Sequencing of harvester work during standard cuttings and in areas with windbreaks

Szewczyk G., Sowa J. M., Grzebieniowski W., Kormanek M., Kulak D., Stańczykiewicz A. (2014). Sequencing of harvester work during standard cuttings and in areas with windbreaks. Silva Fennica vol. 48 no. 4 article id 1159. https://doi.org/10.14214/sf.1159

Highlights

- In standard cutting stands and thinning areas with windbreaks there occurred three-activity operational cycles. In mature stands with windbreaks the occurrence of stable sequences supplemented with five-activity cycles was noted. Consequently, the operational time in post-disaster thinning stands should be increased by 55% whereas in mature stands it should be 30% longer in comparison with standard stands.

Abstract

The aim of the study was to characterize repetitive cycles of harvester operation. The study was conducted in thinning, mature and post-disaster pine stands. The sequences of the activities characteristic of harvester operation were described as time series. In order to detect the cyclic variable structure of the analysed time series, the methodology of the single spectrum Fourier analysis was applied. In standard stands, post-disaster late-thinning stands and mature stands, the existence of stable operational cycles with the length of three activities was discovered while in post-disaster mature stands additional five-activity operational phases were noted. Described in this way, the lengths of the operational cycles of harvesters working in post-disaster areas were higher by about 55% and 30% respectively, as compared to standard thinning and mature stands.

Keywords

time consumption;

time series;

timber harvesting;

harvesters;

post-disaster stands

-

Szewczyk,

University of Agriculture in Krakow, Faculty of Forestry, Institute of Forest Utilization and Forest Technology, Department of Forest and Wood Utilization, Al. 29-Listopada 46, 31-425 Krakow, Poland

E-mail

rlszewcz@cyf-kr.edu.pl

- Sowa, University of Agriculture in Krakow, Faculty of Forestry, Institute of Forest Utilization and Forest Technology, Department of Forest and Wood Utilization, Al. 29-Listopada 46, 31-425 Krakow, Poland E-mail rlsowa@cyf-kr.edu.pl

- Grzebieniowski, University of Agriculture in Krakow, Faculty of Forestry, Institute of Forest Utilization and Forest Technology, Department of Forest and Wood Utilization, Al. 29-Listopada 46, 31-425 Krakow, Poland E-mail wrzoswj@interia.pl

- Kormanek, University of Agriculture in Krakow, Faculty of Forestry, Institute of Forest Utilization and Forest Technology, Department of Forest Work Mechanisation, Al. 29-Listopada 46, 31-425 Krakow, Poland E-mail rlkorma@cyf-kr.edu.pl

- Kulak, University of Agriculture in Krakow, Faculty of Forestry, Institute of Forest Utilization and Forest Technology, Department of Forest and Wood Utilization, Al. 29-Listopada 46, 31-425 Krakow, Poland E-mail rlkulak@cyf-kr.edu.pl

- Stańczykiewicz, University of Agriculture in Krakow, Faculty of Forestry, Institute of Forest Utilization and Forest Technology, Department of Forest and Wood Utilization, Al. 29-Listopada 46, 31-425 Krakow, Poland E-mail rlstancz@cyf-kr.edu.pl

Received 2 April 2014 Accepted 30 September 2014 Published 23 October 2014

Views 159194

Available at https://doi.org/10.14214/sf.1159 | Download PDF

1 Introduction

The application of highly efficient technological systems has been a standard since the early 1990s. The advantages of the mechanized technology of timber harvesting and skidding include primarily high performance and lower unit costs, smaller damage to the environment, improvement of safety conditions (Moskalik 2004; Sowa 2009; Dvořák et al. 2011). Multioperational machines and skidding with the use of forwarders are applied in mature and thinning stands of different age classes not only under easy conditions of timber harvesting in the single-storey and single-species stands of lowland areas but also under mountain conditions and in structurally diverse stands as well as in post-disaster stands (Moskalik and Stampfer 2003; Frutig et al. 2007; Szewczyk and Kulak 2013). Mechanized harvesting technologies are also incorporated in planned cuts in areas previously not available via operational routes, by applying mixed variants including cutting and felling in midfields by means of chain saws or by avoiding straight-line skidding trails. A special research and implementation trend in mechanized timber harvesting technologies concerns adapting harvester cutting heads to operation in deciduous stands (Mederski 2006; Spinelli et al. 2009; Fulvio et al. 2012; Yoshioka et al. 2012; Mederski 2013).

The basic problem concerning assessment of the performance of timber harvesting and skidding lies in their enormous variability, resulting from a large number of diverse and often hardly measurable or totally non-measurable factors, affecting the task performance time. According to Nurek (2007), the variability of performance of the seemingly stable mechanized timber harvesting method in stands of older age classes amounts to approximately 150%. Such a result is associated not only with differences in working conditions but probably also with inaccurate estimation of efficiency, which is determined by two variables: timber volume and bucking. The initial steps of time measurement, i.e. determination of estimation accuracy and the related sample size, are decisive for measurement accuracy. The most accurate time research is carried out on the basis of the working day picture, i.e. observation of all tasks and breaks in the order of their occurrence (Samset 1990; Kärhä et al. 2004; Ovaskainen et al. 2004; Sowa et al. 2007). Such studies last long; hence, as a rule, time consumption is calculated for the operating time; then the appropriate conversion factors are used in order to determine the share of the non-production activity categories in a shift (Backhaus 1990; Sowa et al. 2006; Zečić et al. 2005; Nurminen et al. 2006; Spinelli and Visser 2008). Since the measurements concern such sequences of repetitive tasks and supporting activities that are characteristic of specific worksites, the key issue is to determine the structure of those operational cycles in which the duration and the relative arrangement of activities are characteristic of stand conditions and technologies. Under standard harvesting conditions, harvester operation is characterized by a certain repeatability (Szewczyk 2011) and determination of the time consumption of harvesting a single tree (converted into min/m3) is simple: it consists of measuring the number of steps forming an operational cycle (Danilović et al. 2011; Picchio et al. 2012). The situation is different in post-disaster stands, in which the problem of high variability of the working time structure has been noted (Jakubowski et al. 2005; Szewczyk and Stańczykiewicz 2012). Determination of the time consumption of harvester work under such conditions may be carried out on the basis of an analysis of differences between the structures of operating cycles, by comparing their lengths under standard conditions and conditions after hurricanes. Such a study could constitute the foundation to be used for determination of co-factors that increase the time consumption of mechanized timber harvesting in post-disaster areas, where the standards that are currently in force are general and require verification of the time consumption increase (e.g. currently in Poland the maximum increase amounts to 30% of the time shift).

2 Research aim and scope

The aim of the study was to develop a model which would characterize time consumption in areas with windbreaks, based on the structure of the repetitive cycles of harvester operator work, including activity succession and the average length of the duration of the entire work sequence. Research was conducted in pine stands where management cutting with the character of late thinning was performed (TP), in mature stands (R) and, thirdly, in stands whose age corresponded to that of thinning stands (WL-TP) and mature stands (WL-R) and where windbreaks were being removed. An algorithm was specified in the group of stands with standard treatments performed, in which the operation structure variability should be relatively small, as well as in post-disaster areas, where a significantly higher variablity should be expected.

3 Material and methods

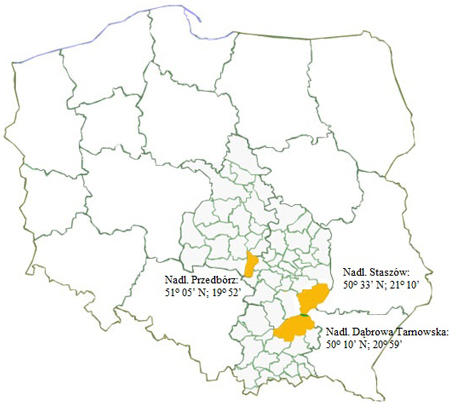

The timber handling areas under research were situated in three Regional Directorates of State Forests in central Poland, in lowland Scots pine forests (Fig. 1). The forest taxation descriptions of the stands where the measurements were performed are presented in Table 1.

Fig. 1. Location of the research areas. The research was conducted in mature stands (Staszów Forest District) and in post-disaster areas (Dąbrowa Tarnowska Forest District and Przedbórz Forest District).

| Table 1. Characteristics of the research areas. View in new window/tab. |

Work measurement was carried out in the years 2007–2013 in standard stands, i.e. thinning and mature ones, and in post-disaster stands (after hurricanes) with the corresponding structure and age. The post-disaster areas in which the measurements were performed, had formed in 2007 due to two hurricanes. In both locations there was large-area damage; in one case, the total amount of wood destroyed was 44 000 m3 while in the other the wind had destroyed approximately 450 000 m3 of wood in an area of over 3600 hectares. Those were the first post-disaster areas in Poland where the removal of the effects of a hurricane was done with the use of mechanized technology applying harvesters and forwarders on a large scale. Even then there appeared a problem of the correct estimation of time consumption of the work. In the fragments of standard stands characterized by full density and by homogeneity with respect to their forest taxation characteristics (diameter at breast height, height, species composition) as well as in those parts of post-disaster stands in which large-area damage with the character of windbreak had occurred, a constant time study of harvester operation was carried out with the working day picture method. Time measurement was recorded using the PSION Workabout microcomputers with the “Timing” software in order to conduct the timings (Szewczyk 2010; Sowa and Szewczyk 2013). The registered duration of the operations was grouped in specific categories adopted in accordance with the IUFRO standards (Björheden 1991) (Table 2). Theoretically, a large measurement database of working time could be obtained using the data from the harvester computer system. The StanForD control and measurement standard has functioned already since the 1980s (Dvořák et al. 2011). However, due to the possible problem of low accuracy of the data obtained in this way, especially considering large variability of the work, it was decided to measure the time manually (Purfürst and Erler 2011). Medium-class harvesters were used in all areas (Jiroušek et al. 2007).

| Table 2. Flow chart presenting the classification of harvester operation times during work in standard areas and in post-disaster stands. Numerical codes referring to the classification applied were used to construct time series. | |||||

| D W t – Direct Work time | Main Work time | M W t | Numerical code of time category | 1,1 | Crane out, positioning, cutting, felling |

| 1,2 | Pulling tree into machine, debranching, cross-cutting | ||||

| Auxiliary Work time | C W t | 2,1 | Travelling time on worksite | ||

| 2,2 | Worksite prepartion time – removing disturbing branches and log fragments hindering access to tree stem being cut | ||||

| 2,4 | Time of log arrangement and timber sorting | ||||

| Unavoidable Delay time | U D t | 2,3 | Technological downtime – breaks due to work organisation, route setting and tree cutting order | ||

Measurements were taken on 10 research plots. During the harvesting and skidding operations, over 4500 trees with a total volume of large timber amounting to over 3700 m3 were removed from the timber handling plots (commercial value timber; in post disaster areas low-quality timber chips were also sold). The measurement basis of the duration of the activities identified covered almost 19 000 cases for all worksites, and continuous measurements were carried out for over 200 hours.

The sequencing of the activities performed while the harvester was working was determined by presenting the measurement data as a time series, i.e. a sequence of observations of a given variable at a fixed time interval (Box and Jenkins 1976). The problem of adapting the time series analysis method to the phenomenon under the present study consisted in the fact that individual cases (the observed activities) did not occur at a fixed interval. In order to convert the time studies of the worksites analysed in the present research into time series, individual observations were coded according to the notation presented in Table 2. Therefore, the occurrence of an activity sequence was treated as a time series in which the names of particular activities, coded as numbers, constituted the observed variable while the succession of activities characteristic of a given worksite (work sequencing) formed the ordering variable.

The resulting time series were subject to strong random fluctuations; therefore, before further analyses, smoothing with the moving average (of equal weights) was performed on them. Time series as opposed to random sampling are characterized by a non-accidental order of observation. This property was used in the present study. The simplest test of the sequencing of certain observations consists in determination of regular fluctuations, i.e. ones with a fixed length (number of observations), known as seasonal variations. In research by Szewczyk (2011), the length of machine operation cycles was determined by adopting such a simplified assumption. However, observations of worksites during timber harvesting and skidding reveal that in the case of high variability of operations it is difficult to indicate the length of stable, repetitive fragments of the working day. In fact, the structure of the succession of time at worksites related to timber harvesting and skidding indicates the presence of several intertwined cycles of different lengths. Determination of the variable cyclic structure of the analysed time series was done using the single Fourier spectrum analysis methodology (Kot et al. 2007; StatSoft Inc. 2009).

4 Results

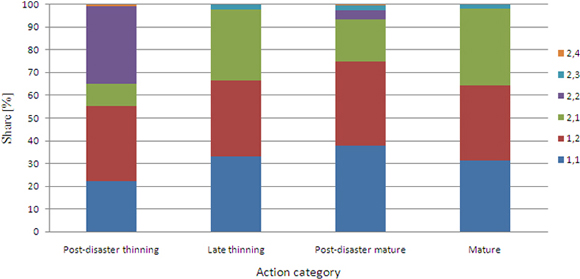

The structure of the harvester operating time in late thinning stands and in areas with windbreaks is presented in Fig. 2.

Fig. 2. Structure of harvester work time in areas of standard utilization and with windbreaks. The activities noted were grouped in respective time categories in accordance with Table 2.

What is noticeable is the share of debranching time in all of the analysed variants. That time accounted for approximately 33–37% of the operating time. Similar shares of the cutting and felling time and of travelling between successive trees were recorded for standard stands. A much larger variety of operations was observed in post-disaster stands. What was characteristic in them was the share of the debranching time, similar in younger and older stands, and a significantly higher share of the cutting time in mature stands (22% as compared to 37%). Perhaps such an image may be associated with difficult working conditions in the first stage of the treatments and the need to perform several cuts on logs which were lying tangled in groups. The share of travelling time, similar in both categories of standard stands, was significantly different on research plots with windbreaks. In post-disaster mature stands, larger thickness and weight of broken trees resulted in the share of travelling that was higher by almost 100% than in standard stands. Worksite preparation occurred only in post-disaster stands and the characteristic feature was a very high share of that time in thinning stands (almost 35%) as compared to mature stands (below 5%).

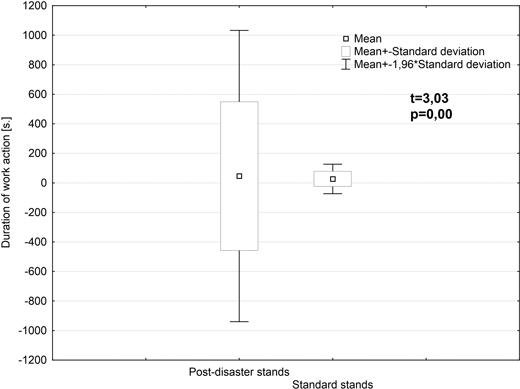

The diversification of duration of each activity was clearly greater in post-disaster areas than standard stands. The significance of the observed differences was confirmed by the results of the t-test (Fig. 3).

Fig. 3. Significance of differences in the duration of harvester work activities in standard stands and those with windbreaks. Larger differentiation of activity duration in post-disaster stands is visible.

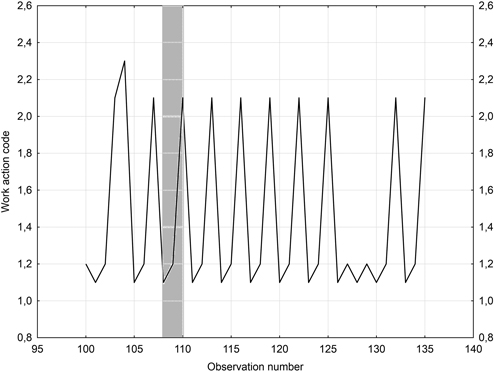

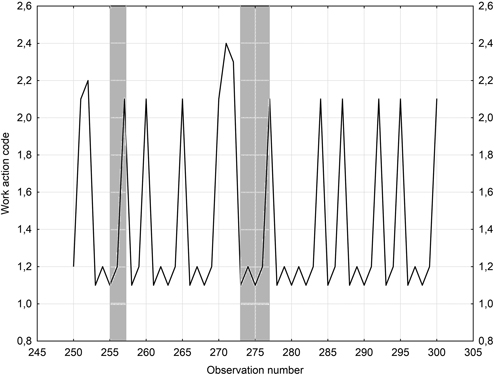

Large variability of work in post-disaster areas was visible in highly dynamic sequencing of the observed activities. Succession of the activities was presented as sequences of the following working times, encoded as numerical values (Table 2). In this way, four time series were formed (TP, R, WL-TP, WL-R), where the sequence of activities was the observed variable (Fig. 4, 5).

Fig. 4. Fragment of a time series of harvester operations – TP (late thinning). The points at which the line is broken indicate the occurrence of a given time category. The cycles described in this paper are marked with grey color.

Fig. 5. Fragment of a time series of harvester operations – WL-R (post-disaster mature). The points at which the line is broken indicate the occurrence of a given time category. The cycles described in this paper are marked with grey color.

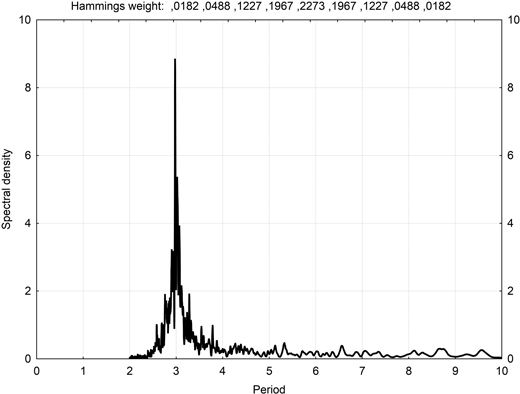

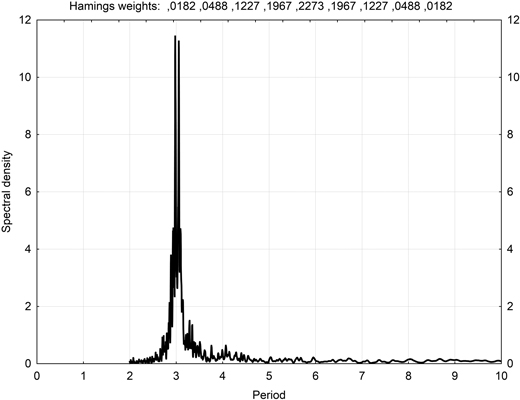

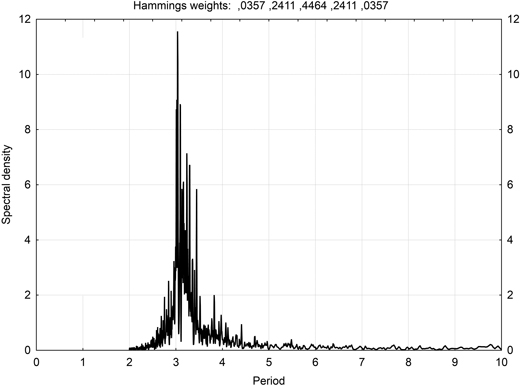

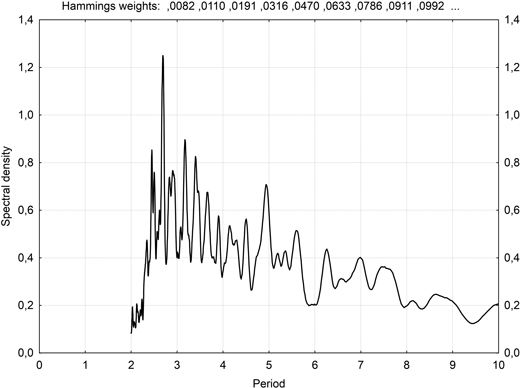

The subsequent observed operations: cutting and felling (1,1), debranching (1,2), travelling (2,2) ..., are arranged in cycles, which were treated as regular fluctuations of a time series. Figs. 6–9 show a graphic analysis of the cyclical nature of the examined time series – fragments of periodograms which precisely determine shorter periods of operational cycles. Since even after smoothing the periodograms showed strong fluctuations, the descriptive data available in the “results” window of the single spectrum Fourier analysis (StatSoft Inc. 2009) were also analysed.

Fig. 6. Fragment of a periodogram of harvester work in late thinning stands (TP). The highest peak of the periodogram shows the strongest operational cycles.

Fig. 7. Fragment of a periodogram of harvester work in mature stands (R). The highest peak of the periodogram shows the strongest operational cycles.

Fig. 8. Fragment of a periodogram of harvester work in stands of the late thinning age class with windbreaks (WL-TP). The highest peak of the periodogram shows the strongest operational cycles. Variation of operation which is slightly larger in comparison with post-disaster stands is visible.

Fig. 9. Fragment of a periodogram of harvester work in stands of the mature age class with windbreaks (WL-R). The highest peak of the periodogram shows the strongest, shortest operational cycles which overlap with longer cycles (the peak for the length of a five-activity cycle).

Harvester work in standard stands and in late-thinning post-disaster stands was performed in stable three-activity cycles (1,1; 1,2; 2,2 – the cycle is highlighted in Fig. 4), as shown by distinct periodogram peaks in Figs. 6–8. In mature post-disaster stands, intertwining cycles of different lengths were noted and the overall variability was generally described by two sequences: a stronger three-activity one and a slightly weaker but clearly visible five-activity one (1,1; 1,2; 2,2 and 1,1; 1,2; 1,1; 1,2; 2,2 – the cycles are indicated in Fig. 5) (Fig. 9).

The presented model of the cyclical nature of harvester operation was used to determine the time consumption of the work in post-disaster areas. The entire database allowed for sampling the lengths of all theoretical three-activity and five-activity cycles on the examined research plots. As the longer cycles were weaker by about 30% in the variant involving mature stands with windbreaks (WL-R), 2/3 of the three-activity operating sequences and 1/3 of the five-activity operating sequences were sampled from the database. The results are summarized in Table 3.

| Table 3. Average duration of a harvester operational cycle in standard stands and in post-disaster areas. | |||||

| Variant, stand | Sample size – number of observations | Number of analysed cycles | Mean duration of work cycle [s] | Difference in relation to standard stands [%] | |

| Name | Symbol | ||||

| Late thinning | TP | 3214 | 957 | 88 | |

| Mature | R | 3132 | 925 | 60 | |

| Post-disaster mature | WL-R | 6761 | 1252 | 113 | +28 |

| Post-disaster thinning | WL-TP | 5639 | 988 | 93 | +55 |

The above data indicate that the duration of a harvester operation cycle in stands with windbreaks is about 30% higher in the class of late-thinning stands and about 50% higher in the class of mature stands in comparison with standard stands. It is by such percentage that the the current standards of the time consumption of harvester operation should be raised in the case of post-disaster stands.

5 Discussion

Damage to forests caused by wind constitutes more than half of all biotic and abiotic damage. Increased dynamism of weather changes, observed in recent years, has caused more and more frequent large-area destruction of forests. Since the 1960s in Europe about 130 episodes of hurricanes of various origins have been noted, and the average annual damage to forests by the year 2000 had amounted to approximately 35 million m3 of wood (Schelhaas et al. 2003). A further increase in the extent of stand damage should be expected, at least until appropriate forest management projects and properly conducted cultivation operations enhance the resistance of forest stands (Schraml 1990). Almost 90% of damage caused by wind is created in the autumn and winter, with a clear dominance of windbreaks and windthrows.

It is a very complex task to design the technological processes in post-disaster areas. This is associated with high concentration of wood, high accident risk and usually a short time of area clean-up (Bort et al. 1990; Brzózko and Kaluga 2010; Schraml 1990). Particularly difficult conditions of timber harvesting occur in areas with windbreaks and windthrows. Because of the great diversity of damage caused by wind, such as tearing of root systems, trunk bending with hardly recognizable stress, trees with gate-like breaks, the observed work efficiency is very differentiated even within stands whose structure is similar.

Research concerning the work, time and actions performed are the basis for understanding and description of technological processes in forestry (Samset 1990; Spinelli and Visser 2008; Sowa and Szewczyk 2013). When analysing the forest work process concerning felling and bucking, where individual operations and activities are very short, a relatively easy but much simplified method of variability analysis is pooled analysis using a synthetic diagram, illustrating the shares of each category of activities in a work shift. Such a research model was adopted in the first analyses within the framework of the present research. Detailed observations of the work must also incorporate determination of activity succession. Only on this basis can optimisation activities be introduced. Analyses based on observations of the sequencing and duration of individual operations are defined as analytical methods (Szewczyk and Sowa 2011; Szewczyk 2011). Such a research model was adopted in subsequent steps within the framework of the present research.

Analyses of the working time structure which apply synthetic diagrams are a standard in all studies analysing the performance of multi-operational machines (Kärhä et al. 2004). Harvester operation in thinning stands is characterized by the dominance of effective activities with respect to auxiliary ones. In stands of older age classes, the share of auxiliary times decreases mainly at the expense of lengthening the debranching time. According to research by Moskalik (2004), in late thinning the ratio of the effective time to the auxiliary time is approximately 35% to 60%, while in mature stands it is approximately 50% to 37%. Similar trends have also been demonstrated by Nurminen et al. (2006), Laitila et al. (2008), Danilović et al. (2011), Picchio et al. (2012). The results obtained in the present study for standard areas are part of the models described for mature stands (M W t = 64%, C W t + U D t = 35%). The trends observed in thinning areas (M W t = 66%, C W t + U D t = 33%) could be related to the age of the analysed stands, which were in the final stage of thinning. The structure of harvester operating time in post-disaster areas is different in comparison with standard stands. According to Mahler and Bort (1990), under such conditions in mature stands the effective working time is prolonged (by about 70%) whereas in the group of auxiliary times the passage between successive worksites is increased by up to approximately 20%. There is also the time of worksite preparation. In the present study, this trend was confirmed entirely: in the variant of mature post-disaster stands, the share of effective working time was 74% while the share of travelling was 19%. Difficult working conditions were reflected by the emergence of the times of: timber arrangement, technological downtime associated with the planning of subsequent operations and preparation of worksites, whose total share in the operating time was 7%. In thinning stands, because of higher stand density, the share of worksite preparation time, associated with the work needed to ensure access to the place of felling cut performance, increased significantly (34%). Greater differentiation of the working time structure in post-disaster areas was derived from the harvester operation technology that was totally different from the one used in standard stands. In the course of their handling, logs that were tight and partly blocked by other trees often required pulling in the vicinity of the machine so as to preserve its stability during debranching. A significant share of travelling was due to the need to reduce the burden on the head because pulling the piled-up logs by means of its rotation could cause damage. Similar remarks on the operation technology in areas with windbreaks may be found in the study by Brzózka and Kaluga (2010).

The analytical method is based on measurements performed with the method of the working day picture or a time study. The starting point of such research is a division of technological operations into individual activities; and the key issue is to determine the level of detail of the time division so that the results obtained characterize the examined variability well. The current trend towards merging the observed operations into larger “operational groups”, present in the German REFA classifications (Organisation 2008), certainly facilitates measurements and their further analysis; however, it complicates the study of the homogeneity of the sample and identification of the causes of the apparent variability. In practice, the European forestry also uses the IUFRO classification (1995), whose starting point were the time divisions proposed by Samset (1990) and the Standard for Forest Data and Communications classifications, used for the mechanized technology level (Skogforsk 2012). The divisions of operating cycles used in research on the work of multi-operational machines generally include several operations: travelling, positioning of the head at the tree which is being cut, cutting and felling, debranching and assortment bucking (Ovaskainen et al. 2004; Kärhä et al. 2004; Jiroušek et al. 2007; Szewczyk 2011; Picchio et al. 2012), divided in respect of time in order to determine the time consumption of each activity (Spinelli et al. 2002).

An issue that is very rarely tested is the key aspect of time studies, namely the sequencing of activities, limiting research to the arbitrary assumption of repetitiveness of machine operating cycles. Research on the work in forestry, taking into account recognition of the sequence of operations, was presented by Palmroth (2011). The use of the Viterbi algorithm made it possible to decode the sequences of hidden states that would most likely be able to produce a sequence of observations. The structure of repetitive activities performed by machine operators, identified in that way, were used to define the operator work systems, i.e. the human factor in the mechanized technology model. In the Markov chain, observations form sequences of events in which the probability of each event depends only on the previous result. While the use of such a methodology for the operation of machinery in the course of standard cuts is justified (as confirmed by the results of the present study in thinning and mature stands), in the case of work in post-disaster stands the large variability of work and the existence of cycles of different lengths seem to determine the need to adopt other solutions. The basis for determining the operating time are time studies, i.e. measurements of repetitive activities. Therefore, determination of the length of the cycles is essential in research related to performance. Previous studies by Szewczyk (2011) on the time consumption of harvester work had assumed the existence of cycles of equal length but the inference accuracy was not sufficient. The characteristics of the cyclical nature of activities revealed by single spectrum Fourier analysis, presented in this study, took into account primarily the occurrence of the strongest sequences but also revealed the existence of other types of variation, the knowledge of which is essential for understanding the overall harmonic structure of the analysed time series. The occurrence of five-activity cycles, noted in the present study in mature stands with windbreaks, was associated with the periodic performance of two shearing kerfs in the initial phase of handling subsequent trees. Such cycles were enforced by a larger volume of trees and by stresses occurring in the wood. The handling of trees with a smaller volume in post-disaster stands in the thinning age class was possible in shorter, three-activity sequences, as in standard stands.

As demonstrated in the present study, the trend towards the occurrence of longer cycles in post-disaster thinning stands, as compared to mature stands, is not in contradiction to the opposite trend observed in other studies. In general, studies use the concept of the time consumption of timber harvesting, which depends not only on time (the length of a cycle) but also on the volume of the harvested timber. The present study describes the length of a repetitive operational cycle. Given the greater unit volume of the trees being handled in mature stands as compared with thinning areas, the time consumption of the activities described should exactly correspond to the models proposed e.g. by Dvořák (2010), in which a higher time consumption is assumed for post-disaster sites in stands of older age classes.

6 Findings and conclusions

The occurrence of significant differences was shown in the structure of the operating time in areas with windbreaks as compared to standard stands. Greater diversification of activities and an increase in the share of auxiliary time was characteristic of areas with windbreaks.

In late-thinning stands, mature stands and thinning areas with windbreaks there occurred three-activity cycles. Mature stands with windbreaks showed the occurrence of strong three-activity sequences supplemented by longer, five-activity cycles. On this basis, it should be assumed that at the stage of preparing the working time standards for post-disaster thinning stands the operating time should be increased by approximately 55%, while in mature stands by about 30%, as compared to standard stands.

The present study allows for optimisation of the performance of time studies. They should be carried out for precisely defined cycles, the description of which, especially in a situation of high variability, is possible on the basis of the presented methodology of analysis of the cyclical nature of time series.

The analyses performed confirmed the correctness of the methodological assumptions concerning the possibility to describe the sequencing of harvester operation with the time series method. The methodology elaborated in the course of the present research constitutes a development of analyses used in econometrics; however, the approach proposed is an innovative solution, unprecedented in research of forestry work.

The approach presented in the paper may also be applied to other worksites as well as different technologies and methods of forest management.

References

Backhaus G. (1990). Die Allgemeinen Zeiten im forstlichen Arbeitsstudium. Forsttechnische Informationen 1: 1–5.

Björheden R. (1991). Basic time concepts for international comparison of time study reports. Journal of Forest Engineering 2: 33–39.

Bort U., Mahler G., Pfeil C. (1990). Sturmholzaufarbeitung mit Kranvollernten. AFZ Wald 25–26: 640–641.

Box G.E.P., Jenkins G.M. (1976). Time series analysis: forecasting and control. San Francisco, Holden-Day. 575 p.

Brzózko J., Kaluga T. (2010). Investigations on technological process of after-calamity site preparation to logging with the harvester. Annals of Warsaw University of Life Sciences – SGGW, Agriculture (Agricultural and Forest Engineering) 56: 79–87.

Danilović M., Tomašević I., Gačić D. (2011). Efficiency of John Deere 1470 ECOIII harvester in poplar plantations. Croatian Journal of Forest Engineering 2: 533–548.

Dvořák J. (2010). Operation time consumption of high-powered harvester in salvage felling. Electronic Journal of Polish Agricultural Universities 4: 1–12.

Dvořák J., Bystrický R., Hošková P., Hrib M., Jarkovská M., Kováč J., Krilek J., Natov P., Natovová L. (2011). The use of harvester technology in production forests. Folia Forestalia Bohemica, Kostelec nad Černými lesy. 156 p.

Frutig F., Fahrni F., Stettler A., Egger A. (2007). Mechanisierte Holzernte in Hanglagen. Wald und Holz 4: 47–52.

Fulvio Di F., Bergström D., Kons K., Nordfjell T. (2012). Productivity and profitability of forest machines in the harvesting of normal and overgrown willow plantations. Croatian Journal of Forest Engineering 1: 25–37.

IUFRO 1995. WP 3.04.02. Forest work study nomenclature. Test edition valid 1995–2000. Department of Operational Efficiency, Swedish University of Agricultural Sciences, Garpenberg. 16 p.

Jakubowski M., Bębenek M., Mederski P. (2005). Struktura czasu pracy pracowników zatrudnionych przy pozyskiwaniu drewna w drzewostanach dotkniętych klęską wiatrołomów i wiatrowałów. In: Giefing D.F., Mederski P. (eds.). Zagadnienia współczesnej ergonomii w sektorach leśnym, drzewnym i rolnym. Polskie towarzystwo Ergonomiczne oddz. Poznański, Katedra Użytkowania Lasu Wydział Leśny, AR Poznań. p. 48–51.

Jiroušek R., Klvač R., Skoupý A. (2007). Productivity and costs of the mechanized cut-to-length wood harvesting system in clear-felling operations. Journal of Forest Science 10: 476–482.

Kärhä K., Rönkkö E., Gumse S. (2004). Productivity and cutting costs of thinning harvesters. International Journal of Forest Engineering 2: 43–56.

Kot M.S., Jakubowski J., Sokołowski A. (2007). Statystyka. Statsoft Polska Sp. z o.o. Warszawa. 520 p.

Laitila J., Ranta T., Asikainen A. (2008). Productivity of stump harvesting for fuel. International Journal of Forest Engineering 2: 37–47.

Mahler G., Bort U. (1990). Kranvollerntereinsatz bei der sturmholzaufarbeitung. AFZ 14–15: 366–368.

Mederski P.S. (2006). A comparison of harvesting productivity and costs in thinning operations with and without midfield. Forest Ecology and Management 224: 286–296. http://dx.doi.org/10.1016/j.foreco.2005.12.042.

Mederski P.S. (2013). Możliwości zastosowania harwestera do pozyskiwania drewna w mieszanych drzewostanach brzozowo-sosnowych. Wydawnictwo Uniwersytetu Przyrodniczego w Poznaniu, Poznań. 109 p.

Moskalik T. (2004). Model maszynowego pozyskiwania drewna w zrównoważonym leśnictwie polskim. Wydawnictwo SGGW, Warszawa. 134 p.

Moskalik T., Stampfer K. (2003). Efektywność pracy harwestera Valmet 911 Snake w warunkach górskich. Sylwan 4: 91–98.

Nurek (2007). Metoda oceny efektywności maszynowego pozyskiwania drewna w warunkach lasów polskich. Wydawnictwo SGGW Warszawa, Warszawa. 116 p.

Nurminen T., Korpunen H., Uusitalo J. (2006). Time consumption analysis of the mechanized cut-to-length harvesting system. Silva Fennica 40(2): 335–363. http://dx.doi.org/10.14214/sf.346.

Organisation in der Forstwirtschaft – mit REFA-Methoden zu effizienten Arbeitsprozessen. (2008). Verband für Arbeitsgestaltung, Betriebsorganisation u. Unternehmensentwicklung. 283 p.

Ovaskainen H., Uusitalo J., Väätäinen K. (2004). Characteristics and significante of a harvester operator’s working technique in thinnings. International Journal of Forest Engineering 2: 67–77.

Palmroth L. (2011). Performance monitoring and operator assistance systems in mobile machines. Tampere University of Technology. 115 p.

Picchio R., Sirna A., Sperandio G., Spina R., Verani S. (2012). Mechanized harvesting of eucalypt coppice for biomass production using high mechanization level. Croatian Journal of Forest Engineering 1: 15–24.

Purfürst F.T., Erler J. (2011). The human influence on productivity in harvester operations. International Journal of Forest Engineering 2: 15–22.

Samset I. (1990). Some observations on time and performance studies in forestry. Meddeleser fra Norsk Institutt for Skogforskning. 80 p.

Schelhaas M., Nabuurs G., Schuck A. (2003). Natural disturbances in the European forests in the 19th and 20th centuries. Global Change Biology 11: 1620–1633. http://dx.doi.org/10.1046/j.1365-2486.2003.00684.x.

Schraml E. (1990). Bewältigung der Schneebruch-katastrophe 1981 in Bayern. AFZ/Der Wald 45: 1168–1169.

Sowa J.M. (2009). Współczesne pożytki z lasu. In: Starzyk R.J. (ed.). Leśnictwo w górach i regionach przemysłowych. Wydawnictwo Uniwersytetu Rolniczego w Krakowie, Kraków. p. 129–152.

Sowa J.M., Leszczyński K., Szewczyk G. (2006). Human energy expenditure in late thinning performed in mountain spruce stands. Acta Scientiarium Polonorum. Silvarum Colendarum Lignaria 1: 73–80.

Sowa J.M., Kulak D., Szewczyk G. (2007). Costs and efficiency of timber harvesting by NIAB 5-15 processor mounted on a farm tractor. Croatian Journal of Forest Engineering 2: 177–184.

Sowa J.M., Szewczyk G. (2013). Time consumption of skidding in mature stands performed by winches powered by farm traktor. Croatian Journal of Forest Engineering 2: 255–265.

Spinelli R., Visser R. (2008). Analyzing and estimating delays in harvester operations. International Journal of Forest Engineering 1: 36–41.

Spinelli R., Owende P.M., Ward S.M. (2002). Productivity and cost of CTL harvesting of Eucalyptus Globulus stands using excavator-based harvesters. Forest Products Journal 1: 67–77.

Spinelli R., Ward S.M., Owende P.M. (2009). A harvest and transport cost model for eucalyptus spp. fast-growing short rotation plantations. Biomass and Bioenergy 33: 1265–1270. http://dx.doi.org/10.1016/j.biombioe.2009.05.010.

Skogforsk (2012). StanForD. http://www.skogforsk.se/en/About-skogforsk/Collaboration-groups/StanForD/. [Cited 19 March 2014].

StatSoft Inc. (2009). STATISTICA (data analysis software system), version 9.0. https://www.statsoft.com/. [Cited 19 March 2014].

Szewczyk G. (2010). Czasochłonność zrywki konnej w drzewostanach trzebieżowych. Sylwan 1: 52–63.

Szewczyk G. (2011). Variability of the harvester operation time in thinning and windblow areas. In: Starzyk R.J. (ed.). Technology and ergonomics in the service of modern forestry. Publishing House of the University of Agriculture in Krakow, Kraków p. 183–196.

Szewczyk G., Kulak D. (2013). Kosztochłonność pozyskania drewna harwesterem w drzewostanach przebudowywanych z zastosowaniem cięć częściowych. Sylwan 4: 243–252.

Szewczyk G., Sowa J.M. (2011). Analiza szeregów czasowych jako narzędzie badania struktury czasu pracy operatorów maszyn leśnych. In: Górska E. (ed.). Współczesne i przyszłe wyzwania ergonomii. Oficyna Wydawnicza PW, Warszawa. p. 384–397.

Szewczyk G., Stańczykiewicz A. (2012). Model szacowania pracochłonności pozyskiwania drewna w drzewostanach ze śniegołomami. Leśne Prace Badawcze 2: 167–173.

Yoshioka T., Sugiura K., Inoue K. (2012). Application of a sugarcane harvester for harvesting of willow trees aimed at short rotation forestry: an experimental case study in Japan. Croatian Journal of Forest Engineering 1: 5–14.

Zečić Ž., Krpan A.P.B., Vukušić S. (2005). Productivity of C Holder 870 F tractor with double drum winch Igland 4002 in thinning beech stands. Croatian Journal of Forest Engineering 2: 49–57.

Total of 47 references