The mental workload of harvester operators working in steep terrain conditions

Szewczyk G., Spinelli R., Magagnotti N., Tylek P., Sowa J. M., Rudy P., Gaj-Gielarowiec D. (2020). The mental workload of harvester operators working in steep terrain conditions. Silva Fennica vol. 54 no. 3 article id 10355. https://doi.org/10.14214/sf.10355

Highlights

- We analysed a harvester operator’s perception of his work environment as slope gradient increased

- Increasingly difficult work conditions (steeper terrain) were reflected by increased eyeball activity

- Fixation duration increased with slope gradient, while the duration of saccades was shorter

- Variation of the eyeball movement cycles was also related to work difficulty caused by slope gradient.

Abstract

The use of modern multi-functional forestry machines has already been associated with central nervous system fatigue induced by high mental workload. As these machines are being used under increasingly difficult terrain conditions, further knowledge is required on the expected aggravation of operators’ mental workload, so that suitable work/rest schedules can be developed. Within such a context, the aim of this study was to gauge aggravations of mental workload derived from increasing slope gradient. Measurements of eye activity were obtained from a representative harvester operator working in corridors with the following mean inclinations: 9%, 23% and 47%. The duration, frequency and trajectory of eye movements were used to determine the harvester operator’s mental workload, on the assumption that worsening work conditions would be reflected by increased eyeball activity. The number of fixations during the performance of all tasks increased with the increasing slope gradient. Similarly, fixation duration increased with slope gradient. The mean duration of saccades when working on a 23% slope was 5% shorter compared to work under a 9% gradient. A further significant shortening of saccade duration (~22%) occurred when working on a 47% slope. The good match between eye activity cycles and work cycles, visible especially on steep slopes, indicates that mental workload is related to work conditions. Overall, operating a forest harvester on steep slopes results in a greatly increased mental workload and calls for suitable rest schedules.

Keywords

logging;

ergonomics;

eye tracking;

fatigue;

gaze behaviour

-

Szewczyk,

University of Agriculture in Krakow; al. 29 Listopada 46, 31-425 Kraków, Poland

E-mail

rlszewcz@cyf-kr.edu.pl

- Spinelli, National Research Council of Italy, Firenze, via Madonna del Piano, 10 50019 – Sesto Fiorentino, Italy E-mail spinelli@ivalsa.cnr.it

- Magagnotti, National Research Council of Italy, Firenze, via Madonna del Piano, 10 50019 – Sesto Fiorentino, Italy E-mail natascia.magagnotti@ibe.cnr.it

- Tylek, University of Agriculture in Krakow; al. 29 Listopada 46, 31-425 Kraków, Poland E-mail rltylek@cyf-kr.edu.pl

- Sowa, University of Agriculture in Krakow; al. 29 Listopada 46, 31-425 Kraków, Poland E-mail janusz.sowa@urk.edu.pl

- Rudy, State Forests, Biłgoraj Forest District, ul. Zamojska 96, 23-400 Biłgoraj, Poland E-mail rudy.piotrek@o2.pl

- Gaj-Gielarowiec, State Forests, Barycz Forest District, Barycz 69, 26-200 Końskie, Poland E-mail dominika.gaj@gmail.com

Received 19 April 2020 Accepted 2 July 2020 Published 17 July 2020

Views 122607

Available at https://doi.org/10.14214/sf.10355 | Download PDF

1 Introduction

Forest harvesters are complex machines specifically designed to fell tress, remove their limbs and cross-cut the stem into logs of pre-defined size (Chiorescu and Grönlund 2001). They are the essential components of the modern CTL harvesting system, based on harvesters and forwarders (Spinelli et al. 2014). These machines were already used in the Nordic countries during the 1970s (Hakkila 1989; Nordfjell et al. 2010) and they have become increasingly popular also outside their boundaries and in the rest of Europe and of the world (Spinelli et al. 2010; Mederski et al. 2016). Originally conceived for clear cuts in flatland softwood stands, these machines are now used for the final felling and the thinning of stands with different age and structure, in a variety of terrain types (Moskalik and Stampfer 2003; Szewczyk et al. 2014). Even where the availability of cheap labour makes motor-manual harvesting a competitive option, there is wide interest in introducing mechanization in order to rationalize production and anticipate future labour shortages (Passicot and Murphy 2013). Compared with traditional motor-manual felling, harvesters offer much improved worker comfort and safety (Bell 2002). These advantages are so attractive that loggers all over the world have adopted the new technology well beyond the work conditions under which it was first developed, applying it to close-to-nature forestry (Hånell et al. 2000), hardwood stands (Wang and Ledoux 2005) and steep terrain (Frutig et al. 2007). Today, mechanized CTL harvesting is the most popular system in Europe and accounts for approximately 60% of all wood cut in Europe, and up to 95% of the harvest in Finland, Norway and Sweden (Lundbäck et al. 2018). In fact, harvesters are leading the transition of the logging sector towards mechanized harvesting in Eastern Europe as well (Kocel 2010; Moskalik et al. 2017).

One of the new frontiers of mechanized harvesting is steep terrain, traditionally reserved for motor-manual felling and cable yarding, but now increasingly conquered by CTL ground-base machines with the main goals of improving worker comfort and safety by placing operators inside protected cabs (Visser and Stampfer 2015). Conventional harvesters are designed for gradients of up to 35% and encounter difficulties when working in mountain conditions, characterized by steep slopes and great spatial diversity (Spinelli and Magagnotti 2011). However, their slope gradient limit can be stretched to 50% if the path is carefully chosen and soil conditions are favourable (Stampfer and Steinmüller 2001). Dedicated steep-terrain harvesters can actually tread slopes of up to 60–65% (Moskalik and Stampfer 2003), and this limit can be further exceeded resorting to winch-assist technology, which has become increasingly popular in recent years (Visser and Stampfer 2015). Finally, trees growing on steep slopes can be felled safely and efficiently by operators sitting in a comfortable and protected cab.

However, shifting from a physically tiresome and much slower motor-manual work technique to a fast-pace fully mechanized work technique has resulted in aggravation of the cognitive demands placed on the operators (Heinimann 2007). Harvester drivers are now exposed to a mental workload that was not observed in manual or semi-mechanized operations. In particular, mental workload derives from two main and opposite causes: task complexity – which requires concentration and coordination – and task simplicity characterised by a number of repetitions – which generates a state of reduced alertness as a side effect of the long-term performance of monotonous tasks (Grzywiński and Hołota 2006). Furthermore, due to the highly variable working conditions in forestry, even the seemingly stable job of the harvester operator shows large variability in the length of work cycles and in the workload (Szewczyk et al. 2014; Szewczyk and Sowa 2017). These factors cause fatigue, which leads to reduced concentration, difficulty focusing, slower and weaker perception, decreased motivation and emotional disorders (Wykowska 1994; Grzywiński 2007). As a result, work efficiency declines, while the risk of accidents increases (Sullman and Gellerstedt 1997; Berger 2003).

This situation is common to all fast-pace mechanized forest work, regardless of slope gradient, but it is known that mental workload is strongly affected by environmental factors, and slope gradient represents one the most important such factors when working in mountain areas (Sullman and Gellerstedt 1997). Determining the mental workload experienced by the operators who work under challenging environmental conditions is a very important point for the design of safe and efficient technologies and work practices. In particular, the system of rest breaks should be adjusted to the workload level (Grandjean 1991). Therefore, it is important to determine with some accuracy the specific workloads experienced under specific work conditions, and within this context, harvester work in steep terrain is becoming an increasing common work condition that calls for immediate attention.

The goal of this study was to offer a preliminary contribution in that sense, by making a first attempt at estimating the mental workload of a harvester operator working in steep terrain. The study method was based on the observation of gaze behaviour, which had already been used for assessing operator workload in a number of occupations (Di Stasi et al. 2016; Di Nocera et al. 2016), although still very seldom in forestry work (Häggström et al. 2015). Many studies have confirmed that various eye activity measures – such as blinks, fixations, and saccades (i.e. changes of fixation points) – are useful estimates of the mental workload experienced by operators engaged in a wide range of occupations and tasks (Tokuda 2008; Marquart et al. 2015). For example, long fixation durations indicate long processing of information, which testifies to a harder cognitive task (Rayner 1988). Therefore, the specific aim of our research was to determine the effect of slope gradient on the mental workload of a harvester operator: this was obtained by determining whether the changing slope gradient would be associated to changes in eye activity, as defined by fixations, count and duration of saccades and eye activity sequence. In the future, this same information could be used to better describe the entire course of the task, offering a quantitative description of its cognitive characteristics (Häggström et al. 2015).

2 Materials and methods

The research was conducted in Italy, in the Appennine mountain range, near Futa Pass in the province of Firenze. The work site was a Douglas fir (Pseudotsuga menziesii (Mirb.) Franco) plantation, established in the late 1960s on former agricultural land. At the time of the study, the stand was undergoing a selection thinning from below aimed at removing 35% of the total tree number. An essential description of the study stand is presented in Table 1.

| Table 1. Characteristics of the research area on which we tested the effect of slope gradient on the mental workload of the harvester operator. | |

| Location | Azienda La Dogana |

| Municipality | Barberino di Mugello |

| Province | Firenze |

| Coordinates | 44°03´N, 11°14´E |

| Category of cutting | Late thinning |

| Species | Douglas fir |

| Age [years] | 50 |

| Density [trees ha–1] | 910 |

| Stocking [m3 ha–1] | 650 |

| Mean removal tree DBH [cm] | 24 |

| Mean tree height [m] | 25 |

| Mean trunk volume of removed tree [m3] | 0.48 |

| Slope [%] | 9–47 |

Harvesting was performed according to the mechanized CTL system, using a harvester and a forwarder. In particular, trees were felled and processed into 3.8 m and 5.0 m long saw logs using a John Deere 1270B harvester equipped with a John Deere 762C head. This machine was 11 years old and had ca. 20 000 h on its clock. During operation, the harvester moved down the slope, opening extraction corridors at 20 m intervals, perpendicular to the contour lines. The inclination of the harvester was only longitudinal. After examining several corridors, two of them were selected for the study. These corridors were 200 m long, had a suitable and representative variation in slope gradient and were traced across a portion of the stand which was homogenous and representative of the general conditions (tree size, form and spacing) of the forest. The machine was not fitted with winch-assist equipment and moved freely on its own six wheels. Traction chains were fitted on the first and third axle.

Harvest trees had not been previously marked by the forester, but were selected by the operator, who had completed appropriate training on stand-tending measures. This was a thirty-four-year-old professional with ten years’ experience in this job, and known by the researchers for several years, during which he had given ample proof of professional competence and motivation. The study operator had no diagnosed visual disorders. Before starting, the harvester operator was informed about the method of measurement and the purpose of the test, and his consent was obtained.

Before starting the experimental measurements, the slope gradient of each corridor section was measured using a Tru Pulse 36B laser rangefinder (Laser Technology Inc., Centennial, CO). Slope gradient was measured in homogenous sections, with the mean inclination: 9%, 23% and 48%.

During harvesting in the selected corridor, variations in the eye activity of the harvester operator were recorded using a set of Tobii Pro Glasses 2 Eye-Tracker (Table 2). The system recorded the reflection of infrared light from the eye of the operator to determine the points the operator was looking at. The eye-tracking glasses were connected through Wi-Fi to a portable computer, running the dedicated Tobii Pro Glasses Controller software (Gomolka at al. 2020). Study measurements started after ca. 60 min of warm-up and eye-tracker calibration.

| Table 2. Technical data of the Tobii Pro Glasses 2 Eye-tracker. | |

| Eye-tracker | |

| Sampling frequency | 50–100 Hz (in respect to eye-trackers the sampling frequency means the number of identified locations of fixation points per second; this frequency determines the quality of results and the accuracy of measurements) |

| Cameras | 4 |

| Scene camera FOV | 82° horizontally, 52° vertically |

| Scene camera parameters | h.264; 1920 × 1080 pixels; @25 fps |

| Field of view | 160° |

| Diagonal of scene camera FOV | 90°; 16:9 |

| Sound recording | Yes |

| Weight | 45 g |

| Battery | 120 min |

| Recording Station | |

| Connection | HDMI, Micro USB, 3.5 mm Jack |

| Frequency | 2.4 GHz & 5 GHz band |

| Dimensions | 130 × 85 × 27 mm |

| Weight | 312 g |

A single recording session lasted approximately 30 minutes. After each session, the operator’s work was stopped, the data record was saved and the next recording session was eventually started after recalibrating the apparatus. Two or three complete recording sessions (films) were logged in for each of the four sections of the test corridors. After the work was completed, the operator was left alone to rest for about 30 min, to allow physiological activity to stabilize. Then, measurement with the eye-tracker was carried out during the rest period, after stabilization. The resting interval took place outside the harvester’s cabin, in the stand in which the work was conducted. The operator therefore viewed and recorded a similar scene as during thinning, except for the fact that he was resting, rather than working. During the rest break, the operator sat and ate a meal, and he did not perform any official duties.

The video material obtained during the field research was processed using the Tobii Pro Lab Analyser version 1.102 software (Tobii AB, CO). For the purpose of activity categorization, the harvester work was split into the following tasks (Magagnotti and Spinelli 2012):

Felling – this task commenced when the harvester head was being positioned at the base of the stem (e.g. extending the boom out to reach for the tree) and finished when the feed rollers started pulling the cut stem through the delimbing knives;

Processing – this task commenced when the feed rollers started pulling the stems through the delimbing knives, and finished when the tree top was dropped onto the forest floor;

Moving – this task commenced when the machine moved to a new work station after discarding the top of the last processed tree, and finished when the new position was reached and the harvester head reached the base of the next tree to be cut.

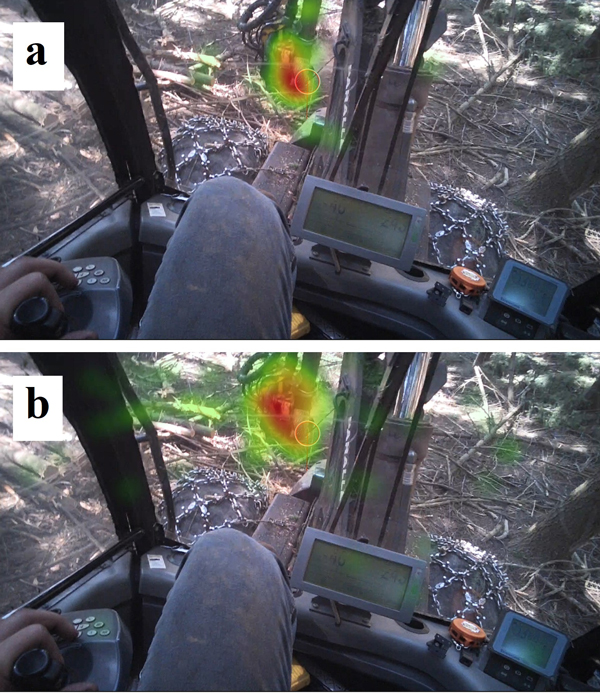

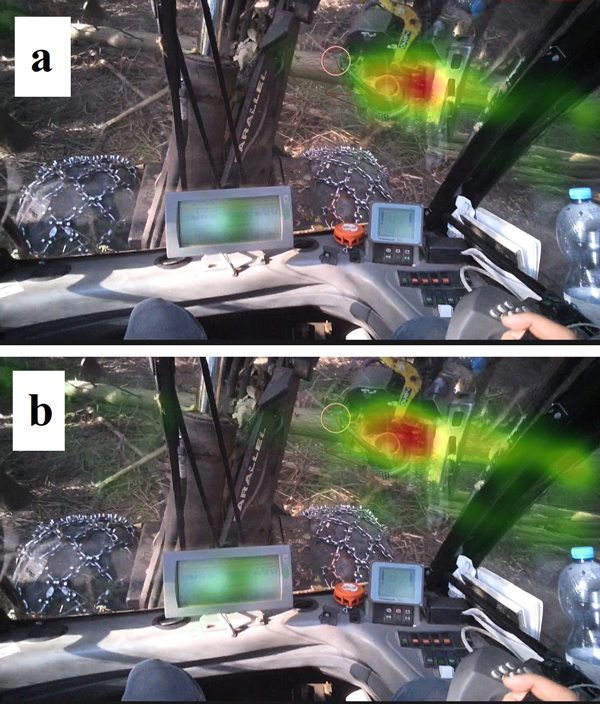

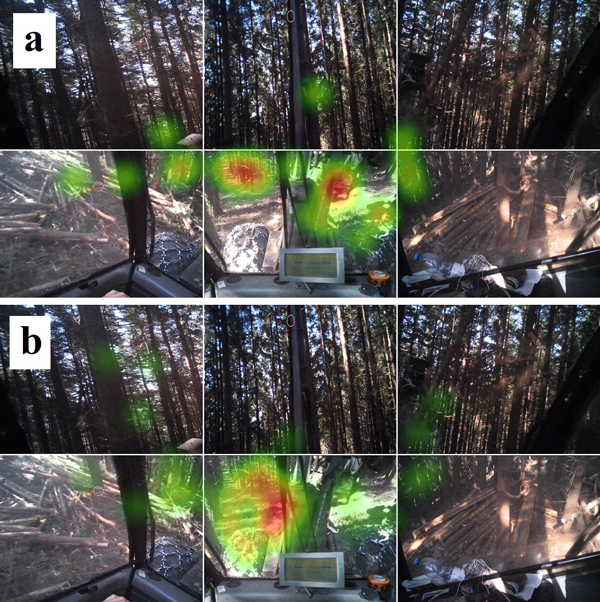

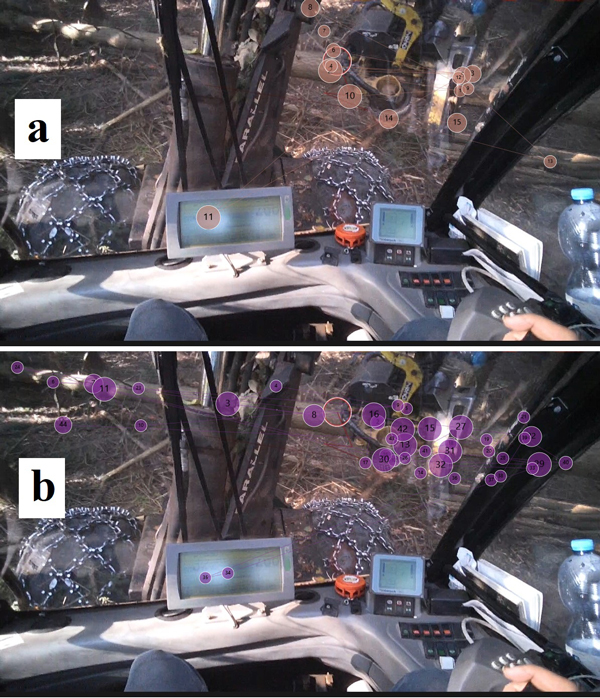

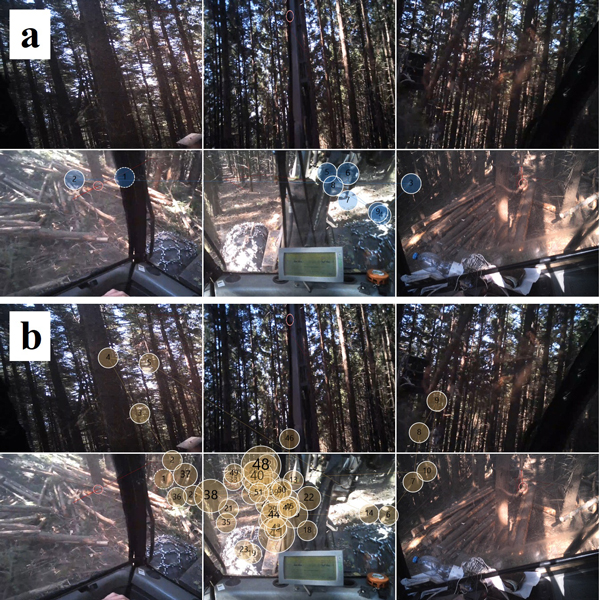

Heat maps and gaze plots were built on the basis of selected average frames of recorded movies. To facilitate comparisons, we used the same photos for all slopes. Since during felling and processing the operator’s orientation field was narrow, snapshots were prepared in the form of screen shots of the selected film frame. In the case of a snapshot taken during vehicle passage, the operator watched the area around the machine and looked into the stand. This explains why a sheet consisting of several, joined scenes seen from the vehicle was prepared in order to accurately show the points of eye focus.

Recordings were scanned (manually mapped to mark fixation points on gaze plots) using the standard Tobii Pro Lab I-VT (Attention) filter (Olsen 2012). The Attention Filter in Pro Lab is essentially the Tobii Pro IV-T Filter, with the velocity threshold parameter set at 100 degrees s–1 instead of the default 30 degrees s–1. The Attention filter is considered best for the analysis of recordings that are carried out in dynamic situations. This filter was used in the construction of gaze plots. Analyses of the duration of eye fixations were performed using pre-selected recordings by means of the standard fixation filter configured in Tobii Pro Lab, with the following default settings: Gap fill-in (interpolation) = disabled; eye selection = average; noise reduction = moving median; I-VT fixation classifier = threshold 30 degrees s–1; maximum time between fixations = 75 ms; maximum angle between fixations = 0.5 degrees; minimum fixation duration = 60 ms.

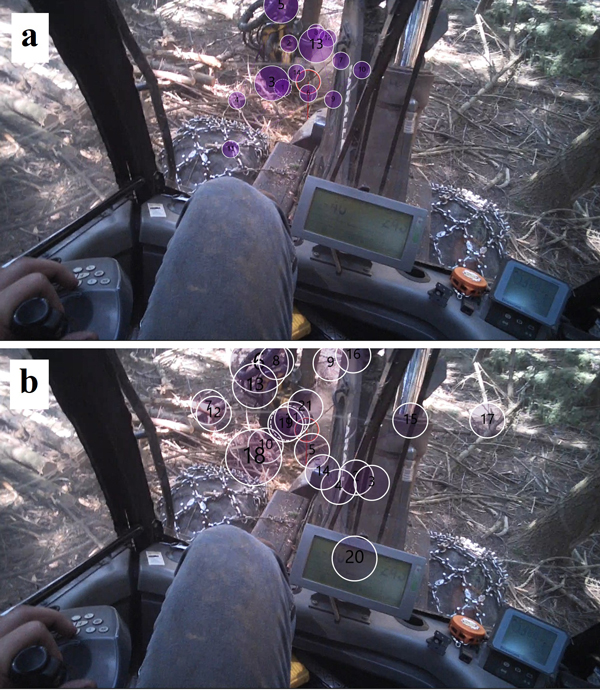

Gaze plots were prepared on the basis of the film material depicting work on one average tree under each of the three ground slope treatments. Since processing (i.e. debranching and crosscutting) of an entire tree resulted in a large number of eye fixations and an unclear graphic image, gaze plots were also assembled for the bucking of a single saw log. Heat maps for each task were prepared on the basis of work on five subsequent trees. The scanning locations were often difficult to recognize visually, due to the dynamic nature of the work and the variable lighting, hence we adopted a margin of error of about 25 cm in a given area (Häggström et al. 2015). In the previously described snapshots, subsequent fixation points were marked in designated areas of interest (the area of interest covered the whole picture) for felling, processing and moving.

Given the non-normal distribution of fixation duration data, the significance of the differences between the medians of the analysed variables for the different treatments (slope gradient) was tested using the Kruskal-Wallis nonparametric test. The link between visual activity and the level of difficulty of the task was also assessed by analysing the variability of fixation duration (Recarte and Nunes 2000). This was determined by presenting the measurement data as a time series, i.e. a sequence of observations of a given variable as a function of time (Box and Jenkins 1976; Szewczyk et al. 2014). The time series (for each category of terrain gradient as represented in the four sections of the test corridors) were subject to strong random fluctuations; therefore, before further analyses, the raw data were smoothed using a moving average (with equal weights). The analyses used the characteristic of a time series that, unlike random trials, had the observations in a non-random order. The cyclical character of fixation duration was a measure of the variability of the harvester operator’s work on different slopes. Since large variability of the fixation time sequences was observed, cycles with constant duration were not analysed (Szewczyk 2011). Instead, the analysis focused on alternating sequences of varying fixation duration. To estimate the variability of the cyclic structure of the time series, Fourier’s singular spectrum analysis method was used (Kot et al. 2007; StatSoft Inc. 2009).

3 Results

The fixation duration dataset was created by analysing over 170 minutes of video, including 150 min of work and 20 min of rest. Heat maps and gaze plots were based on >730 fixation points each. Differences between fixation duration during work and during rest were based on 27 758 focal points, which were recorded during the scanning of videos. The fixation point heat maps and gaze plots show that the area of interest was significantly wider when working on steeper slopes than in flatter areas, for all tasks: felling, processing and moving (Figs. 1–6). When working on gentle slopes, the gaze plot included the harvester head and the tree stem portion in its immediate vicinity. On steeper slopes, the visual scene included a significantly wider area of interest, with fixation points set on the tree stem being negotiated, the surroundings of the stem and – in the case of moving – the stand in front of the machine.

Fig. 1. Tree cutting with the harvester on a 9% (a) and 47% (b) slope with heat maps of fixation points – when the eyeballs are in a state of relative rest and visual information is retrieved from the environment.

Fig. 2. Tree processing with the harvester on a 9% (a) and 47% (b) slope with heat maps of fixation points – when the eyeballs are in a state of relative rest and visual information is retrieved from the environment.

Fig. 3. The harvester moving on a 9% (a) and 47% (b) slope with heat maps of fixation points – when the eyeballs are in a state of relative rest and visual information is retrieved from the environment.

Fig. 4. Tree cutting with the harvester on a 9% (a) and 47% (b) slope with a gaze plot, showing the trajectories of fast movements between fixation points.

Fig. 5. One log of a tree processed with the harvester on a 9% (a) and 47% (b) slope with a gaze plot, showing the trajectories of fast movements between fixation points.

Fig. 6. The harvester moving on a 9% (a) and 47% (b) slope with a gaze plot, showing the trajectories of fast movements between fixation points.

In general, the number of saccades increased when working in steep terrain (Figs. 4–6). This difference was especially marked for the processing task, when the number of saccades per single log increased from 15 to 42 as slope gradient increased from 9% to 48%; conversely, the average duration of the saccades became 22% shorter (from 227 ms to 176 ms). In fact, a small but significant reduction in the duration of saccades (5% – from 227 ms to 214 ms) was already visible when slope gradient increased to 23% (Kruskal-Wallis: N = 27 758; H = 477.2472; p = <0.001). Fixation duration increased with slope, by an average of 22% for every 10% of inclination.

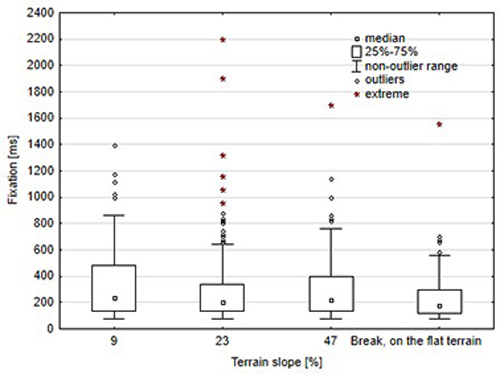

The coefficient of variation (CV) of the fixation duration for individual terrain slopes ranged from 108% for a slope gradient of 23% to 84% for the other inclinations. The most stable eye activity occurred during the rest period, when 50% of the fixations ranged from 120 to 300 ms, with very few outliers and extreme observations. Eye movements during work were characterised by greater variability, which was evident in the greater interquartile range, number of outliers and extreme fixations (Fig. 7).

Fig. 7. Duration of the harvester operator’s fixation during work in the stand with the analysed slope gradients.

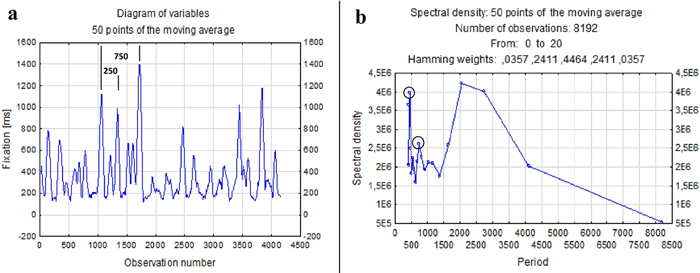

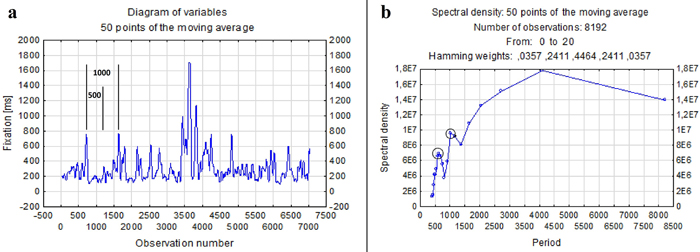

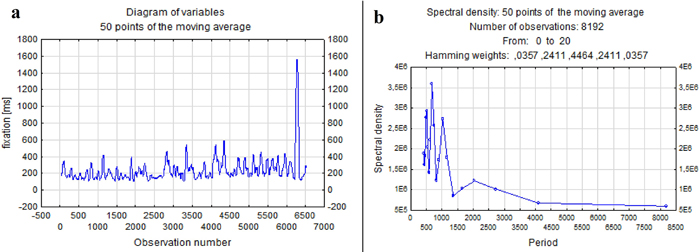

Subsequent fixation times were arranged in cycles, which were treated as regular fluctuations of a time series. These cycles were considered to be repetitive periods of variable eye activity. Figs. 8–10 present a graphical analysis of the time series: some segments of the periodograms clearly indicate shorter work cycles. Since the periodograms showed strong fluctuations even after smoothing, the descriptive data available in the “results” window for the Fourier (spectral) analysis of a single variable were also analysed (StatSoft Inc. 2009).

Fig. 8. A fragment of a time series (a) and a periodogram – entire database (b) of fixation duration during the harvester operator’s work in the terrain with 9% slope gradient. View larger in new window/tab.

Fig. 9. A fragment of a time series (a) and a periodogram – entire database (b) of fixation duration during the harvester operator’s work in the terrain with 47% slope gradient. View larger in new window/tab.

Fig. 10. A fragment of a time series (a) and a periodogram – entire database (b) of fixation duration during the harvester operator’s rest period. View larger in new window/tab.

When working in steep terrain (47% gradient), each cycle included approximately 1000 fixations, which was twice as high as recorded during work in flat terrain or during breaks. Work on steep slopes was characterised by clearly visible, rhythmically occurring long fixation durations, which were especially extended during processing. The periodic sequences visible in Fig. 9a indicate that the eye activity of the operator was related to work difficulty, caused by slope gradient. Under these conditions, overlapping cycles of different lengths were visible, with the general variability described essentially by two levels, with lengths of 500 and 1000 fixations (Fig. 9b). For work in gentle terrain (9% slope gradient), cycles of fixation duration were not closely associated with actual cycles. The ten peaks (long fixation durations) on the diagram in Fig. 8a correspond to felling and processing, where the latter is characterised by the longest fixations. A fixation cycles comprised about 250 and 750 fixations (Fig. 8b). Fixation variability during rest breaks was clearly lower (Fig. 10a,b).

The study also yielded some interesting collateral information on the mental workload imposed by individual sub-tasks. The largest number of fixations (i.e. 451) was observed during processing of an entire tree. During felling, the operator focused seven times less often: 65 fixations per tree. The number of fixation points during moving was slightly higher than in the case of felling, and amounted to 104 per tree. The average fixation duration across all slopes while processing one tree was 87 ms. The longest average fixations were observed for processing (150 ms), which was also the sub-task that took the longest time to complete. Felling and moving were characterized by similar fixation time values: 63 ms and 49 ms, respectively.

4 Discussion

First of all, it is important to state upfront the limitations of this study so that any conclusions are interpreted with the due caution, especially when it comes to generalization. In fact, the main limitation of this study is the reference to one specific stand, machine system and operator. The minimum sample size for eye-tracking studies to provide reliable benchmark figures is estimated at six people for qualitative research, and 30 people for quantitative research (Apanowicz 2002). However, due to the destructive nature of logging work and the great variability of the environmental factors encountered in any forest, it is very difficult to repeat the measurements under the same or similar conditions. At the same time, heterogeneity of the eye tracking results among operators does pose a problem (Häggström et al. 2015). Therefore, we carefully selected the machine and operator employed in this study. In particular, the machine was the European best-seller among all purpose-built harvesters, and the most widespread model at the global level (Spinelli et al. 2011). Similarly, the operator also fulfilled all the specifications for a professional harvester operator, and had the mean age and experience recorded for operators of this type in Italy (Spinelli et al. 2013). Furthermore, this study was not aimed at producing general benchmarks but only to gauge the effect of extreme slope gradient on the mental workload of harvester operators, and it remains valid as long as only one variable is changed at one time (i.e. slope gradient) all the rest being unchanged.

The mental workload and the fatigue associated with various types of forestry tasks have already been studied using scientific methods, including: measurement of electrodynamic activity, determination of cardiovascular activity, electromyography, monitoring of respiratory frequency and amplitude, measurement of temperature, and electroencephalography (Stampfer 1998; Filo 2014; Spinelli et al. 2015; Aalmo et al. 2016; Tadeusiewicz et al. 2017). Due to the high complexity and cost of the equipment required for objective measurements, subjective survey methods are also used to measure mental workload and fatigue, such as the Japanese Fatigue Feeling Scale and the NASA TLX method (Hart and Staveland 1988). Sullman and Gellersted (1997), Berger (2003), and Grzywiński and Hołota (2006), studied the mental workloads of forest workers with subjective methods and found that the mental effort required from harvester operators, and the psychological strain imposed on them, were very high. However, the limitations of using subjective methods to measure mental workload do not allow researchers to delve deeply into research problems. Respondents have varied levels of emotional involvement in completing the questionnaires and it is very difficult to account adequately for individual differences. Therefore, these methods are best used to supplement other objective measurement methods (Spinelli et al. 2020).

The trajectories of the fixation points and their concentration on specific targets reflect the cognitive process of acquiring visual information about the surrounding environment. This is part of a specific working pattern developed by the driver with his experience of the specific task at hand. Furthermore, the trajectories of saccadic movements suggest the existence of a serial component in processing the visual scene (Yarbus 1967; Noton and Stark 1971a,b). Goldberg and Kotval (1999) associated the duration of saccades with a properly designed interface, the layout of which prompts the user where to direct his gaze. In general, the shorter duration of the fixations recorded for easy terrain may indicate a lighter cognitive demand and the use of experience (Bertram et al. 2013; Przybyło et al. 2019). The precise and optimal trajectories of saccadic movements, visible in the gaze plots during work activities, are characteristic of highly skilled and experienced people.

Under the more difficult conditions caused by a steeper terrain gradient, the task required additional “scans” of the visual scene, which explains the significantly higher time of duration of fixations. Our observations time of saccades, confirm the findings of other scientists (Tokuda 2008), that cognitive workload – in our case work under steep terrain conditions – causes an increase of mental workload. The range of saccades decreased significantly as slope gradient increased, which is consistent with the research conducted by May et al. (1990). In that regard, it is important to notice that the harvester operator observed in this study showed these clear signs of an increased mental workload only when negotiating the steepest segments in the corridor, which suggests the machine was being used at the limits of its capacity and the operator was well aware of that.

The duration of fixations is often regarded as a measure of the cognitive effort invested in the processing of information gathered from the surrounding environment (Rayner 1998): a longer fixation time may indicate more extensive processing of the data that is currently in the visual field (Duchowski 2007), which may result from the inherent complexity of such data, the greater difficulty in processing it and the longer time required to compare the viewed elements with their memory representation (Buswell 1935). On the other hand, the duration of fixations becomes shorter with increasing image complexity, since more individual details must be examined singularly (Molnar 1981; Duchowski 2007). That may explain – for instance – why the average duration of fixations in this study (87 ms) was lower than the results published by Rayner and Castelhano (2007) for recognition of a still study scene (260–330 ms). The same principle explains why in this study shorter fixations were recorded during tree processing, which required the acquisition of a more detailed visual work scene compared with the other tasks (Molnar 1981; Duchowski 2007).

On the other hand, the longer duration of fixations recorded on steep terrain could be related to the necessity of collecting additional information while operating in extreme conditions. This inference is supported by the much larger number of fixations, which are associated with the efficiency of scanning the examined object (Goldberg and Kotval 1999), and with its significance and visibility during visual scanning (Poole et al. 2004).

The cortical centres of the brain are involved in making decisions about the saccade-based transfer of gaze to individual points in the visual environment at any given moment; this makes it possible to study the decision-making processes related to purposeful exploration of the environment. The “mind-eye” theory of Nielsen and Pernice (2010) relates eye activity to cognitive process. In most cases, the type of eye movement reflects the systematic acquisition of information from the environment, based on the interpretation of the meaning of incoming sensory data (Lindsay and Norman 1977). The variable number of fixations observed in our study thus constitutes a “record of the work process”, as it is closely related to that process (Kanizsa 1976) and should therefore accurately reflect the changing mental condition of the operator. In some cases, saccadic movements are performed automatically, as if outside the cognitive process. This happens, for instance, when a movement is detected in the peripheral vision and a saccade is directed towards the source of the movement. The peripheral image indicates the direction and distance of the arrangement of objects that may become subsequent fixation points, but the peripheral optical image itself is highly imperfect and out of focus (Młodkowski 1998). Therefore, it is probable that some fixations recorded during tree processing (i.e. delimbing and cross-cutting) were caused by such reflexive saccades caused by movements of the harvester head along the tree stem. Of additional interest is the fact that the aggravation of mental workload caused by an increase in slope gradient was the most visible in the tree processing task, rather than in the other tasks. In principle, one may expect that mental effort in steep terrain is highest when moving the machine from one station to the next one, rather than operating the machine functions in a stationary position. However, processing requires much accuracy and when the work is performed in steep terrain, the task is made especially difficult by the tendency of the processed stem to slide downhill, due to gravity. In a thinning operation, the problem is compounded by the risk of the sliding stem to collide with the surrounding residual trees, that must be avoided as much as possible. Therefore, harvester operators confront a very difficult task when processing the trees cut during thinning in steep terrain, and that clearly showed in this study.

The visual scene of the harvester operator during felling the tree and moving in the corridor was much less dynamic. The association of the harvester operator’s mental workload with the fixation duration was probably based on the length of eyeball activity cycles. The good match between the sequence of eye activity cycles and that of work cycles – which was especially strong in steep terrain – indicates a relationship between working conditions and the degree of mental workload. In particular, a rhythmic and accurate match between the two sequences points to the reduced capacity for performing multiple work tasks at the same time and the need for focusing on each task individually, which is the reasonable thing to do when the task becomes more difficult and/or work conditions prevent multi-tasking, for instance when moving and processing at the same time. In turn, that would offer a further explanation to the lower productivity normally experienced with increasing slope gradient (Spinelli et al. 2010).

5 Conclusions

Increased visual activity indicated that the harvester operator experienced heavier mental workload when slope gradient increased from 9% to 47%. In particular, the duration of fixations was associated with the level of difficulty of the work, which increased with slope gradient. At the same time, the amplitude of saccades decreased significantly and their frequency increased, pointing to the far more intense scanning of the visual space. This was especially marked for activities characterised by larger movements of the working tool (boom extension/retraction) and complexity (head positioning), such as tree felling and processing (i.e. delimbing and cross-cutting). Variability in the eye activity of the harvester operator indicated a strong influence of slope gradient and sub-task type on mental workload, suggesting the latter may double as terrain gradient changes from quasi-flat to steep. However, because memory resources are also extensively used during work, and because reflexive eye movements probably occur, it is difficult to accurately measure the total increase of mental workload. These findings can be used in designing suitable work and rest schedules, and provide good justification for increasing the frequency of rest pauses when operating in steep terrain.

Acknowledgments

The research was financed under grant number no. OR.271.3.06.2016. “Cybernetic rules for conducting thinnings in pine stands introduced to post-disaster areas” and grant no. 720757 “Tech4Effect”, released from the Bio Based Industries Joint Undertaking under the European Union’s Horizon 2020 Programme. We especially acknowledge the forestry company Pinter Valentino for providing biomass for the experiments. We would like to thank Editage (www.editage.com) for English language editing.

References

Aalmo G.O., Magagnotti N., Spinelli R. (2016). Forest workers and steep terrain winching: the impact of environmental and anthropometric parameters on performance. Croatian Journal of Forest Engineering 37(1): 97–105.

Apanowicz J. (2002). Metodologia ogólna. [The general methodology]. Bernardinum, Gdynia, Poland. 154 p.

Bell J. (2002). Changes in logging injury rates associated with use of feller-bunchers in West Virginia. Journal of Safety Research 33(4): 436–471. https://doi.org/10.1016/S0022-4375(02)00048-8.

Berger C. (2003). Mental stress on harvester operators. In: Proceedings of the 36th international symposium on forestry mechanisation. High-tech forest operations for mountainous terrain. October 5–9, 2003. Schlägl, Austria. p. 1–10.

Bertram R., Helle L., Kaakinen J.K., Svedström E. (2013). The effect of expertise on eye movement behaviour in medical image perception. PloSOne 8(6) article e66169. 15 p. https://doi.org/10.1371/journal.pone.0066169.

Box G.E.P., Jenkins G.M. (1976). Time series analysis: forecasting and control. 2nd ed. Englewood Cliffs, N.J Prentice-Hall, San Francisco, USA. 575 p.

Buswell G.T. (1935). How people look at pictures. A study of the psychology and perception in art. The University of Chicago Press, Oxford, England. 106 p.

Chiorescu S., Grönlund A. (2001). Assessing the role of the harvester within the forestry-wood chain. Forest Products Journal 51(2): 77–84.

Di Nocera F., Mastrangelo S., Proietti Colonna S., Steinhage A., Baldauf M, Katara A. (2016). Mental workload assessment using eye-tracking glasses in a simulated maritime scenario. In: de Waard D., Brookhuis K.A., Toffetti A., Stuiver A., Weikert C., Coelho D., Manzey D., Ünal A.B., Röttger S., Merat N. (eds.). Proceedings of the human factors and ergonomics society europe chapter 2015 annual conference. https://www.hfes-europe.org/human-factors-user-experience-in-everyday-life-medicine-and-work/.

Di Stasi L., Diaz-Piedra C., Rieiro H., Sánchez Carrión J., Martin Berrido M., Olivares G., Catena A. (2016). Gaze entropy reflects surgical task load. Surgical Endoscopy 30: 5034–5043. https://doi.org/10.1007/s00464-016-4851-8.

Duchowski A. (2007). Eye tracking methodology. Theory and practice. Springer-Verlag, London, UK. 328 p.

Filo P. (2014). The ergonomic characteristics of forwarders with stationary and rotating cabs. In: Sowa J.M. (ed.). The role of forest utilization and ergonomics in modern forestry. Uniwersytet Rolniczy w Krakowie, Kraków, Poland.

Frutig F., Fahrni F., Stettler A., Egger A. (2007). Mechanisierte Holzernte in Hanglagen. Wald und Holz 4: 47–52.

Goldberg J.H., Kotval X.P. (1999). Computer interface evaluation using eye movements: methods and constructs. International Journal of Industrial Ergonomics 24(6): 631–645. https://doi.org/10.1016/S0169-8141(98)00068-7.

Gomolka Z., Kordos D., Zeslawska E. (2020). The application of flexible areas of interest to pilot mobile eye tracking. Sensors 20(4) article 986. https://doi.org/10.3390/s20040986.

Grandjean E. (1991). Physiologishe Arbeitsgestaltung. Leitfaden der Ergonomie. 4th ed. OTT Verlag, Thun, Zürich, Switzerland. 388 p.

Grzywiński W. (2007). Ergonomia i ochrona pracy w leśnictwie. [Ergonomics and labour protection in forestry]. Wydawnictwo Akademii Rolniczej w Poznaniu, Poznań, Poland. 128 p.

Grzywiński W., Hołota R. (2006). Subjective assessment of the fatigue of forest workers based on Japanese questionnaire. Acta Scientiarum Polonorum Silvarum Colendarum Ratio et Industria Lignaria 5(1): 27–37.

Häggström C., Englund M., Lindroos O. (2015). Examining the gaze behaviors of harvester operators: an eye-tracking study. International Journal of Forest Engineering 26(2): 96–113. https://doi.org/10.1080/14942119.2015.1075793.

Hakkila P. (1989). Logging in Finland. Acta Forestalia Fennica 207: 1–39. https://doi.org/10.14214/aff.7654.

Hånell B., Nordfjell T., Eliasson L. (2000). Productivity and costs in shelterwood harvesting. Scandinavian Journal of Forest Research 15(5): 561–569. https://doi.org/10.1080/028275800750173537.

Hart S.G., Staveland L.E. (1988). Development of NASA-TLX (task load index): results of empirical and theoretical research. In: Hancock P.A., Meshkati N. (eds.). Human mental workload. North Holland Press, Amsterdam. https://doi.org/10.1016/S0166-4115(08)62386-9.

Heinimann H.R. (2007). Forest operations engineering and management – the ways behind and ahead of a scientific discipline. Croatian Journal of Forest Engineering 28(1): 107–121.

Kanizsa G. (1976). Subjective contours. Scientific American 234(4): 48–53. https://doi.org/10.1038/scientificamerican0476-48.

Kocel J. (2010). Development of the forestry services sector in Poland. Folia Forestalia Polonica 52(1): 44–53.

Kot M.S., Jakubowski J., Sokołowski A. (2007). Statystyka. [Statistics]. Statsoft Polska Sp. z o.o., Warszawa, Poland. 520 p.

Lindsay P.H., Norman D.A. (1977). Human information processing: an introduction to psychology. 2nd ed. Academic Press, New York, USA. 777 p. https://doi.org/10.1016/C2013-0-07414-2.

Lundbäck M., Häggström C., Nordfjell T. (2018). Worldwide trends in the methods and systems for harvesting, extraction and transportation of round wood. Proceedings of the 6th international forest engineering conference, April 16–19 2018, Rotorua, New Zealand. p. 1–3.

Magagnotti N., Spinelli R. (eds.) (2012). Good practice guidelines for biomass production studies. COST Action FP-0902 and CNR IVALSA, Siesto Fiorentino, Italy. ISBN 978-88-901660-4-4. https://www.researchgate.net/publication/283419641_Good_practice_guidelines_for_biomass_production_studies_COST_Action_FP-0902_WG_2_Operations_research_and_measurement_methodologies. [Cited 17 April 2020].

Marquart G., Cabrall C., de Winter J. (2015). Review of eye-related measures of drivers’ mental workload. 6th international conference on applied human factors and ergonomics (AHFE 2015) and the affiliated conferences, AHFE 2015. Procedia Manufacturing 3: 2854–2861. https://doi.org/10.1016/j.promfg.2015.07.783.

May J.G., Kennedy R.S., Williams M.C., Dunlap W.P., Brannan J.R. (1990). Eye movement indices of mental workload. Acta Psychologica 75(1): 75–89. https://doi.org/10.1016/0001-6918(90)90067-P.

Mederski P.S., Karaszewski Z., Rosińska M., Bembenek M. (2016). Dynamika zmian liczby harwesterów w Polsce oraz czynniki determinujące ich występowanie. [Dynamics of harvester fleet change in Poland and factors determining machine occurrence]. Sylwan 160(10): 795–804.

Młodkowski J. (1998). Aktywność wizualna człowieka. [Human visual activity]. Wydawnictwo Naukowe PWN, Warszawa, Łódź, Poland. 385 p.

Molnar F. (1981). About the Role of Visual Exploration in Aesthetics. In: Day H. (ed.). Advances in intrinsic motivation and aesthetics. Plenum Press, New York. p. 385–413. https://doi.org/10.1007/978-1-4613-3195-7_16.

Moskalik T., Stampfer K. (2003). Efektywność pracy harwestera Valmet 911 Snake w warunkach górskich. [Productivity of the harvester Valmet 911 Snake under the mountain conditions]. Sylwan 147(4): 91–98.

Moskalik T, Borz S, Dvořák J, Ferenčík Michal, Glushkov S, Muiste P, Lazdiņš A, Styranivsky O. (2017). Timber Harvesting Methods in Eastern European Countries: a Review. Croatian Journal of Forest Engineering 38. 231–241.

Nielsen J., Pernice K. (2010). Eyetracking web usability. 1st ed. New Riders, Berkeley, CA, USA. 437 p.

Nordfjeld T., Bjorheden R., Thor M., Wästerlund I. (2010). Changes in technical performance, mechanical availability and prices of machines used in forest operations in Sweden from 1985 to 2010. Scandinavian Journal of Forest Research (25)4: 382–389. https://doi.org/10.1080/02827581.2010.498385.

Noton D., Stark L. (1971a). Eye movements and visual perception. Scientific American 224(6): 34–43.

Noton D., Stark L. (1971b). Scanpaths in saccadic eye movements while viewing and recognizing patterns. Vision Research 11(9): 929–942. https://doi.org/10.1016/0042-6989(71)90213-6.

Olsen A. (2012). The Tobii I-VT fixation filter algorithm description. Tobii Technology. 21 p. https://www.tobiipro.com/siteassets/tobii-pro/learn-and-support/analyze/how-do-we-classify-eye-movements/tobii-pro-i-vt-fixation-filter.pdf. [Cited 17 April 2020].

Passicot P., Murphy G.E. (2013) Effect of work schedule design on productivity of mechanised harvesting operations in Chile. New Zealand Journal of Forest Science 43(1) article 2. 10 p. https://doi.org/10.1186/1179-5395-43-2.

Poole A., Ball L.J., Phillips P. (2004). In search of salience: a response time and eye movement analysis of bookmark recognition. In: Fincher S., Markopolous P., Moore D., Ruddle R. (eds.). People and computers XVIII – design for life. Proceedings of HCI 2004. Springer-Verlag, London, UK. https://doi.org/10.1007/1-84628-062-1_23.

Przybyło J., Kańtoch E., Augustyniak P. (2019). Eye tracking-based assessment of affect-related decay of human performance in visual tasks. Future Generation Computer Systems 92: 504–515. https://doi.org/10.1016/j.future.2018.02.012.

Rayner K. (1998). Eye movements in reading and information processing: 20 years of research. Psychological Bulletin 124(3): 372–422. https://doi.org/10.1037/0033-2909.124.3.372.

Rayner K., Castelhano M.S. (2007). Eye movements during reading, scene perception, visual search, and while looking at print advertisements. https://www.researchgate.net/publication/228380912_Eye_movements_during_reading_scene_perception_visual_search_and_while_looking_at_print_advertisement. [Cited 17 April 2020].

Recarte M., Nunes L. (2000). Effects of verbal and spatial-imagery task on eye fixations while driving. Journal of Experimental Psychology: Applied 6(1): 31–43. https://doi.org/10.1037/1076-898X.6.1.31.

Spinelli R., Magagnotti N. (2011). The effects of introducing modern technology on the financial, labour and energy performance of forest operations in the Italian Alps. Forest Policy and Economics (13)7: 520–524. https://doi.org/10.1016/j.forpol.2011.06.009.

Spinelli R., Hartsough B., Magagnotti N. (2010). Productivity standards for harvesters and processors in Italy. Forest Products Journal 60(3): 226–235. https://doi.org/10.13073/0015-7473-60.3.226.

Spinelli R., Magagnotti N., Picchi G. (2011). Annual use, economic life and residual value of cut-to-length harvesting machines. Journal of Forest Economics 17(4): 378–387. https://doi.org/10.1016/j.jfe.2011.03.003.

Spinelli R., Magagnotti N., Facchinetti D. (2013).Logging companies in the European mountain: an example from the Italian Alps. International Journal of Forest Engineering 24(2): 109–120. https://doi.org/10.1080/14942119.2013.838376.

Spinelli R., Lombardini C., Magagnotti N. (2014) The effect of mechanization level and harvesting system on the thinning cost of Mediterranean softwood plantations. Silva Fennica 48(1) article 1003. https://doi.org/10.14214/sf.1003.

Spinelli R., Aalmo G.O., Magagnotti N. (2015). The effect of a slack-pulling device in reducing operator physiological workload during log winching operations. Ergonomics 58(5): 781–790. https://doi.org/10.1080/00140139.2014.983184.

Spinelli R., Magagnotti N., Labelle E. (2020). The effect of new silvicultural trends on mental workload of harvester operators. Croatian Journal of Forest Engineering 41(2). https://doi.org/10.5552/crojfe.2020.747.

Stampfer K. (1998). Stress and strain effects of forest work in steep terrain. In: Heinimann H.R., Sessions J. (eds.). IUFRO/FAO seminar on forest operations in Himalayan forests with special consideration of ergonomic and socio-economic problems in Thimphu/Bhutan, 20–23 October 1997. Kassel University Press, Kassel, Switzerland. p. 113–119.

Stampfer K., Steinmüller T. (2001). A new approach to derive a productivity model for the harvester “Valmet 911 Snake”. In: Proceedings of the international mountain logging and 11th Pacific Northwest Skyline symposium – a forest engineering odyssey, 10–12 December 2001, Seattle, Washington, USA. p. 254–262

StatSoft Inc. (2009). STATISTICA (data analysis software system), version 9.0. https://www.statsoft.com. [Cited 17 April 2020].

Sullman M., Gellerstedt S. (1997). The mental workloads of mechanized harvesting. New Zealand Forestry 11: 48.

Szewczyk G. (2011). Variability of the harvester operation time in thinning and windblow areas. In: Sowa J.M. (ed.). Technika i Ergonomia w służbie współczesnego leśnictwa. [Technology and ergonomics in the service of modern forestry]. Wydawnictwo Uniwersytetu Rolniczego w Krakowie. p. 183–196.

Szewczyk G., Sowa J.M. (2017). The accuracy of measurements in a time study of harvester operations. New Zealand Journal of Forestry Science 47 article 24. https://doi.org/10.1186/s40490-017-0105-3.

Szewczyk G., Sowa J.M., Grzebieniowski W., Kormanek M., Kulak D., Stańczykiewicz A. (2014). Sequencing of harvester work during standard cuttings and in areas with windbreaks. Silva Fennica 48(4) article 1159. https://doi.org/10.14214/sf.1159.

Tadeusiewicz R., Tylek P., Adamczyk F., Kiełbasa P., Jabłoński M., Bubliński Z., Grabska-Chrząstowska J., Kaliniewicz Z., Walczyk J., Szczepaniak J., Juliszewski T., Szaroleta M. (2017). Assessment of selected parameters of the automatic scarification device as an example of a device for sustainable forest management. Sustainability 9(12) article 2370. https://doi.org/10.3390/su9122370.

Tokuda S. (2008). Using saccadic eye movements to measure mental workload. Journal of Vision 8(17) article 86. https://doi.org/10.1167/8.17.86.

Visser R., Stampfer K. (2015). Expanding ground-based harvesting onto steep terrain: a review. Croatian Journal of Forest Engineering (36)2: 321–331.

Wang J., Ledoux C. (2005). Simulating cut-to-length harvesting operations in Appalachian hardwoods. International Journal of Forest Engineering 16(2): 11–27. https://doi.org/10.1080/14942119.2005.10702510.

Wykowska M. (1994). Ergonomia. [Ergonomics]. Wydawnictwo AGH, Kraków, Poland. 186 p.

Yarbus A.L. (1967). Eye movements and vision. Plenum Press, New York. 222 p. https://doi.org/10.1007/978-1-4899-5379-7.

Total of 67 references.