Harvesting efficiency and understory damage with different cutting methods on two storied stands of silver birch and Norway spruce

Niemistö P., Korpunen H., Nuutinen Y. (2024). Harvesting efficiency and understory damage with different cutting methods on two storied stands of silver birch and Norway spruce. Silva Fennica vol. 58 no. 2 article id 23065. https://doi.org/10.14214/sf.23065

Highlights

- With careful, well-timed harvesting of overstory birch, it is possible to successfully use initial understory spruce in producing the next tree generation

- Preserving understory spruce when cutting overstory birch reduced harvesting productivity by 30% in comparison to unpreserved harvesting

- Removal of overstory birch had a positive correlation in cutting productivity but negative correlation in the quality of remaining understory spruce.

Abstract

Uneven-aged forests set certain challenges for cut-to-length harvesting work. It is a challenge to cost-effectively remove larger trees while leaving a healthy understory for regrowth. The study’s aim was to evaluate productivity and costs of harvesting two-storied Silver birch (Betula pendula Roth) and Norway spruce (Picea abies (L.) H. Karst.) stands by creating time consumption models for cutting, and using existing models for forwarding. Damage to the remaining understory spruce was also examined. Four different harvesting methods were used: 1) all dominant birches were cut; 2) half of them thinned and understory was preserved; compared to 3) normal thinning of birch stand without understory; and 4) clear cutting of two-storied stand. Results showed the time needed for birch cutting was 26–30% lower when the understory was not preserved. Pulpwood harvesting of small sized spruces that prevent birch cutting was expensive, especially because of forwarding of small amounts with low timber density on the strip roads. Generally, when taking the cutting and forwarding into account, the unit cost at clear cuttings was lowest, due to lesser limitations on work. It was noted that with increasing removal from 100 to 300 m3 ha–1, the relative share of initial undamaged spruces after the harvest decreased from 65 to 50% when the aim was to preserve them. During summertime harvesting, the amount of stem damage was bigger than during winter. In conclusion, two-storied stands are possible to transit to spruce stands by accepting some losses in harvesting productivity and damages on remaining trees.

Keywords

productivity;

thinning;

costs;

harvesting damage;

mixed stand;

continuous cover;

multistorey forest

-

Niemistö,

Natural Resources Institute Finland (Luke), Natural resources, Kampusranta 9 C, FI-60320 Seinäjoki, Finland

https://orcid.org/0000-0002-9152-2108

E-mail

ext.pentti.niemisto@luke.fi

https://orcid.org/0000-0002-9152-2108

E-mail

ext.pentti.niemisto@luke.fi

-

Korpunen,

Norsk institutt for bioøkonomi (NIBIO), Division of Forest and Forest Resources, Department of Forest operations and digitalization, Divisjon for skog og utmark, Avdeling for Driftsteknikk og digitalisering, Høgskoleveien 8, 1433 Ås, Norway

https://orcid.org/0000-0001-9749-5684

E-mail

heikki.korpunen@nibio.no

https://orcid.org/0000-0001-9749-5684

E-mail

heikki.korpunen@nibio.no

-

Nuutinen,

Natural Resources Institute Finland (Luke), Production systems, Yliopistokatu 6 B, FI-80100 Joensuu, Finland

https://orcid.org/0000-0003-3360-4444

E-mail

yrjo.nuutinen@luke.fi

https://orcid.org/0000-0003-3360-4444

E-mail

yrjo.nuutinen@luke.fi

Received 26 October 2023 Accepted 14 March 2024 Published 28 March 2024

Views 60077

Available at https://doi.org/10.14214/sf.23065 | Download PDF

1 Introduction

In Nordic countries, a mixed forest formed of coniferous and deciduous trees usually develops by natural regeneration or by planting or sowing after clear-cutting (Kuusela 1990). A mixed forest can be one storied, with different tree species developing in approximately the same canopy layer. In a two storied stand (TSS), some of the tree species form the lower canopy layer beneath the upper dominating canopy layer (Oliver and Larson 1990). Thus, in TSS, at least two different tree species grow in two sizes of canopy layers, which are managed simultaneously. In the boreal forest, the upper layer of TSS usually consists of light demanding birch (Betula pendula Roth) with natural downy birch, (B. pubescens Ehrh.) or Scots pine (Pinus sylvestris L.) (Akujärvi et al. 2016). Shade-tolerant Norway spruce (Picea abies (L.) H. Karst.) dominates the lower layer, called understory. The spatial and size structure of naturally regenerated understory is often uneven (Laiho 1983).

In Nordic countries, the most TSS research information is on birch dominated stands with spruce understory as the lower canopy layer. According to studies and practical experience, TSS management is possible if the soil is sufficiently fertile, in which case spruce and birch growth in TSS is greater than if only one tree species were grown (Jonsson 1962; Fries 1964, 1974; Mielikäinen 1980, 1985; Frivold 1982; Folkesson and Bärring 1982; Agestam 1985; Pukkala et al. 1994). In contrast, the management of pine dominated two-storied stands has information only in few studies (Isomäki 1979; Niemistö and Valkonen 2021; Niemistö 2022).

TSS forests maintain greater and longer-term forest cover than one-storied forests. However, most often, sooner or later, they lead to clear cutting and can be regenerated artificially or naturally. TSS can serve as a starting point for continuous cover forestry (CCF) (Niemistö and Valkonen 2021; Nuutinen et al. 2021) because it contributes to five silvicultural principles, as stated by Puetmann et al. (2015):

• Partial harvesting rather than clear-cutting,

• Preferential use of natural regeneration,

• Developing structural diversity and spatial variability within forests,

• Fostering mixed species stands,

• Avoidance of intensive site management practices such as soil cultivation, herbicide application and fertiliser input.

It must be noted that CCF is most successful in uneven structured stands where trees of different sizes and ages grow together (Lähde et al. 1999; Laiho et al. 1999; Pommering et al. 2004; Tahvonen 2009; Mason et al. 2021; Siipilehto et al. 2023). The structure and condition of standing trees after cutting determine stand development and the timing of the next thinning. Its success is therefore crucial. Avoiding damages to remaining trees is essential because, for example, root rot caused by Heterobasidion parviporum fungi can spread easily among understory spruces (Piri and Korhonen 2001). Additionally, according to Siren (1998), in thinning, the probability of bark damage on remaining trees was 1.75-fold during summer in comparison to other seasons.

According to Surakka and Sirén (2007), working environment affects both productivity and costs of cutting and forwarding (= harvesting) quality. Harvesting quality refers to the state of the standing trees and soil after cutting and forwarding. Working environment includes harvesting technical factors: a) amount of removal (m3 per hectare), b) size distribution of removed trees (m3 per stem) and c) bearing capacity, slope and stoniness of terrain. These factors also apply in TSS which was also noted by Grönlund and Eliasson (2019), who pointed out that in birch shelterwood removal the logging operation economics are dependent on the amount of roundwood removal.

The structure of timber assortments and volume of removal in first CCF selection cutting is generally good for harvesting productivity. Laamanen (2014) explored the structure of eight executed CCF logging sites. The basal area for the sites before cutting was 19.0–29.7 m2 ha–1 and volume 157–285 m3 ha–1. After cutting, respectively, 6.6–14.3 m2 ha–1 and 46–121 m3 ha–1. The volume of removal was 110–231 m3 ha–1 and the average stem size of removal 0.251–0.410 m3.

The focus of forest research on approaches in harvester operations began with technical development of forest machines in the 1970s. It has since expanded to effects of the working environment, harvester forwarder chain and operators’ professionalism (Nuutinen 2013). When comparing harvesting productivity, costs and damage of remaining trees between different cutting methods, the impact of the harvester’s operator has been identified as a major factor in many studies (Sirén 1998; Ryynänen and Rönkkö 2001; Väätäinen et al. 2006; Kariniemi 2006; Palander et al. 2012). At its highest, in selective thinning, productivity differences between harvester operators have been as high as 40% (Väätäinen et al. 2006). The differences between operators increase as working environments become more difficult (Kariniemi 2006). Choosing the trees to be removed and care of standing trees and seedlings is challenging.

However, up to now, harvester’s working methods have been developed mostly for traditional selective thinning from below (Ovaskainen 2009). Here, primarily, the smallest, poorer and possibly damaged trees are removed (Mielikäinen and Valkonen 1991; Mäkinen et al. 2006; Karlsson et al. 2012; Niemistö et al. 2018). Thus, there is a lack of developed harvester work methods especially in challenging cutting environment for the operator e.g. in dense unmanaged and uneven size structured stands (Nuutinen et al. 2021), which TSS forests often are. To date, there are only few TSS harvesting work studies. Their results suggest that the cost-effectiveness of TSS harvesting is lower than traditional one storied methods (Lageson 1997; Eliasson et al. 1999; Hånell et al. 2000; Niemistö et al. 2012; Grönlund and Eliasson 2019).

The harvester’s working method in CCF selection cuttings of mature stands are close to harvester work in TSS (Surakka and Sirén 2007; Niemistö et al. 2012; Sirén et al. 2015; Niemistö and Jylhä 2023). In both methods the largest trees are removed, making growth space for smaller standing trees. Special attention is paid to promoting the emergence of new seedlings. According to these studies, a dense understory reduces visibility which slows down the harvester’s work. This also increases damage to the standing trees more than in selective thinning, where mainly the smallest trees are removed. Nevertheless, according to recent findings by Manner et al. (2023) the productivity of CCF selection harvesting work is dependent on stem volume of removed trees, therefore removal of largest trees from upper layer is beneficial situation. In the review by Bianchi et al. (2023) was also founded that the harvested stem volume was the main factor in various CCF cost management models. Also, Manner and Ersson (2023) pointed out that the forwarding work productivity in CCF selection is dependent on the log concentration on the stip roads, and the density of remaining trees had minor effect on work productivity, and these findings, in TSS harvesting environment can be seen advantageous.

We had five main aims for the study: The first aim was to evaluate how spruce understory in mature birch stands can be effectively managed to ensure they remain healthy and sufficiently dense for supporting the growth of future tree generations, while also keeping harvesting costs reasonable. Second aim was to evaluate the implications of preserving understory in release thinning operations in comparison to conventional thinning practices, considering productivity reduction and elevated harvesting costs. The third aim focused on evaluating the long-term consequences of balancing cost efficiency and sustainable forest management practices. We also aimed to evaluate the effects of implementing release thinning versus release cutting, while emphasizing presumably diminished productivity and elevated unit costs of harvesting operations. The fifth aim was to map the circumstances where it would be economically viable to clear down merchantable understory stems instead of harvesting them.

2 Materials and methods

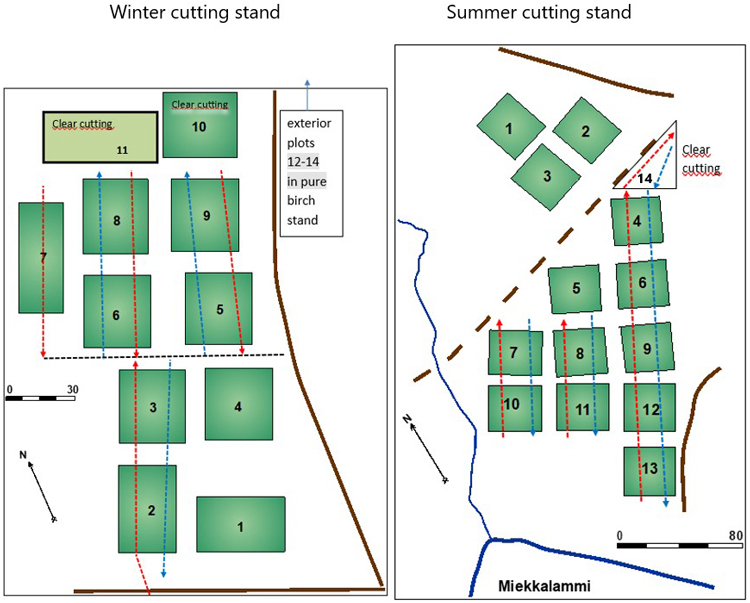

2.1 Experiments

The field trials were carried out in two experiments of planted silver birch (Betula pendula) with natural spruce understory. The test cuttings were carried out in Äänekoski (coordinates: 62.69338, 25.82424) in early winter 2020 (winter cutting stand) and in Lammi (61.26465, 24.97780) in summer 2020 (summer cutting stand). In the experiments, 2000 birches per hectare were planted in 1969 and 1970 (Niemistö 1997). According to the Finnish site type classification (Cajander 1949), the experiments were on medium fertile sites (Myrtillus type). During the test cuttings, birches were 51 years old. The test cuttings were carried out in a rectangular 30 × 33.3 m study unit (1000 m2) where two strip roads were placed approximately at a distance of ¼×plot width from opposite edges of the unit (Fig. 1).

| ||||

| Treatment | Plots in winter cutting | Plots in summer cutting | Study units in time study | Study units in damage study |

| RTH Release thinning | 6, 9 | 6, 10*, 11, 12 | 8** | 5 |

| TH Thinning | 8 (exterior 14) | 3 | ||

| RLC Release cutting | 2, 3, 5, 7 | 4, 7, 8, 9, 13 | 14** | 9 |

| CC Clear cutting | 10, 11 (ext. 12, 13) | 14 | 6 | |

| No cutting | 1, 4 | 1, 2, 3, 5 | ||

| * = Cancelled because of ready strip roads. ** = Video recording was missing in the “entry” during the summer cutting plots 4, 6, 9, 12, and 13. | ||||

Fig. 1. The treatments and harvester’s working methods in winter cutting stand and in summer cutting stand. The strip roads (- - -) and cutting directions (sequences: red = entry, blue = re-entry) and treatments were placed according to this figure. The treatments are defined in Table 1. | ||||

The treatments and harvester’s working methods in the study units: release thinning (RTH), thinning (TH), release cutting (RLC) and clear cutting (CC), are defined in Table 1 and Fig. 1‒2.

| Table 1. The treatments and harvester’s working methods used on the plots of two storeyed stands of silver birch (Betula pendula) and Norway spruce (Picea abies). | ||

| Symbol | Treatment (cutting and harvester’s working method) | Definition |

| RTH | Release thinning | 50–60% of dominant birch layer was cut with precautions against damage to the lower spruce understory. |

| TH | Thinning | 50–60% of the birches were cut without care of few or no understory spruces. |

| RLC | Release cutting | All dominating birches were removed with precautions against damage to the lower spruce understory. |

| CC | Clear cutting | All trees were removed in the study units that had few or no understory spruces. |

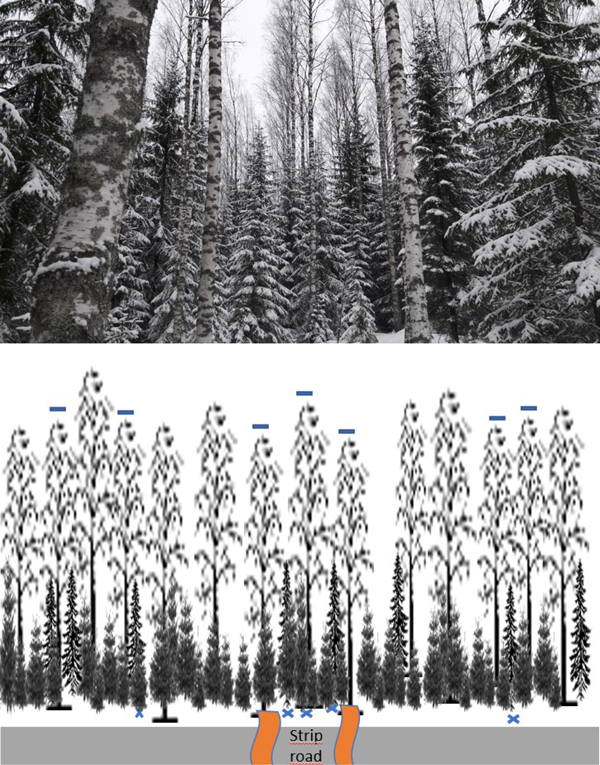

Fig. 2. The photo from winter cutting stand in Äänekoski just before cutting and the scheme of treatment RTH (release thinning), when about half of birches will be cut (–) and also pulp wood sized spruces from the strip road as well as some spruces hindering birch cutting on the area outside roads (X). In treatment release cutting (RLC) all birches will be cut.

Prior to the treatments, all trees in the study units were mapped and measured by species and diameter at breast height (dbh) (mm) every five years (in Table 2, Niemistö 1997). In each study unit, the height (dm) of 20 sample trees was measured by tree species. In addition, the diameter (mm) at 6 m height (d6.0) and the height (dm) of base of the living crown of sample birches were measured. By using the KPL – calculation program (Heinonen 1994), species- and study unit-wise models were used to predict the unmeasured tree heights and crown heights of tally trees. The type of height model was Näslund (1936). Stem volumes were calculated by species-wise volume functions (Laasasenaho 1982) based on dbh and height, and d6.0 for birch. In the winter cutting stand (12 plots) and the summer cutting stand (9 plots), before the treatments, the dominant height (mean of 100 thickest birches per ha) was 27 m and 25 m, average crown base 12.5 and 12.9 m, mean height of 600 highest understory spruces per ha 9.5 m and 13.0 m and mean diameters 9.6 cm and 11.9 cm, respectively.

| Table 2. Stand characteristics before treatments and the thinning removal of birch. The treatments are described in Table 1. | ||||||||

| Treatment | Nb. of plots | Silver birch | Norway spruce | |||||

| D1.3 (cm)* | N (ha–1) | G (m2 ha–1) | Vcommercial (m3 ha–1) | N (ha–1) | H (m)* | D1.3 (cm)* | ||

| Crowing stock before cutting: | ||||||||

| RTH winter cutting: mean | 2 | 21.1 | 610 | 21.6 | 257 | 1425 | 6.8 | 5.6 |

| st. deviation | 2.1 | 127 | 0.2 | 14 | 92 | 1.4 | 0.4 | |

| RTH summer cutting: mean | 3 | 20.8 | 357 | 11.9 | 134 | 1650 | 11.1 | 9.8 |

| st. deviation | 1.9 | 110 | 2.0 | 21 | 185 | 0.3 | 0.2 | |

| TH winter cutting: mean | 2 | 20.2 | 875 | 27.2 | 300 | - | - | - |

| st. deviation | 2.5 | 389 | 10.1 | 150 | - | - | - | |

| RLC winter cutting: mean | 4 | 19.9 | 718 | 18.7 | 213 | 1365 | 7.0 | 5.5 |

| st. deviation | 4.7 | 635 | 8.9 | 88 | 660 | 1.1 | 1.8 | |

| RLC summer cutting: mean | 5 | 18.5 | 732 | 17.6 | 199 | 1790 | 11.0 | 9.4 |

| st. deviation | 3.2 | 489 | 6.1 | 72 | 141 | 1.0 | 0.7 | |

| CC winter cutting: mean | 4 | 21.8 | 445 | 17.6 | 191 | 124 | 8.7 | 10.4 |

| st. deviation | 3.1 | 22 | 4.0 | 66 | 212 | - | - | |

| CC summer cutting: | 1 | 18.7 | 837 | 23.6 | 263 | 492 | 13.0 | 12.4 |

| Thinning removal: | ||||||||

| RTH winter cutting: mean | 2 | 24.8 | 290 | 10.2 | 122 | |||

| st. deviation | 1.8 | 42 | 1.1 | 22 | ||||

| RTH summer cutting: mean | 3 | 20.8 | 207 | 6.8 | 77 | |||

| st. deviation | 1.9 | 68 | 1.3 | 14 | ||||

| TH winter cutting: mean | 2 | 20.4 | 622 | 16.3 | 180 | |||

| st. deviation | 1.6 | 295 | 5.3 | 65 | ||||

| * = arithmetic mean. | ||||||||

The treatments RLC and RTH were randomly assigned for the experiments. The treatments CC and TH were assigned subjectively in order to be as comparable as possible to treatments RLC and RTH.

Two different single grip harvester brands were used in test cuttings:

• In winter cutting stand, the base machine was six-wheeled John Deere 1170G, with an engine power of 155 kW, a length and width of 7080 mm and 3700 mm. It was fitted with tracks and equipped with a boom-John Deere CH6, with a reach of 11 m and harvester head-John Deere H413. Its weight was 15500 kg. The operator had 5 years of professional experience.

• In summer cutting stand, the base machine was a six-wheeled Ponsse Scorpion 2016, with an engine power of 210 kW, a length and width of 8020 mm and 3085 mm. It was fitted with tracks and equipped with a boom-Ponsse C50, with a reach of 11 m and harvester head-Ponsse H5 vm 2016. Its weight was 27500 kg. The operator had 10 years of professional experience.

The operators were trained to carry out test cutting pragmatically and efficiently so that the spruce understory remained sufficiently dense and vibrant. The birches were processed for plywood logs and pulpwood logs of 3 m length and the biggest spruces for free length of pulpwood logs.

2.2 Time and motion study

The time and motion study (Niebel 1988; Nuutinen 2013) of harvester work was conducted by video recording of the harvesters’ work performance in each study unit during daylight conditions. The E0 of harvester work was recorded into four main work processes according to Table 3. One action camera was mounted inside the harvester’s cabin in the front window for filming the movements of harvester’s boom and head. In total 21 study units were recorded. The operation time was recorded using the continuous timing method (Niebel 1988; Nuutinen 2013). A time and motion study tool developed using Microsoft Visual Basic in Excel (Niemistö et al. 2012) was used by two professional observers to record and analyse the time consumption of the video material (Table 4 and 5). The output of harvester work was recorded through the harvester’s on-board production statistics system: time and volume of each processed stem per study units. Solid stem volumes were measured after cutting their tops at a small end, diameter of 6 cm over bark (= commercial stem volume).

| Table 3. Main work processes used in time and motion study of harvesters’ working methods in two-storied stands. | |

| Main work process | Description |

| Cutting birches | Started when the boom began to swing toward a tree and ended after the final cross-cut through the last log of the stem. Included work phases: extend the boom and grasp, felling, processing (delimbing and cross-cutting the logs). |

| Cutting spruces | As above for birch. |

| Moving | Started when the harvester moved forward or backward and ended when the harvester stops. Included work phases: moving backward and forward between working locations and in the working location (Nuutinen 2013). |

| Arranging products | Started when the boom started to move and ended when the head was ready for the next tree. Included work phases: bunching and sorting logs, moving tops and branches, removal of understory from around standing trees that must be felled and work planning maximum 100 seconds (= time when harvester has no functions). |

| Table 4. Mean work time consumption (sec tree–1) and its standard deviation (±SD) recorded from the video material devoted to each main work process and treatment; n = number of basic observations. | ||||||||||||

| Main work process | Treatment | |||||||||||

| Release thinning (RTH) | Release cutting (RLC) | Thinning (TH) | Clear cutting (CC) | |||||||||

| sec tree–1 | ±SD | n | sec tree–1 | ±SD | n | sec tree–1 | ±SD | n* | sec tree–1 | ±SD | n* | |

| Cutting birch | 29.7 | 9.3 | 158 | 27.1 | 10.6 | 635 | 31.8 | 12.2 | 64 | 24.7 | 8.6 | 277 |

| Cutting spruce | 13.6 | 4.7 | 97 | 15.1 | 5.7 | 174 | 14.3 | 4.7 | 107 | |||

| Moving | 9.2 | 6.5 | 176 | 8.7 | 6.5 | 341 | 8.4 | 6.2 | 39 | 6.5 | 5.4 | 161 |

| Arranging products | 10.5 | 5.2 | 56 | 11.9 | 7.1 | 104 | 11.8 | 7.1 | 8 | 11.5 | 6.0 | 44 |

| * = exterior plots are not included. | ||||||||||||

| Table 5. The characteristics of the test cutting’s removal of silver birch and Noway spruce. The treatments are described in Table 1. | ||||||||||||

| Treatment | No. of plots | Cutting sequences* | No. of stems | Arithmetic mean dbh (cm) | Commercial volume (m3) | Commercial mean stem volume (m3)** | ||||||

| Birch | Spruce | Birch | Spruce | Birch | Spruce | Birch | Spruce | |||||

| Mean** | ±SD | Mean** | ±SD | |||||||||

| RTH | 5 | 8 | 158 | 97 | 19.7 | 3.2 | 11.7 | 2.5 | 49.2 | 5.6 | 0.311 | 0.058 |

| RLC | 9 | 14 | 635 | 174 | 18.7 | 2.9 | 11.3 | 2.0 | 159.9 | 8.9 | 0.252 | 0.051 |

| TH | 2 | 3 | 112 | - | 18.3 | 4.6 | - | 32.3 | - | 0.288 | ||

| CC | 5 | 6 | 302 | 80 | 19.9 | 4.4 | 13.2 | 3.1 | 97.1 | 4.7 | 0.322 | 0.059 |

| Total | 21 | 30 | 1207 | 351 | 19.1 | 3.4 | 11.6 | 2.3 | 338.5 | 19.2 | 0.280 | 0.055 |

| * = Sequences according to cutting direction: 1 = entry, 2 = re-entry. “Entry” meant cutting through the plot with uncut forest on both sides of the harvester and “re-entry” meant at least the other side of cutting sector bordered a recently managed forest area. ** = Commercial mean stem volume (m3) = Commercial Volume (m3) / No. of stems. | ||||||||||||

In this study, E0 is defined as productive machine work time excluding delays. The workplace time (E15) includes delay events that fall within a maximum duration of 15 minutes which can be related back to the productive harvesting work (Björheden 1991). Long-term forestry studies have shown that E15 represents the actual harvesting work (Magagnotti and Spinelli 2012). The E0 for birches and spruces was split in relation to their operation time by study units and cutting direction (= cutting sequence). In this study, the sequences were “entry”, where cutting through the plot with uncut forest on both sides of the harvester, and “re-entry”, where at least the other side of the cutting sector bordered a recently cut forest area.

2.3 Harvesting costs

In this study, harvesting includes harvester work and forwarding to roadside storage. Harvester work E0 productivity (m3 E0h–1) was converted into E15 productivity (m3 E15h–1) by coefficient 1.1 (Jylhä et al. 2019). Harvester work E15h cost was 125 € h–1. Harvester work E15h productivity was based on the time consumptions of experiments in this study which were calculated separately for birch and spruce. Forwarding productivity was calculated by Manner’s et al. (2013) time consumption models which allow estimation of the forwarding of multiple timber assortments in the same load. The timber assortments were assumed to be forwarded in 8 m3 loads. For the models, it was assumed that the average distances of driving unloaded and loaded were 300 m and 200 m and for driving speed 3.4 and 2.9 km h–1, respectively (Manner et al. 2016). The E0 forwarding productivity (m3 E0h–1) was converted into E15 productivity (m3 E15h–1) using coefficient 1.2 (Laitila 2008). E15h cost for forwarder was 95 €. Hourly price rates are based on anonymous professional interviews.

2.4 Harvesting damage

Before the treatments, the understory was mapped and measured by dbh (mm) and height (dm). After the treatments, in autumn 2020, the phenomena of harvesting damage to understory spruces were measured as a number of damaged spruces. The dependence of proportion of undamaged or damaged trees of the harvest removal in treatments were estimated using linear regression. Proportions of damaged trees of the total number of spruces before treatments were calculated using the classification below.

0= undamaged (no visible damage)

1 = crown damage (the crown is broken off or clearly damaged)

2 = stem damage (bark or trunk is damaged)

3 = tilted tree

4 = collapsed (fallen or broken tree at the base)

5 = cut or cleared (removing of understory spruces hindering birch cutting or harvester moving)

2.5 Statistical analyses

Statistical analyses were conducted to examine the effect of the treatments (Table 1) on the time consumption of harvester work and on the proportion of stem damage of spruces after the treatments. In each case, the hypothesis (H1) was that there are significant differences between treatments by using a null hypothesis (H0) claiming that differences would not exist. Mixed linear models were applied (Mixed Linear package in IBM SPSS Statistics Version 27, IBM Corp 2021). The model was formulated as:

![]()

where:

Yijk = dependent variable for cutting sequence k on plot j in stand i (time consumption E0min m–3)

β = intercept

β1 = effect of treatment as a categorical variable

β2 = coefficient for covariates X

Xijk = covariate values for cutting sequence k on plot j in stand i (Vmean = Mean stem volume, m3 and NBremov = Number of romoved stems, ha–1 or Harvest removal, m3 ha–1 and Prior treatm. Nsp = Total number of understory spruces before treatment, ha–1)

μi = random effect of stand, machines and operators

εijk = random error

Time consumption (E0min m–3) of cutting birches and pulpwood-sized spruces separately was calculated by models 1–3, including all work processes as a function of the treatments (Table 1) and average commercial stem volume (Vmean, m3 per stem). Another significant continuous variable in the models for birches was the number of removed birches (NBremov, nb ha–1). Furthermore, the cutting sequence (direction) was tested in the time consumption models as a dummy variable “entry/re-entry”, that was dependent on the study design used here. In RLC and RTH, at the opening of strip roads, all spruces and birches were first removed from the strip road. Only reason to remove some spruces from the area between the strip roads was to enable the felling of upper birch layer. In CC all spruces were cut and in TH no spruces were present. Thus, the target of cutting birches and spruces differed from each other depending on treatments and therefore the both tree species needed their own time consumption models (Fig. 1‒2, Tables 1–2 and 4).

Harvest damage models 4–6 were built as a function of birch removal (Harvest removal, m3 ha–1) and density of understory spruces before cutting (Prior treatment. Nsp, nb ha–1). The whole plots were used as study units.

Justified stand parameters were used alongside the stand level data means of work productivity and costs for illustrating the outcomes and comparing different treatments of this study. The mean stem size was justified in our productivity calculations to be 0.3 m3 per stem for birch and 0.050 m3 per stem for spruce in all treatments. The productivity was calculated by models 1 and 3. In practice, thinning removal of birch is about half of removals in CC and RLC. We justified it to be 600 stems per ha in CC and RLC, but 300 stems per ha in both thinning methods. The spruce merchantable removal was justified to be 600 stems per ha in CC and 200 stems per ha in RTH and RLC.

3 Results

3.1 Distribution of effective work time

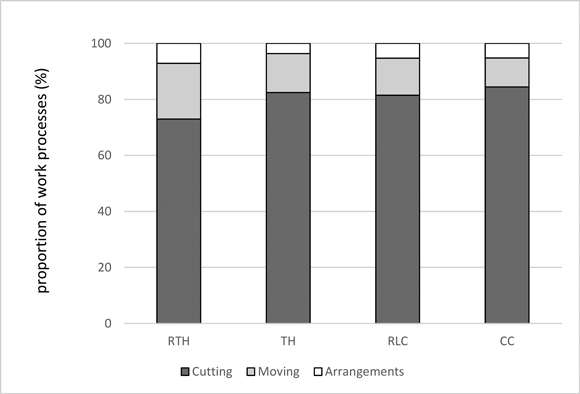

The time consumption structure of the main work processes of RLC and TH was similar. However, the average proportion of main work processes cutting spruces and birches was highest in CC and lowest in RTH, on average, 84% and 73% (Fig. 3). In RTH, the proportions of main work process moving and arranging of 20% and 7% were highest. In RTH, the work phases moving forward and moving backward repeated on average 3.1 times per m3 and averaged 1.5–1.8 times for all other treatments, respectively. Thus, in RHT, the number of work phases moving forward and backward per removal volume was highest. The density of working locations was on the same level for all treatments. However, the volume of removal per working location was lowest in RTH.

Fig. 3. Average relative time consumption of the main work processes of the thinning treatments for spruces and birches. The treatments are defined in Table 1. The main work processes and work phases are defined in Table 3.

3.2 Time consumption of cutting

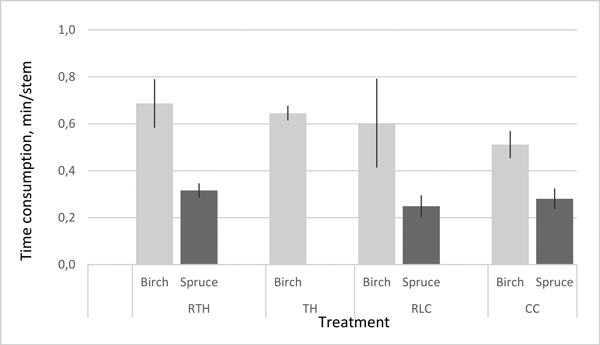

In RLC, the average time consumption per stem of cutting birches was 0.6 min, but in CC it was 16% lower and in release thinning (RTH) 12% higher (Fig. 4). The reason for this was that in RTH the removal was low and the damage to smaller spruces had to be avoided when felling the dominating birches, which slowed down the harvester work. In all treatments, the average time consumption per stem of cutting spruces was on the same level. The time consumption variation (SD) between plots (study units) was highest in RLC.

Fig. 4. The average time consumption of main work processes cutting birches and spruces for the treatments. Line segments identify the ±SD of time consumption values in each treatment, which are defined in Table 1.

The E0 of the main work process of cutting averaged in RLC and TH 2.40 min m–3. In CC, it was 23% lower (1.84 min m–3) and in RTH 6% higher (2.55 min m–3). Cutting birches and spruces (moving and arranging excluded) averaged in CC lowest 1.55 min per m3 and in both TH and RLC 1.97 min m3.

3.3 Time consumption models

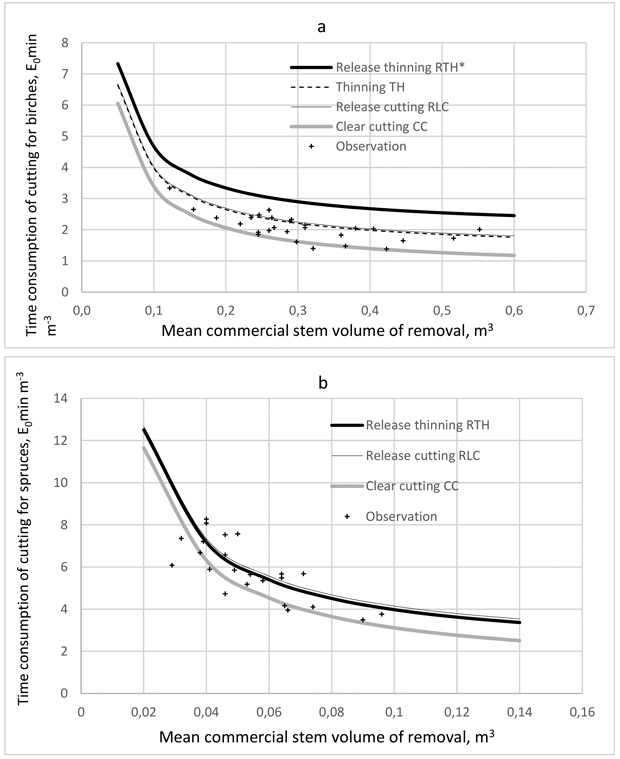

According to models 1 and 2 (Table 6), the time consumptions of RLC and TH, 2 and 4 min m–3 with mean stem volumes of 0.1 and 0.4 m3 (Fig. 5a) were midway between the lowest of CC and the highest of RTH. Furthermore, in model 2, the cutting direction was nearly statistically significant (p = 0.17). The time consumption in the direction “re-entry” was 0.08 min m–3 lower than in the direction “entry”, where uncut forest bordered the cutting zone on both sides.

| Table 6. Statistical information of regression models for time consumption of main work process cutting (defined in Table 3). Dependent variables: E0min m–3 of cutting birches and cutting spruces. Thinning treatments are defined in Table 1. | ||||||

| Parameter: | Model 1: Cutting birches (N = 27, Pseudo R2 = 0.89) | Model 2: Cutting birches (N = 27, Pseudo R2 = 0.89) | Model 3: Cutting spruces (N = 23, Pseudo R2 = 0.72) | |||

| F-value | Sig. | F-value | Sig. | F-value | Sig. | |

| Intercept | 47.16 | 0.000 | 46.24 | 0.000 | 6.42 | 0.019 |

| Treatment | 4.80 | 0.010 | 5.46 | 0.006 | 2.98 | 0.072 |

| 1/Vmean, m–3 | 63.18 | 0.000 | 60.84 | 0.000 | 41.93 | 0.000 |

| NBremov, ha–1 | 6.38 | 0.019 | 7.14 | 0.014 | ||

| Treatment × NBrem | 3.55 | 0.031 | 3.68 | 0.028 | ||

| Direction | 2.05 | 0.167 | ||||

| Fixed effects | Coefficient | Sig. | Coefficient | Sig. | Coefficient | Sig. |

| Intercept | 0.6117 | 0.008 | 0.670 | 0.004 | 0.9815 | 0.154 |

| RTH | 0.0675 | 0.819 | 0.199 | 0.514 | 0.8604 | 0.066 |

| TH | 0.5868 | 0.123 | 0.584 | 0.117 | ||

| RLC | 0.6300 | 0.005 | 0.711 | 0.002 | 1.0309 | 0.024 |

| CC | 0 | 0 | 0 | |||

| 1/Vmean, m–3 | 0.2658 | 0.000 | 0.258 | 0.000 | 0.2133 | 0.000 |

| NBremov, ha–1 | 0.0002 | 0.477 | 0.0003 | 0.305 | ||

| RTH × NBremov | 0.0022 | 0.028 | 0.0020 | 0.047 | ||

| TH × NBremov | 0.00001 | 0.980 | 0.00003 | 0.954 | ||

| RLC × NBremov | –0.0004 | 0.248 | –0.0005 | 0.164 | ||

| CC × NBremov | 0 | 0 | ||||

| Entry | 0.0792 | 0.167 | ||||

| Re-entry | 0 | |||||

| Random effects | Estimate | Std. error | Estimate | Std. error | Estimate | Std. error |

| Residual | 0.0193 | 0.0058 | 0.0184 | 0.0057 | 0.5141 | 0.1587 |

Fig. 5. Time consumption of main work process cutting birches (Model 1) with the average density of birch removal of 550 stems ha–1 (a) and cutting understory spruces (Model 3) (b). The treatments are defined in Table 1. The main work processes and work phases are defined in Table 3. * = The curve of release thinning (RTH) lays above the observation points with 250 removed birches ha–1 on average instead of 550 stems ha–1 for the curve.

The main work process cutting birches accelerated significantly as the mean volume of removal increased to 0.3 m3 per stem (Fig. 5a). The time consumption of RTH was approximately double that of CC when the removal density was the same. RLC increased the time consumption by 0.6 min m–3 compared to CC. Between RLC – all dominating birches were removed and TH -dominating birch layer without spruce understory was thinned, the difference was small. As the density of birch removal increased by 100 stems per hectare, the cutting time increased in treatments CC and TH by about 1.5 second per processed cubic meter, more in RTH, but even decreased 1.2 seconds in RLC. (NBremov coefficients in Table 6).

According to Model 3 (Table 6) the time consumption of spruce in RLC (all birches cut) and RTH (half of birches cut) were on the same level, being 6 and 4 min m–3 for average stem volume of 50 dm3 and 100 dm3 (Fig. 5b). In CC, the time consumption of cutting understory spruces was approximately 1 min m–3 lower.

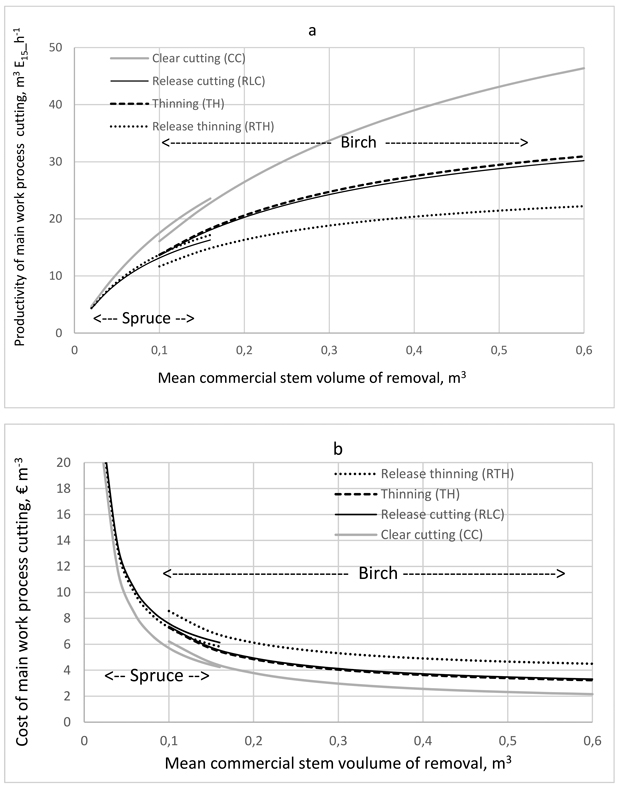

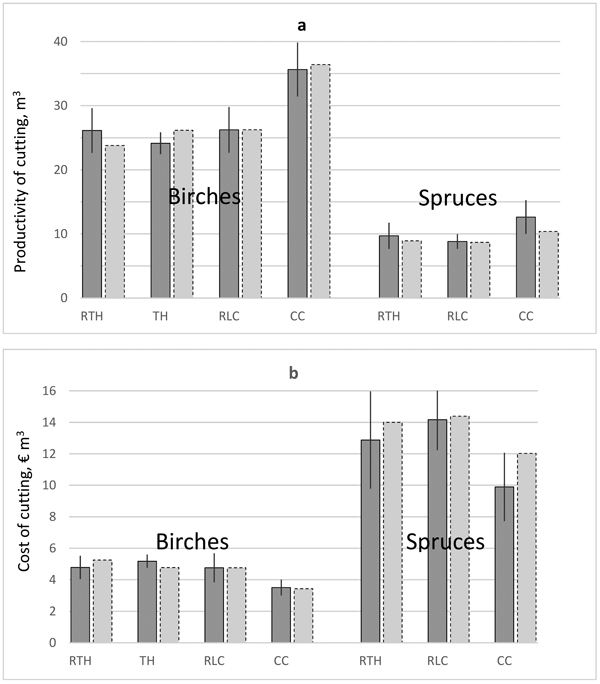

The E15h productivity of clear cutting of birches (CC) was 25–54% higher than the productivity of RLC when the average volume of removal increased from 0.150 to 0.600 m3. The respective superiority was 23–50% compared to TH and up to 50–209% compared to RTH (Fig. 6a). In CC and RLC, the productivity of cutting small understory spruces levelled with the birches of equal size but in RTH the productivity was not lower than in RLC as it was for birches.

Fig. 6. E15 average productivities (a) and costs (b) of main work processes cutting birches and understory spruces for thinning treatments. The treatments are defined in Table 1. The main work processes and work phases are defined in Table 3.

In practical work, the amount of removal and mean stem size vary between the cutting treatments. In the modelling data, the variation in mean size for birch was low between the treatments (0.252–0.322 m3 in Table 5), but differences in stem number were large (207–875 stems per ha in Table 2). Including the effect of plot-level differences in removal, the E15h mean productivities and variation are presented in Fig. 7a. As mentioned above, we justified removals (birch: 600 stems ha–1 in CC and RLC, 300 stems ha–1 in TH and RTH; and spruce: 600 stems ha–1 in CC, and 200 stems ha–1 in RTH and RLC) and birch stem volume to 0.3 m3 and spruce to 0.050 m3 in order to compare the productivity differences between treatments when applying models 1 and 3 (Table 6).

Fig. 7. Average E15 productivities (a) and costs (b) of the main work process of cutting for treatments as the means in study data (solid bars) and calculated by models 1 and 3 for justified stand parameters according to practice (dashed bars). Line segments identify the ±SD of values in each thinning treatment. The treatments are defined in The main work processes and work phases are defined in Table 3.

According to the justification, the E15h productivities were:

• For cutting birches in clear cut (CC) 36.4 m3 h–1 and in RLC 26.3 m3 h–1

• For thinning birches 26.2 in TH and 23.8 m3 h–1 in RTH m3 h–1

• The values for spruces were 10.4 m3 h–1 in CC and 8.8 m3 h–1, in RTH and RLC when the majority of spruces was preserved.

3.5 Harvesting costs

The E15 cost of main work processes cutting birches and cutting understory spruces according to mean stem volumes (Models 1 and 3 in Table 6) are presented in Fig. 6b where the average removal of 550 birches per ha was used in the models. For CC in study data, the mean E15 cost of main work process cutting was 3.5 € m–3 for birches and, with practical justification above 3.4 € m–3 (Fig. 7b). In the other treatments it was 4.8–5.2, respectively. In the justified conditions, the cost of main work process cutting of understory spruces was 12.0 € m–3 in CC and 14.0–14.4 € m–3 when the majority of spruces was preserved.

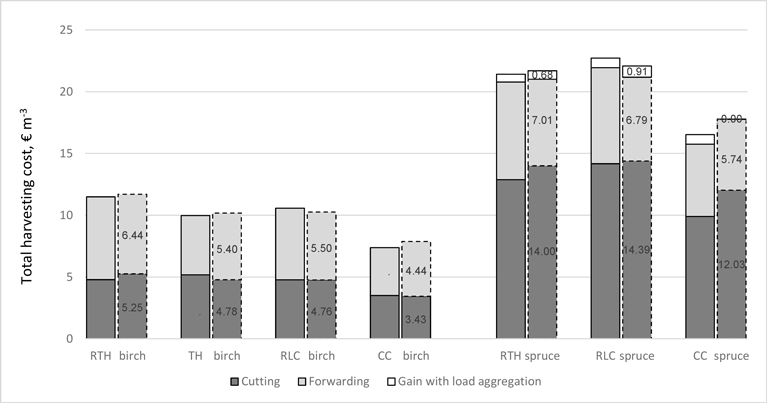

The forwarding cost of birch pulp wood was calculated per load according to Manner (2013). For birch saw logs and spruce pulpwood, two of Manner’s (2013) methods of calculation were used 1) each timber assortment separately, or 2) aggregated in the same loads. However, the increase of 0.6 € m–3 for forwarding cost was made in RTH and RLC according to models of Niemistö et al. (2012) where the consumption of the loading time in forwarding was 0.55 E15 min m–3 higher when the understory was preserved. The strip road removals of the treatments were in the range of 21–37 m3/100 m for birch pulpwood, 3.5–6.0 m3/100 m for birch saw logs, 1.8–2.2 m3/100 m for spruce pulpwood and the E15 forwarding productivity was 20–26, 16–17 and 13–15 m3 h–1 in separate loads, respectively.

Harvesting (= harvester work and forwarding) E15 costs were calculated for birch and spruce (Fig. 8). There was no difference in forwarding costs of birch when forwarding birch logs and spruce pulpwood in the same load or separately in their own loads. In study data, the aggregation-loads of two timber assortments reduced the spruce pulpwood forwarding cost by 0.63–0.78 € m–3, depending on spruce removal. However, with justified stand parameters the removal of spruce was 30 m3 ha–1 in clear cutting and no gain was achieved by aggregation.

Fig. 8. Harvesting (harvester work and forwarding) costs with separate timber assortment loads or aggregation-loads of birch plywood logs and spruce pulpwood logs as the means in study data (solid bars) and calculated by models for justified stand parameters according to practice (dashed bars). The treatments are defined in Table 1.

In RLC, the total harvesting cost of birches per cubic meter was 10.6 € m–3 on average in study data and 10.3 € m–3 with justified conditions, 30% higher than in CC (Fig. 8). The mean harvesting costs of birch in RTH and TH were 49% and 29% higher than in CC, respectively. The average harvesting cost of spruce in RTH and RLC, including aggregation-loads in forwarding, was 21.1 € m–3, 19% higher than in CC with three-fold-pulpwood removal in the justified stand conditions.

3.6 Harvesting damage

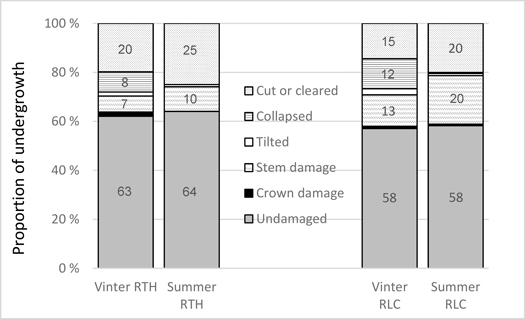

The proportion of undamaged spruces was at the same level in both experiments (Fig. 9). However, on average it was slightly lower in RLC (58% on average) compared to RTH (63% on average). The proportion of collapsed or tilted spruces was higher in winter cutting stand 1, but the proportion of cut or cleared spruces was higher in summer cutting stand 2. Consequently, the proportion of lost spruces (cut, cleared, collapsed and tilted) was 20–29%, being lowest in RLC in summer cutting, where on the other hand, the amount of minor damage for spruces was highest, at 20%. The number of crown damage was low in every case compared to stem damage.

Fig. 9. Harvesting damage of understory spruces in release thinning (RTH) and release cutting (RLC) in winter cutting stand 1 and summer cutting stand 2. The treatments are described in Table 1, stand characteristics before treatments in Table 2.

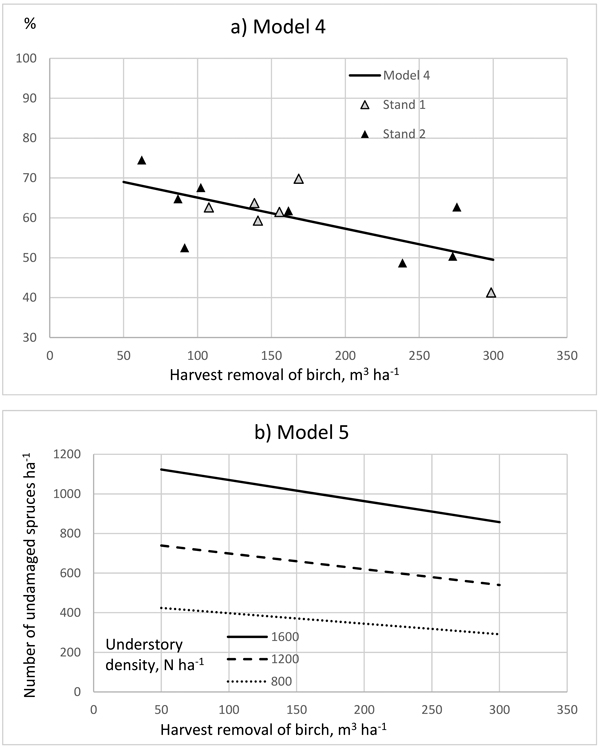

According to models 4‒6, the greater the birch removal, the more the understory spruces were damaged (Table 7, Fig. 10‒11). The birch removal was higher in RLC than in RTH, and thus there was no significant difference in appearance of damage between these two treatments. According to model 4, the proportion of undamaged spruces of understory decreased from 70% to 50% when the removal of birch increased from 50 to 300 m3 ha–1 (Fig. 10a). According to model 5, the density of undamaged spruces for future crop was over 600 per ha, when the prior-treatment density of understory was more than 1200 spruces per ha (Fig. 10b).

| Table 7. Statistical information of regression models 4–6 for the undamaged and stem damaged proportions (%) of prior to treatment number of understory spruces in both release cutting (RLC) and release thinning (RTH). No significant difference in appearance of damage between RLC and RTH. | |||||

| Variable | Coefficient | Std. error | Denominator df | t-value | Sig. |

| Dependent = % of undamaged spruces of post treatment understory, NStand 1 = 6 ja NStand 2 = 8 | |||||

| Model 4 (Pseudo R2 = 0.43) | |||||

| Fixed effects: | |||||

| Intercept | 72.901 | 4.472 | 12 | 16.30 | 0.000 |

| Harvest removal, m3 ha–1 | –0.0780 | 0.025 | 12 | –3.15 | 0.008 |

| Random effects | Estimate | Std. error | |||

| Stand | * | * | |||

| Residuals | 47.79 | 19.50 | |||

| Model 5 (Pseudo R2 = 0.43) | |||||

| Fixed effects: | |||||

| Intercept | 39.133 | 17.38 | 3.45 | 2.25 | 0.098 |

| Harvest removal, m3 ha–1 | –0.0664 | 0.020 | 9.24 | –3.29 | 0.009 |

| Prior treatm. Nsp, ha–1 | 0.0215 | 0.0095 | 8.05 | 2.27 | 0.052 |

| Random effects | Estimate | Std. error | |||

| Stand | 163.8 | 298.3 | |||

| Residuals | 29.7 | 14.0 | |||

| Dependent = % of stem damaged spruces of post treatment understory, NStand 1 = 6 ja NStand 2 = 8 | |||||

| Model 6 (Pseudo R2 = 0.72) | |||||

| Fixed effects: | |||||

| Intercept | 3.746 | 3.030 | 10 | 1.237 | 0.244 |

| Stand 1 (Stand 2 = reference) | –4.772 | 2.548 | 10 | –1.873 | 0.091 |

| Harvest removal, m3 ha–1 | 0.077 | 0.016 | 10 | 4.780 | 0.001 |

| Random effects | Estimate | Std. error | |||

| Residuals | 19.94 | 8.92 | |||

| * = The covariance parameter is redundant. | |||||

Fig. 10. Average proportion (a) and number per ha (b) of undamaged understory spruces (per study units) in winter cutting stand 1 and summer cutting stand 2 after the treatments according to models 4 and 5 (Table 7).

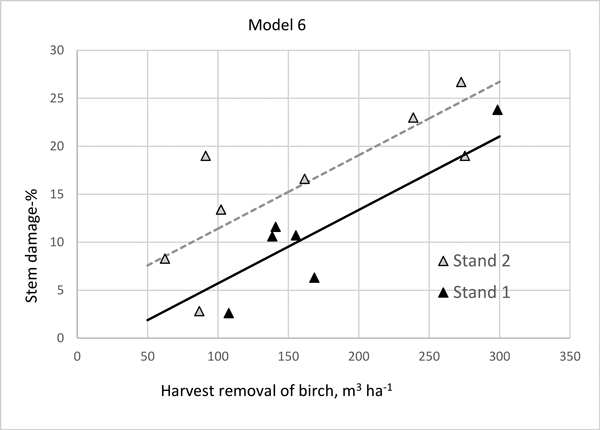

Fig. 11. Average proportion of stem damaged understory spruces in winter cutting stand 1 and summer cutting stand 2 after the treatments according to model 6 (Table 7).

According to model 6, the proportion of stem damaged spruces was significantly higher in summer cut stand 2 than in winter cut stand 1, but any significant interaction with birch removal was not found. The effect of prior to treatment density of spruce understory on the proportion of stem damaged spruces was not significant in this study.

Most of the lost spruces were located in the strip road. According to model 6 (Table 7), the proportion of stem damaged understory spruces increased from 5 to 25% when the birch removal increased. In summer cutting stand 2, the amount of stem damage was 5.7% units higher on average than in winter cutting stand 1 (Fig. 11).

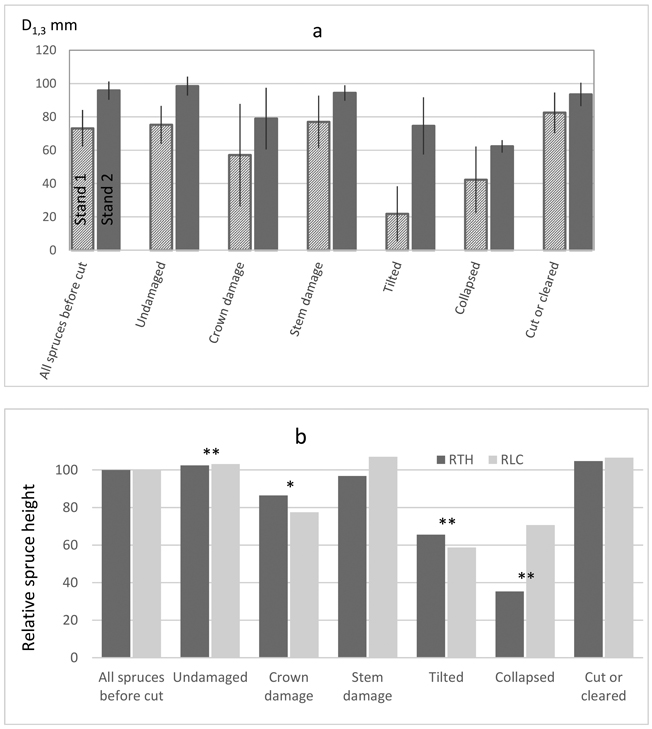

The undamaged spruces were slightly taller than average. However, the difference in diameter compared to the damaged ones was only 2–3 mm (Fig. 12a). The difference was due to the crown damaged and especially tilted and collapsed spruces being much smaller than the average size (Fig. 12b).

Fig. 12. Means and standard deviations (vertical lines) of dbh of undamaged and damaged understory spruces in terms of mm in winter cutting stand 1 and summer cutting stand 2 (a) and in terms of % in treatments RTH and RLC (100 = all spruces before treatments) (b). * means that the size of spruces differ significantly from that of all spruces with a risk < 5%. * means a risk < 10%, respectively. The treatments are defined in Table 1.

4 Discussion

This study was one of the first of its kind to encompass the productivity, structure of working method, costs and damage of two-storied stand harvesting from stump to roadside storage. Empirical data on harvester time consumption, productivity and damage of standing trees were collected during harvester’s actual work in two storied stands. The cutting environments of each experiment were compared to clear-cutting. Operator and base machine factors were kept as constant as was practically possible: each experiment had its own harvester and operator. The experiments of this study were established by the Finnish Forest Research Institute (Metla) as forest thinning trials (Niemistö 1997) and maintained by the Natural Resources Institute Finland (Luonnonvarakeskus, Luke). In the experiments, the spatial distribution of spruces and birches were also even. Professional researcher group ensured that the trials and data collection were conducted logically in both experiments.

Varying removals were executed in above mentioned thinning experiments with real combinations of stem numbers and mean sizes for actual cutting work. On the other hand, partly due to practical limitations, the productivity levels and costs of our study are not generally applicable because they are limited to the working environments of individual experiments. This was especially noticed when scrutinising the TH treatment time consumption results where we noticed illogical unexplained overestimation. But the relative differences in the studied cutting methods can be generalised when the working environments (e.g. stems and volume per hectare) and size structure (volume per stem) of over- and understories are similar.

The experimental arrangements of this study were set according to the availability of applicable plots, where the initial 33.3 × 30 m plots were divided in half, which was not as practically suitable as 20 × 50 meters. However, according to findings by Jylhä et al. (2023) in continuous cover forestry on peatland soils, the difference in cutting productivity was small between 15 and 20 meter strip road widths. Furthermore, the maximum boom reach (10 m) is seldom possible. This is because, in thinning work, standing trees will block the harvester head from swinging perpendicularly up to maximum reach towards the target tree.

The harvester’s working method treatments RTH and RLC were randomly focused for the study units. The controlled experimental arrangement of our study produced useful information about the structure and volume or thinning removal in different harvesting environments. Thus, this study’s experimental data can be linked to previously recorded forestry management data. In this case, it is possible to obtain valuable information on the interaction of harvesting and timber production in two storied forests.

Our study indicates that the constant caution around the understory slows down the harvester’s cutting procedure, for example with birch stem volume of 300 dm3, the release thinning was roughly 50% slower than clear cutting. Correspondingly, the productivity of spruce understory release cutting decreased by 26% for birch and 30% for small spruces compared to clear-cutting. Previous research on two-storied forests has focused on forestry management, therefore there is very little research on the harvesting of two-storied forests in Nordic countries. The findings of previous research also indicate somewhat similar causal relationships in cutting productivity. Hånell et al. (2000) found that the time consumption of TSS cutting was 11–16% higher than in CC. Lageson (1997) studied the effect of thinning methods on the harvester’s productivity and harvesting damage of the remaining stand. The study concluded that thinning from above increased thinning ratio 24–31% compared to thinning from below (i.e. the relationship between the mean dbh of removal to standing trees) which increased the harvester’s productivity 22–39%, respectively. Eliasson et al. (1999) compared TSS harvester productivity to clear cutting and found that the productivity in TSS decreased 16–40%. Niemistö et al. (2012) investigated the harvesting of dominated downy birches in order to retain young understory spruces. Retaining the small spruces (1200 stems per hectare) in downy birch pulpwood cutting decreased the productivity of harvester work by 11–17 % compared with clear cutting, where the understory was not preserved.

From a forwarding working environment perspective, TSS presents the same challenges as CFF as there were more than one tree species and the stand structure was unevenly structured with a dense understory and no pre-clearing before harvesting. The cost of forwarding was assumed to increase in this study because the piles of timber assortments were dispersed due to care around growing seedlings. In TSS, log bunches along the strip road are small and scattered which makes forwarder’s loading more difficult (Niemistö et al. 2012). Also, Väätäinen et al. (2006) found that increased amount of timber assortments increased the time consumption of loading in forwarding.

The structure and condition of growing stock after thinning determines the development of the forest and timing of future forest management. In TSS and CCF, in the centre of near future thinnings are trees of height between 5–15 m. According to numerous studies, 10–20% of them are damaged in the first mechanised selective cutting and the most common damage is top breakage (Fjeld and Granhus 1998; Hämäläinen 2014; Sirén ym. 2015; Nyman 2016). Grönlund and Eliasson (2019) found out that in their birch shelterwood removal study majority (83%) of the harvesting damages were caused by harvester.

Our numbers do not completely correspond with the previous studies in this topic because we used the percentage of total number of understory spruces before treatment, which was 21–28 % for cut or cleared or collapsed ones. According to Vanha-Majamaa (2002) and Surakka et al. (2011), the damage proportions of small trees between 0.5 and 3 m height were in the range of 2–61% of remaining trees in mechanised CCF selective thinning. The proportion of damage was greater the closer the trees were to the strip road and the greater the volume of removal per hectare. In the simulation study of Miettinen (2005), when felling trees away from the strip road, 45% of initial seedlings were exposed to damage. When trees were felled on the strip road as much as possible, 38% of seedlings were exposed to damage. According to our results, summer cutting caused more damages to the understory in comparison to winter operations. This is similar to Siren’s (1998) discovery of the significantly higher risk of damage during summer harvestings. Findings from Eliasson et al. (2003) also indicate that the temperature during harvesting can play a role in the occurrence of harvesting damage. Niemistö et al. (2012) found out that the share of undamaged understory spruce, with varying stand density, reduced when the number of removed overstory birch increased. This correlation was also found in our study.

Based on the findings of our study we suggest that there are 5 main theses concerning cutting operations in two-storied stands. Our answers based on the results in silver birch-Norway spruce stands in the justified circumstances are:

1. It is possible to leave understory stands healthy and dense enough to grow a productive future tree generation with reasonable harvesting costs. The reasonable density of undamaged spruces for future growing of a stand 550–750 per ha was achieved, when the prior-treatment density of understory was 1200 spruces per ha and harvest removal of birch was 50–300 m3 ha–1 (Fig. 10b). Prior-treatment density 1000 per ha can be enough if the removal is lower than 100 m3 per ha. The width and amount of strip roads are crucial because the spruces on them were completely lost. Besides lost spruces, there was a notable amount of bark or stem damaged spruces between strip roads, increasing from 5% to 25% with increasing harvest removal (Fig. 11), 5%-units more in summer cutting compared to winter cutting, where on the other hand, top and crown damage was more common.

2. The decrease in productivity and increase in cost of harvesting operations caused by preserving understory in the release cutting of the whole overstory is considered as a long-term investment low enough to grow the next spruce generation compared to the corresponding clear cut with artificial regeneration. The productivity of cutting overstory birches was 20–36% lower than that of clear cutting when mean stem volume increased from 0.150 m3 to 0.500 m3 (Fig. 6a). In cutting of understory spruces as pulpwood, the relative difference between the methods was on same level. For birch, the total harvesting cost was 10.3 € per m3 in release cutting being 30% higher than in clear cut (Fig. 8). For spruce, the total cost was 21.2 € per m3 being 19% higher compared to clear cut, in which the removal of spruces was three-fold. The main reason for these differences was higher time consumption for moving and arranging products with dispersed and smaller piles of timber assortments when spruces were preserved in release cutting. At stand level, the additional cost caused by preserved understory was 464 € ha–1 for release cutting compared to clear cutting of an equal stand.

3. The decrease in productivity and increase in cost of harvesting operations caused by preserving understory in the release thinning for half of overstory is considered as a long-term investment low enough to grow two-storied stand compared to the corresponding thinning and growing of pure birch stand. The productivity of thinning overstory birches was 12–22% lower than that of normal thinning when mean stem volume increased from 0.100 m3 to 0.400 m3 (Fig. 6a). For birch, the total harvesting cost was 11.7 € per m3 in release thinning being 15.0% higher than in the normal one (Fig. 8). A reason for the relatively small difference in total cost can be that a greater proportion of removal was cut on strip roads in both methods. At stand level, the additional cost caused by preserved understory was 347 € ha–1 for release thinning compared to the normal one without understory.

4. The reduced productivity and increased unit cost of harvesting operations caused by release thinning for half of overstory is considered as a long-term investment low enough to grow two-storied stand compared to the release cutting of whole overstory and growing the understory as the next tree generation. The productivity of thinning overstory birches was 18–32% lower than that of total birch removal when mean stem volume increased from 0.100 m3 to 0.400 m3 (Fig. 6a). In cutting of understory spruces as pulpwood, there was no significant difference between the methods. For birch, the total harvesting cost in release cutting was 14% lower than in release thinning (Fig. 8). A reason for this difference was lower removal of thinning birches compared to total removal of birches in challenging conditions of two-story stands.

5. In certain conditions, it can be economically viable to clear down small-sized but merchantable understory trees instead of harvesting them. According to data from Niemistö and Jylhä (2023), the time consumption of clearing an understory tree was 5.4 s and thus the cost is 0.19 € per a tree. With a mean size of 0.050 m3, the cost of harvesting understory spruce as pulpwood in RTH or RLC was 1.06 € per tree (0.05 × 21.1). Hence, the real cost of harvesting understory spruces as pulpwood compared to clearing down was 17.4 € per m3 in the justified conditions above. With mean size of 0.040 m3 and 0.030 m3, the real cost of harvesting spruce pulpwood was about 19.7 and 23.6 € per m3 respectively, when the removal stayed at level of 10 m3 per ha.

5 Conclusions

Two-storied forests are possible to harvest successfully using the current forest machines and methods although the harvesting costs are higher, and the damage to growing stock bigger compared to traditional selective thinning methods. Whenever the harvester operator must take care around the remaining trees – which also cause a visible obstacle – the harvesting productivity decreases.

Clear cutting of a two storied stand caused the lowest operation costs in comparison to the optional harvesting methods where the understory was preserved. Even though this study does not cover a thorough evaluation of regeneration costs, it is obvious that preserving the understory trees during harvesting will have positive cost impacts during the forest rotation period. Thereby, we detect a need to take the economics of the different harvesting methods over the full rotation time of understory spruce into account in future studies.

This study offers practical help in planning and timing the release of understory spruce and with correlating the volumetric removal of the dominant tree layer with harvesting damage. Furthermore, to minimise the risk of damage to the remaining trees in the operations, the season and temperature should be taken into account. Harvesting requires special care in order to avoid treetop breaks in winter and bark and stem damage in summer.

All our study units were representative from the practical Nordic forestry viewpoint and reached requirements (both pre- and post-harvesting) set by the Finnish forest management recommendations for producing productive forest in the future. Based on the recommendation, all studied units were favourable for successful forest management after harvesting the dominant canopy. According to our findings, from economic and forest management viewpoints, it is possible to successfully use modern CTL single-grip harvester in retaining understory spruces in downy birch dominated two storied stands.

Declaration on the availability of research materials

The data are available from the authors upon reasonable request.

Author’s contributions

PN: Experimental arrangement; Data acquisition; Conceptualization; Data analysis; Interpretation of results; Writing – original draft; Writing – review & editing; Final approval of the manuscript to be published.

HK: Conceptualization; Data analysis; Interpretation of results; Writing – review & editing.

YN: Funding acquisition; Conceptualization; Data analysis; Interpretation of results; Writing – review & editing.

Acknowledgments

We are gratefull to UPM Kymmene and Metsähallitus Forestry Ldt for arrangement and executing the field trials, and the editors and reviewers for comments and suggestions to improve the quality of this manuscript.

Funding

This study was supported by Luke’s CCFBASIS - Technological and conceptual basis for Continuous Cover Forestry (grant number 41007-00182900), Luke’s SecureLog - Data fusions securing feedstock supply to bioeconomy (grant number 41007-00211300); Nibio’s Harvesting operations in continuous cover environments (HOCCE project);and under the European Union’s Horizon 2020 research and innovation programme UNITE - Forest-Human-Machine Interplay -project (grant number 337 655).

References

Agestam E (1985) En produktionsmodell för blandbestånd av tall, gran och björk i Sverige. [A growth simulator for mixed stands of pine, spruce and birch in Sweden]. Sveriges lantbruksuniversitet, Institutionen för skogsproduktion, Rapport 15.

Akujärvi A, Lehtonen A, Liski J (2016) Ecosystem services of boreal forests – carbon budged mapping at high resolution. J Environ Manage 181: 498–514. https://doi.org/10.1016/j.jenvman.2016.06.066.

Bianchi S, Ahtikoski A, Muhonen T, Holmström E, Valkonen S, Nuutinen Y (2023) Evaluation of operating cost management models for selection cutting in Scandinavian continuous cover forestry. IForest 16: 218–225. https://doi.org/10.3832/ifor4204-016.

Björheden R (1991) Basic time concept for international comparisons of time study reports. J For Eng 2: 33–39. https://doi.org/10.1080/08435243.1991.10702626.

Cajander AK (1949) Forest types and their significance. Acta For Fenn 56. https://doi.org/10.14214/aff.7396.

Eliasson L (1999) Simulation of thinning with a single-grip harvester. Forest Sci 45: 26–34.

Eliasson L, Bengtsson J, Cedergren J, Lageson H (1999) Comparison of single-grip harvester productivity in clear-and shelterwood cutting. J For Eng 10: 43–48.

Eliasson L, Lageson H, Valinger E (2003) Influence of sapling height and temperature on damage to advance regeneration. Forest Ecol Manag 175: 217–222. https://doi.org/10.1016/S0378-1127(02)00180-9.

Fjeld D, Granhus A (1998) Injuries after selection harvesting in multi-storied spruce stands – the influence of operating systems and harvest intensity. J For Eng 9: 33–40. https://doi.org/10.1080/08435243.1998.10702716.

Folkesson B, Bärring U (1982) Exempel på en riklig björkförekomsts inverkan på utvecklingen av unga tall- och granbestånd i norra Sverige. [Some examples of the influence of an abundant occurrence of birch on the development of young Norway spruce and Scots pine stands in north Sweden]. Sveriges lantbruksuniversitet, Institutionen för skoglig herbologi, Rapport 1.

Fries J (1964) Vårtbjörkens produktion i Svealand och södra Norrland. [Yield of Betula verrucosa Ehrh. in Middle Sweden and southern North Sweden]. Stud For Suec 14. https://res.slu.se/id/publ/125215.

Fries J (1974) Björk och gran. I: Framtidsskogen – skogsproduktionens mål och medel. [Birch (Betula pendula and B. pubescens) and Norway spruce (Picea abies)]. Skogshögskolan, Institutionen för skogsproduktion, Rapporter och uppsatser 33: 30–37.

Frivold L (1982) Bestandsstruktur og produksjon i blandingsskog av björk (Betula verrucosa Ehrh.) og gran (Picea abies (L.) Karst.) i sydost-Norge. [Stand structure and yield of mixed stands of birch (Betula verrucosa Ehrh.) and spruce (Picea abies (L.) Karst.) in southeast Norway]. Meldinger fra Norges Lantbrukshögskole 90.

Grönlund Ö, Eliasson L (2019) Birch shelterwood removal – harvester and forwarder time consumption, damage to understory spruce and net revenues. J For Eng 30: 26–34. https://doi.org/10.1080/14942119.2019.1595943.

Hämäläinen J (2014) Poimintahakkuun nykykäytännöt: työohjeistus, ajanmenekki ja korjuujälki. [Practices of Selective Harvesting: Work Instructions, Time Consumption, and Logging Quality]. Master’s thesis, University of Helsinki. http://urn.fi/URN:NBN:fi:hulib-201508103453.

Hånell B, Nordfjell T, Eliasson L (2000) Productivity and costs in shelterwood harvesting. Scand J Forest Res 15: 561–569. https://doi.org/10.1080/028275800750173537.

Heinonen J (1994) Koealojen puu- ja puustotunnusten laskentaohjelma (KPL). Käyttöohje. [Programme for the calculation of tree and stand base values. Instructions for use]. The Finnish Forest Research Institute Research Papers 504. http://urn.fi/URN:ISBN:951-40-1369-7.

Isomäki A (1979) Kuusialikasvoksen vaikutus männikön kasvuun, tuotokseen ja tuottoon. [The effect of spruce understory on the increment, yield and returns of a pine stand]. Folia For 392. http://urn.fi/URN:ISBN:951-40-0390-X.

Jonsson B (1962) Om barrblandskogens volymproduktion. [Yield of mixed coniferous forests]. Meddelanden från statens skogsforskningsinstitut 50.

Jylhä P, Jounela P, Koistinen M, Korpunen H (2019) Koneellinen hakkuu : Seurantatutkimus. [Mechanised cutting : Follow-up Study]. Natural Resources Institute Finland (Luke), Natural resources and bioeconomy studies 13/2024. http://urn.fi/URN:ISBN:978-952-326-717-6.

Kariniemi A (2006) Kuljettajakeskeinen hakkuukonetyönmalli – työn suorituksen kognitiivinen tarkastelu.[Operator-specific model for mechanical harvesting – cognitive approach to work performance]. Helsingin yliopiston Metsävarojen käytön laitoksen julkaisuja 38. http://hdl.handle.net/1975/443.

Karlsson L, Bergsten U, Ulvcrona T, Elfvring B (2012) Long-term effects of growth and yield of corridor thinning in young Pinus sylvestris stands. Scand J For Eng 28: 28–37. https://doi.org/10.1080/02827581.2012.702222.

Kuusela K (1990) The dynamics of boreal coniferous forests. SITRA 112. ISBN 951-563-274-9.

Laamanen V (2014) Poimintahakkuukohteiden puuston rakenne, korjuutekniset olosuhteet, korjuukustannukset ja korjuujälki. [Structure of selection cutting stands, logging conditions, logging costs and logging damages.] Master’s thesis, University of Helsinki. http://urn.fi/URN:NBN:fi:hulib-201507212322.

Laasasenaho J (1982) Taper curve and volume functions for pine, spruce and birch. Commun Inst For Fenn 108. http://urn.fi/URN:ISBN:951-40-0589-9.

Lageson H (1997) Effects of thinning type on the harvester productivity and on the residual stand. J For Eng 8: 7–14.

Lähde E, Laiho O, Norokorpi Y (1999) Ekometsänhoidon perusteet ja mallit. [Fundamentals and Models of Eco-Forest Management.] Finnish Forest Research Institute Research Papers 736. http://urn.fi/URN:ISBN:951-40-1685-8.

Laiho O (1983) Kuusen luontaisesta uudistumisesta. [Natural Regeneration of Spruce]. Finnish Forest Research Institute Research Papers 94: 32–41. http://urn.fi/URN:NBN:fi-metla-201207201985.

Laiho O, Lähde E, Norokorpi Y, Saksa T (1999) Metsän rakenne ja kehitys. [Structure and development of forest]. In: Lähde E (ed) Luontaisesti syntyneiden sekametsien kehitys ja metsänhoito. [Development and management of naturally regenerated mixed forest]. Finnish Forest Research Institute Research Papers 719: 6–32. http://urn.fi/URN:ISBN:951-40-1665-3.

Laitila J (2008) Harvesting technology and the cost of fuel chips from early thinnings. Silva Fenn 42: 267–283. https://doi.org/10.14214/sf.256.

Magagnotti N, Spinelli R (eds) (2012) Good practice guidelines for biomass production studies. COST Action FP-0902, WG 2 Operations research and measurement methodologies.

Mäkinen H, Isomäki A, Hongisto T (2006) Effect of half-systematic thinning on the increment of Scots pine and Norway spruce in Finland. Forestry 79: 103–121. https://doi.org/10.1093/forestry/cpi061.

Manner J, Ersson BT (2023) A pilot study of continuous cover forestry in boreal forests: do remaining trees affect forwarder productivity? J For Sci. 69: 317–323. https://doi.org/10.17221/44/2023-JFS.

Manner J, Nordfjell T, Lindroos O (2013) Effects of the number of assortments and log concentration on time consumption for forwarding. Silva Fenn 47, article id 1030. https://doi.org/10.14214/sf.1030.

Manner J, Nordfjell T, Lindroos O (2016) Automatic load level follow-up of forwarders’ fuel and time consumption. Int J For Eng 27(3): 151–160. https://doi.org/10.1080/14942119.2016.1231484.

Manner J, Karlsen T, Ersson BT (2023) A pilot study of continuous cover forestry in boreal forests: decreasing the harvest intensity during selection cutting increases piece size, which in turn increases harvester productivity. J For Sci 69: 172–177. https://doi.org/10.17221/22/2023-JFS.

Mason WL, Diaci J, Carvalho J, Valkonen S (2021) Continuous cover forestry in Europe: usage and the knowledge gaps and challenges to wider adoption. Forestry 95: 1–12. https://doi.org/10.1093/forestry/cpab038.

Mielikäinen K (1980) Mänty-koivusekametsiköiden rakenne ja kehitys. [Structure and development of mixed pine and birch stands]. Commun Inst For Fenn 99.3. http://urn.fi/URN:NBN:fi-metla-201207171129.

Mielikäinen K (1985) Koivusekoituksen vaikutus kuusikon rakenteeseen ja kehitykseen. [Effect of an admixture of birch on the structure and development of Norway spruce stands]. Commun Inst For Fenn 133. http://urn.fi/URN:ISBN:951-40-0711-5.

Mielikäinen K, Valkonen S (1991) Harvennustavan vaikutus varttuneen metsikön tuotokseen ja tuottoihin Etelä-Suomessa. [Effect of thinning method on the yield of middle-aged stands in southern Finland]. Folia For 776. http://urn.fi/URN:ISBN:951-40-1167-8.

Miettinen A (2005) Paikkatietoanalyysien soveltaminen eri-ikäisrakenteisten metsien hakkuiden tutkimuksessa. Päättötyö, paikkatiedonhallinnan erikoistumisopinnot. [Application of Spatial Analysis in the Study of Harvesting in Uneven-Aged Forests. Thesis, Specialized Studies in Geospatial Information Management]. Häme University of Applied Sciences.

Näslund M (1936) Skogsförsöksanstaltens gallringsförsök i tallskog. [Forest research institute’s thinning experiments in pine forests]. Meddelanden från Statens Skogsförsöksanstalt 29.

Niebel BW (1988) Motion and time study, Richard D. Irwin. Inc., Homewood.

Niemistö P (1997) Ensiharvennuksen ajankohdan ja voimakkuuden vaikutus istutetun rauduskoivikon kasvuun ja tuotokseen. [The impact of the timing and intensity of the first thinning on the growth and yield of planted downy birch stand.] Metsätieteen aikakauskirja – Folia Forestalia 4/1997: 439–454. https://doi.org/10.14214/ma.6232.

Niemistö P (2022) Typpilannoituksen ja harventamisen kasvuvaikutukset kaksijaksoisessa mänty-kuusisekametsässä. [The growth effects of nitrogen fertilization and thinning in a two-story pine-spruce mixed forest.] Metsätieteen aikakauskirja, article id 10774. https://doi.org/10.14214/ma.10774.

Niemistö P, Jylhä P (2023) Puunkorjuun ajanmenekki ja kustannukset jatkuvapeitteisessä suometsien kasvatuksessa – tapaustutkimus. [Time consumption and harvesting cost in continuous cover management of peatland forests – a case study]. Suo 74: 1–24.

Niemistö P, Valkonen S (2021) Growth response to thinning in two-storied mixed stands of Scots pine and Norway spruce. Scand J Forest Res 36: 448–459. https://doi.org/10.1080/02827581.2021.1961017.

Niemistö P, Korpunen H, Laurén A, Salomäki M, Uusitalo J (2012) Impact and productivity of harvesting while retaining young understorey spruces in final cutting of downy birch. Silva Fenn 46: 81–97. https://doi.org/10.14214/sf.67.

Nuutinen Y (2013) Possibilities to use automatic and manual timing in time studies on harvester operations. Diss For 156. https://doi.org/10.14214/df.156.

Nuutinen Y, Miina J, Saksa T, Bergström D, Routa J (2021) Comparing the characteristics of boom-corridor and selectively thinned stands of Scots pine and birch. Silva Fenn 55, article id 10462. https://doi.org/10.14214/sf.10462.

Nyman D (2016) Kalhyggesfritt skogsbruk – lätt avverkning eller hård gallring? En översikt av vår nygamla skogsbruksmetod. Yrkeshögskolan NOVIA. Examensarbete för skogsbruksingenjör (YH-examen). Utbildningprogrammet för naturbruk. [Clearcut-free forestry – easy harvesting or intensive thinning? An overview of our newly revived forestry method]. Thesis for Forest Management Engineer, Novia University of Applied Sciences, Raseborg.

Oliver C, Larson B (1990) Forest stand dynamics. McGraw-Hill, New York.

Ovaskainen H (2009) Timber harvester operators’ working technique in first thinning and the importance of cognitive abilities on work productivity. Diss For 79. https://doi.org/10.14214/df.79.

Palander T, Ovaskainen H, Tikkanen L (2012) An adaptive work study method for identifying the human factors that influence the performance of a human-machine system. Forest Sci 58: 377–389. https://doi.org/10.5849/forsci.11-013.

Piri T, Korhonen K (2001) Infection of advance regeneration of Norway spruce by Heterobasidion parviporum. Can J Forest Res 31: 937–942. https://doi.org/10.1139/x01-021.

Ryynänen S, Rönkkö E (2001) Harvennusharvestereiden tuottavuus ja kustannukset. [Productivity and expenses associated with thinning harvesters]. Työtehoseuran julkaisuja 381, Helsinki.

Siipilehto J, Sarkkola S, Nuutinen Y, Mehtätalo L (2023) Predicting height-diameter relationship in uneven-aged stands in Finland. For Ecol Manage 549, article id 121486. https://doi.org/10.1016/j.foreco.2023.121486.

Sirén M (1998) Hakkuukonetyö, sen korjuujälki ja puustovaurioiden ennustaminen. [One-grip harvester operation, its silvicultural result and possibilities to predict tree damage]. Doctoral thesis. Finnish Forest Research Institute Research Papers 697. http://urn.fi/URN:ISBN:951-40-1635-1.

Sirén M, Hyvönen J, Surakka H (2015) Tree damage in mechanized uneven-aged selection cuttings. Croat J For Eng 36: 33–42.

Surakka H, Sirén M (2007) Poimintahakkuiden puunkorjuun nykytietämys ja tutkimustarpeet. [Current knowledge and research needs in selective logging and wood harvesting]. Metsätieteen aikakauskirja 4/2007: 373–390. https://doi.org/10.14214/ma.5983.

Surakka H, Sirén M, Heikkinen J, Valkonen S (2011) Damage to saplings in mechanized selection cutting in uneven-aged Norway spruce stands. Scand J Forest Res 26: 232–244. https://doi.org/10.1080/02827581.2011.552518.

Tahvonen O (2009) Optimal choice between even- and uneven-aged forestry. Nat Resour Model 22: 289–321. https://doi.org/10.1111/j.1939-7445.2008.00037.x.

Väätäinen K, Ala-Fossi A, Nuutinen Y, Röser D (2006) The effect of single grip harvester’s log bunching on forwarder efficiency. Balt For 12: 67–69.

Vanha-Majamaa I, Jalonen J, Hautala H (2002) Puusto, taimettuminen ja muu kasvillisuus. [Stand, regeneration, and other vegetation]. Monta-tulosseminaari 17.5.2002, Helsinki.

Total of 64 references.