Comparing forwarder boom-control systems based on an automatically recorded follow-up dataset

Manner J., Mörk A., Englund M. (2019). Comparing forwarder boom-control systems based on an automatically recorded follow-up dataset. Silva Fennica vol. 53 no. 2 article id 10161. https://doi.org/10.14214/sf.10161

Highlights

- Boom-tip control saves time compared to the conventional system

- This study introduced a field-study design enabling establishment of causal relationships during ordinary forwarding operations

- Although the study design requires some extra arrangements, it efficiently combines the representativeness of conventional follow-up datasets with establishment of causal relationships that traditionally have been possible only through observational time studies or standardized experiments.

Abstract

Crane work is the most time-consuming work element in forwarding. Hence, assist systems like boom-tip control are of interest. The first commercially available boom-tip control for forwarders was introduced in 2013. In this study we analysed whether replacing conventional boom control (CBC) with John Deere’s version of boom-tip control (named Intelligent Boom Control, IBC), increases crane-work productivity. We used data automatically gathered from 10 final-felling stands, covering typical logging conditions for southern, central and northern Sweden. Two John Deere 1510E and two John Deere 1910G forwarders were operated by seven experienced operators during the follow-up study, covering 1238 loads in total. A split-plot design was applied to isolate effects of the boom-control system being used (CBC, IBC). We found that using IBC for loading work (crane work and driving included) saved 5.2% of productive machine time compared to using CBC (p ≤ 0.05). The corresponding saving when using IBC for unloading work was 7.9% (p ≤ 0.05). Depending on geophysical factors, this corresponds to approximately 4% savings in productive machine time for forwarding as a whole, including pure transport (with and without load). Moreover, the study introduced in cut-to-length context a novel field-study design to collect a large follow-up dataset in the course of ordinary forwarding operations. We found the study design to be a cost-efficient way to combine the representativeness of conventional follow-up datasets with the ability to establish causal relationships. Establishment of causal relationships has traditionally been possible only through observational time studies or standardized experiments.

Keywords

automation;

cut-to-length logging;

haulage;

crane work;

extraction;

boom-tip control

-

Manner,

The Forestry Research Institute of Sweden (Skogforsk), Uppsala Science Park, SE-751 83 Uppsala, Sweden

http://orcid.org/0000-0002-4982-3855

E-mail

jussi.manner@skogforsk.se

http://orcid.org/0000-0002-4982-3855

E-mail

jussi.manner@skogforsk.se

- Mörk, The Forestry Research Institute of Sweden (Skogforsk), Uppsala Science Park, SE-751 83 Uppsala, Sweden E-mail anders.mork@skogforsk.se

- Englund, The Forestry Research Institute of Sweden (Skogforsk), Uppsala Science Park, SE-751 83 Uppsala, Sweden E-mail martin.englund@skogforsk.se

Received 17 March 2019 Accepted 10 July 2019 Published 24 July 2019

Views 87209

Available at https://doi.org/10.14214/sf.10161 | Download PDF

1 Introduction

A typical fully mechanised Nordic cut-to-length logging system consists of at least one harvester and at least one forwarder. A harvester fells, limbs and crosscuts the stems into logs of different assortments. A forwarder picks up the logs and delivers them to a roadside landing. In general, crane work (rather than driving) is the most time-consuming work element in forwarding (Kellogg and Bettinger 1994; Nurminen et al. 2006; Brunberg and Lundström 2016; Manner et al. 2016). Nevertheless, the time required for driving and crane work depends on many factors, including the terrain conditions, extraction distance, assortment-specific log concentrations at the harvesting site, and the assortment combination of the load (Manner et al. 2013; Manner et al. 2016; Strandgard et al. 2017). Hence, the productivity of a forwarder is dependent on route planning, trafficability, and crane manoeuvrability. These factors, especially the first two, are clearly connected. The development of an effective routing algorithm is essential for improving the productivity of the forwarding process (Rönnqvist et al. 1999; Flisberg et al. 2007; Hosseini et al. 2019), but may not be sufficient.

The increasing demand for timber is pushing logging operations towards terrain with weak bearing capacity like peatlands. Thus, innovations that can increase trafficability or reduce the impact on soil are of interest (Ala-Ilomäki et al. 2011; Edlund et al. 2013; Ågren et al. 2014; Sirén et al. 2019). Moreover, logging operations’ impact on soil may also be indirectly reduced by increasing the payload-to-weight ratio of the machinery, for instance, by coupling a trailer to a forwarder (see e.g. Lindroos and Wästerlund 2014). Alternatively, the need for multiple passes (and hence the impact on soil) can be reduced by increasing the number of assortments transported in a load (Kellogg and Bettinger 1994; Manner et al. 2013). However, increasing the number of assortments in a load complicates the crane work (Nurminen et al. 2006; Manner et al. 2013). Thus, improving crane-work productivity is of high interest; not only because of the large relative proportion of time it often takes but also its interactions with other aspects affecting forwarding work.

Crane-work productivity can be improved through mechanical innovations. One such innovation is the “tilt-grapple” that enables a bunch of logs to be tilted vertically into an upright position (Nilsson 2013; Häggström et al. 2016; Kaleja et al. 2018). This should improve a forwarder’s crane-work productivity especially in thinnings, because of logs in a vertical position can be steered more easily around the remaining trees during the loading-crane cycles. A second mechanical innovation is the “assortment-handling grapple”. In addition to the conventional claws, an assortment-handling grapple has a pair of extra claws, which enable the operator to handle two piles of different assortments during one loading-crane cycle. Different product generations of assortment-handling grapple have been studied in a machine simulator and during real-world forwarding operations (Brunberg and Lundström 2016; Mörk et al. 2017; Englund et al. 2018a; Petaja et al. 2018).

Besides mechanical innovations, a forwarder’s crane-work productivity could possibly be improved by automating recurrent boom-movement patterns, or at least some part of them (Westerberg 2014). Theoretical algorithms designed to automate forwarder-crane functions have been introduced in recent years (Ortiz Morales et al. 2014; La Hera and Ortiz Morales 2015). In addition, fully sensorized forwarder cranes have now been commercially available for several years (e.g. Cranab 2013). However, at the time of writing, automated crane concepts have only been implemented on test beds and in machine simulators (Hansson and Servin 2010; Englund et al. 2017).

Instead of automating specific boom-movement patterns, automation can also be used to facilitate manual crane work performed by the operators. “Boom-tip control” is an example of this type of automation. When working with a conventional boom control (CBC), the operator manually controls the movements of each boom independently and combines those movements into the desired boom-tip path. In contrast, if the crane is equipped with boom-tip control, the operator does not need to control each joint separately but (s)he directly controls the movement of the boom tip.

Unlike full automatization of recurrent crane movements, boom-tip control has been used in practice for several years. In 2013, John Deere Forestry introduced their version of a boom-tip control system, called Intelligent Boom Control (IBC; John Deere 2013). Some other forest-crane manufactures have also introduced boom-tip control technology, including Ponsse and Palfinger, whose systems are respectively called “PONSSE Active Crane” (Ponsse 2018) and “Smart Control” (Palfinger 2018).

The development of boom-tip control for forestry applications began as early as the 1980s (Löfgren 1989; Löfgren et al. 1994; Löfgren and Wikander 2009). The steering principles of CBC and IBC are described in Section 2.1. Manner et al. (2017) found that using IBC, instead of CBC, improves the crane-work productivity of beginner-level operators (i.e. students at vocational school) because of the improved crane manoeuvrability provided by IBC. However, the authors also noted that the promising results from their study should be supplemented by a field study involving professional machine operators.

Hence, the objective of the present study was to examine whether IBC affects the productivity of professional forwarder operators. Moreover, we assessed the feasibility of using an automatically recorded follow-up dataset in comparative study on forwarding.

2 Material and methods

2.1 Boom-control systems

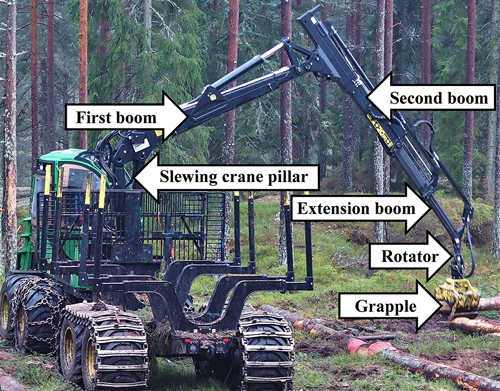

The structure and technical principles of knuckle-boom cranes used on forwarders have been described in detail by various authors, including Gerasimov and Siounev (1998, 2000). Therefore, we only briefly describe the functionality of a forwarder crane. A vertical crane pillar rotates around its axis, thereby achieving the slewing motion of the whole boom system (Fig. 1). Loads are lifted and lowered primarily by manipulating the first boom (also called a “pivoting mid boom”), and secondarily by manipulating the second boom (also called an “outer boom”). The distance between the crane pillar and boom-tip (the “reach”) is controlled by three adjustable parameters: the length of the extension boom, the angle between the crane pillar and the first boom, and the angle between the first- and second booms.

Fig. 1. The knuckle-boom system used in Nordic cut-to-length forwarders consists of a slewing crane pillar, first boom (or “pivoting mid boom”), second boom (or “outer boom”), extension boom, rotator and unlimited rotatable grapple.

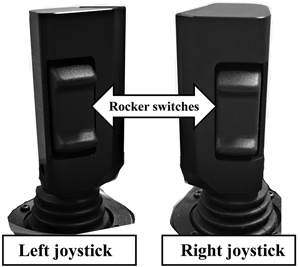

The controls for a forwarder crane consist of left and right joysticks (Fig. 2). Whether the machine is equipped with IBC or not, the crane controls (i.e. joysticks) are standard and similar for all Nordic cut-to-length forwarders. Each of the joysticks has a rocker switch. Furthermore, controls for opening and closing the grapple, slewing the crane pillar and using the grapple rotator are identical, irrespective of the system (IBC or CBC). In both systems, the left joystick’s left-right actuation slews the crane pillar (i.e. turns the whole boom system), the right joystick’s left-right actuation controls the grapple rotator, and the right rocker switch opens and closes the grapple.

Fig. 2. Standard joysticks used in all Nordic cut-to-length forwarders.

The behaviour of the other controls differs between CBC and IBC. In CBC, the right joystick’s back-forth actuation manipulates the first boom, and the left joystick’s back-forth actuation manipulates the second boom. The left rocker switch controls the length of the extension boom. In contrast, in IBC, the left joystick’s back-forth actuation moves the boom-tip towards or away from the crane pillar, while the right joystick’s back-forth actuation lifts and lowers the boom tip. Use of the left rocker switch is not normally necessary (but the operator may “override” the IBC and use the left rocker switch to control the extension-boom in the same manner as in CBC). Thus, the joysticks’ back-forth actuations in IBC no longer correspond to a specific crane joint or cylinder (as in CBC), rather IBC automatically combines movements of the first- and second booms and the extension boom to achieve the desired movement of the boom-tip. The operator only needs to combine the boom-tip movements, towards-and-away, up-and-down, and slewing in order to achieve the desired path of the boom-tip. IBC requires the crane to be fitted with position sensors in the hydraulic cylinders and software that computes how to achieve the desired boom-tip movement. In contrast, when using CBC, operators must themselves decide how to steer each boom joint and then combine the movements of each boom joint in order to achieve the desired path for the boom-tip.

2.2 Stands, machines and operators in the study

The data used in the study were gathered from final-felling stands during the summer and autumn of 2017. Ten stands were used, located in the Swedish regions of Södra Småland, Södra Bergslagen and Västerbotten, covering typical logging conditions for southern, middle and northern Sweden. The terrain of stands located in southern and middle Sweden was flat. The terrain in northern Sweden was slightly hillier, but posed no practical obstacles to forwarding. The typical number of assortments in the stands varied from five (northern Sweden) to seven (southern Sweden). The tree species were the same in each province, consisting of spruce (Picea abies (L.) H. Karst.), pine (Pinus sylvestris L.) and birch (Betula pendula Roth / B. pubescens Ehrh.).

Four, practically brand-new, John Deere eight-wheeled forwarders were observed during the followed-up study. Two of the machines were model 1510E (payload, 15 tons; power, 164 kW) and the other two were model 1910G (payload, 19 tons; power, 200 kW). All the machines were equipped with a rotating and levelling cabin. Crane reach was 8.5 m for all machines except one 1510E that had a crane with a reach of 10 m. Grapple areas were 0.36 m2 and 0.40 m2 for the 1510E and 1910G machines, respectively. All the machines had different load-spaces: one of the smaller machines (1510E) had “Variable Load Space” (load area varying from 4.4 to 5.3 m2) and the other “Active Load Space” (no definable load area available), while the larger machines (1910G) had either “Wide Load Space” (load area, 6.5 m2) or “Narrow Load Space” (load area, 5.3 m2).

Seven professional operators participated in the study. They were all male with ages ranging from late 20s to early 60s and an average age of approximately 50 years. Working experience varied from a few years to roughly three decades. We are not allowed to provide more detailed information about the operators to ensure their complete anonymity.

The operators had worked more extensively with CBC during the course of their careers, but before the study all of them had been working with IBC. This could have skewed the results of the study in favour of IBC. Therefore, before the data gathering began the operators used CBC to reacquaint them with CBC functionality and -routines.

In practice, professional forwarder operators adjust crane-control settings, such as the boom speed and -acceleration, according to personal preferences. The operators were allowed to choose their settings and no standardized crane-control settings were applied. We asked operators to ensure that all crane settings were properly adjusted. Optimal crane-control settings are system-specific and may differ significantly between CBC and IBC. Guidance from an independent forwarding instructor was available whenever needed, to ensure that optimal crane settings were used for both boom-control systems.

2.3 Variables

In this study, the experimental unit, and hence unit of observation, was one complete forwarder load (excluding the work elements “driving empty” and “driving loaded”, as explained below). Only productive machine (PM) time was included in the study (IUFRO 1995). If no machine function was being used, no time was recorded, whether the engine was idling or not.

TimberLink software, used in John Deere’s forwarders, generally recognizes work elements based on probabilistic computation on the control signals generated by the operator. As TimberLink’s basic principles have been explained in detail by Manner et al. (2016), here we only briefly delineate the interfaces between work elements. The loading phase, in general, starts at the same time as the first Loading-crane cycle and ends when the last Loading-crane cycle finishes. Similarly, the unloading phase starts with the first Unloading-crane cycle and ends with the last Unloading-crane cycle. The time interval between the last Unloading-crane cycle and the first Loading-crane cycle, i.e. the time “driving empty”, was excluded from each load because it is not relevant when comparing boom-control systems. The time interval between the last Loading-crane cycle and the first Unloading-crane cycle, i.e. “driving loaded” was excluded for similar reasons.

Several study variables were identified, and their respective values were recorded for each load. For the loading work these variables were: Loading-crane work only, i.e. excluding simultaneous driving (minutes load–1), Loading drive only, i.e. excluding simultaneous crane work (minutes load–1), Loading drive, i.e. also including simultaneous crane work (minutes load–1), Crane in use during loading-drive time (% of loading-drive time), Loading-crane cycle time (seconds cycle–1), Number of loading-crane cycles (count load–1), Loading-drive distance (m load–1), and Loading-drive speed (km h–1). Speed was measured only when it was non-zero (>0 km h–1). Finally, the entire PM time interval from the start of loading to the end of loading was pooled within each load into a variable Loading phase (minutes load–1).

Variables for the unloading work were: Unloading-crane work only, i.e. excluding simultaneous driving (minutes load–1), Unloading drive, i.e. including simultaneous crane work (minutes load–1), Unloading-crane cycle (seconds cycle–1), Number of unloading-crane cycles (count load–1), and Unloading-drive distance (m load–1). The entire PM time interval from the start of unloading to the end of unloading was pooled within each load into a variable Unloading phase (minutes load–1).

Finally, the Loading phase and Unloading phase variables were summed per load, creating a new variable Loading and Unloading pooled (minutes load–1) as an overall measure of forwarding productivity. Most recorded variables did not directly measure productivity, and some variables did not have any direct relationship with crane work at all (e.g. driving speed). However, such variables were included to improve understanding of any productivity differences found between the boom-control systems, e.g. indications that use of IBC increased operators’ tendencies to engage in simultaneous crane work and driving. This would consequently influence other variables, such as “crane work only”, “simultaneous crane work and driving”, and “driving speed”.

2.4 Randomized follow-up

During the data gathering, each operator used solely one boom-control system (hereafter named “system”) during two consecutive work shifts. Hence, operators switched systems (between CBC and IBC) every second work shift. Each machine was operated by two operators; and both operators worked in the same stands. For instance, if operator 1 used CBC during his first two work shifts, then his colleague operator 2 used IBC during his first two shifts. After that both operators switched the system for the next two shifts, and so on. Hence, the day-to-day working shift schedule was as follows:

Day 1: operator 1 uses CBC, and operator 2 uses IBC.

Day 2: operator 1 uses CBC, and operator 2 uses IBC.

Day 3: operator 1 uses IBC, and operator 2 uses CBC.

Day 4: operator 1 uses IBC, and operator 2 uses CBC.

And so on, until each operator had accomplished at least 10 working shifts per system. Thus, the data gathering covered at least 20 work shifts per operator in total.

This alternation ensured that CBC and IBC were used equally in the study stands. Thus, the levels of the primary factor System were randomly assigned to the experimental units. The number of operators decreased from eight to seven after one operator left the study. However, as the operator in question completed his working shifts as usual, his discontinuity from the study did not directly affect his colleague’s participation in the study.

The schedule and, most importantly, the randomization was not sensitive to deviations from ordinary work. Each operator was provided with a schedule in the form of an Excel spreadsheet. Operators also used the spreadsheet to report disruptions and deviations from normal work routines (such as bridge construction or preparation of strip-roads and landing areas), including start and end times of the disruption. We removed loads that had been affected by such disruptions from the dataset. However, no systematic rule-based filtering was used to remove outliers (cf. Berg et al. 2019). In general, beyond specifying which boom-control system was used, the data-gathering did not require any special arrangements or changes to working practices.

2.5 Acquiring data via on-board computer

TimberLink datafiles from the machines were delivered to John Deere Forestry Oy in Finland, where the TimberLink basic measurements were further processed to generate values, i.e. observations, for the variables described in Section 2.3. Each observation was also tagged with a time label. Follow-up data with this level of resolution is encrypted and not normally accessible.

At the beginning of a shift, each operator logged on to his machine with a unique username. The forwarder’s on-board computer time-labelled each log-in event and saved the information. In addition, the on-board computer time-labelled each change made in the forwarder’s crane mode, including switching between IBC and CBC modes. When IBC was switched off, the system functioned as CBC.

Hence, because each time-, count-, distance- and speed observation was time-labelled, as well as each change of operator (username) and system (CBC or IBC), we could organise all the observations by operator, stand, and system for subsequent statistical analyses. However, we did not have any per-load data on forwarded volumes or assortments.

2.6 Statistical models

The levels of the primary factor, System (CBC, IBC), were randomly assigned to the experimental units. However, complete randomization across all the factors was not possible due to practical limitations, such as the study stands being geographically scattered over a large area, and inclusion of several operators and machines. Thus, randomization across the factors only occurred within a stand, and we applied a “split-plot design” comprising both crossed and nested effects.

The split-plot design has certain limitations. Firstly, we cannot compare the performance of different operators under the same conditions, except for colleagues driving the same machine in the same stand(s). Similarly, as we were required to nest the factor Stand within the factor Operator (or vice versa), the effect of Stand cannot be unambiguously isolated, rather the effect can only be compared over operators driving the same machine. In most cases there was only one study stand per machine anyway. Nevertheless, we can unambiguously compare levels of the factor System (CBC, IBC), which indeed was the main objective of the study. Finally, despite the abovementioned inability to unambiguously isolate all factor effects, the interaction effects of Operator × System and Stand(Operator) × System show whether or not the effect of factor System, in general, varied between the different work conditions and/or operators.

In order to reduce the number of terms in our analyses we did not include “machine” as a factor in the applied statistical models. Thus, the factor Stand did not solely cover stand-specific effects – such as mean-stem volume, tree species, surface roughness, soil-bearing capacity, inclination, weather – but also effects such as machine model, type of crane and load-space. Such a simplification was justified because it did compromise our ability to meet the main objective of the study, i.e. isolate the System affect.

Our dataset did not include load-wise information on forwarded volumes (mass) or assortments (counts, proportions). This limitation was primarily controlled by the randomized design, and secondarily by using Loading- and Unloading-drive distances as covariates in the applied statistical models.

Loading-drive distance reflects the combination of number of loaded assortments and their abundance at the harvesting site (Manner et al. 2013). Thus, Loading-drive distance to some extent covers missing assortment-related variables, and thus may be used as a control variable for loading-work conditions.

Unloading time, in turn, depends on the load structure. However, load structure is an ill-defined term. For instance, the assortment combinations and -proportions can vary significantly. Moreover, the assortments are loaded into the vague “sections” in the load-space (sometimes referred as “loading patterns”, see e.g. Rönnqvist et al. (1999)). In addition, unloading time is dependent on the placement of assortment-piles at the landing. Consequently, modelling unloading time, including all the factors affecting it, is complex. Unloading-drive distance can be considered as a control variable for unloading work, as both disadvantageous load structure and placement of (load-specific) assortment-piles far apart from each other lead to a substantial amount of driving at the landing, hence increasing Unloading-drive distance (Manner et al. 2013; Manner 2015). Covariates were used if they significantly contributed to the model, were considered logical, and there was no risk of them being confounded with treatment effects.

To summarize, the factor System had two levels, Operator had seven levels, and Stand 10 levels. Stand was nested within the Operator. Comparability (CBC, IBC) was ensured primarily through the randomization of conditions for the System, and secondarily through the use of covariates. Most of our statistical modelling was intended to improve statistical power, i.e. error reduction.

Estimated marginal means (EMM), medians, 5th and 95th percentiles were calculated for the dependent variables. After removing loads that had been subject to some disruption, the dataset contained data from 1238 loads (572 using CBC and 666 using IBC). The number of loads per operator varied from 147 to 231. Assumptions for the analysis of covariance (ANCOVA) were satisfied according to Barrett (2011) and Johnson (2016). If data did not meet ANCOVA assumptions the data were transformed accordingly. The general linear model (GLM) was used to analyse the ANCOVA models, and pair-wise differences were analysed using the Tukey-Kramer method. The significance level was set to 5%. Readers are referred to Table 1 in Section 3 for further details on final statistical models. Type III sums of squares (SS), i.e. partial sums of squares, were used to determine the proportion that the given term explained of the variance of the dependent variable. The statistical package Enterprise Guide 7.1 (SAS Institute Inc.) was used for all analyses.

3 Results

3.1 Main effects of the System (CBC and IBC)

Total time consumption for CBC and IBC was 31.8 and 30.0 minutes load–1, respectively (Loading and Unloading pooled, Table 2). The time saving of 5.8% when using IBC was statistically significant.

Productive loading work in total took 23.2 minutes load–1 for CBC and 22.0 minutes load–1 for IBC (Loading phase, Table 2). The time saving of 5.2% when using IBC was statistically significant. Statistically significant differences between the systems were also found for the single work elements of Loading-crane work only and Loading-crane cycle time (Table 1). Loading-crane work only for CBC was 15.1 minutes load–1, while for IBC it was 8.6% less: 13.8 minutes load–1 (Table 2). Correspondingly, Loading-crane cycle time for CBC was 24.2 seconds cycle–1, while for IBC it was 5.6% less: 22.9 seconds cycle–1 (Table 2). However, no statistically significant differences between the systems were found for Crane in use during loading drive (% of time), Loading drive, no crane (minutes load–1), Loading drive (minutes load–1), Number of loading-crane cycles (count load–1) or Loading-drive speed (km h–1) (Tables 1 and 2).

| Table 1. Levels of significance (p-values) and explained variance (R2, adjusted) obtained from the analysis of covariance (ANCOVA) in which a is Operator, b(a) is Stand nested within Operator, c is System, b(a)×c is the fixed interaction between Stand (nested within Operator) and System, and α×c is the fixed interaction between Operator and System. Moreover, d and e are the fixed effects of the covariates Loading-drive distance and Unloading-drive distance. Hyphen “-” means that the covariate did not contribute to the model and was removed from the final model; an empty cell means that the effect was not tested at all. The unit of observation is one load, and the number of loads is 1238. Significant values (p ≤ 0.05) in bold. | ||||||||

| p-value | R2 | |||||||

| Dependent variable (sort) | a | b(a) | c | b(a)×c | a×c | d | e | adj. (%) |

| Loading and Unloading pooled (minutes load–1) | <0.001 | <0.001 | <0.001 | 0.742 | 0.645 | <0.001 (1 | <0.001 (2 | 63.5 |

| Loading phase (minutes load–1) | 0.010 | <0.001 | 0.005 | 0.599 | 0.728 | <0.001 (1 | 65.6 | |

| Loading-crane work only, i.e. no drive (minutes load–1) | <0.001 | <0.001 | <0.001 | 0.284 | 0.055 | <0.001 (1 | 45.3 | |

| Loading drive only, i.e. no crane (minutes load–1) | <0.001 | <0.001 | 0.399 | 0.216 | 0.436 | <0.001 | 87.4 | |

| Loading drive, i.e. including crane work (minutes load–1) | <0.001 | <0.001 | 0.530 | 0.004 | 0.005 | <0.001 | 81.3 | |

| Crane in use during loading drive (% of loading-drive time) | <0.001 | <0.001 | 0.166 | 0.158 | <0.001 | - | 48.1 | |

| Loading-crane cycle time (seconds cycle–1) (1 | <0.001 | <0.001 | <0.001 | 0.029 | 0.184 | - | 39.1 | |

| Number of loading-crane cycles (count load–1) | <0.001 | <0.001 | 0.413 | 0.225 | 0.983 | <0.001 (1 | 51.1 | |

| Loading-drive speed (km h–1) | <0.001 | <0.001 | 0.573 | 0.001 | <0.001 | <0.001 (1 | 68.1 | |

| Unloading phase (minutes load–1) | <0.001 | 0.023 | 0.001 | 0.838 | 0.275 | <0.001 (2 | 41.5 | |

| Unloading-crane work only, i.e. no drive (minutes load–1) (3 | <0.001 | 0.002 | <0.001 | 0.666 | 0.268 | <0.001 (2 | 26.9 | |

| Unloading drive, i.e. including crane work (minutes load–1) | <0.001 | 0.003 | 0.224 | 0.561 | 0.066 | <0.001 | 77.6 | |

| Unloading-crane cycle time (seconds cycle–1) (1 | <0.001 | <0.001 | <0.001 | 0.590 | 0.006 | - | 35.5 | |

| Number of unloading-crane cycles (count load–1) | <0.001 | 0.170 | 0.136 | 0.827 | 0.121 | <0.001 (2 | 18.7 | |

| When meeting the ANCOVA assumptions required, dependent variables and/or covariates were transformed accordingly: 1) Ln transformation 2) Ln + 1 transformation (data included a minor number of zeros) 3) Square-root transformation | ||||||||

| Table 2. Estimated marginal means (EMM) for the dependent variables. EMMs are followed by medians, 5th and 95th per centiles in parentheses. CBC stands for conventional boom control, while IBC stands for Intelligent Boom Control. Relative differences in EMMs, that are statistically significant between the systems (CBC, IBC), are given in percentages (i.e. 100% – IBC/CBC). A hyphen “-” indicates no significant difference between the systems. ANCOVA results are presented in Table 1. | |||||

| CBC | IBC | Significant difference | |||

| Dependent variable (sort) | EMM | Median (5th; 95th) | EMM | Median (5th; 95th) | |

| Loading and Unloading pooled (minutes load–1) (1 | 31.8 | 31.6 (14.1; 56.0) | 30.0 | 28.9 (13.4; 51.3) | 5.8% |

| Loading phase (minutes load–1) (1 | 23.2 | 22.3 (9.3; 43.2) | 22.0 | 20.6 (8.3; 39.2) | 5.2% |

| Loading-crane work only, i.e. no drive (minutes load–1) (1 | 15.1 | 15.1 (5.2; 28.8) | 13.8 | 13.6 (4.5; 24.9) | 8.6% |

| Loading drive only, no crane (minutes load–1) (1 | 4.3 | 3.3 (0.6; 12.2) | 4.3 | 3.4 (0.5; 12.7) | - |

| Loading drive, i.e. including crane work (minutes load–1) (1 | 8.3 | 6.8 (2.0; 19.0) | 8.2 | 6.9 (1.9; 19.3) | - |

| Crane in use during loading drive (% of driving time) | 46.6 | 43.2 (13.6; 88.4) | 48.1 | 40.9 (11.0; 89.9) | - |

| Loading-crane cycle time (seconds cycle–1) (2 | 24.2 | 24.2 (19.2; 32.2) | 22.9 | 22.5 (18.2; 30.0) | 5.6% |

| Number of loading-crane cycles (count load–1) (1 | 43.5 | 43.0 (19.0; 70.0) | 43.0 | 41.0 (19.0; 71.0) | - |

| Loading-drive speed (km h–1) (1 | 1.6 | 1.5 (0.8; 2.6) | 1.6 | 1.7 (0.8; 2.5) | - |

| Unloading phase (minutes load–1) (1 | 8.7 | 8.2 (4.0; 15.3) | 8.0 | 7.6 (3.4; 15.3) | 7.9% |

| Unloading-crane work only, i.e. no drive (minutes load–1) (1, (2 | 7.1 | 7.2 (3.5; 13.1) | 6.4 | 6.7 (3.0; 12.5) | 9.7% |

| Unloading drive (minutes load–1) (1 | 1.3 | 0.8 (0.1; 3.6) | 1.4 | 0.9 (0.1; 4.1) | - |

| Unloading-crane cycle time (seconds cycle–1) (2 | 23.4 | 23.5 (18.5; 32.6) | 21.8 | 22.0 (17.0; 29.0) | 6.8% |

| Number of unloading-crane cycles (count load–1) (1 | 19.1 | 19.0 (9.0; 29.0) | 18.6 | 19.0 (8.0; 30.0) | - |

| 1) EMM at statistically equalized Loading- and/or Unloading-drive distances, i.e. approximately 224 m for Loading-drive distance and 45 m for Unloading-drive distance (exact distances vary slightly depending on whether the covariate was transformed or not, see Table 1) 2) EMMs are back-transformed from the transformed data (see Table 1) | |||||

Unloading in total took 8.7 minutes load–1 for CBC and 8.0 minutes load–1 for IBC (Unloading phase, Table 2). The time saving of 7.9% when using IBC was statistically significant (Table 1). Statistically significant differences between the systems were also found for the single work elements Unloading-crane work only and Unloading-crane cycle time (Table 1). Unloading-crane work only for CBC was 7.1 minutes load–1, while for IBC it was 9.7% less: 6.4 minutes load–1 (Table 2). Correspondingly, Unloading-crane cycle time for CBC was 23.4 seconds cycle–1, while for IBC it was 6.8% less: 21.8 seconds cycle–1 (Table 2). However, no statistically significant differences between the systems were found for Unloading drive (minutes load–1) or Number of unloading-crane cycles (count load–1) (Tables 1 and 2).

3.2 Interactions, Operator- and Stand-wise analyses

All the operators needed less time when using IBC compared to using CBC, according to both separate analyses of time consumption (minutes load–1) for loading- and unloading work, and analysis of pooled within-load data (per-operator data not shown). However, one operator required slightly more time for Unloading phase when using IBC. In contrast to the overall analyses above (i.e. data from all operators and stands pooled), none of these intra-operator differences between the systems was statistically significant (0.107 ≤ p ≤ 1.000, more detailed results not shown), although one operator’s time saving of 14.7% during the Unloading phase when using IBC was statistically significant. Similar results were found for the factor Stand (nested within the factor Operator). Using IBC saved time (minutes load–1) in each stand, but these intra-stand differences between the CBC and IBC were not statistically significant (per-stand data not shown), regardless of whether the time consumption (minutes load–1) was analysed separately for Loading- and Unloading phases, or pooled over the phases (0.271 ≤ p ≤ 1.000, more detailed results not shown). And finally, ANCOVA did not show any significant effects of the terms Operator×System or Stand(Operator)×System on these dependent variables (0.275 ≤ p ≤ 0.838, Table 1).

Moreover, dividing forwarding into smaller work elements did not change the results in any notable way. In most cases no statistically significant effects of the interaction terms Operator × System and Stand(Operator) × System were observed (0.066 ≤ p ≤ 0.983, Table 1). However, in some sporadic exceptions, the System significantly affected intra-operator performance, which in turn resulted in significant interaction effects (p ≤ 0.029, Table 1). However, these statistically significant interaction effects were practically non-existent according to Type III SS (no detailed data shown).

3.3 Control variables

The inclusion of control variables, i.e. the covariates Loading- and Unloading-drive distances, effectively normalized the residual distributions and reduced error. Consequently, GLM procedures were often conducted without transformation of the dependent variable, albeit with a few exceptions (Table 1). In most analyses, covariate(s) explained the largest proportion(s) of the total variation in a dependent variable (Type III SS). For instance, Loading-drive distance explained 60.9% of Loading phase pooled time, while the remaining factors accounted for 4.7% in total (error 34.4%). Furthermore, Unloading-drive distance explained 30.0% of Unloading phase pooled time, while the other factors accounted for 11.5% in total (error 58.5%). Moreover, in addition to the work elements that include driving, the covariates also explained large proportions of the variation in work elements unrelated to driving such as Loading- and Unloading-crane work only (explained proportions 28.1 and 10.9%, respectively).

Finally (for purely descriptive purposes), the arithmetic means of Loading-drive- and Unloading-drive distances were 224.2 and 43.8 m load–1 for CBC; the corresponding values for IBC were 223.6 and 45.9 m load–1, respectively.

4 Discussion

To summarize, the productivity of all operators was enhanced by IBC. Because of large dispersion and small number of observations, the intra-operator comparisons between the systems (CBC, IBC) lacked statistical power. Pooling data across the operators improved the statistical power enough to show a statistically significant productivity difference between the systems. Moreover, covariates Loading- and Unloading-drive distances were the most important factors affecting forwarding work; hence we found them to be usable control variables in (comparative) forwarding studies.

Loading- and unloading work (including the respective driving elements) typically constitutes 65–70% of a forwarder’s total PM time, while pure transport work (i.e. driving empty and loaded) constitutes around 30–35% (Brunberg and Lundström 2016; Manner et al. 2016). IBC’s time saving of 5.8% during the loading- and unloading work corresponds to approximately 4% decrease in total PM time consumption when also “driving empty” and “driving loaded” are included (cf. Table 2). However, the relative time proportions of the work elements are dependent on geophysical factors.

General strengths and weaknesses of automatic data gathering in forest-work studies, which naturally also apply to our study, have been discussed in detail by, for example, Väätäinen et al. (2003), Nuutinen (2013) and Manner (2015). Meanwhile, study-specific weaknesses are addressed in the paragraphs below.

On the one hand, representativeness is a strength of our study: it covered several operators, machines and stands geographically spread across all of Sweden. On the other hand, the representativeness hindered complete randomization across all the factors studied. For instance, it was not practically feasible for all operators (and machines) to work in every stand due to the long distances between the stands. Moreover, it may be feasible for two operators to use two alternative systems within each stand (as in our study), but larger numbers of operators (and/or alternative systems) would be impractical because few stands would be large enough to accommodate them. However, this limitation did not prevent achievement of our main objective as we were able to isolate the System effect, i.e., compare CBC and IBC without the risk of causal fallacy.

Switching the system (between CBC and IBC) more frequently, for instance after every working shift or after every completed load, would theoretically have improved the randomization. However, doing so may have a short-term (detrimental) effect on operator performance, which in turn might be confounded with the System effect. According to results of the study by Englund et al. (2018b), switching systems could have favoured IBC. The influence of this possible confounding effect theoretically increases as the frequency of switching systems increases. Hence, to control this (possible) confounding effect, operators used the same system in two consecutive working shifts. This was a compromise between ensuring sufficient randomization of conditions over the factor System and limiting the confounding effect caused by switching systems. Moreover, participating operators were highly experienced in the use of both systems, which should also have minimized the potential confounding effect.

There were practically no inter-system differences in the variable-wise observation distributions (medians, 5th and 95th percentiles, Table 2). Moreover, neither Number of loading- nor Unloading-crane cycles differed between the systems (Table 2). We did not observe any meaningful inter-system differences for the arithmetic means of Loading- or Unloading distances either (and possible differences would be statistically controlled through covariates anyway). Collectively, this indicates that neither load-sizes nor assortment combinations differed between the compared systems.

In comparative forest-operation studies, productivity is preferably presented as a ratio between roundwood volume (e.g. m3) and time (e.g. minutes). Because our dataset did not include the volumes of the forwarded loads, we have reported productivity results per load instead. Weighing the loads and converting the weights into volumes could be feasible, but this solution would have required the machines to have been fitted with scales. However, the relative differences (or lack of significant differences) would be the same whether the results are given per load or unit volume (m3), given that the load sizes between the systems were equal.

In comparative forwarding studies it is preferable to present intra-operator results (Englund et al. 2017, 2018a). However, due to the small number of loads per operator (in the follow-up context) we have presented figures solely for pooled data (across the operators). In follow-up studies in the future the number of observations per operator should be increased.

In the introduction we emphasized the importance of sustaining crane-work efficiency even when increasing the number of assortments forwarded together in a load. Furthermore, we identified three commercially available products that are known to increase crane-work productivity: boom-tip control, tilt-grapple, and assortment-handling grapple. Hitherto these innovations have only been studied in isolation, but it may be worth investigating whether some additional (holistic) advantage may be gained by using them together. Englund et al. (2018a) found that use of an assortment-handling grapple saves time only when there are no remaining trees between the piles loaded during the same crane cycle, due to the extra time required to steer bunches of logs around the remaining trees. However, the use of a tilt-grapple together with an assortment-handling grapple might reduce the extra time required. Such a “tiltable assortment-handling grapple” configuration would ideally be steered by a boom-tip control system.

4.1 Conclusions

The results show that boom-tip control significantly increases forwarding productivity. Hopefully, this awareness helps the forest-machinery sector to focus their research- and development resources regarding the crane-steering principles.

Funding for forest-work research is often scarce. Hence, it is important to find cost-effective methods for conducting comparative (field) studies on new technological innovations or alternative working methods during ordinary logging operations. This study introduced in a cut-to-length context novel field-study design to collect a large follow-up dataset in the course of ordinary forwarding operations. Although, the applied study design required some minor adjustments to normal working practices, we found it to be a cost-efficient way to combine the representativeness of conventional follow-up datasets with the ability to establish causal relationships. Establishment of causal relationship has traditionally been possible only through observational time studies or standardized experiments. Thus, we found the applied study design to be a feasible approach for future comparative studies of forwarding technology and working practices.

Acknowledgements

We thank participating operators and other staff at the Swedish forest companies Sveaskog, Holmen Skog, and SCA Skog. In addition, we thank Sees-editing Ltd. and Back Tomas Ersson (SLU) for revising the English. This study was financed by Skogforsk.

References

Ågren A.M., Lidberg W., Strömgren M., Ogilvie J., Arp P.A. (2014). Evaluating digital terrain indices for soil wetness mapping – a Swedish case study. Hydrology and Earth System Sciences 18: 3623–3634. https://doi.org/10.5194/hess-18-3623-2014.

Ala-Ilomäki J., Högnäs T., Lamminen S., Sirén M. (2011). Equipping a conventional wheeled forwarder for peatland operations. International Journal of Forest Engineering 22(1): 7–13. https://doi.org/10.1080/14942119.2011.10702599.

Barrett T.J. (2011). Computations using analysis of covariance. WIREs Computational Statistics 3(3): 260–268. https://doi.org/10.1002/wics.165.

Berg S., Ersson B.T., Manner J. (2019). Distance driven and driving speed when forwarding during final felling in central-Sweden. Journal of Forest Science 65(5): 183–194. https://doi.org/10.17221/23/2019-JFS.

Brunberg T., Lundström H. (2016). Tidsåtgång och bränsleåtgång vid användning av sortimentsgripen 2014. [Evaluation of assortment grapple 2014 in terms of processing time and fuel consumption]. Arbetsrapport nr. 909-2016. Skogforsk, Uppsala.

Cranab AB. (2013). The first fully sensorized forwarder crane. Press Release. 30th of May 2013.

Edlund J., Keramati E., Servin M. (2013). A long-tracked bogie design for forestry machines on soft and rough terrain. Journal of Terramechanics 50(2): 73–83. https://doi.org/10.1016/j.jterra.2013.02.001.

Englund M., Mörk A., Andersson H., Manner J. (2017). Delautomation av skotarkran – utveckling och utvärdering i simulator. [Semi-automated forwarder crane – development and evaluation in a simulator]. Arbetsrapport nr. 932–2017. Skogforsk, Uppsala.

Englund M., Berg S., Mörk A., Manner J. (2018a). Sortimentshanterande grip. [Assortment-handling grapple]. Arbetsrapport nr. 994-2018. Skogforsk, Uppsala.

Englund M., Mörk A., Gelin O., Eliasson L. (2018b). Påverkan av kranspetsstyrning på nya skogsmaskinförares utveckling. [Effects of boom tip control on the learning progress of new forest machine operators]. Arbetsrapport 968-2018. Skogforsk, Uppsala.

Flisberg P., Forsberg M., Rönnqvist M. (2007). Optimization based planning tools for routing of forwarders at harvest areas. Canadian Journal of Forest Research 37(11): 2153–2163. https://doi.org/10.1139/X07-065.

Gerasimov Y.Y., Siounev V.S. (1998). Forest machinery crane compound scheme synthesis: “skeleton” part. Journal of Forest Engineering 9(1): 25–30.

Gerasimov Y.Y., Siounev V.S. (2000). Forest machinery crane compound scheme synthesis: optimization of hydraulic cylinder operating mechanisms. Journal of Forest Engineering 11(1): 73–79.

Häggström C., Öhman M., Burström L., Nordfjell T., Lindroos O. (2016). Vibration exposure in forwarder work: effects of work element and grapple type. Croatian Journal of Forest Engineering 37(1): 107–118.

Hansson A., Servin M. (2010). Semi-autonomous shared control of large-scale manipulator arms. Control Engineering Practice 18(9): 1069–1076. https://doi.org/10.1016/j.conengprac.2010.05.015.

Hosseini A., Lindroos O., Wadbro E. (2019). A holistic optimization framework for forest machine trail network design accounting for multiple objectives and machines. Canadian Journal of Forest Research 49(2): 111–120. https://doi.org/10.1139/cjfr-2018-0258.

IUFRO WP 3.04.02 (1995). Forest work study nomenclature. Test edition valid 1995–2000. Department of Operational Efficiency, the Swedish University of Agricultural Science.

John Deere (2013). News and Announcements. https://www.deere.com/en/our-company/news-and-announcements/. [Cited 12 Dec 2018].

Johnson T.R. (2016). Violation of the homogeneity of regression slopes assumption in ANCOVA for two-group pre-post designs: tutorial on a modified Johnson-Neyman procedure. The Quantitative Methods for Psychology 12(3): 253–263. https://doi.org/10.20982/tqmp.12.3.p253.

Kaleja S., Petaja G., Zimelis A., Puzuls K. (2018). Increase of forwarding productivity and reduction of tree damages in thinning by use of loading grapple with tilt function. 17th International Scientific Conference Engineering for Rural Development 23–25.5.2018 Jelgava, Latvia. Latvian State Forest Research Institute “Silava”. https://doi.org/10.22616/ERDev2018.17.N148.

Kellogg L.D., Bettinger P. (1994). Thinning productivity and cost for mechanized cut-to-length system in the Northwest Pacific coast region of the USA. Journal of Forest Engineering 5(2): 43–52. https://doi.org/10.1080/08435243.1994.10702659.

La Hera P., Ortiz Morales D. (2015) Model-based development of control systems for forestry cranes. Journal of Control Science and Engineering 2015 article id 256951. https://doi.org/10.1155/2015/256951.

Lindroos O, Wästerlund I. (2014). Theoretical potentials of forwarder trailers with and without axle load restrictions. Croatian journal of forest engineering 35(2): 211–219.

Löfgren B. (1989). Kranspetsstyrning. [Boom-tip control]. Meddelande nr 18. Skogforsk, Uppsala.

Löfgren B., Attebrant M., Landström M., Nordén B., Petersson N.F. (1994). Kranspetsstyrning – en utvärdering. [Boom-tip control – Evaluation]. Redogörelse nr 1. Skogforsk, Uppsala.

Löfgren B., Wikander J. (2009). Kinematic control of redundant knuckle booms. International Journal of Forest Engineering 20(1): 22–30. https://doi.org/10.1080/14942119.2009.10702572.

Manner J. (2015). Automatic and experimental methods to studying forwarding work. Doctoral thesis. Acta Universitatis Agriculturae Sueciae 2015:128. Swedish University of Agricultural Sciences. ISBN 978-91-576-8454-7. http://urn.kb.se/resolve?urn=urn:nbn:se:slu:epsilon-e-3069.

Manner J., Nordfjell T., Lindroos O. (2013). Effects of the number of assortments and log concentration on time consumption for forwarding. Silva Fennica 47(4) article 1030. https://doi.org/10.14214/sf.1030.

Manner J., Palmroth L., Nordfjell T., Lindroos O. (2016). Load level forwarding work element analysis based on automatic follow-up data. Silva Fennica 50(3) article 1546. https://doi.org/10.14214/sf.1546.

Manner J., Gelin O., Mörk A., Englund M. (2017). Forwarder crane’s boom tip control system and beginner-level operators. Silva Fennica 51(2) article 1717. https://doi.org/10.14214/sf.1717.

Mörk A., Englund M., Brunberg T. (2017). Utvärdering av sortimentsgripen i simulator. [Evaluation of assortment grapple tested in a simulator]. Arbetsrapport nr. 924-2017. Skogforsk, Uppsala.

Nilsson G. (2013). Griptiltens effekt på skotarens produktivitet. [Effects of grapple-tilt on forwarder productivity]. Master’s thesis. Sveriges lantbruksuniversitet, Institutionen för skoglig resurshushållning, Umeå.

Nurminen T., Korpunen H., Uusitalo J. (2006). Time consumption analysis of the mechanized cut-to-length harvesting system. Silva Fennica 40(2): 335–363. https://doi.org/10.14214/sf.346.

Nuutinen Y. (2013). Possibilities to use automatic and manual timing in time studies on harvester operations. Doctoral thesis. Dissertationes Forestales 156. University of Eastern Finland, School of Forest Sciences. https://doi.org/10.14214/df.156.

Ortiz Morales D., Westerberg S., La Hera P.X., Mettin U., Freidovich L., Shiriaev A.S. (2014). Increasing the level of automation in the forestry logging process with crane trajectory planning and control. Journal of Field Robotics 31(3): 343–363. https://doi.org/10.1002/rob.21496.

Palfinger (2018). Highlights of epsilon products 2018. https://www.palfingerepsilon.com/en/EPSILON-Interforst/EPSILON-Highlights. [Cited 13 Feb 2019].

Petaja G., Kaleja S., Zimelis A., Lazdins A. (2018). Comparison of productivity of standard and accumulating forwarder grapple in thinning. 17th International Scientific Conference Engineering for Rural Development 23–25.05.2018 Jelgava, Latvia. Latvian State Forest Research Institute “Silava”. https://doi.org/10.22616/ERDev2018.17.N143.

Ponsse (2018). https://www.ponsse.com/products/. [Cited 13 Feb 2019].

Rönnqvist M., Westerlund A., Carlsson D. (1999). Extraction of logs in forestry using operations research and geographical information systems. Proceedings of the 32nd Annual Hawaii International Conference on Systems Sciences. HICSS-32. https://doi.org/10.1109/HICSS.1999.772610.

Sirén M., Ala-Ilomäki J., Lindeman H., Uusitalo J., Kiilo K.E.K., Salmivaara A., Ryynänen A. (2019). Soil disturbance by cut-to-length machinery on mid-grained soils. Silva Fennica 53(2) article 10134. https://doi.org/10.14214/sf.10134.

Strandgard M., Mitchell R., Acuna M. (2017). Time consumption and productivity of a forwarder operating on a slope in a cut-to-length harvest system in a Pinus radiata D. Don pine plantation. Journal of Forest Science 63(7): 324–330. https://doi.org/10.17221/10/2017-JFS.

Väätäinen K., Ovaskainen H., Asikainen A., Sikanen L. (2003). Chasing the tacit knowledge – automated data collection to find the characteristics of a skillful harvester operator. In: Iwarsson Wide M., Hallberg I. (eds.). 2nd Forest Engineering Conference. Proceedings. Posters: Technique and Methods. Arbetsrapport 539: 3–10. Skogforsk, Uppsala.

Westerberg S. (2014). Semi-automating forestry machines: motion planning, system integration, and human-machine interaction. Doctoral thesis. Robotics and control lab, Umeå University. http://urn.kb.se/resolve?urn=urn:nbn:se:umu:diva-89067.

Total of 43 references.