Analysis of decision-making processes for strategic technology investments in Swedish large-scale forestry

Jonsson R., Woxblom L., Björheden R., Nordström E.-M., Blagojevic B., Lindroos O. (2022). Analysis of decision-making processes for strategic technology investments in Swedish large-scale forestry. Silva Fennica vol. 56 no. 3 article id 10755. https://doi.org/10.14214/sf.10755

Highlights

- When making development decisions, respondents representing six relatively large users of forest technology aimed to maximize economic criteria without falling below threshold values for criteria such as operator well-being, soil rutting, and wood value

- Collaboration between users, manufacturers, and researchers was found to be important

- Decision-making could be improved by using tools such as problem-structuring methods, simulations, and optimization.

Abstract

Technological development gives forest companies opportunities to maintain competitiveness in the highly cost-sensitive market for forest products. However, no previous studies have examined the technological development decisions made by forest companies or the support tools used when making them. We therefore aimed to describe and analyze 1) the processes used when making such decisions, 2) the associated decision situations, and 3) the use of and need for decision support tools in these processes, with a harwarder concept as case. Semi-structured interviews were conducted with respondents from six forestry organizations. Two theoretical frameworks were used to analyze the interviews, one for unstructured decision processes and one for decision situations. The respondents’ descriptions of their decision processes were consistent with those observed in other industries, and it was shown that decision-making could potentially be improved by investing more resources into diagnosing the problem at hand. The main objective in decision-making was to maximize economic criteria while satisfying threshold requirements relating to criteria such as operator well-being, soil rutting, and wood value. When facing large uncertainties, interviewees preferred to gather data through operational trials and/or scientific studies. If confronted with large uncertainties that could not be reduced, they proceeded with development only if the potential gains exceeded the estimated uncertainties, and implemented innovations in a stepwise manner. These results indicate a need for greater use of existing decision-support tools such as problem-structuring methods to enable more precise diagnoses, simulations to better understand new innovations, and optimization to better evaluate their theoretical large-scale potential.

Keywords

information needs;

qualitative analysis;

harwarder;

forest technology development;

semi-structured interviews;

unstructured decision processes

-

Jonsson,

The Forestry Research Institute of Sweden (Skogforsk), Uppsala Science Park, SE-751 83 Uppsala, Sweden

E-mail

rikard.jonsson@skogforsk.se

- Woxblom, The Forestry Research Institute of Sweden (Skogforsk), Uppsala Science Park, SE-751 83 Uppsala, Sweden E-mail lotta.woxblom@skogforsk.se

- Björheden, The Forestry Research Institute of Sweden (Skogforsk), Uppsala Science Park, SE-751 83 Uppsala, Sweden E-mail rolf.bjorheden@skogforsk.se

- Nordström, Swedish University of Agricultural Sciences, Department of Forest Resource Management, SE-901 83 Umeå, Sweden E-mail eva-maria.nordstrom@slu.se

- Blagojevic, University of Novi Sad, Department of Water Management, Trg D. Obradovica 8, 21000 Novi Sad, Serbia E-mail bosko.blagojevic@polj.edu.rs

- Lindroos, Swedish University of Agricultural Sciences, Department of Forest Biomaterials and Technology, SE-901 83 Umeå, Sweden E-mail ola.lindroos@slu.se

Received 20 May 2022 Accepted 9 November 2022 Published 17 November 2022

Views 82461

Available at https://doi.org/10.14214/sf.10755 | Download PDF

Supplementary Files

1 Introduction

Forest products are sold on a highly competitive and cost-conscious market, forcing producers such as forest companies and forest owners’ associations (FOAs) to pursue constant rationalization. In Sweden, one response to this is the long tradition of collaboration in technology development between users of forestry technology, machine manufacturers, and researchers. This collaboration is colloquially known as the ‘development triangle’ (Ager 2017) and is vitally important: ideas developed without consulting manufacturers may be impossible to construct with current knowledge, failure to consult users may make it impossible to fulfil specific operational goals, and the performance of systems developed without the involvement of researchers may be poorly characterized before their large-scale introduction, delaying progress towards operational goals. Since the 1950s, the technology used in logging operations in Swedish forestry has evolved from manual and motor-manual methods with horse-drawn transport to the fully mechanized, technologically advanced two-machine system that became dominant in the 1990s, partly thanks to the collaborations in the ‘development triangle’ (Ager 2017). The users were initially large forest companies, who had the financial resources to invest in innovations that were taken from concept to series manufactured technology, and the development pace was high between 1960 and 1990. During the 1990ies, the users actively shifted from owning the technology themselves to hiring contractors. This outsourcing process allowed companies and FOAs to shift their risk taking from forest operations to other branches of their organizations (Eriksson 2016). However, it also weakened the formerly close collaboration between the three groups within the ‘development triangle’ and made it harder for ideas to be transferred to manufacturers for further testing because the contractors lacked the financial resources to support development. The traditional users thus became more like proxies for the actual users in the development process. Consequently, in part because of outsourcing, development stagnated in terms of productivity, costs, and innovation, and even regressed to a degree (Björheden 2014; Eriksson 2016; Ager 2017).

Technological development gives forest companies opportunities to maintain competitiveness, both by implementing incremental innovations such as intelligent boom control (Zemánec and Fil’o 2022) and through disruptive innovations such as new machine systems (Lindroos 2012). Incremental innovations are minor improvements of existing technology, allowing manufacturers and users to gain advantages by drawing on their existing competences. Conversely, disruptive innovations are based on new technologies and thus require the shaping of new knowledge within the manufacturer, and sometimes also within the users (Veryzer 1998; Thomond and Lettice 2002; King and Baatartogtokh 2015; Si and Chen 2020). Therefore, disruptive innovations are harder to implement than incremental ones but are sometimes needed to establish new paradigms and prevent loss of market share to competitors.

Decisions regarding innovations can determine an organization’s future, since their success is a product of their decisions (Simon 1960). Decisions may range from structured to unstructured. Structured decisions are usually repetitive and can be facilitated by following well-defined routines. Conversely, unstructured decisions are characterized by novelty and complexity; they are the natural beginning of something new and may be followed by structured decision procedures (Simon 1960). Strategic efforts are hence typically unstructured, but organizations active in fast changing environments may adapt strategies through structured decision processes because of its high frequency.

There are three groups of decision theories. For a long time, research on decision-making viewed humans as fully rational actors, in accordance with theories developed through normative research. This is within the first group. However, observational studies on decision-making revealed that humans are not so rational after all, which gave birth to descriptive research which is within the second group. The growing knowledge of what decision-makers should do (in the form of normative decision theories) and what they actually do (in the form of descriptive decision theories) led to the emergence of prescriptive decision theories, which seek to provide aids and guidelines to help people make the most rational decisions possible despite our irrational nature, which is within the third group (Dillon 1998; Bohman 2021). The uses of these three groups of theories can be understood by considering bias in decision-making. Biases may be either cognitive or motivational. When someone has a decision to make, normative theories can be used to identify the optimal decision based on the person’s objectives. However, the person may make a non-optimal decision because of their biases, which can be understood by adopting a descriptive perspective. Finally, drawing on the prescriptive perspective, we can provide formal advice, a checklist, or some other kind of intervention to help that person make more rational decisions in the future despite their biases (Montibeller and von Winterfeldt 2015a,b).

Because decision-making in development efforts can be complex, a range of different theories have been developed to understand and describe them. Several of these theories focus on the innovation process (Utterback and Abernathy 1975; Narvekar and Jain 2006) or processes with specific contexts such as those by forest owners (Lönnstedt 1997) or leisure travelers (Martin et al. 2012). However, there are also theories that have been developed to be applied in a variety of contexts (Mintzberg et al. 1976). The decisions made during development can be described in terms of their urgency, which ranges from “crisis” to “opportunity” (Mintzberg et al. 1976), and also based on characteristics such as certainty – uncertainty, the number of decision-makers and criteria that are involved, and whether the range of alternatives is discrete or continuous. There may also be differences in terms of spatial and temporal scale, and the different types of products and services that are involved (Kangas et al. 2015). The theory of Kangas et al. (2015) captures the characteristics of decisions in a generally applicable way that is highly suitable for extending reasoning about decisions as well as supports such as decision support tools. Decision support tools are widely defined, i.e. covering tools from low to high complexity, in contrast to decision support systems which generally are defined more precise and with higher complexity (Borges et al. 2014; Vacik and Lexer 2014).

Every organization and business faces the challenge of making decisions, but this work focuses specifically on decisions relating to forestry technology, with Sweden as a case country. The forest sector has a long tradition of testing new and potentially disruptive innovations by performing comparative studies in which the innovation is compared to the established technology under similar conditions. If the innovation shows the potential to compete in a large enough share of the relevant operations, correlation studies are performed to systematically evaluate the impact of different performance-affecting conditions (Bergstrand 1987). Such studies are typically done by scientific organizations. Despite its benefits, this approach also has limitations. First, operators typically perform better when studied than during day-to-day operations; this is known as the Hawthorne effect (Mayo 1933; Kuitto 1994; Sirén and Aaltio 2003). It is also common for operators’ performance to improve over time (Björheden 1997, 2001; Junginger et al. 2005; Purfürst 2010). Some of this information can be captured through operational trials, where new technology is tested by being used as the standard operational resource in a forestry organization.

The driving forces of forestry development can be divided into three categories: new technology, new legislation/regulations, and new products (Lindroos et al. 2017). During the last few decades, there have been examples within all three categories such as partial automation, increased demands for consideration of environmental criteria, and extraction of tops and branches as new products for bioenergy applications (Lindroos et al. 2017). The complexity of decision-making has also increased due to the need to simultaneously consider factors that have become more prominent in recent decades, such as climate change and operator well-being (Vacik and Lexer 2014; Jakobsson et al. 2021). However, little is known about how decisions concerning forestry technology development are made and what support tools are used in the decision-making process, especially at the strategic level but also partly on the tactical level (Blagojević et al. 2019).

The Harwarder Collaboration Group (HCG) was set up during the 1990s as a forum for users to discuss specifications for new machine concepts and share relevant experiences and results from scientific studies, and as such also serving as a forum for discussions on strategic issues. Its members include representatives of large integrated forest companies and FOAs that can actively contribute to such efforts. Here, “integrated” means that the forest companies own or control both the source (the forests) and the receiver (the industries) and control every link in their supply chain. They typically achieve this by outsourcing harvesting and logistical operations in their own forests and in privately owned forests where they have bought harvesting rights. At the start of this study, six such users, the Forestry Research Institute of Sweden (Skogforsk), and various large Manufacturers were members of the HCG (Jonsson et al. 2016). The group has served as a platform for evaluating several machine concepts, mainly harwarders (Bergkvist 2010; Jonsson 2021). The most recent was the Komatsu X19 harwarder concept, which was delivered by the Manufacturer during the spring of 2014 and was subject to several studies over the following years (Jonsson 2021).

The use of suitable decision-support tools is important when users are evaluating technical concepts such as the harwarder, as a basis for whether to buy a machine. Many different decision support tools are available, and the characteristics of the decision situation determine which one is most appropriate in a given case. Decision suggestions/alternatives can for example be obtained through optimization, which provides a suggested best alternative given a defined objective and constraints. One can also use Multi-Criteria Decision Analysis methods (MCDA-methods), which can handle multiple criteria/objectives as well as situations involving multiple decision-makers, or operations research techniques such as simulations, which can improve both understanding of the decision to be made and assessment of the relevant risks based on assumptions about how a machine or process works (Kangas et al. 2015). There are also other tools, such as conjoint analysis, which has similarities with MCDA (Kühmaier et al. 2019). Unfortunately, there is little in scientific literature on which support tools are mainly employed by users in decision making concerning technology investments.

To bridge this knowledge gap, members of the HCG employed by six Swedish forest technology users (major forest companies and a FOA) were interviewed using a three-step approach aiming to describe and analyze: 1) the decision processes used when making choices about investments and resource allocations in forestry technology development in general, 2) the decision situations involved in the case of the harwarder and other technical investments, and 3) the use of and need for decision support tools. Decisions regarding the harwarder concept Komatsu X19 was used as a case.

2 Materials and methods

2.1 Theoretical framework

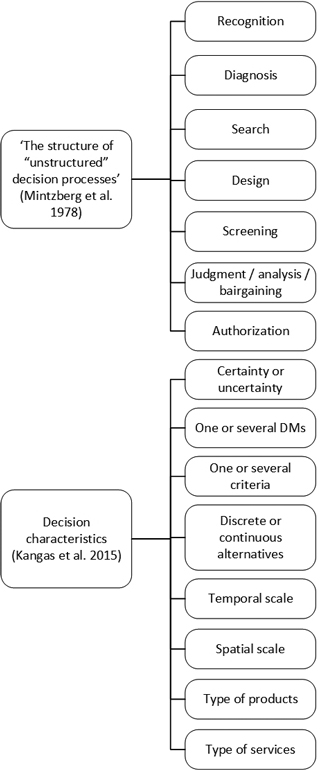

The conceptual framework used to analyze the decision process was based on the structure of “unstructured” decision processes put forward by Mintzberg et al. (1976). The various decision situations were characterized as suggested by Kangas et al. (2015). Both are further presented in the following.

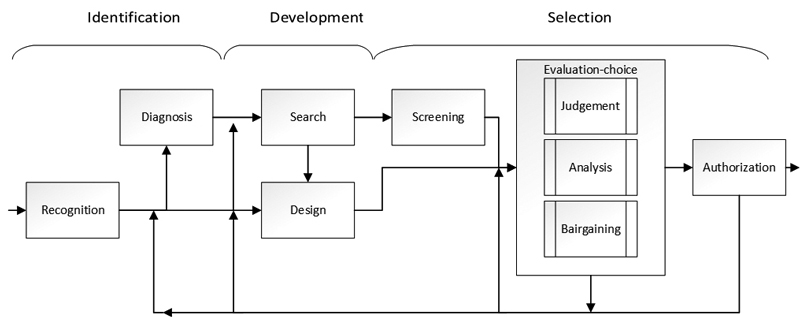

“Unstructured” decision processes have three phases – identification, development, and selection – that are divided into a total of seven routines (Simon 1960; Mintzberg et al. 1976). The respondents’ decision processes, decision situations, and decision support tools are described using the approach of Mintzberg et al. (1976) as a basis. The complexity of the Mintzberg et al. (1976) model was previously shown to be suitable for analyzing business organizations (Martin et al. 2012).

The identification phase involves two routines. The first is recognition, in which the trigger is identified and its urgency is categorized (crisis, problem, or opportunity) to determine the action threshold. In a crisis, the decision-maker generally aims to avoid negative consequences that will follow if actions are not taken; in such cases, one or a few stimuli/triggers can be enough to start a decision-process, meaning that the action threshold is low. Problems are characterized by a mixture of risks of negative consequences and potential for gains, resulting in a somewhat higher action threshold. In an opportunity situation, the triggers are the potential for positive consequences, sometimes in multiple areas, but the action threshold is usually high. The second identification routine is diagnosis, in which the recognized decision situation is clarified and defined through evaluation of causes and effects. It is preferably, but not necessarily, done through a formalized procedure.

The development phase involves two routines: search, which aims to find suitable solutions that are already available, and design, which is invoked if search fails and new solutions must be designed.

The selection phase involves three routines. The first is screening, in which superfluous solutions are eliminated, leaving only feasible ones for investigation. The second is evaluation-choice, which has three sub-routines: analysis, in which the consequences of the alternatives are examined, often by experts; bargaining, in which multiple important decision-makers or stakeholders negotiate about the options and their content; and judgment, where an authorized decision-maker makes the final decision. The final routine is authorization, in which the decision is anchored in the lowest necessary decision instance or with crucial stakeholders (Fig. 1) (Mintzberg et al. 1976).

Fig. 1. The structure of “unstructured” decision processes according to Mintzberg et al. (1976).

Decision-making according to the “unstructured” decision process depends on multiple factors and may involve only some or all of these routines. Moreover, it may involve only a single cycle through the process or multiple iterations may be needed to reach an actionable decision. The number of involved routines and the cycling through the process depends on several factors, such as urgency and previous knowledge (Mintzberg et al. 1976).

The decision situations were defined and classified according to Kangas et al. (2015) with the characteristics 1) certainty or uncertainty relating to the respondents’ perception of the decision situation, 2) number of decision-makers and 3) criteria in a decision situation, 4) whether the alternatives are discrete or continuous, 5) temporal (strategic, tactical or operational) and 6) spatial scale (e.g. stand, regional, national level) and what type of 7) products and 8) services that were included. The temporal scale demands further explanation, due to the papers content. It involves strategic planning, promoting the organizations’ success by creating policies and objectives and has no upper time limit, tactical planning, with implementing the strategic plan during an upcoming period and allocating necessary resources. The tactical planning lays the foundation for the operational planning, which consists of executing the tasks defined in the tactical. The responses about used or necessary basis for decisions were interpreted as a decision support tool (Kangas et al. 2015), which also included certain information.

2.2 Interviews

A qualitative approach was adopted because this work focuses on people’s decision-making processes and knowledge (Bliss and Martin 1989). Semi-structured interviews were used to map the respondents’ experiences of their organization’s decision-making processes and use of support tools. Whether enough respondents are interviewed can for instance be shown through the extent of repeated information (Dworkin 2012). The questions were open-ended and either general or specific towards a certain topic (Supplementary file S1) (Creswell and Poth 2018). The interview proceeded until the interviewer had received responses on all questions.

As the purpose of this study was to describe and analyze decisions related to the case of the harwarder, the respondents were all chosen from the HCG. This was to ensure that both the interviewer and the respondents were well informed about the subject and had experience from the same set of decisions (Table 1).

| Table 1. The criteria for selection of respondents and a brief presentation of respondents’ data. Semi-structured interviews were conducted by the main author, face-to-face. | |

| Category | Description |

| Criteria for selecting respondents | 1) Experience of R&D at a forest company or FOA at staff level or similar 2) Experience from working in the Harwarder Collaboration Group |

| Number of respondents | 6 from forest companies*, 1 from a FOA |

| Current roles of respondents | Staff manager, project leader or specialist |

| Education of respondents | University degree in forestry, engineering, or similar |

| Experience in the forest sector, years | 10–30 years, 27 on average, in operational, tactical, and/or strategic activities |

| * Two respondents undergoing a role transition were chosen from one user. | |

All seven respondents were interviewed by the main author, who explained the study’s purpose, the chosen approach with questions from an interview-guide, and the confidentiality procedures before the interviews began. All interviews were recorded on a cell phone using a recording application. The interviews were conducted between November 2017 and January 2018. At the start of each interview, the interviewer briefly explained how the interview would proceed. The respondent was then interviewed using the questions of the interview guide (Suppl. file S1). The interviews were face-to-face and lasted for 1–3 hours. The guide had 3 parts: part 1 contained questions about the respondent’s background in forestry, part 2 enquired about HCG-related processes and decisions, and part 3 encompassed questions concerning the routines comprising the structure of “unstructured” decision processes. The guide was designed to provide a better understanding of decision characteristics and necessary information when making decisions, for interpretation of suitable decision support tools. In some cases the interviews followed the structure of the guide sequentially, progressing from the first question to the last with suitable follow-up questions, but most of them followed a random path guided by the flow of conversation between the interviewer and the respondent. The interviews were transcribed manually. To ensure that no misunderstandings occurred when interpreting the interviews, transcripts of the interviews were given to the respondents, who then reviewed them and either approved their contents or provided clarifications if misunderstandings were present.

The transcripts were analyzed by the main author. Taking inspiration from Graneheim and Lundman (2004), these were analyzed 1) using the structure of “unstructured” decision processes (Mintzberg et al. 1976) as a framework for interpreting how the users act, and 2) by examining the characteristics of the decisions (Kangas et al. 2015) to understand the underlying needs. The seven routines from the “unstructured” decision processes and the decision characteristics were used as codes, and the support tools that were used or appeared to be needed were interpreted during the analysis (Fig. 2). A meaning unit could both be interpreted as describing a decision process routine, a decision characteristic and a support tool that was used or needed. The answers were interpreted by their content, regardless of the expected code according to the question asked by the interviewer. The codes and support tools from the transcripts were then analyzed to identify similarities and differences.

Fig. 2. The coding tree for the analysis of the interview transcripts, was based on two theoretical frameworks.

2.3 The case: Swedish forestry technology development efforts

The forest sector contributes substantially to Sweden’s Gross Domestic Product (Holgert 2021), employing approximately 115 000 individuals directly and generating around 10 percent of Sweden’s yearly exports of products (Skogsindustrierna 2022). It faces competition both from other sectors and from other countries. In 2020, 47 percent of Sweden’s forest area belonged to private forest owners. Of this area, 56 percent was owned by members of a FOA (LRF 2022), 24 percent was owned by private companies, while 28 percent was owned by the state, municipalities, or other entities (SCB 2022). The respondents’ organizations harvested approximately 36 million cubic meters (solid stem volume under bark) during 2020, representing 48 percent of the total volume harvested in Sweden. They mainly executed their harvesting operations through contractors, but many of the users also had their own harvesting resources. They also had the financial resources to invest in technology research and development, unlike their contractors, which is why contractors were not interviewed.

The rotation time for even-aged forestry varies between 50 and 100+ years because of differences in growth rates. A typical management cycle starts with site preparation and planting, followed by pre-commercial thinning, thinning(s) for roundwood, and final felling (Albrektson et al. 2012). During 2020, a total of 74.4 million cubic meters (solid stem volume under bark) were harvested in Sweden (Skogsstyrelsen 2022) using the cut-to-length method with harvesters and forwarders (Lundbäck et al. 2021). These machines are technically advanced and require trained operators. During the same year, 358 new harvesters and 450 new forwarders were sold in Sweden (Maskinleverantörerna 2022). Consequently, the market for these machines is small and dominated by a few Manufacturers. The machines were mainly bought and operated by small-scale contractors who own only a few machines each (Häggström et al. 2013; Eriksson 2016; Kronholm et al. 2021). The contractors generally have little or no capacity to participate in development efforts (Ager 2014), unlike forest companies and FOAs.

In the 70 years from 1950 to 2020, harvesting operations have evolved from using axes, hand saws, and horses to being fully mechanized with harvesters and forwarders (Eriksson 2016; Nordfjell et al. 2019). The planning of operations is important for understanding the development issues and is commonly divided across three time-frames: strategic, tactical, and operational planning. Strategic planning concerns decisions with long-term consequences such as deciding whether to continue using the cut-to-length-method. Tactical planning is intermediate-term planning such as planning of machine fleet composition to ensure there are sufficient resources to meet demand. Operational planning involves executing the tactical plan by scheduling the machine fleet, planning how to harvest the stands, and doing the actual harvesting. Tactical and operational planning is a major element of the forest companies’ and FOAs’ regular activities, whereas strategic planning is generally given less attention and is performed at varying frequencies (Carlsson et al. 2006; Borges et al. 2014; Segura et al. 2014; Blagojević et al. 2019).

3 Results

3.1 Decision processes

Recognition. When asked to describe their decision processes, all respondents but one frequently mentioned the recognition routine (i.e. recognizing a situation that may prompt the initiation of a decision process), but the descriptions of this routine varied (Table 2). In terms of the crisis-problem-opportunity scale, it appeared that decisions were most frequently made about problems, particularly operational problems. Initiating a process to introduce new technology was often described as difficult because operations were mainly performed by contractors: “There are many good ideas, but none of the contractors have the resources to implement them”. This is presumably because most contractors own only a few machines, have a limited number of employees, and focus mainly on solving operational issues rather than tactical or strategic ones. Many of the respondents assisted operational staff; as one put it, “the development units work more half-operationally than strategically today”. Their view was that this raised the thresholds that needed to be overcome for initiating tests of new solutions. However, they still saw opportunities and potential positive effects of trying out promising new technologies, including opportunities to gain knowledge and generate spin-off projects. For instance, one respondent said that “we wanted to learn something new and participate in productivity development”. The respondents’ visions and expectations could also influence development efforts; one of them noted that “we want to drive the development in our geographical area” and added that it was important to maintain this effort over time because the “price for our forest-based industries’ raw materials increases over time, so we must become more rational”. Many had high decision thresholds, meaning that large and/or multiple stimuli were needed to initiate a decision-making process, and only limited resources were available to support these processes. Collaboration between technology users, manufacturers, and researchers was considered important, but respondents did not feel that all three groups needed to be equally involved in development efforts; as one put it, “it is not critical that researchers participate in a technical development project, but there is definitely a strong need for manufacturers and users”.

Diagnosis of the decision situation was the least frequently mentioned decision process routine (Table 2); around half of the respondents mentioned it occasionally, while the rest did not discuss it at all. Diagnosis was considered relevant when starting a development project building on an earlier project that was seen as a partial failure. In such cases, there was sometimes a perceived need to answer critical questions, for example “what was wrong with the old one, why build a new one?”, before starting a new project, such as for a new machine system.

The search routine (i.e. seeking solutions based on existing technology) was rarely mentioned as a part of the decision process. One respondent described a general search by saying that “different divisions’ personnel meet occasionally to discuss possible development projects”. Another respondent mentioned a search for suitable test operators when conducting scientific studies (i.e. time studies), although this appeared to relate to operational rather than strategic development efforts.

The design routine was mentioned much more frequently than search, suggesting a need for tailor-made new solutions. When planning for design within a project, the respondents considered it important to define the project’s objectives, participants, and expectations, as well as the threshold for proceeding with the project. They preferred to tackle development projects in a series of small steps but were willing to take larger steps with a focus on thoroughly testing one thing at a time if a project was working out well. One respondent described this approach by saying “to get through large project, begin with small steps – a sense of certainty will follow”. They also noted that once a project was started, project decisions had to be made. To support this process, one respondent said that they decided to “monitor the machine being tested as though it were an ordinary operational machine” but also noted that “it is hard to incorporate development projects into daily activities. The people doing the work have to be included from the start”. The latter remark suggests a lack of established routines for testing new machines or technology. However, the same respondent also noted that they “choose experienced operators who can deal with some setbacks”, indicating a degree of organizational experience with operational trials. Another respondent described how a machine being tested could gain acceptance: “you need a strong manufacturer, who might want to see good results, after which a few contractors will buy [the new machine]. Other contractors will then see how useful it can be, creating a ripple effect”. The respondents also recognized the transformative potential of new technology, as illustrated by the remark that “technological development redraws the map, it outweighs politics and organizations. For example, automation will probably redraw the map”. Several respondents mentioned collaborations between users, manufacturers, and researchers in design of tests. However, many of them also said that they preferred to test new technology by themselves, as illustrated by the following quote: “it can be good that others do tests, but we want to test things ourselves […] and when we decide to do it, we go for it quite wholeheartedly”. Another interviewee said that they followed a project model that provided a clear structure. Two respondents wanted research partners to take on more responsibility for leading projects and producing better project plans, and another said that they had sufficient resources to lead and analyze projects. However, most of the respondents said that they needed help from external actors to coordinate scientific studies and analyses.

Screening (of possible solutions) as a part of the decision process was not mentioned at all by any respondents during the interviews.

Judgment/analysis/bargaining (JAB) (i.e. deciding, analyzing possible solutions, and/or bargaining between stakeholders). This was the most frequently mentioned decision-making routine. The decisions mentioned in the interviews were made in collaborative groups (i.e. with other users, manufacturers, and/or research organizations) or within the respondents’ organizations. Many of the decisions concerned project-related issues such as where to test a machine; one respondent said that “it is important to test a machine in varying stand conditions, and to rapidly answer the stated questions”. One respondent said that “once we’ve reached an initial conclusion about something, we do a simple evaluation. If the conclusion is supported, we do a larger evaluation, and if it is supported again, we do a more thorough evaluation”, demonstrating the existence of a structured working procedure for evaluation and deciding on innovations. A general goal in development projects was to “get far enough for a manufacturer to take over”. The respondents said that to decide whether to participate in a project, the new technology had to meet the same operational goals as the established technology.

Authorization. About half of the respondents mentioned situations where authorization was necessary, like when a project or a development budget needed approval from a board of directors, but such situations were rare.

| Table 2. The relative frequencies at which interviewees mentioned the use of different decision-making routines, arranged by the routines’ order of occurrence in the model of Mintzberg et al. (1976). Frequency is categorized using a scale where 1 and 7 represent the lowest and highest frequencies, respectively. Descriptions covers a synthesis of the respondents’ replies for each routine. | ||

| Routine | Relative frequency | Description |

| Recognition | 5 | Problems, stemming from motives for participating in development and reducing costs while maintaining acceptable social and environmental performance |

| Diagnosis | 2 | Have we gathered relevant information to start? Are we doing relevant things? |

| Search | 4 | Searching for new technology |

| Design | 6 | Redesign of technology similar to what we want to develop |

| Screening | 1 | |

| Judgment/Analysis/ Bargaining | 7 | Analysis by researchers, tests within the respondents’ organization and those of other users, decisions within the own organization’s development group |

| Authorization | 3 | Anchoring with the board of directors, and sometimes also by contractors |

To summarize, the respondents generally indicated that they and their development units coordinated development projects and operational trials on their own and/or with other users. Moreover, they collaborated with research organizations when conducting trials, and sometimes also when analyzing trials. They considered it positive for users, manufacturers, and researchers to participate in development efforts, but they did not consider this to be essential in all projects. They also thought that it was positive to be able to draw on external expertise in project leading and analysis.

3.2 Decision characteristics

The decisions and decision situations described by the interviewees varied with respect to several characteristics, including the level of (un)certainty, the number of decision makers, the number of criteria to be satisfied, whether the range of alternatives under consideration was discrete or continuous, the spatial and temporal scales of the decisions, and the types of products and services involved. The number of answers is shown in Table 3.

The uncertainties, here listed before described further, that were mentioned most frequently by respondents related to the impacts of variation in stand conditions. The second most frequently mentioned type of uncertainty related to other users’ decisions. Less frequently mentioned were uncertainties relating to operators’ impact on productivity, improvements in technology when going from concepts to series manufactured machines, general economic impacts, raw material supply, and clarity on issues such as time frames and objectives in development projects. Uncertainties associated with stand conditions mainly related to the difficulty of identifying stand conditions in which the new technology was most likely to outperform existing alternatives. In relation to uncertainty regarding the decisions of other users, the respondents highlighted the value of being able to independently make the best decision for their own organization. They also discussed dependence on the decisions of others, particularly collaborators, when making decisions about progressing from small-scale operational trials of new technologies to ordering series manufactured implementations of those technologies. Respondents said that when other users made decisions that seemed illogical, they wished to learn more about their collaborators’ reasons rather than blindly going along with those decisions. Two respondents also said that their own management teams had encouraged them to move forward despite unresolved uncertainties when a project was considered sufficiently important. These situations generally arose when the potential gain resulting from a project outweighed the expected potential negative consequences. Finally, two respondents pointed out that a decision support tool provided by researchers was too complex, indicating an apparent knowledge gap between the users’ personnel and the researchers.

The respondents mentioned that they had the relevant information for zero up to four things, i.e. certainties, in technology development. Even though little overlap was seen, some common certainties were interest and knowledge within the respondent’s own organization and the expected costs of new but well-tested technologies.

Decision situations were described based on the criteria defining the decision problem; each respondent mentioned between 4 and 14 such criteria. Costs (such as logging costs) were the most frequently mentioned criteria, followed by productivity (which can be regarded as an element of cost) and the operator environment. Machine availability, environmental benefits (defined broadly), and minimizing soil rutting in the terrain were mentioned at the same lower frequency. Typical comments about costs included “chasing costs is a constant mission” and “decreasing logging costs is the goal”. The operator environment was mostly mentioned in relation to the need to comply with legislation, i.e. to avoid falling below legally mandated minima, but it was also described as something to maximize for the sake of attractiveness, for example to help contractors find and retain good operators. Overall, the respondents saw costs (minimizing logging costs) as the main objective in development decision-making, with environmental and social criteria being regarded almost as constraints in the process.

The decision situations were characterized by discrete options since the choices under discussion related mainly to machines or machine systems. Decisions were commonly made by a manager and/or by consensus in a development unit, but with input from those performing the work (like contractors) or individuals with specialized knowledge (like wood value specialists). Two respondents explicitly described projects that included personnel from different areas of the supply chain, ranging from forest to industrial sites.

On the spatial scale, decisions involved matching test machines to suitable stand conditions and evaluating their competitive potential on scales ranging from one to several operational units (e.g. machine system teams). The question of the potential market space of new machines (i.e. whether they would be very specialized or competitive on large scales) was also mentioned.

Decisions concerning the temporal scale related to strategic, tactical, and operational issues, such as the delivery of raw material to industrial sites and the need for flexibility. One respondent stated that their organization’s development strategy was to develop existing systems in the short term and test automation and spin-offs in the long term.

The type of products that decisions concerned were forest machines, i.e. hardware. None of the respondents mentioned any decisions relating to the development of services.

| Table 3. Characteristics of development decisions as described by the respondents, interpreted through the framework of Kangas et al. (2015). | |

| Decision characteristic | Description |

| Certainties or uncertainties | 2–10 per respondent. Examples included stand conditions (7), operators’ impact on productivity (4), and other users’ decisions (3) |

| One or several criteria | 4–14 per respondent. Examples included costs (27), operator environment (9), and machine availability (4) |

| Discrete or continuous alternatives | Discrete; machines/machine systems |

| One or several decision-makers | One or few, frequently with input from influential executers/experts (contractors, wood value specialists etc.) |

| Spatial scale | In which kinds of stands and how many stands will the new technology perform better than current alternatives? |

| Temporal scale | Strategic, tactical, and operational impact |

| Type of product | Machine systems/machines and operation services (logging and logistics) |

To summarize, the most common uncertainty related to the contexts in which new technologies would have the greatest potential to compete with established alternatives. Additionally, economic criteria were central to decision-making, the alternatives under consideration were discrete, and some important spatial and temporal aspects were mentioned.

3.3 Decision support tools

In the following presentation we distinguish between the decision support tools used and those that appeared to be needed by the respondents’ organizations. In some cases, respondents expressed an underlying need for a decision support tool but did not use one, either because the appropriate tool was not available to them or had not yet been developed. We do not investigate these issues further. Note also that we treat information as a decision support tool. The tools are listed below, with following explanations. The support tool that respondents most frequently mentioned a need for was information about suitable stand conditions for the new technology, i.e. stand conditions where it was most likely to outcompete established technology. Other decision support tools that were mentioned as potentially needed included tools for calculating costs, estimates of potential development when a technology is advanced towards series manufacturing, results from operational trials within the respondents’ organizations, information on the technology’s theoretical ability to compete in large-scale operations, and interview-based information on the working environment and well-being of operators. Scientific studies and operational trials were performed on new technology to evaluate its likely performance if advanced to series manufacturing, which required estimates of the technology’s likely development trajectory.

The decision support tools used by the respondents included cost analyses, productivity analyses based on scientific time studies, and operational trials conducted within their organizations. The results and conclusions of trials and analyses conducted by other users were also used, sometimes in a supportive manner (as one respondent put it, “they might be right”) and sometimes to motivate further investigations within the respondents’ organizations based on concerns that “their conclusion might differ from ours”. When knowledge supplied by researchers, the conclusions of internal studies, and conclusions from studies conducted by other users all pointed in the same direction in a logical way, the respondents felt confident in deciding whether to proceed with a project or terminate it. Interviews with operators were also used as sources of information on operator well-being to support decision-making.

Hard facts in general (quantitative information from scientific studies or operational trials) and calculations (cost estimations) more specifically were vital decision support tools. When relevant facts were unavailable, for example when dealing with questions about subjective views on working environments, machine operators could be interviewed and their views could be included in the decision-making process as a variable (if there was no contradiction with research findings). Economic criteria were of major concern to the respondents. Other criteria such as operator well-being/working environment, wood value and rut-free logging were treated as constraints; in such cases, simply satisfying legally (or by certification) mandated thresholds was considered sufficient. Respondents considered it their responsibility to interpret research results and communicate them internally to help the operational arm of their organization. If they faced uncertainties when deciding whether to implement a technology, they preferred to learn more through scientific studies and/or operational trials. When facing uncertainties that could not be reduced through additional scientific studies or operational trials, they implemented the technology in a stepwise manner, but only if the potential gain was large enough to compensate for the estimated uncertainty.

To summarize, the respondents described a need for information from both research and other users but preferred to perform their own operational trials. In the face of large uncertainties, they preferred to gather more information, but if it was hard to get, they would proceed with stepwise development in cases where the potential gains were large enough.

4 Discussion

4.1 Observations and comparisons

According to the theory of Mintzberg et al. (1976), ”unstructured” decision processes can be broken down into seven distinct routines. Based on the interviews conducted in this work, the relative frequencies at which these routines are performed when making development decisions in the forest sector are similar to those previously reported for similar decision processes in manufacturing firms (Mintzberg et al., 1976), which have many similarities with forest organizations. The only difference is that diagnosis was more frequent than authorization in our study. This might indicate that the respondents’ development units were more influential than those of the manufacturing firms studied by Mintzberg et al. (1976). Mintzberg et al. also reasoned that organizations in general would benefit from having a formalized diagnosis routine. However, few of the organizations in their study had one and even fewer of our respondents mentioned one.

Uncertainties about the potential market space of new technologies indicate a need to plan activities to address these uncertainties (e.g. operational trials as well as scientific time and cost studies) early in a development project. Respondents frequently talked about referring to other users’ conclusions and collaboration in general, revealing the importance and impact of connections between the users. Li and Nguyen (2017) have argued that competitors often gain advantages through collaboration in innovation efforts and offered some recommendations to help sustain long-term collaborations, which are applicable in various contexts. One of the most important benefits of such collaborations may be the spillover effect, i.e. the value obtained by transferring discoveries to other projects and parts of the organizations. The spillover effect is particularly important because many innovations fail but lessons can be learned from failures (West 2021). This was specifically mentioned by one respondent as a reason for participating in joint development projects. Also potentially important is dual creation of value, which is about ensuring that all collaboration partners participate actively and gain something from the collaboration. A previous study (Ager 2017) similarly identified collaborations as solid starting points for technical development projects.

Several respondents mentioned that it can be hard to implement suggestions offered by researchers because of competing priorities and a lack of experience in consulting the scientific literature. Also, decision situations use to have several criteria, but an overall economic objective. This may be aided by Multi-Criteria Decision Analysis (Blagojevic et al. 2018). The respondents frequently mentioned that they both find support in scientifically produced knowledge and participate actively in scientific studies. According to Hughes et al. (2011), practitioners such as the respondents of this study can be divided into 1) the enthusiasts, who participate actively; 2) the uncommitted, who are open to collaboration with research but rarely do it in practice; and 3) the cynics, who have negative opinions of academia and its ideas. Most of our respondents seemed to belong to the first category, which is very positive from a development perspective, but some seemed to fall into the second category because they mentioned gaps in need of bridging. Gaps between research and practice can be bridged in several ways, including through publications in hybrid journals that are neither purely scientific nor popular publications but a blend of the two (Hughes et al. 2011), rotation of staff between practice and research (Tkachenko et al. 2017), and increased collaboration between researchers, practitioners, and educators (Burke and Rau 2010).

The respondents suggested that uncertainties about issues such as where new technologies will be most effective could be reduced by conducting operational trials to gather further data, or by drawing information from other users’ trials and scientific studies. They also noted that it is difficult to accurately predict how new technology will be received by operational staff and contractors, and whether it will live up to expectations and estimates of its potential. The respondents also described stepwise implementation approaches that can be modified as experience accumulates. The respondents’ comments indicated that they dealt with two of the three types of uncertainty included in the model of Blennow and Sallnäs (2006): knowledge uncertainty, which they typically reduced by collecting additional data, and uncertainties of outcome, which were typically alleviated by implementing technology development in a stepwise manner. As such, the respondents’ approaches agree well with the model of Blennow and Sallnäs (2006). Uncertainties of outcome can also be referred to as ‘risks’ (Pasalodos-Tato et al. 2013).

Some respondents described stepwise technology development processes whose implementation required large steps and benefited significantly from knowledge held within the organization, which served as a source of competitive advantage. Technologies developed in this way could be seen as disruptive/revolutionary, and processes of this sort were mainly driven by large manufacturers. The clear dominance of large manufacturers in the development of potentially disruptive technologies together with the long-term dominance of a single machine system (the two-machine system, with harvester and forwarder) in the Swedish forest sector might indicate that disruptive innovations are being held back by large manufacturers. However, this possibility is contradicted by two facts: first, there are several large competing manufacturers with no monopoly, and second, both large manufacturers and independent innovators (ATL 2009) have attempted to introduce alternative machine systems. This suggests that although disruptive innovations have not achieved commercial success, large manufacturers retain significant capacity for innovation and users are at the very least willing to test potentially disruptive innovations. In contrast, the users’ development units are generally small, so their capacity to implement disruptive innovations is limited regardless of their intentions. The market for forest machines can be described as pulling, where users order machines from the manufacturers. This both has pros and cons, where manufacturers are ensured buyers of all produced machines whereas a market with push would put higher pressure on manufacturers to develop the most competitive innovations. This would be interesting to analyze further in future studies.

It was hard to determine whether alternative technical solutions were examined before or after deciding on the criteria for evaluating solutions in the development processes described by the participants of this study. The respondents in the study of Mintzberg et al. (1976) frequently evaluated alternatives before determining criteria, showing that this approach is common. Keeney (2009) distinguishes between alternative-focused and value-focused decision-processes, the latter of which could equally well be described as being “criteria-focused” (authors’ comment). The main difference is that alternatives are identified at an early stage in the former case and used to clarify the values (i.e. criteria) that are then used in their evaluation. Such processes tend to be reactive. The opposite is true in value-focused processes, which enable a more active and creative way of selecting alternatives. Keeney (2009) has therefore argued strongly for the benefits of the value-focused approach.

The respondents frequently mentioned that decisions were based on facts when possible. In decisions characterized by uncertainty, decision makers may avoid logical reasoning and instead decide intuitively (Riabacke 2006). We cannot determine whether the decisions discussed by the respondents of this study were based on intellect or intuition. However, when significant uncertainties exist, it can be hard to distinguish between intuition and intellect because the intellect can guide both intuition and analysis, and intuition might even be trainable (Buchanan and O `Connell 2006). Because the number of ongoing development processes in the forest sector is currently much lower than it was during the period of rapid mechanization between 1960 and 1990, decision makers have limited opportunities to develop and train their intuition.

The respondents described their working practices during technology development efforts. However, there did not appear to be any formally structured processes. Decision-makers are subject to several biases that may cause them to make non-optimal decisions even in cases where the available information would make a more rational decision possible. Previous studies have identified effective tools for overcoming such biases, including checklists and routines known as debiases (Montibeller and von Winterfeldt 2015a,b). The fact that such tools are apparently not used as much as expected in the respondents’ organizations despite being familiar to researchers may indicate that academic knowledge transfer to the forest sector has been limited. However, this may have changed since the interviews were conducted, but a substantial change is unlikely.

4.2 Strengths and weaknesses

The responses were not clear enough to distinguish between uncertainties of knowledge, outcome and value, so further research on the uncertainties associated with technological development decision-making in forest organizations is warranted (Blennow and Sallnäs 2006).

This study captured the experiences of seven respondents representing six users. The respondents played key roles in development efforts and their employers are among the largest and most influential organizations in the Swedish forest sector. The generalizability of the results obtained is thus likely to be good. However, gathering more data would have made the results both deeper and wider. More users could have been included, and more respondents within each organization, to reduce the influence of variation in different respondents’ ways of describing how they work. However, such variation is unlikely to have significantly affected the results because there were extensive similarities between the responses of the different interviewees. According to Creswell and Poth (2018), observation is a key source in qualitative studies, so complementing the interviews with observational studies and analyses of internal policies, guidelines, and routines could have increased the generalizability of the results. This approach was not adopted because the time required to collect such data and the costs of doing so are both substantial, but it could be worth investigating in a future study. Because this work is one of only a few studies on decision-making in technological development processes within the forest sector, it is expected that there would be scope for increasing its generalizability. We used the decision process of Mintzberg et al. (1976) as a framework for analyzing the users’ responses. This provided a good base for interviews and analyses, and we do not see any comparable alternatives.

4.3 Future studies

It would be interesting to use Mintzberg et al. (1976) as a framework for investigating the decision processes within research organizations. Because the purpose of such organizations is to conduct investigations and collaboration is important in their work, it is likely that different research organizations would collaborate in such a project and be keen to investigate and critically analyze their own decision processes to find ways of improving. Manufacturers’ decision processes would also be interesting to investigate, but for this purpose it would be preferable to use a framework with a greater emphasis on innovation, such as that of Narvekar and Jain (2006). Unlike research organizations, manufacturers may view their decision processes as a source of competitive advantage that they would be unwilling to share fully. Because collaboration between researchers, manufacturers, and users is seen as an important factor in their joint success, it would be interesting to investigate the overlaps between their decision processes.

The absence of clear and well-rehearsed routines or guidelines can indicate a lack of suitable tools or models. Such an absence could be eased in three ways. First, decision-making in technological development could be improved by introducing one or a few easily grasped problem-structuring methods (Mingers and Rosenhead 2004) and a process for evaluating and making decisions about new technology. Second, insourcing of research competence could enable users to undertake more independent development efforts. Third, improvements in the competence of research and other expert organizations could enable deeper collaboration with users. Frequent collaboration on development projects could have an additional advantage in that it might improve transparency when applying Multi-Criteria Decision Making-methods (Blagojević et al. 2019).

To improve and better understand decision-making, we recommend to consider the following: 1) Since there were relatively few diagnosis efforts, it may be beneficial to determine whether implementing such routines would lead to improvements. Problem-structuring methods are well suited for this task. 2) The decision situations described by the respondents involved choosing between discrete alternatives (machines/machine systems) and had a spatial component (matching technologies to stands), suggesting that decision-making performance could be improved by making greater use of operations research techniques such as simulations to increase understanding of new technology, and optimization to clarify the technology’s theoretical large-scale potential. 3) Having described and analyzed the decision-processes in user organizations, it would be interesting to do the same for research organizations and manufacturers. While the framework of Mintzberg et al. (1976) may be suitable for analyzing research organizations, a framework with a greater emphasis on innovation such as that of Narvekar and Jain (2006) may be better for manufacturers.

5 Conclusions

When designing this study, we expected to obtain a clear picture of the processes and objectives of the respondents’ development units as well as the constraints to which they are subject and their preferred support tools. We found that the respondents expressed clear aims and constraints, but their processes were less well defined and support tools were not consistently used. The academic literature often emphasizes the difference between normative and descriptive views; this study focused on the descriptive view and revealed some discrepancies from the normative view, suggesting that prescriptive aids could be beneficial. The respondents’ main objective in development processes was to maximize economic gain without falling below threshold levels for other criteria such as operator well-being, soil rutting, and wood value.

This survey has shown that the users’ development units appeared to focus on coordinating operational trials on their own or in collaboration with researchers or other users, as well as performing some analyses. The respondents emphasized the importance of collaboration between users, manufacturers, and researchers, which is consistent with previous scientific findings. When preparing to make decisions, they listened to input from research and other organizations but preferred to rely on data from operational trials conducted within their organization. When facing large uncertainties, they preferred to gather data through operational trials and/or scientific studies. If uncertainties could not be reduced in this way, they proceeded only if the potential gains exceeded the estimated uncertainties and implemented innovations stepwise.

These results indicate a need for greater use of existing decision-support tools, including problem-structuring methods to obtain a more precise diagnosis, operations research techniques such as simulations to better understand new innovations, and optimizations to better grasp their theoretical large-scale potential. Finally, the results obtained suggest that it would be interesting to describe and analyze the decision-processes of research organizations and manufacturers.

Declaration on the availability of indata

The interviews were recorded and transcribed, but to enable transparent discussions during the interviews, the respondents were ensured that all content will be stored in a safe location anonymously. The input data are therefore not available for other users.

Acknowledgements

We thank the respondents for participating in this study. We also thank Lars Eliasson at Skogforsk for help with yearly harvesting volumes for the respondents’ organizations.

Funding

This study was funded by the Forestry Research Institute of Sweden (Skogforsk).

Authors contributions

The study was initiated and designed by all authors. The interviews were done by Rikard Jonsson with help from Lotta Woxblom. Rikard Jonsson interpreted the data and results with help from the other authors. Rikard Jonsson wrote most of the paper, but with writing help from Lotta Woxblom regarding interviews and interpretations, Ola Lindroos and Rolf Björheden regarding forest technology development, and Eva-Maria Nordström and Bosko Blagojevic regarding decision-making. All authors helped with interpreting the results and critically revising the manuscripts.

References

Ager B (2014) Skogsarbetets humanisering och rationalisering från 1900 och framåt. [Humanization and rationalization of forest work from 1900 and onwards]. Doctoral thesis, Luleå University of Technology. ISBN 978-91-7439-844-1.

Ager B (2017) Nedslag i skogsbrukets teknikhistoria. [Crucial points in the technology history of forestry]. Rapport 11, Swedish University of Agricultural Sciences.

Albrektson A, Elfving B, Lundqvist L, Valinger E (2012) Skogsskötselns grunder och samband. [The Forest Management series: the basics and and connections]. Skogsskötselserien 1, Skogsstyrelsen, Jönköping.

ATL (2009) Gremo bygger Besten. [Gremo builds Besten]. https://www.atl.nu/gremo-bygger-besten. ATL – Lantbrukets affärstidning. Updated 15 April 2009; Accessed 14 February 2022.

Bergkvist I (2010) Drivare i svenskt skogsbruk – erfarenheter och möjligheter till utveckling. [The harwarder in Swedish forestry – experiences and potential for further development]. Redogörelse 1, Skogforsk.

Bergstrand K-G (1987) Planering och analys av skogstekniska tidsstudier. [Planning and analysis of time studies on forest technology]. Meddelande 17, Forskningsstiftelsen Skogsarbeten.

Björheden R (1997) Studies of large scale forest fuel supply systems. Acta Univ agric Suec, Silv 31: 1–23. ISBN 9157653151.

Björheden R (2001) Learning curves in tree section hauling in central Sweden. Int J For Eng 12: 9–18.

Björheden R (2014) Drivkrafterna bakom den tekniska utvecklingen i skogen. [Driving forces behind the forest technology development]. Skogshistoriska Sällskapets Årsskrift 2014: 52–59.

Blagojević B, Jonsson R, Björheden R, Nordström E-M, Lindroos O (2019) Multi-Criteria Decision Analysis (MCDA) in forest operations – an introductional review. Croat J For Eng 40: 191–2015.

Blennow K, Sallnäs O (2006) Decision support for active risk management in sustainable forestry. J Sustain For 21: 201–212. https://doi.org/10.1300/J091v21n02_12.

Bliss JC, Martin AJ (1989) Identifying NIPF management motivations with qualitative methods. Forest Sci 35: 601–622.

Bohman S (2021) Web applications for large-scale decision support: preference elicitation, modeling and visualization. Doctoral thesis, Report Series 21-005, Department of Computer and Systems Sciences, Stockholm University. ISBN 978-91-7911-665-1.

Borges JG, Nordström E-M, Garcia Gonzalo J, Hujala T, Trasobares A (2014) Computer-based tools for supporting forest management. The experience and the expertise world-wide. Report of Cost Action FP 0804 Forest Management Decision Support Systems (FORSYS). https://res.slu.se/id/publ/60316.

Buchanan L, O`Connell A (2006) A brief history of decision making. Harvard Bus Rev 84:32–41.

Burke LA, Rau B (2010) The research–teaching gap in management. Acad Manag Learn Edu 9: 132–143. https://www.jstor.org/stable/25682438.

Carlsson D, D’Amours S, Martel A, Rönnqvist M (2006) Supply chain management in the pulp and paper industry. Working paper DT-2006-AM-3, Université Laval Québec.

Creswell JW, Poth CN (2018) Qualitative inquiry and research design, 4rth ed. SAGE Publications. ISBN 9781506330204.

Dillon SM (1998) Descriptive decision making: comparing theory with practice. Proceedings of 33rd ORSNZ Conference, New Zealand. University of Auckland, Auckland.

Dworkin S (2012) Sample size policy for qualitative studies using in-depth interviews. Arch Sex Behav 41: 1319–1320. https://doi.org/10.1007/s10508-012-0016-6.

Eriksson M (2016) Developing client-supplier alignment in Swedish wood supply. Doctoral thesis, Acta Univ agric Suec 32: 1–91. ISBN 978-91-576-8567-4.

Graneheim UH, Lundman B (2004) Qualitative content analysis in nursing research: concepts, procedures and measures to achieve trustworthiness. Nurs Educ Today 24: 105–112. https://doi.org/10.1016/j.nedt.2003.10.001.

Häggström C, Kawasaki A, Lidestav G (2013) Profiles of forestry contractors and development of the forestry-contracting sector in Sweden. Scand J Forest Res 28: 395–404. https://doi.org/10.1080/02827581.2012.738826.

Holgert H (2021) Autonomous forest machines – enable technology shift with new business models. Master of Science Thesis TRITA-ITM-EX 2021:619, KTH Royal Institute of Technology.

Hughes T, Bence D, Grisoni L, O’regan N, Wornham D (2011) Scholarship that matters: academic–practitioner engagement in business and management. Acad Manag Learn Edu 10: 40–57.

Jakobsson R, Olofsson E, Ambrose-Oji B (2021) Stakeholder perceptions, management and impacts of forestry conflicts in southern Sweden. Scand J Forest Res 36: 68–82. https://doi.org/10.1080/02827581.2020.1854341.

Jonsson R (2021) Drivare i föryngringsavverkning – en sammanfattning av studier utförda av Skogforsk i samarbete med Drivargruppen 2014–2020. [Harwarder in final fellings – a synthesis of studies performed by Skogforsk in collaboration with the Harwarder Collaboration Group 2014–2020]. Arbetsrapport nr. 1083, Skogforsk.

Jonsson R, Jönsson P, Lundström H (2016) Prestation och kostnader för slutavverkningsdrivare Komatsu X19 med snabbfäste. [Performance and cost in final felling for Komatsu X19 harwarder with quick hitch]. Arbetsrapport nr. 911, Skogforsk.

Junginger M, Faaij A, Björheden R, Turkenburg WC (2005) Technological learning and cost reductions in wood fuel supply chains in Sweden. Biomass Bioenerg 29: 399–418. https://doi.org/10.1016/j.biombioe.2005.06.006.

Kangas A, Kurttila M, Hujala T, Eyvindson K, Kangas J (2015) Decision support for forest management, 2nd ed. Managing Forest Ecosystems 30. https://doi.org/10.1007/978-3-319-23522-6.

Keeney RL (2009) Value-focused thinking: a path to creative decisionmaking. Harvard University Press. ISBN: 0-674-93197-1.

King AA, Baatartogtokh B (2015) How useful is the theory of disruptive innovation? MIT Sloan Manage Rev 57: 77–90.

Kronholm T, Larsson I, Erlandsson E (2021) Characterization of forestry contractors’ business models and profitability in Northern Sweden. Scand J Forest Res 36: 491–501. https://doi.org/10.1080/02827581.2021.1973087.

Kühmaier M, Harrill H, Ghaffariyan MR, Hofer M, Stampfer K, Brown M, Visser R (2019) Using conjoint analyses to improve cable yarder design characteristics: an Austrian yarder case study to advance cost-effective extraction. Forests 10, article id 165. https://doi.org/10.3390/f10020165.

Kuitto J (1994) Puutavaran koneellinen hakkuu ja metsakuljetus. [Mechanized cutting and forest haulage]. Metsateho Report 410: 1–30.

Li M, Nguyen B (2017) When will firms share information and collaborate to achieve innovation? A review of collaboration strategies. Bottom Line 30: 65–86. https://doi.org/10.1108/BL-12-2016-0039.

Lindroos O, La Hera P, Häggström C (2017) Drivers of advances in mechanized timber harvesting – a selective review of technological innovation. Croat J For Eng 38: 243–258.

Lönnstedt L (1997) Non‐industrial private forest owners’ decision process: a qualitative study about goals, time perspective, opportunities and alternatives. Scand J Forest Res 12: 302–310. https://doi.org/10.1080/02827589709355414.

LRF (2022) Skogsägarföreningarna. [The Forest Owner’s Associations]. https://www.lrf.se/om-lrf/organisation/branschavdelningar/lrf-skogsagarna/skogsagarforeningarna/. Accessed 15 February 2022.

Lundbäck M, Häggström C, Nordfjell T (2021) Worldwide trends in methods for harvesting and extracting industrial roundwood. Int J For Eng 32: 202–215. https://doi.org/10.1080/14942119.2021.1906617.

Martin D, Sharma A, Woodside AG (2012) Structure and process modeling of seemingly unstructured leisure‐travel decisions and behavior. Int J Contemp Hosp M 24: 855–872. https://doi.org/10.1108/09596111211247209.

Maskinleverantörerna (2022) Skogsmaskinstatistik leveranser Sverige. [Forest machine statistics deliveries Sweden]. https://www.maskinleverantorerna.se/sites/default/files/ML%20skogsmaskinstatistik%202010-2020%20-%20web.pdf. Accessed 10 February 2022.

Mayo E (1933) The human problems of an industrial civilization. Macmillan Company, New York, NY.

Mingers J, Rosenhead J (2004) Problem structuring methods in action. Eur J Oper Res 152: 530–554. https://doi.org/10.1016/S0377-2217(03)00056-0.

Mintzberg H, Raisinghani D, Theoret A (1976) The structure of ”unstructured” decision processes. Admin Sci Quart 21: 246–275. https://doi.org/10.2307/2392045.

Montibeller G, Winterfeldt von D (2015a) Biases and Debiasing in Multi-criteria Decision Analysis. 48th Hawaii International Conference on System Sciences, pp 1218–1226. https://doi.org/10.1109/HICSS.2015.148.

Montibeller G, Winterfeldt von D (2015b) Cognitive and motivational biases in decision and risk analysis. Risk Anal 35: 1230–1251. https://doi.org/10.1111/risa.12360.

Narvekar RS, Jain K (2006) A new framework to understand the technological innovation process. J Intellect Cap 7: 174–186. https://doi.org/10.1108/14691930610661845.

Nordfjell T, Öhman E, Lindroos O, Ager B (2021) The technological development of forwarders in Sweden between 1962 and 2012 and of sales between 1975 and 2017. Int J For Eng 30: 1–13. https://doi.org/10.1080/14942119.2019.1591074.

Pasalodos-Tato M, Mäkinen A, Garcia-Gonzalo J, Borges J, Lämås T, Eriksson L (2013) Assessing uncertainty and risk in forest planning and decision support systems: review of classical methods and introduction of new approaches. For Syst 22: 282–303. https://doi.org/10.5424/fs/2013222-03063.

Purfürst FT (2010) Learning curves of harvester operators. Croat J For Eng 31: 89–97.

Riabacke A (2006) Managerial decision making under risk and uncertainty. IAENG Int J Comput Sci 32: 1–7.

SCB (2022) Fastighetstaxeringsregistret bearbetat av Skogsstyrelsen. [The property taxation register processed by the Swedish Forest Agency]. http://pxweb.skogsstyrelsen.se/sq/55d871cb-f1f6-47d2-861a-96b85ccf1a36. Accessed 15 February 2022.

Segura M, Ray D, Maroto C (2014) Decision support systems for forest management: a comparative analysis and assessment. Comput Electron Agr 101: 55–67. https://doi.org/10.1016/j.compag.2013.12.005.

Si S, Chen H (2020) A literature review of disruptive innovation: what it is, how it works and where it goes. J Eng Technol Manage 56, article id 101568. https://doi.org/10.1016/j.jengtecman.2020.101568.

Simon HA (1960) The new science of management decision. Harper & Brothers. https://doi.org/10.1037/13978-000.

Sirén M, Aaltio H (2003) Productivity and costs of thinning harvesters and harvester-forwarders. Int J For Eng 14: 39–48. https://doi.org/10.1080/14942119.2003.10702468.

Skogsindustrierna (2022) Skogsnäringens betydelse för ekonomi och välfärd. [The importance of the forest industry for the economy and welfare]. https://www.skogsindustrierna.se/om-skogsindustrin/branschstatistik/ekonomisk-betydelse2/. Accessed 16 February 2022.

Skogsstyrelsen (2022) Bruttoavverkning 2019 och preliminär statistik för 2020. [Gross felling 2019 and preliminary statistics for 2020]. Statistiska meddelanden JO0312 SM 2101.

Thomond P, Lettice F (2002) Disruptive innovation explored. 9th IPSE International Conference on Concurrent Engineering: Research and Applications. Cranfield University, Cranfield, England.

Tkachenko O, Hahn H-J, Peterson SL (2017) Research–practice gap in applied fields: an integrative literature review. Hum Resour Dev Rev 16: 235–262. https://doi.org/10.1177/1534484317707562.

Utterback JM, Abernathy WJ (1975) A dynamic model of process and product innovation. Omega 3: 639–656. https://doi.org/10.1016/0305-0483(75)90068-7.

Vacik H, Lexer MJ (2014) Past, current and future drivers for the development of decision support systems in forest management. Scand J Forest Res 29: 2–19. https://doi.org/10.1080/02827581.2013.830768.

Veryzer RW (1998) Discontinuous innovation and the new product development process. J Prod Innovat Manag 15: 304–321. https://doi.org/10.1111/1540-5885.1540304.

West S (2021) Sam West: the museum of failure. Res Technol Manag 64: 72. https://doi.org/10.1080/08956308.2020.1842628.

Zemánec T, Fil’o P (2022) Influence of intelligent boom control in forwarders on performance of operators. Croat J For Eng 43: 47–64.

Total of 66 references.