The cost competitiveness of conifer stumps in the procurement of forest chips for fuel in Southern and Northern Finland

Laitila J., Ranta T., Asikainen A., Jäppinen E., Korpinen O.-J. (2015). The cost competitiveness of conifer stumps in the procurement of forest chips for fuel in Southern and Northern Finland. Silva Fennica vol. 49 no. 2 article id 1280. https://doi.org/10.14214/sf.1280

Highlights

- Pre-grinding and integrated screening is a way of guaranteeing fuel quality, but, when the stumps’ ash content is six per cent or below, the procurement costs are higher than with grinding of stumps at the plant. Because of high transportation costs, stump harvesting is the most profitable in Southern Finland, where there is greater availability of stumps than in Northern Finland.

Abstract

The aim of this study was to evaluate cost competitiveness, at regional level, of various systems for stump transportation and grinding, and to compare the results to the procurement costs of delimbed stems from early thinnings at the stand and regional level. The accumulation and procurement costs of stumps and delimbed stems were estimated within a 100-kilometer radius from two power plants located in Kouvola and in Kajaani. The analyses were performed as simulated treatments in clear cuts and thinnings of young stands, using existing productivity and cost functions, alternative ash percentages for stump wood, and yield calculations based on the forest industry regeneration felling stand data and the sample plots data of the National Forest Inventory of Finland. The results were expressed as Euros per solid cubic meter (€ m–3) and Euros per megawatt hour (€ MWh–1). The results highlight the need to improve stump fuel quality and increase the heating value. The procurement cost of stumps was about 1 € MWh–1 lower in Kouvola compared to Kajaani, when using conceivable ash content of 6% for stumps ground at the plant, and ash content of 1.5% for stumps pre-ground at the roadside landing. The procurement costs of stumps were, on average, 0.55 € MWh–1 lower compared to delimbed stems in Kouvola, and on average 0.6 € MWh–1 higher in Kajaani. Pre-grinding and integrated screening is a feasible way to guarantee the fuel quality expressed as ash content already at roadside landings, but the procurement costs are higher compared to grinding stumps at the plant, when the ash content of ground stumps is 6% or less.

Keywords

stumps;

quality;

delimbed stems;

pre-grinding;

procurement;

heating value

-

Laitila,

Natural Resources Institute Finland (Luke), Bio-based Business and Industry, P.O. Box 68, FI-80101 Joensuu, Finland

E-mail

juha.laitila@metla.fi

- Ranta, Lappeenranta University of Technology, Sammonkatu 12, FI-50130 Mikkeli, Finland E-mail tapio.ranta@lut.fi

- Asikainen, Natural Resources Institute Finland (Luke), Bio-based Business and Industry, P.O. Box 68, FI-80101 Joensuu, Finland E-mail antti.asikainen@metla.fi

- Jäppinen, Lappeenranta University of Technology, Sammonkatu 12, FI-50130 Mikkeli, Finland E-mail eero.jappinen@lut.fi

- Korpinen, Lappeenranta University of Technology, Sammonkatu 12, FI-50130 Mikkeli, Finland E-mail olli-jussi.korpinen@lut.fi

Received 20 November 2014 Accepted 19 February 2015 Published 26 March 2015

Views 281796

Available at https://doi.org/10.14214/sf.1280 | Download PDF

1 Introduction

1.1 Energy strategy and forest chips resources

In 2007, the Council of Europe accepted the proposal of the European Commission that the EU member countries should produce 20% of their energy using renewable sources by the year 2020. Each member country has its own target, and in Finland, the EU obligates an increase in the share of renewable energy sources in energy consumption from 28.5% to 38% by the year 2020 (Valtioneuvosto 2008). The Finnish long-term climate and energy strategy assigns wood-based energy an important role in achieving this goal, and the most important means of increasing the consumption of wood for energy in the future is the utilization of forest chip resources. Currently, processing residues from the forest industry are the most important source of wood-based fuels, but these by-products can be considered to be fully utilized at the present time (Torvelainen et al. 2014). According, for example, to Laitila et al. (2008a), the technically harvestable annual residual forest biomass potential for energy was 15.9 million m3 (solid). The technically harvestable potential consisted of 6.9 million m3 of whole trees from early thinning, 6.5 million m3 of logging residues from final fellings, and 2.5 million m3 of spruce stumps from final fellings.

The Ministerial Working Group of the Finnish Government for climate and energy policy has set the target that 13.5 million solid cubic meters of forest chips – that is, logging residues and stumps from final fellings and small trees from early thinning – will be used for energy in 2020 (Työ- ja elinkeinoministeriö 2010). In the year 2013, Finnish heating and power plants consumed 18.7 million m³ of wood fuels, of which 8.0 million m3 comprised forest chips (Torvelainen et al. 2014). About 44% of these forest chips were made of small diameter thinning wood produced in the tending of young stands, and 34% was produced from logging residues in final felling. The share of the stump and root wood was 15%, while 7% of forest chips were produced from large and rotten roundwood (Torvelainen et al. 2014). In addition, about 0.7 million m3 of forest chips are used annually to heat small-sized dwellings, including farms and both detached and terraced houses (Torvelainen et al. 2014).

The recovery of logging residues from final fellings is more cost-competitive than harvesting small trees from early thinnings and stumps from final fellings (Ryymin et al. 2008; Laitila et al. 2010a; Laitila et al. 2013). The difference in the production cost is caused by the high cost of cutting small trees and extracting stumps, whereas in off- and on-road transportation, as well as in comminution, the cost differences between logging residues, stumps, and energy wood from thinnings are rather small (Ryymin et al. 2008; Laitila et al. 2010a). Small stem sizes, low removals per hectare, dense undergrowth, and difficult terrain on the harvesting site all result in low productivity and high logging costs in early thinnings (Kärhä et al. 2005; Kärhä 2006; Laitila 2008; Oikari et al. 2010; Belbo 2010; Belbo 2011; Petty and Kärhä 2011). The value of raw material can also be low in relation to logging costs (Sirén and Tanttu 2001; Jylhä et al. 2010; Jylhä 2011). In the long term, neglect of thinnings will backfire, increasing the natural drain and slowing both diameter growth at stand level and the forest-owner’s flow of income. Therefore, early thinning operations are subsidized for silvicultural reasons, which enables the energy wood harvesting activities for energy production (Ahtikoski et al. 2008; Petty and Kärhä 2011).

1.2 Procurement of stumps and delimbed stems for fuel

Coniferous rootstock is considered to be a promising energy source because it contains higher concentrations of the energy-rich component lignin and extractives than stem wood (Hakkila 1975; Hakkila 1976; Hakkila 1989; Nurmi 1997; Eriksson-Näslund and Gustavsson 2008; Berg 2014). Norway spruce (Picea abies) is the most interesting species for stump harvesting, because it is easier to harvest and clean than Scots pine (Pinus sylvestris) (Nylinder 1977; Hakkila 2004). Impurities in the harvested stumps are a quality problem, as the stumps and roots usually include some rocks and soil (Spinelli et al. 2005; Laitila et al. 2010a; Laurila and Lauhanen 2010; Anerud and Jirjis 2011; Anerud 2012; Anerud et al. 2013). The effective heating value of wood biomass is the main parameter defining its quality as fuel. In addition to moisture content, ash content is one of the major factors decreasing the calorific value of the stump wood, and high levels of mineral contaminants can also affect ash melting behavior during combustion, leading to sintering and drift problems (Anerud and Jirjis 2011; Anerud et al. 2013). Low profitability, together with uncertainty about fuel quality, hampered earlier attempts to use stumps as fuel, both in Finland and Sweden (Hakkila 2004; Björheden 2006).

The stumps are uprooted and split using a tracked excavator, and impurities are shaken off by the crane movements (Laitila et al. 2008; Lazdins et al. 2009; Lindroos et al. 2010; Athanassiadis et al. 2011; Tolosana et al. 2011; Kärhä 2012; Berg et al. 2012; Czupy and Horvath-Szovati 2013; Berg et al. 2014; Berg 2014). Shaking off the impurities from the extracted stumps take a relatively large proportion of the excavator’s working time, and stump shaking by the crane movements also causes stress to the driver (Laitila 2008; Kärhä 2012). However, despite this time-consuming cleaning process, the considerable variations in contamination levels result in widely varying concentrations of ash being reported. For example, Anerud and Jirjis (2011) have reported ash content ranging between 2% and 7% for freshly ground stumps, and in the study by Nuutinen et al. (2013), the ash content of seasoned stumps was 13%. In the study by Korpinen et al. (2007), the ash content of the hog fuel samples varied from 1% to 24%, and, for most samples, the ash content was below 10%. In truck transporting of split stumps, Palander et al. (2011) have reported fallen contaminant amounts of 2200 kilos per road-trip at the bottom of the load space, when transporting split stumps from the roadside landing to the terminal or combine heat and power (CHP) plant.

Harvesting as delimbed stems from thinnings is increasing due to better chip quality and transport economy compared to whole tree harvesting (Laitila and Väätäinen 2012; Laitila 2012; Torvelainen 2014). Harvesting of delimbed stems is a promising way to simplify procurement operations (Laitila 2012), and it has been estimated that the role of comminuting at the plant in the production of chips from small-sized thinning wood will increase in the future (Kärhä 2011). Compared to fuel chips made of logging residues or stumps, the quality of thinning wood chips is significantly higher. Delimbed material produces uniform fuel stock devoid of needles, branches, and mineral soil contaminants, which may be a significant benefit at some power plants (Nurmi and Hillebrand 2007).

In Finland, the majority of stumps are ground either at the plant or at terminals with heavy and often stationary grinders (Strandström 2013). The transportation of stumps calls for a special biomass truck with a solid bottom and side panels, and economical transport distances are short, owing to the small potential payloads (Ranta and Rinne 2006; Palander et al. 2011; Wolfsmayr and Rauch 2014; Eriksson et al. 2014a; Eriksson et al. 2014b). Recently, effective mobile grinders suitable for the comminution or pre-comminution of stumps at roadside landings have been introduced (von Hofsten and Granlund 2010; Kärhä et al. 2011b; Nuutinen et al. 2014), and there are also grinder units capable of integrated grinding and screening of stump wood for fuel at roadside landings (Laitila and Nuutinen 2015). The truck- or semitrailer-mounted grinder is used in a similar manner to mobile chippers in the chipping of logging residues and small-diameter trees (Asikainen 2010). The grinder moves from landing to landing, with the comminuted material transported to the end-user by standard truck-trailer units (Asikainen 2010). Systems based on comminution at the landing increase the payload of trucks, since the comminuted material is less bulky, and thereby reduce transport costs (Eriksson et al. 2014a; Eriksson et al. 2014b). Screening also reduces the amount of fine material contaminants at the source and increases the quality of the produced fuel (Eriksson et al. 2013; Dukes et al. 2013; Laitila and Nuutinen 2015). Thanks to screening, an ash content of 0.4–2.3% for ground stumps has been reported, while the wood-matter losses have been rather nominal (Laitila and Nuutinen 2015).

1.3 Aim of the study

Bulky stumps can be pre-processed, comminuted, and transported in different ways, and if the system is analyzed properly, it can reduce the supply costs, improve quality, and help deliver fuel at a more competitive price. The aim of this study was, at regional level, to evaluate the cost competitiveness of various systems for stump transportation and grinding, and to compare the results to the procurement costs of delimbed stems. The accumulation and procurement costs of stumps and delimbed stems were estimated within a 100-kilometer radius from two power plants located in Kouvola in South Finland, and in Kajaani in North Finland. The analyses were performed as simulated treatments in clear cuts and thinnings of young stands, using existing productivity and cost functions, alternative ash percentages for stump wood, and yield calculations based on the forest industry stand data and the sample plots data of the National Forest Inventory of Finland (cf. Ranta 2002; Laitila et al. 2010b; Laitila 2012). The results were expressed as Euros per solid cubic meter (€ m–3) and Euros per megawatt hour (€ MWh–1). In this study, the comparison of the alternative supply chains and raw materials started with organizing the procurement activities; continued onto the logging, comminution, and transportation; and ended with delivery of the fuel chips to the end-user. Subsidies and stumpage prices were excluded from consideration in the study.

2 Material and methods

2.1 Productivity and cost parameters of the procurement system

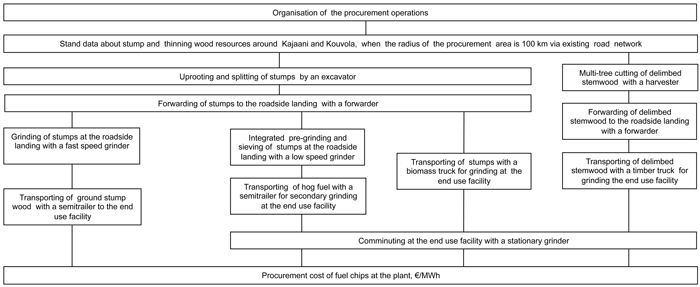

The production stages of supply chains of this study are demonstrated in Fig. 1. It was assumed that a conventional harvester-forwarder chain was used in logging operations in early thinning, and harvesting stumps from clear cuts was based on the excavator-forwarder chain. The delimbed stems were transported to the end-use facility using a conventional timber truck, and comminuted with a stationary grinder. For stumps, there were three options: 1) grinding to an acceptable fuel fraction at the landing, 2) pre-grinding and sieving at the landing and final comminution at the end-use facility, or 3) transporting harvested stump with a biomass truck for comminution at the end use facility (Fig. 1). The organization cost, 2.5 € m–3, which corresponds to the average organization cost of industrial roundwood procurement in Finland (Strandström 2014), was set as constant for all raw materials and supply chains in this study.

Fig. 1. The supply chains of this study by the main work stages. View larger in new window/tab.

The productivity of cutting delimbed stems using the multi-tree processing technique was based on the study of Laitila and Väätäinen (2013). The stump extraction was modeled with a crawler excavator equipped with an extraction device (Laitila et al. 2008b). Forwarding productivity with delimbed stems was calculated by means of the model of Kuitto et al. (1994), and the forwarding productivity for split stumps was obtained from a study by Laitila (2010). The payloads (Table 1) were set in line with the work of Laitila et al. (2010a). The gross effective time (E15h) coefficients (Table 1) for cutting, forwarding, and stump extraction were based on research by Jylhä et al. (2010) and Laitila et al. (2010a). The total length of the strip road network at the thinning stand was assumed to be 600 m ha–1, based on an average strip road spacing of 20 m (Niemistö 1992). At stump harvesting sites, the strip road network was assumed to be 450 m ha–1 due to pre-piling of stumps during stump extraction (Laitila 2010). The hourly cost data of forest machines are described in Table 2.

| Table 1. The productivity parameters for the supply chains (Fig. 1). | ||||

| Delimbed stems | Pre-ground stumps | Ground stumps | Split stumps | |

| Gross effective time (E15h) coefficient for cutting/uprooting | 1.3 | 1.4 | 1.4 | 1.4 |

| Payload of the forwarder, m³ | 9.0 | 8.6 | 8.6 | 8.6 |

| Gross effective time (E15h) coefficient for forwarding | 1.3 | 1.2 | 1.2 | 1.2 |

| Payload in transport by road, m³ | 67 | 25 | 27 | 32 |

| Loading time in transport by road, minutes | 50 | 44 | 54 | 62 |

| Unloading time in transport by road, minutes | 37 | 27 | 27 | 56 |

| Cost of grinding and pre-grinding at the roadside landing, € m–3 | - | 5.4 | 7.1 | - |

| Grinding productivity at the end use facility with the stationary grinder, loose-m3 E15h–1 | 180 | 270 | - | 180 |

| Cost of grinding at the end use facility with the stationary grinder, € m–3 | 2.8 | 1.9 | - | 2.8 |

The delimbed stems were transported to the plant using a conventional timber truck with a trailer (Laitila et al. 2009; Laitila and Väätäinen 2011), assuming a payload of 67 m3, which corresponds to a novel truck-trailer unit having a legal maximum weight of 76 tonnes (Anttila et al. 2012). The ground and pre-ground stump wood were transported from the roadside landing to the end-use facility using a semitrailer with a load space of 95 m3. The payload of the ground stump wood was 27 m3, and for the pre-ground stump wood the payload was 25 m3 (Nuutinen et al. 2014; Laitila and Nuutinen 2015). Split stumps were transported to the end-use facility using a biomass truck with a 150 m3 load space and a payload of 32 m3 (Ranta and Rinne 2006; Kärhä et al. 2011a; Palander et al. 2011). The time consumption of driving, with full load and empty load, was calculated as a function of transportation distance, according to the speed functions of Nurminen and Heinonen (2007). The hourly cost data of vehicles are described in Table 3 and payload parameters in Table 1.

The loading time for ground and pre-ground stumps (Table 1) is linked to grinders operating hour productivity (E15h). When using the fast-speed grinder, the loading time was estimated be 54 minutes per load, and with low-speed grinder the pre-grinding time was 44 minutes per load (Nuutinen et al. 2014; Laitila and Nuutinen 2015). The unloading time at the delivery hopper of the CHP plant or to the stationary grinder of the plant was 27 minutes per semitrailer load for both ground and pre-ground stumps (Table 1). The loading time of delimbed stems (Table 1) was estimated to be 50 minutes at the roadside landing, and the unloading time (Table 1) to the delivery hopper of the CHP plant stationary grinder was 37 minutes per load (Laitila et al. 2009; Laitila and Väätäinen 2011). For split stumps (Table 1), the loading time at the roadside landing was 62 minutes, and the unloading time to the stationary grinder was 56 minutes per load (Ranta and Rinne 2006; Kärhä et al. 2011a; Palander et al. 2011).

The grinding productivity of delimbed stems and split stumps at the end-use facility with the stationary grinder was estimated to be 180 loose-m3 E15h–1 and with pre-ground stumps 270 loose-m3 E15h–1 (Rinne 2010; Kärhä et al. 2011a). The solid percentage of acceptable fuel fraction was estimated to be 28% (Nuutinen et al. 2014), which means that the grinding costs (Table 1) were 2.8 € m–3 for stumps and delimbed stems, and 1.9 € m–3 for pre-ground stumps, when the operating-hour cost of the stationary grinder was 140.3 € E15h–1 (Table 2). The pre-grinding and grinding costs (Table 1) of stumps were 5.4 € m–3 and 7.1 € m–3, with corresponding hourly costs of 185.2 € E15h–1 and 213.8 3 € E15h–1 for low- and fast-speed grinders (Table 2) and the above-mentioned loading times per semitrailer load at the roadside landing (Table 1).

| Table 2. Hourly cost details of the harvesting machines and grinders. | ||||||

| Harvester | Forwarder | Excavator | Low-speed grinder | Fast-speed grinder | Stationary grinder | |

| Purchase price, € | 478 000 | 260 000 | 160 000 | 703 000 | 730 000 | 2 200 000 |

| Salvage value, € | 135 190 | 45 001 | 65 000 | 190 766 | 198 093 | 134 460 |

| Lifespan, years | 4.7 | 7.2 | 6 | 7 | 7 | 15 |

| FIXED COSTS: | ||||||

| Depreciation, € a –1 | 69 146 | 27821 | 15 833 | 73 176 | 75 987 | 137 703 |

| Interest, € a –1 | 12 664 | 6400 | 6400 | 19 339 | 20 082 | 49 443 |

| Insurance, € a –1 | 1985 | 1400 | 500 | 9430 | 9430 | 9430 |

| Administration, € a –1 | 11 691 | 3700 | 3700 | 7500 | 7500 | 7500 |

| LABOR COSTS: | ||||||

| Annual gross effective working time, h | 3213 | 2087 | 1200 | 2200 | 1700 | 3800 |

| Annual working time, h | 3780 | 2318 | 1760 | 3115 | 2615 | 3800 |

| Degree of machine utilization, % | 85 | 90 | 68 | 71 | 65 | 100 |

| Average wage for a worker, € h–1 | 16.9 | 15.0 | 13.3 | 17 | 17 | 5.61 |

| Indirect wage costs, % | 112 | 131 | 83 | 68 | 68 | 68 |

| Wage costs total, € a–1 | 135 941 | 80 393 | 42 801 | 88 964 | 74 684 | 35 814 |

| OPERATING COSTS: | ||||||

| Fuel price, € l –1 | 0.87 | 0.87 | 0.87 | 0.87 | 0.87 | 0.54 |

| Fuel cost, € a–1 | 41 930 | 21 784 | 17 435 | 133 521 | 108 302 | 115 443 |

| Oil and lubricant cost, € a –1 | 4935 | 1219 | 3796 | 5547 | 3772 | 16 863 |

| Service and maintenance cost, € a –1 | 24 428 | 9944 | 1380 | 50 610 | 46 410 | 135 660 |

| Translocation costs, € a –1 | 16 325 | 11 499 | 1000 | - | - | - |

| Risk and profit margin, € a –1 | 9571 | 4925 | 2803 | 19 404 | 17 308 | 25 393 |

| TOTAL COSTS: | 328 616 | 169 084 | 96 248 | 407 492 | 363 475 | 533 249 |

| Operating hour cost, € E15–1 (Value-added tax 0%) | 102.3 | 81.0 | 80.2 | 185.2 | 213.8 | 140.3 |

| Table 3. Hourly cost details of the truck-trailer units. | |||

| Timber truck | Biomass truck | Semitrailer unit | |

| Purchase price of tractor, € | 204 000 | 182 000 | 105 000 |

| Salvage value, € | 55 000 | 55 000 | 30 000 |

| Lifespan, years & kilometers | 4 & 480 000 | 4 & 480 000 | 8 & 720 000 |

| Purchase price of trailer, € | 70 000 | 90 000 | 80 000 |

| Salvage value, € | 5000 | 5000 | 10 000 |

| Lifespan, years & kilometers | 8 & 960 000 | 8 & 960 000 | 12 & 1 080 000 |

| Purchase price of timber crane, € | 71 500 | 71 500 | - |

| Salvage value, € | 5000 | 5000 | - |

| Lifespan, years | 4 | 4 | - |

| FIXED COSTS: | |||

| Depreciation, € a –1 | 58 850 | 56 225 | 13 832 |

| Interest, € a –1 | 13 820 | 13 740 | 7 400 |

| Insurance, € a –1 | 8600 | 8600 | 5500 |

| Administration, € a –1 | 8678 | 8626 | 7406 |

| LABOR COSTS: | |||

| Annual gross effective working time, h | 5400 | 6000 | 3938 |

| Annual working time, h | 5670 | 6300 | 4056 |

| Degree of machine utilization , % | 95 | 95 | 97 |

| Average wage for a worker, € h–1 | 17 | 17 | 17 |

| Indirect wage costs, % | 68 | 68 | 68 |

| Daily allowance, € a–1 | 6000 | 6000 | 3380 |

| Wage costs total, € a–1 | 167 935 | 185 928 | 119 209 |

| OPERATING COSTS: | |||

| Fuel price, € l –1 | 1.16 | 1.16 | 1.16 |

| Fuel cost, € a–1 | 87 000 | 80 736 | 46 980 |

| Tire cost, € a –1 | 11 786 | 10 821 | 6988 |

| Service and maintenance cost, € a –1 | 19 000 | 21 000 | 14 000 |

| Risk and profit margin (3%), € a –1 | 11 619 | 11 928 | 6845 |

| TOTAL COSTS: | 387 260 | 397 600 | 228 160 |

| Operating hour cost, € E15–1 (Value-added tax 0%) | 72 | 66 | 58 |

2.2 Hourly cost calculations of machines and vehicles

The operating costs (excluding a value-added tax) of the machines and vehicles (Tables 2 and 3) were calculated per gross effective hour (E15h) using the common machine cost calculation method (e.g. Harstela 1993; Ackerman et al. 2014), and the costs are presented in Euros (€). The costs included both time-dependent costs (e.g. capital depreciation, interest expenses, labor costs, insurance fees, and administration expenses) and variable operating expenses (e.g. fuel, repairs, service, and machine transfers). In addition to the annual total cost, 5% was added to take into account the risk of entrepreneurship for grinders, and 3% for conventional machines and vehicles. Capital costs were calculated using an interest rate of 4%. The calculation values, for example, for labor costs, fuel, insurance fees, repairs, and service expenses were obtained from Koneyrittäjien Liitto ry (the Trade Association of Finnish Forestry and Earth Moving Contractors) and Metsäalan Kuljetusyrittäjät ry (the Association of Forest Industry Road Carriers). Average prices of machines and vehicles were obtained from the manufacturers.

2.3 Estimation of the potential supply of delimbed stems and stumps

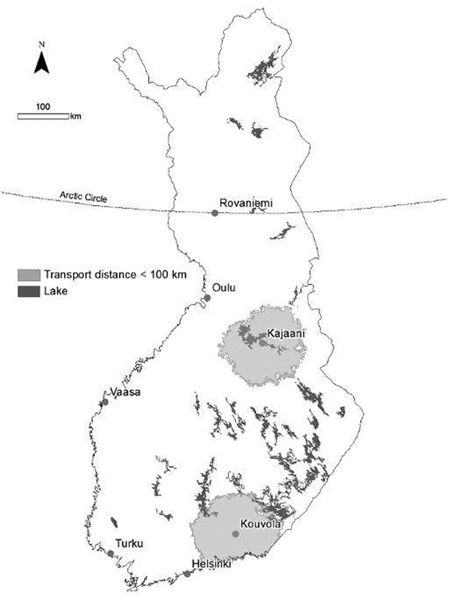

The estimated accumulation of forest chips from young forests around the cities of Kouvola and Kajaani (Fig. 2) was based on sample plot data from the 9th Finnish National Forest Inventory (NFI9), and satellite images and other auxiliary data were used to down-scale the data from forestry-center level to municipality level (Tomppo et al. 1998). Calculations of forest-chip resources were made for the young thinning stands (dominant height > 7 m, dbh 8–16 cm) needing improvement in thinning within the first five-year period. The area that an NFI sample plot represents in a certain municipality and stand development was calculated according to the methodology described earlier by Laitila et al. (2010b). This existing stand data was evaluated to be valid to use in procurement cost calculations, since major changes in the composition of stands were not going to happen.

Fig. 2. The procurement areas around Kajaani and Kouvola, where the radius is 100 km via the existing road network.

The removal of stem wood was calculated for each sample plot by simulating the thinning of a young stand according to silvicultural guidelines (Metsäkeskus Tapio 1994). In the simulation, trees tallied to the plot were first sorted by diameter. Starting from the smallest tree, trees were harvested until the basal area of the remaining trees reached the recommended basal area after thinning. The volume of the removed stems was then totaled. Trees with a dbh of more than 9.5 cm were classified as industrial roundwood, while those with a dbh of less than 9.5 cm and more than 4 cm were classified as energy wood. Trees of less than 4 cm dbh were not included in the total accumulation. In the total accumulation, trees were not classified as industrial roundwood or pure energy wood, because all trees were harvested for energy when the maximum allowable removal of industrial roundwood was less than 25 m3 per hectare and the minimum accumulation of timber fraction was 25 m3 or more per hectare.

The bucking and bolt volume of the delimbed stem wood was calculated as a function of tree species, as were the average height and dbh of trees in the NFI sample plot. For the usable stem part, the minimum top diameter was 4 cm and the length 3–5 meters. The bucking simulation and volume calculation for the NFI sample plots were done using the Excel-based ComBio-program (Pasanen et al. 2014). With ComBio, the calculation was based on the taper curve models by Laasasenaho (1982).

The calculations of transportation distances of delimbed stems, via the existing road network, to Kouvola and Kajaani, were based on GIS analysis and databases of forestry companies from the year 2000 (Asikainen et al. 2001; Laitila et al. 2010b). The transportation distance from municipality x to Kajaani/Kouvola was the average transportation distance from the felling stands of municipality x. The average transportation distance varied from 6 to 100 kilometers around Kouvola (mean 71 km), and from 19 to 100 kilometers around Kajaani (mean 79 km). For the procurement cost calculation, the average forwarding distance in each municipality was also calculated in a similar way for each municipality. Around Kouvola, the forwarding distances varied between 100 and 350 meters (mean 219 m), and around Kajaani between 115 and 350 meters (mean 243 m). The basic stand data of delimbed stems is collected in Table 4.

| Table 4. The basic stand data estimates for delimbed stems and stumps around Kajaani and Kouvola. The abbreviation SD = standard deviation. | ||

| Kajaani | Kouvola | |

| Average volume of stems harvested, dm3 | 24 (SD 11) | 28 (SD 12) |

| Average removal, number of stems per hectare | 1907 (SD 344) | 1721 (SD 244) |

| Average removal, m3 of stems harvested per hectare | 43 (SD 16) | 48 (SD 20) |

| Average volume of stumps harvested, dm3 | 87 (SD 32) | 140 (SD 40) |

| Average diameter of stumps harvested, cm | 27 (SD 4) | 34 (SD 4) |

| Average removal, number of stumps per hectare | 599 (SD 319 ) | 444 (SD 203) |

| Average removal, m3 of stumps harvested per hectare | 48 (SD 21) | 62 (SD 26) |

The supply potential calculations of stump biomass were based on a UPM Forest database of regeneration fellings from the year 2002. This data was evaluated to be valid to use in procurement cost calculations, since major changes in neither the volumes of felling areas nor the composition of stands were going to happen. The stand data included position data and attribute data of stands, such as felled roundwood volumes by tree species, felling time of the year, forwarding distance, average stem volume, and felling area. The radius of the procurement area via the existing road network was 100 kilometers in Kajaani and Kouvola (Fig. 2), and distances from stands to the CHP plant were calculated with the GIS application (cf. Ranta 2002). The transportation distances from stands to the CHP plant varied from 6 to 100 kilometers around Kouvola (mean 70 km), and from 4 to 100 kilometers around Kajaani (mean 60 km). The variation in the forwarding distances was 50–1000 meters for stands around Kajaani (mean 246 m), and 30–950 meters around Kouvola (mean 259 m).

The stump and root wood volumes at the stands were estimated to be 28% of the total volume of spruce and pine roundwood, and the recovery rate of conifer stumps was 95% (Laitila et al. 2008a). The estimation of the average breast height diameter at the stand was based on the average stem volume of industrial roundwood and the taper curve models of Laasasenaho (1982), and the average breast height diameter was further converted to stump diameter by the coefficient 1.33 (Hakkila 1976). Stump volume for procurement cost calculations was determined from stump diameter using stump mass models from Hakkila (1976) and basic densities of stump wood (Hakkila 1975). Stump volume was further increased by a coefficient of 1.17, since Hakkila’s mass model excluded roots with a diameter of less than 5 cm. The coefficient used is based on operational observations of the yield of stump wood from harvested stands (Hakkila 2004).

Some of the stands were restricted from further calculations based on stand selection criteria. These criteria were:

- Removal of stumps at the stand is ≥ 40 m3 and the area of the stand is ≥ 1 hectare.

- Spruce dominates. The volume of spruce roundwood at the stand is ≥ 55%.

After selection, the number of stump harvesting stands was 297 in Kajaani and 560 in Kouvola. The basic stand data of stumps is collected in Table 4.

2.4 Fuel-property parameters

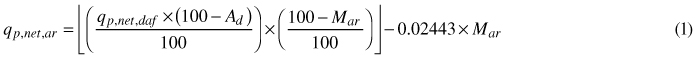

The net calorific value (at constant pressure) as received (the moist chips) was calculated from a net calorific value of the dry and ash-free, according to the following equation (Alakangas 2005):

where

qp,net,ar = the net calorific value (at constant pressure) as received (MJ kg–1)

qp,net,daf = the net calorific value (at constant pressure) on a dry and ash-free basis (MJ kg–1)

Mar = the moisture content as received

Ad = the ash content on a dry basis

0.02443 = the correction factor of the enthalpy of vaporization at 25 °C

Basic densities (kg m–3) for stumps and delimbed stems were used according to Hakkila (1978) by tree species. Correspondingly, tree species-specific net calorific values of dry matter (MJ kg–1) were used according to Nurmi (1993) for stem wood, and for conifer stumps values from Hakkila (1978) were used. Moisture content of 31% was used for stumps (Laurila and Lauhanen 2010) and moisture content of 40% for delimbed stems (Hakkila 1989; Nurmi and Hillebrand 2007; Laurila and Lauhanen 2012; Laitila 2008; Nuutinen et al 2014). Moisture content was held constant within each system during availability and procurement cost calculations.

Handling, transportation, and screening of stump material tends to lower the contaminant content (Korpinen et al. 2007; Laitila et al. 2008; Athanassiadis et al. 2011; Anerud and Jirjis 2011; Palander et al. 2011; Anerud 2012; Kärhä 2012; Fogdestam et al. 2012; Dukes et al. 2013; Anerud et al. 2013; Nuutinen et al. 2013; Eriksson et al. 2013; Eriksson et al. 2014a; Eriksson et al. 2014b; Berg 2014; Laitila and Nuutinen 2015). When stumps are ground directly to an acceptable fuel fraction at the landing, the amount of upgrading vibration is the lowest and the ash content of ground stump material is the highest. Ash contents of 18%, 12%, and 6% were assumed for system: 1) grinding to an acceptable fuel fraction at the landing. Respectively, ash contents of 6% and 1.5% were assumed for system: 2) pre-grinding and sieving at the landing and final comminution at the end-use facility, and ash contents of 12%, 6%, 1.5% for system: 3) transporting harvested stump using a biomass truck for comminution at the end-use facility. Delimbed stems were considered to be free of adhering contaminants. The validity of alternative ash content values for sensitivity analyses of supply chains was verified via an extensive literature review and discussions with wood-fuel managers of procurement organizations and power plants.

3 Results

3.1 Harvesting potential of stumps and delimbed stems

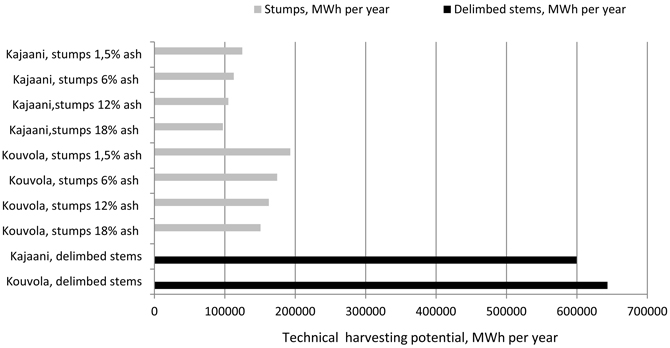

The availability analysis attested that, around Kajaani, the technical harvesting potential of stumps was 54 399 m3 and the harvesting potential of delimbed stems was 267 516 m3 per year. Correspondingly, in Kouvola, the harvesting potential was 84 136 m3 for stumps and 294 721 m3 for delimbed stems. The energy content of the delimbed stems was 599 673 MWh per year in Kajaani and 643 560 MWh per year in Kouvola (Fig. 3). The energy content of stumps around Kajaani was 124 734–97 353 MWh per year, depending on the ash content of ground stump material, and correspondingly 192 986–150 691 MWh per year around Kouvola (Fig. 3).

Fig. 3. The technical harvesting potential of delimbed stems and stumps for fuel (MWh per year) around the cities of Kajaani and Kouvola, when using alternative contaminant contents for ground stumps.

3.2 Cost structure of fuel chips

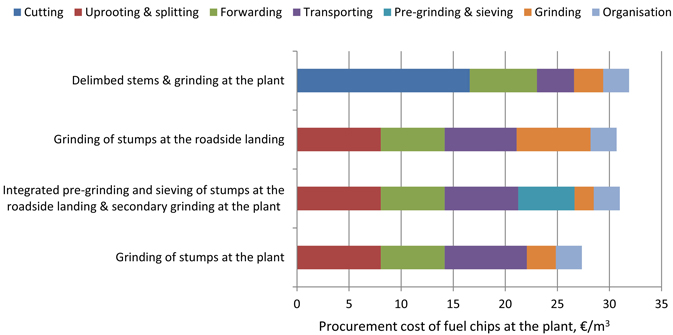

The procurement cost of fuel chips at stand level varied from 27.4 to 31.9 € m-3 at the plant, depending on the supply chain and raw material used (Fig. 4). The cost calculations were made for stands where harvesting conditions corresponded to the average harvesting conditions around Kouvola (Table 4). The supply chain based on grinding stumps at the plant was the most cost-efficient, while the procurement of delimbed stems was the most expensive, when costs were expressed as Euros per solid cubic meter (€ m-3). The supply chains based on two-phase grinding or direct grinding of stumps were at the same procurement cost level, and the difference was just 0.3 € m–3 (Fig. 4). The cutting costs of delimbed stems (16.6 € m–3) were more than 60% of total procurement costs, and forwarding costs (6.5 € m–3) were about 25%. The harvesting cost of stumps at the roadside landing was the same for all three supply chains. The cost of splitting and uprooting stumps was 8.1 € m–3 and the cost of stump forwarding was 6.1 € m–3 (Fig. 4).

Fig. 4. The procurement cost structure of the supply chains and raw materials of this study. The off-road transportation distance is 219 m, and the on-road transportation distance is 50 km.

The procurement cost comparisons of the supply chains and raw materials were calculated as a function of the on-road transportation distance (1–150 km) in Fig. 5. The stand conditions and cost parameters were similar to Fig. 4, and costs were expressed as Euros per solid cubic meter (€ m-3). The supply chain based on grinding stumps at the roadside landing was the most cost-effective system for all transportation distances (Fig. 5). The procurement costs of fuel chips made of delimbed stems were lower for supply chains based either on two-phase grinding or direct grinding of stumps, when the transportation distance was more than 93 km or 78 km (Fig. 5). The procurement cost difference between supply chains based on either two-phase grinding or direct grinding of stumps was 0.12 € m–3 when the transportation distance was 15 kilometers, and the cost difference favoring direct grinding of stumps at the roadside landing grew to 0.7 € m–3 when the transportation distance was 150 km (Fig. 5).

Fig. 5. The procurement cost comparison of the supply chains and raw materials as a function of on-road transportation distance.

The independent variables for uprooting productivity with stumps and for cutting productivity with delimbed stems were the volume of harvested stumps/stems (dm3) and the number of harvested stumps/stems per hectare (Laitila et al. 2008b; Laitila and Väätäinen 2013). For forwarding productivity, the independent variables were the cutting/uprooting removal per hectare (m3/ha) and forwarding distance (Kuitto et al. 1994; Laitila 2010). The harvesting productivity and cost were determined for the whole stand data in the procurement areas of Kouvola and Kajaani (Figs. 6, 7 and 8). The average productivity and cost values for cutting, uprooting, and forwarding in the procurement areas are presented in Table 5.

| Table 5. Productivity and cost values for cutting, uprooting, and forwarding in the procurement areas of Kajaani and Kouvola. The abbreviation SD = standard deviation. | ||

| Kajaani | Kouvola | |

| Average cutting productivity for harvested delimbed stems, m3 E15h–1 | 5.1 (SD 1.0) | 5.1 (SD 1.3) |

| Average cutting cost for harvested delimbed stems, € m–3 | 20.8 (SD 3.9) | 21.0 (SD 4.8) |

| Average forwarding productivity for harvested delimbed stems, m3 E15h–1 | 11.9 (SD 0.9) | 12.3 (SD 0.9) |

| Average forwarding cost for harvested delimbed stems, € m–3 | 6.9 (SD 0.5) | 6.6 (SD 0.5) |

| Average uprooting productivity for harvested stumps, m3 E15h–1 | 7.6 (SD 1.5) | 9.2 (SD 0.9) |

| Average uprooting cost for harvested stumps, € m–3 | 10.8 (SD 2.6) | 8.6 (SD 1.1) |

| Average forwarding productivity for harvested stumps, m3 E15h–1 | 12.7 (SD 2.2) | 12.9 (SD 2.3) |

| Average forwarding cost for harvested stumps, € m–3 | 6.6 (SD 2.2) | 6.5 (SD 1.4) |

3.3 Procurement costs of stumps and delimbed stems for energy

The harvesting costs at the sample plots of NFI and regeneration fellings were calculated using the productivity models and cost parameters described above. The transportation costs were calculated as a function of transportation distances from stands in the procurement area to Kajaani and Kouvola. The standwise procurement costs of fuel chips at the Kajaani and Kouvola plants were calculated, totaling the harvesting, comminution, transportation and overhead costs of stumps and delimbed stems. The accumulation and procurement cost data of fuel chips were summarized, and data was sorted according to the procurement costs for each classification and supply chain. The cumulative accumulation of fuel chips at marginal procurement cost was calculated for alternative supply chains, and the cost at plant was expressed as Euros per megawatt hour (€ MWh–1), according to the fuel-property parameters of stumps and delimbed stems (Figs. 6, 7 and 8).

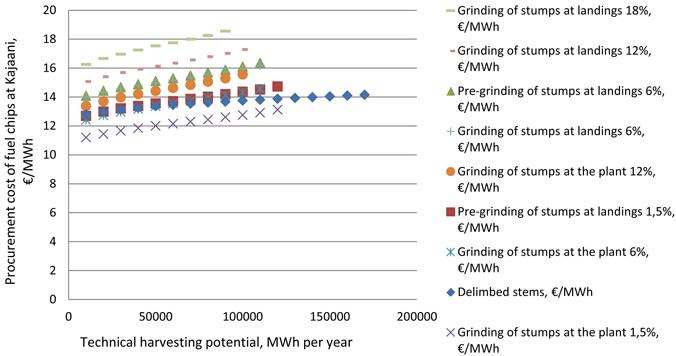

Fig. 6. The procurement cost of fuel chips around Kajaani when using alternative supply chains and alternative contaminant contents for ground stumps, as a function of harvesting potential.

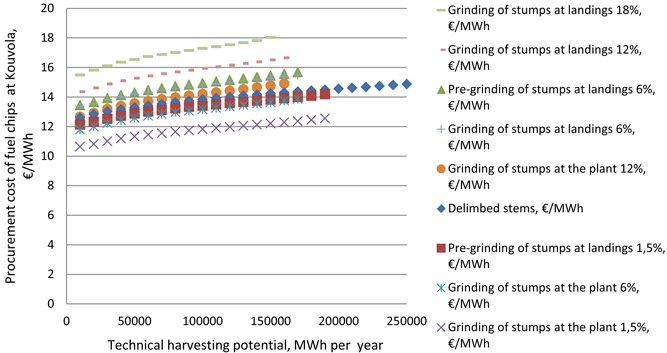

The supply chain based on grinding stumps at the plant with a speculative ash content of 1.5% was the most cost-efficient procurement method, both in Kajaani and Kouvola, when the annual procurement of fuel chips was 100 000 MWh (Figs. 6 and 7). Harvesting of delimbed stems was the second best procurement option in Kajaani (Fig. 6), and grinding of stumps at the plant with an ash content of 6% was the second best option in Kouvola (Fig. 7). In Kajaani, the next best options were grinding of stumps (ash 6%) at the plant and pre-grinding of stumps (ash 1.5%) at the roadside landing (Fig. 6). Correspondingly, in Kouvola, pre-grinding of stumps (ash 1.5%) at the roadside landing was the third most cost-competitive option and the procurement of delimbed stems was the fourth most cost-competitive option (Fig. 7). Due to high contaminant content, the supply chain based on direct grinding of stumps at the roadside landing was considered to be the least cost-competitive, both in Kajaani and Kouvola (Figs. 6 and 7).

Fig. 7. The procurement cost of fuel chips around Kouvola when using alternative supply chains and alternative contaminant contents for ground stumps, as a function of harvesting potential.

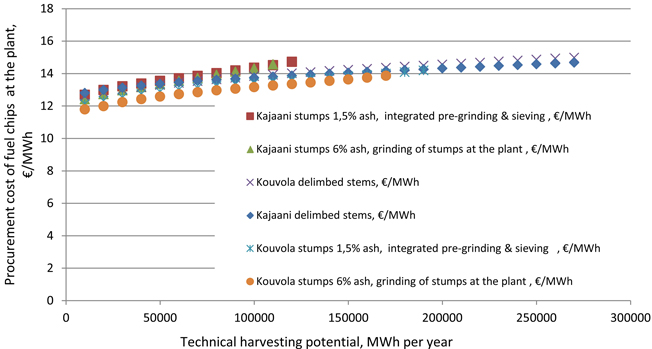

The procurement cost of stumps in Kouvola were about 1 € MWh–1 lower compared to Kajaani, when using conceivable ash content of 6% for stumps ground at the plant and ash content of 1.5% for stumps pre-ground at the roadside landing (Fig. 8). The procurement cost of delimbed stems from first thinnings was similar in Kajaani and Kouvola (Fig. 8). The procurement costs of stumps were, on average, 0.55 € MWh–1 lower compared to delimbed stems in Kouvola, and on average 0.6 € MWh –1 higher in Kajaani (Fig. 8). Around Kouvola, stumps were remarkably bigger (Table 4) and availability was higher (Fig. 3) compared to Kajaani. Transportation costs of stumps are higher (Figs. 4 and 5) compared to delimbed stems, which favors stump harvesting in regions where the availability of stumps is high and transportation distances comparatively short.

Fig. 8. The procurement costs of ground stumps and delimbed stems chips in Kajaani and Kouvola, as a function of harvesting potential.

4 Discussion

In this study, the comparison was made at the stand level or regional level, which meant that the normal fluctuation of interactions, for example, in cutting, stump lifting, forwarding, comminuting, transporting, and receiving fuel chips at the plant were not considered. The fluctuation of interactions directly affects the degrees of utilization of machines and vehicles, and also the number of machines and vehicles required. Several forest technology studies have noted that interactions leading to waiting and queuing result in increased costs (e.g. Asikainen 1995; Talbot et al. 2003; Väätäinen et al. 2005; Spinelli and Visser 2009; An and Searcy 2010; Asikainen 2010; Holzleitner et al. 2013; Belbo and Talbot 2014; Eriksson 2014a; Eriksson 2014b). For example, in the cost of comminution and transportation, the bias varies between 10–20% (Asikainen 1995; Asikainen 2010), depending on the transportation distance if the interactions of comminution and transportation capacity are not considered. In order to get more realistic information on the real-life situation, discrete-event modeling of procurement systems in the prevailing operating environment are required (Asikainen 1995; Talbot et al. 2003; Asikainen 2010; An and Searcy 2010; Belbo and Talbot 2014; Eriksson 2014a; Eriksson 2014b). The statistic model does not take random impacts into considerations and therefore yields more optimistic results than the dynamic simulation model does (Asikainen 2010). When the imbalance becomes larger, the results produced by the static and the dynamic model converge. Systems wherein the individual operations are independent of each other are more predictable.

Reliable knowledge of energy wood resources and procurement costs is needed when planning new plant investments (Möller and Nielsen 2007) or making decisions on both strategic and operational levels (Rauch 2013) about raw materials or supply chains. In this study, by using the sample plot data of NFI and stand data of regeneration fellings, it was possible to perform a detailed regional plant-specific fuel chip procurement cost and availability analysis when using alternative raw materials and supply chains. The calculation method enabled the use of time consumption functions for different production stages, linked with worksite and fuel quality factors for different supply chains. The results of this study concerning the factors affecting the productivity of the procurement systems were logical, and the results concerning the procurement costs of fuel chips were reasonable, when using supply systems based on comminuting at the plant. In smaller plants, due to small grinding volumes, the construction of a stationary grinder is not economically feasible.

The productivity figures for stump extraction and splitting (Laitila et al. 2008b) in harvesting environments in the vicinity of Kajaani and Kouvola are similar to values from parallel stump-lifting research in Finland and Latvia (Lazdins et al. 2009; Laitila 2010; Kärhä 2012). Athanassiadis et al. (2011) found lower productivity levels than in the study reported upon here, but the difference can be explained by operator experience in lifting work and efficiency in cleaning and splitting of uprooted stumps (Laitila 2010; Kärhä 2012). Several studies have shown that the operator is the factor with the most significant effect on harvesting productivity (e.g. Sirén 1998; Ovaskainen 2009; Lindroos 2010; Purfurst 2010; Palander et al. 2012). Productivity for cutting of delimbed stems with a multi-tree processing technique was slightly higher in the study of Laitila and Väätäinen (2013) than productivity values obtained in the parallel Finnish research (Rieppo and Mutikainen 2011; Kärhä et al. 2011c; Kärhä et al. 2011d). Relative to cutting productivity with whole trees (Kärhä 2006; Di Fulvio et al. 2011), productivity in cutting of delimbed stems (Laitila and Väätäinen 2013) was slightly lower.

The productivity parameters for pre-grinding and grinding at the roadside landing (Nuutinen et al. 2014; Laitila and Nuutinen 2015) were similar to those in parallel Finnish and Swedish studies using identical grinding machinery (Kärhä et al. 2011b; Eliasson et al. 2012). Mobile comminution of stumps is under continuous development, and novel published studies of ground stump transport are limited (cf. Nuutinen et al. 2014; Laitila and Nuutinen 2015). In a Swedish discrete-event simulation study (Eriksson 2014a; Eriksson 2014b), the values used were 35% solid volume for ground and pre-ground stumps and 20% for split stumps. The corresponding values used in our study were 28% for ground stumps, 26% for pre-ground stumps, and 21% for split stumps. According to Uusvaara and Verkasalo (1987), the solid volume content of ground wood payloads is about 10% lower than that of wood chip payloads. The lower compactness is due to the belt conveyer line of grinders and shredders, which is not able to compress during loading as well as chippers equipped with a blower or thrower can (e.g. Uusvaara and Verkasalo 1987). The low compactness decreases the per-truck payload and results in higher costs in long-distance transport. Ground stumps are dry material, so the loads are limited by volume rather than weight.

In the Swedish discrete-event simulation study (Eriksson et al. 2014a), for a distance of 10 km, transportation of split stumps produced the lowest cost for procurement of stumps for fuel. For distances of 30 km to 70 km, stand size determined whether to comminute or not before transport. For longer distances, grinding before transport proved to be necessary (Eriksson et al. 2014a). The deviations from the results of our study can be explained by the simulation method, discussed above, with regard to solid volume and payload in road based transport. In our study, ground and pre-ground stumps were transported with semi-trailer units having a lower cargo volume than do conventional chip-truck–trailer units, which were employed in the study of Eriksson et al. (2014a). In addition, transporting split stumps by truck was considered to be a cleaning method in our study (cf. Palander et al. 2011), whereas Erikson et al. (2014a; 2014b) assumed an equal or even greater ash content for stumps ground at the end-use facility relative to a supply chain based on direct grinding to an acceptable level at the landing.

The results of this highlighted the need to improve stump fuel quality and increase the heating value. In addition, the dislocation of impurities and ash from the plant cause remarkable costs, but that was neglected in this study. Based on the results of previous studies, it can be assumed that careful lifting has an influence on the ash content and heating value. Moreover, the number of different work phases in the stump processing chain has the same influence. However, the fuel is required during the late fall and winter months, when the contaminant can be firmly attached to the wood leading to high ash content. Pre-grinding and integrated screening make a feasible way to guarantee the fuel quality, expressed as ash content, already at roadside landings, but the procurement costs are higher compared to grinding stumps at the plant when the ash content of ground stumps is 6% or less.

There is a need to develop logistical models for procurement and storage, because supply and demand for fuels is often diachronic, and screening of stump wood is more effective when material is unfrozen (Laitila and Nuutinen 2015). In order to guarantee a reliable supply of fuels from roadside landings during the cold season and year-round utilization of mobile grinding machinery, there is an obvious need to store ground stump wood in buffer stacks at terminals and plants at least a few weeks before combustion (Laitila et al. 2010a). Pre-ground stumps have been found to be tolerant wood material for buffer storing, and the main reasons for the observed unresponsiveness of heat generation were that the produced hog fuel was coarse, fines had been sieved away, and wood material was dry (Laitila and Nuutinen 2015).

The stumpage price and subsidies for thinning wood were excluded from this study, which must be taken into account when making further analyses about the prices of forest fuels at the plant (Ahtikoski et al. 2008; Laitila 2012; Petty and Kärhä 2011). In the present study, the whole potential was treated as an integral entity, despite the organizational territories of procurement organizations. In practice, potential calculations are made separately for each forest company or alliance. This will significantly decrease the potential at the plant level and will increase procurement costs because of the need for a larger procurement area to satisfy demand. Furthermore, the estimated potential did not take into account the consumption of forest chips by existing plants. It must also kept in mind that most of the larger plants use the mix of fuels and forest chips as only one component. The optimal share of fuel in the mix also depends on the availability and price of other fuels. In addition, the contaminant content of stumps might limit the share of stump wood in the fuel mix of power and heating plants, if the fuel quality is not guaranteed properly.

References

Ackerman P., Belbo H., Eliasson L., de Jong A., Lazdins A., Lyons J. (2014). The COST model for calculation of forest operations costs. International Journal of Forest Engineering 25(1): 75–81. http://dx.doi.org/10.1080/14942119.2014.903711.

Ahtikoski A., Heikkilä J., Alenius V., Sirén M. (2008). Economic viability of utilizing biomass energy from young stands – the case of Finland. Biomass and Bioenergy 32(11): 988–996. http://dx.doi.org/10.1016/j.biombioe.2008.01.022.

Alakangas E. (2005). Properties of wood fuels used in Finland – BIOSOUTH-project. Technical Research Centre of Finland, VTT. Project report PRO/P2030/05. 90 p. + app. 10 p.

An H., Searcy S.W. (2012). Economic and energy evaluation of a logistic system based on biomass modules. Biomass and Bioenergy (46): 190–202. http://dx.doi.org/10.1016/j.biombioe.2012.09.002.

Anerud E. (2012). Stumps as fuel – the influence of handling method on fuel quality. Doctoral thesis. Swedish University of Agricultural Sciences. 60 p.

Anerud E., Jirjis R. (2011). Fuel quality of Norway spruce stumps – influence of harvesting technique and storage method. Scandinavian Journal of Forest Research 26(3): 257–266. http://dx.doi.org/10.1080/02827581.2011.561807.

Anerud E., Jirjis R., Gebresenbet G. (2013).Cleaning of harvested Norway spruce stumps using a vibration-based method. International Journal of Forest Engineering 24(2): 121–128. http://dx.doi.org/10.1080/14942119.2013.798934.

Anttila P., Korpilahti A., Väätäinen K. (2012). Puutavaran maantiekuljetusten kehittämispyrkimyksiä Suomessa ja Ruotsissa. [Development trends of timber transportation in Finland and Sweden]. Metsätieteen aikakauskirja 3/2012: 179–186. [In Finnish].

Asikainen A. (1995). Discrete-event simulation of mechanized wood-harvesting systems. Doctoral thesis. University of Joensuu, Faculty of Forestry, Research Notes 38. 86 p.

Asikainen A. (2010). Simulation of stump crushing and truck transport of chips. Scandinavian Journal of Forest Research 25(3):245–250. http://dx.doi.org/10.1080/02827581.2010.488656.

Asikainen A., Ranta T., Laitila J., Hämäläinen J. (2001). Hakkuutähdehakkeen kustannustekijät ja suurimittakaavaisen hankinnan logistiikka. [Cost factors and large-scale procurement of logging residue chips]. University of Joensuu, Faculty of Forestry, Research Notes 131. 107 p. [In Finnish].

Athanassiadis D., Lindroos O., Nordfjell T. (2011). Pine and spruce stump harvesting productivity and cost using a Pallari KH 160 stump lifting tool. Scandinavian Journal of Forest Research 26(5): 437–445. http://dx.doi.org/10.1080/02827581.2011.573502.

Belbo H. (2010). Comparison of two working methods for small tree harvesting with a multi tree felling head mounted on farm tractor. Silva Fennica 44(3): 453–464. http://dx.doi.org/10.14214/sf.142.

Belbo H. (2011). Efficiency of accumulating felling heads and harvesting heads in mechanized thinning of small diameter trees. Linnaeus University Dissertations 66/2011. 42 p.

Belbo H., Talbot B. (2014). System analysis of ten supply chains for whole tree chips. Forests 5: 2084–2105. http://dx.doi.org/10.3390/f5092084.

Berg S. (2014). Technology and systems for stump harvesting with low ground disturbance. Doctoral thesis. Swedish University of Agricultural Sciences. 83 p.

Berg S., Bergström D., Athanassiadis D., Nordfjell T. (2012).Torque required to twist and cut loose Scots pine stumps. Scandinavian Journal of Forest Research 27(8): 724–733. http://dx.doi.org/10.1080/02827581.2012.721002.

Berg S., Bergström D., Nordfjell T. (2014). Simulating conventional and integrated stump- and roundwood harvesting systems: a comparison of productivity and costs. International Journal of Forest Engineering 25(2): 138–155. http://dx.doi.org/10.1080/14942119.2014.941640.

Björheden R. (2006). Drivers behind the development of forest energy in Sweden. Biomass and Bioenergy 30(4): 289–295. http://dx.doi.org/10.1016/j.biombioe.2005.07.005.

Czupy I., Horvath-Szovati E. (2013). Vertical force requirement for stump lifting. Journal of Forest Science 59(7): 267–271.

Di Fulvio F., Kroon A., Bergström D., Nordfjell T. (2011). Comparison of energy-wood and pulpwood thinning systems in young birch stands. Scandinavian Journal of Forest Research (26)4: 339–349. http://dx.doi.org/10.1080/02827581.2011.568951.

Dukes C.C., Shawn A.B., Greene W.D. (2013). In-wood grinding and screening of forest residues for biomass feedstock applications. Biomass and Bioenergy 54: 18–26. http://dx.doi.org/10.1016/j.biombioe.2013.02.032.

Eliasson L., Granlund P., von Hofsten H., Björheden R. (2012). Studie av en lastbilsmonterad kross – CBI 5800. [Study of a truck-mounted CBI 5800 grinder]. Arbetsrapport från Skogforsk 775-2012. 16 p. [In Swedish with English summary].

Eriksson A., Eliasson L., Hansson P.-A., Jirjis R. (2014a). Effects of supply chain strategy on stump fuel cost: a simulation approach. International Journal of Forestry Research. Article ID 984395. 11 p.

Eriksson A., Eliasson L., Jirjis R. (2014b). Simulation-based evaluation of supply chains for stump fuel. International Journal of Forest Engineering 25(1): 23–36. http://dx.doi.org/10.1080/14942119.2014.892293.

Eriksson G., Bergström D., Nordfjell T. (2013). The state of the art in woody biomass comminution and sorting in Northern Europe. International Journal of Forest Engineering 24(3): 194–215. http://dx.doi.org/10.1080/14942119.2013.852391.

Eriksson-Näslund L., Gustavsson L. (2008). Biofuels from stumps and small roundwood: costs and CO2 benefits. Biomass and Bioenergy 32(10): 897–902. http://dx.doi.org/10.1016/j.biombioe.2008.01.017.

Fogdestam N., Granlund P., Eliasson L. (2012). Grovkrossning och sållning av stubbar på terminal. [Coarse grinding of stumps and sieving of the produced hog fuel]. Arbetsrapport Från Skogforsk 768-2012. 9 p. [In Swedish with English summary].

Hakkila P. (1975). Kanto- ja juuripuunkuoriprosentti, puuaineen tiheys ja asetoniuutteitten määrä. [Bark percentage, basic density and amount of acetone extractives in stump and root wood]. Folia Forestalia 224. 14 p. [In Finnish with English summary].

Hakkila P. (1976). Kantopuu metsäteollisuuden raaka-aineena. [Stumpwood as industrial raw material]. Folia Forestalia 292. 39 p. [In Finnish with English summary].

Hakkila P. (1978). Pienpuun korjuu polttoaineeksi. [Harvesting small-sized wood]. Folia Forestalia 342. 38 p. [In Finnish with English summary].

Hakkila P. (1989). Utilization of residual biomass. Springer series in wood science. Springer-Verlag. 568 p. http://dx.doi.org/10.1007/978-3-642-74072-5.

Hakkila P. (2004). Developing technology for large-scale production of forest chips. Wood Energy Technology Programme 1999–2003. Technology Programme Report 6/2004. National Technology Agency. 98 p.

Holzleitner F., Kanzian C., Höller N. (2013). Monitoring the chipping and transportation of wood fuels with a fleet management system. Silva Fennica 47(1) article 899. 11 p. http://dx.doi.org/10.14214/sf.899.

Jylhä P. (2011). Harvesting of undelimbed Scots pine (Pinus sylvestris L.) from first thinnings for integrated production of kraft pulp and energy. Dissertationes Forestales 133. 73 p.

Jylhä P., Dahl O., Laitila J., Kärhä K. (2010). The effect of supply system on the wood paying capability of a kraft pulp mill using Scots pine harvested from first thinnings. Silva Fennica 44(4): 695–714. http://dx.doi.org/10.14214/sf.454.

Kärhä K. (2006). Whole-tree harvesting in young stands in Finland. Forestry Studies 45: 118–134.

Kärhä K. (2011). Industrial supply chains and production machinery of forest chips in Finland. Biomass and Bioenergy 35(8): 3404–3413. http://dx.doi.org/10.1016/j.biombioe.2010.11.016.

Kärhä K. (2012). Comparison of two stump-lifting heads in final felling Norway spruce stand. Silva Fennica 46(4): 625–640. http://dx.doi.org/10.14214/sf.915.

Kärhä K., Jouhiaho A., Mutikainen A., Mattila M. (2005). Mechanized energy wood harvesting from early thinnings. International Journal of Forest Engineering 16(1): 15–26.

Kärhä K., Mutikainen A., Hautala A. (2011a). Saalasti Murska 1224 HF käyttöpaikkamurskauksessa. [Saalasti Murska 1224 HF 5000 stationary grinder operating at the power plant]. Metsätehon tuloskalvosarja 7/2011. 61 p. [In Finnish].

Kärhä K., Hautala A., Mutikainen A. (2011b). Crambo 5000 kantojen tienvarsimurskauksessa. [Crambo 5000 and crushing of stumps at roadside landings]. Metsätehon tuloskalvosarja 4/2011. 48 p. [In Finnish].

Kärhä K., Kumpare T., Keskinen S., Petty A. (2011c). Ponsse Ergo/H7 rankapuun hakkuussa ensiharvennuksella. [Cutting of multi-stem delimbed shortwood with a Ponsse Ergo/H7]. Metsäteho Oy:n tuloskalvosarja 1/2011. 43 p. [In Finnish].

Kärhä K., Mutikainen A., Keskinen S., Petty A. (2011d). Valmet 901.4/350.1 rankapuun hakkuussa ensiharvennuksella. [Cutting of multi-stem delimbed shortwood with a Valmet 901.4/350.1 for first-thinning stands]. Metsäteho Oy:n tuloskalvosarja 11/2011. 37 p. [In Finnish].

Korpinen O.-J., Ranta T., Jäppinen E., Hämäläinen E., Laitila J. (2007). Forest fuel supply chain based on terminals and stumps. In: Savolainen M. (ed.). Bioenergy 2007. 3rd International Bioenergy Conference and Exhibition from 3rd to 6th of September 2007, Jyväskylä, Finland. Proceedings. FINBIOn julkaisusarja – FINBIO Publications 36: 399–404.

Kuitto P.-J., Keskinen S., Lindroos J., Oijala T., Rajamäki J., Räsänen T., Terävä J. (1994). Puutavaran koneellinen hakkuu ja metsäkuljetus. [Mechanized cutting and forest haulage]. Metsäteho Report 410. 38 p. [In Finnish].

Laasasenaho J. (1982). Taper curve and volume functions for pine, spruce and birch. Communicationes Instituti Forestalis Fenniae 108. 74 p.

Laitila J. (2008). Harvesting technology and the cost of fuel chips from early thinnings. Silva Fennica 42(2): 267–283. http://dx.doi.org/10.14214/sf.256.

Laitila J. (2010). Kantojen korjuun tuottavuus. [Productivity of stump harvesting]. Metlan työraportteja/Working Papers of the Finnish Forest Research Institute 150. 29 p. [In Finnish]. http://www.metla.fi/julkaisut/workingpapers/2010/mwp150.htm.

Laitila J. (2012). Methodology for choice of harvesting system for energy wood from early thinning. Dissertationes Forestales 143. 68 p. http://www.metla.fi/dissertationes/df143.htm.

Laitila J., Nuutinen Y. (2015). Efficiency of integrated grinding and screening of stump wood for fuel at roadside landing with a low-speed double-shaft grinder and a star screen. Croatian Journal of Forest Engineering 36(1): 19–32.

Laitila J., Väätäinen K. (2012). Truck transportation and chipping productivity of whole trees and delimbed energy wood in Finland. Croatian Journal of Forest Engineering 33(2): 199–210.

Laitila J., Väätäinen K. (2013). The cutting productivity of the excavator-based harvester in integrated harvesting of pulpwood and energy wood. Baltic Forestry 19(2): 289–300.

Laitila J., Asikainen A., Anttila P. (2008a). Energiapuuvarat. [Energy wood resources]. In: Kuusinen M., Ilvesniemi H. (eds.). Energiapuunkorjun ympäristövaikutukset, tutkimusraportti. Tapion ja Metlan julkaisuja. p. 6–12. [In Finnish].

Laitila J., Ranta T., Asikainen A. (2008b). Productivity of stump harvesting for fuel. International Journal of Forest Engineering 19(2): 37–46.

Laitila J., Kärhä K., Jylhä P. (2009). Time consumption models and parameters for off- and on-road transportation of whole-tree bundles. Baltic Forestry 15: 105–114.

Laitila J., Leinonen A., Flyktman M., Virkkunen M., Asikainen A. (2010a). Metsähakkeen hankinta- ja toimituslogistiikan haasteet ja kehittämistarpeet. [Challenges and development needs of forest chips procurement and delivery logistics]. VTT Tiedotteita/Research Notes 2564. 143 p. [In Finnish].

Laitila J., Heikkilä J., Anttila P. (2010b). Harvesting alternatives, accumulation and procurement cost of small-diameter thinning wood for fuel in Central Finland. Silva Fennica 44(3): 465–480. http://dx.doi.org/10.14214/sf.143.

Laitila J., Väätäinen K., Asikainen A. (2013). Comparison of two harvesting methods for complete tree removal on tree stands on drained peatlands. Suo – Mires and Peat 64(2–3): 77–95.

Laurila J., Lauhanen R. (2010). Moisture content of Norway spruce stump wood at clear cutting areas and roadside storage sites. Silva Fennica 44(3): 427–434. http://dx.doi.org/10.14214/sf.140.

Laurila J., Lauhanen R. (2012). Weight and volume of small-sized whole trees at different phases of the supply chain. Scandinavian Journal of Forest Research (27)1: 46–55. http://dx.doi.org/10.1080/02827581.2011.629621.

Lazdins A., Von Hofsten H., Dagnija L., Lazdans V. (2009). Productivity and costs of stump harvesting for bioenergy production in Latvian conditions. Engineering for Rural Development symposium, in Jelgava, Latvia, on 28–29 May 2009. p. 194–201.

Lindroos O. (2010). Scrutinizing the theory of comparative time studies with operator as a block effect. International Journal of Forest Engineering (21)1: 20–30.

Lindroos O., Henningsson M., Athanassiadis D., Nordfjell T. (2010). Forces required to vertically uproot tree stumps. Silva Fennica 44(4): 681–694. http://dx.doi.org/10.14214/sf.135.

Metsäkeskus Tapio. (1994). Luonnonläheinen metsänhoito – metsänhoitosuositukset. [Silvicultural recommendations for natural forestry]. Metsäkeskus Tapion julkaisu 6/1994. 72 p. [In Finnish].

Möller B., Nielsen P.S. (2007). Analysing transport costs of Danish forest wood chip resources by means of continuous cost surfaces. Biomass and Bioenergy 31(5): 291–298. http://dx.doi.org/10.1016/j.biombioe.2007.01.018.

Niemistö P. (1992). Runkolukuun perustuvat harvennusmallit. [Thinning models based on the number of stems]. Finnish Forest Research Institute, Research Papers 432. 18 p. [In Finnish].

Nurmi J. (1997). Heating values of mature trees. Acta Forestalia Fennica 256. 28 p.

Nurmi J., Hillebrand K. (2007). The characteristics of whole-tree fuel stocks from silvicultural cleanings and thinnings. Biomass and Bioenergy 31(6): 381–392. http://dx.doi.org/10.1016/j.biombioe.2007.01.010.

Nurminen T., Heinonen J. (2007). Characteristics and time consumption of timber trucking in Finland. Silva Fennica 41(3): 471–487. http://dx.doi.org/10.14214/sf.284.

Nuutinen Y., Laitila J., Rytkönen E. (2014). Grinding of stumps, logging residues and small diameter wood using a CBI 5800 grinder with a truck as a base machine. Baltic Forestry 20(1): 176–188.

Nylinder M. (1977). Upptagning av stubb- och rotved. [Harvesting of stump and root wood]. Skogsarbeten Redogörelse 5/77. 19 p. [In Swedish].

Oikari M., Kärhä K., Palander T., Pajuoja H., Ovaskainen H. (2010). Analyzing the views of wood harvesting professionals related to the approaches for increasing the cost-efficiency of wood harvesting from young stands. Silva Fennica 44(3): 481–495. http://dx.doi.org/10.14214/sf.144.

Ovaskainen H. (2009). Timber harvester operators’ working technique in first thinning and the importance of cognitive abilities on work productivity. Dissertationes Forestales 79. 62 p. http://www.metla.fi/dissertationes/df79.htm.

Palander T., Salonen J., Ovaskainen H. (2011). Kanto- ja juuripuun kaukokuljetuksen kustannusrakenne. [Cost structure of stump- and root wood on-road transportation]. Metsätieteen aikakauskirja 4/2011: 294–299. [In Finnish]. http://www.metla.fi/aikakauskirja/abs/fa11/fa114294.htm.

Palander T., Ovaskainen H., Tikkanen L. (2012). An adaptive work study method for identifying the human factors that influence the performance of human-machine system. Forest Science 58(4): 377–389. http://dx.doi.org/10.5849/forsci.11-013.

Pasanen K., Laitila J., Pykäläinen J., Anttila P. (2014). Using the ComBio decision support system to assess whether energy wood and/or pulpwood should be harvested in young forests. International Journal of Forest Engineering 25(1): 51–65. http://dx.doi.org/10.1080/14942119.2014.903614.

Petty A., Kärhä K. (2011). Effects of subsidies on the profitability of energy wood production of wood chips from early thinnings in Finland. Forest Policy and Economics 13(7): 575–581. http://dx.doi.org/10.1016/j.forpol.2011.07.003.

Purfurst F.T. (2010). Learning curves of harvester operators. Croatian Journal of Forest Engineering 31(2): 89–97.

Ranta T. (2002). Logging residues from regeneration fellings for biofuel production – a GIS based availability and cost supply analysis. Acta Universitatis Lappeenrantaensis 128. 180 p.

Ranta T., Rinne S. (2006). The profitability of transporting uncomminuted raw materials in Finland. Biomass and Bioenergy 30(3): 231–237. http://dx.doi.org/10.1016/j.biombioe.2005.11.012.

Rauch P. (2013). Improving the primary forest fuel supply chain. Bulletin of the Transilvania University of Brasov, Series II, 6(55): 1–8.

Rieppo K., Mutikainen A. (2011). Naarva EF28 integroidussa ja energiapuun hakkuussa. [Using Naarva EF28 for integrated and delimbed energy wood harvesting]. TTS:n tiedote: metsätyö, -energia ja yrittäjyys 8/2011 (753). 6 p. [In Finnish with English summary].

Rinne S. (2010). Energiapuun haketuksen ja murskauksen kustannukset. [The cost of wood fuel chipping and crushing]. Master’s thesis. Lappeenranta University of Technology. 102 p. [In Finnish with English summary].

Ryymin R., Pohto P., Laitila J., Humala I., Rajahonka M., Kallio J., Selosmaa J., Anttila P., Lehtoranta T. (2008). Metsäenergian hankinnan uudistaminen. [Reform of forest energy procurement]. HSE Executive Education 8. 81 p. [In Finnish].

Sirén M. (1998). Hakkuukonetyö, sen korjuujälki ja puustovaurioiden ennustaminen. [One-grip harvester operation, its silvicultural result and possibilities to predict tree damage]. Doctoral thesis. Finnish Forest Research Institute, Research Papers 694. 179 p. [In Finnish with English summary].

Sirén M., Tanttu V. (2001). Pienet hakkuukoneet ja korjuri rämemännikön talvikorjuussa. [Small one-grip harvesters in first thinnings for pine bogs]. Metsätieteen aikakauskirja 4/2001: 599–614. [In Finnish]. http://www.metla.fi/aikakauskirja/abs/fa01/fa014599.htm.

Spinelli R., Visser R. (2009). Analyzing and estimating delays in wood chipping operations. Biomass and Bioenergy 33(3): 429–433. http://dx.doi.org/10.1016/j.biombioe.2008.08.003.

Spinelli R., Nati C., Magagnotti N. (2005). Harvesting and transport of root biomass from fast growing poplar plantations. Silva Fennica 39(4): 539–548. http://dx.doi.org/10.14214/sf.365.

Strandström M. (2013). Metsähakkeen tuotantoketjut Suomessa vuonna 2012. [Production chains of forest chips in Finland in 2012]. Metsätehon tuloskalvosarja 4/2013. 24 p. [In Finnish].

Strandström M. (2014). Puunkorjuu ja kaukokuljetus vuonna 2013. [Harvesting and long-distance transportation 2013]. Metsätehon katsaus 50. 4 p. [In Finnish with English summary].

Talbot N., Nordfjell T., Suadicani K. (2003). Assessing the utility of two integrated harvester-forwarder machine concepts through stand-level simulation. International Journal of Forest Engineering (14)2: 31–44.

Tolosana E., Laina R., Martínez-Ferrari R., Ambrosio Y. (2011). Recovering of forest biomass from Spanish hybrid poplar plantations. Biomass and Bioenergy 35(7): 2570–2580. http://dx.doi.org/10.1016/j.biombioe.2011.02.007.

Tomppo E., Katila M., Moilanen J., Mäkelä H., Peräsaari J. (1998b). Kunnittaiset metsävaratiedot 1990–94. Metsätieteen aikakauskirja – Folia Forestalia 4B/1998: 619–839. [In Finnish].

Torvelainen J. (2014). Energiapuun kauppa, huhti–kesäkuu 2014. [The trade of forest chips, April–June 2014]. Metsätilastotiedote 43/2014. 6 p. [In Finnish].

Torvelainen J., Ylitalo E., Nouro P. (2014). Puun energiakäyttö 2013. [Wood consumption in energy generation in the year 2013]. Metsätilastotiedote 31/2014. 7p. [In Finnish]. http://www.metla.fi/tiedotteet/metsatilastotiedotteet/2014/puupolttoaine2013.htm.

Työ- ja elinkeinoministeriö. (2010). Suomen kansallinen toimintasuunnitelma uusiutuvista lähteistä peräisin olevan energian edistämisestä direktiivin 2009/28/EY mukaisesti. [National action plan of Finland on the promotion of the use of energy from renewable sources following Directive 2009/28/EC]. 10 p. [In Finnish].

Uusvaara O., Verkasalo E. (1987). Metsähakkeen tiiviys ja muita teknisiä ominaisuuksia. [Solid volume content and other technical properties of forest chips]. Folia Forestalia 683. 53 p. [In Finnish with English summary].

Väätäinen K., Asikainen A., Eronen J. (2005). Improving the logistics of biofuel reception at the power plant of Kuopio city. International Journal of Forest Engineering 16(1): 51–64.

Valtioneuvosto. (2008). Pitkän aikavälin ilmasto- ja energiastrategia. [Long-term climate and energy strategy]. Valtioneuvoston selonteko eduskunnalle 6. päivänä marraskuuta 2008. 130 p. [In Finnish].

von Hofsten H., Granlund P. (2010). Effektivare transport om stubbarna grovkrossas på avlägg. [Haulage gains from crushing stumps to coarse chips at landing]. Resultat från Skogforsk 2/2010. 4 p. [In Swedish with English summary].

Wolfsmayr U.J., Rauch P. (2014). The primary forest fuel supply chain: a literature review. Biomass and Bioenergy (60): 203–221. http://dx.doi.org/10.1016/j.biombioe.2013.10.025.

Total of 101 references