RETRACTED: Evaluation of the productivity and costs of excavator-based mechanized tree planting in Finland based on automated data collection

Kemppainen K., Kärhä K., Laitila J., Sairanen A., Kankaanhuhta V., Viiri H., Peltola H. (2024). RETRACTED: Evaluation of the productivity and costs of excavator-based mechanized tree planting in Finland based on automated data collection. Silva Fennica vol. 58 no. 5 article id 24047. https://doi.org/10.14214/sf.24047

Highlights

- With proper site selection and competent machine operators, it is possible to achieve a higher productivity than 200 seedlings per operating hour in excavator-based mechanized planting

- The hectare-based regeneration costs from excavator-based mechanized planting can be 5% lower than those of conventional manual planting chains

- The most cost-efficient planting chain was a continuously advancing mounder combined with manual planting.

Abstract

The poor cost-effectiveness of mechanized planting (MECP) is the main reason for the low mechanization rate of planting. In this study, we investigated the productivity of the mechanized excavator-based planting of Norway spruce (Picea abies [L.] H. Karst.) seedlings based on data collected by the Risutec Asta documentation system. We also compared the costs of a MECP chain with two different manual planting (MAP) chains, where mounding was carried out by a crawler excavator (EXC) or a continuously advancing mounder (CONT). The MECP of seedlings was carried out using an EXC equipped with a Risutec PM-160 planting device. Generally, the nine study sites in western Finland contained few surface obstacles (e.g., the logging residues had mainly been harvested), which made the conditions very suitable for MECP. The average production time taken by the MECP was 9 h ha-1. The operating hour (G15-h) productivity averaged 215 seedlings G15-h-1 , with the mean planting time being 13.8 s seedling-1. Loading 160 seedlings into the seedling cassette took approximately 10 min (3.8 s seedling-1). Overall, the cost of the MECP was about 5% lower than for the EXC + MAP. However, when productivity was set at <200 seedlings G15-h-1 , the cost of the MECP was higher than that of the EXC + MAP. Based on our findings, the most cost-efficient planting chain was CONT + MAP. However, based on our results, the required level of productivity can be achieved if the sites are suitable for MECP and the machine operators are skilled.

Keywords

site preparation;

cost-efficiency;

mechanization;

forest regeneration;

planting machine;

site selection

-

Kemppainen,

School of Forest Sciences, University of Eastern Finland (UEF), P.O. Box 111, FI-80101 Joensuu, Finland; Natural Resources Institute Finland (Luke), Yliopistokatu 6, FI-80100 Joensuu, Finland

https://orcid.org/0009-0000-6184-8812

E-mail

kalle.kemppainen@uef.fi

https://orcid.org/0009-0000-6184-8812

E-mail

kalle.kemppainen@uef.fi

-

Kärhä,

School of Forest Sciences, University of Eastern Finland (UEF), P.O. Box 111, FI-80101 Joensuu, Finland

https://orcid.org/0000-0002-8455-2974

E-mail

kalle.karha@uef.fi

https://orcid.org/0000-0002-8455-2974

E-mail

kalle.karha@uef.fi

-

Laitila,

Natural Resources Institute Finland (Luke), Yliopistokatu 6, FI-80100 Joensuu, Finland

https://orcid.org/0000-0003-4431-3319

E-mail

juha.laitila@luke.fi

https://orcid.org/0000-0003-4431-3319

E-mail

juha.laitila@luke.fi

-

Sairanen,

School of Forest Sciences, University of Eastern Finland (UEF), P.O. Box 111, FI-80101 Joensuu, Finland

https://orcid.org/0009-0008-8632-3797

E-mail

anttsair@student.uef.fi

https://orcid.org/0009-0008-8632-3797

E-mail

anttsair@student.uef.fi

-

Kankaanhuhta,

Natural Resources Institute Finland (Luke), Yliopistokatu 6, FI-80100 Joensuu, Finland

https://orcid.org/0000-0001-5785-5972

E-mail

ville.kankaanhuhta@luke.fi

https://orcid.org/0000-0001-5785-5972

E-mail

ville.kankaanhuhta@luke.fi

-

Viiri,

UPM-Kymmene Plc, UPM Forest, Peltokatu 26 C 4, FI-33100 Tampere, Finland

https://orcid.org/0000-0003-3952-9481

E-mail

heli.viiri@upm.com

https://orcid.org/0000-0003-3952-9481

E-mail

heli.viiri@upm.com

-

Peltola,

School of Forest Sciences, University of Eastern Finland (UEF), P.O. Box 111, FI-80101 Joensuu, Finland

https://orcid.org/0000-0003-1384-9153

E-mail

heli.peltola@uef.fi

https://orcid.org/0000-0003-1384-9153

E-mail

heli.peltola@uef.fi

Received 30 July 2024 Accepted 22 October 2024 Published 31 October 2024

Views 66087

Available at https://doi.org/10.14214/sf.24047 | Download PDF

Supplementary Files

![]() This article has been retracted.

This article has been retracted.

The authors found the following error in the cost calculations: the total cost of the kilometre allowances for the machine operators was calculated based on the number of sites across all planting chains (e.g., 0.57 €/km × 50 km × 50 sites), whereas it should have been calculated based on the number of shifts during the forest management season (e.g., 0.57 €/km × 50 km × 150 shifts). The correction in the calculations slightly affected the results of the cost analyses, but the conclusions remained the same.

Revised article is published: https://doi.org/10.14214/sf.25004

1 Introduction

The aim of forest regeneration is to establish new and well-growing seedling stands cost-effectively and promptly after final felling. Successful forest regeneration provides a setting for sustainable wood production. For this reason, it is important to choose forest regeneration methods suitable for the site (Äijälä et al. 2019; Luoranen et al. 2020). Today, Norway spruce (Picea abies [L.] H. Karst.) and Scots pine (Pinus sylvestris L.) seedlings are the most-planted tree species in the Nordic countries (Sikström et al. 2020; Peltola and Vaahtera 2023; Skogsstyrelsen 2023; Solvin et al. 2023). In Finland, Norway spruce seedlings have been the most common plantings since the early 2000s (Peltola and Vaahtera 2023).

In Finland and Sweden, mechanical soil preparation methods, such as disc trenching and mounding, are commonly carried out before seedlings are planted (Sikström et al. 2020). The increasing planting of Norway spruce has significantly increased the use of mounding, which has been found to be a proper soil preparation method for spruce seedlings (Örlander and Nilsson 1999; Luoranen 2007; Saksa and Kankaanhuhta 2007; Kankaanhuhta et al. 2009; Korhonen et al. 2010; Saksa 2011; Laine et al. 2019). It has also become the main soil preparation method in Finland (Peltola and Vaahtera 2023). In Norway, the use of mechanical soil preparation is not as common as in Finland and Sweden because the operating conditions are more challenging due to the rocky and steep terrain (Sikström et al. 2020).

In recent years in Finland, slightly more than 70 000 ha (70%) of forest regeneration area have been planted annually, mainly manually (Peltola and Vaahtera 2023). Correspondingly, in 2023, the amount of mechanized tree planting was only 282 ha (Luonnonvarakeskus 2024). The peak year of mechanized planting (MECP) was 2017, when about 4% of the total planting area was planted using planting machines (3100 ha) (Peltola and Vaahtera 2023). Since then, the area of MECP has decreased noticeably. This is contradictory to the expected development of its use. For example, Strandström and Pajuoja (2013) suggested that, in Finland, 35% of the total planting area would be planted mechanically by the 2020s. Mechanized planting has not become widespread elsewhere, either (Ersson et al. 2018; Ramantswana et al. 2020).

It was believed that the rising costs of forest regeneration and a shrinking workforce availability would rapidly increase the use of MECP (Strandström et al. 2009; Nilsson et al. 2010; Hallongren et al. 2012; Strandström and Pajuoja 2013). However, this has not been the case for several reasons. The first, and most important, reason is that MECP has not so far been sufficiently cost-effective compared with conventional forest tree planting chains, where soil preparation and manual planting (MAP) is done separately (Arnkil and Hämäläinen 1995; Rummukainen et al. 2002; Strandström et al. 2011; Hallongren et al. 2014; Timonen et al. 2019). Currently, for the most part, crawler excavator (EXC)-based planting machines are used in Finland and Sweden (Laine et al. 2016; Ersson et al. 2018). The productivity of EXC-based planting machines should be more than 190 seedlings per gross effective operating hour (G15-h, including short [<15 min] delays) to achieve the competitiveness of MAP chains (Strandström et al. 2011; Hallongren et al. 2014). This level of productivity can be reached by employing skilled machine operators and selecting appropriate sites (Laine 2017). At present, the average productivity of EXC-based planting machines is approximately 130–300 seedlings per effective operating hour (G0-h, excluding delays) under boreal forest conditions (Rummukainen et al. 2002; Saarinen 2006; Rantala et al. 2009; Rantala and Laine 2010; Laine and Rantala 2013; Laine and Saarinen 2014).

In addition to productivity, the small annual planting area per machine, the small average size of the worksites, and the low utilization of planting machines have been considered as bottlenecks in MECP (Kärhä et al. 2014; Laine et al. 2016; Ersson et al. 2018; Timonen et al. 2019). The planting area of EXC-based planting machines needs to be larger than 100 ha per working season to make it a profitable business (Laine 2017). This area of MECP corresponds to a work period of 4–5 months with the MECP performed in two work shifts (Laine and Syri 2012). In order not to increase the proportion of machine relocations too much, the average size of the planting site needs to be larger than 1 ha (Strandström et al. 2009; Strandström et al. 2011). Moreover, ideally, the base machine would be employed elsewhere after the planting season (Laine and Syri 2012; Ersson et al. 2018).

From a quality point of view, MECP is at least as high quality as MAP. The high work quality of EXC-based MECP has been proven in many previous studies, conducted over several decades (Saarinen 2006; Luoranen et al. 2011; Laine and Rantala 2013; Laine and Saarinen 2014). For example, Luoranen et al. (2011) observed that 88% of the seedlings were alive after 3 years of MECP, which is a good result for forest regeneration success. The advantage of MECP compared with MAP is that the seedlings are always planted deep enough into a fresh mound. Previous studies have shown that deep planting is beneficial for seedlings because it can reduce the risk of frost and drought damage (Sahlén and Goulet 2002; Luoranen and Kiljunen 2006; Luoranen and Viiri 2016) and improve their growth (Viiri and Luoranen 2017).

The quality of MECP is affected by site conditions. In particular, soil stoniness, logging residues, and stumps disturb the work of planting machines. The removal of slash and stumps, together with the selection of a suitable worksite, significantly improves the quality and productivity of MECP (Saarinen 2006; Rantala et al. 2009). In addition to the proper conditions, the skills of the machine operator influence the quality of the work. Work quality can be ensured by effective quality management, self-monitoring, and setting clear quality criteria for the work (Kalland 2002; Harstela et al. 2006; Kankaanhuhta et al. 2010; Äijälä et al. 2019). Self-monitoring of the work quality provides reliable information on forest management quality (Haataja et al. 2018). Nowadays, there are also real-time documentation systems available that can automatically monitor the planting density and the area of MECP (Risutec 2024a).

The mechanization of planting is still thought to be the next logical direction in the development of resource-efficient forest management. However, high operating costs in relation to low productivity are the main reasons why MECP has not become common. Contrastingly, the current cost-competitiveness of MECP compared to conventional MAP chains has not been studied under boreal forest conditions in the 2020s. The latest studies evaluating the productivity and costs of MECP have mostly focused on tree plantations in the Southern Hemisphere (Guerra et al. 2019; Bayne et al. 2024; Soler et al. 2024). Meanwhile, forest regeneration costs have increased in Finland (Luonnonvarakeskus 2024). Therefore, it is essential to evaluate the current regeneration costs of MECP and MAP chains.

The aim of this study was to investigate the long-term productivity and costs of the mechanized EXC-based planting of tree seedlings. The productivity calculations were based on data collected by the Risutec Asta documentation system, considering the production time consumed at the planting worksites, the loading time of the seedling cassette, the planting time per seedling, and the G15-h productivity. We also compared the planting costs of a MECP chain to conventional forest tree planting chains – that is, two different MAP chains – where mounding was carried out by an EXC or by a continuously advancing mounder (CONT).

2 Material and methods

2.1 Study sites

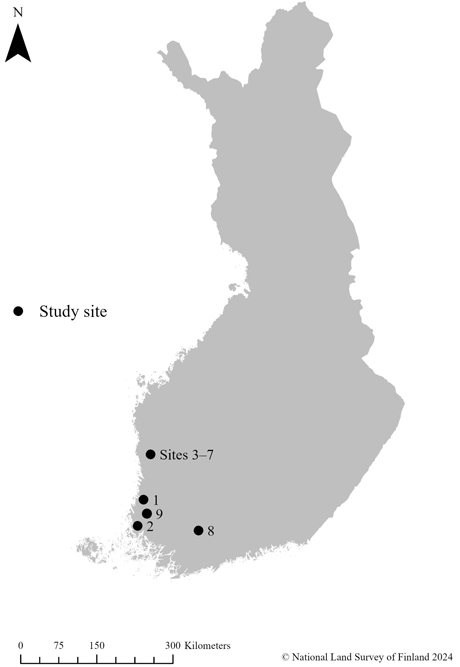

Spatial data, collected by the Risutec Asta documentation system, were used to define the time consumption and productivity of EXC-based planting machines. The data comprised nine Norway spruce planting sites of UPM-Kymmene Plc in western Finland (Fig. 1).

Fig. 1. The nine planting sites of the study located in western Finland, five of them too close to be distinguished on the map. The coordinates of the study area are 60°41’52”N–61°59’38”N and 21°36’24”E–23°48’49”E. The map was created using ArcGIS Pro (version 3.1.0) software.

The MECP was performed by a machine entrepreneur with three employees during the planting seasons of 2019 and 2020. Two of the machine operators, including the entrepreneur himself, had about 10 years of work experience in MECP. The other two machine operators had worked with planting machines for two planting seasons. A total of 71 903 seedlings (40.6 ha) were planted at the study sites (Table 1). The area of the planting sites varied from 1.6 to 7.9 ha (average 4.5 ha). The average number of seedlings planted per hectare was 1771. Based on Cajander’s (1926) forest type classification, the site class was mainly mesic heat forest (Myrtillus type). The class of topsoil stoniness of the site was determined by visual estimation as stoneless, normal stoniness (normal), or stony. The stoniness class was mostly normal, although one site was stony. One planting site was a stoneless peatland, but otherwise the sites were mineral soils. Logging residues had been harvested from seven of the planting sites, and stumps together with logging residues had been harvested from one of those sites. Neither logging residues nor stumps had been harvested from the other two planting sites.

| Table 1. Information on the planting sites of the study (1–9). The topsoil stoniness class (soil stoniness) of the site was visually determined as being either stoneless, normal, or stony. | ||||||||

| Site | Area (ha) | Soil class1 | Site class2 | Soil stoniness | Slash harvested (yes/no) | Stumps harvested (yes/no) | Seedlings planted (pcs) | Planting density (pcs ha–1) |

| 1 | 3.7 | P | VT | Stoneless | No | No | 6736 | 1821 |

| 2 | 1.6 | M | MT | Stony | No | No | 2626 | 1641 |

| 3 | 5.6 | M | MT | Normal | Yes | No | 10 444 | 1865 |

| 4 | 7.9 | M | MT | Normal | Yes | No | 14 495 | 1835 |

| 5 | 3.5 | M | MT | Normal | Yes | No | 5743 | 1641 |

| 6 | 4.6 | M | MT | Normal | Yes | No | 7882 | 1713 |

| 7 | 7.2 | M | MT | Normal | Yes | No | 12 269 | 1704 |

| 8 | 3.0 | M | OMT | Normal | Yes | Yes | 5406 | 1802 |

| 9 | 3.5 | M | MT | Normal | Yes | No | 6302 | 1801 |

| Total | 40.6 | 71 903 | ||||||

| Average | 4.5 | 1771 | ||||||

| 1 Soil class: P = peatland, M = mineral soil. 2 Site class according to Cajander (1926): VT = Vaccinium vitis-idaea type (sub-xeric heath forests), MT = Vaccinium myrtillus type (mesic heath forests), OMT = Oxalis–Myrtillus type (herb-rich heath forests). | ||||||||

2.2 Machinery and software

The planting work was carried out using a Hyundai 140 LCM-9A crawler excavator (engine power: 87 kW, working weight: 17 t) equipped with a Risutec PM-160 planting device. The Risutec PM-160 is designed for medium-sized (over 13 t) excavators and is suitable for boreal forest conditions (Risutec 2024b). The seedling cassette of the PM-160 can be loaded with 160 seedlings at a time (Risutec 2024b). The planting device plants the seedling after making a spot mound, so the seedlings are always planted in a freshly prepared mound. After planting, double-sided compaction is performed around the seedling (Risutec 2024b).

Risutec has also developed the Global Positioning System (GPS)-based Asta documentation system for reporting the performance of forestry operations (Risutec 2024a). The system can be used to monitor MECP, soil preparation, and the tending of seedling stands (Risutec 2024a). The site-specific data includes the location information and timestamps for each mechanically planted seedling, the area of the worksite, the total number of seedlings planted, and the planting density (Risutec 2024a).

The location of, and time data for, the planting points were stored when the machine operator pressed the Asta system button on the excavator’s joystick (Risutec 2024a). The accuracy of the location data was about 1 m, but this may have varied depending on the operating conditions (Risutec 2024a). The GPS device was positioned on top of the excavator’s boom, so that the location of the planted seedling was as accurate as possible. The collected Asta data was in GPX file format, which is commonly used to store GPS data.

2.3 Data processing

The GPX data was converted to XML format to facilitate its utilization in Microsoft Excel spreadsheet software. The timestamps of the planted seedlings were presented in chronological order in the data, including the start and end times of planting. The time information was presented in the format “HH:MM:SS” and included the date of the planting work (YYYY-MM-DD).

The dataset included planting times of between 0 and 1 s. This indicated that either a malfunction had occurred in the planting device itself, or the machine operator had input incorrect keystrokes, either accidentally or for another reason. In the data, planting times of less than 4 s often occurred before the seedling cassette was reloaded. This can be attributed to the machine operator ensuring that the seedling cassette was completely empty prior to reloading it. However, so that incorrect observations did not affect the study results, all planting times of less than 4 s were excluded from the final dataset. Following the correction of the data, the percentage reduction in the number of planted seedlings was 1.1%.

For the seedlings planted after delays of more than 15 min, the planting time was set at 9 s. This was done because it was not possible to distinguish, from the delay, what the share of time between the break and the planting work had been. Furthermore, the planting time of the first seedling planted at the worksite was also defined as 9 s because there was no previous timestamp for the first seedling to allow an exact calculation of the planting time.

2.4 Productivity calculations

After editing the data, it was possible to calculate the production time consumed at the worksites (hours), the planting time per seedling (seconds seedling−1), the loading time of the seedling cassette (seconds), and the operating hour productivity (seedlings G15-h−1) based on the timestamps of the planted seedlings.

The production time was determined by calculating the time difference between the first and last timestamps at the planting site. The production time was assumed to end when the delay exceeded 1 h, thus excluding off-site operations, such as relocation transportation of the planting machine or maintenance. Except for one site, each exhibited at least one delay of over 1 h. In general, four operators ran the planting machine almost continuously for 24 h day−1. The working day mainly consisted of three or four shifts with durations of 4–8 h (e.g., Operator 1, 8 h, Operator 2, 4 h, Operator 3, 4 h, Operator 4, 8 h).

The loading time consumption of the seedling cassette was investigated by searching for frequent delays occurring after 160 seedlings had been planted. It was not always possible to discern a clear delay after 160 planted seedlings, probably because the device was reloaded before it was completely empty. Such illogical delays were excluded from the analysis if they occurred after more than 165 planted seedlings or before 155 planted seedlings. Some of the reloading breaks occurred during the shift changes, and these delays were also excluded from the loading time calculation. The total proportion of unclear loading times that were omitted from the final dataset was 18%, with a total of 371 loadings included in the calculation.

The planting time per seedling was calculated by subtracting the timestamp of the previously planted seedling from the timestamp of the planted seedling. The mean planting time per seedling and the frequency of each planting time were calculated for each planting site. All delays of over 15 min plus the seedling cassette loading times were excluded from the calculation of the planting time.

The G15-h productivity included all delays of less than 15 min (i.e., mostly all seedling cassette loading times and other short delays). The calculations were based solely on the full operating hours – that is, the short hours at the end of the planting sites were not included in the calculations.

2.5 Cost analysis

The basic setting of the cost analysis followed previous studies by Strandström et al. (2011) and Hallongren et al. (2014), where the costs of MAP and MECP chains were examined. In addition, the values of several key parameters were consistent across the studies. The purchase prices of the machinery and equipment, as well as the wage costs and employee expenses, were updated to correspond to the levels of 2024.

The cost analyses were conducted using an Excel-based calculator constructed for the purpose of this study. Two scenarios were created for the MAP chain, with soil preparation carried out using either an EXC or a CONT. The MECP chain consisted of an EXC equipped with a Risutec PM-160 planting device. The size of the EXC was 17 t for both the MECP and soil preparation. The base machine for the CONT was a forwarder (engine power: 150 kW, working weight: 18 t).

The soil preparation season was expected to start at the beginning of May and last until the end of October (6 months). The planting season was expected to last 5 months, from May to the end of September. The monthly number of working days was set at 21. During the work year, there were expected to be 30 days of work stoppages – 15 days in the forest management season and 15 days outside the forest management season. It was assumed that the machine operators would work 1.5 shifts, with each shift lasting 8 h. However, MAP was done in one shift. Outside of the forest management season, the base machines were expected to be used in one shift.

The utilization rate is the ratio between the operating time (G15, including short [<15 min] delays) and the working time, which is G15 plus all work delays longer than 15 min, such as time spent on repair, maintenance, and relocating the machine, together with other work delays (Harstela 1991; Kuitto et al. 1994; Väkevä et al. 2001; Jylhä et al. 2019). Thus, the utilization rate illustrates the mechanical availability of the machine and the operational efficiency of the organization (Harstela 1991). Utilization rates of 80%–90% are commonly used in the cost calculations for forest machines in Finland (Strandström et al. 2011; Hallongren et al. 2014; Ahtikoski et al. 2024). In our cost analysis, the utilization rate for the machines used in soil preparation was set at 85%. In MECP, the utilization rate was set to a slightly lower level of 80% due to the considerable time needed for seedling maintenance (e.g., watering the seedlings) during the planting season. Furthermore, handling and transporting the seedlings from storage to the planting site also takes up working time. A more detailed description of the annual worktime, operating work hours, and utilization rates can be found in Table 2.

| Table 2. Productivity levels of mounding and MECP (ha G15-h–1, including short [<15 min] delays) and the machine utilization rates used in the cost analysis of the study. The life spans of the base machines and devices are also given, as well as the total annual work time, operating working hours, and silvicultural use. | |||

| Variable | Base machine | ||

| Excavator (17 t) | Forwarder (18 t) | Excavator (17 t) | |

| Device | |||

| Mounding bucket | Mounder | Planting device | |

| Bracke M24.a | Risutec PM-160 | ||

| Productivity (ha G15-h–1) | 0.167ab | 0.900b | 0.119c |

| Machine utilization rate (%) | 85d | 85d | 80 |

| Life span (h) | |||

| Base machine | 12 000d | 12 000d | 12 000d |

| Device | 7500d | 7500d | 7500d |

| Worktime (h yr–1) | |||

| Total | 2220 | 2220 | 2136 |

| Silvicultural | 1332 | 1332 | 1080 |

| Operating hours (G15-h yr–1) | |||

| Total | 1887 | 1887 | 1709 |

| Silvicultural | 1132 | 1132 | 864 |

| Silvicultural use (ha yr–1) | 189 | 1019 | 103 |

| a Saksa et al. (2002). b Saarinen (2006). c The productivity of the MECP was based on the results of this study. d Same value as used in the studies by Strandström et al. (2011) and Hallongren et al. (2014). | |||

The planting density for all the planting chains was set at 1800 Norway spruce seedlings ha−1 based on Finnish forest management recommendations (Äijälä et al. 2019). The productivity of the MECP was based on the results obtained from this study (215 seedlings G15-h−1, 0.119 ha G15-h−1), with the productivity of the CONT set at 0.900 ha G15-h−1 (Saarinen 2006) and the productivity of the EXC-based mounding defined as 0.167 ha G15-h−1 (Saksa et al. 2002; Saarinen 2006). The productivity of the MAP was derived from the collective labor agreement of Finland (Metsäalan työehtosopimus 2024). The time consumption for MAP varied based on the site conditions and the quality of the soil preparation. It was assumed that the quality of the soil preparation was at least sufficient, and that the site conditions were conducive to planting. The MAP work shift required 1 h for tasks such as fetching and maintaining the seedlings. This equated to an effective planting time of 7 h shift−1. The productivity of the MAP was set at 189 seedlings per effective hour, which equated to an average of 1320 seedlings planted in a single shift when delays were considered (165 seedlings h−1, 0.092 ha h−1).

Table 3 shows the key fixed and variable costs and other parameters of the cost analysis. The purchase prices of the base machines and devices were obtained from the machine dealers. All costs associated with the utilization of the devices (i.e., mounding bucket, CONT, and planting device) were allocated to the operating hours of the forest management season. The assumption was that the machines would require a space in which to be maintained and stored. The annual storage cost of the base machines and devices was derived from the Decree of the Ministry of Agriculture and Forestry on “The Acceptable Unit Costs of Agricultural Investments” (Maa- ja metsätalousministeriön asetus…608/2023). The storage cost of a forwarder and a CONT was slightly higher because the space requirement was greater (Table 3). The annual maintenance and repair costs were 3% of the purchase price of the base machines and devices (Palva 2023) (Table 3). The calculation also considered the cost of tools, fuel tanks, and other accessories purchased to accommodate the site conditions (maintenance supplies) (Table 3). The costs for maintenance supplies in MECP were higher than those for the other planting chains because, in MECP, these costs also included the purchase of a trailer for transporting the seedlings to the site.

| Table 3. Fixed and variable costs and other main parameters of the cost analysis of the study. | |||

| Variable | Base machine | ||

| Excavator (17 t) | Forwarder (18 t) | Excavator (17 t) | |

| Device | |||

| Mounding bucket | Mounder | Planting device | |

| Bracke M24.a | Risutec PM-160 | ||

| Purchase price (€) | |||

| Base machine | 179 000 | 350 000 | 179 000 |

| Device | 5000 | 130 000 | 60 000 |

| Annual depreciation (%) | |||

| Base machine | 15 | 15 | 15 |

| Device | 40 | 40 | 40 |

| Interest rate (%) | 5 | 5 | 5 |

| Storage costs (€ yr–1) | 1058 | 1410 | 1058 |

| Insurance costs (€ yr–1) | 900 | 1800 | 900 |

| Administration costs (€ yr–1) | 8000 | 8000 | 8000 |

| Maintenance supplies (€ yr–1) | 747 | 747 | 1121 |

| Maintenance costs (€ yr–1) | 5520 | 14 400 | 7170 |

| Labor costs | |||

| Hourly wages (€ h–1) | 16.18 | 16.18 | 16.18 |

| Indirect wage cost (%) | 55 | 55 | 55 |

| Kilometer allowance (€ km–1) | 0.57 | 0.57 | 0.67 |

| Fuel and lubrication costs | |||

| Fuel consumption (l h–1) | 9 | 17 | 9 |

| Fuel price (€ l–1) | 1.25 | 1.25 | 1.25 |

| Lubricant consumption (l h–1) | 0.2 | 0.2 | 0.2 |

| Lubrication price (€ l–1) | 3.6 | 3.6 | 3.6 |

| Relocation costs (€ km–1) | 2.35a | 2.35a | 2.35a |

| a Ahtikoski et al. (2024). | |||

The fuel consumption was based on the assessment of the entrepreneurs and machine dealers (Table 3). The price of the fuel was derived from the statistical data provided by Statistics Finland (Tilastokeskus 2024a) (Table 3). No official statistics were available for the lubricant prices, which were instead determined based on current prices from a few different suppliers (Palva 2023; Tilastokeskus 2024b) (Table 3). The lubricant consumption was set at the same level as that used in the calculations of the forestry machinery cost index by Statistics Finland (Tilastokeskus 2024b) (Table 3).

The labor costs consisted of the wage costs, indirect expenses, and compensation for expenses. The hourly wage of the employees was based on either the collective labor agreement in machine work in forestry or the collective labor agreement in forestry (Metsäalan työehtosopimus 2024; Metsäkonealan työehtosopimus 2024). The hourly wage with expenses was €23.27 h−1 for MAP (indirect cost wage rate 70%) (Table 3). For the soil preparation and MECP, the wage was €25.08 h−1 (indirect cost wage rate 55%). The machine operator’s per-kilometer allowance was set at €0.57 km−1 (Metsäkonealan työehtosopimus 2024). For the planting work (MAP and MECP), the kilometer allowance was higher (€0.67 km−1) on the assumption that the workers would transport the seedlings by trailer to the site (Metsäalan työehtosopimus 2024). The journey to and from the worksites was 50 km per day for all workers. The average size of the soil preparation and planting sites was 2 ha. The average distance between the sites for machine relocation was 20 km, with relocation costs of €2.35 km−1 across all chains (Ahtikoski et al. 2024). Finally, the calculated operating hour costs for the EXC during mounding were €67.40 G15-h−1, €79.70 G15-h−1 for the EXC during tree planting, and €130.60 G15-h−1 for the CONT.

3 Results

3.1 Time consumption and productivity

The total production time for the study was 357 h. The site area-weighted (geometric) average of production time was 8 h 47 min ha−1, with the longest production time being about 11 h ha−1 (Site 9) and the shortest around 8 h ha−1 (Site 5). The production time of less than 9 h ha−1 was achieved at six study sites (Sites 2 and 4–8). Delays of more than 15 min, but less than 1 h, accounted for 6% of the total production time (i.e., the total G15 was approximately 335 h).

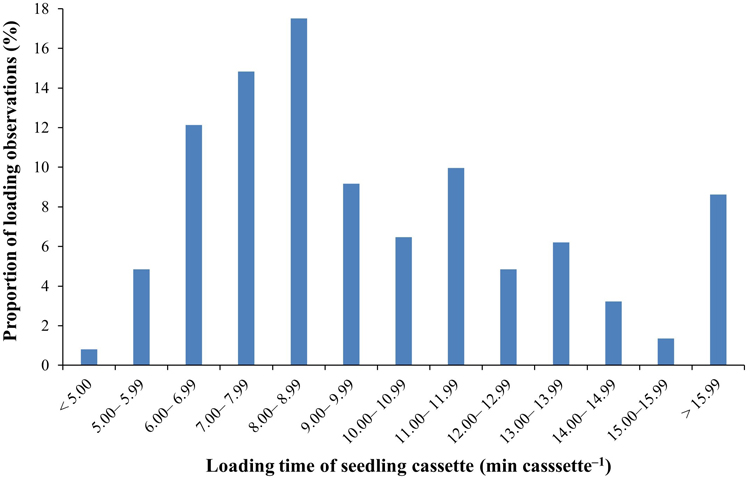

The average time consumed when loading the seedling cassette was a little over 10 min (Table 4). This signified that the average time consumed in loading a single seedling was 3.8 s. The longest loading time averaged 12 min 38 s (Site 6), whereas the shortest average time to refill the seedling cassette was 8 min 30 s (Site 3). The time spent loading the seedling cassette comprised 21% of the total production time when the average loading time was considered (10 min 8 s).

| Table 4. Average loading time consumption of the seedling cassette by site (1–9) and average of all loading times in the study. The seedling cassette of the Risutec PM-160 was loaded with 160 seedlings at a time. | ||||||||||

| Loading time | Site number | Average | ||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | ||

| min.s | 11.34 | 9.29 | 8.30 | 8.39 | 10.17 | 12.38 | 10.15 | 10.54 | 10.57 | 10.08 |

About 60% of the loading times were less than 10 min (Fig. 2). The most common loading time class was 8.00–8.99 min (18%), but the data also contained loading times over 15 min (10%). Loading times of less than 5 min were rare, with only 0.8% included in this category.

Fig. 2. Distribution of the seedling cassette loading times, with 371 loading time observations included in the final data of this study.

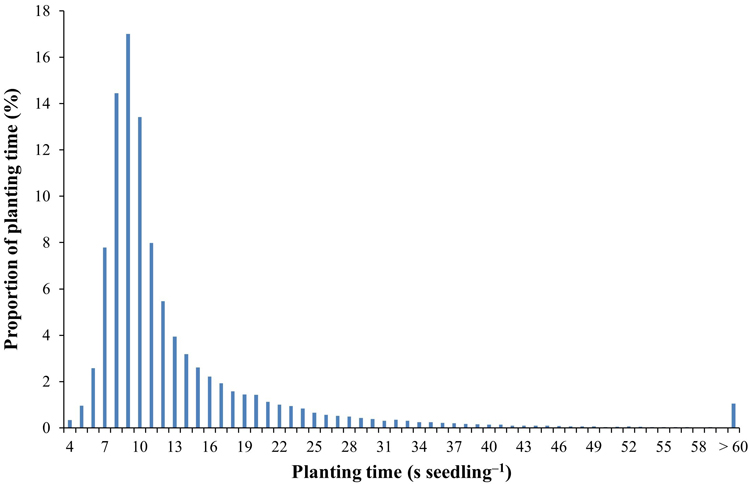

The most frequently recorded planting time was 9 s seedling−1 (17%) (Fig. 3). Approximately 93% of the planting time observations were less than 25 s. Planting times of more than 60 s seedling−1 constituted 1.1% of the total observations (Fig. 3). The mean planting time per seedling was 13.8 s, with no delays exceeding 15 min or loadings of the seedling cassettes. Including the mean loading time of the seedling cassette (3.8 s seedling−1), the planting time average was 17.6 s seedling−1.

Fig. 3. Distribution of the planting times based on the data from this study.

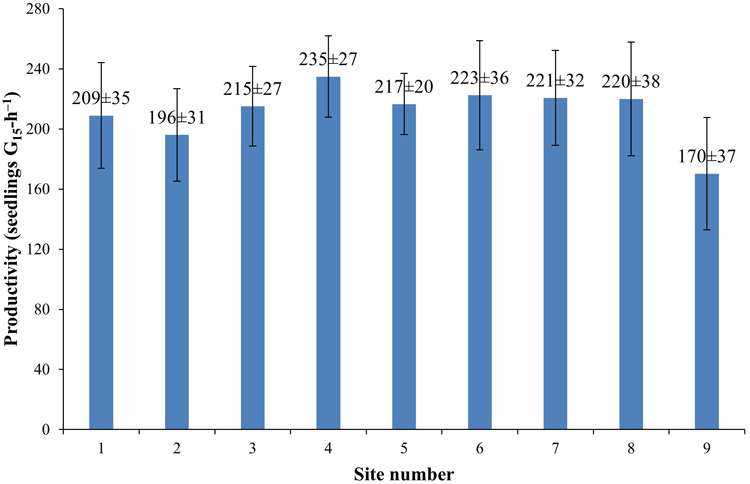

The highest productivity (235 seedlings G15-h−1) was observed at Site 4, and the lowest (170 seedlings G15-h−1) at Site 9 (Fig. 4). The average productivity of all operating hours was 215 seedlings G15-h−1. The standard deviation of G15-h productivity ranged from 20 to 38 seedlings G15-h−1 across the sites (Fig. 4). In the nighttime, between 10 p.m. and 6 a.m., productivity was, on average, 4% lower than in daytime, although, at four of the study sites (Sites 1, 3, 5, and 8), the nighttime productivity was 2%–8% higher than in the daytime.

Fig. 4. Operating hour productivity (seedlings G15-h–1, including short [<15 min] delays) and standard deviation of operating hour productivity by planting site (1–9) of the study.

3.2 Costs

3.2.1 Cost-competitiveness

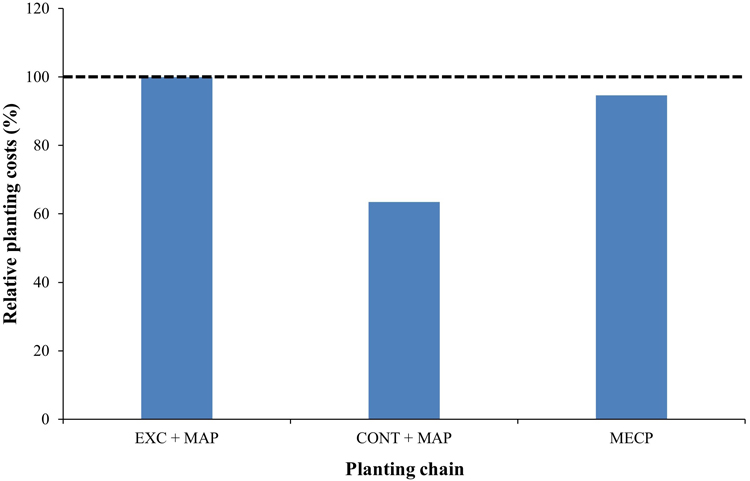

The MECP chain was 5% cheaper than the conventional planting chain (EXC + MAP), meaning that EXC-based mounding followed by MAP was the most expensive planting chain (Fig. 5). The most cost-effective planting chain was the CONT combined with MAP (CONT + MAP), although the costs per G15-h were the highest in this chain. The unit cost per planted seedling was €0.39 seedling−1 (EXC + MAP), €0.25 seedling−1 (CONT + MAP), and €0.37 seedling−1 (MECP). The MAP cost accounted for 43% (EXC + MAP) and 68% (CONT + MAP) of the total cost per hectare in the MAP chains.

Fig. 5. Relative hectare-based costs of each planting chain (EXC + MAP = excavator-based mounding and manual planting; CONT + MAP = continuously advancing mounding and manual planting; MECP = excavator-based mechanized planting). The operating costs of EXC + MAP are given as 100%, with the costs of the other planting chains being proportional to EXC + MAP.

3.2.2 Sensitivity analysis

The minimum required productivity for MECP was 202 seedlings G15-h−1 (0.112 ha G15-h−1) to make it a competitive option for planting work (Table 5). A productivity level below this threshold would result in a higher hectare-based cost than in other planting chains. To illustrate this, the hectare-based cost for MECP was 12% higher than for EXC + MAP when the productivity was set below 180 seedlings G15-h−1. To compete with CONT + MAP, the productivity of MECP needed to increase from 215 to 325 seedlings G15-h−1 (0.18 ha G15-h−1).

| Table 5. Effect of the purchase price of the MECP base machine on the relative hectare-based costs (100 = EXC + MAP) when the price changed by ±15%, ±25%, and ±35% in the sensitivity analysis of the study. For each price category of the base machine, the minimum productivity required for MECP to be a competitive option for planting is given. | ||||

| Price change | Purchase price | Relative cost | Requested productivity | |

| (%) | (€) | (ha G15-h−1) | (seedlings G15-h−1) | |

| –35 | 116 350 | 88 | 0.105 | 189 |

| –25 | 134 250 | 90 | 0.107 | 193 |

| –15 | 152 150 | 92 | 0.109 | 196 |

| 0 | 179 000 | 95 | 0.112 | 202 |

| 15 | 205 850 | 98 | 0.117 | 211 |

| 25 | 223 750 | 100 | 0.119 | 214 |

| 35 | 241 650 | 102 | 0.121 | 218 |

The hectare-based costs for MECP increased by 19% when the base machine was not utilized outside the planting season. In this case, profitability could be enhanced by extending the working hours during the planting season. For example, increasing the amount of work to 20 h day−1 (2.5 shifts day−1) during the planting season made MECP a competitive option, even if the base machine was not utilized outside of the season. With a utilization rate of 85%, MECP was approximately 9% cheaper per hectare than EXC + MAP. However, decreasing the utilization rate from 80% to 70% made MECP the most expensive planting chain.

When the average size of the planting site was decreased from 2.0 to 0.7 ha in MECP, the hectare-based cost was the same as for EXC + MAP. Proportionally, the hectare-based cost of CONT + MAP increased the most when the mean site size of all planting chains was set to 0.7 ha. Nevertheless, CONT + MAP was still the cheapest planting chain when the planting area was set at 0.2 ha. Increasing the planting area to 5 ha reduces the cost of MECP, but not significantly.

On average, the productivity of MAP needed to be about 200 seedlings planted per hour (0.11 ha h−1, 1600 seedlings shift−1) to make EXC + MAP more cost-efficient than MECP. The productivity of mounding with an EXC would need to increase to 0.185 ha G15-h−1 (330 mounds G15-h−1) to beat MECP. The mean productivity of the CONT would need to be less than 0.2 ha G15-h−1 to make the hectare-based costs the same as for MECP.

In MECP, the purchase price of the base machine would need to increase by 25% before the hectare-based costs would be the same as for EXC + MAP (Table 5). Correspondingly, a reduction of 15% in the purchase price would result in a 3% reduction in hectare-based costs in relation to EXC + MAP. The minimum required productivity level for a profitable business would decrease by 13 seedlings G15-h−1 if the price of the MECP base machine was 35% lower (Table 5).

4 Discussion

4.1 The productivity of mechanized planting

The time consumption and productivity of the MECP was determined based on data from more than 70 000 seedlings planted at nine sites. On average, it took approximately 9 h to plant 1 ha using the Risutec PM-160 planting device. In general, the operating conditions were very suitable for MECP.

Based on our findings, it took an average of 3.8 s to load a single seedling into a seedling cassette. This is more than in previous studies, where the time consumption per loaded seedling has been 2.3–3.1 s seedling−1 (Rantala et al. 2009; Laine and Saarinen 2014). The loading time of the seedling cassette constituted 21% of the total production time. In previous studies, the time spent refilling seedling cassettes has accounted for 12%–20% of the effective working time (Rantala et al. 2009; Liepiņš et al. 2011; Guerra et al. 2019). We also found that the data contained loading delays of more than 15 min (10%), which is twice as long as the entrepreneur himself estimated to be the average loading time with no other tasks.

The average planting time without refilling the seedling cassette or without other delays over 15 min was about 13.8 s seedling−1. Other studies have determined planting times of between 10.9 and 22.8 s seedling−1 (Ersson et al. 2011; Laine and Rantala 2013; Laine and Saarinen 2014; Vēsmiņš et al. 2020). Laine and Saarinen (2014) observed that the average planting time of the Risutec APC planting device was 22.8 s seedling−1, but they also pointed out that the automatic feeding system of the planting device had not functioned as intended, resulting in malfunctions. The Risutec APC planting device was still in the prototype phase at the time of that study, which might explain the greater time consumption per planted seedling than in our study. The average planting time of the Bracke P11.a planter has been determined to be 12.8–14.9 s seedling−1 (Ersson et al. 2011; Laine and Saarinen 2014), whereas the average planting time of the two-headed M-Planter has been recorded as 10.9 s seedling−1 with no seedling cassette loading time (Laine and Rantala 2013).

In this study, MECP was mainly performed on slash-harvested sites, which can increase the productivity of MECP by 18% (Saarinen 2006). Therefore, slash removal may explain the higher mean productivity (215 G15-h−1) than that observed in previous studies (<200 seedlings G15-h−1), which were often conducted under more variable operating conditions than in this study. Laine and Saarinen (2014) estimated the productivity of the Risutec APC planter to be 163 seedlings G15-h−1 with slash- and stump-harvested worksites. However, in the study by Strandström (2018), the productivity of the Risutec PM-160 planter was 195 seedlings G15-h–1, which is closer to our finding. The productivity of different planting devices, including the Bracke and M-Planter, has been observed to vary considerably, in a range of 130–355 seedlings G0-h–1 (Rummukainen 2002; Saarinen 2006; Rantala et al. 2009; Rantala and Laine 2010; Liepiņš et al. 2011; Laine and Rantala 2013; Laine and Saarinen 2014; Guerra et al. 2019; Soler et al. 2024).

The average productivity was at an excellent level, although there were variations in productivity between the planting sites. The mean productivity of greater than 210 seedlings G15-h−1 was achieved at six sites. By contrast, at Sites 2 and 9, the mean productivity was less than 200 seedlings G15-h−1. Site 2 was rocky, and the logging residues had not been harvested, which probably contributed to the lower productivity compared to the other planting sites of this study. However, based on the background information, the mean productivity should have been higher at Site 9. Furthermore, considerable variation in productivity was observed at the sites, as evidenced by the relatively high standard deviation, which was up to 38 seedlings G15-h−1. Some of the observed variations can be attributed to differences between the machine operators. In addition, there will also always be some degree of variation in the internal conditions of planting sites.

The competence of the machine operators and the suitability of the worksites have previously been identified as key factors influencing the productivity of MECP (Rantala and Laine 2010; Laine et al. 2016; Laine 2017). The mean productivity of an inexperienced machine operator can be more than 60% lower than that of an experienced operator (Rantala and Laine 2010). Here, the sites were planted by an experienced entrepreneur. Moreover, the sites were found to be highly suitable for MECP, on average. When considered alongside the background factors, our results demonstrate that, with suitable site selection and competent machine operators, it is possible to achieve the desired level of productivity.

The data relating to soil condition is particularly important and necessary in planning regeneration operations, to ensure that the most suitable methods are used in the regeneration chain. From the perspective of MECP, it is essential to have comprehensive information on soil stoniness, but so far, there is no such information available (Kärhä et al. 2014; Timonen et al. 2019). At present, soil stoniness is estimated by terrain measurements (Laine and Syri 2012; Kärhä et al. 2014), which is an inefficient method of soil data collection. The lack of stoniness data is one of the limiting factors in the large-scale use of MECP in Finland (Kärhä et al. 2014; Timonen et al. 2019). In recent years, efforts have been made to develop more efficient methods to determine topsoil (<30 cm) stoniness (Melander et al. 2019; Karjalainen et al. 2022). However, these new methods are not yet widely in use.

4.2 The cost-efficiency of planting chains

The setting of the cost analysis followed the works of Strandström et al. (2011) and Hallongren et al. (2014). Some of the values of the parameters used in our cost analysis were set at the same levels. These included the lifespans of the base machines and devices, the productivities of mounding and MAP, and the utilization rates of the machines used in soil preparation. The similarity between the settings facilitated comparison of the results of the analyses, although there were also some differences in the cost calculations.

In terms of the economic viability of MECP, it is essential that the planting work be sufficiently productive in relation to the operating costs. The minimum productivity level for MECP has been estimated to be 190 seedlings G15-h−1 to beat a conventional planting chain (Strandström et al. 2011; Hallongren et al. 2014). However, the corresponding minimum required level was approximately 10 seedlings G15-h−1 higher in our study. Nevertheless, the MECP chain was able to achieve this limit. In previous studies, the productivity level of MECP has been determined to be lower. Hallongren et al. (2014) calculated that the cost of the MECP chain was up to 20% higher in comparison with the conventional planting chain. In their analysis, the productivity of MECP was set at about 150 seedlings G15-h−1 – 30% less than the productivity observed in this study.

The results of our sensitivity analyses showed that, when the area of planting was set below 1 ha, the planting costs increased across all planting chains. In particular, the costs of CONT + MAP increased when the average size of the site was set to 0.2 ha–0.7 ha. On small sites, the share of machine relocation costs increases significantly (Rummukainen et al. 2002; Rantala et al. 2010; Strandström et al. 2011; Hallongren et al. 2014). Despite this, in our analysis, the hectare-based costs of CONT + MAP were still lower than in other planting chains. We also found that a change in the base machine’s purchase price did not significantly affect the profitability of MECP, which aligns with the findings of Hallongren et al. (2014).

In line with our study, the cost-competitiveness of CONT has also been determined in some previous studies (Rantala et al. 2010; Strandström et al. 2011; Hallongren et al. 2014). In our study, CONT + MAP accounted for 63% of the cost of EXC + MAP. The productivity of MECP could increase considerably from the current level to compete with CONT + MAP. However, CONT is more sensitive to operating conditions than EXC-based mounders (Saksa et al. 2018), so from a work quality point of view, it is not recommended to use CONT + MAP at all regeneration sites. Consequently, CONT + MAP requires a more accurate site selection compared to EXC + MAP.

Based on our sensitivity analysis, the productivity requirement for MAP was almost 200 seedlings h−1. While this is not an impossible target, it is challenging to achieve at every planting site. For example, the collective agreement has determined the time consumption for planting based on the quality of the soil preparation and the soil type, with the productivity of planting work varying at about 145–195 seedlings h−1 (excluding seedling fetching, etc.) (Metsäalan työehtosopimus 2024). Also, it is important to acknowledge that it is challenging to enhance the productivity of MAP beyond the current level, whereas there is considerable potential for the development of MECP chains. For instance, current seedling production has been developed in favor of MAP. Therefore, developing better seedling materials, packaging, and logistics for MECP chains might be the best ways of improving cost-efficiency (Ersson 2014; Laine 2017; Ersson et al. 2022).

Due to labor shortages, there may not be enough employees available for MAP in the future, which will eventually be a much bigger problem than the costs of planting work. Thus far, the labor shortage has not had a strong impact on the planting work because foreign seasonal labor has been available in Finland (Poikonen et al. 2023). However, the need for labor is likely to continue to increase as the number of self-employed forest owners decreases (Kankaanhuhta et al. 2018). As forest owners engage in fewer and fewer forest management activities, the demand for entrepreneurs who provide forest management services will increase (Kankaanhuhta et al. 2018). Mechanized planting already requires 20% fewer employee resources than MAP chains, thus the mechanization of planting can reduce the need for labor (Hallongren et al. 2014).

A financially viable business requires enough working hours per year. The results of this study support the assertion that the base machine should have an alternative use outside of the planting season. Correspondingly, during the planting season, the planting machine should be in maximum use so that the annual costs of the planting device do not increase too much. According to Laine (2017), the minimum annual amount of MECP is at least 130–150 ha, which is still a valid practical recommendation for a profitable business. At the productivity level of our study, MECP should be performed for 5 months in two shifts to give an annual planting area of 140 ha. Implementing MECP in two shifts decreases the operating cost and improves cost-effectiveness.

In addition to annual working hours, the utilization of machinery has played a key role in the profitability of MECP. In our study, a 70% utilization rate was determined to be a critical figure in the competitiveness of MECP. In previous follow-up studies, machine utilization has varied by about 60%–80% for MECP (Arnkil and Hämäläinen 1995; Rantala and Laine 2010; Soler et al. 2024). Rantala and Laine (2010) illustrated the variation between machine operators with various levels of work experience, using the share of effective working time in total working time, which varied from 66% to 89% (average 80%). This proves the significant influence of experience and skill on the utilization of machines, in addition to productivity, which in turn has a profound impact on the profitability of MECP.

4.3 Research data and methods

Despite the quite large dataset, because the study sites were planted by one entrepreneur, the results of this study cannot be generalized to cover the whole MECP chain in Finland. It is also important to note that quality should always be considered when the aim is to improve the cost-effectiveness of work through mechanization. For example, if the mechanization of planting work would reduce planting costs but also result in considerably lower regeneration success than in MAP, it would not be worthwhile. In this study, we did not investigate the MECP from a qualitative point of view. However, the forest regeneration results could be followed on these planting sites over the coming years to determine whether the MECP resulted in at least decent, or even better, regeneration results than from MAP, the latter being assumed based on previous studies (Saarinen 2006; Luoranen et al. 2011; Laine and Rantala 2013; Laine and Saarinen 2014; Lazdiņa et al. 2019).

The main challenge with the calculation of time consumed was that it was not possible to specify more precisely what activities, other than planting, had been performed outside or during the work. For example, the time consumed in seedling maintenance and other off-site tasks could not be determined from the data. However, based on the results, we found that the share of delays of more than 15 min, but less than 1 h, was 6% of the total planting time. A more detailed examination of the different work phases would have required video recordings of the planting work (Laine and Rantala 2013; Laine and Saarinen 2014; Kärhä et al. 2018; Pohjala et al. 2024). Spatial data analysis would also have been possible because the location and timestamp of each planted seedling was known. In future studies, Asta data could be used to investigate, for example, how soil moisture and slopes affect the productivity of MECP.

To increase the cost-effectiveness of MECP from the level of existing EXC-based one- and two-headed planters, continuously advancing planting machines should be more available and used. To address this development, a new generation of continuously advancing planting machines entered the market in the 2020s. The Finnish Risutec Forest Maker and the Swedish PlantMax planting machines, for instance, prepare the soil and plant the seedlings continuously, with two planting units in two rows, which make them highly productive (Ersson 2022; Metsälehti 2023). It is evident that continuously advancing planting machines can enhance productivity, albeit this does not necessarily imply a significant improvement in cost-effectiveness (Hallonborg et al. 1995). Consequently, further investigation is required to assess the productivity, cost, and quality implications of these novel MECP concepts in the future.

5 Conclusion

To conclude, our study showed how productivity affects the cost-efficiency of MECP. Our findings indicate that an adequate level of productivity can be achieved if the worksites are suitable for MECP (e.g., the logging residues have been harvested) and the machine operators are competent. Currently, cost-effective MECP requires the mean productivity of more than 200 seedlings G15-h−1, a sufficient utilization rate, and an adequate number of working hours per year. The results support the view that continuously advancing planting machines will be needed in the future to improve productivity and cost-efficiency from the current level. The existing EXC-based planting devices are capable of satisfactory performance regarding cost-effectiveness and quality. Despite this, the area of MECP is still small in Finland. Consequently, the potential of MECP is not currently being adequately exploited in Finland.

Authors’ contributions

Conceptualization (KKe, KKä, JL, AS, HV), data acquisition (KKe, AS, KKä, HV), data curation (KKe, AS), methodology and data analysis (KKe, KKä, JL, AS), writing – original draft preparation and visualization (KKe), funding acquisition (HP), and supervision (KKä, VK, JL, HP). All authors commented on and reviewed the manuscript, as well as having read and agreed to the published version of the manuscript.

Acknowledgments

The authors would like to thank Managing Director Jussi Aikala, Development Director Henrik Janer, and Sales Manager Henri Syvänen from Risutec Ltd and the planting entrepreneur Toni Lainio for their great assistance during this study. We would also like to thank UPM-Kymmene Plc for providing the planting sites for the study.

Funding

This research was funded by the Research Council of Finland (formerly the Academy of Finland) through the UNITE flagship (Decision number 357906). It was also supported by the Faculty of Science, Forestry and Technology of the University of Eastern Finland and the Natural Resources Institute Finland through 50% salary positions for the doctoral researcher Kalle Kemppainen (from January 2024) under the LUMETO Doctoral Program.

Declaration of openness of research materials, data, and code

The data are available upon request from Kalle Kemppainen or through the open research repository (https://doi.org/10.5281/zenodo.13986113).

References

Ahtikoski A, Väätäinen K, Anttila P, Laitila J, Mutanen A, Lindblad J, Sikanen L, Routa J (2024) The effects of the EU’s forest-related policies on harvesting costs in Finland. Silva Fenn 58, article id 23018. https://doi.org/10.14214/sf.23018.

Äijälä O, Koistinen A, Sved J, Vanhatalo K, Väisänen P (2019) Metsänhoidon suositukset – metsänhoito. [Finnish forest management recommendations]. Tapion julkaisuja. ISBN 978-952-5632-75-0.

Arnkil R, Hämäläinen J (1995) Bräcke Planter- ja Ilves-istutuskoneiden tuottavuus ja työjälki. [Bräcke Planter and Ilves tree planting machines]. Metsätehon Katsaus 1/1995.

Bayne K, Botero J, Parker R, Baker M, Dixon B, Schoonderwoerd R, Rolando C (2023) A review of the performance of the M-Planter in New Zealand. Precision Silviculture Programme, Report No. PSP-T008.

Cajander AK (1926) The theory of forest types. Acta For Fenn 29, article id 7193. https://doi.org/10.14214/aff.7193.

Ersson BT (2014) Concepts for mechanized tree planting in southern Sweden. Doctoral thesis, Swedish University of Agricultural Sciences, Acta Universitatis Agricultural Sueciae 2014:76. https://res.slu.se/id/publ/60997.

Ersson BT (2022) Mechanized tree planting – analysis of the PlantmaX tree planting machine’s potential on Swedish forestland owned by non-industrial private forest owners. SLU Skogsmästarskolans Rapportserie 2022:01. https://res.slu.se/id/publ/115788.

Ersson BT, Bergsten U, Lindroos O (2011) The cost-efficiency of seedling packaging specifically designed for tree planting machines. Silva Fenn 45: 379–394. https://doi.org/10.14214/sf.108.

Ersson BT, Laine T, Saksa T (2018) Mechanized tree planting in Sweden and Finland: current state and key factors for future growth. Forests 9, article id 370. https://doi.org/10.3390/f9070370.

Ersson BT, Sundblad L-G, Manner J (2022) Cost analysis of seedling supply systems adapted for mechanized tree planting: a case study from southern Sweden. Silva Fenn 56, article id 10663. https://doi.org/10.14214/sf.10663.

Guerra S, Soler R, Sereghetti G, Oguri G (2019) An evaluation of the economics and productivity of fully mechanised tree seedling planting in Brazil. South For 81: 281–284. https://doi.org/10.2989/20702620.2019.1615225.

Haataja L, Kankaanhuhta V, Saksa T (2018) Reliability of self-control method in the management of non-industrial private forests. Silva Fenn 52, article id 1665. https://doi.org/10.14214/sf.1665.

Hallonborg U, von Hofsten H, Mattsson S, Hagberg J, Thorsén Å, Nyström C, Arvidsson H (1995) Maskinell plantering med Silva Nova: Nuvarande status samt utvecklingsmöjligheter i jämförelse med manuell plantering. [Mechanized planting with the Silva Nova tree planter: recent state and feasibility compared with manual planting]. SkogForsk, Redogörelse 6/1995.

Hallongren H, Laine T, Juntunen M-L (2012) Metsänhoitotöiden koneellistamisesta ratkaisu metsuripulaan. [Is the mechanization of silvicultural work a solution for labor shortage]. Metsätieteen aikakauskirja, article id 6459. https://doi.org/10.14214/ma.6459.

Hallongren H, Laine T, Rantala J, Saarinen V-M, Strandström M, Hämäläinen J, Poikela A (2014) Competitiveness of mechanized tree planting in Finland. Scand J For Res 29: 144–151. https://doi.org/10.1080/02827581.2014.881542.

Harstela P (1991) Work studies in forestry. Silva Carelica 18. Gummerrus Kirjapaino Oy, Jyväskylä.

Harstela P, Helenius P, Rantala J, Kanninen K, Kiljunen N (2006) Tehokkaan toimintakonseptin kehittäminen metsänhoitopalveluun. [Developing an effective concept for a forest management service]. Working Papers of the Finnish Forest Research Institute 23. http://urn.fi/URN:ISBN:978-951-40-1995-1.

Jylhä P, Jounela P, Koistinen M, Korpunen H (2019) Koneellinen hakkuu: seurantatutkimus. [Mechanized cutting: follow-up study]. Luonnonvarakeskus, Luonnonvara- ja biotalouden tutkimus 11/2019. http://urn.fi/URN:ISBN:978-952-326-717-6.

Kalland F (2002) Metsänuudistamisen laadun hallinta. Kokemuksia teollisuuden metsistä. [Quality management of forest regeneration. Experiences in forests owned by forest industries]. Metsätieteen aikakauskirja, article id 6544. https://doi.org/10.14214/ma.6544.

Kankaanhuhta V, Saksa T, Smolander H (2009) Variation in the results of Norway spruce planting and Scots pine direct seeding in privately-owned forests in southern Finland. Silva Fenn 43: 51–70. https://doi.org/10.14214/sf.217.

Kankaanhuhta V, Saksa T, Smolander H (2010) The effect of quality management on forest regeneration activities in privately-owned forests in southern Finland. Silva Fenn 44: 341–361. https://doi.org/10.14214/sf.157.

Kankaanhuhta V, Ämmälä M, Vierula J (2018) Liiketoimintaosaaminen ja kumppanuusverkostot metsäpalveluyrittäjien palvelutarjonnan kasvun avaimia. [Business expertise and partnership networks as a key to the growth of provision of forest services]. Metsätieteen aikakauskirja, article id 10011. https://doi.org/10.14214/ma.10011.

Kärhä K, Hynönen A, Laine T, Strandström M, Sipilä K, Palander T, Rajala PT (2014) Koneellinen metsänistutus ja sen tehostaminen Suomessa. [Mechanized planting and its enhancement in Finland]. Metsätehon Raportti 233.

Kärhä K, Anttonen T, Poikela A, Palander T, Laurén A, Peltola H, Nuutinen Y (2018) Evaluation of salvage logging productivity and costs in windthrown Norway spruce-dominated forests. Forests 9, article id 280. https://doi.org/10.3390/f9050280.

Karjalainen V, Tokola T, Malinen J (2022) Prediction of topsoil stoniness using soil type information and airborne gamma-ray data. Can J For Res 52: 27–37. https://doi.org/10.1139/cjfr-2021-0001.

Korhonen KT, Ihalainen A, Miina J, Saksa T, Viiri H (2010) Metsänuudistamisen tila Suomessa VMI10:n aineistojen perusteella. [State of forest regeneration in Finland based on VMI10 data]. Metsätieteen aikakauskirja, article id 6943. https://doi.org/10.14214/ma.6943.

Kuitto PJ, Keskinen S, Lindroos J, Oijala T, Rajamäki J, Räsänen T, Terävä J (1994) Puutavaran koneellinen hakkuu ja metsäkuljetus. [Mechanized cutting and forest haulage]. Metsätehon Raportti 410. ISBN 951-673-139-2.

Laine T (2017) Mechanized tree planting in Finland and improving its productivity. Dissertationes Forestales 239. https://doi.org/10.14214/df.239.

Laine T, Rantala J (2013) Mechanized tree planting with an excavator-mounted M-Planter planting device. Int J For Eng 24: 183–193. https://doi.org/10.1080/14942119.2013.844884.

Laine T, Saarinen V-M (2014) Comparative study of the Risutec automatic plant container (APC) and Bracke planting devices. Silva Fenn 48, article id 1161. https://doi.org/10.14214/sf.1161.

Laine T, Syri M (2012) Koneellisen metsänistutuksen opas. [Guide for mechanized planting]. Suomen metsäkeskus/Metsäntutkimuslaitos. http://urn.fi/URN:NBN:fi-fe201705246885.

Laine T, Kärhä K, Hynönen A (2016) A survey of the Finnish mechanized tree-planting industry in 2013 and its success factors. Silva Fenn 50, article id 1323. https://doi.org/10.14214/sf.1323.

Laine T, Luoranen J, Ilvesniemi H (2019) Metsämaan muokkaus: kirjallisuuskatsaus maanmuokkauksen vaikutuksista metsänuudistamiseen, vesistöihin sekä ekologiseen ja sosiaaliseen kestävyyteen. [Forest soil preparation: a literature review on the effects of soil preparation on forest regeneration, water systems, and ecological and social sustainability]. Luonnonvarakeskus, Luonnonvara- ja biotalouden tutkimus 58/2019. http://urn.fi/URN:ISBN:978-952-326-813-5.

Lazdiņa D, Dumins K, Saksa T, Makovskis K (2019) Evaluation of forest tree planting effectiveness. In: Malinovska L, Osadcuks V (eds) Eighteenth International Scientific Conference on Engineering for Rural Development, Jelgava, 22–24 May 2019. Latvia University of Life Sciences and Technologies, Latvia, pp 227–232. https://doi.org/10.22616/ERDev2019.18.N306.

Liepiņš K, Lazdiņa D, Lazdiņš A (2011) Productivity and cost-effectiveness of the M-Planter tree planting machine in Latvian conditions. Baltic For 17: 308–313.

Luonnonvarakeskus (2024) Silvicultural and forest improvement work – statistics database. Natural Resources Institute Finland. https://www.luke.fi/en/statistics/silvicultural-and-forest-improvement-work. Accessed 16 September 2024.

Luoranen J, Kiljunen N (2006) Kuusen paakkutaimien viljelyopas. [Manual for growing Norway spruce container seedlings]. Metsäntutkimuslaitos, Suonenjoki. http://urn.fi/URN:ISBN:978-951-40-1997-5.

Luoranen J, Viiri H (2016) Deep planting decreases risk of drought damage and increases growth of Norway spruce container seedlings. New For 47: 701–714. https://doi.org/10.1007/s11056-016-9539-3.

Luoranen J, Saksa T, Finér L, Tamminen P (2007) Metsämaan muokkausopas. [Soil preparation manual for forest lands]. Metsäntutkimuslaitos, Suonenjoki. http://urn.fi/URN:ISBN:978-951-40-2059-9.

Luoranen J, Rikala R, Smolander H (2011) Machine planting of Norway spruce by Bracke and Ecoplanter: an evaluation of soil preparation, planting method and seedling performance. Silva Fenn 45: 341–357. https://doi.org/10.14214/sf.107.

Luoranen J, Saksa T, Uotila K (2020) Metsänuudistaminen. [Forest regeneration]. Bookwell Oy, Porvoo. ISBN 978-952-338-082-0.

Maa- ja metsätalousministeriön asetus maatalouden investointien hyväksyttävistä yksikkökustannuksista. [Decree of the Ministry of Agriculture and Forestry on the acceptable unit costs of agricultural investments]. Decree number 608/2023. https://www.finlex.fi/fi/laki/alkup/2023/20230608. Accessed 13 June 2024.

Melander L, Ritala R, Strandström M (2019) Classifying soil stoniness based on the excavator boom vibration data in mounding operations. Silva Fenn 53, article id 10068. https://doi.org/10.14214/sf.10068.

Metsäalan työehtosopimus (2024) Metsäalan työehtosopimus 2024–2026. [Collective labor agreement in forestry, 2024–2026]. https://www.teollisuusliitto.fi/tyoelama/tyoehtosopimukset/teknologiasektori/metsaala/. Accessed 25 May 2024.

Metsäkonealan työehtosopimus (2024) Metsäkonealan työehtosopimus 2024–2026. [Collective labor agreement in machine work in forestry, 2024–2026]. https://www.teollisuusliitto.fi/tyoelama/tyoehtosopimukset/teknologiasektori/metsakoneala/. Accessed 25 May 2024.

Metsälehti (2023) Risutec Forest Maker – liian iso Suomeen. [Risutec Forest Maker – too big for Finland]. https://www.metsalehti.fi/artikkelit/liian-iso-suomeen/#dc0cc7ed. Accessed 25 May 2024.

Nilsson U, Luoranen J, Kolström T, Örlander G, Puttonen P (2010) Reforestation with planting in northern Europe. Scand J For Res 25: 283–294. https://doi.org/10.1080/02827581.2010.498384.

Örlander G, Nilsson U (1999) Effect of reforestation methods on pine weevil (Hylobius abietis) damage and seedling survival. Scand J For Res 14: 341–354. https://doi.org/10.1080/02827589950152665.

Palva R (2023) Konetyön kustannukset ja tilastolliset urakointihinnat 2022. [Machinery costs and statistical contract prices 2022]. TTS:n julkaisuja 471. https://www.tts.fi/wp-content/uploads/2023/10/Konetyon-kustannukset-ja-tilastolliset-urakointihinnat-2022.pdf. Accessed 11 July 2024.

Peltola A, Vaahtera E (2023) Silviculture. In: Niinistö T, Peltola A, Räty M, Sauvula-Seppälä T, Torvelainen J, Uotila E, Vaahtera E (eds) Finnish statistical yearbook of forestry 2022. Luonnonvarakeskus, pp 59–76. http://urn.fi/URN:ISBN:978-952-380-584-2.

Pohjala J, Vahtila M, Ovaskainen H, Kankare V, Hyyppä J, Kärhä K (2024) Effect of prior tree marking on cutting productivity and harvesting quality. Croat J For Eng 45: 25–42. https://doi.org/10.5552/crojfe.2024.2213.

Poikonen P, Karvinen S, Kallioniemi M (2023) Bofori-projektin arvioita metsätalouden työvoimatilanteesta ja töiden laadunhallinnasta. [The Bofori project’s estimates of the labor situation and quality management of work in forestry]. Luonnonvarakeskus, Luonnonvara- ja biotalouden tutkimus 41/2023. http://urn.fi/URN:ISBN:978-952-380-678-8.

Ramantswana M, Guerra SPS, Ersson BT (2020) Advances in the mechanization of regenerating plantation forests: a review. Curr For Rep 6: 143–158. https://doi.org/10.1007/s40725-020-00114-7.

Rantala J, Laine T (2010) Productivity of the M-Planter tree-planting device in practice. Silva Fenn 44: 859–869. https://doi.org/10.14214/sf.125.

Rantala J, Harstela P, Saarinen V-M, Tervo L (2009) A techno-economic evaluation of Bracke and M-Planter tree planting devices. Silva Fenn 43: 659–667. https://doi.org/10.14214/sf.186.

Rantala J, Saarinen V-M, Hallongren H (2010) Quality, productivity and costs of spot mounding after slash and stump removal. Scand J For Res 25: 507–514. https://doi.org/10.1080/02827581.2010.522591.

Risutec (2024a) PM tree planting machine for wet conditions. PM Tree Planting Machine – Risutec. https://risutec.fi/pm-tree-planting-machine/. Accessed 22 April 2024.

Risutec (2024b) Risutec Asta for contactors mounted forestry. Asta for contracting – Risutec. https://risutec.fi/asta-mounted-forestry-gps/. Accessed 22 April 2024.

Rummukainen A, Tervo L, Kautto K (2002) Ilves- ja Bräcke-istutuskoneet – tuottavuus, työnjälki ja kustannukset. [Ilves and Bräcke forest planting machines – productivity, quality of work and cost]. Finnish Forest Research Institute Research Papers 857. http://urn.fi/URN:ISBN:951-40-1837-0.

Saarinen V-M (2006) The effects of slash and stump removal on productivity and quality of forest regeneration operations – preliminary results. Biomass Bioenerg 30: 349–356. https://doi.org/10.1016/j.biombioe.2005.07.014.

Sahlén K, Goulet F (2002) Reduction of frost heaving of Norway spruce and Scots pine seedlings by planting in mounds or in humus. New For 24: 175–182. https://doi.org/10.1023/A:1021378228524.

Saksa T (2011) Kuusen istutustaimien menestyminen ja tukkimiehen tuhot eri tavoin muokatuilla uudistamisaloilla. [The success of planted Norway spruce seedlings and pine weevil damages in regeneration areas prepared with various methods]. Metsätieteen aikakauskirja, article id 6634. https://doi.org/10.14214/ma.6634.

Saksa T, Kankaanhuhta V (2007) Metsänuudistamisen laatu ja keskeisimmät kehittämiskohteet Etelä-Suomessa. [Quality of forest regeneration and key development targets in southern Finland. Final report of the forest regeneration quality management project]. Metsäntutkimuslaitos, Suonenjoki. http://urn.fi/URN:ISBN:978-951-40-2040-7.

Saksa T, Tervo L, Kautto K (2002) Hakkuutähteen korjuun vaikutukset metsän uudistamiseen. [The effects of slash removal on forest regeneration]. In: Alakangas E (ed) Puuenergian teknologiaohjelman vuosikirja 2002. [The yearbook of the Finnish wood energy technology program, 2002]. VTT Symposium 221. Otamedia Oy, Espoo, pp 249–268.

Saksa T, Miina J, Haatainen H, Kärkkäinen K (2018) Quality of spot mounding performed by continuously advancing mounders. Silva Fenn 52, article id 9933. https://doi.org/10.14214/sf.9933.

Sikström U, Hjelm K, Holt Hanssen K, Saksa T, Wallertz K (2020) Influence of mechanical site preparation on regeneration success of planted conifers in clearcuts in Fennoscandia – a review. Silva Fenn 54, article id 10172. https://doi.org/10.14214/sf.10172.

Skogsstyrelsen (2023) Forest seedlings delivered for planting. The official statistics of Sweden. https://www.skogsstyrelsen.se/en/statistics/subject-areas/forest-seedlings-delivered-for-planting/. Accessed 23 May 2024.

Soler R, Guerra S, Oguri G, Rodrigues S (2024) Economic evaluation and performance of a tree planting machine performing in two different slope classes and conditions of harvesting slash. Croat J For Eng 45: 15–24. https://doi.org/10.5552/crojfe.2024.2209.

Solvin T, Sundheim F, Proschowsky G, Leisgaard T, Ylioja T, Tynkkynen T, Skúlason B, Björgvinsson H, Stokke E, Myhre M, Edvardsson E, Uggla C (2023) Statistics: forest seeds and plants in the Nordic region 2023. NordGen Publication Series 2023:02.

Strandström M (2018) Koneellisen istutuksen ajanmenekki/tuotos – Risutec PM160-istutuslaitteella varustetulla kaivukoneella. [Time consumption and productivity of mechanized planting using an excavator equipped with a Risutec PM-160 planting device]. Metsätehon Tuloskalvosarja 4/2018.

Strandström M, Pajuoja H (2013) Metsäsektorin työvoimatarve – Savotta 2020. [Future labor demand in the Finnish forestry sector – Savotta 2020 calculations]. Metsätehon Raportti 224.

Strandström M, Hämäläinen J, Pajuoja H (2009) Metsänhoidon koneellistaminen – Visio ja T&K-ohjelma. [The mechanization of silvicultural work – Vision and R&D program]. Metsätehon Raportti 206.

Strandström M, Saarinen V-M, Hallongren H, Hämäläinen J, Poikela A, Rantala J (2011) Koneellisen istutuksen ja taimikonhoidon kilpailukyky. [The competitiveness of mechanized forest tree planting and pre-commercial thinning]. Metsätehon Raportti 218.

Tilastokeskus (2024a) Consumer prices of liquid fuels. Statistics Finland’s free-of-charge statistical databases. https://stat.fi/en/statistical-data. Accessed 25 May 2024.

Tilastokeskus (2024b) Metsäalan kone- ja autokustannusindeksi. [Forestry machinery and vehicle cost index]. https://stat.fi/tup/kustannusindeksit/metsaalan-kone-ja-autokustannusindeksi.html. Accessed 25 May 2024.

Timonen T, Kärhä K, Oikari M, Peltola H, Kuusiniemi K, Piipponen J (2019) State-of-art of mechanized planting and pre-commercial thinning operations in Finland. In: Berg S, Talbot B (eds) Forest Operations in Response to Environmental Challenges. Proceedings of the Nordic-Baltic Conference on Operational Research (NB-NORD), 3–5 June 2019, Honne, Norway. NIBIO Book 5(6), pp 72.

Väkevä J, Kariniemi A, Lindroos J, Poikela A, Rajamäki J, Uusi-Pantti K (2001) Puutavaran metsäkuljetuksen ajanmenekki. [Time consumption of timber haulage]. Metsätehon Raportti 123.

Vēsmiņš G, Lazdiņa D, Luguza S (2020) Possibility of using excavator with head Risutec TK-120 for mechanical regeneration of conifers. In: Briedis D (ed) Fifteenth International Scientific Conference – Students on their Way to Science, Jelgava, 24 April 2020. Latvia University of Life Sciences and Technologies, Latvia, pp 42.

Viiri H, Luoranen J (2017) Deep planting of Norway spruce seedlings: effects on pine weevil feeding damage and growth. Scand J For Res 47: 1468–1473. https://doi.org/10.1139/cjfr-2017-0192.

Total of 79 references.