Procurement costs of cereal straw and forest chips for biorefining in South-East Finland

Laitila J., Lehtonen E., Ranta T., Anttila P., Rasi S., Asikainen A. (2016). Procurement costs of cereal straw and forest chips for biorefining in South-East Finland. Silva Fennica vol. 50 no. 5 article id 1689. https://doi.org/10.14214/sf.1689

Highlights

- Procurement cost at the plant was 59 € dry tonne –1 when the annual procurement volume of biomass was 100 000 tonnes. Of that amount, the proportion of logging residues was 58.4%, stumps 24.3% and delimbed stems 17.3%

- Cereal straw represents an important source of biomass in Kouvola but the cost competiveness is poor compared the procurement costs of forest chips due to high baling and transporting costs.

Abstract

In Finland the increasing use of biofuel in transport presupposes a search for new raw material sources for biorefining. The aim of this study was, at the regional level, to compare the procurement costs of logging residues, stumps, delimbed stems and cereal straw for biorefining. The accumulation and procurement costs of forest chips and cereal straw were estimated within a 100-kilometre transporting distance via existing road network from an end-use-facility located in Kouvola in South-East Finland. The analyses were performed as simulated treatments in thinnings of young stands, cereal fields and regeneration fellings using existing productivity and cost functions and yield calculations based on crop statistics, the forest industry stand data and the sample plots data of the National Forest Inventory of Finland. Accumulation of raw material assortments and costs of production stages were defined per dry tonnes. Subsidies and raw material prices were excluded from consideration in the study. The results indicate that recovering logging residues requires lower costs than utilization of stumps, delimbed stems or cereal straw. Cereal straw represents an important source of biomass in Kouvola but the cost competiveness is poor compared the procurement costs of forest chips. When the annual procurement volume of biomass was 50 000 dry tonnes the cost at the plant was 49 € dry tonne –1 and biomass was comprised totally of logging residues. Procurement cost grew to 59 € dry tonne –1 when the annual procurement volume of biomass was doubled to 100 000 dry tonnes. Of that amount, the proportion of logging residues was 58.4%, stumps 24.3% and delimbed stems 17.3%. First cereal straw dry tonnes were delivered to end-use-facility, when procurement cost grew to 60 € dry tonne –1 and annual procurement volume of biomass was 110 000 dry tonnes.

Keywords

supply chains;

stumps;

young stands;

logging residues;

delimbed stems;

agrobiomass

-

Laitila,

Natural Resources Institute Finland (Luke), Bio-based Business and Industry, P.O. Box 68, FI-80101 Joensuu, Finland

E-mail

juha.laitila@luke.fi

- Lehtonen, Natural Resources Institute Finland (Luke), Green Technology, Halolantie 31A, FI-71750 Maaninka, Finland E-mail eeva.lehtonen@luke.fi

- Ranta, Lappeenranta University of Technology, LUT School of Energy Systems, Laboratory of Bioenergy, Lönnrotinkatu 7, FI-50100 Mikkeli, Finland E-mail tapio.ranta@luke.fi

- Anttila, Natural Resources Institute Finland (Luke), Bio-based Business and Industry, P.O. Box 68, FI-80101 Joensuu, Finland E-mail perttu.anttila@luke.fi

- Rasi, Natural Resources Institute Finland (Luke), Bio-based Business and Industry, Survontie 9A, FI-40500 Jyväskylä E-mail saija.rasi@luke.fi

- Asikainen, Natural Resources Institute Finland (Luke), Bio-based Business and Industry, P.O. Box 68, FI-80101 Joensuu, Finland E-mail antti.asikainen@luke.fi

Received 22 August 2016 Accepted 14 November 2016 Published 17 November 2016

Views 198848

Available at https://doi.org/10.14214/sf.1689 | Download PDF

1 Introduction

Several objectives regarding renewable energy and bioenergy have been set both on the national and EU level with the goal of reducing greenhouse gas emissions, use of fossil fuels and dependence on imported fuels (Directive 2009/28/EC 2009; Ministry of Employment and the Economy 2013; Alm 2015). In addition, increased bioenergy is considered to provide employment and regional political benefits (Ahtikoski et al. 2008; Berggren et al. 2008; Simon et al. 2010; Ministry of Employment and the Economy 2013; Alm 2015). As an EU member country, Finland’s binding national target is a 38% share of renewable energy as a proportion of total consumption by 2020 and a 10% share in transportation (Ministry of Employment and the Economy 2013; Alm 2015). Finland has also set its own national target of 20% for transportation (Ministry of Employment and the Economy 2013; Alm 2015).

In Finland the majority of bioenergy is derived from wood and energy use of agro biomasses and municipal waste has been scarce (Alm 2015). The forest resources in Finland have been steadily increasing and this development is predicted to continue (Asikainen et al. 2012; Sokka et al. 2015; Koponen et al.2015). The majority of wood energy use comprises forest industry black liquors, bark, and sawdust and forests chips (Alm 2015). Use of these by-products in energy production is highly dependent on the production structure and volume of the forest industry. Heat and combined heat and power plants (CHP) are the main consumers of solid biomasses (Alm 2015). Manufacturing liquid biofuels in biorefineries for traffic from biomasses is a subject of increasing interest (Ministry of Employment and the Economy 2013; Alm 2015).

In the year 2014, Finnish heating and power plants consumed 18.7 million m³ of solid wood fuels, of which 10.2 million m³ (solid) were forest industry by-products and 7.6 million m³ comprised forest chips (Ylitalo 2015). A majority of the forest industry by-products, which usually are used directly within the plant area in producing heat and power, were bark (7.1 million m³) and sawdust (2.2 million m³). About 49% of forest chips were produced from small-diameter thinning wood produced in the management of young stands and 36% was produced from logging residue from final fellings (Ylitalo 2015). The share of the stump and root wood was 11%, while 6% of forest chips were produced from large-sized timber unsuitable for processes of forest industries (Ylitalo 2015).

The total consumption of wood-based fuels (black liquor, solid wood fuels and firewood) in renewable energy production accounted for 78% in 2014 (Alm 2015). Consumption of solid wood fuels in heating and power plants accounted solely for 30.6% of the total renewable energy (Alm 2015). Consumption of hydroelectric power accounted for 11%, wind power 1% and consumption of other renewable energy sources 10% (Alm 2015). The group of other energy sources comprises the share of energy produced by heat pumps, recovered fuels, biogas and other biofuels in energy consumption (Alm 2015).

In Finland, the balance of the demand and supply of wood fuels varies greatly by region, which increases transportation costs. The southern and coastal areas have a higher population, which leads to a situation wherein their potential is insufficient for covering the high demand for wood energy (Ranta et al. 2012; Anttila et al. 2014). Increasing the targeted biofuel use presupposes finding new logistical supply solutions, but also new raw material sources. In biorefining manufacturing liquid biofuels or gaseous biofuels the available forest chip feedstock combines challenging properties such as great diversity in shape, bulkiness, small-piece size, and scattered occurrence with low relative value, heterogeneity and, often, contaminations increasing ash content, tear, wear, and damage to equipment and machines (Spinelli et al. 2011; Routa et al. 2013; Cambero et al. 2015). Production of agro biomasses for non-food purposes has been criticized as this has been seen competing with food and feed, but field crop residues unsuitable for food or fodder are considered as raw material for bioenergy (von Weymarn 2007; Pahkala and Lötjönen 2012). Estimates of straw availability must take into account its primary uses in agriculture for soil fertilization, animal husbandry and carbon improvers in the soil (Scarlat et al. 2010; Rozakis et al. 2013).

The cost competitive use of cereal straw as fuel is more difficult than those other domestic biomasses and thus it has been a marginal feedstock in Finnish renewable energy production (Ministry of Employment and the Economy 2013; Alm 2015). This is due to the low density of energy, and the high ash, chlorine and alkali metals contents of straw, as well as also the melting properties of ash (Ahokas et al. 1983; Alakangas 2000). Feeding conveyers at bioenergy plants are designed for much more energy-dense fuels, which also hampers the use of agro biomasses (Lindh et al. 2009; Korpinen et al. 2015). The low density of matter and shape of round bales decrease payload and increases truck transportation costs (Lindh et al. 2009; Pahkala and Lötjönen 2012; Lötjönen and Paappanen 2013). From the supply logistic point of view, cereal straw is a challenging feedstock because supply and demand is diachronic, the harvest season in autumn is short and weather-sensitive and dry material losses during storing due to rewetting or mildewing are common (Paappanen et al. 2011; Pahkala and Lötjönen 2012; Korpinen et al. 2015).

In spite of the bad experiences in combined heat and power production (CHP) and heating, cereal straw represents an interesting potential source for biorefining in southern and coastal areas of Finland (Korpinen et al. 2015), where forest industry by-products and harvesting residues from silvicultural and logging operations (cascading flows of wood) can be considered to be highly utilized in renewable energy production (Ranta et al. 2012; Anttila et al. 2014). In contrast, in the eastern and northern parts of Finland the animal bedding demand exceeds the technical harvesting potential of cereal straw (Korpinen et al. 2015). It was found that the technical harvesting potential of cereal straw was 1.0 million dry tonnes per year in the whole country (Korpinen et al. 2015). When the animal bedding demand (0.4 million dry tonnes per year ) was taken into account was the techno-economic harvesting potential for energy or biorefining purposes thus 0.6 million dry tonnes per year (Korpinen et al. 2015).

Different wood species and biomass assortments have different characteristics that impact the economics in biorefining manufacturing liquid biofuels or gaseous biofuels (Demirbas 2001; McKendry 2002). The selection of conversion process and technologies is determined by the type and quantity of available biomass, and the desired form of fuel. Biochemical processes, such as ethanol production through hydrolysis and fermentation, and thermochemical processes, such as pyrolysis and gasification are the most suitable ones to convert biomass into liquid biofuels (Demirbas 2001; McKendry 2002; Cambero et al. 2015). Biogas is produced by micro-organisms from biodegradable organic material under anaerobic conditions and the main components of biogas are methane and carbon dioxide (Höhn et al. 2014). There are several optional techniques available for refining biogas to biomethane (Starr et al. 2012). In addition to its use as traffic fuel, biomethane gas can also be used in heat and power production (Höhn et al. 2014).

1.1 Aim and implementation of the study

The aim of this study was, at a regional level, to compare the procurement costs of logging residues, stumps, cereal straw and delimbed stems from young stands for biorefining. The results allow information for more detailed further planning, feasibility evaluation and strategic decision making of biomass resource utilization. The harvesting methods and supply chains factored into the cost comparison were selected in order to ensure homogenous and impurity-free wood material for the biorefining process. For example, trees from young stands were harvested as delimbed offering stem wood stock devoid of needles and branches (Laitila 2012; Laitila and Väätäinen 2012; Laitila and Väätäinen 2013). The dislocation of mineral soil impurities was guaranteed with the integrated sieving and pre-grinding of stumps (Laitila and Nuutinen 2015).

The accumulation and procurement costs of forest chips and cereal straw were estimated within a 100-kilometer transporting distance via existing road network from the end-use-facility located in Kouvola in South-East Finland. Kouvola is located in a region where there is abundant availability of cereal straw and forest chips is great and solid wood fuels can be considered to be highly utilized in renewable energy production (Ranta et al. 2007; Ranta et al. 2012; Anttila et al. 2014; Korpinen et al. 2015). The analyses were performed as simulated treatments in cereal fields, clear cuts and thinnings of young stands, using existing productivity and cost functions, statistics and yield calculations based on the crop statistics, the forest industry stand data and the sample plots data of the National Forest Inventory of Finland (Höhn et al. 2014; Laitila et al. 2015).

Accumulation of raw material assortments and costs of production stages were defined per dry tonne, not per megawatt hour (MWh), because energy use of forest and cereal straw biomass were excluded to the study. In this study, the comparison of the alternative raw materials started with organizing the procurement activities; continued onto the logging or baling, transportation, comminution and ended with delivery of the biomass to the end-user. Subsidies and raw material prices were excluded from consideration in the study because reliable price statistics are not available for all assortments and subsidies change often. It was assumed that forest and straw biomass from the procurement area was freely available without competition with other end-user groups.

2 Material and methods

2.1 Estimation of the technical harvesting potential of forest and straw biomass

The estimated accumulation of delimbed stems from young forests around the city of Kouvola (60°52´N, 26°42´E) was based on sample plot data from the 9th Finnish National Forest Inventory (NFI), and satellite images and other auxiliary data were used to down-scale the data from the Forestry-Centre level to the municipality level (Tomppo et al. 1998). This existing stand data (Laitila et al. 2015) was evaluated to be valid to use in procurement cost calculations, since major changes in the composition of young stands were not predicted.

The bucking and bolt volume of the delimbed stems was calculated as a function of tree species, as were the average height (m) and diameter (cm) of trees in the NFI sample plot. For the usable stem part, the minimum top diameter was 4 cm and the length 3–5 metres (Laitila et al. 2015). The bucking simulation and volume calculation for the NFI sample plots were done using the Excel-based ComBio-programme (Pasanen et al. 2014). The minimum accumulation of delimbed stems was 25 m3 or more per hectare (Laitila et al. 2015). The basic stand data is collected in Table 1. The forwarding distances of delimbed stems varied between 100 and 350 metres (mean 219 m) (Laitila et al. 2015).

| Table 1. The basic stand data estimates for delimbed stems, stumps and logging residues around Kouvola. The abbreviation SD = standard deviation. | |

| Kouvola | |

| Average volume of delimbed stems harvested, dm3 | 28 (SD 12) |

| Average removal, number of delimbed stems per hectare | 1721 (SD 244) |

| Average removal, m3 of delimbed stems harvested per hectare | 48 (SD 20) |

| Average forwarding distance of delimbed stems, m | 219 (SD 37) |

| Average volume of stumps harvested, dm3 | 140 (SD 40) |

| Average diameter of stumps harvested, cm | 34 (SD 4) |

| Average removal, number of stumps per hectare | 444 (SD 203) |

| Average removal, m3 of stumps harvested per hectare | 62 (SD 26) |

| Average forwarding distance of stumps, m | 259 (SD 173) |

| Average removal, m3 of logging residues harvested per hectare | 64 (SD 41) |

| Average forwarding distance of logging residues, m | 261 (SD 172) |

The supply potential calculations of stumps and logging residues were based on an UPM Forestdatabase of regeneration fellings from the year 2002 (cf. Laitila et al. 2015). The stand data included position data and attribute data of stands, such as felled roundwood volumes by tree species, felling time of the year, forwarding distance (m), average stem volume (m3), and felling area (ha). Regeneration felling data consisted of all clear and seed wood felling stands harvested in private and company forests by UPM timber sourcing in 2002.

The stump and root wood volumes (m3) at the stands were estimated to be 28% of the felled Norway spruce (Picea abies) and Scots pine (Pinus sylvestris) industrial roundwood volumes, and the recovery rate of conifer stumps was 95% (Laitila et al. 2008a). The estimation of the average breast height diameter at the stand was based on the average stem volume of industrial roundwood and the taper curve models of Laasasenaho (1982), and the average breast height diameter was further converted to stump diameter by the coefficient 1.33 (Hakkila 1976).

Stump volume for procurement cost calculations was determined from stump diameter using stump mass models from Hakkila (1976) and basic densities (kg m–3) of stump wood (Hakkila 1975). Stump volume was further increased by a coefficient of 1.17, since Hakkila’s mass model excluded roots with a diameter of less than 5 cm. The coefficient used is based on operational observations of the stump wood yield from harvested stands (Hakkila 2004).

The amount of logging residues (branches, tops and offcuts) at the stand was estimated from felled industrial roundwood volumes (m3). For Norway spruce, Scots pine and broadleaved trees (Betula pendula, Betula pubescens and Populus tremula) the biomass expansion factors were 44%, 21% and 21%, respectively (Asikainen et al. 2001; Ranta 2002). The volume of extractable logging residues was then estimated by converting the available amount with the value of 70% (Asikainen et al. 2001).

Some of the regeneration felling stands were restricted from further calculations based on stand selection criteria. For stumps and logging residues these minimum stand selection criteria for further calculations were:

• Removal of stumps and logging residues at the stand is ≥ 40 m3

• The volume of spruce roundwood at the stump harvesting stand is ≥ 55%.

The total number of regeneration felling stands was 1562 (2921 hectares). After selection, the number of stump and logging residue harvesting stands was 560 (1395 hectares) and 987 (2268 hectares), respectively. The basic stand data is collected in Table 1. The variation in the forwarding distances was 30–950 metres for stump harvesting stands (mean 259 m) and for logging residue stands 30–999 metres (mean 261 m). The solid volumes of stumps, logging residues and delimbed stems were converted to dry masses according to basic densities (360–490 kg m–3) of Hakkila (1975, 1978) by tree species.

The estimation of straw potential from cereal cultivation was based on the study by Höhn et al. (2014). Small cereal fields having a straw potential ≤ 11.5 dry tonne were restricted from the technical harvesting potential and procurement cost calculations. In the study by Höhn et al. (2014) it was estimated that the available cereal straw was 3 dry tonnes per hectare. High harvesting losses of cereal straw can occur if the stubble height adjustment is set too high (von Weymarn 2007). Typically, farmers are unwilling to decrease the height adjustment because they are afraid of stones and rough ground that could damage the combine harvester.

The radius of the procurement area via the existing road network was 100 kilometres in Kouvola, and distances from stands and fields to the biorefinery location were calculated using a GIS application (e.g. Ranta 2002). The transportation distances of stumps from stands to the CHP plant varied from 6 to 100 kilometres around Kouvola (mean 70 km). The corresponding transportation distances were 6–100 kilometres for delimbed stems (mean 71 km), 5–100 kilometres for logging residues (mean 69 km) and 3–100 kilometres for cereal straw (mean 61 km). It was assumed that all forest and agro biomass from the procurement area was freely available.

2.2 Productivity and cost parameters of the procurement system

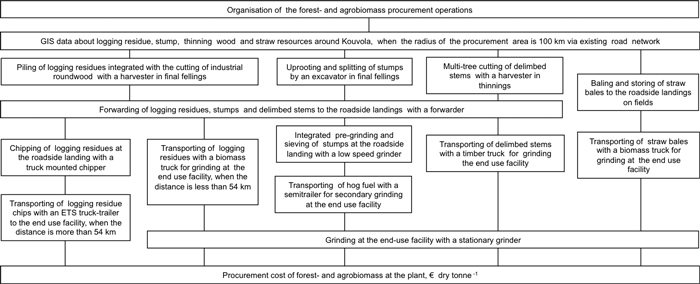

The production stages of the supply chains in this study are demonstrated in Fig. 1. Costs of production stages were first defined per solid volume (€ m–3) or round bale (€ bale–1), and in final summing the costs were converted to dry masses (€ dry tonne –1). In the procurement cost calculations the moisture content of 40% was used for delimbed stems, 31% for stumps, 15% for cereal straw and 53% for logging residues (Nuutinen et. al 2014; Höhn et al. 2014; Laitila et al. 2015). The solid volumes of wood biomass were converted to dry masses according to basic densities (kg m–3) of Hakkila (1975, 1978) by tree species. The organization cost, 2.5 € m–³, which corresponds to the average organization cost of industrial roundwood procurement in Finland (Strandström 2014), was set as constant for all raw materials and supply chains in this study.

Fig. 1. The supply chains of this study by the main work stages. View larger in new window/tab.

Cereal straws were baled with a fixed chamber round baler and bales were carried to a storage pile with a farm tractor equipped with a front loader (Fig. 1). The width and diameter of the round bales were 122 cm by 125 cm, and the volume was 1.5 m3. The dry matter densities of round bales (128.4 kg m–3) were calculated based on the model of Lötjönen and Paappanen (2013) and the dry mass of the round bale was 192.3 kg. The baling (8.44 € bale–1) and haulage (2.1 € bale–1) costs were based on actual cost (excluding a value-added tax, VAT 0%) and were obtained from the recent statics of the TTS Institute (Palva 2015).

The hourly costs (Table 2) for logging, transporting and comminuting machinery of forest biomass were obtained from the studies of Laitila et al. (2015) and Laitila et al. (2016). It was assumed that a conventional harvester-forwarder chain was used in logging operations in early thinning, and harvesting stumps from clear cuts was based on the excavator-forwarder chain (Fig. 1). In the harvesting of logging residues the piling of tops and branches was integrated into the cutting of round wood by changing the working method in order to allow logging residues to pile up along the strip road. The cost of piling logging residues was estimated to be 0.5 € m–3 based on interviews with professionals. The cutting method is adapted so that logging residues are piled during timber processing and only the residues needed to improve the soil bearing capacity are left on the strip roads. Forwarding of logging residues to the roadside landing was carried out with a forwarder (Fig. 1).

| Table 2. The hourly costs for logging, transporting and comminuting machinery (VAT 0%). | |

| Hourly cost, € | |

| Harvester for cutting delimbed stems | 102.3 |

| Forwarder for forwarding logging residues, stumps and delimbed stems | 81.0 |

| Excavator for lifting and splitting stumps | 80.2 |

| Truck-mounted chipper for chipping logging residues at roadside landings | 213.8 |

| Low-speed grinder for pre-grinding stumps at roadside landings | 185.2 |

| Stationary grinder for grinding forest and agro biomass at the end-use facility | 140.3 |

| Timber truck for transporting delimbed stems | 72.0 |

| Biomass truck for transporting straw bales and loose logging residues | 66.0 |

| Semitrailer unit for transporting pre-ground stumps | 58.0 |

| Truck-trailer unit for transporting logging residue chips | 79.8 |

The delimbed stems were transported to the end-use facility using a conventional timber truck, and comminuted with a stationary grinder (Fig. 1). Stumps were sieved and pre-ground at the landing (Laitila and Nuutinen 2015) and transported with semitrailer to final comminution at the end-use facility. The aim of the integrated sieving and pre-grinding was to decrease the mineral contaminant content of the stump wood and increase payload. Straw bales were transported with a biomass truck for comminution at the end-use facility. For logging residues (cf. Fig. 4), there were two options: 1) Transporting loose logging residues with a biomass truck for comminution at the end-use facility, when the on-road transportation distance is less than 54 km or 2) chipping to an acceptable fraction at the roadside landing, when the on-road transportation distance is more than 54 km (Fig. 1).

The productivity of cutting delimbed stems using the multi-tree processing technique was based on the study of Laitila and Väätäinen (2013). The stump extraction was modelled with a crawler excavator equipped with an extraction device (Laitila et al. 2008b). Forwarding productivity with delimbed stems was calculated by means of the model of Kuitto et al. (1994), and the forwarding productivity for logging residues and split stumps were obtained from studies by Asikainen et al. (2001) and Laitila (2010). The payloads (Table 2) were set in line with the work of Laitila et al. (2010). The gross effective time (E15h) coefficients (Table 3) for cutting, forwarding, and stump extraction were based on research by Jylhä et al. (2010), Laitila et al. (2010) and Laitila et al. (2015). The total length of the strip road network at the thinning and regeneration stands were assumed to be 600 m ha–1, based on an average strip road spacing of 20 m (Niemistö 1992). At stump harvesting sites, the strip road network was assumed to be 450 m ha–1 due to pre-piling of stumps during stump extraction (Laitila 2010).

| Table 3. The productivity parameters for the forest biomass supply chains (Fig. 1). | |||

| Stumps | Logging residues | Delimbed stems | |

| Gross effective time (E15h) coefficient for E0h productivity of cutting/uprooting | 1.4 | - | 1.3 |

| Payload of the forwarder, m³ | 8.6 | 7.8 | 9.0 |

| Gross effective time (E15h) coefficient for E0h productivity of forwarding | 1.2 | 1.2 | 1.3 |

| Payload in transport by road, m³ | 25 | 25 or 38.0–49.9 | 67 |

| Loading time in transport by road, minutes | 44 | 62 or 68.1–81.7 | 50 |

| Unloading time in transport by road, minutes | 27 | 60 or 30 | 37 |

| Grinding productivity at the end-use facility with the stationary grinder, loose-m3 E15h–1 | 270 | 270 | 180 |

The delimbed stems were transported to the plant using a conventional timber truck with a trailer (e.g. Laitila et al. 2009; Laitila and Väätäinen 2012), assuming a payload of 67 m³ (Table 2), which corresponds to a novel truck-trailer unit having a legal maximum weight of 76-tonne (Anttila et al. 2012; Laitila et al. 2015) and 24-tonne empty weight. The pre-ground stump wood was transported from the roadside landing to the end-use facility using a semitrailer with a load space of 95 m3. The payload of the pre-ground stump wood was 25 m3 (Laitila and Nuutinen 2015). Straw bales and loose logging residues were transported to the end-use facility using a biomass truck-trailer unit with a 150 m3 load space. The payload was 25 m3 of logging residues (Ranta and Rinne 2006) or 60 round bales (Lindth et al. 2009). Logging residue chips produced at the roadside landings were transported with a 69-tonne modern truck-trailer (Laitila et al. 2016) equipped with steering axles at the rear end of the trailer (ETS). The truck-trailer unit had a 157.4 m3 load space and 27-tonne empty weight. With logging residue chips the payload was restricted by the load carrying capacity of the truck-trailer (Laitila et al. 2016). The permissible payload varied from 38.0 to 49.9 m3 (Table 3) and it was calculated for each stand as a function of basic densities of tree species (Hakkila 1978), moisture content (53%) and solid content percentage (40%) of wood chips. The time consumption of driving, with full load and empty load, was calculated as a function of on-road transportation distance, according to the speed functions of Nurminen and Heinonen (2007).

The loading time for pre-ground stumps (Table 3) is linked to grinder productivity. When using the low-speed grinder, the loading time was estimated be 44 minutes per load (Laitila and Nuutinen 2015). The unloading time of pre-ground stumps to the stationary grinder of the plant was 27 minutes per semitrailer load (Table 3). The loading time of delimbed stems (Table 3) was estimated to be 50 minutes at the roadside landing, and the unloading time (Table 3) to the delivery hopper of the stationary grinder was 37 minutes per load (Laitila et al. 2009; Laitila and Väätäinen 2012). For loose logging residues and straw bales (Table 3), the loading time at the roadside landing was 62 minutes, and the unloading time to the stationary grinder was 60 minutes per load (Ranta and Rinne 2006; Kärhä et al. 2011a). When transporting logging residue chips (Table 3), the chipper’s productivity was 52.8 m3 E0h–1 (Föhr et al. 2010; Kärhä et al. 2011b). In addition, a fixed value of 25 minutes was assumed for the indirect loading time of truck-trailers, which is the time required for manoeuvring trucks and trailers during loading at a roadside landing, for example (Windisch et al. 2015).

The pre-grinding cost of stumps and chipping cost of logging residues were 5.4 € m–3 and 5.99 € m–3, with corresponding hourly costs of 185.2 € E15h–1 and 213.8 € E15h–1 for the low-speed grinder and truck-mounted chipper (Table 2).The grinding productivity of delimbed stems at the end-use facility with the stationary grinder was estimated to be 180 loose-m3 E15h–1 and with logging residues and pre-ground stumps 270 loose-m3 E15h–1 (Kärhä et al. 2011a). The solid percentage of acceptable fuel fraction was estimated to be 28% (Nuutinen et al. 2014), which means that the grinding costs were 2.8 € m–3 for delimbed stems, and 1.9 € m–3 for logging residues and pre-ground stumps, when the operating-hour cost of the stationary grinder was 140.3 € E15h–1 (Laitila et al. 2015). The grinding cost of straw bales, expressed as € per dry tonne, was expected to be equivalent to the average grinding cost of pre-ground stumps (Table 3) based on interviews with professionals.

3 Results

3.1 Technical harvesting potential forest and cereal straw biomass

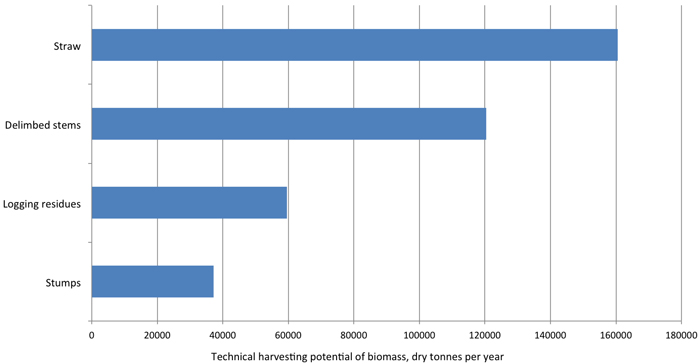

The availability analysis verified that, within 100 km transporting distance from Kouvola, the technical harvesting potential of forest and cereal straw biomass was total 377 582 dry tonnes per year (Fig. 2). The percentage of cereal straw was 43% of the total biomass potential in this case-study. The portion of delimbed stems, logging residues and stumps were 32%, 16% and 10%, respectively (Fig. 2).

Fig. 2. The technical harvesting potential of forest and cereal straw biomass around the city of Kouvola, within 100 km transporting distance via the existing road network. View larger in new window/tab.

3.2 Cost structure of forest and straw biomass

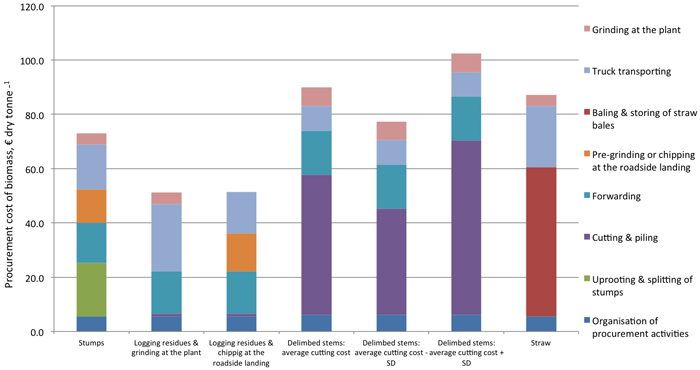

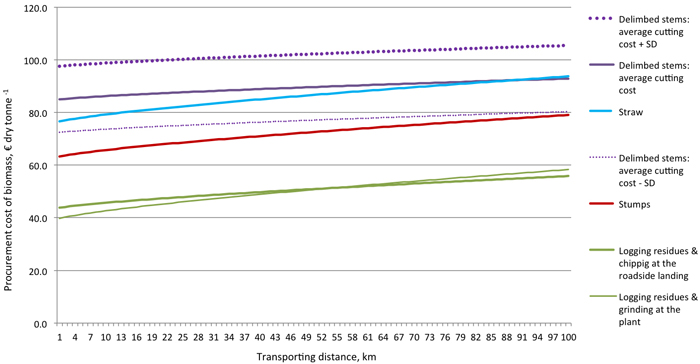

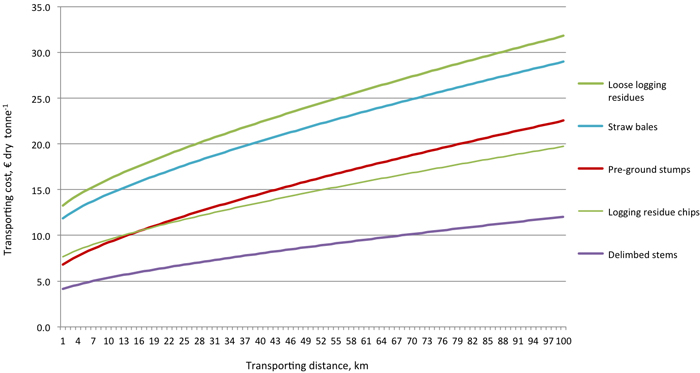

The procurement cost of forest and cereal straw biomass at the stand level varied from 51.30 to 102.45 € dry tonne –1, depending on the supply chain and raw material used (Fig. 3), when the on-road transportation distance was 54 km and the calculations were based on average cost values of work phases around Kouvola (Table 3). The results indicate that recovering logging residues requires lower costs than utilization of stumps, delimbed stems or cereal straw (Fig. 3 and 4). The difference in the production costs is mainly caused by the cost of cutting of delimbed stems, uprooting of stumps and baling of cereal straw. The piling of branches and tops alongside strip roads is integrated with roundwood cutting, which reduces cost compared to the separate work stage. The on-road transportation distance of 54 km was the break-even point for the supply chains based on chipping logging residues at the roadside landing or grinding at the plant (Fig. 3 and 4). In Fig. 4 the procurement cost comparisons of the supply chains and raw materials were calculated as a function of the on-road transportation distance (1–100 km) and the cost parameters were similar to Fig. 3.

Fig. 3. The procurement cost structure of the supply chains and raw materials of this study. The on-road transportation distance is 54 km and the costs of work phases are based on average values. View larger in new window/tab.

Fig. 4. The procurement cost of the supply chains and raw materials of this study as a function of transportation distance and average costs. View larger in new window/tab.

Stumps had the second lowest procurement costs in the cost comparison (Fig. 3 and 4). In stump harvesting the volume of harvested stumps was considerably bigger compared to stems from young forests (Table 1), which improved productivity and reduced costs (Table 4). Furthermore, in clearcut areas the protecting of standing trees did not limit the productivity of stump harvesting and the operating hour costs of an excavator-based stump harvester were also somewhat lower compared to those of a conventional timber harvester (Table 2). The average procurement cost of delimbed stems and cereal straw were at the same level, when the on-road transportation distance was 54 km (Fig. 3). Baling and transporting straw bales to storage was the largest cost component in the cereal straw supply chain (Fig. 3, Table 4).

| Table 4. Average cost values for harvesting forest and cereal straw biomass in the procurement area of Kouvola. The abbreviation SD = standard deviation. | ||||

| Stumps | Logging residues | Delimbed stems | Straw | |

| Average cost of uprooting stumps, cutting & piling of logging residues and delimbed stems or baling of straw: € dry tonne –1 | 19.58 | 1.10 | 51.66 | 43.90 |

| SD | 2.44 | 0.04 | 12.56 | - |

| Min | 15.17 | 1.00 | 24.72 | - |

| Max | 39.08 | 1.23 | 98.93 | - |

| Average cost of off-road transporting: € dry tonne –1 | 14.78 | 15.54 | 16.20 | 8.75 |

| SD | 3.11 | 3.92 | 1.75 | - |

| Min | 10.43 | 9.49 | 10.76 | - |

| Max | 27.18 | 38.02 | 20.88 | - |

| Average cost of on-road transporting: € dry tonne –1 | 18.60 | 17.73 | 10.09 | 23.39 |

| SD | 3.36 | 2.21 | 2.08 | 3.93 |

| Min | 8.30 | 13.52 | 4.06 | 12.69 |

| Max | 22.8 | 25.92 | 13.85 | 29.05 |

| Average cost of comminuting: € dry tonne –1 | 16.50 | 11.33 | 6.84 | 4.21 |

| SD | 0.18 | 3.14 | 0.58 | - |

| Min | 16.00 | 5.58 | 5.68 | - |

| Max | 16.70 | 14.74 | 7.73 | - |

| Average cost of organization: € dry tonne –1 | 5.67 | 5.51 | 6.15 | 5.67 |

| SD | 0.06 | 0.18 | 0.52 | - |

| Min | 5.52 | 5.01 | 5.10 | - |

| Max | 5.75 | 6.16 | 6.94 | - |

Cutting was the largest cost component in the delimbed stems supply chain (Fig. 3, Table 4), and stem volume is the factor explaining cost-efficiency. Profitable thinning wood harvesting comes about through having a large enough stem volume. In young forests there was a great variation in stem volume (Table 1) and the lowest and highest cutting costs were 24.72 and 98.93 € dry tonne –1 (Table 3). The average cutting cost of delimbed stems was 51.66 € dry tonne –1 and standard deviation (SD) was 12.56 (Table 3). Within the standard deviation, the cutting costs of delimbed stems were in the range of 39.10–64.21 € dry tonne –1 and procurement costs in the range of 89.90–102.45 € dry tonne –1, respectively (Fig. 3).

Forwarding costs of stumps, logging residues and delimbed stems were at the same level (Fig. 3, Table 4). The two-phase stump grinding (Fig. 3) increased the comminuting costs of stumps and the average total cost was 16.50 € dry tonne –1 (Table 4). Chipping cost of logging residues at the roadside landing was 14.00 € dry tonne –1 and grinding cost at the plant was 4.35 € dry tonne –1 (Fig. 3). The average comminuting cost of logging residues was 11.33 € dry tonne –1 in the procurement area of Kouvola (Table 4).The average grinding costs of delimbed stems and straw bales at the plant were 6.84 and 4.21 € dry tonne –1 (Fig. 3 and Table 4), respectively. The organization cost (2.5 € m–³), was a constant for all raw materials and supply chains in this study but due to variation of basic densities of tree species and raw materials the average organization cost varied from 5.51–6.15 € dry tonne –1 (Fig. 3 and Table 4).

Due to small payload and long loading and unloading time the on-road transportation costs of loose logging residues and straw bales were the highest (Fig. 5). These two assortments and pre-ground stumps were also the most cost sensitive to changes in transportation distance. Pre-ground stumps are transported with the semitrailer having a smaller payload compared to a timber truck or chip truck (Table 3), which increases transportation costs (Fig. 5). With loose logging residues the low grinding costs at the plant compensate for the high on-road transportation costs and the supply chain is cost competitive up to a transportation distance of 54 km (Fig. 4). For that longer distance chipping at the roadside landing and transporting logging residues as chips is a feasible choice (Fig. 4). A large payload and efficient loading and unloading enables cost-efficient transportation of delimbed stems (Fig. 5) and compensates for the high cutting cost of delimbed stems in comparison with other raw materials. Compared to straw bales, loose logging residues and stumps the procurement costs of delimbed stems raise more slowly when the radius of the procurement area and transportation distance increases (Fig. 4).

Fig. 5. The transportation costs of raw materials of this study as a function of transportation distance. View larger in new window/tab.

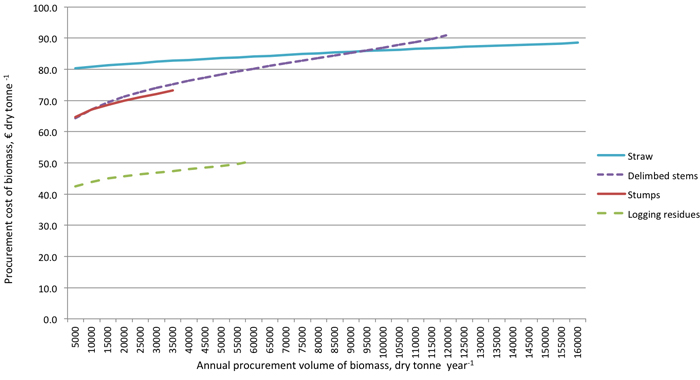

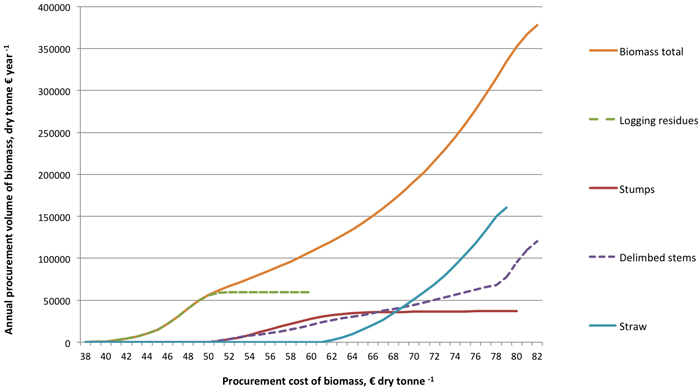

3.3 Procurement cost of forest and straw biomass

The harvesting costs at the sample plots of NFI, regeneration fellings and fields were calculated using the productivity models and cost parameters described above. The on-road transportation costs were calculated as a function of transportation distances from stands and fields in the procurement area to Kouvola. The stand- and fieldwise procurement costs of biomasses at the Kouvola plant were calculated totalling the costs of all work phases. The accumulation and procurement cost data of biomass assortments were summarized, and data was sorted according to the procurement costs (Fig. 6 and 7). The annual cumulative accumulation of each biomass assortment (Fig. 6) and total biomass (Fig. 7) at marginal procurement cost were calculated, and the cost at plant was expressed as euros per dry tonne (€ dry tonne –1).

Fig. 6. The procurement cost of forest and agro biomass assortments as a function of annual procurement volume (dry tonne year–1) around Kouvola. View larger in new window/tab.

Fig. 7. The annual procurement volume of biomass around Kouvola as a function of procurement cost (€ dry tonne –1). View larger in new window/tab.

Logging residues had the lowest procurement costs to Kouvola (Fig. 6 and 7). The cost at the plant varied in range of 42.46–50.60 € dry tonne –1 as a function of annual procurement volume of logging residue biomass (Fig. 6). Stumps had the second lowest procurement costs and the cost at the plant varied in range of 64.69–73.31 € dry tonne –1 (Fig. 6). Due to cutting costs, delimbed stems had the greatest variation in the procurement costs. The costs at the plant varied in range of 64.28–91.04 € dry tonne –1 as a function of annual procurement volume of delimbed stems (Fig. 6). Cereal straw had the highest procurement costs and it varied in range of 80.32–88.49 € dry tonne –1 at the plant (Fig. 6).

When the annual procurement volume of biomass was 50 000 dry tonnes the cost at the plant was 49 € dry tonne –1 and biomass was compromised totally of logging residues (Fig. 7). Procurement cost grew to 59 € dry tonne –1 when the annual procurement volume of biomass was doubled to 100 000 dry tonnes. Of that amount, the proportion of logging residues was 58.4%, stumps 24.3% and delimbed stems 17.3% (Fig. 7). When the annual procurement volume of biomass was 200 000 dry tonnes the proportion of stumps was 18.0%, logging residues 29.3%, delimbed stems 23.2% and cereal straw 29.5% (Fig. 7). The cost of biomass at the plant was 71 € dry tonne –1.

4 Discussion and conclusion

The results presented here have an advantage over previous approaches since both forest and agro biomasses were included in the study and such comprehensive results about procurement costs have not have not been previously published in Finland. The herein used methodology employs time consumption functions, productivity parameters and cost factors of various phases of the sub-operations included in the production systems. The biomass procurement cost data was linked with worksite conditions and biomass availability in order to obtain reliable information about the procurement cost of forest chip assortments and cereal straw for biorefining.

In the study reported upon here, the comparison was done at a regional level with a static spreadsheet-based calculation approach, so the normal fluctuation of interactions in, for example logging, comminuting, transporting materials, and receiving fuel chips at the plant were not considered. The statistic model does not take random impacts into consideration and therefore yields more optimistic results than the dynamic simulation model (Asikainen 2010). When the imbalance becomes larger, the results produced by the static and the dynamic model converge (Asikainen 2010). Systems wherein the individual operations are independent of each other are more predictable (Erikson et al 2014). Biorefinery requires a constant supply of biomass through the year, which facilitates logistical planning, compared to heating and power plants, where supply and demand curves of fuel are often asynchronous (Wolfsmayr and Rauch 2014). During the cold season of the year, the chipping machinery and transportation equipment are in intensive use, while during the summer months the problem is lack of work (Laitila 2012; Windisch 2015) when supplying biomass to heating and power plants.

The procurement costs of cereal straw were higher compared to forest biomass assortments. The balance of the demand and supply of forest biomass assortments by existing plants were not considered, which will reduce the cost difference between forest and agro biomass assortments. On the other hand the supply potential calculations of logging residues and stumps were based on databases of regeneration felling stands of one big forest company. In practice the regional supply potential of stumps and logging residues is higher because locally there exist several family-owned sawmills and two other big forest companies that operate nationwide in Finland (Ranta et al. 2007). It must also be kept in mind that most of the larger plants use a mix of fuels and forest chips are only one component. The optimal share of fuel in the mix also depends on the availability and price of other fuels (Laitila et al. 2015). However, with increasing demand and competition for forest chips, transportation distances will become longer, which increase costs (Nivala et al. 2015). The increasing demand and competition will also increase the prices of raw material assortments.

Based on earlier studies (Asikainen et al. 2001; Ranta 2002; Anttila et al. 2014; Nivala et al. 2016) it can state, that forest chip resources in Kouvola region do not remarkable differ those observed elsewhere in South or Central Finland. Based on the stand data of regeneration fellings of three major forest companies (UPM, Stora Enso and Metsä Group) in 2000 the technical harvesting potential of logging residues was 280 000 dry tonnes per year in Kouvola (Asikainen et al. 2001). Methodology and parameters were identical to herein used, but due to more extensive stand data of regeneration fellings, the technical harvesting potential of logging residues was almost five times bigger in that case study. Also the fluctuation in the annual level of industrial roundwood removals in regeneration fellings have regionally an impact to the technical harvesting potential of by products such as logging residues and stumps (Asikainen et al. 2001; Ranta 2001; Thorsén et al. 2011; Eriksson et al. 2012; Berg et al. 2015; Börjesson et al. 2015; Eriksson 2016; Nivala et al. 2016).

Baling and transporting of cereal straw forms a significant share of the procurement costs (Fig. 3). The easiest way to increase payloads would be to harvest cereal straw as large square bales as their density is higher and the bale shape is more suited to truck transport compared to cylindrical round bales (Lindh et al. 2009; Lötjönen and Paappanen 2013). At present it is impossible to obtain the full load bearing capacity of the biomass truck but the payload of square bales can be 30–60% larger than those of round bales (Lindh et al. 2009; Lötjönen and Paappanen 2013). However, large square balers are rare in Finland and they are more expensive and heavier than round balers used in conventional agriculture. Special purpose machinery increase baling costs and in addition a heavy baler might compact soil on cereal fields (Lindh et al. 2009; Lötjönen and Paappanen 2013). For these practical reasons harvesting of cereal straw is based on round baling in Finland (Lötjönen and Paappanen 2013).

Cereal straw represents an important source of biomass in South-East Finland but the cost competiveness is poor when comparing the procurement costs to forest biomass assortments. Similar results have been reported also from Poland (Berggren et al. 2008). However, research and demonstration projects developing biorefining technologies are underway which might improve economical utilization of cereal straw. Biomass used for biorefining must meet both chemical and physical technical specifications (Spinelli et al. 2011; Suadicani and Gamborg 1999) and raw material characteristics have a significant impact on yield, efficiency and stability of conversion processes. The most homogenous chips can be produced from stemwood, while much more heterogeneous chips are produced from logging residues (Suadicani and Gamborg 1999). Impurities may prevent the use of stumps as feedstock, for example in the pyrolysis process, in which feedstock-purity requirements are generally higher than in combined heat and power production with fluidized bed boilers (Jäppinen et al. 2014).

Acknowledgements

The work was implemented under the ongoing strategic research consortium project FORBIO (3500010200), for which funding from the Strategic Research Council of the Academy of Finland is acknowledged.

References

Ahokas J., Ståhlberg P., Maaskola I. (1983). Olki polttoaineena. [Cereal straw as fuel]. Tutkimusselostus no 30. Vakola – State research institute of engineering in agriculture and forestry. 88 p.

Ahtikoski A., Heikkilä J., Alenius V., Sirén M. (2008). Economic viability of utilizing biomass energy from young stands – the case of Finland. Biomass and Bioenergy 32(11): 988–996. http://dx.doi.org/10.1016/j.biombioe.2008.01.022.

Alakangas E. (2000). Suomessa käytettyjen polttoaineiden ominaisuuksia. [Properties of wood fuels used in Finland]. Technical Research Centre of Finland, VTT, Espoo. VTT Tiedotteita – VTT Research Notes 2045. 172 p. (In Finnish with English summary).

Alm M. (2015). Uusiutuva energia. [Renewable energy]. Ministry of Employment and the Economy. Sector report 3/2015. 69 p. [In Finnish with English summary].

Anttila P., Korpilahti A., Väätäinen K. (2012). Puutavaran maantiekuljetusten kehittämispyrkimyksiä Suomessa ja Ruotsissa. [Development trends of timber transportation in Finland and Sweden]. Metsätieteen aikakauskirja 3/2012: 179–186. [In Finnish].

Anttila P., Nivala M., Laitila J., Flyktman M., Salminen O., Nivala J. (2014). Metsähakkeen alueellinen korjuupotentiaali ja käyttö vuonna 2020. [Regional potential and use of forest energy in the year 2020]. Working Papers of the Finnish Forest Research Institute 313. 55 p. [In Finnish].

Asikainen A. (2010). Simulation of stump crushing and truck transport of chips. Scandinavian Journal of Forest Research 25(3): 245–250. http://dx.doi.org/10.1080/02827581.2010.488656.

Asikainen A., Ranta T., Laitila J., Hämäläinen J. (2001). Hakkuutähdehakkeen kustannustekijät ja suurimittakaavaisen hankinnan logistiikka. [Cost factors and large-scale procurement of logging residue chips]. University of Joensuu, Faculty of Forestry, Research Notes 131. 107 p. [In Finnish].

Asikainen A., Ilvesniemi H., Sievänen R., Vapaavuori E., Muhonen T. (eds.) (2012). Bioenergia, ilmastonmuutos ja Suomen metsät. [Bioenergy, climate change and Finnish forests]. Working Papers of the Finnish Forest Research Institute 240. 211 p.

Berg S., Bergström D., Nordfjell T. (2015). Effect of stump size and timing of stump harvesting on ground disturbance and root breakage diameter. Silva Fennica 49(5) article 1312. 17 p. http://dx.doi.org/10.14214/sf.1312.

Berggren M., Ljunggren E., Johnsson F. (2008). Biomass co-firing potentials for electricity generation in Poland – matching supply and co-firing opportunities. Biomass and Bioenergy 32(9): 865–879. http://dx.doi.org/10.1016/j.biombioe.2007.12.017.

Börjesson M., Athanassiadis D., Lundmark R., Ahlgren E.O. (2015). Bioenergy futures in Sweden – system effects of CO2 reduction and fossil fuel phase-out policies. Global Change Biology, Bioenergy 7(5): 1118–1135. http://dx.doi.org/10.1111/gcbb.12225.

Cambero C., Sowlati T., Marinescu M., Roser D. (2015). Strategic optimization of a forest residues to bioenergy and biofuel supply chain. International Journal of Energy Research (39)4: 439–452. http://dx.doi.org/10.1002/er.3233.

Demirbaş A. (2001). Biomass resource facilities and biomass conversion processing for fuels and chemicals. Energy Conversion and Management 42(11): 1357–1378. http://dx.doi.org/10.1016/S0196-8904(00)00137-0.

Directive 2009/28/EC (2009). On the promotion of the use of energy from renewable sources and amending and subsequently repealing Directives 2001/77/EC and 2003/30/EC.2009.04.23. Off J EU 2009;L 140:16e62.

Eriksson A. (2016). Improving the efficiency of forest fuel supply chains. Doctoral thesis no. 2016:101. Faculty of Natural Resources and Agricultural Sciences. 73 p.

Eriksson A., Eliasson L., Jirjis R. (2014). Simulation-based evaluation of supply chains for stump fuel. International Journal of Forest Engineering 25(1): 23–36. http://dx.doi.org/10.1080/14942119.2014.892293.

Eriksson G., Athanassiadis D., Bergström D., Nordfjell T., Bergsten U. (2012). Production costs and markets for pellet chips: case studies in Northern Sweden. International Journal of Forestry Research, article 302014. 12 p. http://dx.doi.org/10.1155/2012/302014.

Föhr J., Karttunen K., Ranta T. (2010). Energiapuun tienvarsihaketus. [Chipping of energy wood at the roadside landing]. In: Karttunen K., Föhr J., Ranta T. (eds.). Energiapuuta Etelä-Savosta. Lappeenrannan teknillinen yliopisto, Tutkimusraportti 7: 71–79. [In Finnish].

Hakkila P. (1975). Kanto- ja juuripuunkuoriprosentti, puuaineen tiheys ja asetoniuutteitten määrä. [Bark percentage, basic density and amount of acetone extractives in stump and root wood]. Folia Forestalia 224. 14 p. [In Finnish with English summary].

Hakkila P. (1976). Kantopuu metsäteollisuuden raaka-aineena. [Stumpwood as industrial raw material]. Folia Forestalia 292. 39 p. [In Finnish with English summary].

Hakkila P. (1978). Pienpuun korjuu polttoaineeksi. [Harvesting small-sized wood]. Folia Forestalia 342. 38 p. [In Finnish with English summary].

Hakkila P. (2004). Developing technology for large-scale production of forest chips. Wood Energy Technology Programme 1999–2003. Technology Programme Report 6/2004. National Technology Agency. 98 p.

Höhn J., Lehtonen E., Rasi S., Rintala J. (2014). A Geographical Information System (GIS) based methodology for determination of potential biomasses and sites for biogas plants in southern Finland. Applied Energy 113: 1–10. http://dx.doi.org/10.1016/j.apenergy.2013.07.005.

Jäppinen E., Korpinen O.-J., Laitila J., Ranta T. (2014). Greenhouse gas emissions of forest bioenergy supply and utilization in Finland. Renewable and Sustainable Energy Reviews 29 (2014): 369–382. http://dx.doi.org/10.1016/j.rser.2013.08.101.

Jylhä P., Dahl O., Laitila J., Kärhä K. (2010). The effect of supply system on the wood paying capability of a kraft pulp mill using Scots pine harvested from first thinnings. Silva Fennica 44(4): 695–714. http://dx.doi.org/10.14214/sf.454.

Kärhä K., Mutikainen A., Hautala A. (2011a). Saalasti Murska 1224 HF käyttöpaikkamurskauksessa. [Saalasti Murska 1224 HF 5000 stationary grinder operating at the power plant]. Metsätehon tuloskalvosarja 7/2011. 61 p. [In Finnish].

Kärhä K., Hautala A., Mutikainen A. (2011b). Heinola 1310 ES hakkuutähteiden ja pienpuun haketuksessa. [Chipping of logging residues and whole trees with Heinola 1350 ES drum chipper]. Metsätehon tuloskalvosarja 9/2011. 33 p. [In Finnish].

Koponen K., Sokka L., Salminen O., Sievänen R., Pingoud K., Ilvesniemi H., Routa J., Ikonen T., Koljonen T., Alakangas E., Asikainen A., Sipilä K. (2015). Sustainability of forest energy in Northern Europe. VTT Technology 237. 94 p.

Korpinen, O-J., Ranta T., Lötjönen T., Lehtonen E. (2015). Geographical distribution of techno-economic harvest potential of straw for energy use and biorefining in Finland. Bioenergy 2015, Jyväskylä, Finland 2.–4.9.2015. Proceedings. p. 35–40.

Kuitto P.-J., Keskinen S., Lindroos J., Oijala T., Rajamäki J., Räsänen T., Terävä J. (1994). Puutavaran koneellinen hakkuu ja metsäkuljetus. [Mechanized cutting and forest haulage]. Metsäteho Report 410. 38 p. [In Finnish].

Laasasenaho J. (1982). Taper curve and volume functions for pine, spruce and birch. Communicationes Instituti Forestalis Fenniae 108. 74 p.

Laitila J. (2010). Kantojen korjuun tuottavuus. [Productivity of stump harvesting]. Working Papers of the Finnish Forest Research Institute 150. 29 p. [In Finnish].

Laitila J. (2012). Methodology for choice of harvesting system for energy wood from early thinning. Dissertationes Forestales 143. 68 p. http://dx.doi.org/10.14214/df.143.

Laitila J., Nuutinen Y. (2015). Efficiency of integrated grinding and screening of stump wood for fuel at roadside landing with a low-speed double-shaft grinder and a star screen. Croatian Journal of Forest Engineering 36(1):19–32.

Laitila J., Väätäinen K. (2012). Truck transportation and chipping productivity of whole trees and delimbed energy wood in Finland. Croatian Journal of Forest Engineering 33(2): 199–210.

Laitila J., Väätäinen K. (2013). The cutting productivity of the excavator-based harvester in integrated harvesting of pulpwood and energy wood. Baltic Forestry 19(2): 289–300.

Laitila J., Asikainen A., Anttila P. (2008a). Energiapuuvarat. [Energy wood resources]. In: Kuusinen M., Ilvesniemi H. (eds.). Energiapuunkorjun ympäristövaikutukset, tutkimusraportti. Publications of Tapio and Metla. p. 6–12. [In Finnish].

Laitila J., Ranta T., Asikainen A. (2008b). Productivity of stump harvesting for fuel. International Journal of Forest Engineering 19(2): 37–46.

Laitila J., Kärhä K., Jylhä P. (2009). Time consumption models and parameters for off- and on-road transportation of whole-tree bundles. Baltic Forestry 15: 105–114.

Laitila J. Leinonen A., Flyktman M., Virkkunen M., Asikainen A. (2010). Metsähakkeen hankinta- ja toimituslogistiikan haasteet ja kehittämistarpeet. [Challenges and development needs of forest chips procurement and delivery logistics]. VTT Tiedotteita/Research Notes 2564. 143 p. [In Finnish].

Laitila J., Ranta T., Asikainen A., Jäppinen E., Korpinen O.-J. (2015). The cost competitiveness of conifer stumps in the procurement of forest chips for fuel in Southern and Northern Finland. Silva Fennica 49(2) article 1280. http://dx.doi.org/10.14214/sf.1280.

Laitila J., Asikainen A., Ranta T. (2016). Cost analysis of transporting forest chips and forest industry by-products with large truck-trailers in Finland. Biomass and Bioenergy 90: 252–261. http://dx.doi.org/10.1016/j.biombioe.2016.04.011.

Lindh T., Paappanen T., Rinne S., Sivonen K., Wihersaari M. (2009). Reed canary grass transportation costs – reducing costs and increasing feasible transportation distances. Biomass and Bioenergy 33: 209–212. http://dx.doi.org/10.1016/j.biombioe.2008.05.019.

Lötjönen T., Paappanen T. (2013). Bale density of reed canary grass spring harvest. Biomass and Bioenergy 51: 53–59. http://dx.doi.org/10.1016/j.biombioe.2012.12.041.

McKendry P. (2002). Energy production from biomass (part 2): conversion technologies. Bioresource Technology 83(1): 47–54. http://dx.doi.org/10.1016/S0960-8524(01)00119-5.

Ministry of Employment and the Economy. (2013). Kansallinen energia- ja ilmastostrategia. Valtioneuvoston selonteko eduskunnalle 20. päivänä maaliskuuta 2013. VNS 2/2013 vp. [National Climate and Energy Strategy. Government report to Parliament on 20 March 2013].MEE Publications. Energy and the climate 8/2013. 55 p. [In Finnish with English summary].

Niemistö P. (1992). Runkolukuun perustuvat harvennusmallit. [Thinning models based on the number of stems]. Finnish Forest Research Institute, Research Papers 432. 18 p. [In Finnish].

Nivala M., Anttila P., Laitila J. (2015). A GIS-based comparison of long-distance supply of energy wood for future needs from young forests to the coast of Finland. International Journal of Forest Engineering 26(3): 185–202.

Nivala M., Anttila P., Laitila J., Salminen O., Flyktman M. (2016). A GIS-based methodology to estimate the regional balance of potential and demand of forest chips. Journal of Geographic Information System 8: 633–662. http://dx.doi.org/10.4236/jgis.2016.85052.

Nurminen T., Heinonen J. (2007). Characteristics and time consumption of timber trucking in Finland. Silva Fennica 41(3): 471–487. http://dx.doi.org/10.14214/sf.284.

Nuutinen Y., Laitila J., Rytkönen E. (2014). Grinding of stumps, logging residues and small diameter wood using a CBI 5800 grinder with a truck as a base machine. Baltic Forestry 20(1):176–188.

Paappanen T., Lindh T., Impola R., Järvinen T., Tiihonen I., Lötjönen T., Rinne S. (2011). Ruokohelven hankinta keskisuomalaisille voimalaitoksille. [The procurement of reed canary grass for power plants in Central Finland]. VTT Tiedotteita – Research Notes 2577. 148 p. [In Finnish with English summary].

Pahkala K., Lötjönen T. (eds.) (2012). Peltobiomassat tulevaisuuden energiaresurssina. [Field biomass as energy resource for the future]. MTT Raportti 44. 58 p.

Palva R. (2015). Konetyön kustannukset ja tilastolliset urakointihinnat. [The cost of machine work and the statistics of contractor prices]. Työtehoseuran tiedote, Maataloustyö ja tuottavuus 3:661. 12 p.

Pasanen K., Laitila J., Pykäläinen J., Anttila P. (2014). Using the ComBio decision support system to assess whether energy wood and/or pulpwood should be harvested in young forests. International Journal of Forest Engineering 25(1):51–65. http://dx.doi.org/10.1080/14942119.2014.903614.

Ranta T. (2002). Logging residues from regeneration fellings for biofuel production – a GIS based availability and cost supply analysis. Lappeenranta University of Technology, Acta Universitatis Lappeenrantaensis 128. 180 p.

Ranta T., Rinne S. (2006). The profitability of transporting uncomminuted raw materials in Finland. Biomass and Bioenergy 30(3): 231–237. http://dx.doi.org/10.1016/j.biombioe.2005.11.012.

Ranta T., Lahtinen P., Elo J., Laitila J. (2007). The effect of CO2 emission trade on the wood fuel market in Finland. Biomass and Bioenergy (31)8:535–542. http://dx.doi.org/10.1016/j.biombioe.2007.01.006.

Ranta T. , Korpinen O. , Jäppinen E., Karttunen K. (2012). Forest biomass availability analysis and large-scale supply options. Open Journal of Forestry 2(1): 33–40. http://dx.doi.org/10.4236/ojf.2012.21005.

Routa J., Asikainen A., Björheden R., Laitila J., Röser D. (2013). Forest energy procurement – state of the art in Finland and Sweden. WIREs Energy and Environment 2(6): 602–613. http://dx.doi.org/10.1002/wene.24.

Rozakis S., Kremmydas D., Pudełko R., Borzeecka-Walker M., Faber A. (2013). Straw potential for energy purposes in Poland and optimal allocation to major co-firing power plants. Biomass and Bioenergy 58: 275–285. http://dx.doi.org/10.1016/j.biombioe.2013.06.011.

Scarlat N., Martinov M., Dallemand J. (2010). Assessment of the availability of agricultural crop residues in the European Union: potential and limitations for bioenergy use. Waste Management (30)10: 1889–1897. http://dx.doi.org/10.1016/j.wasman.2010.04.016.

Simon D., Tyner, WE., Jacquet F. (2010).Economic analysis of the potential of cellulosic biomass available in France from agricultural residue and energy crops. Bioenergy Research 3: 183–193. http://dx.doi.org/10.1007/s12155-009-9061-y.

Sokka L., Koponen K., Keränen J.T. (2015). Cascading use of wood in Finland – with comparison to selected EU countries. Research Report VTT-R-03979-15. 25 p.

Spinelli R., Nati C., Sozzi L., Magagnotti N., Picchi G. (2011). Physical characterization of commercial woodchips on the Italian energy market. Fuel 90(6): 2198–2202. http://dx.doi.org/10.1016/j.fuel.2011.02.011.

Starr K., Gabarrell X., Villalba G., Talens L., Lombardi L. (2012). Life cycle assessment of biogas upgrading technologies. Waste Management (32)5: 991–999. http://dx.doi.org/10.1016/j.wasman.2011.12.016.

Strandström M. (2014). Puunkorjuu ja kaukokuljetus vuonna 2013. [Harvesting and long-distance transportation 2013]. Metsätehon katsaus nro 50. 4 p. [In Finnish with English summary].

Suadicani K., Gamborg C. (1999). Fuel quality of whole-tree chips from freshly felled and summer dried Norway spruce on a poor sandy soil and a rich loamy soil. Biomass and Bioenergy 17(3):199–208. http://dx.doi.org/10.1016/S0961-9534(99)00039-2.

Thorsén Å., Björheden R., Eliasson L. (eds.) (2011). Efficient forest fuel supply systems, composite report from a four year. R&D programme 2007–2010. Skogforsk, Uppsala. 113 p.

Tomppo E., Katila M., Moilanen J., Mäkelä H., Peräsaari J. (1998). Kunnittaiset metsävaratiedot 1990–94. Metsätieteen aikakauskirja – Folia Forestalia 4B/1998: 619–839. [In Finnish].

von Weymarn N. (ed.) (2007). Bioetanolia maatalouden selluloosavirroista. [Cellulosic side streams of agriculture as a raw material for bioethanol production]. VTT Tiedotteita – Research Notes 2412. 44 p. [In Finnish].

Windisch J., Väätäinen K., Anttila P., Nivala M., Laitila J., Asikainen A., Sikanen L. (2015). Discrete-event simulation of and information-based raw material allocation process for increasing the efficiency of an energy wood supply chain. Applied energy 149: 315–325. http://dx.doi.org/10.1016/j.apenergy.2015.03.122.

Wolfsmayr U.J., Rauch P. (2014). The primary forest fuel supply chain: A literature review. Biomass and Bioenergy (60):203–221. http://dx.doi.org/10.1016/j.biombioe.2013.10.025.

Ylitalo E. (2015). Puun energiakäyttö 2014. [Solid wood fuel consumption in heating and power plants 2014]. http://stat.luke.fi/puun-energiakaytto. [In Finnish].

Total of 75 references.