Productivity of harvesting and clearing of brushwood alongside forest roads

Laitila J., Väätäinen K. (2020). Productivity of harvesting and clearing of brushwood alongside forest roads. Silva Fennica vol. 54 no. 5 article id 10379. https://doi.org/10.14214/sf.10379

Highlights

- The results can be used as a basis to determine in what kinds of cases brushwood biomass should be recovered and where it should be left to decay

- The average volume of harvested brushwood and forwarding distance are the key elements to harvesting productivity with a harwarder

- Stump diameter has a strong impact on clearing productivity of brushwood.

Abstract

Expertise in the cost-efficient utilization and treatment of brushwood on forest roadside sites is limited. In the present study, the productivity of brushwood clearing and harvesting on forest roadside sites was defined by creating time-consumption models or parameters for the aforementioned working methods. Compiled time consumption models and parameters for the brushwood clearing and harvesting can be used as a basis for evaluating alternative management practices and to determine when brushwood biomass should be harvested and when it should be left to decay. The harvesting of brushwood was based on the harwarder system and the clearing of brushwood was done with a spiral cutter, which is a novel accessory for cutting roadside vegetation. Based on the study results, the average volume of harvested brushwood and forwarding distance are the key elements that have an effect on harvesting productivity with harwarders. Correspondingly, stump diameter has a strong impact on the clearing productivity of brushwood. The plot-wise productivity of the spiral cutter in brushwood clearings varied in the range of 0.19–0.61 ha per PMh. An increase in stump diameter slowed down the clearing productivity of the spiral cutter and there was a clear step downward in clearing productivity as the average diameter increased from 30 mm to 40 mm. The machinery under study operated well and there were no interruptions due to machine breakdowns.

Keywords

logging;

energy wood;

time study;

harwarder;

spiral cutter;

whole-trees

Received 18 May 2020 Accepted 10 September 2020 Published 13 October 2020

Views 64166

Available at https://doi.org/10.14214/sf.10379 | Download PDF

1 Introduction

1.1 Background

Finland has approximately 135 000 kilometres of forest roads, most of which have been built from the 1970s to the 1990s (Kiss et al. 2015; Kaakkurivaara 2018). Typically, the width of the forest roadway is 4–5 m and the width of road right-of-way (including side slopes and ditches) is 8–12 m (Uusitalo 2010). Forest roads, which are owned by private forest owners, forest companies or the state forest service, provide access to harvesting sites and enable the transportation of timber from forests to mills, railways or floating terminals (Korpilahti 2008; Kiss et al. 2015; Kaakkurivaara 2018). The road network also eases silvicultural operations, recreation, collection of non-wood products or firefighting and rescue operations (Kiss et al. 2015; Kaakkurivaara 2018; Laschi et al. 2019). The road network needs to be kept in good condition, so that it is able to withstand heavy timber truck and other vehicles (Coulter et al. 2006; Korpilahti 2008; Pellegrini et al. 2013). On dry roads, bearing capacity is higher than that of roads that fail to dry out properly (Korpilahti 2008; Kiss et al. 2015; Kaakkurivaara 2018).

The ditching system plays an important role in the drying of forest roads and overgrown roadside vegetation (brushwood) can obstruct proper drainage if the woody vegetation growing is not cleared on a regular basis (Korpilahti 2008; Kiss et al. 2015; Kaakkurivaara 2018). Clearing cycles and management distances are derived from growing conditions and species; faster growth requires more attention. Woody vegetation effectively prevent the drainage of side ditches and the road surface. In addition, it narrows the width of the functional roadway and limits sight distance, leading to reduced road safety. Such brushwood consists of saplings, bushes and young trees of a range of deciduous plant species mixed with conifers (Korpilahti 2008; Ebenhard et al. 2017). Based on the Finnish national forest road quality standards, in the worst case the roadway and sides are fully covered by brushwood (diameter at 1.3 m height over 5 cm) that it cannot be removed economically by normal road maintenance, e.g. with rotor or chain mulchers (Korpilahti 2008), which are attached, e.g. to a tractor, excavator or harvester. With mulchers, the cutting is based on blunt tools which increase noise and fuel consumption as well as risk of thrown wood splinters into the surroundings, especially if the brushwood is overgrown.

Currently, very little of the brushwood overgrowth is utilized for energy in Finland, and it is almost invariably cut and left to decompose, even if the clearing cost is considerable. The basic economic advantages of brushwood recovery would be the fact that the cost of harvesting could be offset by the existing mulching costs and income from the harvested biomass (Iwarsson-Wide 2009b,c). In addition, it could decrease, e.g. the forest road renovation costs of dilapidated roads, keep the ditches open and improve both the availability and accessibility of forest biomass. Brushwood harvesting has also a negative effect on soil fertility, especially on poor sites and when leaves are also removed from the site, which may restrain coppicing and regrowth (Unrau et al. 2018). In contrast to brushwood mulching, the productivity (m3 per operating hour) and cost efficiency (euros per m3) of mechanized harvesting improves with increasing tree size and harvest intensity (Unrau et al. 2018). Even though the harvesting technologies used in overgrowth brushwood can be similar to those used in conventional forestry, the harvesting costs can be expected to be different in roadside brushwood clearing with smaller tree sizes, smaller harvesting sites and longer forwarding driving distances.

In conventional mechanized thinning, the operator selects the trees to be thinned. In roadside brushwood harvesting, all biomass from a specific area is harvested systematically, the remaining tree stand do not hamper harvesting and the time used on tree selection can be avoided. The cost-efficiency of roadside brushwood harvesting is based on the mass handling of small-sized trees (Unrau et al. 2018). In energy wood harvesting, the most interest has focused on multi-tree handling with accumulating felling heads and harvester heads (Bergström 2009; Kärhä 2011; Laitila 2012; Erber and Kühmaier 2017; Läspä and Nurmi 2018). With these heads, the operator can cut and collect multiple trees in the head before processing them and thus increasing productivity (Bergström 2009; Laitila 2012; Erber and Kühmaier 2017; Läspä and Nurmi 2018). These heads can be mounted on harvesters, excavators or tractors. A harwarder is a dual purpose machine for cutting and forwarding and the harwarder head is capable of cutting, accumulating and processing as well as loading and unloading harvested trees (Laitila and Asikainen 2006; Kärhä 2006; Laitila 2008; Rottensteiner et al. 2008; Iwarsson-Wide 2009c; Belbo 2010). The competitiveness of the harwarder is based on the large proportion of the cutting work in relation to forwarding and to the low relocation costs when compared to operating with the conventional harvesting system using two machines (Kärhä 2006; Laitila 2008; Kärhä et al. 2018). Roadside brushwood stands are easily accessible from existing road networks, but they can be scattered in the landscape and their size may be too small to be economically viable for the two-machine system (harvester and forwarder) which favours the dual purpose machine system.

1.2 Aim of the study

Productivity studies and information from the brushwood clearing and harvesting operations on forest roadside sites are limited (Iwarsson-Wide 2009b,c). In order to have a better understanding of the cost efficiency and profitability of alternative management practices and their operations, more information on productivity is required as conditions can vary greatly from site to site. In the present study, the productivity of brushwood clearing and harvesting on forest roadside sites was defined by creating time-consumption models and parameters for the aforementioned working methods. In addition, tree species specific regression models for height and diameter at breast height (DBH) 1.3 m were derived in which the stump diameter was the independent variable.

The harvesting of brushwood was based on the harwarder in our study and the clearing of brushwood was done with a spiral cutter, which is a novel accessory for cutting roadside vegetation. The functionality of the spiral cutter is based on the rotating spiral, which pulls the material being cut against the sharp blade and cuts it. Compared to traditional chain or reel mulchers the cutting is more energy efficient and it does not toss wood splitters into the surroundings. Compiled time consumption models and parameters for the brushwood clearing and harvesting can be used for evaluating alternative management practices and to determine when brushwood biomass should be harvested and when it should be left to decay.

2 Material and methods

2.1 Machinery studied

2.1.1 Harwarder

The base machine of the harwarder was a 8-wheeled Ponsse Buffalo Dual manufactured in 2018, with an engine power of 205 kW, mass of 24 800 kg (equipped with 900 mm wide KOPA flotation tracks) and load capacity of 14 000 kg (Fig. 1). The length of the load space was 4650 mm and its cross-sectional area 5 m2. The loader model was K90DUAL+ with a 9-metre reach and 160 kilonewton meters (kNm) lifting moment. The loader was equipped with an Epec LoadOptimizer crane scale with an accuracy of 2 kg. The harwarder-operator was skilful, and he had 30 years of work experience in driving harvesters and 15 years of work experience in energy wood harvesting with a harwarder.

Fig. 1. The studied harwarder consisting of a Ponsse Buffalo Dual forwarder and the Moipu 300 F1 harwarder head. The harvesting of brushwood was based on the dual purpose machine system.

The harwarder head was a Moipu 300 F1 equipped with hydraulic shears, feed rollers and delimbing knives (Fig. 1). The maximum cutting diameter with one cut was 30 cm. Multi-tree handling was based on a system that enables the synchronising of the feed roller and delimbing knife functions to operate as an accumulating device. The opening diameter of the delimbing knives was 130 cm, which helps collecting and loading trees with the harwarder head. The height of the harwarder head is 100 cm and it weighs 650 kg (www.moipu.com).

2.1.2 Spiral cutter

The base machine for the JAK SP-180 spiral cutter was a wheeled Neuson 6503 WD mini-excavator manufactured in 2008, with an engine power of 43 kW and mass of 5935 kg. The JAK SP-180 spiral cutter was attached to the tip of the excavator boom (Fig. 2). The device was hydraulically powered, and the flow rate of the excavator’s hydraulic system was 186 litres per minute. The weight and operating width of the JAK SP-180 spiral cutter was 295 kg and 180 cm, respectively. The manufacturer’s recommended maximum cutting diameter was 50–70 mm for the JAK SP-180 spiral cutter.

Fig. 2. JAK SP-180 spiral cutter was attached to the boom tip of wheeled Neuson 6503 WD mini-excavator. The clearing of brushwood was done with the spiral cutter in the study.

The JAK SP-180 spiral cutter was made up of three rotating spirals with fixed underlying plate-shaped blades (Fig. 2). Rotating spiral pulls the material being cut until the sharp-edged blade cuts it off and brushwood falls backwards. The low rotation speed of the spirals (370 round per minutes) minimizes the risk of thrown wood splinters and other damage to the surroundings. The JAK SP-180 spiral cutter was made of high-strength and wear-resistant steel which allows the lightweight structure of the device, which means that smaller carrier vehicles (min 5000 kg) can also be used. The excavator-operator had over two years working experience with the spiral cutter, and in addition, he was also the inventor and developer of the JAK SP-180 spiral cutter.

2.2 Time study plots and brushwood measurements

Time studies were carried out on a private forest road where clearing of brushwood had been done randomly, or then neglected totally. The forest road had been built in the late 1980s and was located in Iisalmi in Eastern Finland (63°26´N, 26°59´E). The width of the forest roadway was 4.5 m and the width of the road area (including side slopes and ditches) averaged 10.5 m. Alongside the forest road, 80 time study plots for the harwarder and 13 time study plots for the spiral cutter were established. When establishing the time study plots, the aim was that the number and volume of trees varied between the plots. In addition, for the harwarder harvesting, road sections where the size of brushwood was bigger compared to those cleared with the spiral cutter were selected. The length of the rectangular time study plots were 25 m and the widths equalled the measured work path. The width of the time study plot was, on average 3.0 m for the harwarder and 1.8 m for the spiral cutter. The boundaries of the time study plots alongside the forest road were marked by means of marking paints and ribbons.

The initial data from the time study plots were based on stump diameter measurements by tree species which were carried out after harvesting and clearing. The stump diameter was measured at 10 cm height from the ground to an accuracy of 1 mm while the tree species was determined visually. All stump diameters by tree species were measured from the spiral cutter time study plots and coverage of the measurement was thus 100%. For the harwarder time study plots, two rectangular (5 m long and 3 m wide) sample plots were established that were located five m from the beginning and end of the time study plot. The coverage of the sample plot measurements was 40% of the total time study plot area of the harwarder.

The stump diameter data by tree species was complemented with sample tree data which consisted measured information about the tree height, DBH and diameter at the stump height (10 cm from the ground). The accuracy of the tree height measurements were 10 cm and the diameters were measured to an accuracy of 1 mm. The randomly selected sample trees were measured while establishing time study plots for the harwarder and the spiral cutter before beginning of the time studies. The number of sample trees were 202 for all the time study plots. Based on the sample tree measurement data, tree specific regression models for height and DBH were derived in which the tree species specific stump diameter was the independent variable. The regression models were used to describe the brushwood properties of the time study plot before harvesting or clearing. The height of the measured sample trees varied in the range of 1.7–15.4 m and the DBH varied in the range of 12–163 mm. The average height and DBH of the sample trees were 6.3 m with a standard deviation (SD) of 2.5 m and 72 mm (SD 32). The stump diameter of the sample trees varied in the range of 21–225 mm and the average stump diameter of the sample trees was 87 mm (SD 36).

The measured sample tree data were combined as a data matrix and based on that were derived tree specific regression models for height and DBH in which the tree species specific stump diameter was the independent variable. The derived regression models, together with Repola (2006, 2008, 2009) and Repola et al. (2007) biomass models in which the independent variables were height and DBH, were used to describe the brushwood properties and dimensions on the time study plots before harvesting and clearing.

DBH and the tree height were strongly dependent on stump diameter. The tree species specific regression models for height and DBH as well as statistical characteristics of regression models are detailed in Table 1.

| Table 1. The statistical characteristics of tree species specific regression models for height and DBH in which the stump diameter (x1, x2, x3 and x4 for the stump diameters of birch, spruce, pine and other broadleaves in respective order) is the independent variable. | ||||||||||

| Tree model | Dependent variable | R2 | F-test | N | Term | Constant/Coefficient | t-test | |||

| F-value | p | Estimate | Std. error | t-value | p | |||||

| DBH | DBHBirch | 0.946 | 521.531 | <0.001 | 31 | Constant | –1.268 | 4.359 | –0.291 | 0.773 |

| x1 | 0.830 | 0.036 | 22.837 | <0.001 | ||||||

| DBHSpruce | 0.936 | 824.357 | <0.001 | 57 | Constant | –5.009 | 2.404 | –2.083 | 0.042 | |

| x2 | 0.897 | 0.031 | 28.712 | <0.001 | ||||||

| DBHPine | 0.965 | 2029.299 | <0.001 | 75 | Constant | –3.075 | 1.923 | –1.599 | 0.114 | |

| x3 | 0.875 | 0.019 | 45.048 | <0.001 | ||||||

| DBHOther broadleaf | 0.989 | 3342.685 | <0.001 | 39 | Constant | –5.847 | 1.289 | –4.536 | <0.001 | |

| x4 | 0.933 | 0.016 | 57.816 | <0.001 | ||||||

| Height of the tree | HeightBirch | 0.764 | 97.260 | <0.001 | 31 | Constant | 2.432 | 0.746 | 3.261 | 0.003 |

| x1 | 0.061 | 0.006 | 9.862 | <0.001 | ||||||

| HeightSpruce | 0.827 | 263.788 | <0.001 | 57 | Constant | 0.159 | 0.279 | 0.571 | 0.570 | |

| x2 | 0.061 | 0.004 | 16.242 | <0.001 | ||||||

| HeightPine | 0.965 | 196.838 | <0.001 | 75 | Constant | 2.083 | 0.324 | 14.030 | <0.001 | |

| x3 | 0.046 | 0.003 | 6.419 | <0.001 | ||||||

| HeightOther broadleaf | 0.911 | 391.037 | <0.001 | 39 | Constant | 1.751 | 0.253 | 19.775 | <0.001 | |

| x4 | 0.063 | 0.003 | 6.922 | <0.001 | ||||||

2.3 Time study

2.3.1 Time study of the harwarder

The harwarder time study was conducted between 3 and 5 June 2019 and the brushwood were harvested as not delimbed. The brushwood harvested from the 80 harwarder time study plots was weighted by the crane scale of the Ponsse Buffalo Dual harwarder during unloading and the above-mentioned regression models for height and DBH were needed to estimate brushwood properties (tree species specific biomass of stem wood, stem bark, foliage as well as living branches) and relative proportions of tree species biomass for each harwarder time study plot before harvesting. The weighted biomass was converted to m3 (solid) based on the relative proportions of tree species on the time study plot. The number of harwarder loads weighed was the same as the number of time study plots.

The estimated share of tree species from the total cutting removal was 27% for Scots pine (Pinus sylvestris L.), 33% for Norway spruce (Picea abies (L.) H. Karst.), 20% for Downy birch (Betula pubescens Ehrh.) and 19% for other broadleaved tree species such aspen, alder, rowan and willow. The distribution of tree species biomass on the time study plot was calculated based on Repola (2006, 2008, 2009) and Repola et al. (2007) biomass models in which the independent variables were height and DBH. The weighted cutting removal from time study plots were converted to m3 with the tree species distribution specific green density (kg m–3) values produced by Finnish Forest Research Institute (Ministry of Agriculture and Forestry 2010; Lindblad et al. 2010). The average green density was 912 kg m–3 (SD 15) on the time study plots.

The respective values for the total number of trees harvested and volume were 5257 and 85.5 m3 during the time study. The average volume of the harvested trees varied in the range of 8–111 dm3, the harvesting intensity was 0.08–1.36 harvested trees per m2 (800–13 600 trees per hectare, ha) and the harvesting removal was 0.23–1.87 m3 on the time study plots (30–249 m3 per ha). The volume of trees harvested (dm3) on a time study plot was calculated by dividing the cutting removal (m3) by the number of trees harvested. The number of trees harvested was obtained from the time study in which the number of trees in each grapple bunch during cutting was observed and recorded (Table 2). The average stump diameter was 54 mm and it varied in the range of 32–177 mm on the time study plots. Based on the stump diameter measurements, the estimated average height of trees per time study plot was in the range of 2.7–11.7 m and the average height of trees was 4.2 m (SD 1.3).

| Table 2. Work elements with detailed definitions in harvesting roadside brushwood with the harwarder. | |

| Work element | Definition of the work element |

| Moving between the working locations | Begins when the harwarder starts to move (wheels are turning) and ends when the harwarder stops moving to perform another activity at the working location, e.g. positioning to cut. |

| Positioning to cut | Begins when the boom starts to swing towards the first tree and ends when the empty harwarder head is resting on the tree before the felling cut at stump height begins. With tall trees (higher than 8 m), the harwarder head is first placed halfway along the tree to be felled. |

| Accumulating the felling | Begins when the felling cut starts (either at the stump height or halfway of the tree) and ends when the accumulated tree bunch starts moving to the load space of the harwarder. With tall trees the top is cut first, after which the harwarder head is moved vertically downward and the tree is cut again at the stump height. The number of trees in each harwarder head bunch is observed and recorded. |

| Loading | The harwarder loads directly felled trees to the load space of the harwarder. Begins when the accumulated tree bunch starts moving to the load space of the harwarder and ends when the empty harwarder head start positioning to cut, the load is full or harwarder starts to move to the next working location. |

| Driving loaded or unloaded | Driving with load begins when the brushwood is harvested from the time study plot (harwarder head is positioned for driving loaded and wheels are turning) and ends when the harwarder stops to begin unloading at the landing area. Driving unloaded begins when the load is empty, the harwarder head is positioned for driving unloaded and its wheels are turning. Driving unloaded ends when the harwarder stops at the working location and positioning to cut starts. |

| Sorting of trees placed in the load space of the harwarder | Sorting of trees placed in the load space of the harwarder before the final grip for unloading. |

| Unloading | Starts when the harwarder stops at the landing for unloading and ends when the load is empty and harwarder head is positioned for driving unloaded. The number of harwarder head loads during unloading is recorded. |

Due to the time study’s plot-wise mass measurement method and study layout, the harwarder loads were not completely full. The operational payload data was studied at the same site by a follow-up study which determined the size of a full payload (7 loads and 45 861 kg total) as well as grapple load size during unloading (173 grapple loads total). The follow-up study data was recorded by the harwarder operator and Epec LoadOptimizer crane scale system. The driving distance with load from the time study plot to the roadside landing and back as empty were measured by digital map (www.karttapaikka.fi) to an estimated accuracy of 1 m.

The time study was carried out manually with a Rufco-900 handheld field computer. The time-study observer was placed in the cabin of the harwarder in a position that enabled him to fully observe the harvesting operations and markings with minimal obstruction for the harwarder operator. The working time was recorded through the application of a continuous timing method wherein a clock ran continuously and the times for different phases were separated from each other under distinct numeric codes (Harstela 1991; Magagnotti et al. 2013). During the recording, the cutting functions had the highest priority, followed by the loading, moving, unloading and the arrangement elements. The time for the highest prioritized work element was recorded if multiple work elements were performed simultaneously. Auxiliary time use (e.g. planning of work and preparations) was included in the work phases in which it was observed. Productive machine (PM) time, the working time excluding all delays (IUFRO 1995), was divided into the following work phases as listed in Table 2.

2.3.2 Time study of the spiral cutter

The time study of the spiral cutter was conducted on 13 September 2019. The clearing work was recorded using a video camera (GoPro 6), and the time study was carried out by one researcher who analysed the collected video material. The camera was placed in the cabin of the mini-excavator in a position that enabled it to fully record the clearing operation and the boundary markings of the time study plots with minimal obstruction to the harvester operator. The video material was analysed by continuous timing from a computer screen using the Rufco-900 handheld field computer, and the work elements and time study plots were separated from each other with numerical codes. The work processes were recorded and the productive machine (PM) time on the time study plots divided into work elements according to Table 3.

| Table 3. Work elements with detailed definitions in roadside brushwood clearing with the spiral cutter. | |

| Work element | Definition of the work element |

| Continuous clearing of brushwood | The mini-excavator is driving forward at a steady pace, brushwood is fed continuously to the blades by rotating spirals, brushwood is cut down in a desirable direction (backwards) and the work is not interrupted |

| Slow down clearing of brushwood | The mini-excavator has to slow down the driving speed or stop because brushwood is cut down slowly, improperly or fell in an undesirable direction (towards mini-excavator). The clearing work is partly interrupted, but the spirals continue to rotate either forward or backwards |

The average stump diameter was 37 mm and it varied in the range of 27–54 mm on the time study plots. Correspondingly, the maximum stump diameter was in the range of 34–99 mm on the time study plots. The density of brushwood was 1.8–8.3 stumps per m2 (18 222–83 333 stumps per ha) and the total cross-sectional area of stump diameters were in the range of 5.0–24.5 cm2 per m2 on the time study plots (5.0–24.5 m2 per ha). Based on the stump diameter measurements, the estimated average height of brushwood trees per the time study plot was in the range of 1.9–4.0 m and the average estimated height of trees was 2.9 m (SD 0.7).

2.4 Data analysis

In the modelling of the harwarder work, the recorded plot-wise time study data and the measured harvested brushwood volumes were combined as a data matrix. The time consumption of the five main work elements in the harwarder harvesting (Moving, Cutting, Loading, Unloading and Forwarding) were formulated through the application of regression analysis in which the harvesting conditions, such as volume of harvested trees (dm3), the harvesting intensity (harvested trees per ha), grapple load volume during loading and unloading (m3) and forwarding distance (m) were independent variables. The unit for calculation of productive machine time consumption was seconds per tree, per grapple load volume or per harwarder load, and productivity in harwarder harvesting was expressed in solid cubic metres per productive machine hour time (m3 per PMh).

Statistical analyses were carried out with IBM SPSS Statistics 21.0 statistical software. Different transformations and curve types were tested in order to achieve symmetrical residuals for the derived regression models and in order to ensure the statistical significance of the coefficients. The results of the regression model analyses are detailed in Table 4.

| Table 4. Regression model statistics for harvesting with the harwarder (x1 = number of harvested trees per hectare, x2 = the average volume of the harvested trees (dm3), x3 = grapple load size during loading (m3), x4 = grapple load size during unloading (m3), x5 = forwarding distance (m)). | ||||||||||

| Work phase model | Dependent variable | R2 | F-test | N | Term | Constant/Coefficient | t-test | |||

| F-value | p | Estimate | Std. error | t-value | p | |||||

| Moving | TMoving | 0.881 | 576.779 | <0.001 | 80 | Constant | 0.168 | 0.045 | 3.721 | <0.001 |

| 1/x1 | 4351.5 | 181.2 | 24.016 | <0.001 | ||||||

| Cutting | TCutting | 0.724 | 204.102 | <0.001 | 80 | Constant | –4.571 | 0.680 | –6.719 | <0.001 |

| ln(x2) | 3.400 | 0.238 | 14.286 | <0.001 | ||||||

| Loading | TLoading | 0.848 | 434.187 | <0.001 | 80 | Constant | –8.222 | 5.176 | –1.588 | 0.116 |

| 1/x3 | 7.237 | 0.347 | 20.837 | <0.001 | ||||||

| Number of trees in the grapple | NNumber of trees | 0.487 | 73.960 | <0.001 | 80 | Constant | 1.163 | 0.411 | 2.830 | 0.006 |

| 1/x2 | 53.675 | 6.241 | 8.600 | <0.001 | ||||||

| Unloading | TUnloading | 0.203 | 19.919 | <0.001 | 80 | Constant | 99.030 | 8.259 | 11.990 | <0.001 |

| x4 | –140.211 | 31.416 | –4.463 | <0.001 | ||||||

| Forwarding | TForwarding | 0.900 | 757.519 | <0.001 | 85 | Constant | 24.154 | 3.688 | 6.549 | <0.001 |

| x5 | 0.691 | 0.025 | 27.523 | <0.001 | ||||||

The plot-wise productivity of the spiral cutter in brushwood clearing (PMh) were defined as a function of the cleared area (ha per PMh) or as a function clearing speed (m per s). Both the continuous and slowed down clearing of brushwood were included in the plot-wise time consumption and productivity analysis. Based on the stump diameter measurements, plot-wise productivity was calculated as a function of maximum and average stump diameter, stump density, cross-sectional area of stump diameters and estimated height of brushwood.

3 Results

3.1 Time consumption of working elements in harwarder harvesting

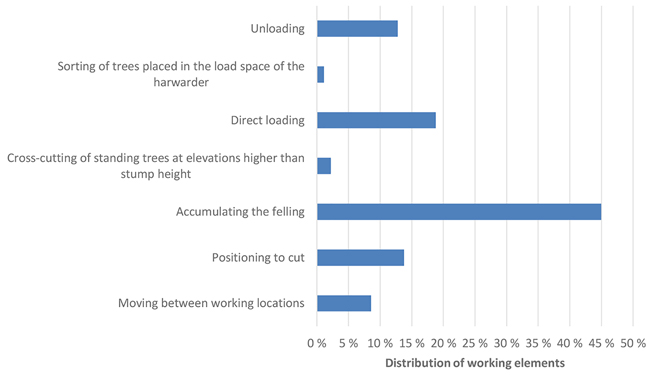

In this time study, moving between working locations represented 9% of the productive machine time (Fig. 3). Positioning to cut and accumulating felling constituted 14% and 45% of the productive machine time in the harvesting of brushwood. Loading and unloading represented 19% and 13% of the productive machine time, respectively. Cross-cutting of standing trees at elevations higher than stump height took 2% of the productive machine time and sorting of trees placed in the load space of the harwarder 1%. Time consumption of driving loaded or unloaded are purely dependent on forwarding distances and because the harwarder loads were not completely full, due to the plot-wise mass measurement method, Fig. 3 focused on analysing the proportion of working elements, which are done with the loader and harwarder head.

Fig. 3. Average proportion of various working elements in the harwarder harvesting of roadside brushwood.

3.2 Time consumption models for harwarder harvesting

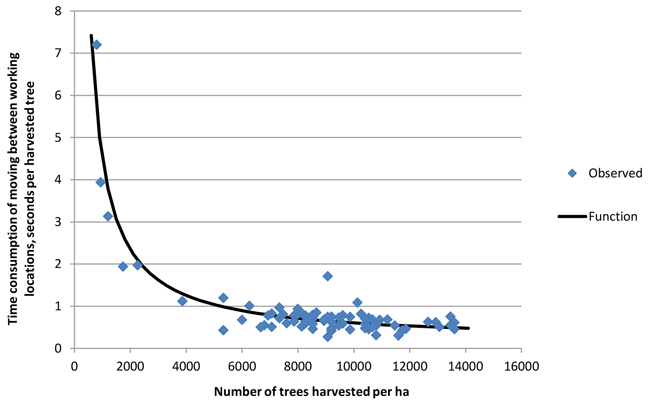

Moving time (TMoving) was dependent on the number of harvested trees per m2. The moving time per tree harvested decreased as the number of trees harvested per ha; in such cases, it was possible to cut more trees from a single work location (Fig. 4). The time consumption of moving was formulated as:

![]()

where

TMoving = moving between working locations, expressed in seconds per harvested tree

x1 = number of harvested trees per ha

Fig. 4. The time consumption of moving between work locations as a function of trees harvested per ha in the harwarder harvesting of roadside brushwood.

Time consumption of multi-tree cutting (TCutting), expressed in seconds per harvested brushwood tree, was modelled from the average volume of harvested tree of each study plot. The time consumptions of multi-tree cutting increased when larger-sized trees were harvested. The working elements of positioning to cut, accumulating felling and cross-cutting of standing trees at elevations higher than stump height were included in the time model of multi-tree cutting. The time consumption of multi-tree cutting was formulated as:

![]()

where

TCutting = time consumption of multi-tree cutting, expressed in seconds per harvested tree

x2 = the average volume of the harvested brushwood trees, dm3

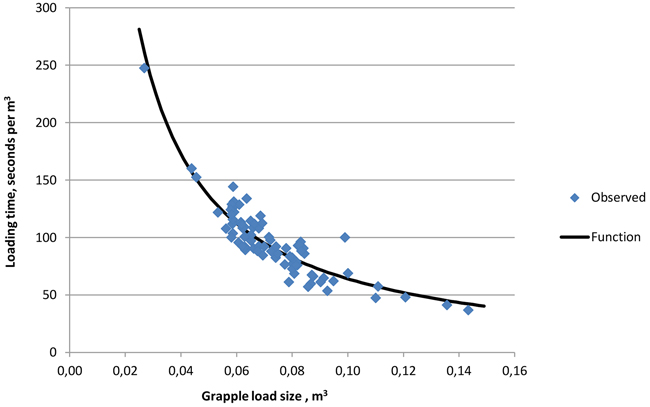

Loading time (TLoading), expressed in seconds per m3, was dependent on the grapple load size during the loading cycle (Fig. 5). The grapple load size (x3) was dependent on the average volume of harvested brushwood trees (Eq. 2) and number of trees in the grapple during loading (Eq. 4).

![]()

where

TLoading = time consumption of loading, seconds per solid cubic metre, m3

x3 = grapple load size during loading (= NNumber of trees × x2), m3

Fig. 5. Time consumption of loading as a function of grapple load size in the harwarder harvesting of roadside brushwood.

The number of trees in the grapple (NNumber of trees) was predicted based on the average volume (dm3) of the harvested trees.

![]()

where

NNumber of trees = number of trees in the grapple during loading

x2 = average volume of harvested brushwood trees, dm3

When modelling the time consumption for unloading (TUnloading) expressed in seconds per m3, the average grapple load size during unloading was the independent variable. In the time studies, the average grapple load size for unloading was 0.26 m3 (min 0.18 m3 – max 0.39 m3) and 0.29 m3 in the follow up study. A total of 5.4 seconds per m3 auxiliary time was added to the unloading time, which was used, e.g. for sorting trees placed in the load space of the harwarder before the final grip for unloading. Time consumption of unloading was formulated as:

![]()

where

TUnloading = time consumption of unloading, seconds per m3

x4 = grapple load size during unloading, m3

5.4 = Sorting of trees placed in the load space of the harwarder. Average handling time, seconds per m3

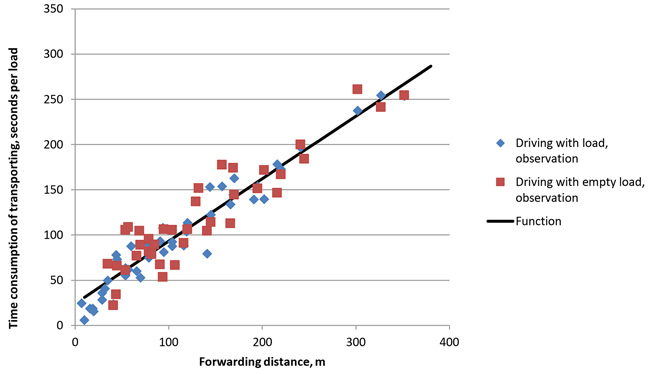

The forwarding distance (Fig. 6) was the independent variable for time consumption of forwarding (TForwarding) using the harwarder on the forest road. The forwarding distance was defined as a mean of driving loaded and driving unloaded distances (Manner et al. 2016). The time consumption of forwarding, expressed in seconds per load, were the same both for driving as loaded and unloaded. Load size was excluded from the model as a second independent variable, since the loads were not full during the time study due to the time study’s plot-wise mass measurement method and study layout. The average payload was 1.07 m3 (SD 0.31) and it varied in the range of 0.23–1.87 m3 during the time study. It is quite obvious that such a small payload does not overload the forwarder’s engines or transmission systems design power, or the frame volume of the whole tree load does not complicate the harwarder’s normal stability. Time consumption of transporting was formulated as:

![]()

where

TForwarding = time consumption of transporting, seconds per load

x5 = forwarding distance, m

Fig. 6. Time consumption of driving loaded and driving unloaded as a function of forwarding distance (m) in the harwarder harvesting of roadside brushwood.

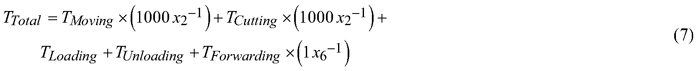

The total harvesting time consumption, seconds per m3, by the harwarder method (TTotal) was obtained by adding up the time consumption values for the main work elements as follows:

where

x2 = the average volume of the harvested brushwood trees, dm3

x6 = the load volume of the harwarder, m3

Based on the follow up study, the average payload of full loads was 7.1 m3. The harvesting productivity per productive machine hour time (m3 PMh–1) was calculated by dividing 3600 seconds by the total harvesting time consumption (TTotal).

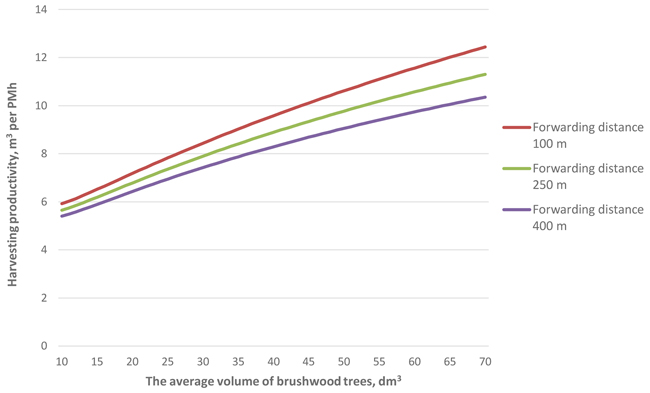

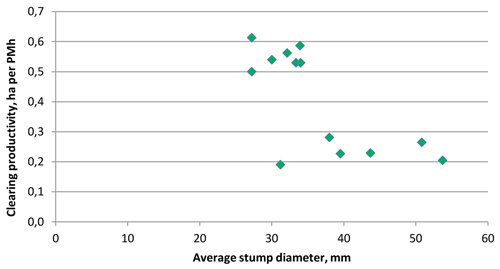

Harvesting productivity was more sensitive to the average volume of harvested brushwood trees than to the forwarding distance (Fig. 7). While the average volume of brushwood trees was doubled from 15 to 30 dm³, harvesting productivity was increased 20% from 6.5 to 8.4 m3 PMh–1 with the forwarding distance of 100 m. Respective productivities were 5.9 and 7.4 m3 PMh–1 with the forwarding distance of 400 m. Alternatively, when analysing clearing productivity as in ha PMh–1, the effect of the average brushwood tree volume was opposite compared to harvesting productivity, the bigger was the average brushwood tree volume the lower was the clearing productivity (Fig. 8). To bear in mind, both results were calculated with the payload of 7.1 m³, and with 6000 trees harvested per hectare.

Fig. 7. The harvesting productivity of roadside brushwood with the harwarder as a function of forwarding distance and average volume of harvested brushwood trees. The harwarder’s payload was 7.1 m3 and the number of harvested trees per ha was 6000.

Fig. 8. The clearing productivity of roadside brushwood with the harwarder as a function of forwarding distance and average volume of harvested brushwood trees. The harwarder’s payload was 7.1 m3 and the number of harvested trees per ha was 6000.

3.4 Efficiency of the spiral cutter

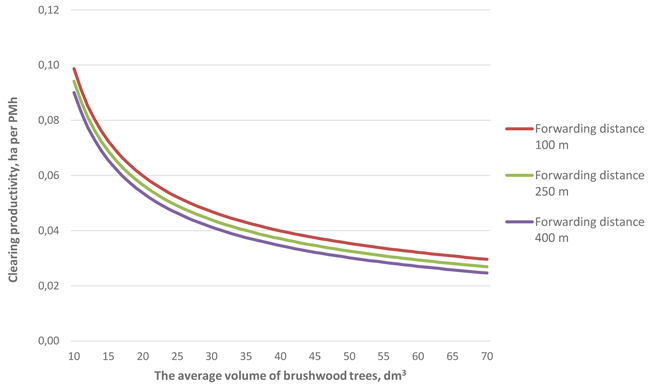

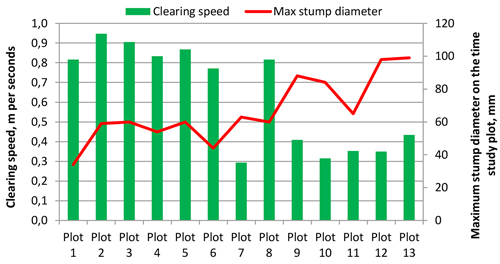

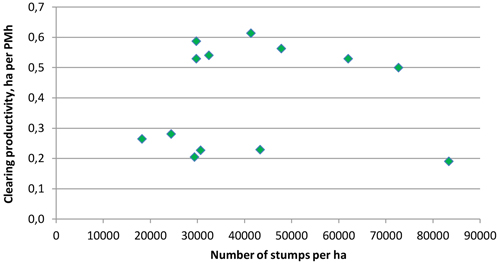

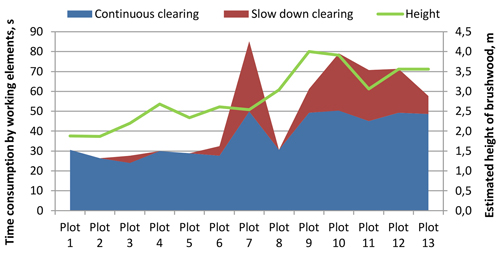

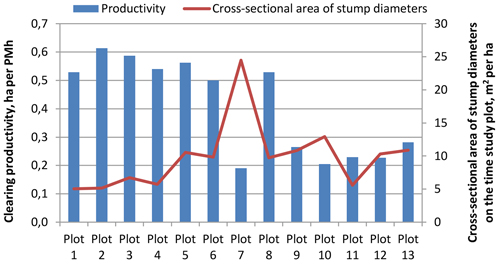

The plot-wise productivity of the JAK SP-180 spiral cutter in brushwood clearing varied in the range of 0.19–0.61 ha per PMh (Fig. 9). Correspondingly, the plot-wise speed of brushwood clearing varied in the range of 0.29–0.95 m per second (Fig. 10). An increase in the average and maximum stump diameter slow down both the clearing productivity and clearing speed of the JAK SP-180 spiral cutter (Figs. 9 and 10) and there was a clear step downward in clearing productivity as the average diameter increased from 30 mm to 40 mm (Fig. 9). Thin brushwood is cut off in one spiral rotation whereas thicker brushwood needs two rotations or more, which slow down clearing speed and productivity (Figs. 9 and 10). The number of stumps per ha had no effect on the time study plot-wise clearing productivity (Fig. 11).

Fig. 9. The time study plot-wise clearing productivity (ha per PMh) of the JAK SP-180 spiral cutter as a function of average stump diameter of brushwood trees, mm.

Fig. 10. The clearing speed (m per s) and the max. brushwood stump diameter (mm) by the study plot of the JAK SP-180 spiral cutter.

Fig. 11. The time study plot-wise roadside brushwood clearing productivity (ha per PMh) of the JAK SP-180 spiral cutter as a function of stump density per ha.

The estimated height of brushwood is strongly dependent on measured stump diameters on the time study plot. An increase in the height of brushwood increased the plot-wise time consumption of working elements and slow down brushwood clearing (Fig. 12). It is obvious that the clearing of robust brushwood takes more time and with high brushwood, the risk that it fell in an undesirable direction and hit the base-machine is also bigger compared to shorter brushwood.

Fig. 12. The time consumption (seconds per time study plot) of continuous clearing and slowed down clearing working elements in brushwood clearing and estimated brushwood height by the time study plots of JAK SP-180 spiral cutter.

The time-study plot number 7, having average stump diameter of 31 mm and density of 83 333 stumps per ha seems to be an outlier, when analysing factors affecting time consumption and efficiency of brushwood clearing with the JAK SP-180 spiral cutter. Based on the stump diameter or brushwood height only, the time consumption should be one of the lowest among the time study plots included to the experiment. Instead, it was the highest in the experiment. Obviously, the high time consumption can be explained with the extraordinary large cross-sectional area of stump diameters on the time study plot number 7 (Fig. 13). The cross-sectional area of stump diameters describes the combined effect of stump diameters and number of stumps on the time study plot.

Fig. 13. The time study plot-wise clearing productivity (ha per PMh) of the JAK SP-180 spiral cutter as a function of cross-sectional area of stump diameters (m2 per ha) by the time study plot.

4 Discussion and conclusions

In this study, time-consumption models for brushwood harvesting, defined productivity parameters for brushwood clearing and derived tree specific regression models for brushwood height and DBH were formulated. Results and formulas can be used in further studies as a basis for evaluating alternative management practices of brushwood cuttings next to forest roads and to determine, when brushwood biomass should be recovered and when it should be left to decay. When applying the results, it is important to remember that the width of the cleared side slope was 3.0 m for the harwarder and 1.8 m for the spiral cutter. The spiral cutter must drive twice so that the width of the cleared area is approximately the same as with the harwarder.

The studied machinery worked well, there were no interruptions due to machine breakdowns and the quality of the work was good (e.g. brushwood was cleared properly and contaminants e.g. roots and soil in the harvested brushwood was excluded). However, when reviewing the results, it has to be taken into account that the results are based on only one, relatively small-scale test, which does not fully correspond to real world work. Therefore, they must not be used, e.g. as a baseline for productivity in determination of unit costs for brushwood harvesting and clearing. Accordingly, a long-term follow-up study would give a more reliable picture of productivity in practice (Magagnotti et al. 2013), as well as of the functional and technical utilization rate of the machinery in varying roadside brushwood conditions, at different times of the year.

In the year 2008 and 2009, Skogforsk carried out two case studies about brushwood harvesting along forest roadsides (Iwarsson-Wide 2009b,c). In the first study, a Valmet 911 equipped with a Bracke C16 circular saw accumulating felling head was used, and felled brushwood was placed in grapple piles at the roadside. In the second study, a Ponsse Dual harwarder with a multi-tree handling, shear felling head (Ponsse EH25) was examined. Felled brushwood was loaded directly and forwarded to storage. In the time study plots, which were 4.5 m wide, the number of stems per hectare varied between 7000 and 4300, and the cutting removal between 39 and 52 tonnes dry matter (oven-dry tonne of forest biomass) per hectare. The average heights of brushwood in the two studies were 5.5 m and 9.2 m, respectively. The average productivity in felling and harvesting were 2.6 and 3.7 tonnes dry matter per PMh, respectively, which are at the same level as our results when the impact of forwarding is considered.

There is a wide variety of studies available on forest road maintenance (Parr and Way 1988; Coulter et al. 2006; Pellegrini et al. 2013; Kiss et al. 2015; Kaakkurivaara 2018; Laschi et al. 2019), but surprisingly there are no studies regarding clearing productivity of brushwood along roadsides, which has traditionally been regarded as a part of regular road maintenance. There exist many studies developing biomass supply systems for forested marginal land (Iwarsson-Wide 2009a,b,c; Di Fulvio et al. 2012; Fernandez-Lacruz et al. 2013; Jyhä et al. 2015; Jylhä and Bergström 2016; Spinelli et al. 2017; Fernandez-Lacruz 2019), but the direct comparison of results is difficult because circumstances, working methods or measurement units are different.

The common practice in forest technology is to use volume or DBH to model biomass removal and harvesting productivity, but, for example, in the study of Fernandez-Lacruz et al. (2013), tree height was chosen as the independent variable when modelling harvesters’ productivity (productive machine time consumption per oven-dry tonne of forest biomass) in the clearing of power line corridors. Better comparability of results and description of circumstances, in addition to plot-wise measurement accuracy, were the reasons why the tree species specific regression models for height and DBH were included in our study and presented in the results.

The density and dimensions of brushwood along the forest roadside varies greatly and the problem is that biomass-rich forest road sections are embedded in the less biomass-rich sections. In some sections of forest roadsides there is plenty of tall brushwood, while others virtually lack brushwood suitable for harvesting, but are an excellent section for clearing. In order to guarantee cost efficient use of existing machinery, accurate methods for assessing and mapping potential sections for brushwood clearing and harvesting along forest roadsides are needed when renovating and maintaining dilapidated forest roads. Lately, a novel laser scanning–based approach identifying forest road sections that fulfil requirements for brushwood harvesting has been developed (Iwarsson-Wide et al. 2013). The accuracy of the approach has been evaluated and result were already correct in 64% of the cases.

Based on the study results, the average volume of harvested brushwood and forwarding distance are the key elements that have an effect on harvesting productivity with the harwarder (Fig. 7). The same has been noted in previous studies early thinnings (Laitila and Asikainen 2006; Kärhä 2006; Rottensteiner et a. 2008). Correspondingly, stump diameter has a strong impact on the clearing productivity of brushwood with the spiral cutter (Fig. 9). In addition to the presented productivity data, income from the harvested brushwood as well as hourly cost of the existing machinery are the key-elements for the comprehensive cost study to determine in what kind of cases roadside brushwood should be recovered and where it should be left to decay.

References

Belbo H. (2010). Comparison of two working methods for small tree harvesting with a multi tree felling head mounted on farm tractor. Silva Fennica 44(3): 453–464. https://doi.org/10.14214/sf.142.

Bergström D. (2009). Techniques and systems for boom-corridor thinning in young dense forests. Acta Universitatis Agriculturae Sueciae 2009:87. 53 p.

Coulter E.D., Sessions J., Wing M.G. (2006). Scheduling forest road maintenance using the analytic hierarchy process and heuristics. Silva Fennica 40(1): 143–160. https://doi.org/10.14214/sf.357.

Di Fulvio F., Bergström D., Kons K., Nordfjell T. (2012). Productivity and profitability of forest machines in the harvesting of normal and overgrown willow plantations. Croatian Journal of Forest Engineering 33(1): 25–37.

Ebenhard T., Forsberg M., Lind T., Nilsson D., Andersson R., Emanuelsson U., Eriksson L., Hultåker O., Iwarsson Wide M., Ståhl G. (2017). Environmental effects of brushwood harvesting for bioenergy. Forest Ecology and Management 383: 85–98. https://doi.org/10.1016/j.foreco.2016.05.022.

Erber G., Kühmaier M. (2017). Research trends in European forest fuel supply chains: a review of the last ten years (2007–2017) – Part one: harvesting and storage. Croatian Journal of Forest Engineering 38(2): 269–278.

Fernandez-Lacruz R. (2019). Improving supply chains for logging residues and small-diameter trees in Sweden. Ph.D. Thesis, Department of Forest Biomaterials and Technology, Swedish University of Agricultural Sciences, Umeå, Sweden. Agriculturae Sueciae 2019:44. https://pub.epsilon.slu.se/16161/

Fernandez-Lacruz R., Di Fulvio F., Bergström D. (2013). Productivity and profitability of harvesting power line corridors for bioenergy. Silva Fennica 47(1) article 904. 23 p. https://doi.org/10.14214/sf.904.

Hakkila P. (1978). Pienpuun korjuu polttoaineeksi. [Harvesting of small-sized wood for fuel]. Folia Forestalia 342. 38 p. [In Finnish]. http://urn.fi/URN:ISBN:951-40-0324-1.

Harstela P. (1991). Work studies in forestry. University of Joensuu. Silva Carelica 18. 41 p.

IUFRO WP 3.04.02. (1995). Forest work study nomenclature. Test edition valid 1995–2000. Department of Operational Efficiency, Swedish University of Agricultural Sciences. 16 p.

Iwarsson-Wide M. (2009a). Teknik och metod Ponsse EH25. Trädbränsleuttag med Ponsse EH25 i kraftledningsgata. [Technique and method Ponsse EH25.Wood fuel recovery with Ponsse EH25 in power line corridor]. Arbetsrapport från Skogforsk nr 681-2009. 14 p. [In Swedish].

Iwarsson-Wide M. (2009b). Skogsbränsleuttag i vägkanter. Prestationsstudie – uttag av skogsbränsle i vägkant med Bracke C16. [Recovery of forest fuel along forest road. Productivity study – recovery of forest fuel along forest road with Bracke C16]. Arbetsrapport från Skogforsk nr 695-2009. 15 p. [In Swedish].

Iwarsson-Wide M. (2009c). Skogsbränsleuttag i vägkanter – prestationsstudie. Uttag av skogsbränsle i vägkant med Ponsse Dual med EH25. [Recovery of forest fuel along forest road. Productivity study – recovery of forest fuel along forest road with Ponsse Dual EH25]. Arbetsrapport från Skogforsk nr 696-2009. 16 p. [In Swedish].

Iwarsson-Wide M., Olofsson K., Wallerman J., Sjödin M., Torstensson P.-O., Aasland T., Barth A., Larsson M. (2013). Effektiv volymuppskattning av biomassa i vägkanter och ungskogar med laserdata. [Effective estimate of biomass volume on roadsides and in young forests using laser data]. Arbetsrapport från Skogforsk nr 804-2013. 48 p. [In Swedish with an English abstract].

Jylhä P., Bergström D. (2016). Productivity of harvesting dense birch stands for bioenergy. Biomass and Bioenergy 88: 142–151. https://doi.org/10.1016/j.biombioe.2016.03.016.

Jylhä P., Hytönen J., Ahtikoski A. (2015). Profitability of short-rotation biomass production on downy birch stands on cut-away peatlands in northern Finland. Biomass and Bioenergy 75: 272–281. https://doi.org/10.1016/j.biombioe.2015.02.027.

Kaakkurivaara T. (2018) Innovative methods for measuring and improving the bearing capacity of forest roads. Dissertationes Forestales 251. 57 p. https://doi.org/10.14214/df.251.

Kärhä K. (2006). Whole-tree harvesting in young stands in Finland. Forestry Studies 45: 118–134.

Kärhä K. (2011). Integrated harvesting of energy wood and pulpwood in first thinnings using the two-pile cutting method. Biomass and Bioenergy 35(8): 3397–3403. https://doi.org/10.1016/j.biombioe.2010.10.029.

Kärhä K., Poikela A., Palander T. (2018). Productivity and costs of harwarder systems in industrial roundwood thinnings. Croatian Journal of Forest Engineering 39(1): 23–33.

Kiss K., Malinen J., Tokola T. (2015). Forest road quality control using ALS data. Canadian Journal of Forest Research 45(11): 1636–1642. https://doi.org/10.1139/cjfr-2015-0067.

Korpilahti A. (2008). Metsäteiden kuntoinventoinnin ja kuntotiedon hyödyntämisen toimintamalli. [Inventory of forest roads quality and operating model for the utilization of collected information]. Metsätehon raportti 202. 60 p. [In Finnish].

Laitila J. (2008). Harvesting technology and the cost of fuel chips from early thinnings. Silva Fennica 42(2): 267–283. https://doi.org/10.14214/sf.256.

Laitila J. (2012). Methodology for choice of harvesting system for energy wood from early thinning. Dissertationes Forestales 143. 103 p. https://doi.org/10.14214/df.143.

Laitila J., Asikainen A. (2006). Energy wood logging from early thinnings by harwarder method. Baltic Forestry 12(1): 94–102.

Laschi A., Foderi C., Fabiano F., Neri F., Cambi M., Mariotti B., Marchi E. (2019). Forest road planning, construction and maintenance to improve forest fire fighting: a review. Croatian Journal of Forest Engineering 40(1): 207–219.

Läspä O., Nurmi J. (2018) Geometrical thinning in energy wood harvesting, International Journal of Forest Engineering 29(3): 171–178. https://doi.org/10.1080/14942119.2018.1493845

Lindblad J., Äijälä O., Koistinen A. (2010). Energiapuun mittaus (27.9.2010). [Measurement of energy wood]. Metsätalouden kehittämiskeskus Tapio ja Metsäntutkimuslaitos. 31 p. [In Finnish].

Magagnotti N., Kanzian C., Schulmeyer F., Spinelli R. (2013). A new guide for work studies in forestry. International Journal of Forest Engineering (24)3: 249–253. https://doi.org/10.1080/14942119.2013.856613.

Manner J., Palmroth L., Nordfjell T., Lindroos O. (2016). Load level forwarding work element analysis based on automatic follow-up data. Silva Fennica 50(3) article 1546. 19 p. https://doi.org/10.14214/sf.1546.

Ministry of Agriculture and Forestry. (2010). Maa- ja metsätalousministeriön asetus kuormainvaa’an käytöstä puutavaran mittauksessa ja erien erillään pidosta annetun maa- ja metsätalousministeriön asetuksen muuttamisesta. [Statute of the Ministry of Agriculture and Forestry for the use of loader-mounted scales in the weighing of timber lots]. (Dnro 666/14/2010, Nro 8/10). 8 p. [In Finnish].

Parr T.W., Way J.M. (1988) Management of roadside vegetation: the long-term effects of cutting. Journal of Applied Ecology 25(3): 1073–1087. https://doi.org/10.2307/2403767.

Pellegrini M., Grigolato S., Cavalli R. (2013). Spatial multi-criteria decision process to define maintenance priorities of forest road network: an application in the Italian Alpine region. Croatian Journal of Forest Engineering 34(1): 31–42.

Repola J. (2006). Models for vertical wood density of Scots pine, Norway spruce and birch stems, and their application to determine average wood density. Silva Fennica 40(4): 673–685. https://doi.org/10.14214/sf.322.

Repola J. (2008). Biomass equations for birch in Finland. Silva Fennica 42(4): 605–624. https://doi.org/10.14214/sf.236.

Repola J. (2009). Biomass equations for Scots pine and Norway spruce in Finland. Silva Fennica 43(4): 625–647. https://doi.org/10.14214/sf.184.

Repola J., Ojansuu R., Kukkola M. (2007). Biomass functions for Scots pine, Norway spruce and birch in Finland. Working Papers of the Finnish Forest Research Institute 53. 28 p. http://urn.fi/URN:ISBN:978-951-40-2046-9.

Rottensteiner C., Affenzeller G., Stampfer K. (2008). Evaluation of the feller-buncher Moipu 400E for energy wood harvesting. Croatian Journal of Forest Engineering 29(2): 117–128.

Spinelli R., Magagnotti N., Schweier J. (2017). Trends and perspectives in coppice harvesting. Croatian Journal of Forest Engineering 38(2): 219–230.

Unrau A., Becker G., Spinelli R., Lazdina D., Magagnotti N., Nicolescu V.N., Buckley P., Bartlett D., Kofman P.D. (eds.) (2018). Coppice forests in Europe. Albert Ludwig University of Freiburg, Freiburg im Breisgau, Germany. 392 p. https://www.eurocoppice.uni-freiburg.de/intern/coppiceineurope-volume/coppice-forests-in-europe-2018-09-10-final-small.pdf.

Uusitalo J. (2010). Introduction to forest operations and technology. JVP Forest Systems Oy. 287 p. ISBN 9789529252695.

Total of 42 references.