Assessing work order information quality in harvesting

Gustafsson Å. (2017). Assessing work order information quality in harvesting. Silva Fennica vol. 51 no. 4 article id 6989. https://doi.org/10.14214/sf.6989

Highlights

- This paper concludes that information quality with regards to accuracy in work order information components pertaining to “Landing – placement and size”, “Cleaning understory trees – not conducted and of low standard”, are lacking and need to be improved in harvesting.

Abstract

Being a logging contractor involves several uncertainties, amongst others, information quality in the work order received from customers. The information quality of work orders is of the utmost importance for logging contactors, in order to be able to plan and conduct work properly. The purpose of this paper is three-fold: 1) identifying work order information components in harvesting, 2) identifying work order information quality dimensions in harvesting and 3) assessing work order information quality in harvesting. The paper is based on interviews and a survey. Various interviews took place in Sweden with professionals within the harvesting industry as well as logging contractors, and thereafter a survey was developed. Random selection was conducted and 100 Swedish logging contractors were contacted by telephone in order to answer the survey, with a response rate of 82% from the sample. The paper concludes that the information quality dimension of accuracy concerns the individual work order information components, whereas timeliness is related to receiving the complete work orders. A factor analysis has been conducted with five factors emerging. The assessment of work order information quality in harvesting implies that the potential for improvement exists with regard to increasing the accuracy of the order information for the components of “Cleaning under story trees – not conducted” and “Cleaning under story trees – of low standard” as well as “Landing – size”, and “Landing – placement”. However, their effect on capacity is utilization needs to be explored.

Keywords

survey study;

logging contractor;

work orders;

work order information components;

factor analysis

Received 6 March 2017 Accepted 15 September 2017 Published 25 September 2017

Views 58721

Available at https://doi.org/10.14214/sf.6989 | Download PDF

1 Introduction

The supply chain for softwood lumber is exposed to continuous competition, while requirements from the outside world are constantly intensifying (Sandström 2014). The supply chain for softwood lumber is divergent in nature (Bajgiran et al. 2016; Gaudreault et al. 2010; Haartveit et al. 2004), implying that the harvested raw material, trees, can be processed in several ways and, thus, that there can be several different intermediate products as well as by-products which are subsequently further diversified in the industrial processes following harvesting operations (Vila et al. 2006; Haartveit et al. 2004). The high heterogeneity of the raw material (Gaudreault et al. 2016) and that the products are considered as commodity products, push members of the supply chain to strive for capacity utilization and to minimize costs (Haartveit et al. 2004).

The start of the supply chain is the forest owner who will act as a seller of timber. In most cases, however, it is the timber buyer who will engage the services of a logging contractor. The timber buyer makes the decisions regarding the harvesting, and the logging contractor carries them out. Some ninety percent of forestry work is conducted by logging contractors (Skogsstyrelsen 2014), hence, logging contractors are important actors in the supply chain for softwood lumber. The logging contractors are small with regard to company size, even if the numbers of slightly larger contractors have increased over the years (Hultåker et al. 2002). A wood harvesting contractor has typically has three to six employees in addition to the contractor. The skills of the individual operator have a substantial impact on the result of the company (Karvinen and Nummelin 2015). Further, in recent years the industry has struggled with several problems, including low profitability (Lefévre 2011), capacity losses (Sandström 2014), and issues regarding information exchange between involved actors (Norrby 2015).

Within the sawmill sector, coordination and integration upstream with the logging contractor is recognized for increasing a sawmill’s competitiveness (Roos et al. 2000). It is well-known that information exchange may lead, directly or indirectly, to enhanced supply chain performance (Sahin and Robinson 2005; Zhou and Benton 2007; Gustavsson and Jonsson 2008). The work order information received by the logging contractor will be what is used in the harvesting and, hence, it is important that it meets the level of quality needed. In the ISO 9000 standards (2005), quality is defined as “the totality of features and characteristics of a product or service that bear on its ability to satisfy stated or implied needs”. According to Juran et al. (2010), quality can be assessed from two different perspectives: either by the degree of meeting (or exceeding) customer demands or by the absence of deficiencies. Information quality (IQ) refers to the quality of information and to the quality of reliability of the information provided. Bergman and Klevsjö (1994) define IQ as “the ability to satisfy stated and implied needs of an information consumer”.

Currently, studies providing a state-of-the-art description of work order IQ in harvesting are lacking. There may be reasons for this, but to solve industry problems it is necessary to have knowledge of a number of preceding questions. The prerequisites for logging contractors to sufficiently conduct their work are specified in the work order provided by the timber buyer. In order to start assessing IQ in harvesting, a first step is to investigate details in the work order. What work order information components are needed to enable an efficient and purposeful harvesting operation by the logging contractor and, thus, should be correctly included in the work order? The IQ of work orders is under debate in the relevant industry forums (Norrby 2015; Skogsentreprenören 2014). In order for members of the supply chain to utilize capacity better and become competitive and increase profitability, timber buyers need to secure quality work order information. Can general studies on work order IQ dimensions (Forslund 2007) be used to study work order IQ in a harvesting context? How can such general studies be adapted to harvesting? The importance of studying the quality of information in context has been stressed by Lillrank (2003).

Knowing the work order information components in the work order between the timber buyer and the logging contractor, and the relevant work order IQ dimensions in a harvesting context, implies that there is a foundation for conducting empirical studies and a need for a state-of-the-art description and analysis. Therefore, the purpose of this paper is three-fold: 1) identifying work order information components in harvesting, 2) identifying order information quality dimensions in harvesting, and 3) assessing work order information quality in harvesting.

2 Materials and methods

The method applied in the different parts (aligned with three-folded purpose) of this research differs. An overview of the data collection method, validation method, and analysis method applied for each respective part of the purpose is illustrated in Table 1.

| Table 1. Overview of method applied based on the different parts of the purpose. | |||

| Purpose | Data collection method | Validation method | Analysis method |

| Purpose part 1; identifying work order information components in harvesting | Semi-structured interviews with logging contractors | Focus group with national trade association | Qualitative data analysis; open coding |

| Purpose part 2; identifying order information quality dimensions in harvesting | Literature study, structured interviews with experts (academic and professional) | Structured interviews with logging industry experts | Qualitative data analysis; selective coding |

| Purpose part 3; assessing work order information quality in harvesting | Survey with logging contractors | Structured interviews with logging industry representative | Quantitative data analysis; frequencies, mean, st. dev., ANOVA and factor analysis using SPSS |

2.1 Identifying work order information components in harvesting

The investigation of information needed for logging contractors started by means of an interview study. According to Bryman and Bell (2013), interviewing is likely the most frequently used research method in qualitative research. Conducting interviews allows for creating a basis for deeper understanding and embracing numerous views on the phenomenon studied (Holme et al. 1997). There are numerous types of interviews, amongst others, the semi-structured interview. Semi-structured interviews refer to a context in which the interviewer has questions (generally as an interview guide) but may alter the sequence of the questions (Bryman and Bell 2013). The interview study consisted of six in-depth interviews with engaged logging contractors. The semi-structured interview guide is presented in Appendix A (see Supplementary file S1). These interviews were conducted at each respondent’s work site in order to enhance understanding of the specific situation. The individual semi-structured interviews focused on the work order information components needed for each in order to conduct their work in order to conduct their work in the most efficient manner. The result of the individual semi-structured interviews laid the foundation for the part concerning work order information components in the survey.

Identifying work order information components in harvesting has been conducted through open coding of the responses’ replies. Coding is the starting point for most forms of qualitative research (Bryman and Bell 2013) and hence open coding is a suitable choice for this research.

Validation of the results from the semi-structured interviews concerning work order information components took place through a focus group with the national trade association for professionals who work in the Swedish forestry sector in order to ensure that all work order information components needed by logging contractors were included. The focus group discussed the work order information components in a manner similar to the respondents in the individual semi-structured interview study. Hence the identified work order information components were validated.

2.2 Identifying work order information quality dimensions in harvesting

The aim of this section is to identify the dimensions of quality in work order information in harvesting. This is accomplished by 1) listing quality dimensions identified in previous studies (theoretical), and 2) selecting those dimensions such as are suitable in this specific, empirical setting. The first part takes its starting point in the theoretical realm of IQ and is based on a literature study performed in one search, whereas the second part is based on an empirical setting in which experts, both from academia and the professional logging industry, have been interviewed to relate the results of the theoretical study to the harvesting industry. The structured interview guide is presented in Appendix B (see Suppl. file S1) and is designed to maximize reliability and validity. The interviews were recorded, transcribed, and sent to the respondents for validation.

The analysis has been carried out by selective coding in order to systematically relate and validate information quality dimensions to the industry. This is aligned with Bryman and Bell (2013).

To validate the dimensions, two follow-up interviews were conducted with logging industry experts in order to relate the industry to the proposed dimensions. The respondents from the follow-up interviews agreed on the description of the industry and the proposed dimension. Regarding the other IQ dimensions, the industry experts found them hard to apply to the harvesting industry.

2.3 Assessing work order information quality in harvesting

The third part of this paper’s purpose is partly descriptive in nature, aimed at understanding and describing the IQ in harvesting, and thereby contributing to the general body of knowledge with regard to IQ and harvesting. A survey, aligned with Forza (2002), ought to be appropriate to use. This research is to be considered as theory-testing as it consists of a theoretical exploration of work order (IQ) dimensions in an additional empirical setting.

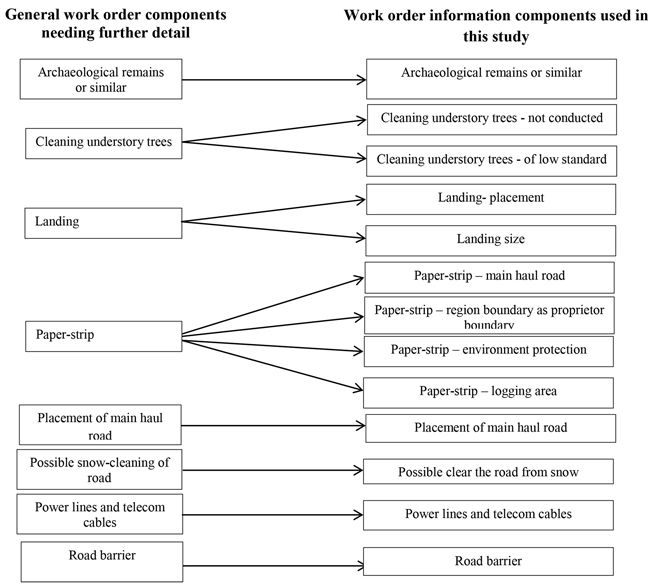

According to Gustavsson and Wänström (2009), IQ is defined as “the ability to satisfy stated and implied needs of an information consumer”; logging contractors are the consumers of information and are thereby suitable for this type of study. The unit of analysis in this case is the individual logging contractor. The survey questionnaire was developed in the fall of 2015. The survey is based on the results from the first two parts of the purpose, see illustration Fig. 1 (“Work order information components used in this study”) and the identified relevant IQ dimensions, see Table 8. The survey was first tested on senior researchers in business logistics and wood material science, and it was then discussed and tested on industry representatives. Appendix C (see Suppl.file S1) shows the survey for this study. Finally, the survey was validated with logging industry representatives.

Fig. 1. Forest harvesting work order components and their origins (general work order components).

Data were collected in 2016. A complete list of certified logging contractors in Sweden was acquired from certification organizations. The lists were merged to a total list of 958 certified logging contractors. Industrial experts validated the way of receiving the list of respondents and consequently also the respondents. To increase the response rate, the author decided to actively participate by making telephone calls to all respondents in order to stress the importance of their contribution and to clarify questions. 100 certified logging contractors (sample size) were selected for participating by using random generator in excel. In total, 118 telephone calls were made and 82 respondents completed the survey, for a response rate of 82 percent. Table 2 provides an overview of information regarding respondents.

| Table 2. Information regarding respondents. | |

| Total number of certified logging contractors | 958 |

| Sample size | 100 |

| Shouldn’t have been on the list (for instance, gone out of business or changed focus area) | 3 |

| Respondents not willing to participate | 5 |

| Respondents not answering despite three calls | 10 |

| Number of answers | 82 |

| Response rate | 82% from the sample, 8.5% from the complete list |

The reliability of the study was ensured by using a standardized measurement instrument in combination with the author’s telephone calls. As the study’s reliability was assured, a prerequisite for validity was obtained (Bryman and Bell 2013). Cronbach alpha is .7, which is an acceptable limit (Hair et al. 2013). Further, follow-up interviews were conducted to assess the reliability and external validity.

The variable accuracy is measured on a 1–7 Likert scale, whereas time is measured on a nominal scale. The empirical data was handled in SPSS, with, for instance, ANOVA test (Bonferroni’s pairwise comparison) and factor analysis. Significant differences in mean between the work order information components have been calculated using a paired-samples t-test (Hair et al. 1998) with the work order information components.

3 Results

3.1 Identifying work order information components in harvesting

The interview study found that information between the logging contractor and the timber buyer is based on the exchange of a harvesting work order. A general work order contains the following matters: cleaning of understory trees, placement of main haul road, paper-strip, landing, possible snow-clearing of the road, road barriers, overhead or underground power lines and telecom cables, and points or areas where special consideration must be taken for archaeological remains or similar or for natural conservation reasons.

Further, the interview study concluded that some areas of the general work order contain components which need to be of higher quality in order for forest contractors to perform their jobs efficiently, and these were specified during the interviews. The frequencies observed for each individual work order information component in harvesting are presented in Table 3. Fig. 1 illustrates the result of the work order information components needing to be enlarged with regard to the general work order components. Fig. 1 also includes those which remain in their initial state.

| Table 3. Frequencies observed for each individual work order information component in harvesting. | |

| Work order information coponent | Frequencies observed |

| Archaeological remains or similar* | 6 |

| Cleaning understory trees – not conducted | 6 |

| Cleaning understory trees – of low standard | 6 |

| Landing – placement | 6 |

| Landing – size | 6 |

| Paper-strip – main haul road | 6 |

| Paper-strip – region boundary asproprietor boundary | 2 |

| Paper-strip – environment protection | 4 |

| Paper-strip – logging area | 5 |

| Placement of main haul road* | 6 |

| Possible clear the road from snow* | 6 |

| Power lines and telecom cables* | 6 |

| Road barrier* | 6 |

| * = General work order information components identified in the harvesting work order. | |

3.2 Identifying work order information quality dimensions in harvesting

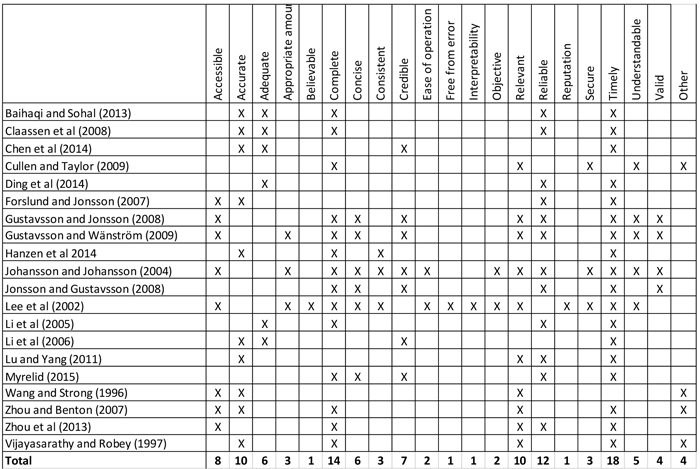

Table 4 identifies previous empirical studies, in other industries, which apply various IQ dimensions.

| Table 4. Overview of empirical studies including applied information quality dimensions. |

According to the interviewees, the logging contractor and timber buyer close annual agreements with specification of the individual work orders (i.e. logging tracts) approximately two weeks in advance. The planning horizon for the individual work orders ranges from four weeks to the last day before starting (it also happens that the individual work order has not been received before the contractors need to start to work). No discussions take place regarding the specific work orders. The yearly agreements specify annual logging volumes as cubic metres or in hours (capacity level). In the forest contract industry sector, the individual logging contractors have a possibility for certification. The individual logging contractors run their businesses, in general, within the family. The business is capital intensive and the turn-over is considered high but the profit level is perceived to be low. Workers are considered to have many occupations, amongst them, machine operator, repairer, and conservationist. Logging contract work is dependent on the weather situation. Large timber buyers have fairly well-developed work orders that are developed by/within the system; work orders could thereafter be downloaded from the company’s web portal with all the required information filled in. The work orders need to be received on time in order for the logging contractors to be able to plan their work. As the work orders are received, however, all of the components are filled in.

3.3 Assessing work order information quality in harvesting

In order to increase the understanding of the IQ dimension of time, frequencies, minimum, maximum, average, and standard deviation were calculated for ordinary circumstances, best cases, and worst cases for receiving the work order in advance. The descriptive statistics including distribution of frequencies are illustrated in Table 5.

| Table 5. Descriptive statistics for the time information quality dimension. | |||

| No of days | No of respondents – Ordinary circumstances | No of respondents – In the best of cases | No of respondents – In the worst of cases |

| 0 | 25 | ||

| 1 | 23 | ||

| 2 | 3 | 3 | 11 |

| 3 | 1 | ||

| 4 | 1 | ||

| 5 | 5 | 3 | 5 |

| 6 | 1 | ||

| 7 | 2 | 3 | 16 |

| 8 | 3 | ||

| 9 | |||

| 10 | 10 | 3 | |

| 11 | |||

| 12 | |||

| 13 | |||

| 14 | 35 | 8 | 1 |

| 15 | 2 | 7 | |

| 16 | |||

| 17 | |||

| 18 | 2 | ||

| 19 | |||

| 20 | 2 | 3 | |

| 21 | 11 | 27 | |

| 22 | |||

| 23 | |||

| 24 | |||

| 25 | 2 | ||

| 26 | |||

| 27 | |||

| 28 | 5 | 19 | |

| 29 | |||

| 30 | 4 | ||

| Total | 82 | 82 | 82 |

| Min | 2 | 2 | 0 |

| Max | 28 | 30 | 14 |

| Average | 14 | 20 | 2 |

| SD | 6.1 | 7.5 | 3.1 |

| SD = standard deviation | |||

Under ordinary circumstances, the average time in advance logging contractors receive their working orders is two weeks (i.e. 14 days). Under beneficial circumstances, the average reaches three weeks (i.e. 20 days), whereas in non-beneficial circumstances, logging contractors get working orders the day in which logging starts. The respondents appear to agree on the non-beneficial circumstances (low standard deviation), while conditions regarding ordinary and beneficial circumstances appear to vary between contractors.

The descriptive statistics for accuracy with regard to each individual work order information component is presented in Table 6, sorted in descendent order.

| Table 6. Descriptive statistics for the accuracy information quality dimension with regard to each specific work order information component. | ||

| Work order information component | Mean | SD |

| Paper-strip – environment protection | 6.50 | .878 |

| Paper-strip – region boundary as proprietor boundary | 6.40 | 1.132 |

| Road barrier | 6.37 | 1.319 |

| Paper-strip – logging area | 6.18 | 1.353 |

| Possible snow-clearing of road | 6.10 | 1.682 |

| Power lines and telecom cables | 5.93 | 1.858 |

| Archaeological remains or similar | 5.88 | 1.927 |

| Placement of main haul road | 5.63 | 1.836 |

| Paper-strip – main haul road | 5.67 | 1.925 |

| Landing – placement | 5.05 | 1.930 |

| Cleaning understory trees – not conducted | 4.93 | 2.193 |

| Cleaning understory trees – of low standard | 3.77 | 2.145 |

| Landing – size | 2.78 | 1.693 |

| SD = standard deviation. | ||

There are large differences amongst the respondents with regard to both means and standard deviations. It appears that the accuracy in the work order information components “Cleaning understory trees – of low standard” and ”Landing – size” does not correspond to accurate actual conditions when the forest contractor starts with a work order (i.e. there is a low level of IQ). The wide range in average indicates that there is high level of information quality in some work order information components and low levels of IQ in others.

The analysis concludes that significance exist, on a <0.000 level, between “Cleaning understory trees – of low standard” and “Landing – size”. However in order to enable identification of differences additional analysis with regard to significant mean differences has been conducted using an ANOVA test (Bonferroni’s pairwise comparison). Results are illustrated in Table 7.

| Table 7. Identification of significant different means using ANOVA (Bonferroni’s pair wise comparison), in alphabetical order. | |

| Work order information component | Significant different with variable |

| Archaeological remains or similar | Cleaning understory trees - not conducted Cleaning understory trees - of low standard Landing – placement Landing – size |

| Cleaning understory trees - not conducted | Archaeological remains or similar Landing – size Paper-strip – environment protection Paper-strip – logging area Paper-strip – region boundary as proprietor boundary Placement of main haul road Possible snow-clearing of road Power lines and telecom cables Road barrier |

| Cleaning understory trees - of low standard | Archaeological remains or similar Landing – size Paper-strip – environment protection Paper-strip – logging area Paper-strip – region boundary as proprietor boundary Placement of main haul road Possible snow-clearing of road Power lines and telecom cables Road barrier |

| Landing – placement | Landing – size Paper-strip – environment protection Paper-strip – logging area Paper-strip – region boundary as proprietor boundary Placement of main haul road Possible snow-clearing of road Power lines and telecom cables Road barrier |

| Landing – size | Archaeological remains or similar Cleaning understory trees - not conducted Cleaning understory trees - of low standard Landing – placement Paper-strip – environment protection Paper-strip – logging area Paper-strip – main haul road Paper-strip – region boundary as proprietor boundary Placement of main haul road Possible snow-clearing of road Power lines and telecom cables Road barrier |

| Paper-strip – environment protection | Cleaning understory trees - not conducted Cleaning understory trees - of low standard Landing – placement Landing – size |

| Paper-strip – logging area | Cleaning understory trees - not conducted Cleaning understory trees - of low standard Landing – placement Landing – size |

| Paper-strip – main haul road | Landing – size |

| Paper-strip – region boundary as proprietor boundary | Cleaning understory trees - not conducted Cleaning understory trees - of low standard Landing – placement Landing – size |

| Placement main haul road | Cleaning understory trees - not conducted Cleaning understory trees - of low standard Landing – placement Landing – size |

| Possible snow-clearing of road | Cleaning understory trees - not conducted Cleaning understory trees - of low standard Landing – placement Landing – size |

| Power lines and telecom cables | Cleaning understory trees - not conducted Cleaning understory trees - of low standard Landing – placement Landing – size |

| Road barrier | Cleaning understory trees - not conducted Cleaning understory trees - of low standard Landing – placement Landing – size |

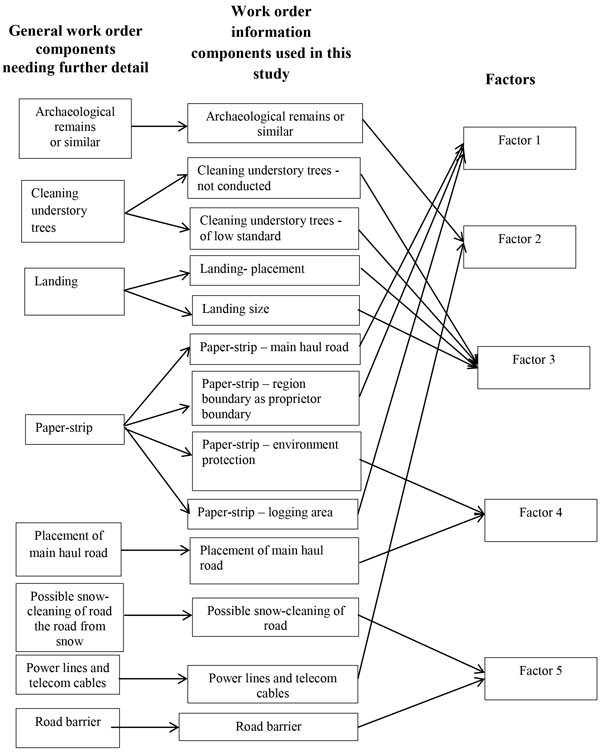

There are significant differences in means between the different work order information components to varying extents; some have differences in means between all work order information components and some have differences in means with only some work order information components. It appears to be complexity amongst the work order information components and interrelationships amongst them. In order to structure this complexity and assess work order information quality in harvesting, a factor analysis has been applied. The reduced factor structure is presented in Table 8. As indicated by Hair et al. (1998), factor loadings greater than +0.3 ought to be considered as significant loadings. All non-significant loadings have been deleted.

| Table 8. Rotated factor matrix. | |||||

| Component | |||||

| 1 | 2 | 3 | 4 | 5 | |

| Paper-strip – region boundary as proprietor boundary | .873 | ||||

| Paper-strip – logging area | .831 | ||||

| Paper-strip – main haul road | .656 | ||||

| Power lines and telecom cables | .873 | ||||

| Archaeological remains or similar | .834 | ||||

| Cleaning under story trees (not conducted) | .649 | ||||

| Cleaning under story trees (of low standard) | .854 | ||||

| Landing – size | .729 | ||||

| Landing – placement | .400 | ||||

| Paper-strip – environment protection | .794 | ||||

| Placement of main haul road | .706 | ||||

| Road barrier | .791 | ||||

| Possible snow-clearing of road | .753 | ||||

| Extraction method: Principal Component Analysis; Rotation method: Varimax with Kaiser Normalization. | |||||

In order to increase the capacity utilization, the accuracy in the IQ regarding the work order information components needs to be improved. Being able to confront the problems with the highest impact on accuracy in IQ implies possessing knowledge with regard to, for instance, their internal ranking. In order to acquire knowledge with regard to work order information components, the mean values for work order information components for each factor is calculated (starting with the highest mean value). The results are illustrated in Table 9.

| Table 9. Mean of work order information components for each factor and internal ranking of the of the respective factor (starting with highest mean value). | ||

| Original factor name | Mean | Internal ranking |

| Factor 1 | 6.083 | 2 |

| Factor 2 | 5.905 | 4 |

| Factor 3 | 4.132 | 5 |

| Factor 4 | 6.065 | 3 |

| Factor 5 | 6.250 | 1 |

4 Discussion

4.1 Identifying work order information components in harvesting

Work order information components are included in the individual work orders. However, some categories appear to lack specification of the sort that could help improve the planning and execution of the work. For instance, in the category of “cleaning understory trees”, the added information of either “not conducted” or “of low standard” could help contractors judge how much work needs to be done, or redone in the case of the latter (where vegetation may have grown too much in the time between the cleaning and the harvesting). Some of these order information components are related to each other, for instance “Cleaning understory trees – not conducted” and “Cleaning understory trees – of low standard”, if the time between cleaning understory trees and harvesting is too long it might be the case that vegetation has grown too much during this time and the work needs to be redone.

Further, the size of the landing ought to be related to the volume of harvesting and deliveries from the landing site. Deliveries are made to respective sawmills and even their storage space for incoming timber must be planned and controlled. The requirement regarding the size of the landing is thus controlled by the entire logistics chain, from forest to finished product.

The work order information component “Paper-strip – region boundary as proprietor” appears to be confusing as the work that is conducted concerns the logging area (i.e. “Paper-strip – logging area”), nevertheless it is mentioned by two respondents. However, the type of information is excessive but it might create security for the logging contractor.

4.2 Identifying work order information quality dimensions in harvesting

As illustrated in Table 10, accuracy, completeness, relevance, reliability, and timeliness are the most commonly acknowledged IQ dimensions. Hence, these five dimensions were selected for further investigation. This is in line with a study by Haug and Stentoft (2011), who study barriers preventing companies from achieving high data quality. The list provided by Haug and Stentoft (2011) verify the results of this theoretical investigation and highlight the same information quality dimensions as chosen for this study: accuracy, completeness, relevance, reliability, and timeliness.

| Table 10. Application in the harvesting industry of five identified information quality dimensions, based on interviews with experts. | |||||

| IQ dimension | Definition | Source | Related to harvesting industry | ||

| Accurate | Free from obvious mistakes | Forslund and Jonsson (2007) | The information should be accordance with reality. Even if the work order is downloaded from the web portal, it needs to reflect the current situation. | ||

| Complete | The extent to which the information is comprehensive | Gustavsson and Jonsson (2008) | The work order and instructions should be understandable for the person conducting the harvesting. The work order contains predefined fields and these are to be comprehensible for the logging contractor. The information quality regarding the completeness of the separate work orders is considered to be rather high; therefore, completeness with regard to information quality will not be assessed further in this study. | ||

| Relevant | The extent to which the information is appropriate for the task and application | Gustavsson and Jonsson (2008) | The work order and attached information should be designed so all needed information is included. It is not possible for the sender to load the work order on the web portal if all fields are not filled in. The information quality regarding the relevance of the separate work orders is considered to be rather high; therefore, relevance with regard to information will not be assessed further in this study. | ||

| Reliable | The probability that the forecast remains unchanged | Gustavsson and Jonsson (2008) | When logging contractors and timber buyers close annual agreements, they do not have discussions regarding the specific work orders. The information quality regarding the reliability of the separate work orders is considered to be rather high; therefore, reliability with regard to information will not be assessed further in this study. | ||

| Timely | Arrives in agreed time | Gustavsson and Jonsson (2008) | The logging contractor and the timber buyer close an agreement on when the work order should be sent to the contractor, normally 2 weeks in advance. Information regarding each work order information component is received together. If the logging contractor has not received the work order, it is impossible to conduct the logging work. The relevance of timeliness is with regard to the work order and not the individual work order components. | ||

In comparing the quality dimensions of the theoretical and real worlds, the proposed dimensions should reflect the industry environment to which they are being applied, as seen in Table 8.

This industry setting is similar to traditional industrial settings in some aspects such as the need for accurate information. However, the application of the particular IQ dimension to this specific empirical setting leads to the conclusion that only the quality of some IQ dimensions ought to be considered. Dimensions not applicable to this specific industry setting are; completeness, relevance, and reliability. They are therefore removed from the list of IQ dimensions to be assessed for improving the IQ in the harvesting industry. The remaining IQ dimension are accuracy and timely in the harvesting industry. This is supported by Sandström (2014), who states that for a contractor to carry out work in a sufficient manner, it is required that the information be available on time and in accordance with reality. The time dimension causes ambiguity: the work order needs to be delivered on time, but as the work order is delivered to the logging contractor, all work order information components are filled in. Timeliness is not valid for the individual work order information components.

4.3 Assessing work order information quality in harvesting

There are large differences amongst the respondents with regard to both means and standard deviations. It appears that the accuracy in the work order information components “Cleaning understory trees – of low standard” and ”Landing – size” does not correspond to accurate actual conditions when the forest contractor starts with a work order (i.e. there is a low level of IQ). The wide range in average indicates that there is high level of IQ in some work order information components and low levels of IQ in others.

In order to simplify the interpretation of the data set, factor analysis is used to analyze interrelationships among the variables. The factor analysis of work order information components identifies five factors. Factor one includes “Paper-strip – region boundary as proprietor boundary”, “Paper-strip – logging area”, and “Paper-strip – main haul road”. They have to do with marking, through paper strips, as ordered by the timber buyer on important areas decided by the timber buyer and timber seller. These work order information components are administrative and preparatory in nature and assist for the logging contractors when conducting the logging. Factor two encompasses “Power lines and telecom cables” and “Archaeological remains or similar”. These work order information components constitute important matters, information marked on the map, which the logging contractors need to be concerned with. When such matters are marked, it assists for the logging contractors to navigate more smoothly. These work order information components are administrative in nature and these preparations are connected to the geographic area in which the logging work is conducted. Factor three comprises “Cleaning understory trees – not conducted”, “Cleaning understory trees – of low standard”, “Landing – size”, and “Landing – placement”. These work order information components constitute preparations the timber buyer is expected to administer before harvesting. These work order information components are related to the preparations that the timber buyer is obliged to arrange for before harvesting and are prerequisite for a logging contractor to be able to do the logging work, as these work order information components have a direct impact on harvesting work. Factor four includes “Paper-strip – environment protection” and “Placement of main haul road”. These are work order information components that the timber buyer is expected to prepare and administer, but they do not have an effect on the actual harvesting. The information regarding protection of the environment is marked to the map, whereas “Placement of main haul road” is determined by the timber buyer. Having environment protection (“paper-strip – environment protection”) is marked to the map assists for the logging contractor, whereas “Placement of main haul road” is a prerequisite. Factor five consists of “Road barrier” and “Possible snow-clearing of road”. These work order information components are practical in nature and relate to the possibility of accessing the area that is going to be harvested. The different factors are of different types and have a different nature and value when conducted for the logging contractor. See Table 11 for an overview of tentative factor characteristics.

| Table 11. Tentative factor characteristics. | |||

| Original factor name | Nature | Type of work preparatory*/ necessity** | Value when conducting work for the logging contractor |

| Factor 1 | Administrative | Preparatory | Prerequisite |

| Factor 2 | Administrative | Preparatory | N.A. |

| Factor 3 | Administrative | Preparatory | Prerequisite |

| Factor 4 | Administrative | Preparatory | Facilitation Prerequisite |

| Factor 5 | Practical | Necessity | N.A. |

| * = preparations the timber buyer is expected to have done before harvesting. ** = necessity in order for the logging contractor to access the area to be harvested. | |||

In order to get an indication of ranking between the factors, means have been calculated. There is a difference in means between work order information components within each factor, even though most of them circulate around an average of 6.0. However, Factor 3, having the lowest mean, seems to contain the work order information components that the logging contractors do not consider accurate to actual conditions when they are about to start a work order, implying that they consider the IQ with regard to these components to be on a low level. Consequently, the accuracy of these work order information components needs to be focused on through continuous work improving the IQ in harvesting, enabling forest contractors to improve their capacity utilization and logging contractors to conduct their work in a sufficient manner. This implies that timber buyers need to increase their ability to satisfy the stated and implied needs of the logging contractors. An overview of the assessment of work order IQ in harvesting is illustrated in Fig. 2.

Fig. 2. Overview of result of the study.

5 Conclusion, future research, and implications

In order for logging contractors to strengthen their position and increase competitiveness, it is necessary that they utilize their equipment to its fullest extent. In order to utilize capacity fully, contractors need to receive accurate work order information components from timber buyers in time. The average time under ordinary circumstances is two weeks, see Table 5. The study concludes that the work order information components that respondents find lacking in the accuracy of IQ are: “Landing – placement”, “Cleaning understory trees – not conducted”, “Cleaning understory trees – of low standard”, and “Landing – size” according to the analysis presented in Tables 6, 7 and 9. In order to improve the IQ in harvesting and meet the needs stressed in Norrby (2015) and Skogsentreprenören (2014), the timber buyer ought to focus on these separate work order information components. In previous studies, several general information quality dimensions have been identified; however, in the harvesting industry, accuracy and timely with regard to the individual work order, while the other IQ dimensions, identified in previous research in other industries, do not appear to be applicable, see Table 10 (this is also stressed by Sandström (2014)). The individual work order information components differ both with regard to mean and standard deviations, see Table 5. The significance in differences in means also varies, even though it appears as if “Landing – placement” and “Landing – size” as well as “Cleaning understory trees”, both “of low standard” and “not conducted”, differ from the other order information components, see Table 6. Surprisingly, these components constitute the third factor in the factor analysis, see Table 7. In continuing research it would be interesting to generate hypotheses with regard to the capacity loss for each factor, particularly the third factor. Further a study on the tentative factor characteristics ought to provide knowledge on IQ in harvesting, see Table 11. This study is based on a selection of respondents, and conducting research with an extended sample would contribute further to the general body of knowledge regarding IQ in harvesting. Further, in order to get a deeper understanding of IQ in harvesting, in-depth case studies with individual logging contactors would provide meaningful information and useful knowledge for information quality in harvesting.

This paper aims at understanding and describing IQ in harvesting, and it thereby contributes to the general body of knowledge with regard to information quality and harvesting. The theoretical implication lies in the application of general information quality dimensions to the harvesting industry. Managerial implications lay rather in the operationalization of work order information components as well as in stressing work order information components lacking in information quality. By confronting and improving these work order information components identified with low information quality (i.e. accuracy), logging contractors can create greater efficiency within the industry.

Acknowledgements

The author extends her gratitude to Skogforsk for support in this study.

References

Baihaqi I., Sohal A.S. (2013). The impact of information sharing in supply chains on organisational performance: an empirical study. Production Planning & Control: The Management of Operations 24(8–9): 743–758. https://doi.org/10.1080/09537287.2012.666865.

Bajgiran O., Zanjani M., Nourelfath M. (2016). The value of integrated tactical planning optimization in the lumber supply chain. International Journal of Production Economics 171(1): 22–33. https://doi.org/10.1016/j.ijpe.2015.10.021.

Bergman B., Klevsjö B. (1994). Quality – from customer needs to customer satisfaction. Studentlitteratur, Lund, Sweden. 654 p.

Bryman A., Bell E. (2013). Business research methods. 3rd ed. Oxford University Press, New York. 778 p.

Chen J.V., Wang C.-L., Yen D.C. (2014). A causal model for supply chain partner’s commitment. Production Planning & Control: The Management of Operations 25(9): 800–813. https://doi.org/10.1080/09537287.2013.764578.

Claassen M.J.T., van Weele A.J., van Raaij R.M. (2008). Performance outcomes and success factors of vendor managed inventory (VMI). Supply Chain Management: An International Journal 13(6): 406–414. https://doi.org/10.1108/13598540810905660.

Cullen A.J., Taylor M. (2009). Critical success factors for B2B e‐commerce use within the UK NHS pharmaceutical supply chain. International Journal of Operations & Production Management 29(11): 1156–1185. https://doi.org/10.1108/01443570911000177.

Ding D.J., Jie F., Parton K.A. Matanda M. (2014). Relationships between quality of information sharing and supply chain food quality in the Australian beef processing industry. The International Journal of Logistics Management 25(1): 85–108. https://doi.org/10.1108/IJLM-07-2012-0057.

Forslund H. (2007). Measuring information quality in the order fulfillment process. International Journal of Quality & Reliability Management 24(5): 515–525. https://doi.org/10.1108/02656710710748376.

Forslund H., Jonsson P. (2007). The impact of forecast information quality on supply chain performance. International Journal of Operations & Production Management 27(1): 90–107. https://doi.org/10.1108/01443570710714556.

Forza C. (2002). Survey research in operations management: a process-based perspective. International Journal of Operations & Production Management 22(2): 151–194. https://doi.org/10.1108/01443570210414310. .

Gaudreault J.G., Forget P., Frayret J.-M., Rousseau A., Lemieux S., Amours S. (2010). Distributed operations planning in the softwood lumber supply chain: models and coordination. International Journal of Industrial Engineering 17(3): 168–189. https://www.researchgate.net/profile/Jonathan_Gaudreault/publication/233785588_Distributed_Operations_Planning_for_the_Softwood_Lumber_Supply_Chain_Optimization_and_coordination/links/54d8d8a50cf2970e4e79df93.pdf.

Gustavsson M., Jonsson P. (2008). Perceived quality deficiencies of demand information and their consequences. International Journal of Logistics research and Applications 11(4): 295–312. https://doi.org/10.1080/13675560801952987.

Gustavsson M., Wänström C. (2009). Assessing information quality in manufacturing planning and control processes. International Journal of Quality & Reliability Management 26(4): 325–340. https://doi.org/10.1108/02656710910950333.

Haartveit E.Y., Kozak R.A., Maness T.C. (2004). Supply chain management mapping for the forest products industry: three cases from western Canada. Journal of Forest Products Business Research 1(5). 31 p.

Hair J., Andersson R., Tatham R., Black W. (2013). Multivariate data analysis. Prentice Hall, USA. 740 p.

Haug A., Arlbjörn Stentoft J. (2011). Barriers to master data quality. Journal of Enterprise Information Management 24(3): 288–303. https://doi.org/10.1108/17410391111122862.

Hazen B.T., Boone C.A., Ezell J.D., Jones-Farmer A. (2014). Data quality for data science, predictive analytics, and big data in supply chain management: an introduction to the problem and suggestions for research and applications. International Journal of Production Economics 154: 72–80. https://doi.org/10.1016/j.ijpe.2014.04.018.

Holme I., Solvang B., Fløistad G., Kjeldstadli K., O’Gorman D. (1997). Forskningsmetodik – om kvalitativa och kvantitativa metoder. Studentlitteratur, Lund, Sweden. 360 p.

Hultåker O., Bohlin F., Gellerstedt S. (2002). Ny entreprenad i skogen – bredda för bättre arbetsmiljö och lönsamhet. Rapport 10. SLU, Institutionen för skogens produkter och marknader, Uppsala.

ISO 9000 standards (2005). ISO 9000:2005. Quality management system: fundamentals and vocabulary.

Johansson E., Johansson M.I. (2004). The information gap between design engineering and materials supply systems design. International Journal of Production Research 42(17): 3787–3801. https://doi.org/10.1080/00207540410001696302.

Jonsson P., Gustavsson M. (2008). The impact of supply chain relationships and automatic data communication and registration on forecast information quality. International Journal of Physical Distribution & Logistics Management 38(4): 280–295. https://doi.org/10.1108/09600030810875382.

Juran J.M., De Feo J.A. (2010). Juran’s quality handbook: the complete guide to performance excellence. E-book, McGraw Hill.

Karvinen S., Nummelin T. (2015). Finnish wood harvesting contractors’ risks in Russia. Silva Fennica 49(5) article 1394. https://doi.org/10.14214/sf.1394.

Lee W.L., Strong D.M., Kahn B.K. Wang R.Y. (2002). AIMQ: a method for information quality assessment. Information & management 40(2): 133–46. https://doi.org/10.1016/S0378-7206(02)00043-5.

Lefévre C. (2011). Svenssons Skog – integrerad skogsentreprenör i södra Sverige. Examensarbete nr: TEK 067/2010, Linnéuniversitetet.

Li S., Rao S., Ragu-Nathan T.S., Ragu-Nathan B. (2005). Development and validation of a measurement instrument for studying supply chain management practices 23(6): 618–641. https://doi.org/10.1016/j.jom.2005.01.002.

Li S., Ragu-Nathan B., Ragu-Nathan T.S., Rao S. (2006). The impact of supply chain management practices on competitive advantage and organizational performance. Omega 34(2): 107–124. https://doi.org/10.1016/j.omega.2004.08.002.

Lillrank P. (2003). The quality of information. International Journal of Quality & Reliability Management 20(6): 691–703. https://doi.org/10.1108/02656710310482131.

Lu Y., Yang D. (2011). Information exchange in virtual communities under extreme disaster conditions. Decision Support Systems 50(2): 529–538. https://doi.org/10.1016/j.dss.2010.11.011.

Myrelid P. (2015). Utilization of shared information for operations planning and control. Licentiate thesis, Chalmers. Technical report L2015:076.

Norrby B. (2015). Bättre relationer ger ett bättre skogsbruk. Vision nr 1. p. 24–26. Skogforsk, Uppsala. https://www.skogforsk.se/produkter-och-evenemang/trycksaker/2015/vision-1-2015/.

Roos A., Flinkman M., Jäppinen A., Warensjö M. (2000). Adoption of value-added processes in Swedish sawmills. Silva Fennica 34(4): 423–430. https://doi.org/10.14214/sf.623.

Sahin F., Rodinsson Jr. E.P. (2005). Information sharing and coordination in make-to-order supply chains. Journal of Operations Management 23(6): 579–598. https://doi.org/10.1016/j.jom.2004.08.007.

Sandström U. (2014). Skogsentreprenörerna verkar för ett hållbart skogsbruk. Skogsentreprenören 1. p. 3. Skogsentreprenörerna, Stockholm.

Skogsstyrelsen (2014). Skogsstatistisk årsbok. Tabell 12.5. p. 244. ISBN 978-91-87535-05-5.

Vila D., Martel A., Beauregard R. (2006). Designing logistics networks in divergent process industries: a methodology and its application to the lumber industry. International Journal of Production Economics 102(2): 358–378. https://doi.org/10.1016/j.ijpe.2005.03.011.

Wang R., Strong D.M. (1996). Beyond accuracy: what data quality means to data consumers. Journal of Management Information Systems 12(4): 5–34. https://doi.org/10.1080/07421222.1996.11518099.

Zhou H., Benton Jr. W.C. (2007). Supply chain practice and information sharing. Journal of Operations Management 25(6): 1348–1365. https://doi.org/10.1016/j.jom.2007.01.009.

Zhou H., Shoua Y., Zhai X., Li L., Wood C., Wu X. (2013). Supply chain practice and information quality: a supply chain strategy study. International Journal of Production Economics 147(part C): 624–633. https://doi.org/10.1016/j.ijpe.2013.08.025.

Total of 41 references.