Discrete event simulation of multimodal and unimodal transportation in the wood supply chain: a literature review

Kogler C., Rauch P. (2018). Discrete event simulation of multimodal and unimodal transportation in the wood supply chain: a literature review. Silva Fennica vol. 52 no. 4 article id 9984. https://doi.org/10.14214/sf.9984

Highlights

- Focus on discrete event simulation, wood supply chain and multimodal transport

- Analyses of 12 review articles and a core of 32 research papers, complemented by 48 related ones

- Research focus from unimodal to multimodal transport to build efficient, resilient, green and socially sustainable supply chains

- Development of robust risk management considering supply risks, demand risks and external risks is needed.

Abstract

This review systematically analyses and classifies research and review papers focusing on discrete event simulation applied to wood transport, and therefore illustrates the development of the research area from 1997 until 2017. Discrete event simulation allows complex supply chain models to be mapped in a straightforward manner to study supply chain dynamics, test alternative strategies, communicate findings and facilitate understanding of various stakeholders. The presented analyses confirm that discrete event simulation is well-suited for analyzing interconnected wood supply chain transportation issues on an operational and tactical level. Transport is the connective link between interrelated system components of the forest products industry. Therefore, a survey on transport logistics allows to analyze the significance of entire supply chain management considerations to improve the overall performance and not only one part in isolation. Thus far, research focuses mainly on biomass, unimodal truck transport and terminal operations. Common shortcomings identified include rough explanations of simulation models and sparse details provided about the verification and validation processes. Research gaps exist concerning simulations of entire, resilient and multimodal wood supply chains as well as supply and demand risks. Further studies should expand upon the few initial attempts to combine various simulation methods with optimization.

Keywords

logistics;

supply chain management;

forest products industry;

decision support systems;

validation and verification of simulation models;

resilient risk management

-

Kogler,

Institute of Production and Logistics, Department of Economics and Social Sciences, University of Natural Resources and Life Sciences, Vienna, Feistmantelstrasse 4, A-1180 Vienna, Austria

https://orcid.org/0000-0001-8811-152X

E-mail

christoph.kogler@boku.ac.at

https://orcid.org/0000-0001-8811-152X

E-mail

christoph.kogler@boku.ac.at

-

Rauch,

Institute of Production and Logistics, Department of Economics and Social Sciences, University of Natural Resources and Life Sciences, Vienna, Feistmantelstrasse 4, A-1180 Vienna, Austria

http://orcid.org/0000-0002-5812-4415

E-mail

peter.rauch@boku.ac.at

http://orcid.org/0000-0002-5812-4415

E-mail

peter.rauch@boku.ac.at

Received 29 March 2018 Accepted 30 October 2018 Published 14 November 2018

Views 209700

Available at https://doi.org/10.14214/sf.9984 | Download PDF

1 Introduction

The use of operations research methods in wood supply chain research created a wide range of strategic, tactical and operational decision support systems (Vacik and Lexer 2014). In general, related scientific literature can be separated in two main research categories. The first focuses on single processes like harvesting, forwarding, transportation, or mill operations, whereas the second highlights integrated issues along these processes considering supply chain management principles (D’Amours et al. 2008; Larsson et al. 2016). Furthermore, driven by a growing bioeconomy and a rising biomass demand, an increasing number of articles widen the focus of (biomass) supply chain studies on sustainability and feasibility issues (Lewandowski 2015; How and Lam 2018). A fundamental supply chain management principle is to emphasize the overall performance of the supply chain in order to compete with other supply chains (Haartveit et al. 2004; Westlund and Furness-Lindén 2010) rather than “trench warfare” or “cherry picking” of individual actors (Gueimonde-Canto et al. 2011), which harms total efficiency. Accordingly, this review article focuses on the wood supply chain connecting forest owners and forest based industries including energy production as part of the wood value chain. Transport is the connective link between dependent system components, and therefore a survey on transport is considered suitable to analyze the significance of supply chain management considerations.

As the wood supply chain is a complex and highly dynamic network due to unpredictable simultaneous interactions, it hardly can be solved optimally. In practice, coordinated processes are applied to cope with this complexity, but fail frequently when unexpected risks occur or changes have to be implemented. This leads to an inefficient supply chain. Although there are optimization as well as simulation models, and even a variety of mixes of both for isolated considerations, simulation models dominate when it comes to wood supply chain management. In contrast, plenty of articles and reviews exists on optimization applied in the forest supply chain (Malladi and Sowlati 2018), however, examples for connecting optimization with simulation are still rare.

In order to deal with such challenges, in addition to Monte Carlo Simulation (MCS), System Dynamics (SD) and Agent-Based Simulation (ABS), the Discrete Event Simulation (DES) approaches are gaining growing importance. Even though all these simulation approaches allow one to include stochastic elements (i.e., randomness of observations is considered), are stepwise converging and software packages (e.g., AnyLogic) support combining them, each method has still its specific field of application. SD describes continuous systems (i.e., infinitesimal time steps), whereas DES and ABS models are discrete (i.e., finite time steps). Unlike SD models with basic stock and flow structure typically covering less details, ABS concentrates on the individual behavior of agents usually providing a complex decision logic and including various details. Due to their abstraction level, both are suitable to only a limited degree for supply chains. In contrast, the intermediate abstraction level (i.e., a medium level of included details) of DES in combination with a straightforward model structure and powerful software enables the mapping of business processes and controlling the system by events. This is appropriate to model a supply chain closer to reality. These advantages led to a broad acceptance of DES among scientists and managers as indicated by the high number of recently published research articles and implemented decision support systems.

Several scientific review articles motivate this combined review, related by either the method (i.e., DES) or research area (i.e., wood supply chain). Oliveira et al. (2016) contribute a detailed meta-analysis and systematic literature review on simulation methods in supply chains, highlighting the suitability of DES for modelling real-world supply chains to support decision makers by analyzing various scenarios, selecting appropriate solutions, and improving both understanding of interactions and performance. They provide a guideline to support implementation of simulation models for supply chains and highlight the trend of combining simulation with optimization methods. Tako and Robinson (2012) compare SD and DES in terms of planning horizon (i.e., strategic and tactical/operational) and conclude that DES is used more frequently with exception of the bullwhip effect where SD is dominant. An eight-step guideline for designing, implementing and evaluating a DES supply chain model is provided by Manuj et al. (2009). They recommend management involvement to review the model in an early stage as it considerably improves trust in gained results.

Focusing on the wood supply chain, D’Amours et al. (2008) explain related strategic, tactical and operational operation research applications and problems. They highlight various difficulties companies face implementing closer supply chain collaborations (e.g., integrating various business units such as forest entrepreneurs, carriers, sawmills, pulp and paper mills). Shashi and Pulkki (2013) comprehensively review literature for supply chain modelling and simulation in general as well as focus on the forest products industry and explain straightforward basics and differences in planning horizon (i.e., strategic, tactic, operative) and simulation models (i.e., DES, SD, ABS and MCS). Moreover, they highlight opportunities of uncertainty considerations and integrated simulation-based optimization models.

A comprehensive overview on the biomass supply chain is provided in Wolfsmayr and Rauch (2014). They describe truck, train and vessel transport, focusing on multimodal transport for different terminal types. Optimization and simulation models are analyzed with regard to decision support for supply chain management. Therefore, they highlight the lack of considerations of stochastic supply disruptions due to environmental impacts or technical defects.

Seay and Badurdeen (2014) track current trends within the biomass supply chain and recommend an integrated approach including process simulation, DES, supply chain optimization and risk assessment to overcome the major challenge of complex and interconnected stakeholder decisions. They refer to DES models that identify possible improvements in different scenarios instead of optimizing supply chain configuration. According to the authors, most models are limited in the integration of sustainability dimensions, risk analysis, long term outcomes or the ability to assess system performance.

Lautala et al. (2015) mention the processes of the biomass supply chain, specialized equipment for biomass transportation and examples of related modelling and simulating applications (i.e., IBSAL, WISDOM, LabTrans, PrevFretes, SIGTrans, BILT). They recognize transportation as a key component in literature and the dominance of truck as primary transport mode. Focusing on multimodal transport, they compare transportation modes (i.e., truck, train and vessel) and recommend to use each transport mode at its best operational scale. Furthermore, they illustrate multi-modal chain cost efficiency of a combined truck and train transportation in comparison with a single-mode truck transportation.

Borodin et al. (2016) focus on uncertainties in agri-supply chain management and provide a historic overview of the development of simulation methods. Mostly the same operations research methods are used to tackle challenges similar to those of the wood supply chain. Atashbar et al. (2016) provide an overview of basic activities and definitions along the biomass supply chain as well as a classification of applied optimization methods in terms of objective function (i.e., minimize costs, maximize profits, maximize net present value, multiple objectives), decision level (i.e., strategic, tactical, operational) and solution method (i.e., optimization, heuristics, simulation). They conclude that future research should concentrate on optimizing the entire supply chain including multimodal transport.

Mirkouei et al. (2017) concentrate on techno-economic modelling and optimization in the biomass supply chain and provide a broad technical background showing that simulation models are not appropriate for calculating optimal solutions, but provide modelling flexibility and improve supply chain understanding. In this narrative review, they chronologically identify purposes, key concepts, challenges, links and solutions and conclude that most studies focus on single topics, especially on harvesting, logistics or storage.

Finally, Opacic and Sowlati (2017) list a selection of DES applications in the forest product sector focusing on fragmented considerations such as the comparison of forest management techniques and harvesting systems, or the evaluation of transportation, logistics and supply chains.

Table 1 summarizes the above mentioned reviews and varying focuses. No review focuses on DES, the wood supply chain and multimodal transport, indicating the need for deeper analyses in this area. The motivation for this work is the suitability of the DES method to contribute to a better understanding of the wood supply chain. DES allows complex supply chain models to be mapped in a straightforward manner to study supply chain dynamics, test alternative strategies, communicate findings and facilitate understanding of various stakeholders. This establishes trust and enables decision makers to gain confidence to implement study results. Therefore, this study illustrates the development of the research area from 1997 until 2017 and pave the way for future applications.

| Table 1. Categorization of related review papers. | |||||||

| Researcher (year) | Region | Journal | DES | OM | WSC | B | MT |

| D’Amours et al. (2008) | CAN | Information Systems and Operational Research | X | X | |||

| Manuj et al. (2009) | USA | International Journal of Physical Distribution & Logistics Management | X | ||||

| Tako and Robinson (2012) | GBR | Decision Support Systems | X | ||||

| Shashi and Pulkki (2013) | CAN | American Journal of Industrial and Business Management | X | X | X | ||

| Seay and Badurdeen (2014) | USA | Current Opinion in Chemical Engineering | X | X | X | ||

| Wolfsmayr and Rauch (2014) | AUT | Biomass & Bioenergy | X | X | X | X | |

| Lautala et al. (2015) | USA | Environmental Management | X | X | X | X | |

| Atashbar et al. (2016) | FRA | IFAC-PapersOnLine | X | X | X | ||

| Borodin et al. (2016) | FRA | European Journal of Operational Research | X | X | X | ||

| Oliveira et al. (2016) | BRA | Simulation Modelling Practice and Theory | X | X | |||

| Mirkouei et al. (2017) | USA | Renewable & Sustainable Energy Reviews | X | X | |||

| Opacic and Sowlati (2017) | CAN | Forest Products Journal | X | X | |||

| Kogler and Rauch (2018) | AUT | Silva Fennica | X | X | X | ||

| DES = Discrete Event Simulation, OM = Optimization Models, WSC = Wood Supply Chain, B = Biomass, MT = Multimodal Transportation | |||||||

Scientific literature was reviewed to determine to what extent the DES approach has been applied in the wood supply chain, especially with focus on multimodal and unimodal transport, and what contradictions, gaps or hot topics have not been addressed thus far. The remainder of the paper is structured as follows: Section 2 states the applied approach; and Section 3 briefly describes the structure of the wood supply chain and basics of DES. Section 4 contains quantitative analysis in a systematic review with charts and classifying tables; and Section 5 aggregates general characteristics as well as contradictions in DES research articles of multimodal and unimodal transportation in the wood supply chain, based on narrative comparisons. Conclusions and future research directions are provided in Section 6.

2 Methodology

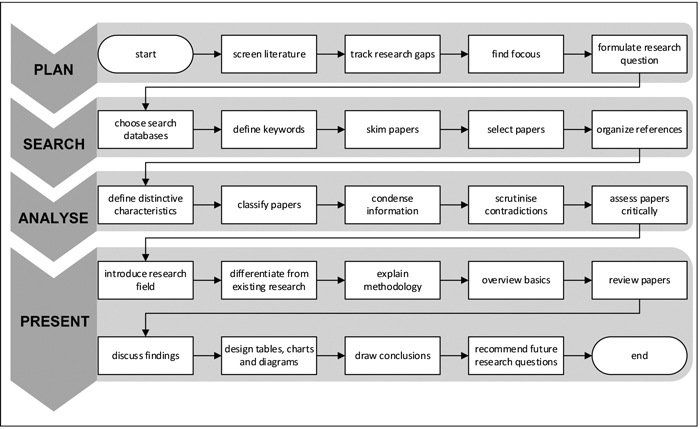

This review combines narrative and systematic elements to merge the benefits of both in terms of comprehensive analyses and standardization. Literature research included the following databases and library services: BokuLitSearch, Crossref, Directory of Open Access Journals, Emerald Insight, Google Scholar, IEEE Xplore, Sage, ScienceDirect, Scopus, Springer Link and Web of Science. The search query was set as follows: (discrete event simulation OR simulation) AND (wood OR timber OR forest OR biomass) AND supply chain. In addition, a modified search vocabulary was considered including the terms multimodal, unimodal, train, railway, vessel, waterway, truck, transport, shipping, hauling, procurement, logistics, decision support systems and simulation modelling. These terms and phrases were mostly found in titles, keywords and abstracts, but also in the full text of articles. Moreover, the reference sections were scanned and papers cited in these articles were investigated. Approximately 150 articles were shortlisted, organized in EndNote X8 and studied in detail. For the majority of cases, articles exclusively dealing with optimization methods were excluded, as well as very old articles, as the focus of this review is on contemporary DES approaches. Moreover, articles not dealing with supply chain issues, but rather single process analysis were rejected as their approach mainly improves profit of a single actor, resulting in costs elsewhere and harming the competitiveness of an entire chain. The selection process resulted in 12 review articles and a core of 32 research papers, complemented by 48 related books, papers published in peer-reviewed journals as well as a handful relevant conference papers. To analyze selected articles, the following classifying parameters were defined: reference (year), risk considered, case study included, simulation period, resolution time, supply network, objective, region, journal, abstraction level, planning horizon, assortment, transport mode, software, data collection, structure, input parameter, statistical analyses, validation and documentation. After assessing each article according to the classifying parameters, a qualitative analysis was conducted prior to compilation. Fig. 1 summarizes the described methodology and the applied working process.

Fig. 1. Methodology of the literature research (cf. Oliveira et al. (2016)).

3 Simulate the wood supply chain by discrete events

The wood supply chain is a complex dynamic network consisting of various actors and material-, service-, financing- and information flows within and between them. The wood passes through different levels of suppliers and customers and is, due to unpredictable and simultaneous interdependencies, not easily controllable. Wood supply chain management deals with relevant decisions to plan, design, operate, control and monitor the wood supply chain to improve efficiency and resilience from an economic, ecologic and social point of view. Wood supply chain research focuses mainly on planning and design to improve the real world wood supply chain by operations research methods. Simulation, especially DES, is an appropriate method to tackle the outstanding issues where analytic calculations fail (Borshchev and Filippov 2004) or a straightforward model structure to communicate findings to stakeholders by animation is required.

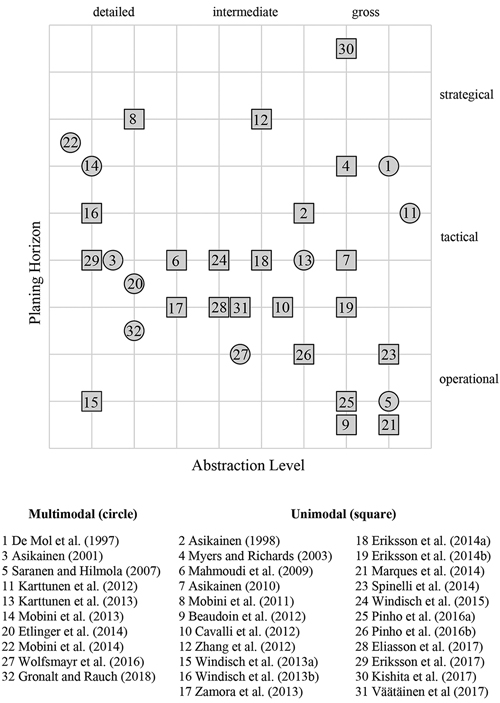

The wood supply chain comprises growing, harvesting, extraction, transporting, storing, (pre-)processing, (re-)using and recycling of wood. Specific planning aspects of the supply chain relating to strategic, tactical and operational horizons are comprehensively described for the forest products industry by D’Amours et al. (2008) and, for biomass supply chains, by Atashbar et al. (2016). Strategic planning (e.g., forest growth, new industry locations, management strategies) considers several years or even decades in advance, while tactical planning (e.g., resource allocation, production, inventory policies) considers months to a year and operational planning (e.g., harvesting, scheduling, transportation) hours, days and weeks (Weintraub 2007; Rauch 2013; Shahi and Pulkki 2013). This planning horizon definition was used for the classification of the 32 research papers in Table 4, Fig. 3 and the related explanations presented. Moreover, the abstraction level is evaluated in this context. Therefore, the term abstraction level is defined as the complexity of a simulation model. The abstraction level assesses the level of detail in the included components, decisions and processes. In this regard, few details only covering part of the supply chain indicate high abstraction level, while many details covering the entire supply chain indicate low abstraction level.

3.1 Transport in the wood supply chain

Wolfsmayr and Rauch (2014) define four different transport means for wood including single echelon unimodal transport (i.e., exclusive truck, train or vessel transport), multi echelon unimodal transport (i.e., transhipment, unchanged transport mode), intermodal transport (i.e., one loading unit on different transport modes) and multimodal transport (i.e., change of transport mode). They indicate that there is a clear dominance of truck transport in research as well as in practice. In case of multimodal transport, transhipments mainly take place at terminals where wood is loaded from trucks to trains (Mahmudi and Flynn 2006; Etlinger et al. 2014; Wolfsmayr et al. 2016; Gronalt and Rauch 2018) or vessels (Karttunen et al. 2012).

Lautala et al. (2015) compare transport modes and conclude that truck transport offers good performance in terms of network coverage, accessibility, speed and flexibility, but has low energy efficiency and capacity per unit. While train transport performs intermediate in all categories, water transport has low network coverage, accessibility, speed and flexibility, but high energy efficiency and capacity per unit.

3.2 Simulation approaches

Abstract mathematical modelling is frequently applied to provide decision support and solve real world problems, if experiments with real objects are difficult or not possible due to expense, danger, inefficiency, duration or other doubts. Particularly, when analytic calculations are complex or simply not possible, simulation offers appropriate means for problem solving (Lehtonen and Holmström 1999; Almeder et al. 2009; Webb et al. 2014). To build a simulation model, both details and less relevant issues are abstracted to focus on important questions with lower complexity. Simulation experiments facilitate both a better understanding of the part of reality modelled and evaluating strategies in various scenarios to support decision making.

Important simulation approaches beside DES are MCS, SD and ABS. The different simulation approaches were developed separately, but move closer together and can be combined (e.g., ABS in DES: forklift drives on a log yard and makes own decisions, SD in ABS: budget for decisions of an individual, SD in DES: an event gets executed shortly before a dam brakes). MCS is often applied to run random sample experiments within other simulation approaches (Borshchev and Filippov 2004). SD fits well for continuous systems with a high abstraction level, whereas DES and ABS models are discrete (Tako and Robinson 2012). DES focuses on events on an intermediate abstraction level compared to the concentration on individual behavior on a low abstraction level in ABS models. Law (2015) provides insight into the above mentioned simulation approaches and the required statistics. Borshchev (2013) and Grigoryev (2015) concentrate on the simulation software AnyLogic and both provide practical guidelines to develop simulation models. A comprehensive evaluation of simulation software can be found in Albrecht (2010).

3.3 Decision support in the wood supply chain by DES

DES with its intermediate abstraction level, universal extendibility with regard to other simulation and optimization approaches, and powerful potential to treat complex, dynamic (i.e., changing variables according to the simulation time) and stochastic (i.e., randomness of observations is considered) systems is a suitable tool to provide decision support for the wood supply chain (Cavalli et al. 2012; Shahi and Pulkki 2013; Opacic and Sowlati 2017; Gronalt and Rauch 2018). The wood supply chain can be represented by queues and activities, where state changes (events) occur at discrete points in time. Specific attributes (e.g., weight restriction, speed, lead time) are assigned to each entity (e.g., people, objects) that uses resources (e.g., personal, machines, vehicles) to determine what happens during the simulation (Tako and Robinson 2012). In DES models, every value above the level of abstraction can be tracked and statistically analyzed at any time (Borshchev 2013). Complex interdependencies of the wood supply chain can be straightforwardly modelled and visually illustrated in an animation to demonstrate model internals to stakeholders. Therefore, results for different model configurations and what-if analyses can be computed and compared providing managers with valuable decision support. For example, the complex interdependencies of the wood supply chain can be visualized in the Wood Supply Game by Fjeld (2001), simulating information and material flows.

According to Manuj et al. (2009), limitations for simulation include the generalization of a population of interest, cases where analytical solutions are possible (i.e., DES compares alternatives, but provides no optimal solutions), and difficulty with interpretation. Banks and Gibson (1997) list ten situations where simulations are not appropriate and Banks et al. (2005) state that simulation models will rarely be the same even when they are constructed by skilled experts.

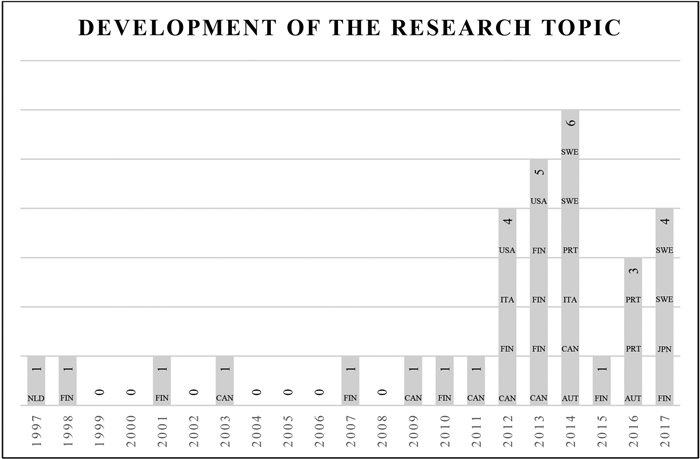

4 Systematic literature review

Thirty-two selected research papers were classified to determine the extent to which DES was applied to transport in the wood supply chain, the majority (27) of which were published in the last ten years (Table 4). Unimodal transport (21) is the predominant transport mode and different biomass assortments (24), the greatest transported good. Fig. 2 shows a rising interest in the analyzed research topic in the last years, indicated by an increasing publication level and a spreading to more countries. The majority of the analyzed papers were published by Finnish (10), Canadian (6), and Swedish (4) research groups and the most popular software used were Witness (7), ExtendSim (6) and AnyLogic (5). All Thirty-two papers were already published in one of 16 different journals, with most publications in the Scandinavian Journal of Forest Research (5), Applied Energy (5), International Journal of Forest Engineering (4) and Silva Fennica (3). Case studies (27) and risk considerations (22) were included in many papers and simulation periods used were one year (10), longer than a year (5), weeks to months (5) and days (4) with minutes (11) as most common resolution time (Table 2, Table 3). Multimodal DES models are summarized in Table 2, illustrating the different research approaches. Table 3 summarizes unimodal DES models by comparing the different research approaches.

Fig. 2. Amount of analyzed papers per year and country.

| Table 2. Multimodal DES models. | |||||

| Reference (year) | RC | CS | Simulation period (resolution time) | Supply network | Objective |

| De Mol et al. (1997) | (X) | 1 year | source, collection, pre-treatment, transhipment, energy plant | gain insight into the costs and energy consumption of logistics | |

| Asikainen (2001) | X | 1 month | harvesting, forwarding, 15 vessel terminals, powered barge / push barge, mill | cost comparison of push barge systems to a powered barge system for waterway transport | |

| Saranen and Hilmola (2007) | X | 2 weeks | 28 rail terminals, railway network, 2 mills | evaluate the competitiveness of a unit train concept by cost considerations | |

| Karttunen et al. (2012) | X | X | 9 months | 3 fuel terminals at harbors, waterway network, 3 bio-power plants | determine the efficiency of waterway transport and compare the costs to truck transport of forest chips for Lake Saimaa |

| Karttunen et al. (2013) | X | 1 year | roadside storage, chipping, container truck transport, terminal, railway transportation, combined heat and power plant | compare the cost-efficiency of a multimodal supply chain with an intermodal container supply chain for long-distance transportation of wood chips by road and rail with a combined simulation and GIS model | |

| Mobini et al. (2013) | X | X | 1 year | 5 suppliers, transportation (10 trucks, railcar, ocean vessel), raw material handling and storage, 1 pellet mill (drying, size reduction, pelletization, cooling, storage, packing, distribution), end customer | estimate delivery cost to customer and CO2 emissions along the wood pellet supply system in scenarios with different fuel types and different raw material mixtures for pellets |

| Etlinger et al. (2014) | X | X | 1 year (minutes) | forest and prehaulage, 4 rail terminals, railway network, 2 saw mills, 2 paper mills | improve efficiency of supply chain and determine transhipment time / cycle time, stock levels at terminals over time, utilization of terminal infrastructure, network capacity and terminal size |

| Mobini et al. (2014) | X | X | 1 year | 5 suppliers, truck transport, export port for incoming rail and outgoing vessels, raw material handling and storage, 1 pellet mill (drying, torrefaction, pelletization, cooling, storage, packing, distribution), end customer in north western Europe, Japan, Korea or China | extend a wood pellets simulation model by developing a torrefaction process module to compare the delivered cost to markets, distribution costs, energy consumption and carbon dioxide emission with those of regular pellets |

| Wolfsmayr et al. (2016) | X | 1 year (minutes) | 3 rail terminals | investigate potentials of existing transhipment infrastructure (rail sidings, storage areas, access roads) for biomass | |

| Gronalt and Rauch (2018) | X | X | 1 year (minutes) | forest and prehaulage, 4 rail terminals, railway network, 2 saw mills, 2 paper mills | compare scenarios for different railway operation schedules (shuttle train vs. single wagon traffic) |

| RC = Risk Considered, CS = Case Study include | |||||

| Table 3. Unimodal DES models. | |||||

| Reference (year) | RC | CS | Simulation period (resolution time) | Supply network | Objective |

| Asikainen (1998) | X | (minutes) | residue storage, terminal, truck with draw bar trailer/semitrailer/interchangeable container, crusher, tub grinder, wheel loader, power plant | compare chipping into truck, chipping onto ground and loading using a wheeled loader, long-distance transport by truck with draw-bar trailer, by truck with a semitrailer and by a truck with interchangeable platforms to quantify the impact of machine interactions in monetary terms | |

| Myers and Richards (2003) | X | 5 years (weeks) | standing inventory, ground-based harvesting, cable based harvesting, transportation, mill yard operations, mill operations | evaluate central tire inflation and cable-based harvesting systems to reduce inventory, handling and holding costs of a mill | |

| Mahmoudi et al. (2009) | X | X | 1 year | forest, felling, skidding, processing, moving, chipping, extracting, power plant gate | develop a simulation model for forest biomass logistics and apply it to the case study of supplying a potential power plant with roadside residues from a mountain pine beetle-infested forest |

| Asikainen (2010) | X | 1 week (minutes) | 50 stump storages, crusher, 1–4 semi-trailer trucks, heat plant | find the optimal number of trucks for different road transport distances of at the landing crushed wood chips and compare the findings of static as well as dynamic simulation approaches | |

| Mobini et al. (2011) | X | X | 20 years | forest, felling, skidding, loading, transportation, delimbing, processing, moving, chipping, extracting, gate of the power plant | use full tree chipping, conventional harvesting and satellite harvesting to simulate forest biomass logistics over the service life of a power plant to measure delivery cost, carbon emissions and moisture content |

| Beaudoin et al. (2012) | X | 1 day (minutes) | loaded trucks with different trailers, 3 mobile loader, stockyard, slasher, wave, scale, stocks | reduce average truck cycle times and loaders driving distances by advantageous loader to truck allocation strategies | |

| Cavalli et al. (2012) | X | X | (minutes) | stump extraction: tractor with forest winch, landing and cross cut operation: tractor with loader, offroad transport: tractor with trailer, on-road transport: truck and trailer, terminal | compare in different scenarios the productivity of a firewood supply chain to evaluate the influence of a forest road network extension, supported by a GIS network analyses of the transportation network |

| Zhang et al. (2012) | X | 20 years (days) | harvest/process, forward to landing, load at landing, transport, unload and store at biorefinery | evaluate a biofuel supply chain by delivered feedstock cost, GHG emissions and energy consumption for different locations and plant size under consideration of low value pulpwood and spring break up in a GIS network | |

| Windisch et al. (2013a) | X | X | not mentioned | finding stands, stand evaluation, negotiation and completion of contract, logging, measurements, chipping, accounting, payment | provide a method for structural analysis of forest fuel supply chains including the measurement of processes and work time expenditure in different operational environments |

| Windisch et al. (2013b) | X | X | not mentioned | finding stands, stand evaluation, negotiation and completion of contract, logging, measurements, chipping, accounting, payment | improve logistics of an integrated round wood and energy wood supply chain by business process reengineering and calculate cost saving potential of new business processes |

| Zamora et al. (2013) | X | X | (minutes) | chipper, truck with single or double trailer, chipping, dumping, transporting, loading/unloading, drop/hook trailers, chipping site, bioenergy facility | minimize mobile chipping processing and transportation costs under uncertainty to improve the efficiency of the forest biomass supply chain in steep slope terrain |

| Eriksson et al. (2014a) | X | not mentioned | 10 harvesting areas, harvesting, forwarding, storage, transport and comminution, fuel delivery, excavator with stump lifter, mobile truck or trailer-mounted grinder, self-loading chip truck with crane and bucket, loose residue stump truck, stationary crusher | evaluate the impact of site characteristics, fuel quality, biomass losses, machine performance on fuel costs to deliver stump fuel at a competitive price | |

| Eriksson et al. (2014b) | X | not mentioned | 20 landings, mobile crusher, 1–3 self-loading chip truck/hook-lift trucks/chip trucks, loose-stump truck, large scale crusher, end user (terminal or heating plant) | model systems for stump comminution and transport from landing to the end user to enhance resource efficiency by quantifying and reducing process costs | |

| Marques et al. (2014) | X | X | 1 day (minutes) | stockyard, trucks, trailers, arrival, queuing, unloading | compute performance metrics, provide visualization and identify bottlenecks in deterministic harvesting and transportation plans generated by optimization techniques, when stochastic events occur |

| Spinelli et al. (2014) | X | X | not mentioned | chipper on the trailer of a farm tractor, farm tractors with trailer bins, loader, forwarder, buffer pile, heavy road trucks | examine the interaction delays between individual units along the logging resides supply chain and criteria for the right chipping location |

| Windisch et al. (2015) | X | X | 1 year | 328 storages, truck-mounted mobile chipper, two truck trailer combinations, CHP plant | compare productivity, transportation distance, moisture content and storage volume of a current supply chain and an information based approach for a forest biomass supply chain |

| Pinho et al. (2016a) | X | (X) | 1 day | depot, 4 wood piles, 2 chippers, 4 trucks, 4 power plants | measure the impact of deterministic behavior, machine delay and stochastic behavior in a daily working plan of a biomass supply chain |

| Pinho et al. (2016b) | X | (X) | 1 day | depot, 4 wood piles, 2 chippers, 4 trucks, 6 power plants | estimate dynamic system behavior of a biomass supply chain to predict deadlocks and impact of disturbances on scheduling |

| Eliasson et al. (2017) | 1 week (minutes) | logging residues, chipper, landing, 3/6 buffer containers, forwarder, 2/3/4 trucks for three containers, heating plant | reduce supply costs for forest chips and increase chipper efficiency, forwarder and container trucks interaction by taking into account the effect of shunting distance, buffer size, truck scheduling and number of trucks available | ||

| Eriksson et al. (2017) | X | (X) | 5 years (minutes) | harvest, store in heaps, forwarding, store at road site, transport and comminute, store at CHP plant, 4 forwarders, 6 chipper trucks | assess delivery strategies due to storage time, fuel quality, transport distance, machine utilization and delivery quality to create benefits for supply company and end user |

| Kishita et al. (2017) | (X) | X | 20 years | import, collecting, chipping, land transportation, timber production, landfill, pelletizing, selling | compare scenarios to examine conditions for a sustainable forest biomass energy life cycle based on CO2 emissions and economic profit |

| Väätäinen et al. (2017) | X | 1 year (minutes) | roadside storages of forest biomass, four forest chip suppliers operating with one truck-mounted chipper and two chip trucks, terminal, wheeled loader, shuttle truck with higher capacity truck and trailer unit, combined heat and power plant | examine the impact of terminal location and investment costs, truck utilization and quality changes in stored forest chips for cost comparisons of direct forest chip supply to the integration of feed-in terminals | |

| RC = Risk Considered, CS = Case Study included | |||||

In Table 4 and Fig. 3, the analyzed research papers are classified based on abstraction level and planning horizon. The planning horizon rates the duration of the planning period. Strategical planning horizons are long-term decisions (e.g., location decision), while tactical planning horizons are medium-term decisions (e.g., resource allocation, production, inventory policies), and operational planning horizons are short-term decision (e.g., loading/unloading, scheduling). Due to sparse descriptions and absent clarifications in some papers, Fig. 3 provides a basic assessment for further investigations. DES is mainly used for tactical (14) and operational (13) planning horizons, evenly distributed over all levels of abstraction.

| Table 4. Classification of the research articles. | |||||||

| Reference (year) | Region | Journal | Abstraction level | Planning horizon | Assortment | Transport mode | Software |

| De Mol et al. (1997) | NLD | Netherlands Journal of Agricultural Science | abstract | tactical | forest biomass | multimodal | ProSim |

| Asikainen (1998) | FIN | Scandinavian Journal of Forest Research | intermediate | tactical | forest chips | unimodal | Witness |

| Asikainen (2001) | FIN | International Journal of Forest Engineering | detailed | tactical | timber | multimodal (vessel) | Witness |

| Myers and Richards (2003) | CAN | Information Systems and Operational Research | abstract | tactical | timber | unimodal | AWESIM |

| Saranen and Hilmola (2007) | FIN | World Review of Intermodal Transportation Research | abstract | operational | timber | multimodal (train) | Quest |

| Mahmoudi et al. (2009) | CAN | Scandinavian Journal of Forest Research | detailed | tactical | forest biomass | unimodal | EXTEND |

| Asikainen (2010) | FIN | Scandinavian Journal of Forest Research | abstract | tactical | forest chips | unimodal | Witness |

| Mobini et al. (2011) | CAN | Applied Energy | detailed | strategical | forest biomass | unimodal | ExtendSim |

| Beaudoin et al. (2012) | CAN | Information Systems and Operational Research | abstract | operational | timber | unimodal | AnyLogic |

| Cavalli et al. (2012) | ITA | Journal of Agricultural Engineering | intermediate | operational | firewood | unimodal | Witness |

| Karttunen et al. (2012) | FIN | Silva Fennica | abstract | tactical | forest chips | multimodal (vessel) | Witness |

| Zhang et al. (2012) | USA | Renewable Energy | intermediate | strategical | forest biomass | unimodal | Arena |

| Karttunen et al. (2013) | FIN | Silva Fennica | intermediate | tactical | forest chips | multimodal (train) | AnyLogic |

| Mobini et al. (2013) | CAN | Applied Energy | detailed | strategical | forest pellets | multimodal (train, ocean vessels) | ExtendSim |

| Windisch et al. (2013a) | FIN | Biomass and Bioenergy | detailed | operational | forest biomass | unimodal | SigmaFlow |

| Windisch et al. (2013b) | FIN | International Journal of Forest Engineering | detailed | tactical | forest biomass | unimodal | SigmaFlow |

| Zamora et al. (2013) | USA | Silva Fennica | detailed | operational | forest chips | unimodal | Arena |

| Eriksson et al. (2014a) | SWE | International Journal of Forestry Research | intermediate | tactical | forest chips | unimodal | ExtendSim |

| Eriksson et al. (2014b) | SWE | International Journal of Forest Engineering | abstract | tactical | forest chips | unimodal | ExtendSim |

| Etlinger et al. (2014) | AUT | HMS Conference Paper | detailed | tactical | saw logs, pulp wood | multimodal (train) | AnyLogic |

| Marques et al. (2014) | PRT | Scandinavian Journal of Forest Research | abstract | operational | timber | unimodal | Simio |

| Mobini et al. (2014) | CAN | Journal of Cleaner Production | detailed | strategical | forest pellets | multimodal (train, ocean vessels) | ExtendSim |

| Spinelli et al. (2014) | ITA | Scandinavian Journal of Forest Research | abstract | operational | forest chips | unimodal | Arena |

| Windisch et al. (2015) | FIN | Applied Energy | intermediate | tactical | forest biomass | not mentioned | Witness |

| Pinho et al. (2016a) | PRT | International Federation of Automatic Control Conference Paper online | abstract | operational | forest biomass | unimodal | SimPy |

| Pinho et al. (2016b) | PRT | International Federation of Automatic Control Conference Paper online | intermediate | operational | forest biomass | unimodal | SimEvents |

| Wolfsmayr et al. (2016) | AUT | Annals of Forest Research | intermediate | operational | timber, forest chips | multimodal (train) | AnyLogic |

| Eliasson et al. (2017) | SWE | Applied Energy | intermediate | operational | forest chips | unimodal | not mentioned |

| Eriksson et al. (2017) | SWE | Applied Energy | detailed | tactical | forest chips | unimodal | ExtendSim |

| Kishita et al. (2017) | JPN | Journal of Cleaner Production | abstract | strategical | forest biomass | unimodal | not mentioned |

| Väätäinen et al. (2017) | FIN | Global Change Biology Bioenergy | intermediate | operational | forest chips | unimodal | Witness |

| Gronalt and Rauch (2018) | AUT | International Journal of Forest Engineering | detailed | operational | timber, forest biomass | multimodal (train) | AnyLogic |

Fig. 3. Categorization according to abstraction level and planning horizon.

In only one paper dealing with multimodal transport (Saranen and Hilmola 2007) and six papers handling unimodal transport (Myers and Richards 2003; Beaudoin et al. 2012; Cavalli et al. 2012; Zamora-Cristales et al. 2013; Eriksson et al. 2014b; Eliasson et al. 2017) the validation method is presented as a separate section. In one other multimodal paper (Mobini et al. 2013) and five unimodal papers (Asikainen 1998; Windisch et al. 2013a; Windisch et al. 2013b; Eriksson et al. 2014a; Windisch 2015), validation methods were at least mentioned.

All other papers did not report on validation, therefore estimations based on method descriptions were used to classify them in Table 5. In De Mol et al. (1997), the model description is very rough and provides no method descriptions. Business process diagrams are an appropriate way to describe a complex model logic, as in Wolfsmayr et al. (2016). Mobini et al. (2013) and (2014) provide clarity and detail in their model descriptions, however, additional information about the verification, validation and establishing credibility process describing the process and outcomes would also enhance these works. Eriksson et al. (2017) and Beaudoin et al. (2012) are good examples of study design, but even here the model documentation could be enhanced by visualizations (i.g., business process diagrams, screenshots, histograms for distribution fitting). Good examples of business process diagrams describing model logic can be found in the works of Windisch et al. (2013a; 2013b; 2015). Zhang (2012) provides good activity and model flow charts and is the only paper where the model is available to the general public online. The only papers in which the applied distribution fitting and testing methods were extensively described were Cavalli et al. (2012), Spinelli et al. (2014) (both used Kolmogorov-Smirnov tests) and Myers and Richards (2003), Zamora-Cristales et al. (2013) and Beaudoin et al. (2012) (all used chi squared goodness of fit tests).

| Table 5. Reported model descriptions in the papers. View in new window/tab. |

5 Narrative literature review

In wood supply chain research, the attention is shifting from optimization models focusing on one single or few processes to modelling the entire supply chain. Little research exists on wood supply chains topics before the 1990s, but, driven by technological and commercial changes (Larsson et al. 2016), a considerable increase is observed for other industries and supply chains such as agriculture (Manuj et al. 2009; Tako and Robinson 2012; Borodin et al. 2016; Oliveira et al. 2016). For forest-based industries, DES models were predominantly developed for wood supply chains with multimodal transport (Table 2) or unimodal transport (Table 3).

The following narrative reflections in this section are supplemented by structural comparisons (Table 4) showing that for example the predominant abstraction level/planning horizon combination are abstract/tactical (5), detailed/tactical (5), abstract/operational (5) and intermediate/operational (5) whereas abstract/strategical (1) and interim/strategical (1) rarely arise. Moreover, within an abstraction level/planning horizon combination similarities and differences can be observed. For example, in the abstract/tactical combination, there are two multimodal transport modes, of which one focuses on vessels as well as forest chips and was developed in Witness (Karttunen et al. 2012). The other has a general focus and was developed with ProSim (De Mol et al. 1997).

5.1 Multimodal transportation

The transport mode of wood can either change (i.e., multimodal transport) through transhipments at a terminal or stay the same (i.e., unimodal transport), mainly in the form of trucks (Wolfsmayr and Rauch 2014). Multimodal transport is beneficial for long distance or high volume transports (Etlinger et al. 2014) and increases the supply security against supply risks as well as contributes to green logistics by increasing rail transport share. In case of wood supply chain disturbances (e.g., due to more frequently occurring natural disasters), robustness of the wood supply chain is of high importance. Robustness (or resilience) is defined as resistant against changes or to have the ability to return quickly to a previously good condition or state after disturbances. This can be achieved by supply chain management including contingency planning and the use of multimodal terminals to provide buffer storage.

Table 2 allows structural analyses of multimodal papers and shows that most multimodal research papers provide information about their case studies, except a few concerns about De Mol et al. (1997), and their simulation period, however, only half of them consider risks. Furthermore, the objectives and supply networks can be compared and provide an overview (e.g., how Mobini et al. developed their model from 2013 to 2014) or reflect the numbers of included rail terminals (e.g., 28 (Saranen and Hilmola 2007), 4 (Etlinger et al. 2014; Gronalt and Rauch 2018), 3 (Wolfsmayr et al. 2016)). The multimodal transportation papers are further categorized by transport mode and follow the structure (1) train, (2) vessel, (3) train and vessel and (4) general.

Firstly, Saranen and Hilmola (2007), Karttunen et al. (2013), Etlinger et al. (2014), Wolfsmayr et al. (2016) and Gronalt and Rauch (2018) solely focus on train transport. Saranen and Hilmola (2007) show the competitiveness of a unit train railway transportation concept (i.e., permanent locomotive equipped with a timber loader) for long distance with competitive prospect even for short distances. Additionally, they defer considerations of risk factors such as disturbances, breakdowns and fluctuations in demand to future studies, similar to Wolfsmayr et al. (2016). Karttunen et al. (2013) combine a GIS with a simulation model to find cost-efficient alternatives for long-distance transportation of forest chips. Therefore, they link multimodal truck and railway transportation and show that total costs of traditional supply chains are 5–19% higher than the corresponding container supply chain. Due to increased maximum road transport limits in Finland, analyses of 9-axle trucks with up to 76 tons would give further insights compared to the used 7-axle trucks with 64 tons in this study. Nonetheless they indicate the advantageousness of intermodal container logistics and train transport to traditional solid-frame transportation for long distances. Etlinger et al. (2014) show in their DES model for multimodal truck-train transport a way to nearly double the amount of round wood transport. Essentially, the numerical experiments with various scenarios result in the recommendation to change the railway operation system from a single wagonload to a shuttle system. Stochastic effects are implemented in the forest and precarriage module to take into account operating conditions (e.g., seasonality, weather conditions). Gronalt and Rauch (2018) analyze and add to the work of Etlinger et al. (2014) through complementary simulation experiments including bottleneck analysis and scenarios for appropriate train schedules. The importance of capacity matches between railway tracks and storage is indicated as well as the fact that throughput of terminals with high utilization can be increased by redesign, ensuring that trucks can be unloaded without hindrances. Similar to Saranen and Hilmola (2007), Gronalt and Rauch (2018) focus on a railway transportation concept, but with a higher level of abstraction regarding supply stations and mills, and a deeper focus on train scheduling. In contrast, Wolfsmayr et al. (2016) only focus on one module for terminal operations and aggregate the upstream and downstream components of the supply chain by in- and outgoing flows. The authors investigate multimodal biomass transport utilizing the same simulation software (i.e., AnyLogic) and case study area (i.e., Austria). Based on two scenarios, where the regular scenario covers a normal supply and the disturbance scenario an oversupply resulting from a storm or bark beetle infestation, daily and yearly transhipment capacities are simulated considering terminal layout bottlenecks and are statistically analyzed with ANOVA. The importance of risk consideration (i.e., stochastic events) along the wood supply in future research is highlighted.

Secondly, Asikainen (2001) and Kattunen et al. (2012) solely concentrate on vessel transport. Asikainen (2001) investigates waterway transport with barge systems from islands to a mill, including logging, loading and unloading modules. The model simulates the supply chain from forest stands to the unloading of the vessels at the mill. For the case study region, a push boat and three barges are more competitive than the powered barge system currently in use. Further improvements can be achieved by loading directly onto the barge by a forwarder over a suitable ramp. In contrast to the multimodal railway transport models, Asikainen (2001) provides insights into logging operations through productivity functions and highlights the benefit of simulation considering machine interactions (e.g., queuing and waiting) for a multimodal waterway supply chain. Kattunen et al. (2012) compare waterway transport of forest chips with truck transport and find benefits in case of loading capacity and bulk density, resulting in a cost advantage of waterway transport to road transport if transportation distance is more than 100 to 150 km. Stochastic effects of speed correction of the vessel-barge combination, loading/unloading events and loading size were handled by random occurring events, where every experiment was repeated five times. Waterway transport can only be cost competitive to supply the south of Finland if harbour and barge logistics are managed efficiently due to high competition in truck transport compared to tugboats and barges given the limited fleet size. The authors aggregate upstream and downstream logistics and interactions before and after terminal operations, as also seen in Saranen and Hilmola (2007). In addition, Kattunen et al. (2012) exclude queuing time and consider only one-way transport, which can be reasonable for truck transport, but not for barge transport systems. Winter months are excluded as waterways are closed due to ice cover in the Lake Saimaa region.

Thirdly, Mobini et al. (2013) and Mobini et al. (2014) cover both train and vessel transport. The entire wood pellets supply chain starting at the source over procurement, truck transportation, storage, pellet production and distribution to customer by truck or for export by train and vessel is modelled by Mobini et al. (2013). The model includes modules for transportation, supplier, pellet mill and customer, while incorporating uncertainties and measuring time, cost and emission. For the included case study, average costs of delivered pellets are shown, which consist of 29% raw material transportation costs and of 30% distribution costs, where a cost reduction potential of about 5% was reported. In a subsequent work, Mobini et al. (2014) indicate with an extended simulation model that torrefaction of biomass prior to densification leads to 9% cheaper pellets, 3% lower energy consumption and 3 kg less carbon dioxide emission per GJ of delivered energy content when transported to Europe. Including a torrefaction process, this pellets supply chain demonstrates the trade-offs between reduced transport costs, higher capital and operating cost and is, therefore, particularly attractive for long transportation distances with ocean vessels.

Lastly, De Mol et al. (1997) do not further declare the observed multimodal transport mode. They design an early simulation model for biomass and respond to network structure and biomass mixture decisions with a mixed-integer linear programming model. Results show higher costs for pre-treatments, multimodal transport and recommend chipping at the energy plant. The authors link strategic and tactical optimization models, but information regarding the simulation model and case study is not provided.

5.2 Unimodal transportation

Unimodal truck transport is advantageous for short transportation distances because no additional transhipment costs and time durations occur, resulting in lower administrative effort compared to multimodal transport. Scientific literature focuses on unimodal transportation with an increase on biomass assortments and, to some extent, firewood and wood pellets over the last years. Another important issue in unimodal transportation is chipping or bundling that increase the energy density of the material. Finally, logistics at wood yards of saw and pulp mills (e.g., truck queuing) define the last analyzed research focus since DES is rarely used to simulate transportation in other supply chain areas (e.g., harvesting or furniture manufacturing).

Structural comparisons of unimodal papers (Table 3) supplement the following narrative analyses and indicate a high number of papers considering risks (17) and including information about case studies (17). Simulation periods of unimodal papers are more heterogeneous than multimodal ones and many (7) authors do not report the simulation period at all. The objective column provides a starting point for further comparisons according to the focal point of the studies (e.g., which papers focus mainly on costs or include a GIS network or emission analyses). The unimodal transportation papers are further categorized by assortment following the structure (1) forest chips, (2) forest biomass, (3) timber and (4) firewood.

Firstly Asikainen (1998), Asikainen (2010), Eriksson et al. (2014b), Eriksson et al. (2014a), Eliasson et al. (2017), Eriksson et al. (2017), Väätäinen et al. (2017), Spinelli et al. (2014) and Zamora et al. (2013) focus on forest chips. Asikainen (1998) indicates the importance of interaction between chipping and transportation of chips for supply systems with direct chipping onto trucks (i.e., hot system) by quantifying their costs. A step-by-step run of a model and observation of graphic animation as verification methods is mentioned, as also seen in Cavalli et al. (2012). Asikainen (1998) compares the outcomes to the results of related studies for validation, but does not include information about a related case study. In a later work, Asikainen (2010) focuses particularly on crushing of stumps and a suitable number of trucks for different road transport distances. It is one of the few studies where static spreadsheet modelling is directly compared to a dynamic DES model and the impact of interactions and random elements are shown. The static model underestimates interaction impacts and provides more optimistic results because random impacts are not considered. Eriksson et al. (2014b) also investigate stump fuel supply chains, but focus more on different comminution techniques and transport distances of one to three trucks. The authors indicate that using a self-loading truck for crushed stumps on the ground is most cost-effective, irrespective of transport distance. Moreover, the balance between the number of trucks, transport distance and the productivity of the crusher is highlighted. The range of the total costs for chip trucks reported by Eriksson et al. (2014b) are comparable to that of Asikainen (2010) and can be used in specific conditions to avoid unfavorable systems. Eriksson et al. (2014a) further improve this ExtendSim-based simulation model by implementing site generation, fuel delivery, harvesting, forwarding and storage modules. The authors highlight the high costs of material losses in later stages compared to earlier ones, resulting in higher handling investments in the material over time. Eriksson and Eliasson (2015) indicate that transporting bulky, uncomminuted stumps, especially for more than 50 km, should be avoided. In addition, direct loading of trucks by crushers reduces machine utilization, which significantly raises supply costs due to the high cost of crushing. In contrast to the common practice of optimizing chipping and transport separately, Eliasson et al. (2017) promote optimization of the entire supply system. By evaluating the main influencing parameters (i.e. transport distance, number of trucks, shift form and chip buffers), the authors favor a system configuration with a buffer of six containers and staggered shifts as well as four trucks for longer (i.e., greater than 50 km) and three trucks for shorter (i.e., 30–50 km) transport distances. Great insight into the behavior of high-performance chip supply systems is provided and shift scheduling was indicated as a main cause of queuing time. The authors suggest that this can be avoided by staggered instead of simultaneous working shift start times of truck drivers. Eriksson et al. (2017) also build on former studies and weather-driven analysis is the center of their work. The authors put great effort on building a comprehensive model explanation including notes on verification and validation, which is rarely found in other simulation studies. The model enables weather driven analyses and results indicate a favorable strategy of supplying dry material during winter and moister biomass during summer. The findings of Väätäinen et al. (2017) show similarities to Windisch et al. (2015) by considering detailed time spans of daily operations in the simulations, but differ in the integration of a terminal system. The terminal system in Väätäinen et al. (2017) indicates the potential of terminals as balancing elements. Low additional costs of 1.4% arise compared to direct supply, even though capacity utilization for mobile chippers in this study is low. In Spinelli et al. (2014), supply costs are shown as a function of extraction distance, operation type and number of chip shuttles. Therefore, chipping at the landing with a chipper and with two shuttles is recommended as an appropriate system configuration, resulting in both low supply costs and low fuel consumption. The authors add a detailed case study of a small scale chip supply chain, which emphasizes, as does Cavalli et al. (2012), the special characteristics of the chipping supply chain in the Italian mountains, where farm tractors and cable cars are used due to steep terrain. The case study of Spinelli et al. (2014) allows the authors to validate their simulation findings with collected real data. It shows a difference of less than 2% and enables the generation of functions by distribution fitting and statistical test, where, in contrast to other studies, normal distribution was avoided due to potentially negative values during simulation runs. Likewise, Zamora et al. (2013) concentrate on steep terrain conditions with limited available space for adding buffer containers or single passage roads. The authors put even more emphasis on detailed data collection applying tracking analysis by manually timing, video recording and spatial-temporal tracking analysis of machine and truck movements, distribution fitting and parameter estimation. This is the only paper that combines optimization, discrete event simulation and GIS methods and explicitly mentions abstraction level. Furthermore, the authors include a comprehensive validation process and statistical analyses to declare the robustness of the model.

Secondly Mahmoudi et al. (2009), Mobini et al. (2011), Zhang et al. (2012), Windisch et al. (2013a), Windisch et al. (2013b), Windisch et al. (2015), Pinho et al. (2016a), Pinho et al. (2016b) and Kishita et al. (2017) cover forest biomass. Mahmoudi et al. (2009) simulate the wood supply chain from a mountain pine beetle-infested forest to a potential power plant, including seasonal fluctuations due to weather conditions. Twenty simulation runs of a one-year period each run are performed. The authors conclude that only about 30% of the annual feedstock demand can be fulfilled unless other harvesting systems and/or feedstock sources are used or a smaller power plant is considered. Sensitivity analyses show that increasing the number of rainy days will increase the average cost of biomass, where forwarding (4%), chipping (40%) and transportation (56%) contribute to the supply cost and transport is accountable to over 60% of the carbon emissions. Moreover, the authors include risk considerations with weather delays, describe the applied method in detail and illustrate the physical flow via flowcharts. They encourage readers to reapply their model to other case studies and provide accurate estimations of relevant variables like the size of power plants, including longer runtimes to simulate the operating life of the power plant. Some of the suggested extensions are later implemented Mobini et al. (2011), who demonstrate the valuable process of further development of existing models based on detailed descriptions. Based on the investigation, the authors enhance the simulation model by adding full-tree chipping for stands with more than 95% fuel wood and a satellite harvesting method for stands between 50% and 95%, while the remaining part is harvested conventionally. Moreover, the simulation runtime is expanded to a 20 year-long service life of a potential power plant by integrating an external shelf-life model. The results of 10 iteration runs show that even though supply has been considerably increased, demand of the power plant still cannot be met during the years 1–3 and 6–9, which require either timber supply from other areas, the use of stored timber from periods of overproduction, incorporating other agricultural biomass or a reduction of the power plant size. The simulation model of Zhang et al. (2012) shows similarities to De Mol et al. (1997) as it also is based on a pull supply chain system, neglects backhaul and risk considerations, and provides decision support for facility location and chipping at the facility. Three submodels cover reading model inputs, supply activities and daily biomass processing, and evaluate greenhouse gas (GHG) emissions, energy use and delivery cost in order to find the best facility location. The study provides detailed descriptions of numerous assumptions and extra effort is made to describe the model functionality supported by maps, diagrams, screenshots, tables and charts. Windisch et al. (2013a) analyze and compare forest biomass supply chains in Germany and Finland by business process mapping with data from expert interviews and panels as a basis for simulation models. They observe that the number of processes in the supply chain is lower in Finland (213) than in Germany (268), in contrast to the work time expenditure on managerial tasks, which is lower in Germany (1381 min 100 m–3) than in Finland (1483 min 100 m–3) and justify this among other reasons by the higher involvement of forest owners and greater independence of contractors in Finland. The importance of business process mapping as a basis for simulation models is underlined and they provide a high level of detail in the case studies. The cost reduction potential (20–39%) of the German wood supply chain organization and management through business process reengineering is addressed in Windisch et al. (2013b). In the first approach, the existing processes are slightly revised by digitalization of data exchange, standardization of data collection, contact reduction, numerical involvement, task elimination and empowerment. The second approach develops two new business processes for sourcing biomass from precommercial thinnings. Windisch et al. (2015) take it one step further and develop a simulation model with seven scenarios based on expert interviews to enhance productivity of a forest wood supply chain during the peak period from December to February. They expand the focus on risk considerations and interrelated simulation aspects through the use of a more powerful simulation environment compared to their earlier works. In contrast to the usage of software packages with graphical user interface based on drag and drop objects, Pinho et al. (2016a) choose an semantic intensive approach with Python`s simulation package SimPy. The model simulates the daily schedule for synchronous chipper and truck combination including chipping, loading, transporting, unloading at power plants and returning to a depot and includes deterministic and stochastic behavior of processing and driving times. In contrast to software systems that provide built-in elements like AnyLogic, Arena and Witness, a clean coding approach for simulation of SimPy is highlighted by Pinho et al. (2015). This expands the capability of a simulation model to the ones of the scripting language Python, but it is more complex and, therefore, extensive programming knowledge is required. Pinho et al. (2016b) revisit former considerations by implementing a similar simulation model in the MATLAB platform SimEvents. The authors focus on chipping as well as transportation and include stochastic failures and breakdowns to measure performance variations initiated by unfinished tasks and increased waiting times. The authors stay in the same problem environment, but change the simulation software and increase the number of nodes slightly to provide concrete output on driving, chipping and idle times as a percentage of executed workload for more profound comparisons of stochastic simulation scenarios. A life-cycle of a Japanese forest biomass energy process is simulated by Kishita et al. (2017) to enhance sustainability and address uncertainty with a scenario-based approach. Carbon dioxide emissions as well as economic profit are measured and a sensitivity analyses identifies electricity selling price and feedstock supply as most critical uncertainties. This case study of a Japanese rural community is a valuable supplement to literature, which is dominated by mainly European and North-American research. It focuses on wood supply chains and takes into account critical factors such as collecting a sufficient amount of wood residues for electricity generation and keeping a high and stable selling price of electricity from wood, which are not considered by other authors as this is less relevant in western countries.

Thirdly, Myers and Richards (2003), Beaudoin et al. (2012) and Marques et al. (2014) concentrate on timber. Myers and Richards (2003) provide considerations of particular relevance to mills. According to the authors, inventories at the mill yard should be reduced by minimizing seasonal shutdowns for harvesting by using cable-based or central tire inflation systems. Beaudoin et al. (2012) address high raw material inventory levels due to seasonal fluctuation and expand the focus to include transport both to and at the mill. By examining unloading operations at the mill stockyard, insights are gained into a rarely considered part of the wood supply chain, which is of importance due to high interrelations. The authors show that the strategy to empty the queue first decreases the average truck cycle time by 14% and the average total travel distances of the loaders by 18%, outperforming first in-first out and longest queue first strategies. Not considered is an upper limit of waiting time for trucks and upstream activities of the wood supply chain is not integrated in the simulation. Nevertheless, their work focus on unloading strategies inspires other authors to refine their simulation models. Similar to Zamora et al. (2013) or De Mol et al. (1997), Marques et al. (2014) combine simulation with optimization, but, like Beaudoin et al. (2012), for designing and managing truck arrival and unloading at a mill. In a three stage approach, the authors generate alternative scenarios in Excel where uncertainty of arrival times is taken into account, solve a truck scheduling optimization problem and simulate the dynamic behavior to measure performance metrics. Their results show that queuing can be reduced when time slots are used and trucks arrive on time. There is potential for improvement, which can be addressed by integrating scenario generation and optimization directly into the simulation software and by covering the entire wood supply chain.

Lastly, Cavalli et al. (2012) quantify in a simulation of a firewood supply chain in Italy a productivity increase by up to 2% if the forest road network is expanded by 5 m ha–1. Due to the enormous task of road network expansion, the productivity increase seems to be too low to justify implementation in practice. Based on a GIS network analysis, the authors model the interrelation between stump extraction, off-road and on-road transportation from forest site to the processing terminal. The results are analyzed graphically as well as by comparing the outcome with case study data. It is mentioned that outcomes are limited to medium gentle terrain, whereas modelling steep terrain is more complex due to cable logging.

6 Conclusion and outlook

First simulations of wood supply chains in the mid-1970s by Aune (1973) and (1974) already indicated the usability of this method to model interactions and random effects. Within the last two decades, increasing computing capacity enabled international research groups to apply the DES method for transport in the wood supply chain. Accordingly, more and more scientists use this method to develop complex simulation models by means of constantly improvement of simulation software. The results of the reviewed studies indicate that DES is well-suited for analyzing interconnected transportation issues on an operational and tactical level. In line with Tako and Robinson (2012), SD can be an appropriate alternative for strategic planning horizons with a low level of detail. Further studies can expand the few initial approaches to combine DES, ABS and SD with optimization. Furthermore, there are other valuable considerations to investigate multimodal (Lindholm and Berg 2005; Mahmudi and Flynn 2006; Rumpu and Vilko 2011; Chesneau et al. 2012; Lautala et al. 2012; Zhang et al. 2016a; Zhang 2016b) or unimodal transport for biomass (Gallis 1996; Hall et al. 2001; Hamelinck et al. 2005; Windisch et al. 2010; Pinho et al. 2015; Sukumara et al. 2015; Devlin et al. 2016; Laitila et al. 2016), chipping (Johnson and Biller 1974; Belbo and Talbot 2014; Zamora-Cristales et al. 2015) and mills (Aune 1973, 1974; Randhawa et al. 1993; Carlsson and Rönnqvist 2005) in wood supply chains, but with less focus on transport or supply chain management as presented in this review.

Although great amounts of research exist concerning biomass transport, due to intensive funding during the last years, it is important to expand knowledge and research into other transport assortments of the entire wood supply chain. Moreover, greater focus from unimodal to multimodal transport considerations in the future could help build efficient, resilient, green and socially sustainable supply chains. Firstly, multimodal transport supports bigger mills, larger catchment areas and longer transport distances because costs can be saved compared to unimodal transport. Secondly, multimodal terminals also improve resilience as storage capacity expands the strategic options for contingency planning to manage risks and disturbances in order to maintain wood supply to mills and prevent costly shut downs. Lastly, as wood procurement managers will be confronted with stricter regulations and social pressure to make transports more ecologically and socially beneficial in the future, multimodal transport can contribute to reduce CO2 emissions and noise pollution. DES can be a useful tool to provide decision support and answer what-if questions during this transition period. In addition, DES allows complex models to be mapped in a straightforward manner to facilitate understanding of stakeholders, especially when no analytic solution exist or will be accepted due to traceability, plausibility or comprehensibility concerns of stakeholders.

Within multimodal wood supply chain studies, a focus on terminal operations was found as a common feature in literature. While research usually concentrates more on finding general solutions, implementation and practical application is more a managerial and consultancy consideration. Therefore, simulation knowledge should be shared between science and practice in order to stimulate implementation of simulation tools for general operational planning (e.g., in ERP systems) of companies. Research gaps exist concerning detailed simulation modules for upstream processes of terminals, which allow a more realistic consideration of relevant supply risks. These risks, as well as demand risks, should be observed in comprehensive case studies and stochastic simulation and optimization studies. Currently, risk is considered rudimentary, mainly as internal transport risks such as machine breakdowns or transport delays and short simulation horizons (i.e., up to one year). Nevertheless, great external risks, uncertainties, disruptions and variations exist such as natural disasters (e.g., windstorm, bark beetle infestation), weather (e.g., rain, ice) and delivery stops of mills. These risks play a major role in supply chain performance and should be proactively managed by robust risk management. Simulation of different risk scenarios in a long-term setting (i.e., up to 10 years) can provide valuable decision support in such scenarios.

Proving if a model is a sound basis for decision making is the main task of the verification and validation process (Sterman 2000). Therefore, verification and validation play a significant role in simulation models and should be improved in the next generation of wood supply chain DES models. Methods such as structural (i.e., step-by-step) walkthroughs, visualization and animation, expert (e.g., professionals and scientists) involvement on a regular basis, extreme scenarios (e.g., use of very high/low parameters) and comparisons of the results with high quality real life case studies or literature data have to be considered. Moreover, statistical analysis of input and output data including maximum likelihood estimates, hypothesis testing (e.g., chi-squared goodness of fit or Kolmogorov-Smirnov test), confidence intervals, distribution fitting, sensitivity and correlation and graphical plots (e.g., histograms, distribution functions, boxplots, Q-Q, P-P and spider web plots) are required as well. Furthermore, also frequent reruns of experiments, inclusion of warming up periods and usage of the same seeds for random generators, a written assumption document, modular design, trace driven debugging, component testing and code review by different people are state of the art and have to be applied, described and further developed. In depth analyses and explanations of validation and verification methods in simulation models can be found in Sargent (2013), Aboud et al. (2009) and Kleijnen (1995).