdocslaid270821a_270821_162547.pdf.

COM(2021) 557 final. Proposal for a Directive of the European Parliament and of the Council amending Directive (EU) 2018/2001 of the European Parliament and of the Council, Regulation (EU) 2018/1999 of the European Parliament and of the Council and Directive 98/70/EC of the European Parliament and of the Council as regards the promotion of energy from renewable sources, and repealing Council Directive (EU) 2015/652, European Commission. https://eur-lex.europa.eu/resource.html?uri=cellar:dbb7eb9c-e575-11eb-a1a5-01aa75ed71a1.0001.02/DOC_1&format=PDF.

COM(2021) 572 final. New EU Forest Strategy for 2030. https://eur-lex.europa.eu/resource.html?uri=cellar:0d918e07-e610-11eb-a1a5-01aa75ed71a1.0001.02/DOC_1&format=PDF.

COM(2021) 706 final. Proposal for a Regulation of the European parliament and of the Council on the making available on the Union market as well as export from the Union of certain commodities and products associated with deforestation and forest degradation and repealing Regulation (EU) No 995/2010. https://eur-lex.europa.eu/resource.html?uri=cellar:b42e6f40-4878-11ec-91ac-01aa75ed71a1.0001.02/DOC_1&format=PDF.

COM(2021) 2800 final. Commission delegated regulation supplementing Regulation (EU) 2020/852 of the European Parliament and of the Council by establishing the technical screening criteria for determining the conditions under which an economic activity qualifies as contributing substantially to climate change mitigation or climate change adaption and for determining whether that economic activity causes no significant harm to any of the other environmental objectives. https://eur-lex.europa.eu/legal-content/EN/TXT/DOC/?uri=PI_COM:C(2021)2800&from=EN.

COM(2022) 304 final. Proposal for a Regulation of the European Parliament and of the Council on nature restoration. https://environment.ec.europa.eu/publications/nature-restoration-law_en.

Council Directive (1992) 92/43/EEC of 21 May 1992 on the conservation of natural habitats and of wild fauna and flora (Habitat Directive). https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A31992L0043.

Delgado-Martínez AM, Pantoja-Timarán F (2015) Análisis estructural para la identificación de variables claves en la Ruta del Oro, Nariño Colombia. Journal of the Facultad de Minas, Universidad Nacional de Colombia, Medellin Campus 82: 27–33.

Directive (2009/147/EC of the European Parliament and of the Council of 30 November 2009 on the conservation of wild birds. https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32009L0147&from=FI.

Eriksson M, Lindroos O (2014) Productivity of harvesters and forwarders in CTL operations in northern Sweden based on large followup datasets. Int J For Eng 25: 179–200. https://doi.org/10.1080/14942119.2014.974309.

Godet M (1994) From anticipation to action. A handbook of strategic prospective. UNESCO Publishing, France.

Godet M (2009) La Prospectiva Estratégica Para Las Empresas Y Los Territorios. Cuaderno Del Lipsor. [The prospective strategy for companies and Regions. Notes of Lipsor. Series of Investigations]. Serie de investigación 10 April 2009.

Godet M, Durance P (2011) Strategic foresight for corporate and regional development. UNESCO-DUNOD, France.

Gordeeva E, Weber N, Wolfslehner B (2022) The New EU forest strategy for 2030 – an analysis of major interests. Forests 13, article id 1503. https://doi.org/10.3390/f13091503.

Hakkila P, Repola J, Lindblad J, Kalaja H, Verkasalo E (2020). Mänty- ja kuusikuitupuun ominaisuudet Etelä-Suomessa – laadun vaihtelu ja hallinta. [Pine and spruce pulpwood characteristics in Southern Finland – quality variation and its management]. Luonnonvara- ja biotalouden tutkimus 25/2020. Luonnonvarakeskus. Helsinki. http://urn.fi/URN:ISBN:978-952-326-949-1.

Jonsson R (2015) Prestation och kostnader i blädning med skördare och skotare. [Performance and costs in selective harvesting with harvester and forwarder]. Arbetsrapport nr. 863, Skogsforsk.

Jonsson R, Rönnqvist M, Flisberg P, Jönsson P, Lindroos O (2023) Country-wide analysis of the potential use of harwarders for final fellings in Sweden. Scand J Forest Res 38: 105–120. https://doi.org/10.1080/02827581.2023.2168045.

Jylhä P, Jounela P, Koistinen M, Korpunen H (2019) Koneellinen hakkuu: seurantatutkimus. [Mechanised felling: a follow-up study]. Luonnonvara- ja biotalouden tutkimus 11/2019. Luonnonvarakeskus, Helsinki. http://urn.fi/URN:ISBN:978-952-326-717-6.

Kärhä K, Poikela A, Palander T (2021) Productivity and costs of harwarder systems in industrial roundwood thinnings. Croat J For Eng 39: 23–33.

Köhl M, Linser S, Prins K, Talarczyk A (2021) The EU climate package “Fit for 55” – a double-edge sword for Europeans and their forests and timber industry. Forest Policy Econ 132, article id 102596. https://doi.org/10.1016/j.forpol.2021.102596.

Lier M, Köhl M, Korhonen KT, Linser S, Prins K, Talarczyk A (2022) The New EU Forest Strategy for 2030: a new understanding of sustainable forest management? Forests 13, article id 245. https://doi.org/10.3390/f13020245.

Liski E, Jounela P, Korpunen H, Sosa A, Lindroos O, Jylhä P (2020) Modeling the productivity of mechanized CTL harvesting with statistical machine learning methods. Int J For Eng 31: 253–262. https://doi.org/10.1080/14942119.-2020.1820750.

Manzano-Solís LR, Díaz-Delgado C, Gómez-Albores MA, Mastachi-Loza CA, Soares D (2019) Use of structural systems analysis for the integrated water resources management in the Nenetzingo river watershed, Mexico. Land Use Pol 87, article id 104029. https://doi.org/10.1016/j.landusepol.2019.104029.

Natural Resources Institute Finland (2022) Statistic database: total roundwood removals by forest ownership category and region in 2021. https://statdb.luke.fi/PxWeb/pxweb/en/LUKE/LUKE__04%20Metsa__02%20Rakenne%20ja%20tuotanto__10%20Hakkuukertyma%20ja%20puuston%20poistuma/01b_Hakkuukertyma_maak.px/. Accessed 26 February 2023.

Nichiforel L, Deuffic P, Jellesmark Thorsen B, Weiss G, Hujala T, Keary K, Lawrence A, Avdibegović M, Dobšinská Z, Feliciano D, Górriz-Mifsud E, Hoogstra-Klein M, Hrib M, Jarský V, Jodłowski K, Lukmine D, Pezdevšek Malovrh S, Nedeljković J, Nonić D, Krajter Ostoić S. Pukall K, Rondeux J, Samara T, Sarvašová Z, Scriban RE, Šilingienė R, Sinko M, Stojanovska M, Stojanovski V, Stoyanov T, Teder M, Vennesland B, Wilhelmsson E, Wilkes-Allemann J, Živojinović I, Bouriaud L (2020) Two decades of forest-related legislation changes in European countries analysed from a property rights perspective. Forest Policy Econ 115, article id 102146. https://doi.org/10.1016/j.forpol.2020.102146.

Öhman K, Eriksson LO (2010) Aggregating harvest activities in long term forest planning by minimizing harvest area perimeters. Silva Fenn 44: 77–89. https://doi.org/10.14214/sf.457.

Pettersson M, Keskitalo ECH (2013) Adaptive capacity of legal and policy frameworks of biodiversity protection considering climate change. Land Use Pol 34: 213–222. https://doi.org/10.1016/j.landusepol.2013.03.007.

Platform on Sustainable Finance: Technical Working Group (2021) Part b – annex: full list of technical screening criteria August 2021. https://finance.ec.europa.eu/document/download/f7383cf5-43b3-45f8-9c6d-ab9571918849_en?filename=210803-sustainable-finance-platform-report-technical-screening-criteria-taxonomy-annex_en.pdf.

Platform on Sustainable Finance: Technical Working Group (2022a) Part b – annex: technical screening criteria March 2022. https://finance.ec.europa.eu/document/download/fd418fe7-7f84-479f-8c47-d75533353808_en?filename=220330-sustainable-finance-platform-finance-report-remaining-environmental-objectives-taxonomy-annex_en.pdf.

Platform on Sustainable Finance: Technical Working Group (2022b) Supplementary: Methodology and technical screening criteria October 2022. Available online: https://finance.ec.europa.eu/system/files/2022-11/221128-sustainable-finance-platform-technical-working-group_en.pdf.

Pülzl H, Wydra D, Hogl K (2018) Piecemeal integration: explaining and understanding 60 years of European Union forest policy-making. Forests 9, article id 719. https://doi.org/10.3390/f9110719.

Regulation (2018) (EU) 2018/841 Inclusion of greenhouse gas emissions and removals from land use, land use change and forestry in the 2030 climate and energy framework, and amending regulation (EU) No 525/2013 and Decision No 529/ 2013/EU. L 156/1. https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=uriserv:OJ.L_.2018.156.01.0001.01.ENG.

Regulation (2020) (EU) 2020/852 of the European Parliament and of the Council of 18 June 2020 on the establishment of a framework to facilitate sustainable investment and amending Regulation (EU) 2019/2088. https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32020R0852&from=EN.

Regulation (2023) (EU) 2023/1115 of the European Parliament and of the Council of 31 May 2023 on the making available on the Union market and the export from the Union of certain commodities and products associated with deforestation and forest degradation and repealing Regulation (EU) No 995/2010. https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32023R1115&qid=1699942817597.

Schier F, Iost S, Seintsch B, Weimar H, Dieter M (2022) Assessment of possible production leakage from implementing the EU Biodiversity Strategy on forest product markets. Forests 13, article id 1225. https://doi.org/10.3390/f13081225.

Talbot B, Nordfjell T, Suadicani K (2003) Assessing the utility of two integrated harvester-forwarder machine concepts through stand-level simulation. Int J For Eng 14: 31–43. https://doi.org/10.1080/14942119.2003.10702476.

Triplat M, Krajnc N (2020) Assessment of costs in harvesting systems using WoodChainManager web-based tool. Croat J For Eng 41: 49–57. https://doi.org/10.5552/crojfe.2020.583.

Väätäinen K, Liiri H, Asikainen A, Sikanen L, Jylhä P, Rieppo K, Nuutinen Y, Ala-Fossi A (2007) Korjureiden ja korjuuketjun simulointi ainespuun korjuussa. [Simulation of harwarders and two-machine systems in timber harvesting]. Working Papers of the Finnish Forest Research Institute 48. http://urn.fi/URN:ISBN:978-951-40-2038-4.

Väätäinen K, Lappalainen M, Asikainen A, Anttila P (2008) Kohti kustannustehokkaampaa puunkorjuuta – puunkorjuuyrittäjän uusien toimintamallien simulointi. [Towards more cost-effective harvesting – simulating the new operating models of the harvesting entrepreneur]. Working Papers of the Finnish Forest Research Institute 73. http://urn.fi/URN:ISBN:978-951-40-2086-5.

Väätäinen K, Lamminen S, Sirén M, Ala-Ilomäki J, Asikainen A (2010) Ympärivuotisen puunkorjuun kustannusvaikutukset ojitetuilla turvemailla − korjuuyrittäjätason simu-lointitutkimus. [Cost impact of year-round harvesting on drained peatlands -a simulation study at harvesting entrepreneur level]. Working Papers of the Finnish Forest Research Institute 184. http://urn.fi/URN:ISBN:978-951-40-2276-0.

Väätäinen K, Hyvönen P, Kankaanhuhta V, Laitila J, Hirvelä H (2021) The impact of fleet size, harvesting site reserve, and timing of machine relocations on the performance indicators of mechanized CTL harvesting in Finland. Forests 12, article id 1328. https://doi.org/10.3390/f12101328.

Väätäinen K, Mutanen A, Anttila P, Laitila J, Routa J, Kniivilä M, Ahtikoski A, Lindblad J (2023) EU-politiikkojen mahdollisia vaikutuksia puun korjuukustannuksiin: kustannuslaskentamallin kehittäminen ja skenaariotarkastelu. [Potential impacts of EU policies on harvesting costs: developing a cost accounting model and scenario analysis.]. Luonnonvara- ja biotalouden tutkimus 37/2023, Natural Resources Institute Finland. http://urn.fi/URN:ISBN:978-952-380-670-2.

Total of 52 references.